Multi-station multicolor hardware product spray coating method and equipment

A multi-station, hardware technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problem of poor electrostatic enveloping effect, uneven surface coating, and manufacturing technology that cannot meet the needs of multiple varieties and small batches To achieve the effect of saving production materials, good product quality, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

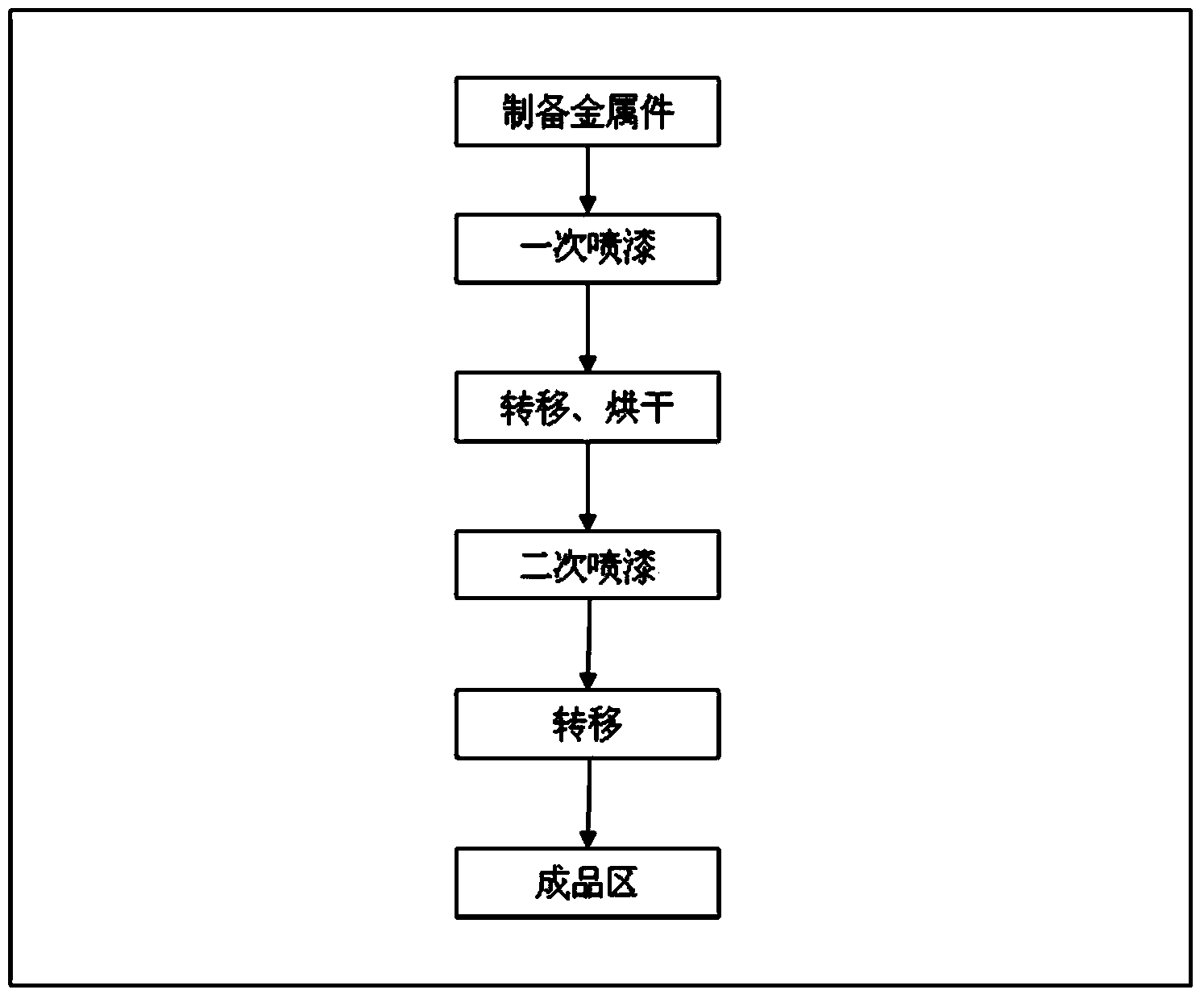

[0034] Embodiment: Referring to Fig. 1, the multi-station and multi-color hardware product spraying method provided by this embodiment includes the following steps:

[0035] (1) Set up a spraying room, and set up a wind speed controller and a humidity controller in the spraying room;

[0036] (2) A plurality of electrostatic automatic spraying machines are installed in the spraying room, and a uniform spray paint layer is formed on the hardware body through the spray guns of the electrostatic automatic spraying machines;

[0037] The first electrostatic automatic spraying machine is installed in the spraying room, and the spraying action is performed under the control of the control system to complete the first color spraying of the multi-color hardware body;

[0038] A second electrostatic automatic spraying machine is set in the spraying room, and the spraying action is performed under the control of the control system to complete the second color spraying of the multi-color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com