All welded steel structured bearing seat of blower fan water-cooling type in large-scale power station, and manufacturing method thereof

A bearing seat, water-cooled technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of difficult casting process, complex bearing seat structure, and affecting corporate reputation, etc., to eliminate casting defects, Good cooling effect and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

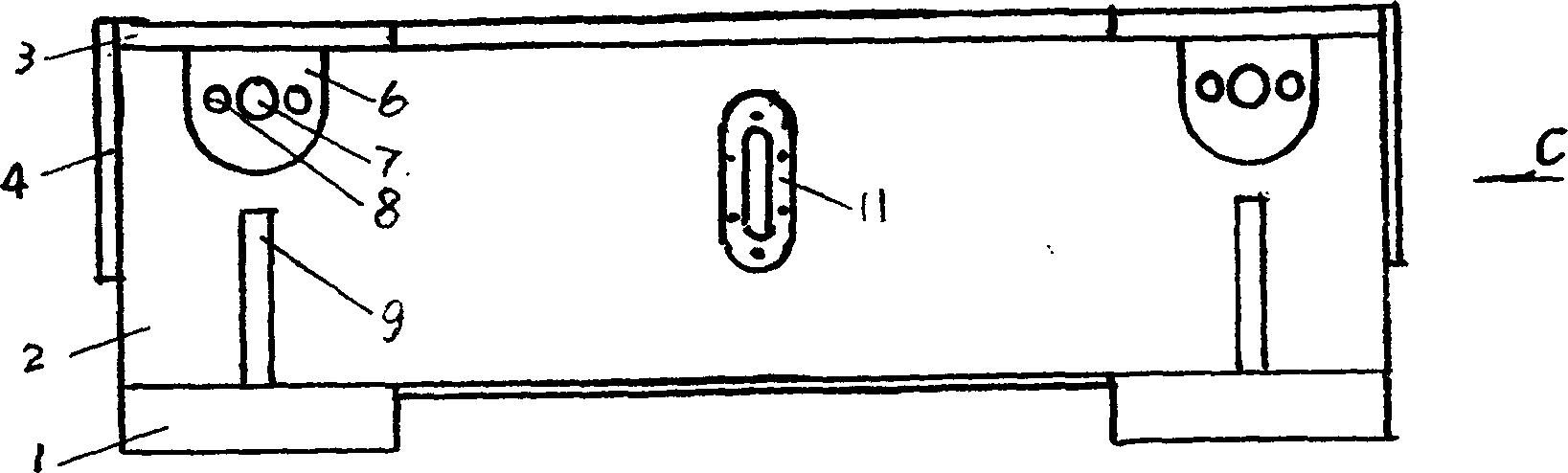

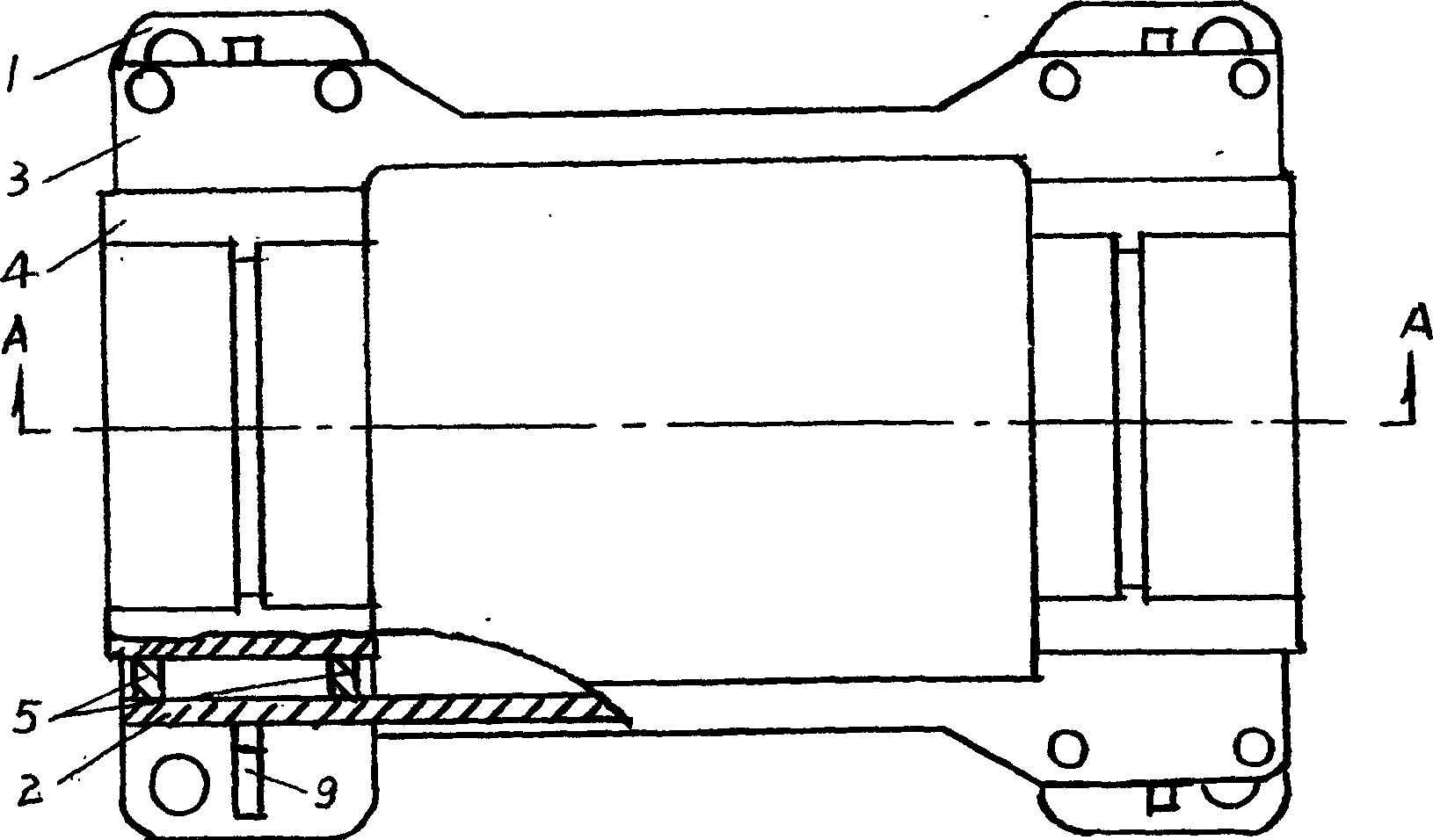

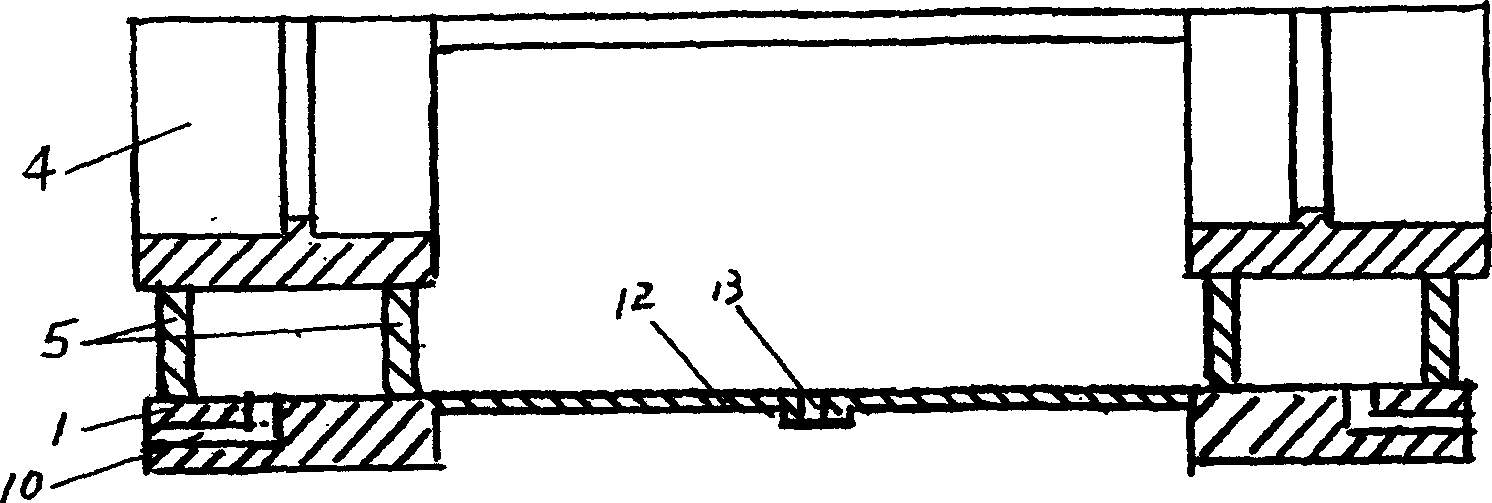

[0053] For cantilever fan bearing housing see Figure 1 to Figure 8 , consisting of a lower seat and an upper cover that cooperate with each other.

[0054] Refer to the structure of the lower seat Figure 1 to Figure 4: It includes a horizontally arranged base 1, two side plates 2 vertically and symmetrically arranged on the base 1, the upper end of the side plate 2 has a horizontally arranged flange 3, and the lower half 4 of the bearing support ring connected with the flange 3, Two liners 5 vertically arranged between the base 1 and the lower half 4 of the bearing support ring, the cavity surrounded by the base 1, the lower half 4 of the bearing support ring, the two liners 5 and the two side plates 2 constitutes The cooling water channel is provided with inlet and outlet flanges 6 on the two side plates 2 respectively. The flange 6 has a hole 7 connecting the cooling water channel and a screw hole 8 for connecting the flange of the external water pipe. The base 1 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com