Sand control sieve pipe and manufacturing method of sand control sieve pipe

A technology of sand control screen and base pipe, which is applied in the direction of manufacturing tools, earth drilling and production fluid, etc. It can solve the problems of increasing the cost of oil extraction and achieve the effect of reducing pipe diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

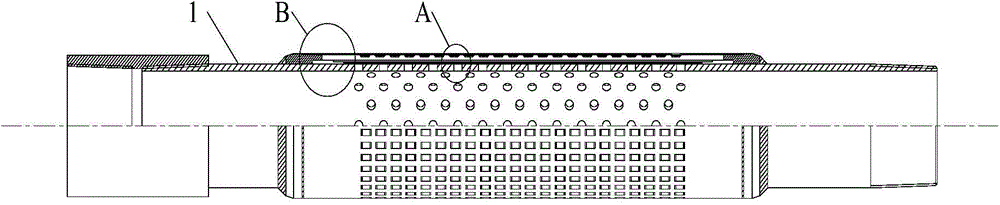

[0079] In order to solve the problem of large sand control screen pipe diameter in the prior art, the present invention provides a sand control screen pipe and a manufacturing method of the sand control screen pipe, in order to reduce the pipe diameter of the sand control screen pipe, so as to reduce the pipe diameter The sand control screen is lowered into the oil and gas wellbore.

[0080] The technical solution of the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

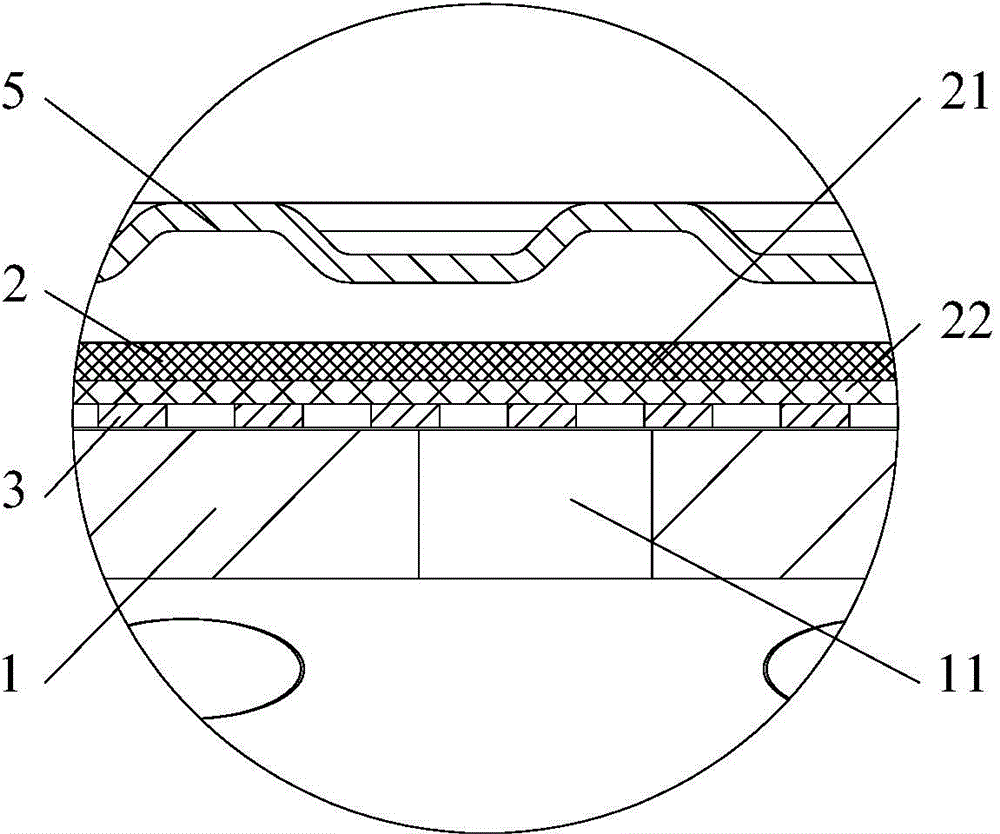

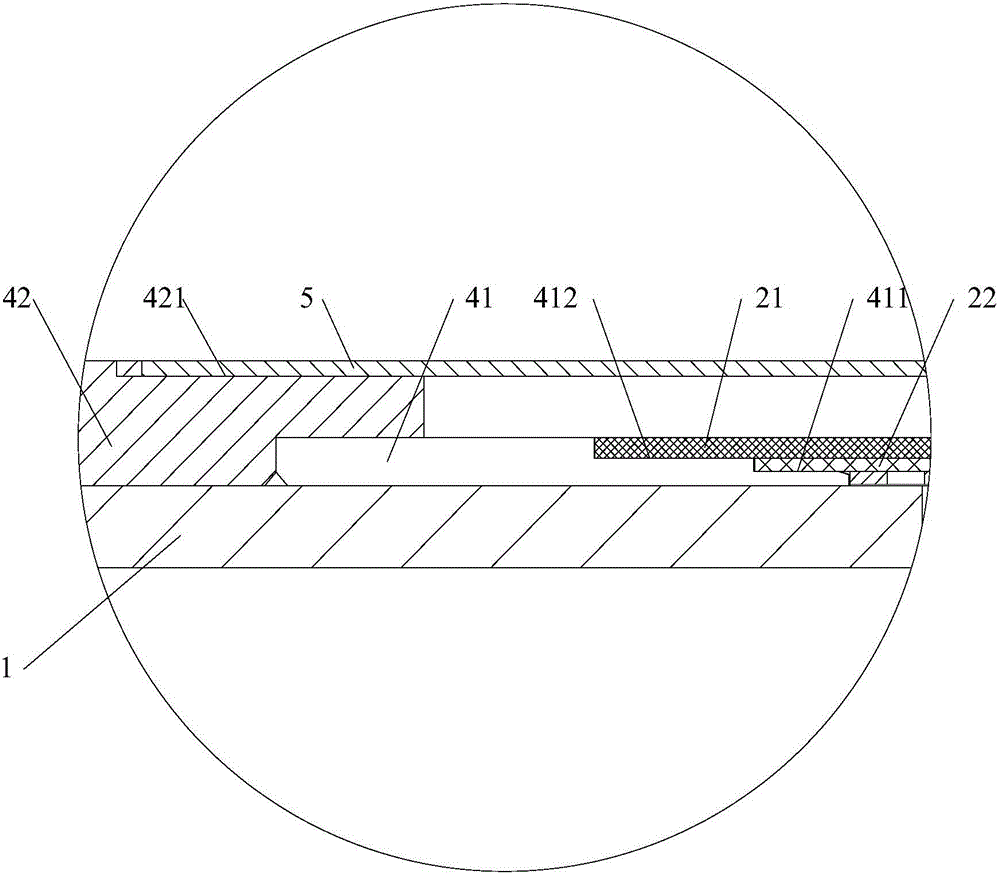

[0081] A sand control screen provided by the present invention includes:

[0082] A base pipe, the pipe wall of which is provided with through holes;

[0083] A filter component, the filter component includes a layer of filter net, the filter net has openings of a first size and diameter, and the first side of the filter net is welded to the second side of the filter net by a welding process A first sleeve structure, the first sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com