Ultra-high temperature passive thin-film temperature sensor and manufacturing method thereof

A technology of film temperature and production method, which is applied in thermometers, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve the problem that temperature sensors cannot accurately measure temperature parameters, etc., to expand the test range and reduce manufacturing. The effect of low cost and saving of production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

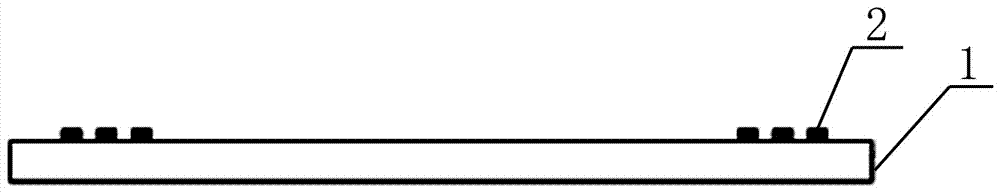

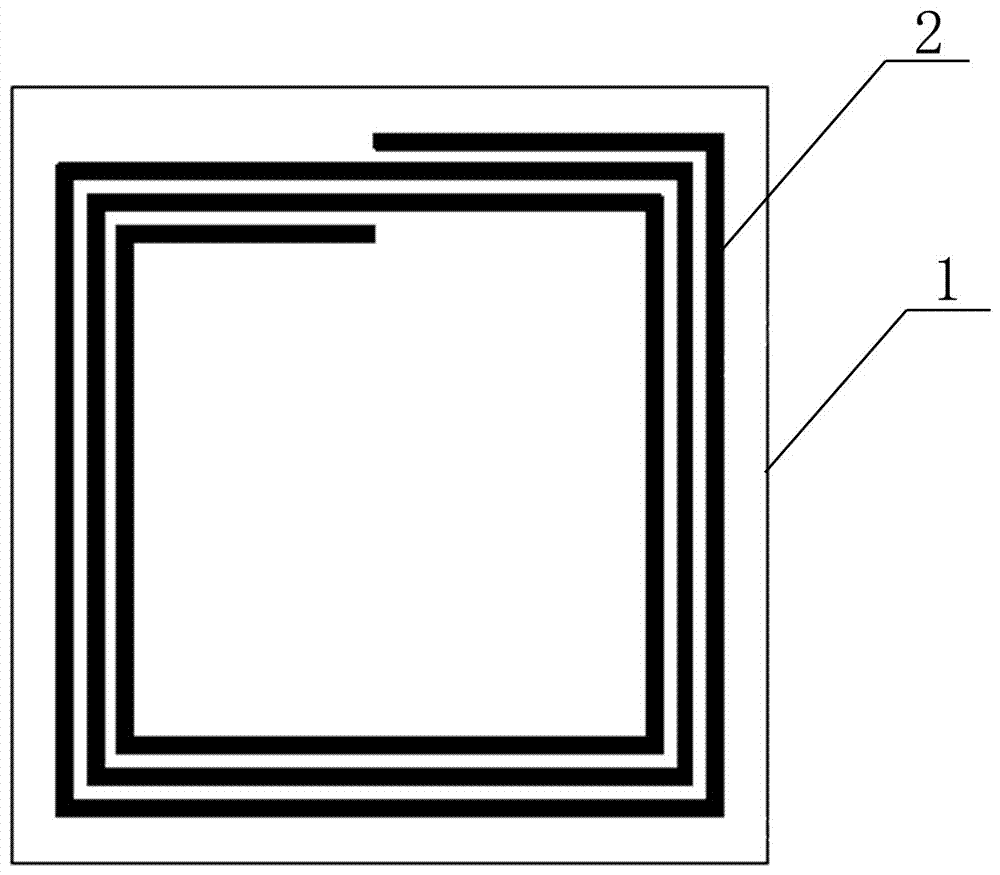

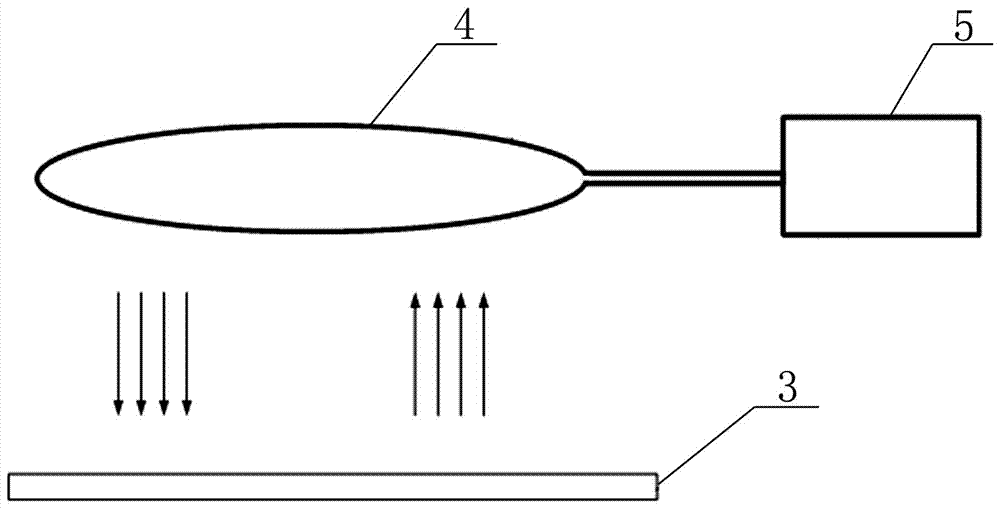

[0042] Such as figure 1 , 2 As shown, an ultra-high temperature passive film temperature sensor includes a dielectric substrate 1 and a planar spiral inductor 2, the dielectric substrate 1 is made of alumina ceramics, the planar spiral inductor 2 is made of platinum metal, and the planar spiral inductor 2 is located at On one side of the dielectric substrate 1, there is a parasitic capacitance in the planar spiral inductor 2, and the planar spiral inductor 2 and the parasitic capacitance form an LC resonant loop.

[0043] According to the relevant theory and experimental results, the Q value of the sensor decreases and the signal strength decreases under high temperature environment. High temperature causes the parasitic capacitance and parasitic resistance of the sensor to increase, and the main reason for signal weakening is the increase of parasitic resistance. Therefore, optimizing the structural size of the sensor and reducing the parasitic resistance are very important...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com