Vehicle suspension performance test device

A test device and vehicle suspension technology, which is applied in the direction of vehicle suspension/shock absorbing mechanism testing, etc., can solve the problems of reducing the reliability of experimental results, and achieve the effects of facilitating early performance testing, reducing development costs, and being easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

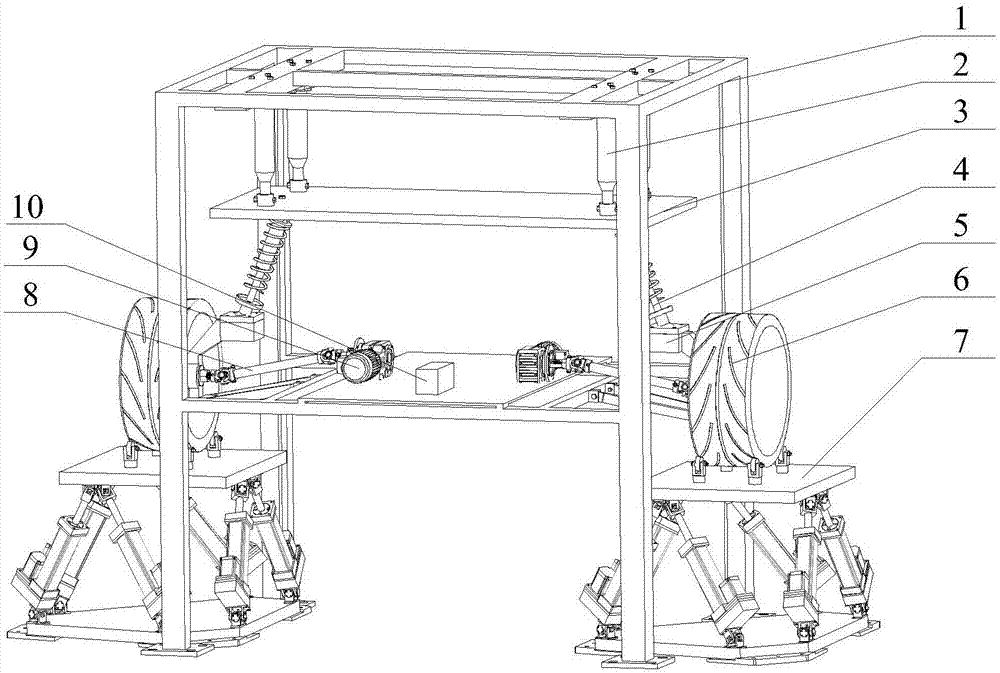

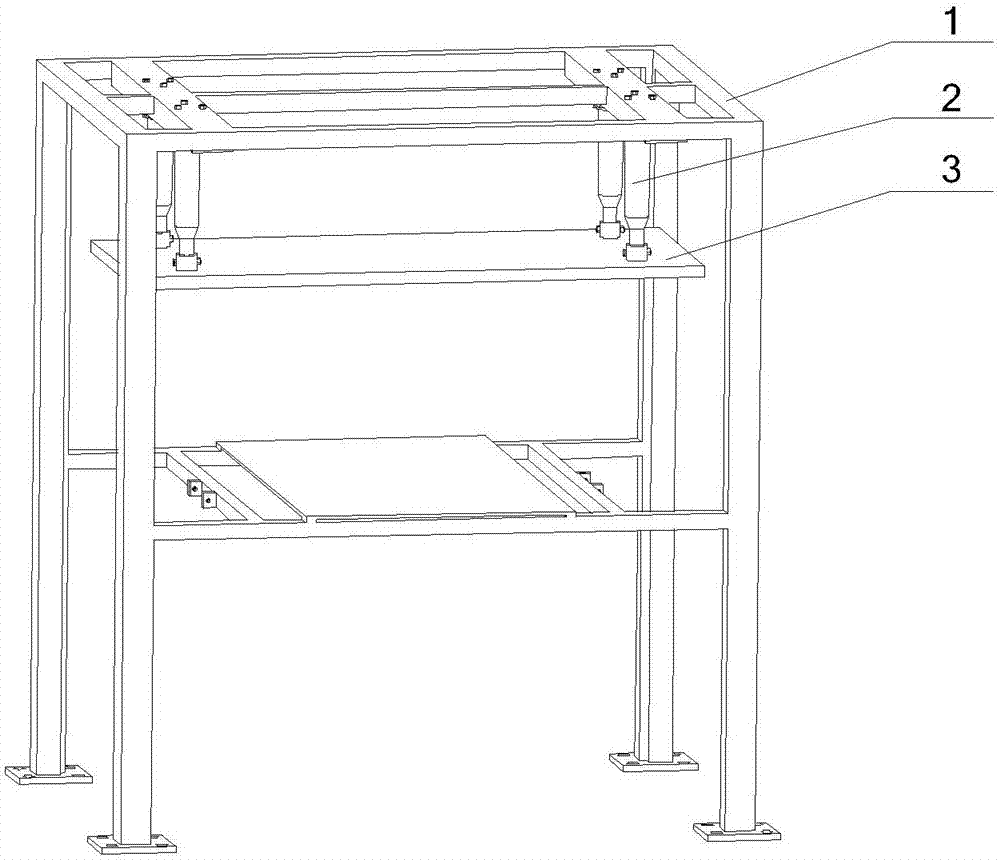

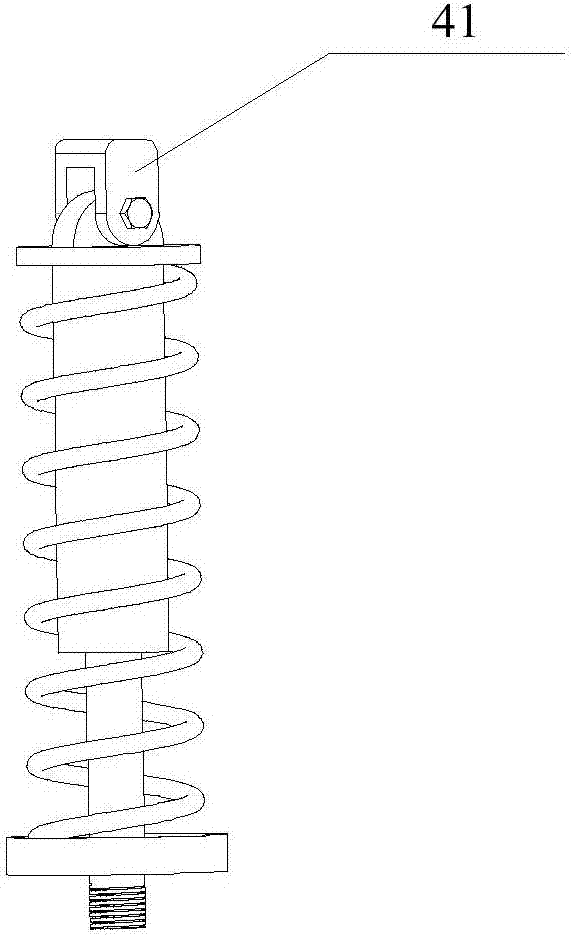

[0021] like figure 1 As shown, the suspension performance testing device of the embodiment of the present invention includes a mounting bracket 1, a hydraulic cylinder 2, a flat plate 3, a suspension 4, a suspension support 5, a rotating device 6, a road condition simulation device 7, a connecting device 8, Drive system 9, test system 10; installation bracket 1 is fixed on the ground by bolts, one end of hydraulic cylinder 2 is fixed on the underside of the beam of installation bracket 1 by screws, and one end is fixedly connected with plate 3 by bolts, and four hydraulic cylinders 2 are simultaneously applied with 1 / 2 of the weight of the car body is loaded on the flat plate 3, the suspension 4 is fixed on the lower side of the flat plate by bolts and connects with the connecting piece 41 to form a rotatable connection, and its lower part is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com