Connection test device, insulation test device and test system of universal test machine

A technology of conduction test and insulation test, which is applied in the direction of measuring device, electronic circuit test, and test of dielectric strength, etc. It can solve the problem that the measurement circuit cannot meet the test requirements, so as to improve the measurement accuracy, ensure stability, and achieve large-scale measurement. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

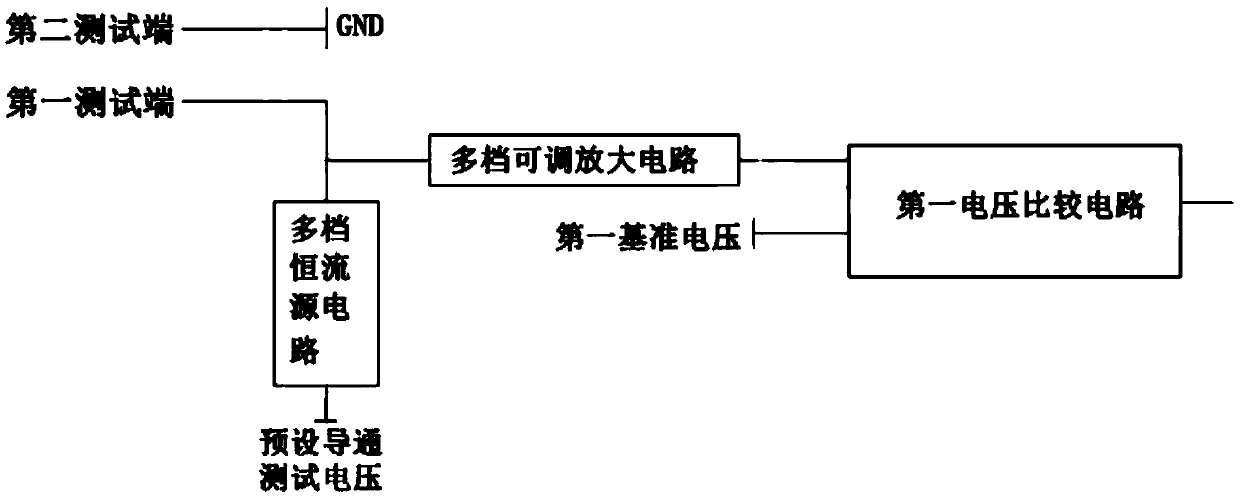

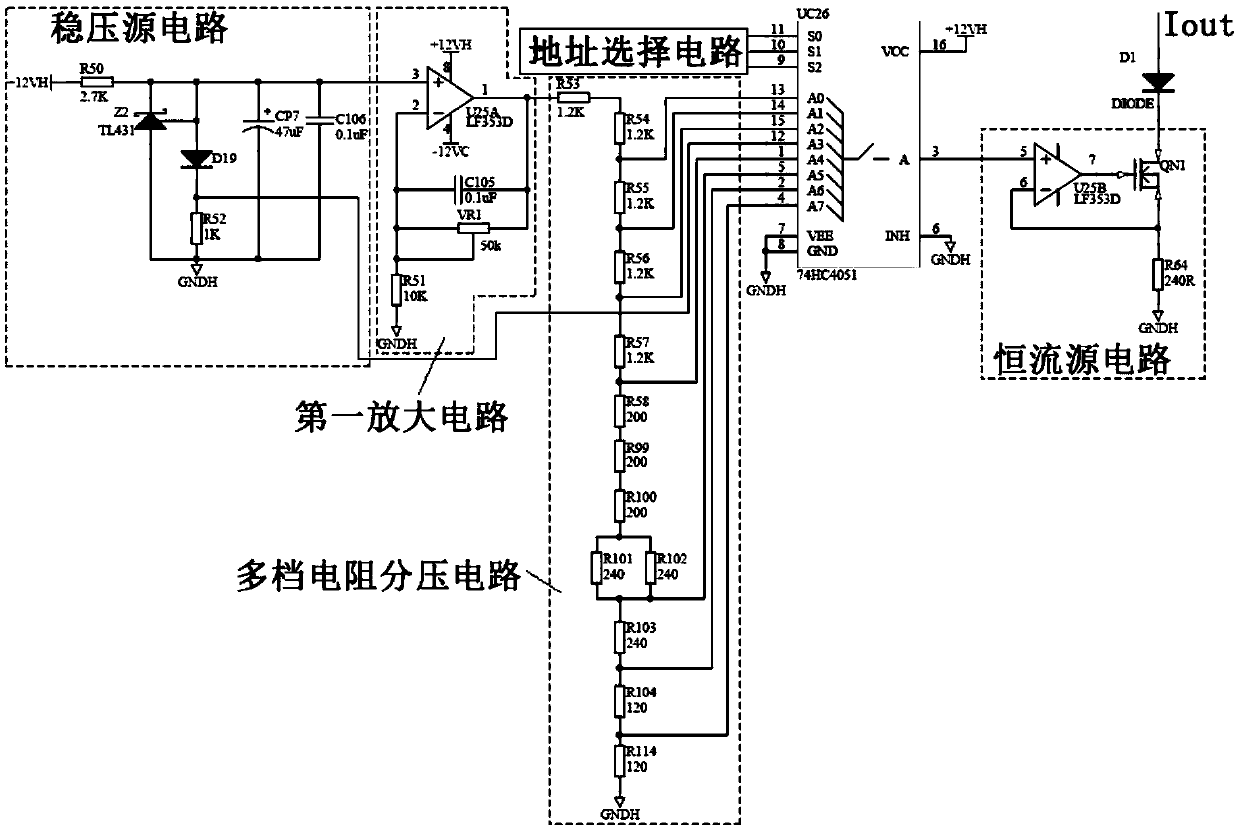

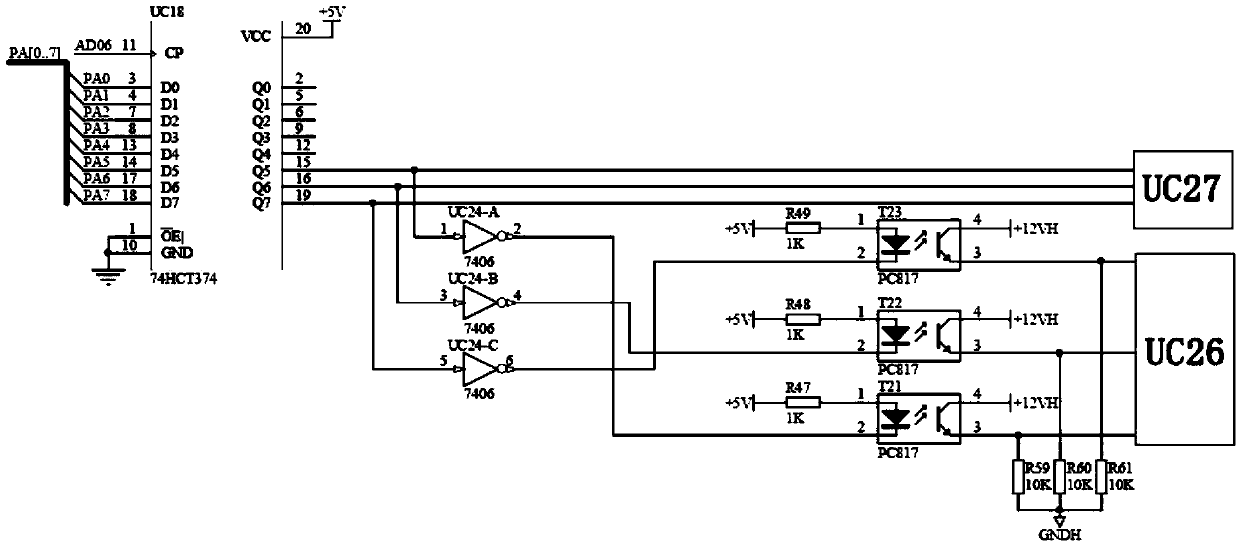

[0066] This embodiment provides a conduction test device. Various control signals and control commands in this embodiment are output by a host computer connected to the conduction test device, such as figure 1 As shown, it includes: a first test terminal, a second test terminal, a multi-level constant current source circuit, a multi-level adjustable amplifier circuit and a first voltage comparison circuit, wherein

[0067] The first test terminal is connected to one end of the multi-level constant current source circuit and the multi-level adjustable amplifier circuit;

[0068] The second test terminal is grounded, and the first test terminal and the second test terminal are used to respectively connect with two test points on the circuit board to be tested, so as to test whether the conduction between the two test points is qualified;

[0069] The other end of the multi-level constant current source circuit is connected to the preset conduction test voltage, which is used to ...

Embodiment 2

[0089] This embodiment provides an insulation testing device. Various control signals and control commands in this embodiment are output by a host computer connected to the insulation testing device, such as Figure 6 As shown, it includes: a third test terminal, a fourth test terminal, an operational amplifier circuit and a second voltage comparison circuit, wherein

[0090] The operational amplifier circuit includes a plurality of feedback circuits and an operational amplifier U17A, one end of the plurality of feedback circuits is respectively connected to the first input terminal of the operational amplifier U17A, and the other end is respectively connected to the output terminal of the operational amplifier U17A as the output terminal of the operational amplifier circuit, The second input terminal of the operational amplifier U17A is grounded;

[0091] Each of the plurality of feedback circuits includes a first feedback resistor and a controllable switch connected in serie...

Embodiment 3

[0099] Such as Figure 7 As shown, this embodiment provides a test system for a general test machine. Various control signals and control commands in this embodiment are output by the host computer connected to the test system, including multi-level constant current source circuits, multi-level An adjustable amplifier circuit, a first voltage comparison circuit, an operational amplifier circuit and a second voltage comparison circuit, a first controllable switch, and fifth and sixth test terminals, wherein

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com