Anode special for oxidation of deep hole aluminum piece hard anode and oxidation method of deep hole aluminum piece hard anode

A hard anodizing and deep-hole aluminum technology, applied in anodizing, electrodes, etc., can solve the problems of uneven oxide film thickness of workpieces, ablation of workpieces and fixtures, and high cost of fixtures, so as to improve the fixing reliability and performance Stable, fast and convenient effect on fixing the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

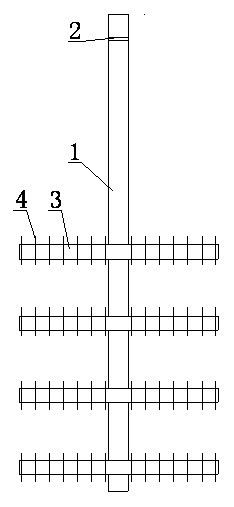

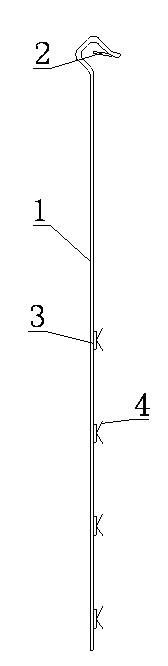

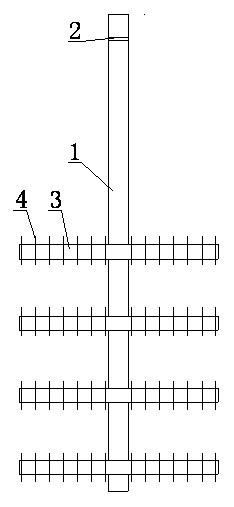

[0022] During specific implementation, a special anode for hard anodizing of deep-hole aluminum parts is obtained by a method comprising the following steps: a. making a preliminary product, the structure of which is as follows: figure 1 and figure 2 As shown, it includes a vertical strip-shaped support rod 1, one end of the support rod 1 has a spring clip 2, and the other end of the support rod 1 is evenly spaced and horizontally connected with a plurality of support bars 3, and the support bars 3 are evenly spaced vertically. A plurality of connecting bars 4 are connected, and the middle part of the connecting bar 4 is connected to the supporting bar 3. The supporting bar 1 and the supporting bar 3 are made of a titanium plate of material TA2 sheet material δ5, and the connecting bar 4 is made of TA2φ2 .5mm titanium wire, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com