Patents

Literature

130results about How to "Conducive to thin design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

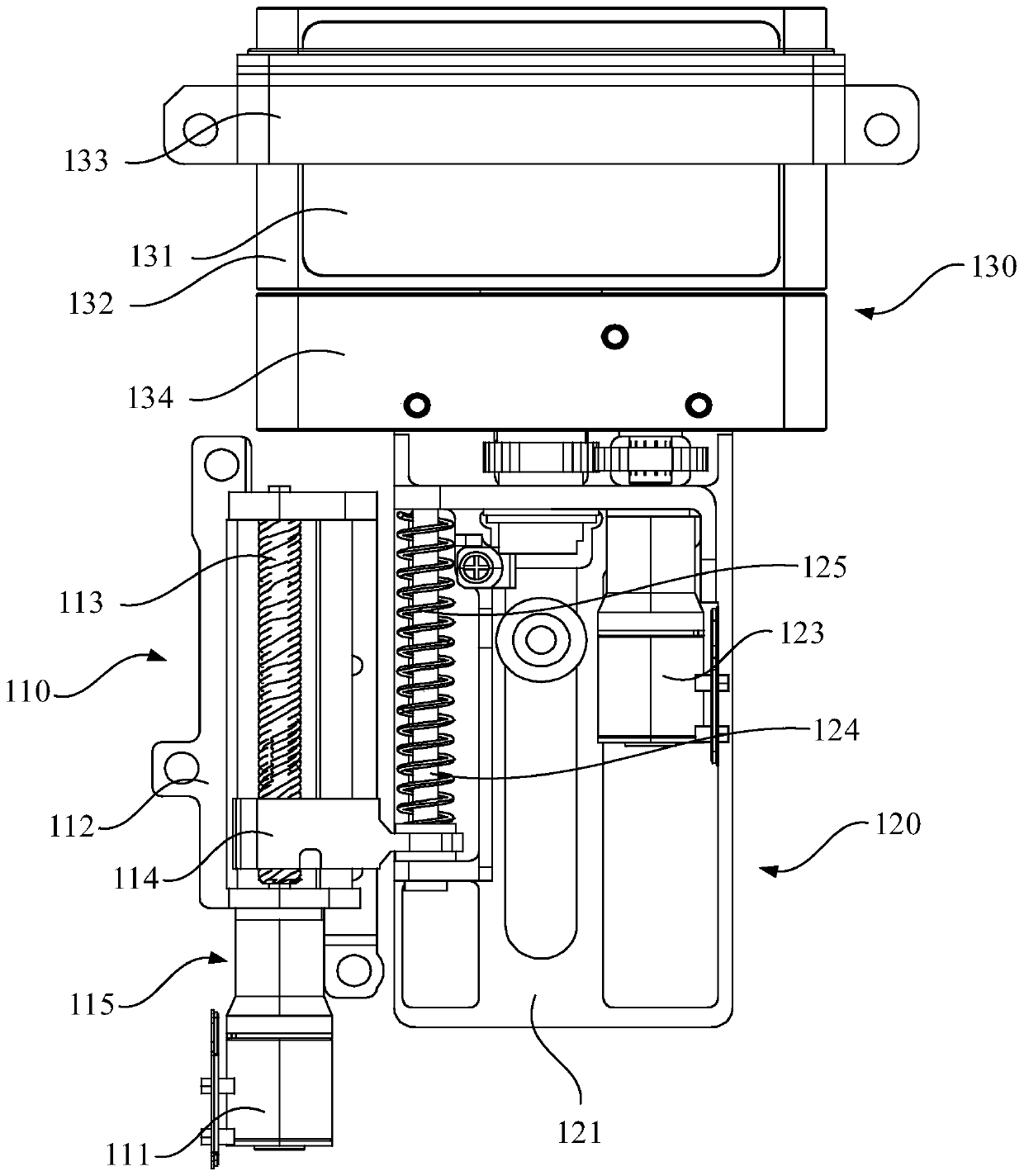

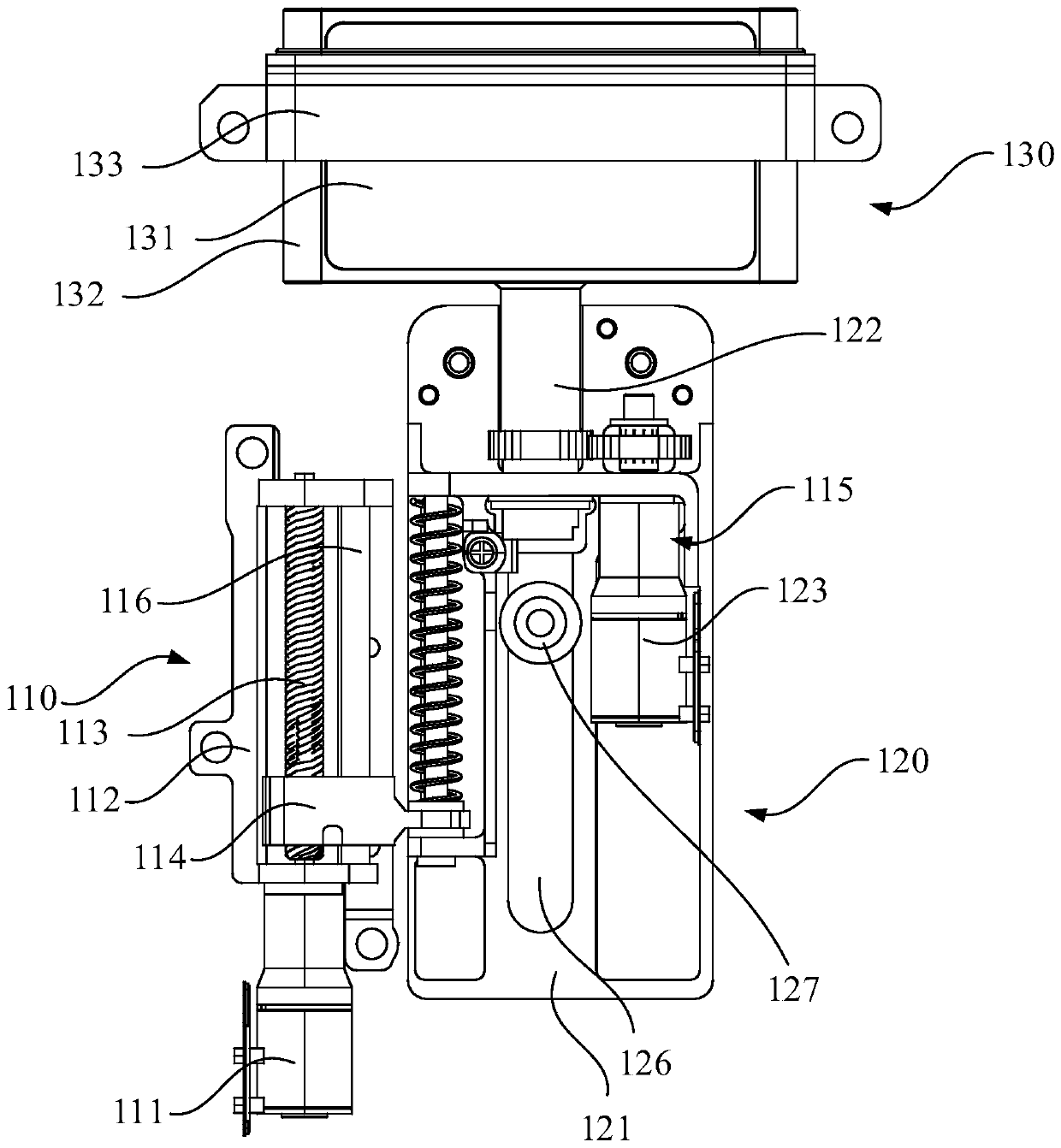

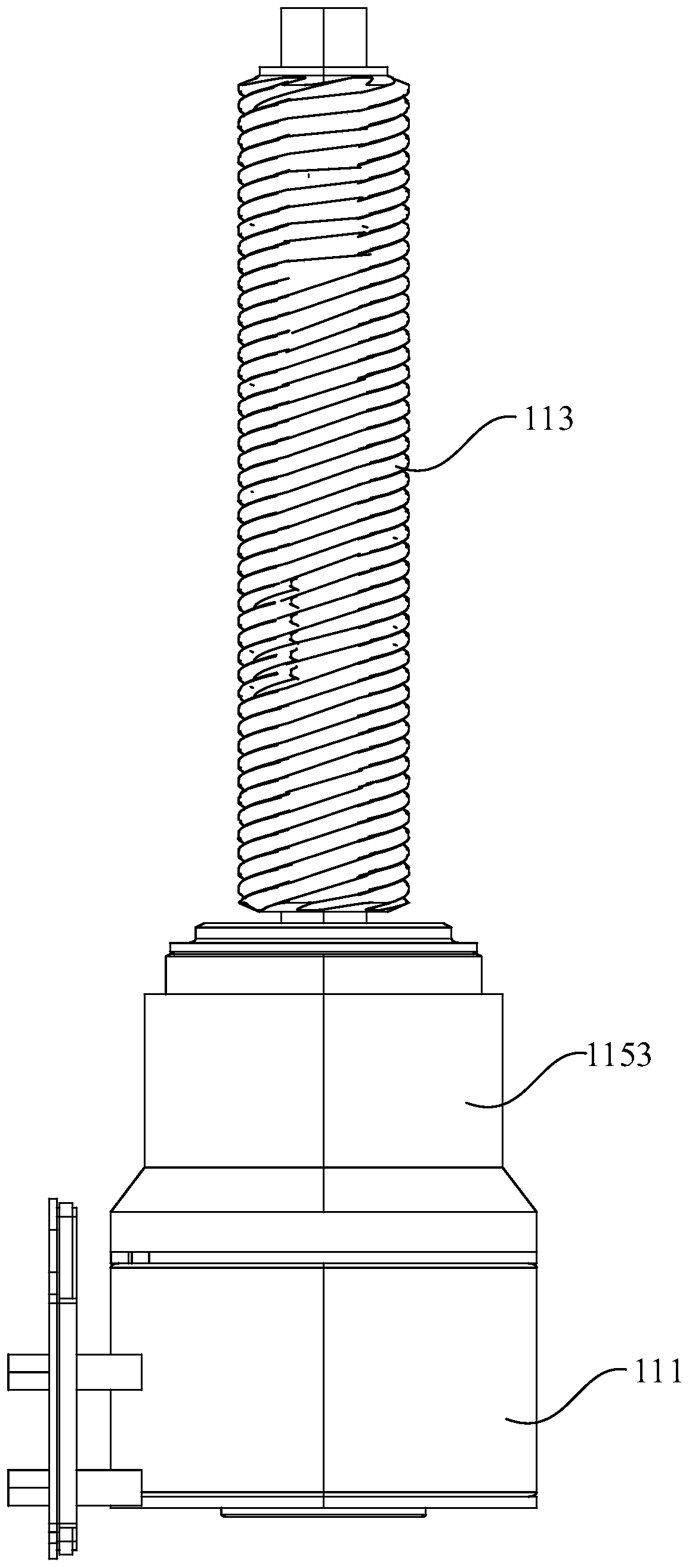

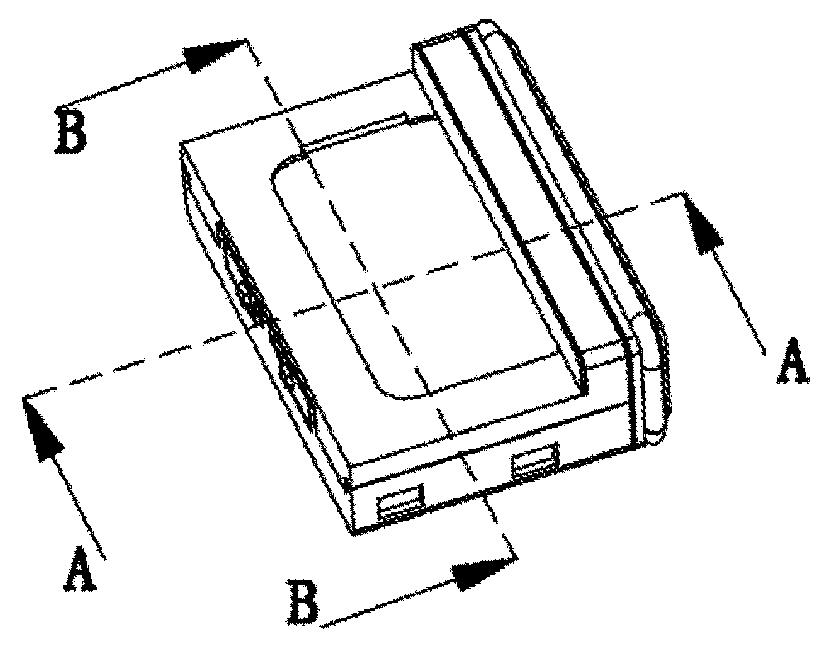

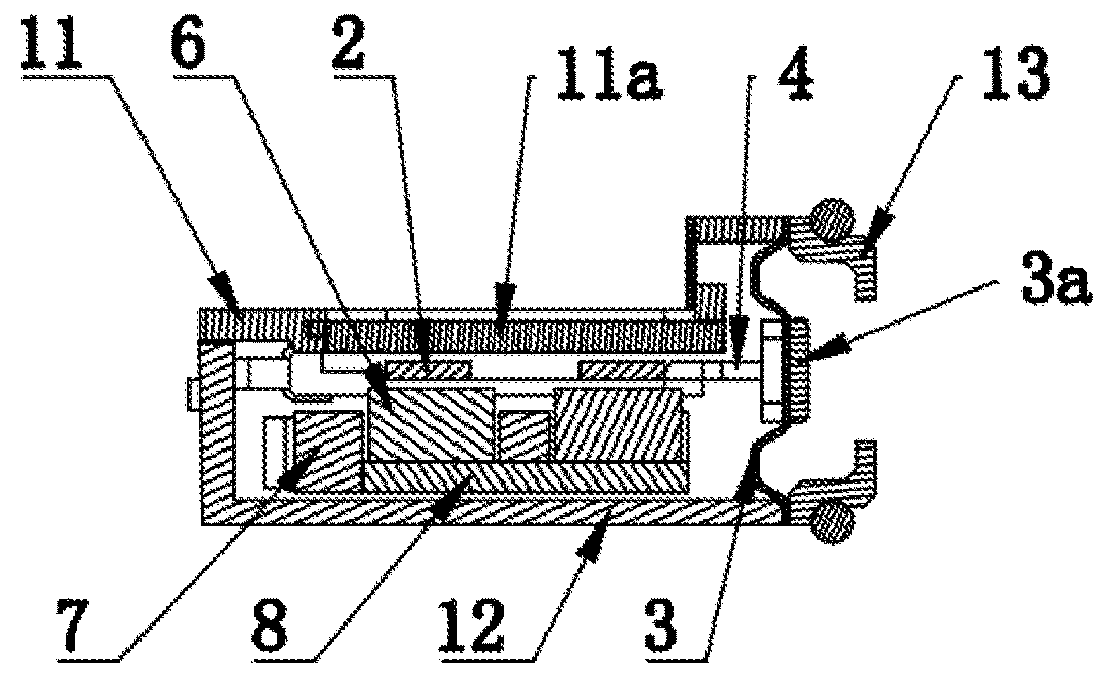

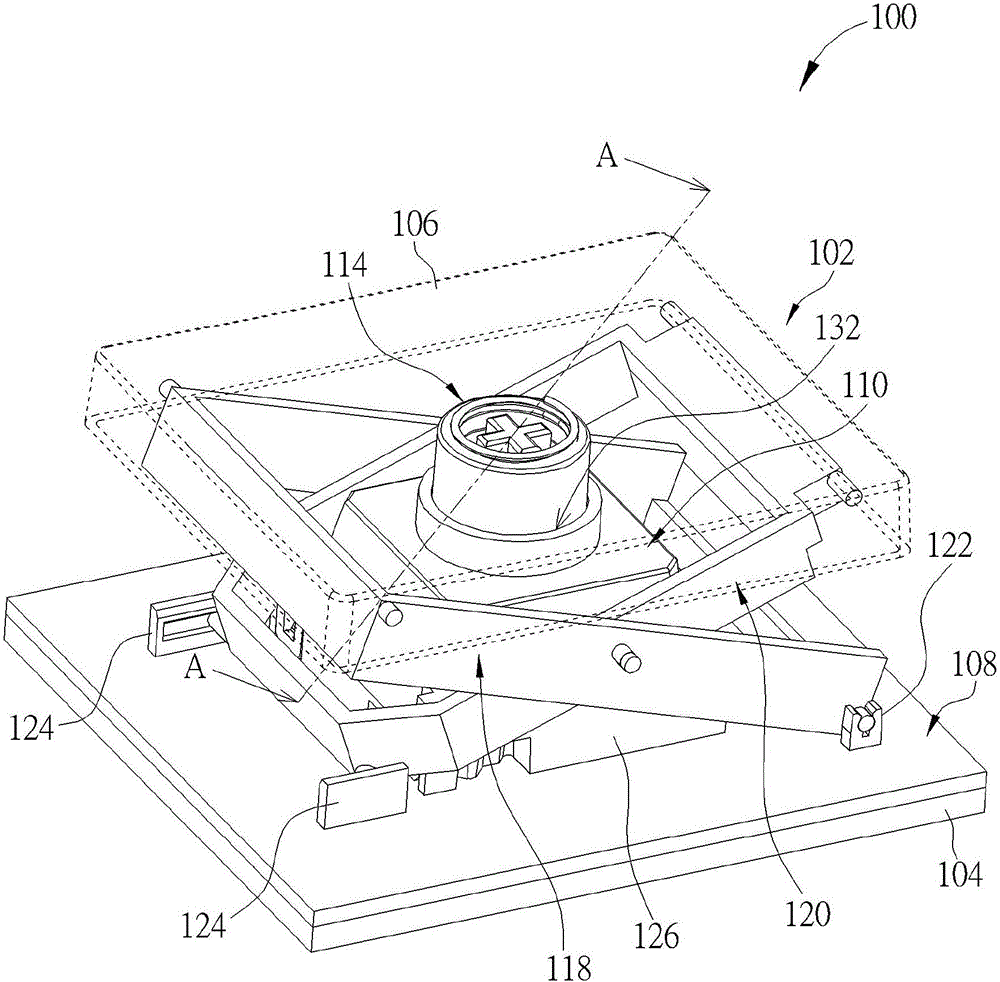

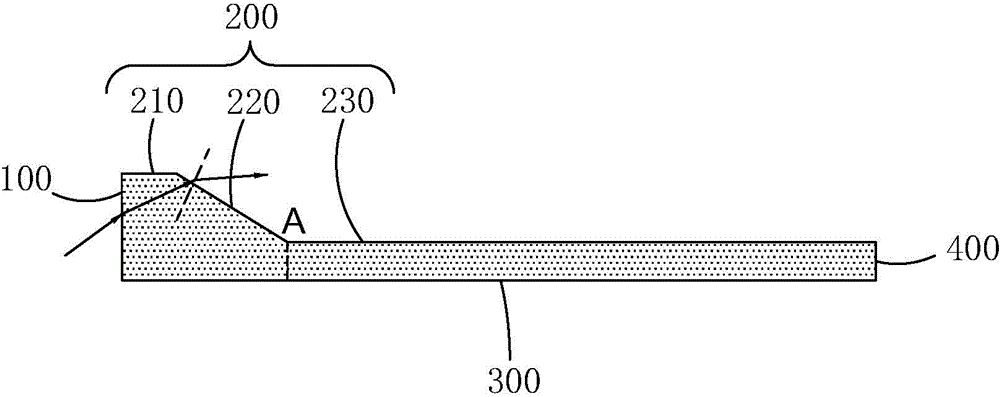

Camera mechanism and electronic equipment

PendingCN110035213AAppearance effectReduce in quantityTelevision system detailsColor television detailsEngineeringControl circuit

The invention provides a camera mechanism and electronic equipment, and belongs to the field of electronic equipment. The camera mechanism comprises a pushing assembly, a rotating assembly and a camera shooting assembly; the rotating assembly comprises a bracket, and an output shaft and a first driving device which are arranged on the bracket; the first driving device is in transmission connectionwith the output shaft and used for driving the output shaft to rotate, one end of the output shaft extends out of the bracket and is connected with the camera shooting assembly, and the output end ofthe pushing assembly is connected with the bracket to push the bracket to move linearly in the axial direction of the output shaft. The electronic equipment comprises a shell, a control circuit and the camera mechanism, the camera mechanism and the control circuit are both arranged in the shell, a pushing assembly of the camera mechanism is fixedly connected with the shell and electrically connected with the control circuit, and a first driving device of the camera mechanism is electrically connected with the control circuit.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

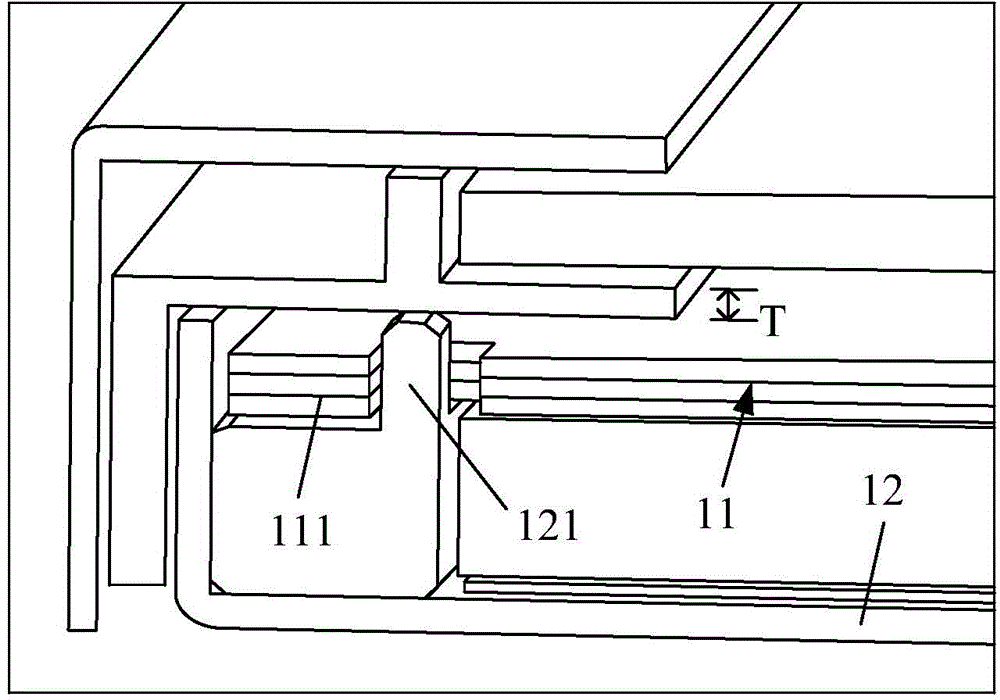

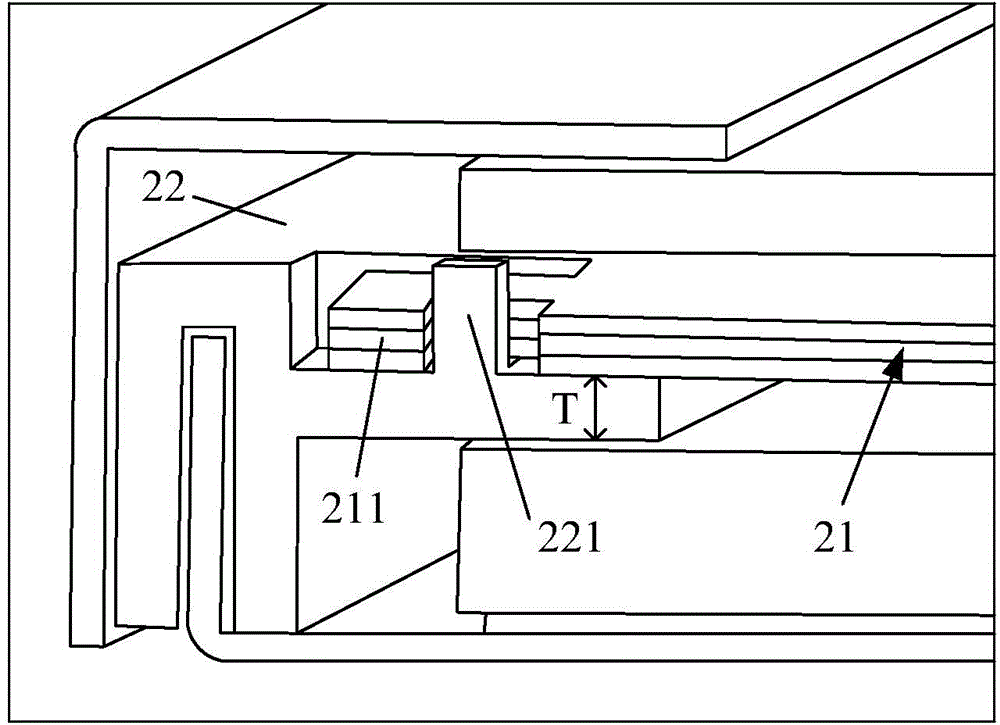

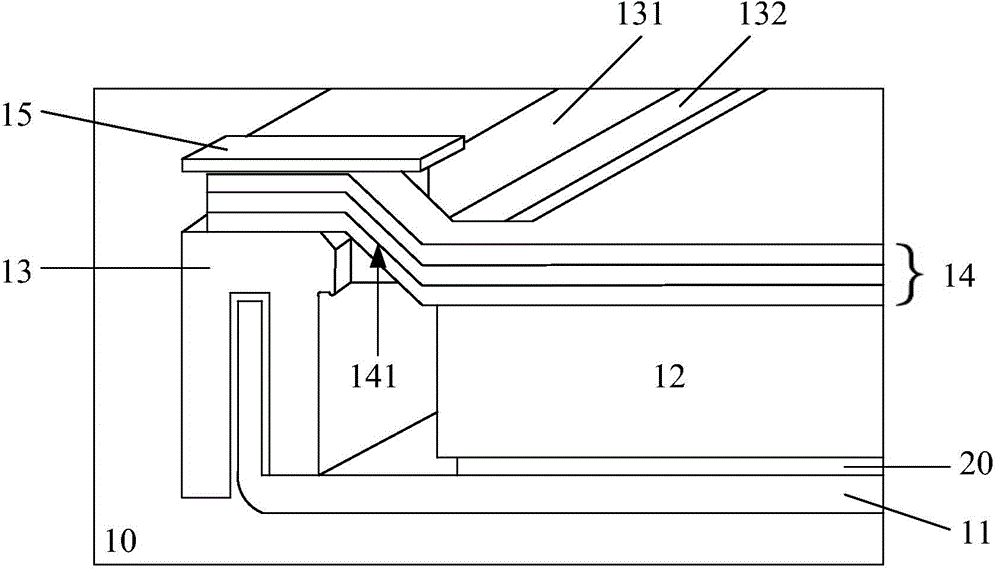

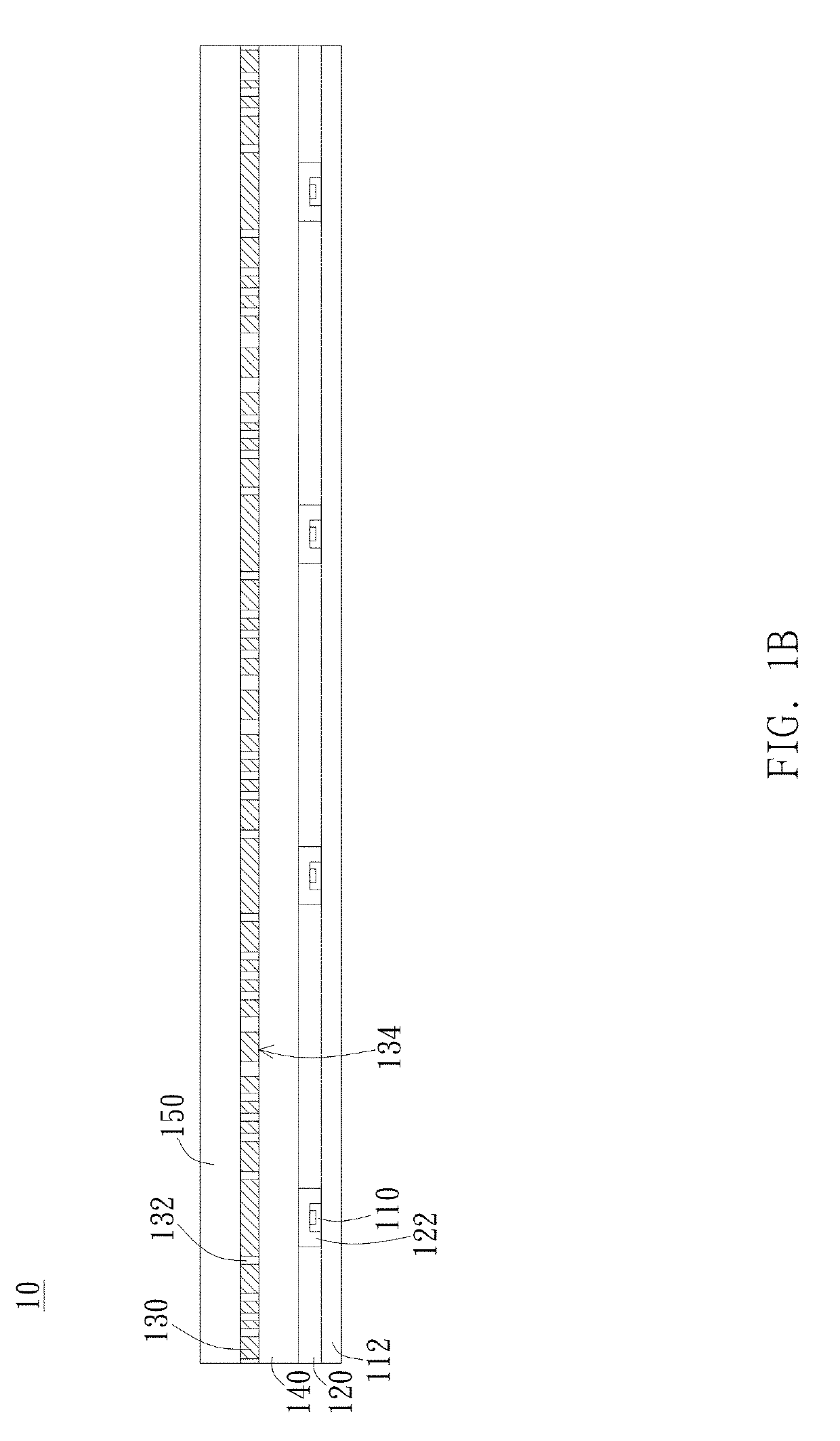

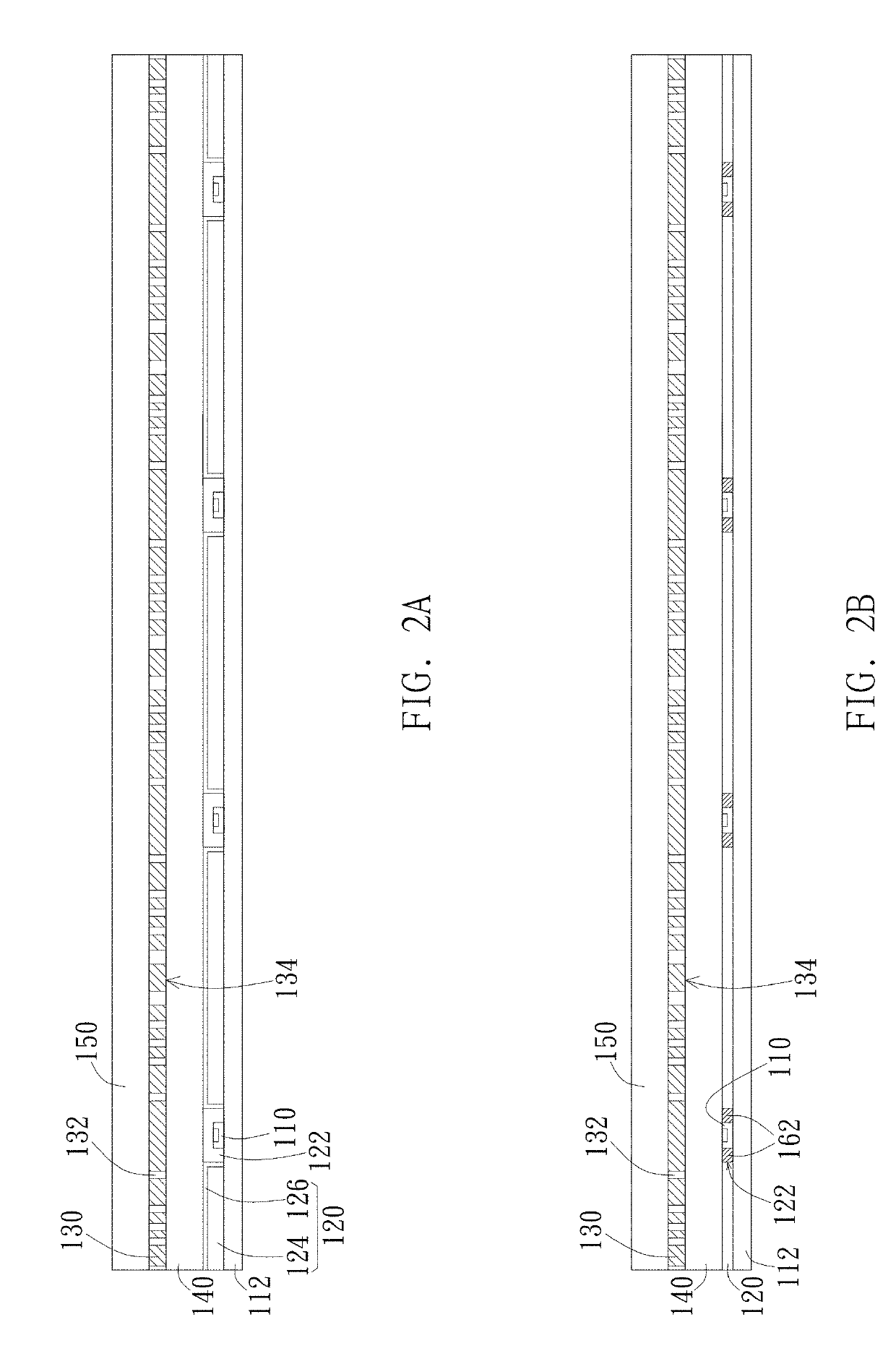

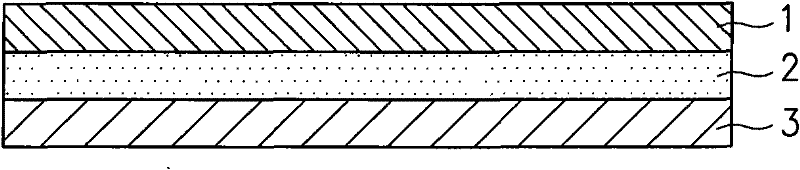

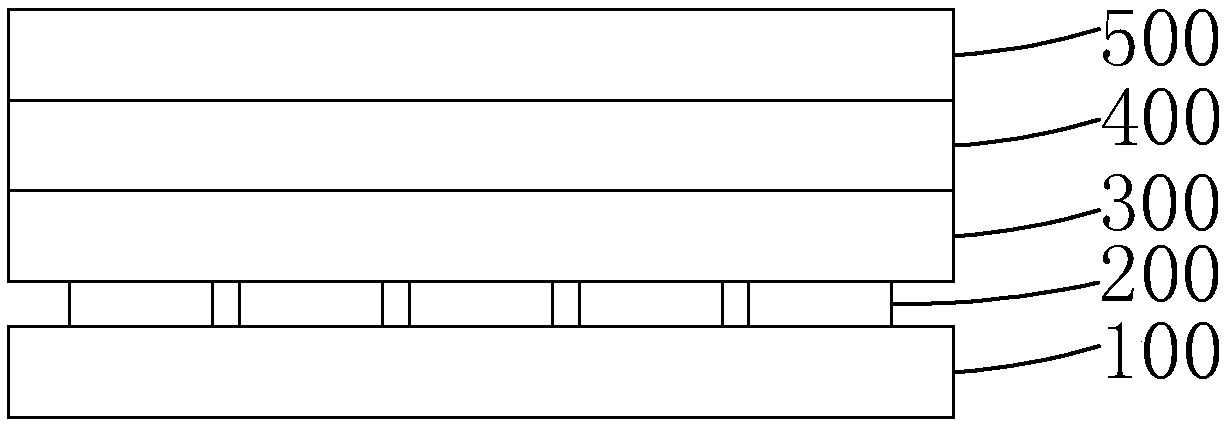

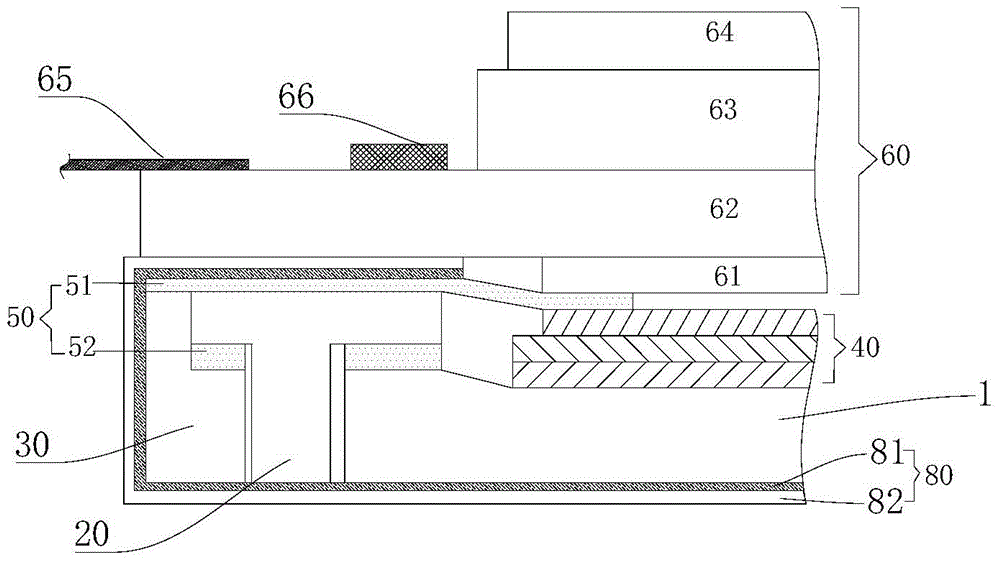

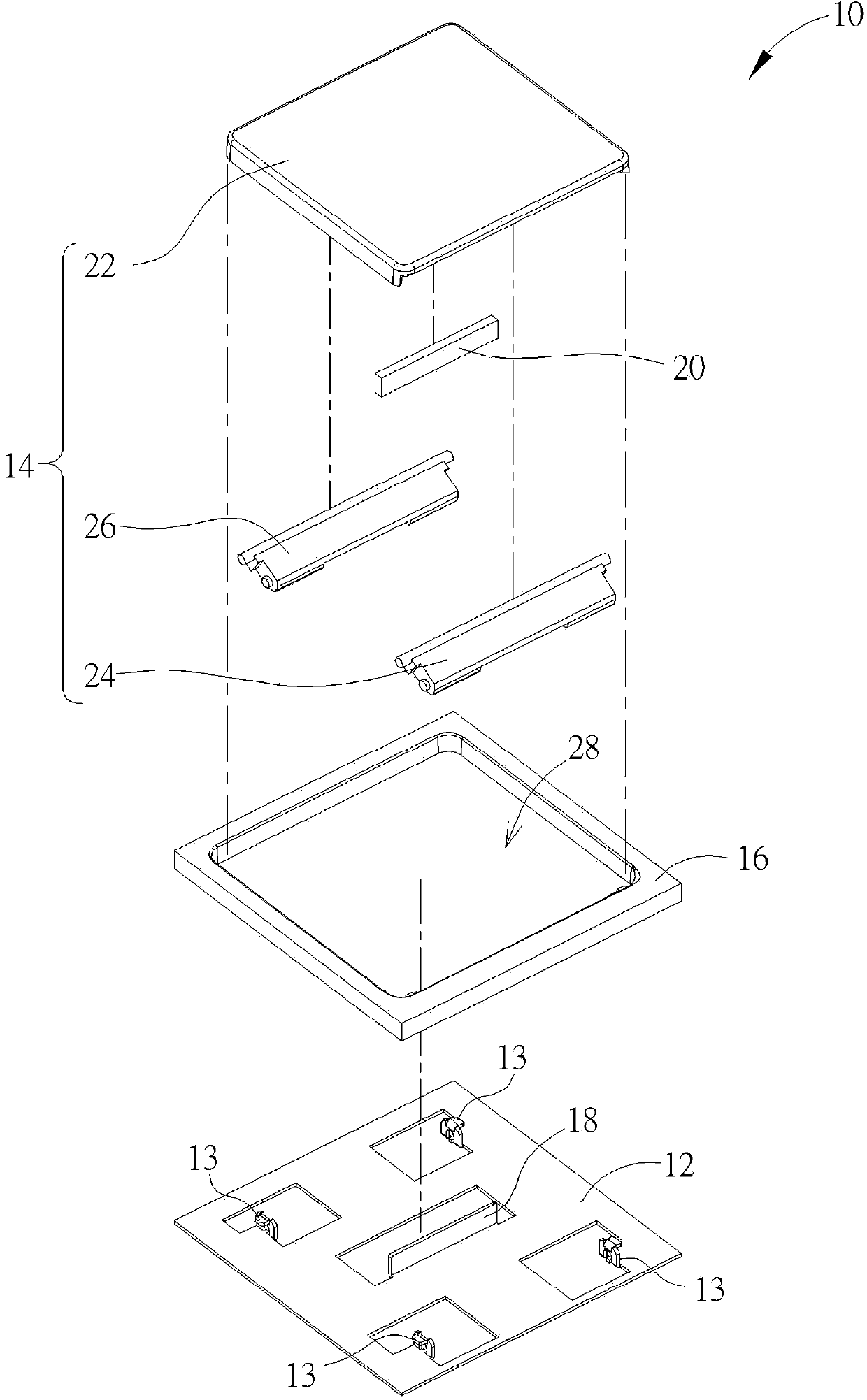

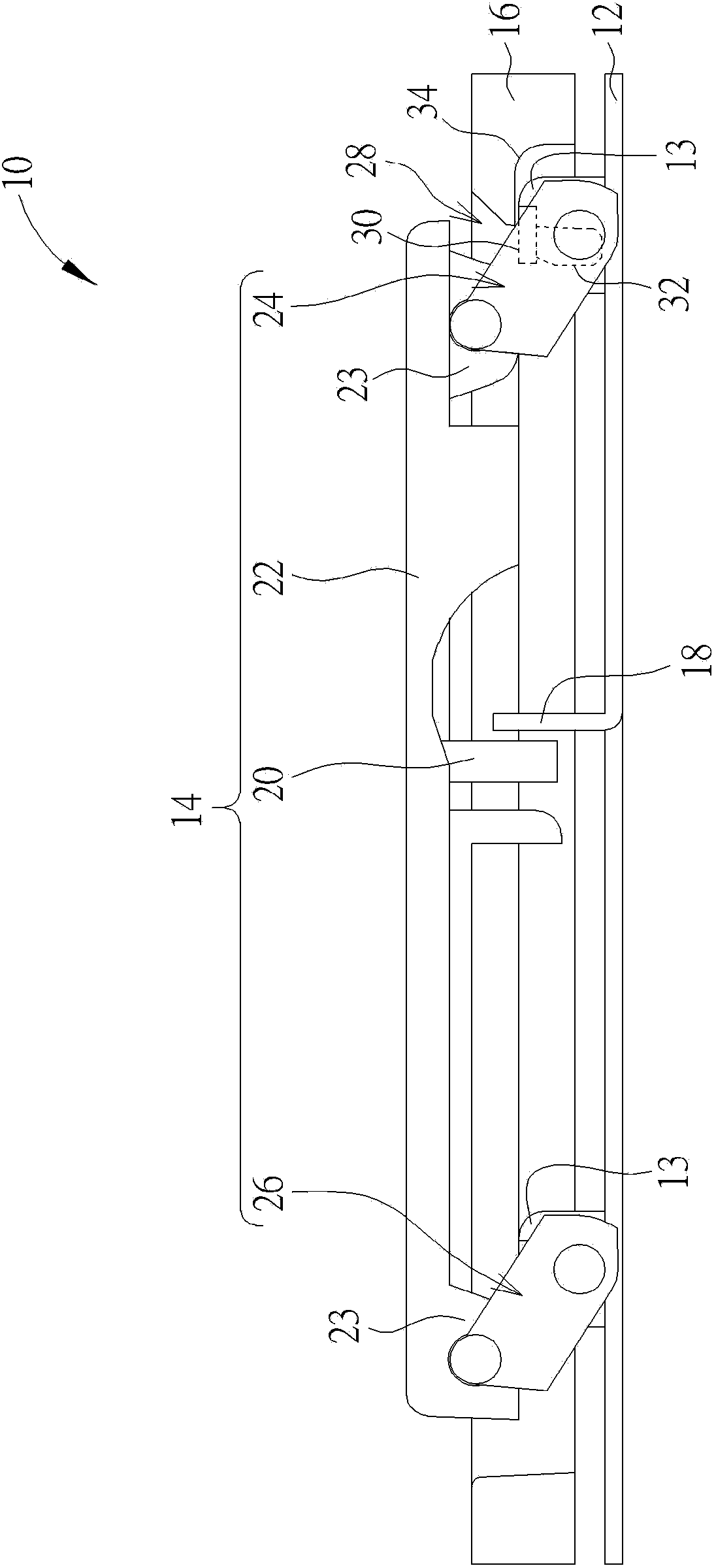

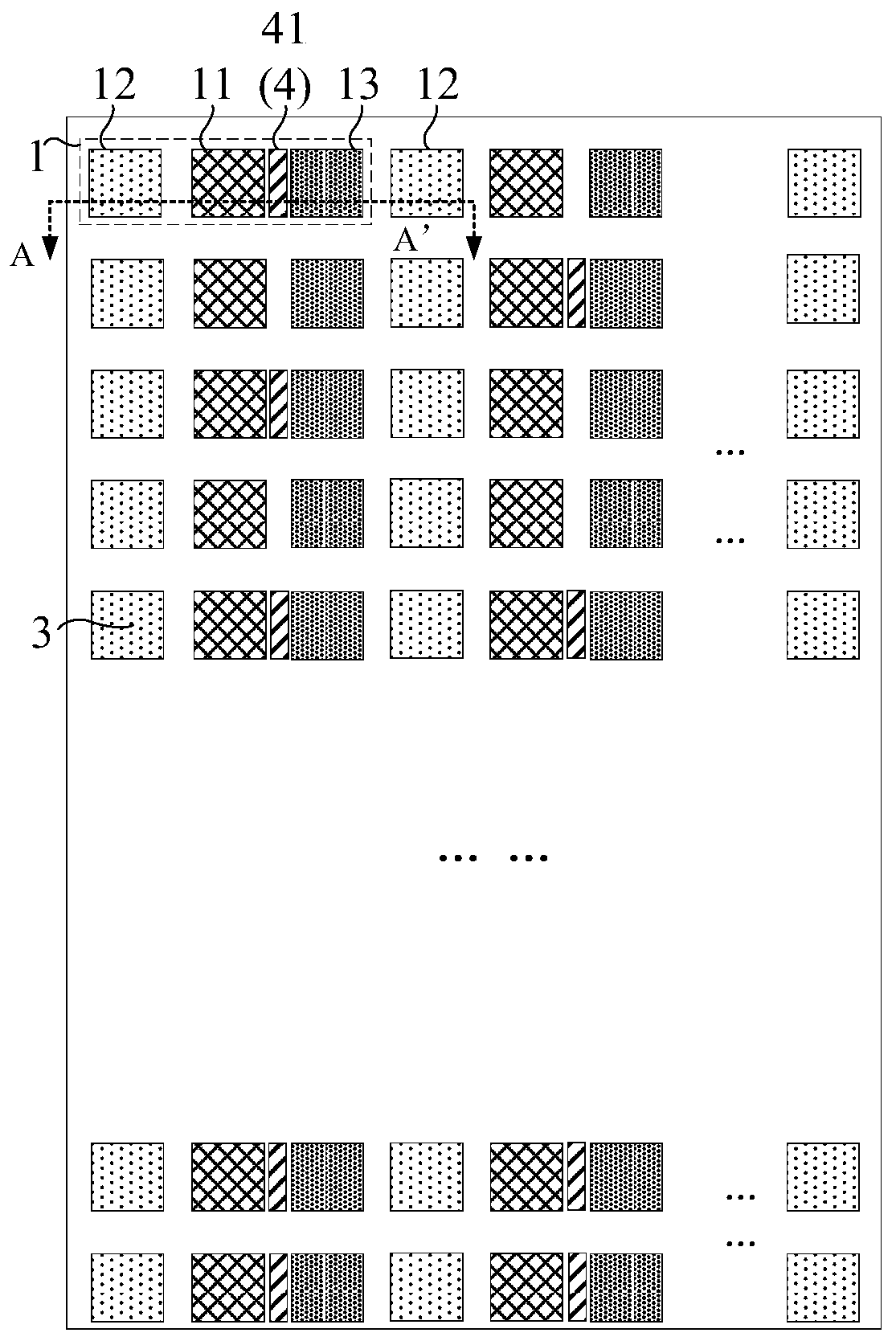

Liquid crystal display device and backlight module

ActiveCN104315415AAvoid misalignmentAchieve positioningOptical light guidesLight fasteningsLiquid-crystal displayLight guide

The invention provides a liquid crystal display device and a backlight module. An optical film group of the backlight module comprises at least one lug portion, each lug portion comprises a barb portion and an extension portion, and each barb portion extends towards a rubber frame from the edge of the optical film group. The rubber frame of the backlight module is provided with a first bearing portion and a second bearing portion, the first bearing portion and the second bearing portion extend towards a light guide plate, the first bearing portion is provided with a containing groove and a retaining portion, and the second bearing portion is used for bearing a display panel and enabling the display panel to be abutted against the first bearing portion. A first notch communicated with the containing groove is formed in the retaining portion, the extension portion is penetratingly arranged in the first notch, the barb portion is contained in the containing groove, and the retaining portion prevents the barb portion from moving towards the light guide plate. Thinning design of the liquid crystal display device is benefitted while positioning of the optical film group is realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

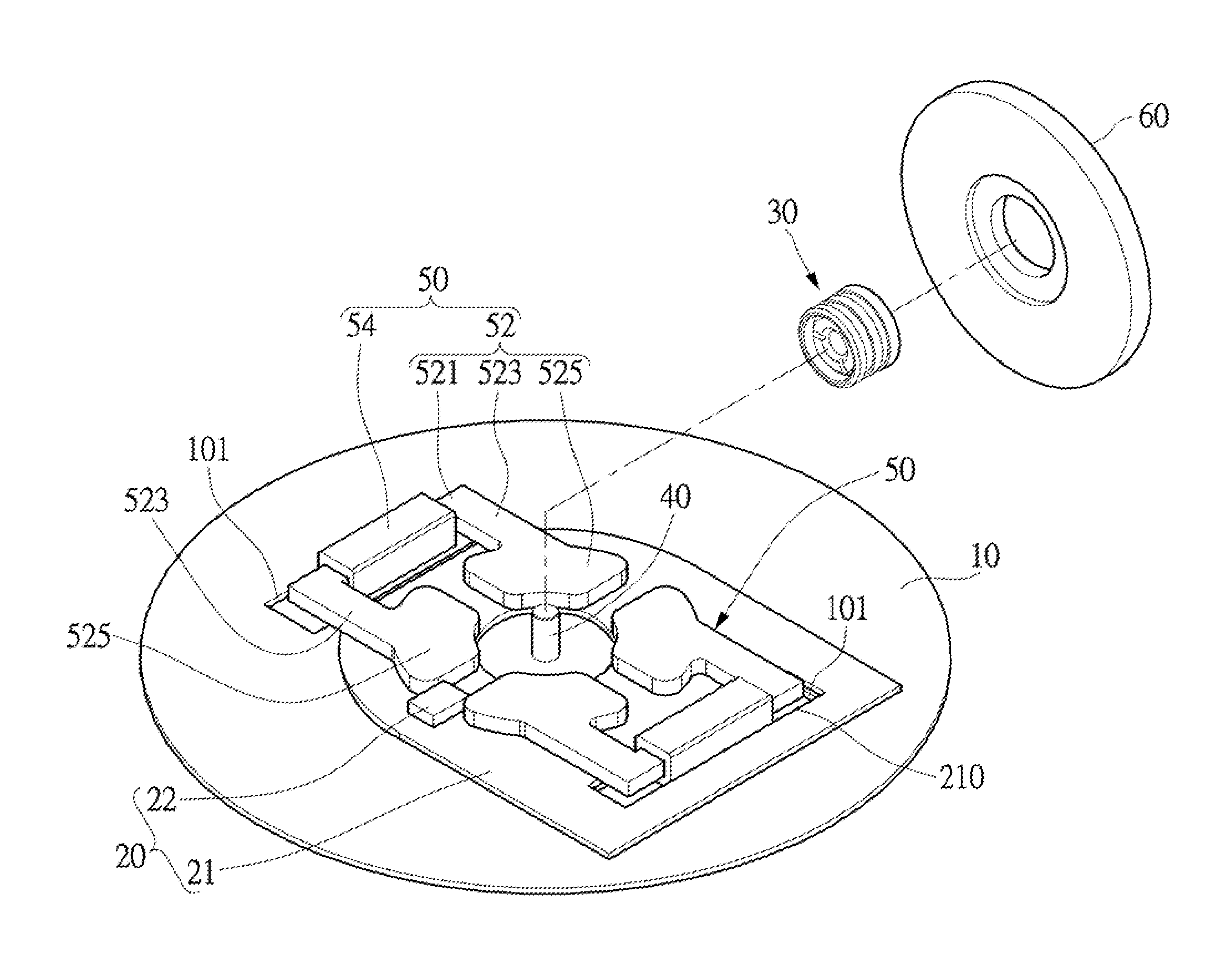

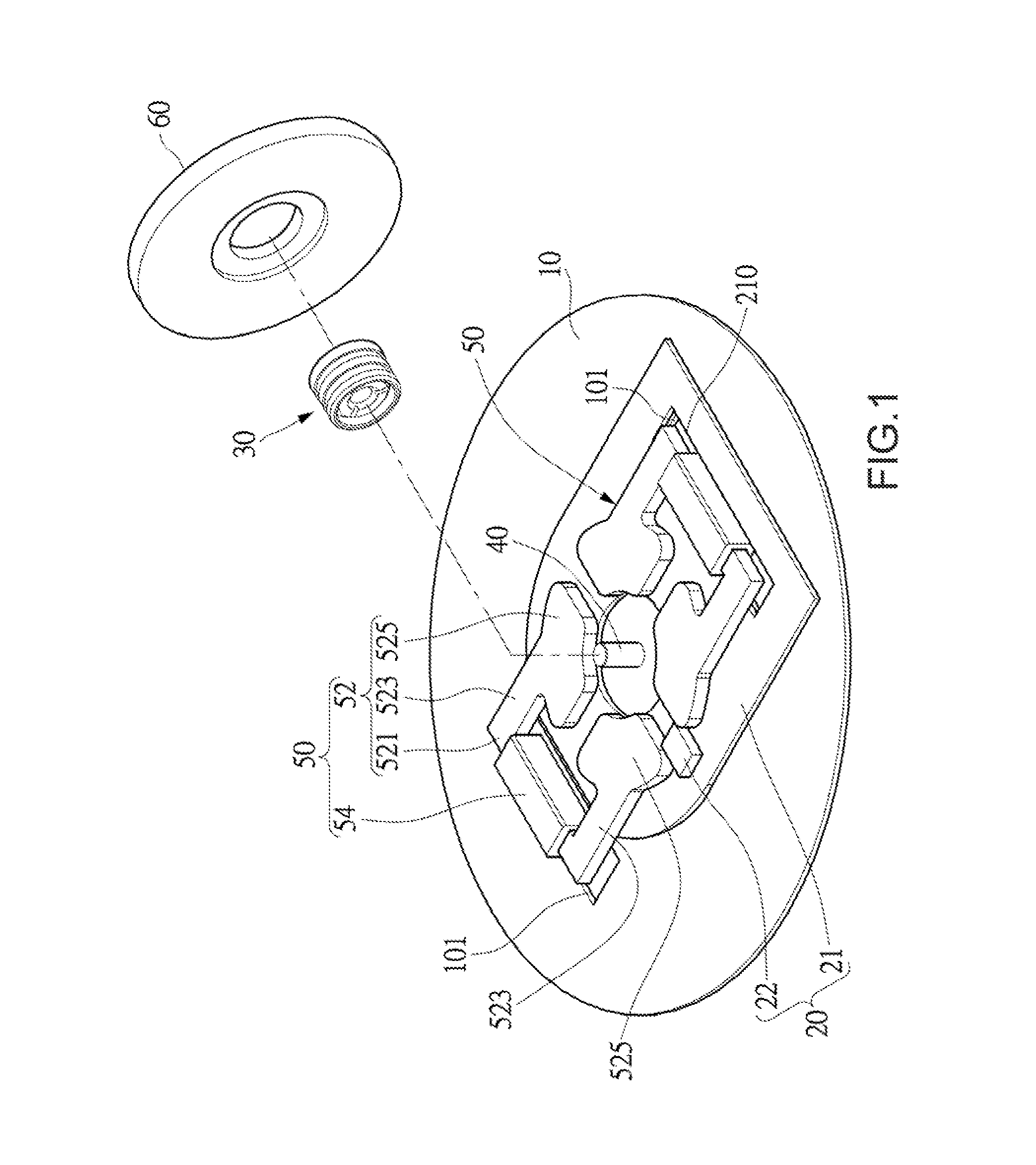

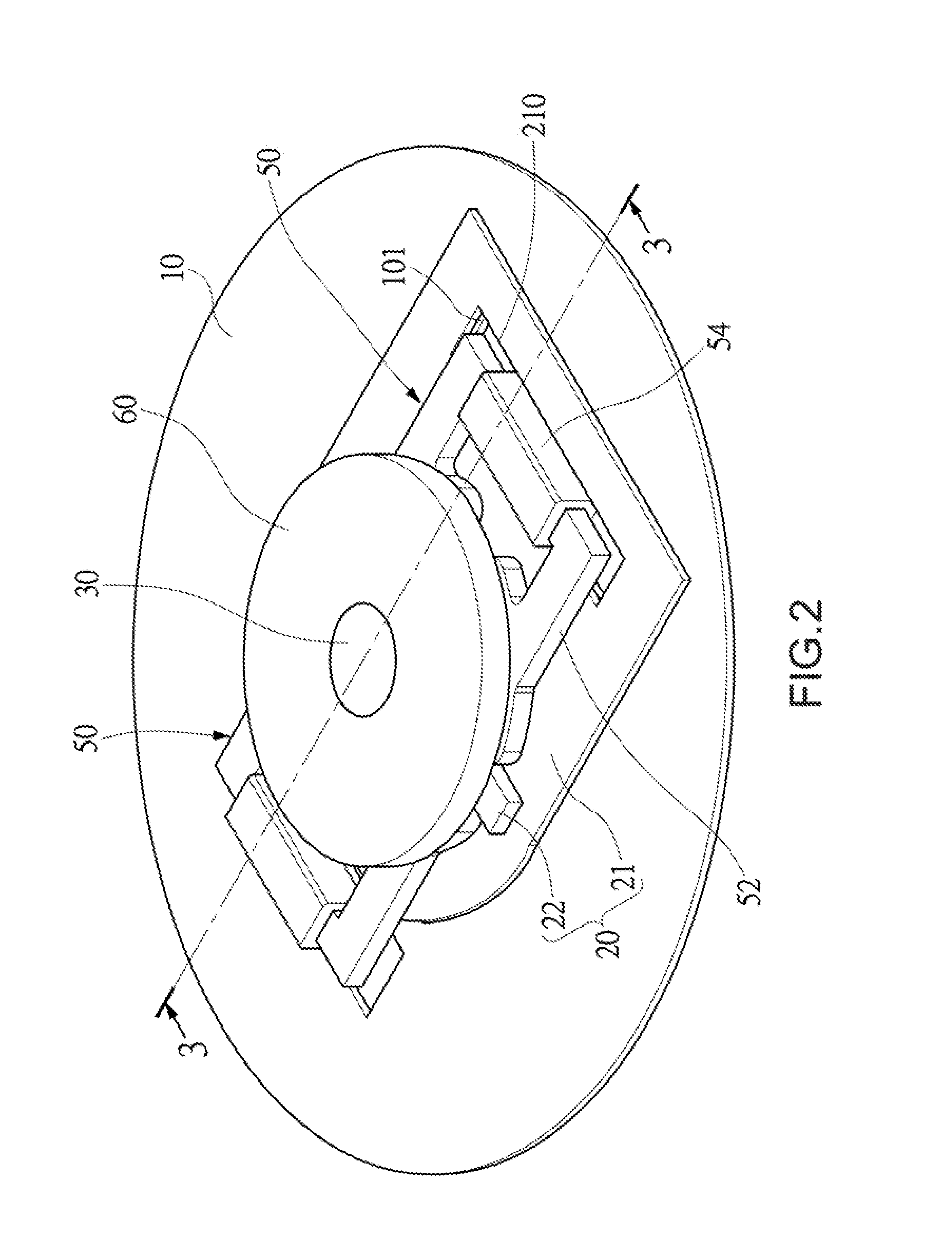

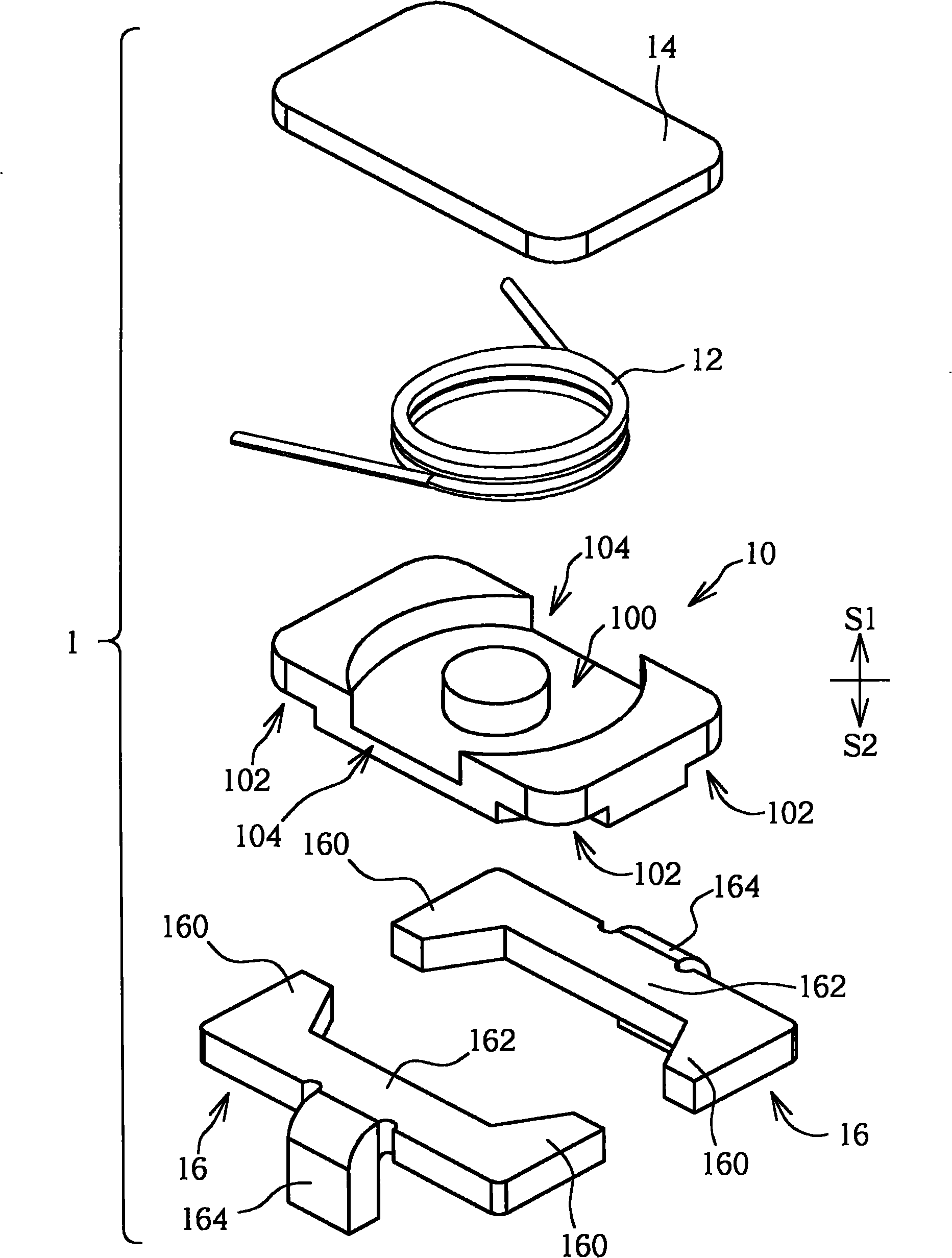

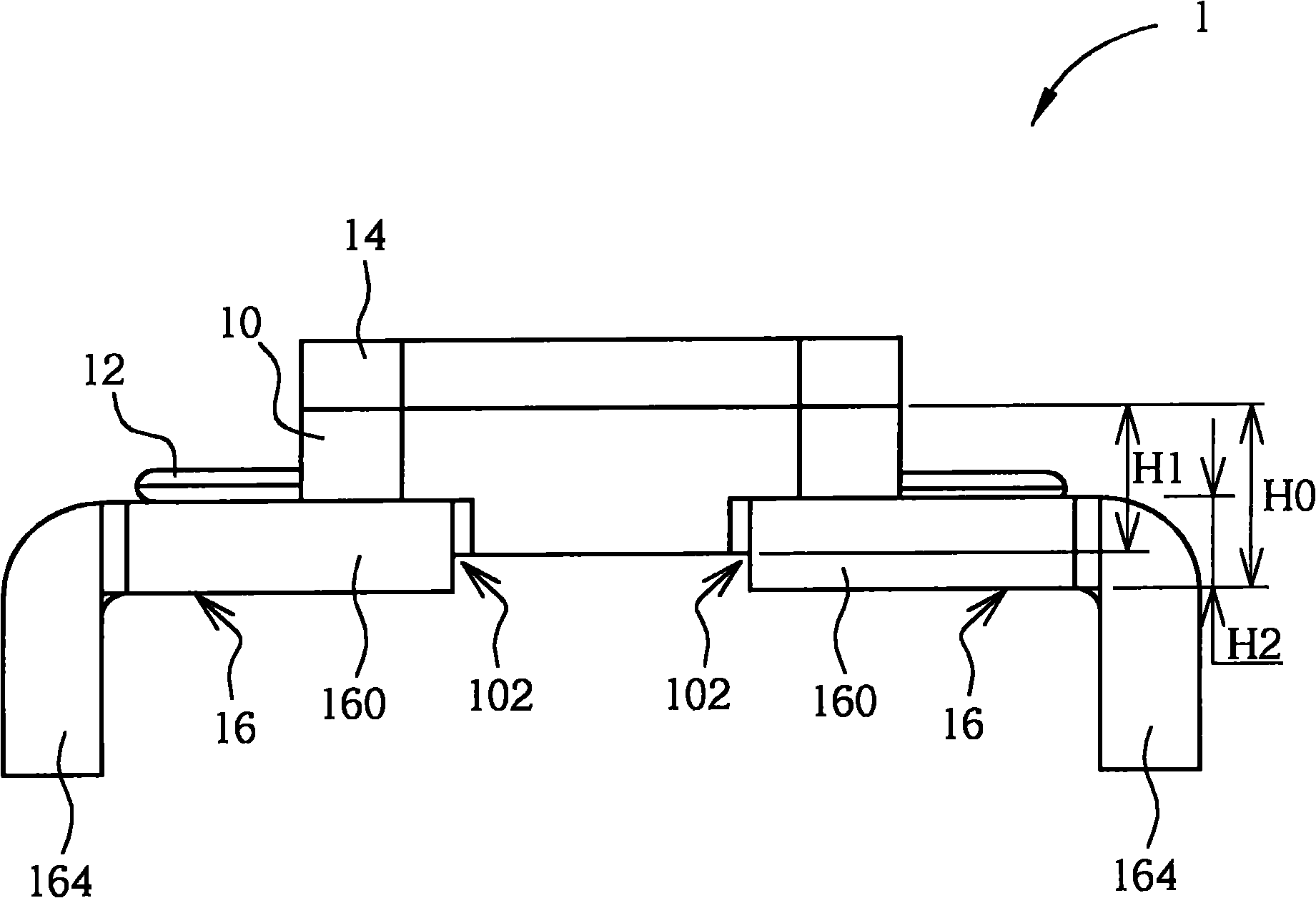

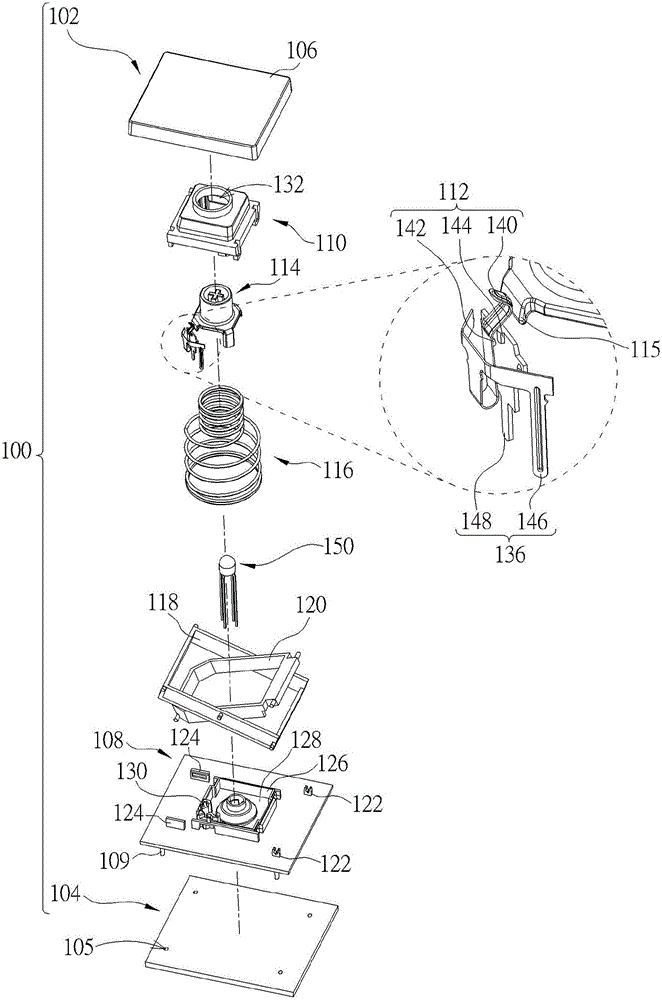

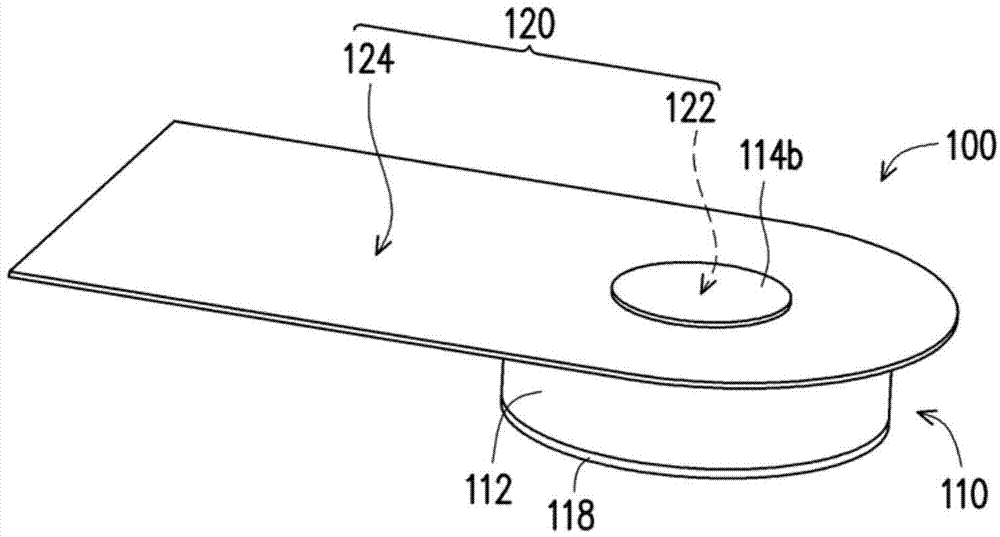

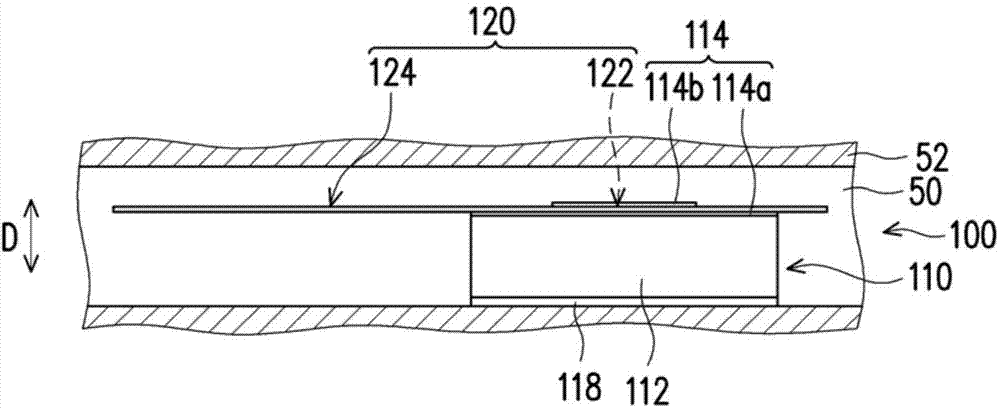

Thin axial gap motor

ActiveUS20150244213A1Easy to manufactureReduce the overall heightAssociation with control/drive circuitsMagnetic circuit rotating partsEngineeringConductor Coil

A thin axial gap motor includes: a base, a circuit unit installed on the base; a stator module including at least one flat permeable frame and at least one winding, and the permeable frame having at least one support arm and an induced magnetic part connected to the at least one support arm, and the winding being wound around the support arm; a rotor module including a flat permanent magnet installed at the top of the induced magnetic parts and having an orthographic projection range corresponsive to the area of the induced magnetic part, and the at least one winding being disposed on an outer side of the permanent magnet; and a pivoting element installed between the base and the rotor module and including a bearing housing and a spindle plugged into the bearing housing for rotating the rotor module with respect to the base.

Owner:COOLER MASTER CO LTD

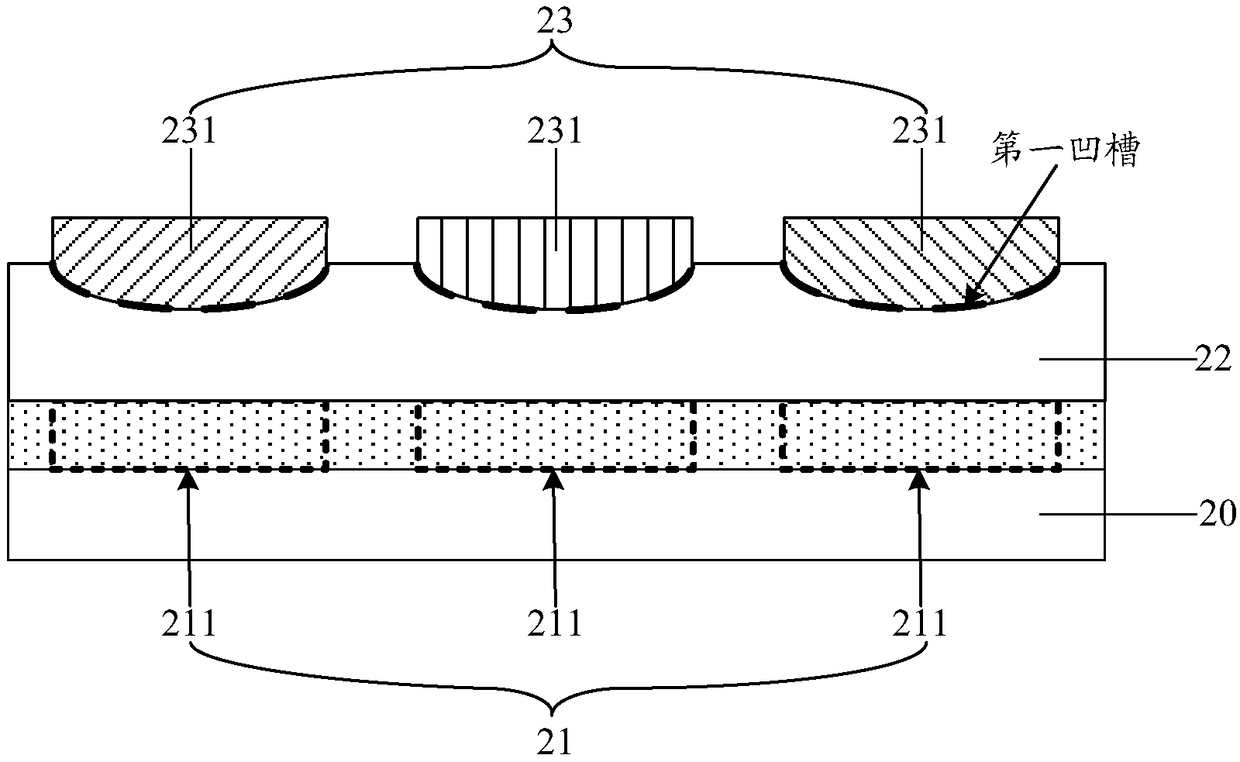

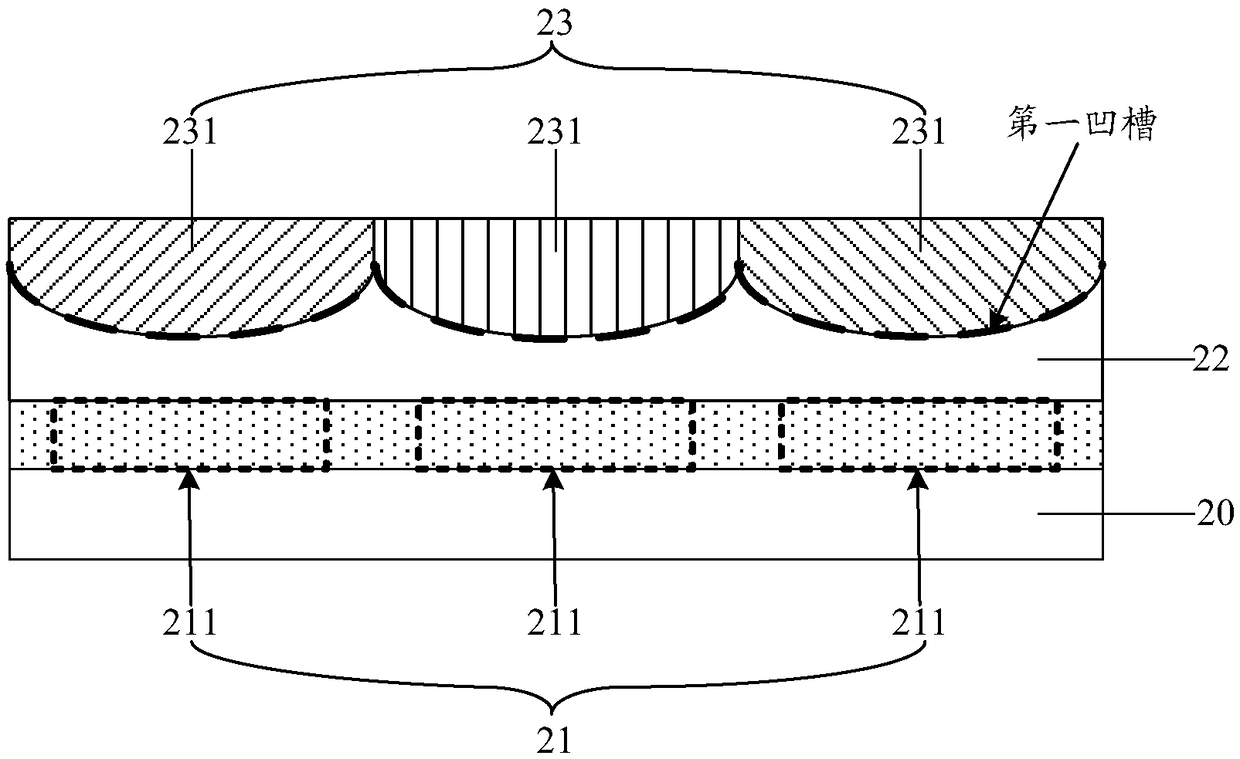

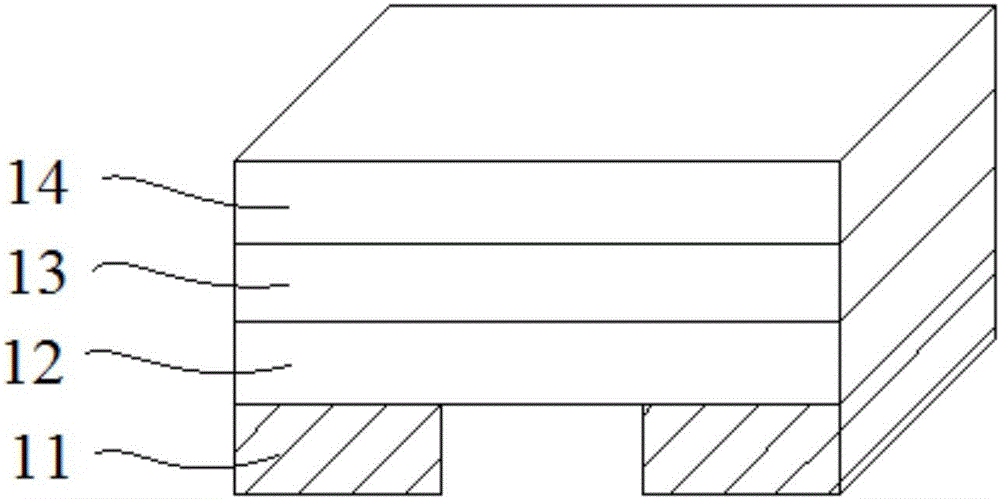

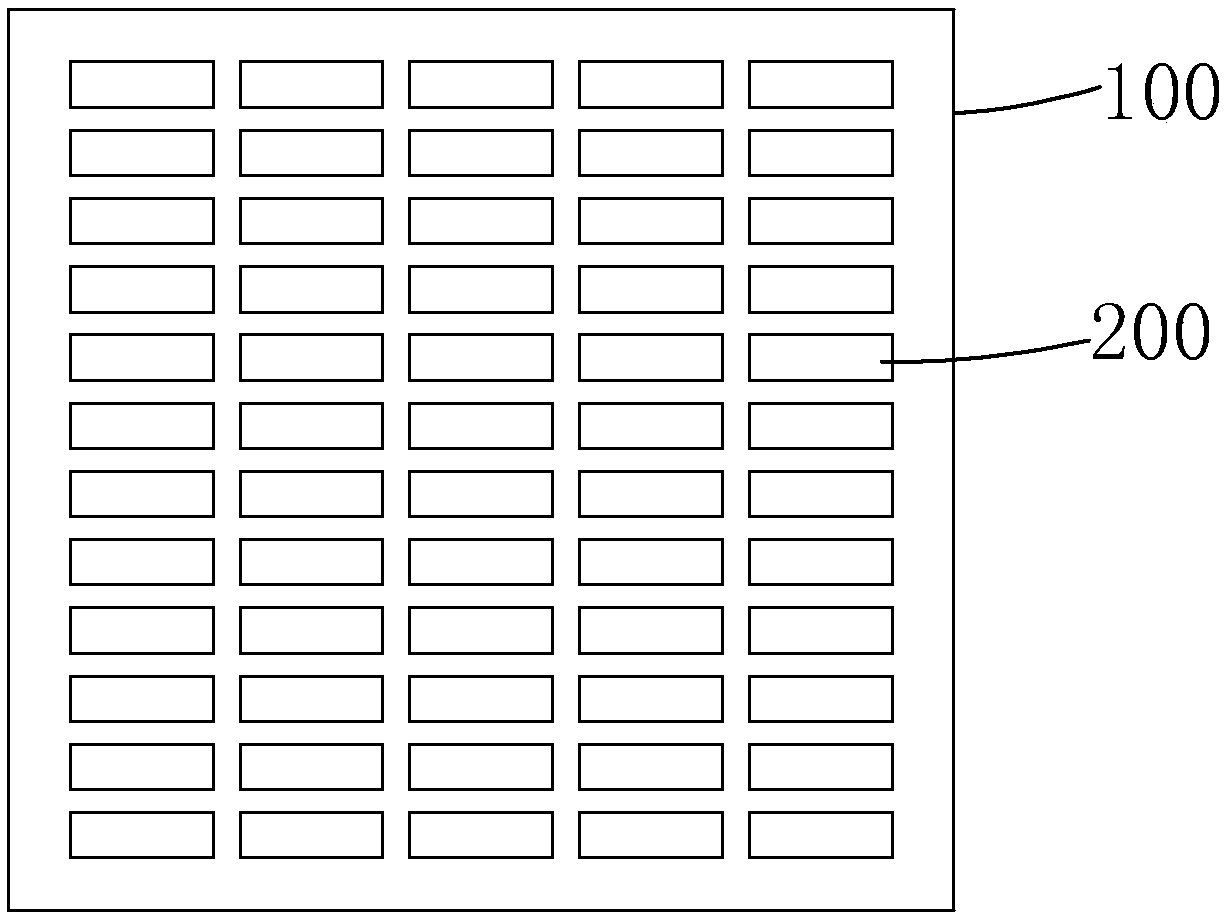

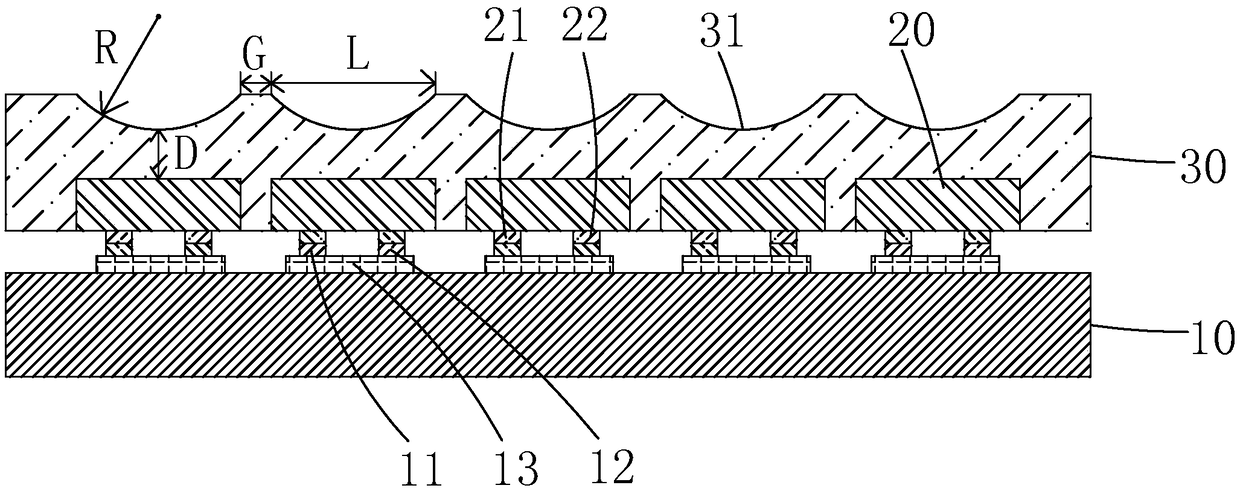

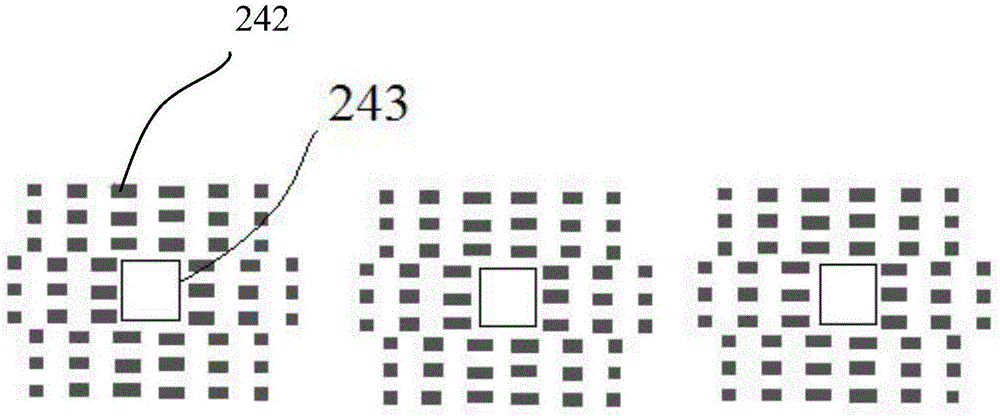

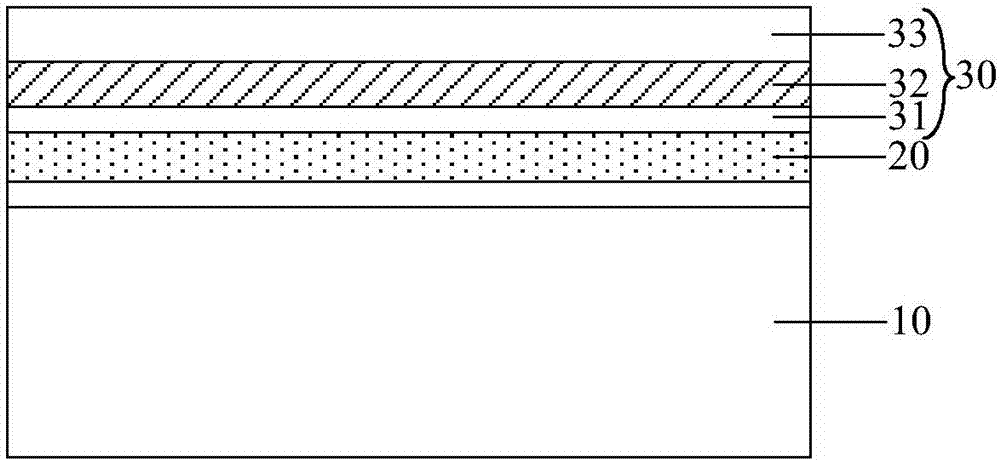

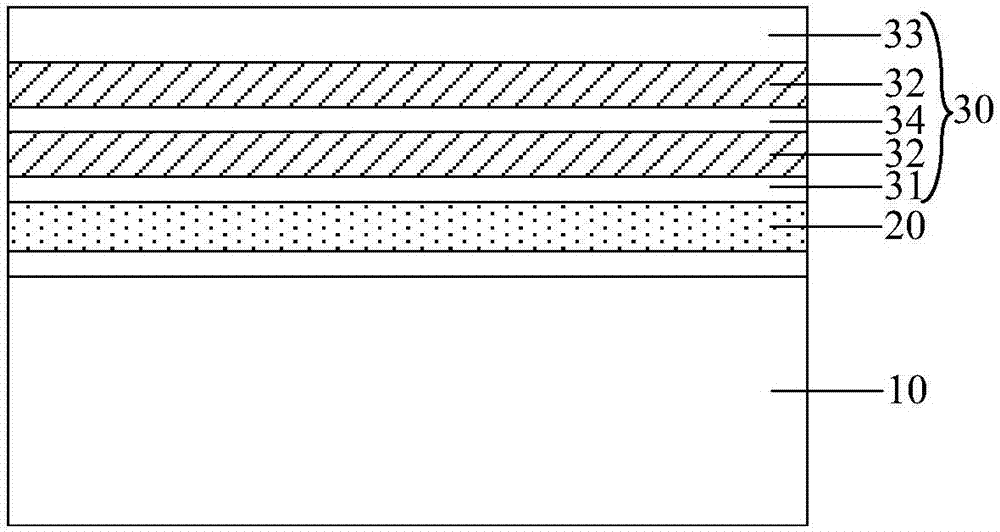

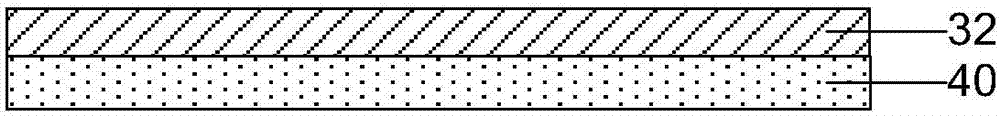

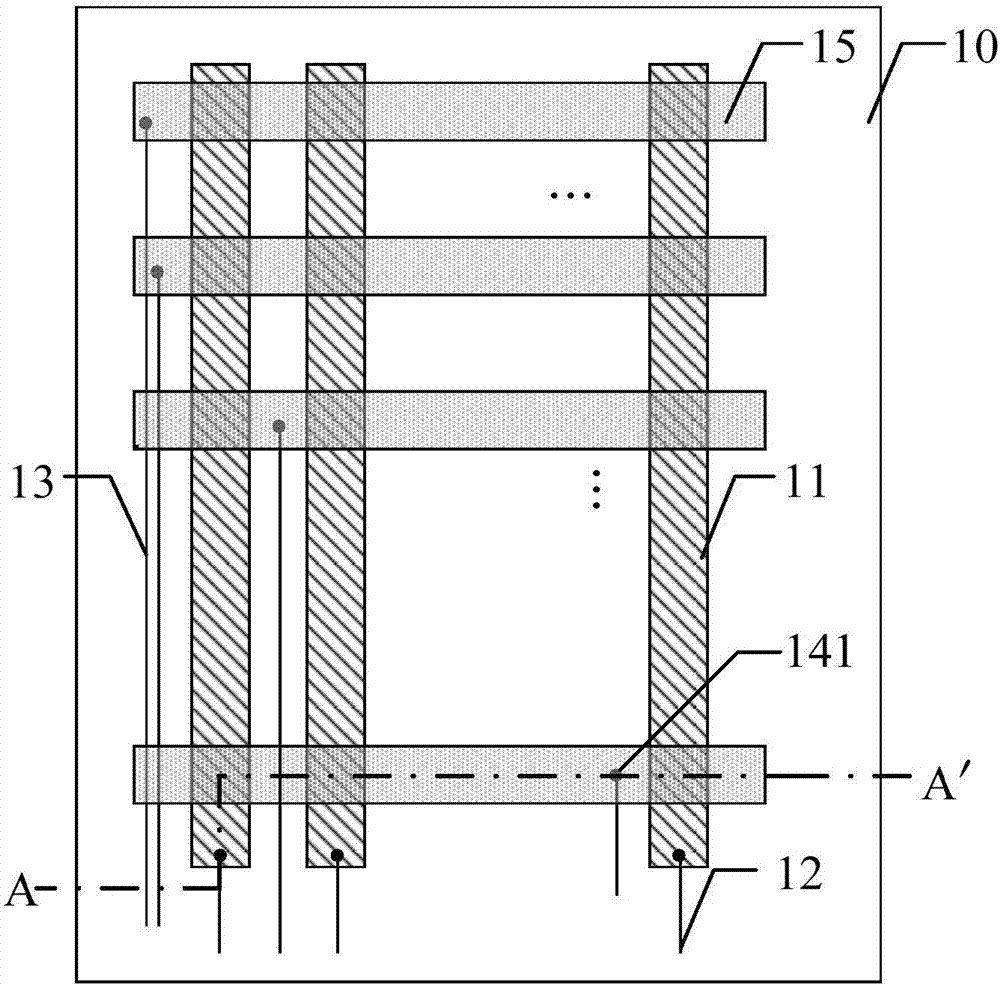

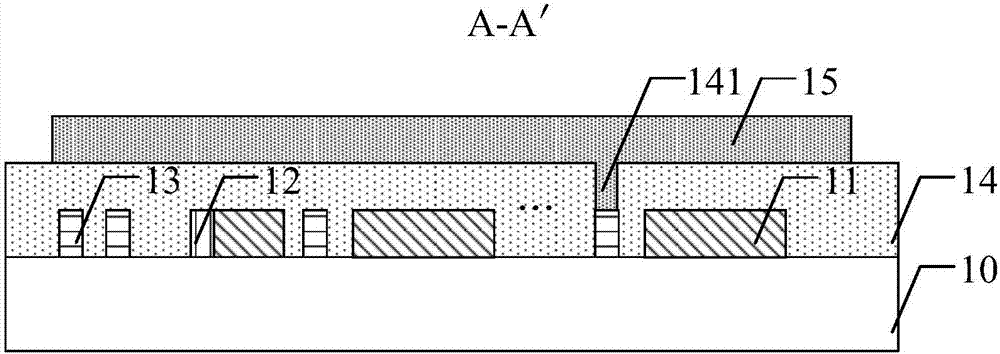

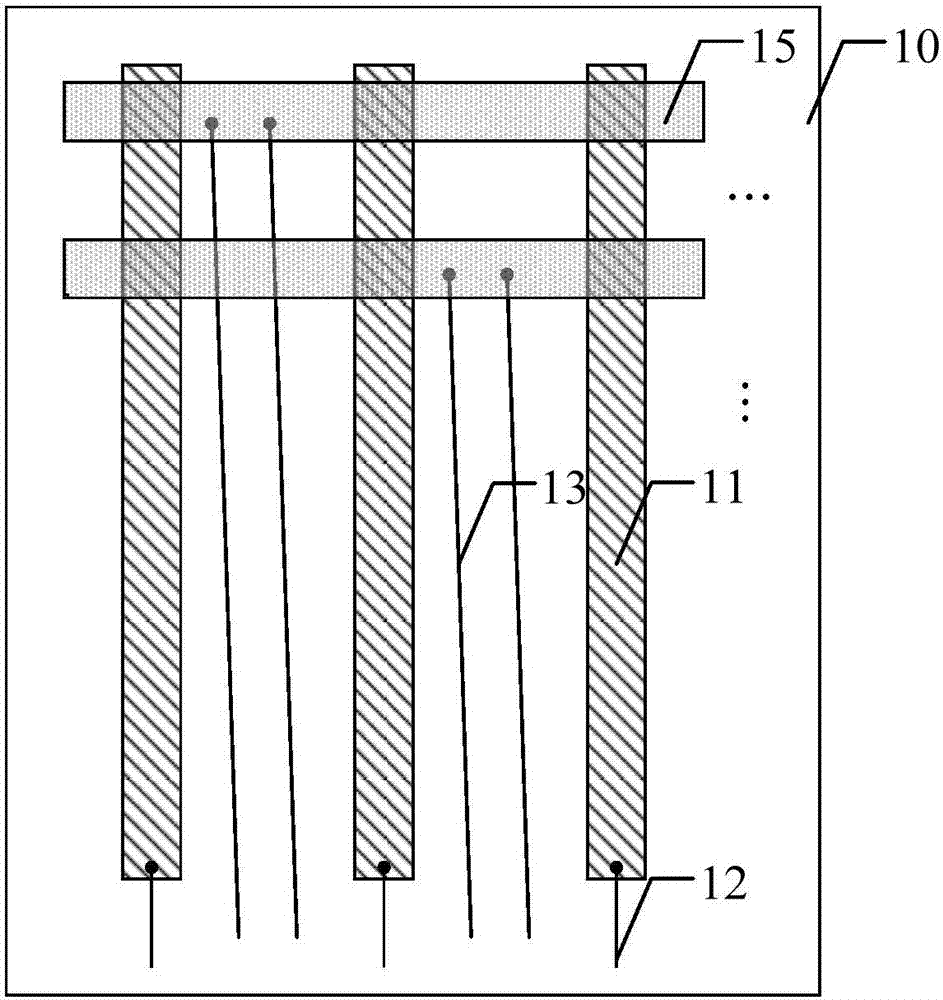

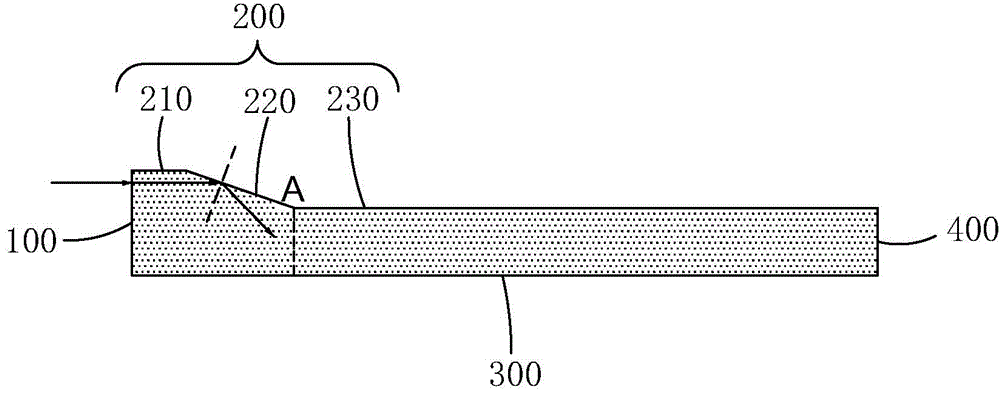

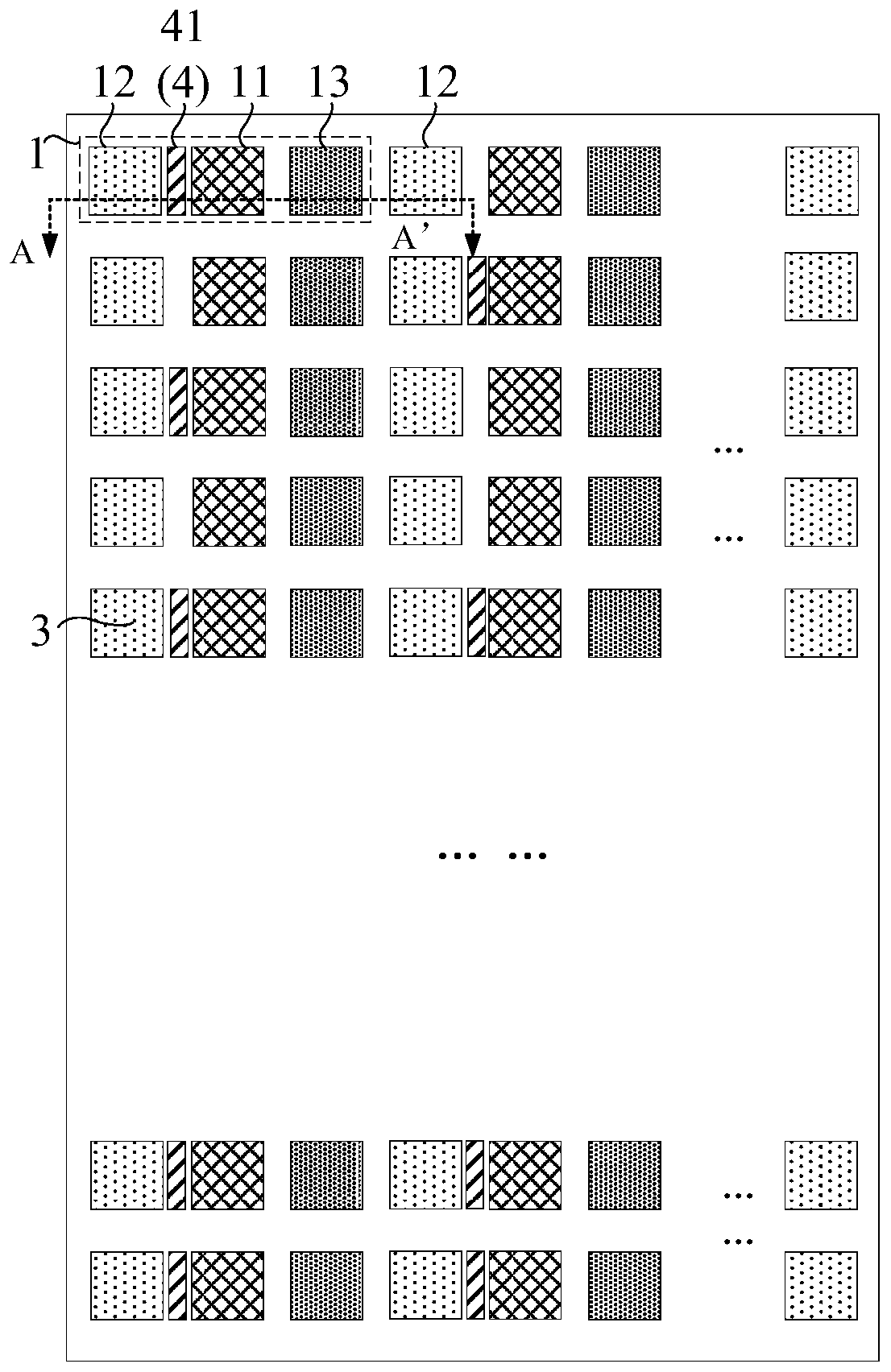

Display device and preparation method thereof

PendingCN108417612AReduce thicknessConducive to thin designSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight reflection

An embodiment of the invention relates to the technical field of display, provides a display device and a preparation method thereof and realizes thickness reduction of the display device on the basisof reduction of external environmental light reflection. The display device comprises a substrate and a light emitting layer on the substrate and further comprises a color filter layer, the light emitting layer comprises a plurality of subpixels, and the color filter layer is arranged on one side, close to a display surface, of the light emitting layer and comprises a plurality of color resistance units. An orthographic projection, on the light emitting layer, of each of the color resistance units covers one of the subpixels. Each of the color resistance units is gradually thickened in a direction perpendicular to a plane of the substrate from the edge to the center of the corresponding color resistance unit.

Owner:BOE TECH GRP CO LTD

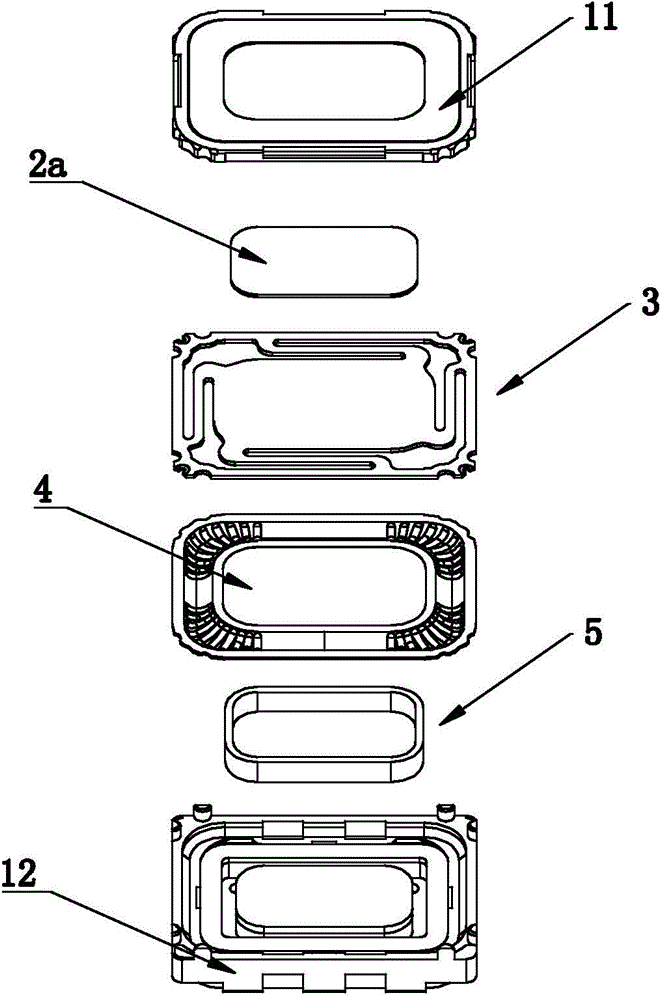

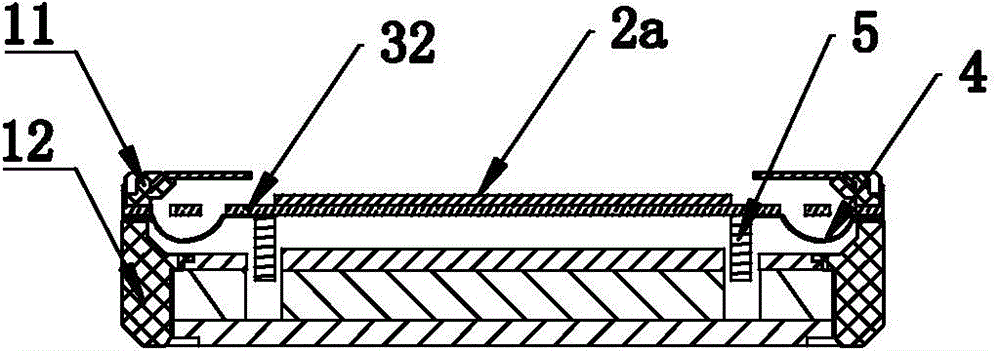

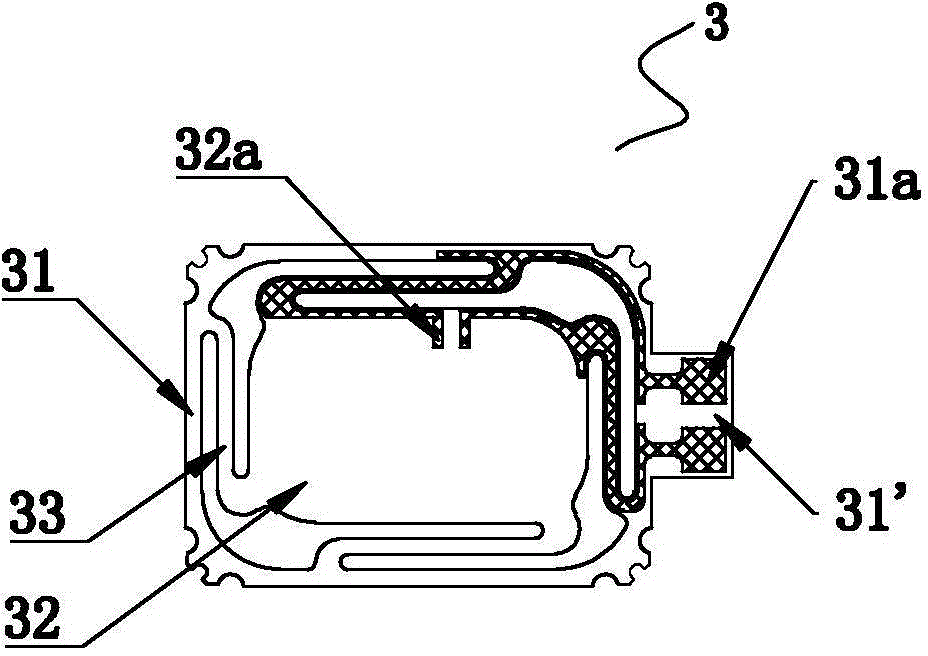

Vibrating sound production device

InactiveCN104883649AGuaranteed sound effectFunction as vibrationLoudspeaker transducer fixingLoudspeakersSound productionVoice coil

The invention discloses a vibrating sound production device. Sound outlet holes of the vibrating sound production device are arranged at a side surface, a vibrating diaphragm corresponds to the sound outlet holes in position, a flat voice coil is vertical with the vibrating diaphragm, magnets are parallel to the voice coil, a vibrating direction of the voice coil avoids the thickness direction, vibrating directions of the magnets and a mass block also avoid the thickness direction, and the mass block is fixedly combined with a shell through elastic pieces, thereby being conducive to reducing the product thickness, improving the product performance and simplifying the production process of products. Therefore, the vibrating sound production device disclosed by the invention has the advantages of high thinning design, good performance and simple assembly.

Owner:GOERTEK INC

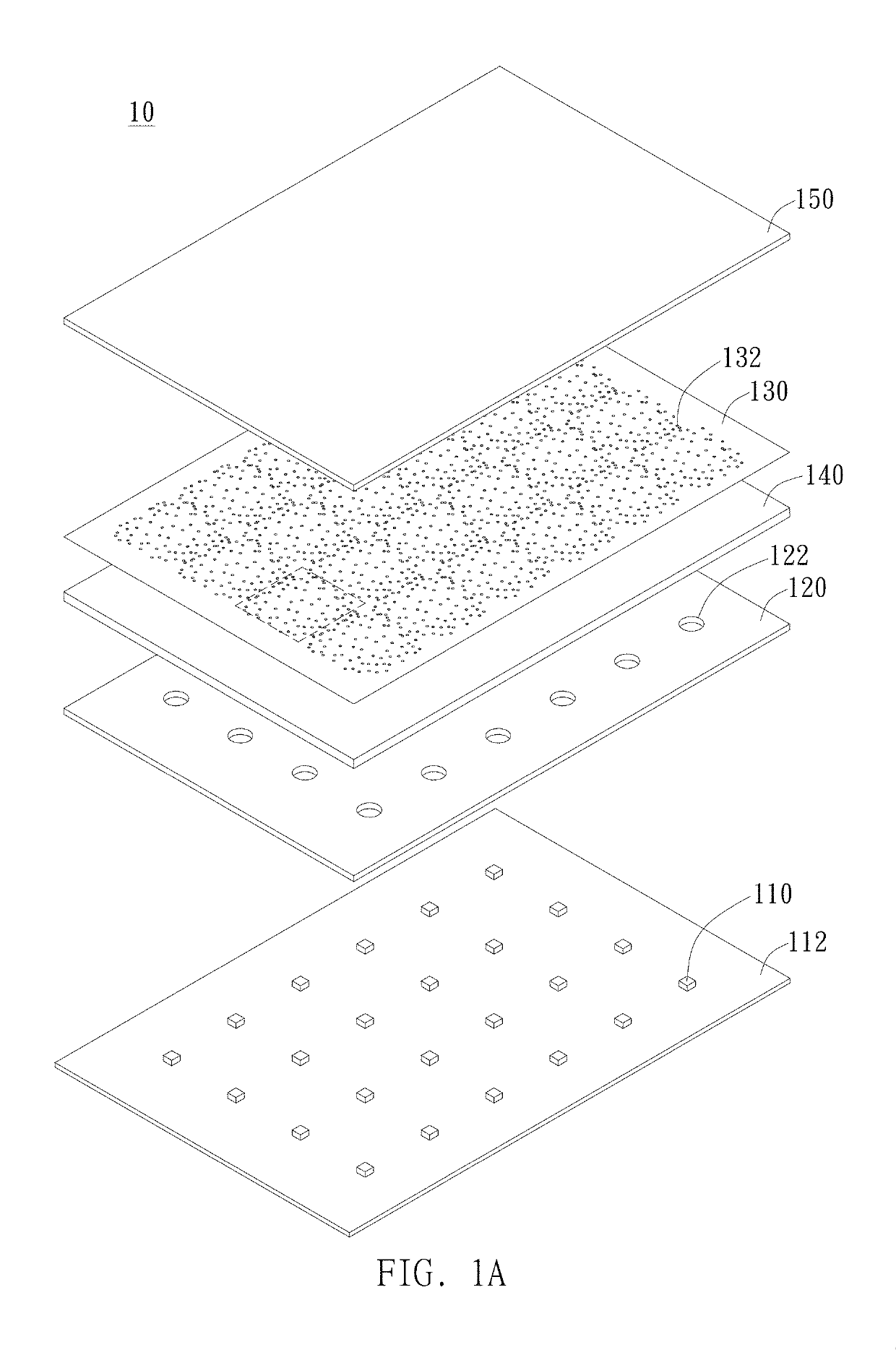

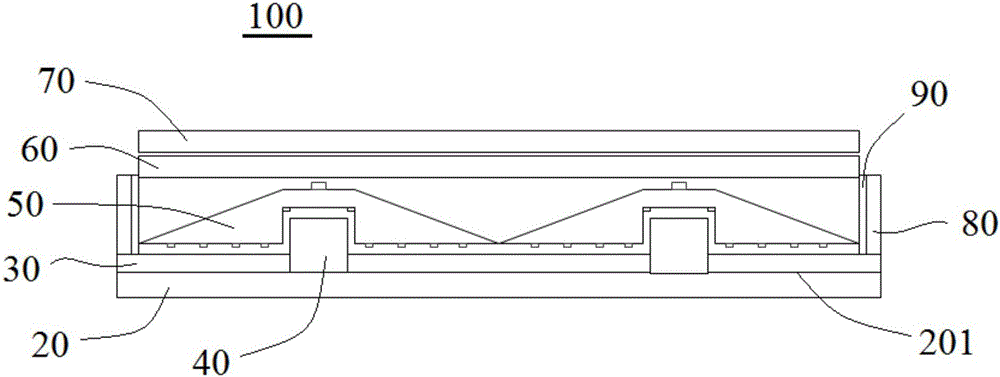

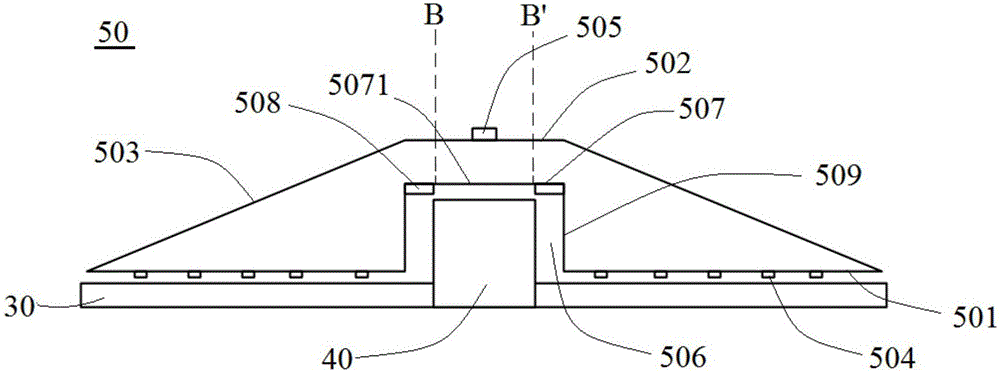

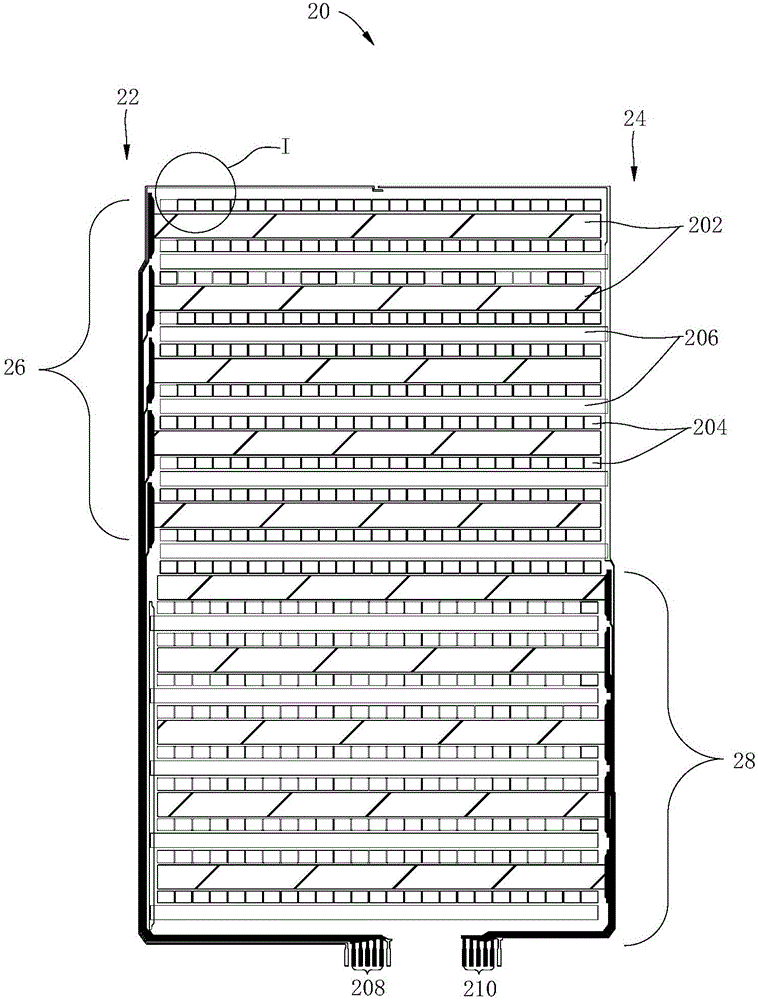

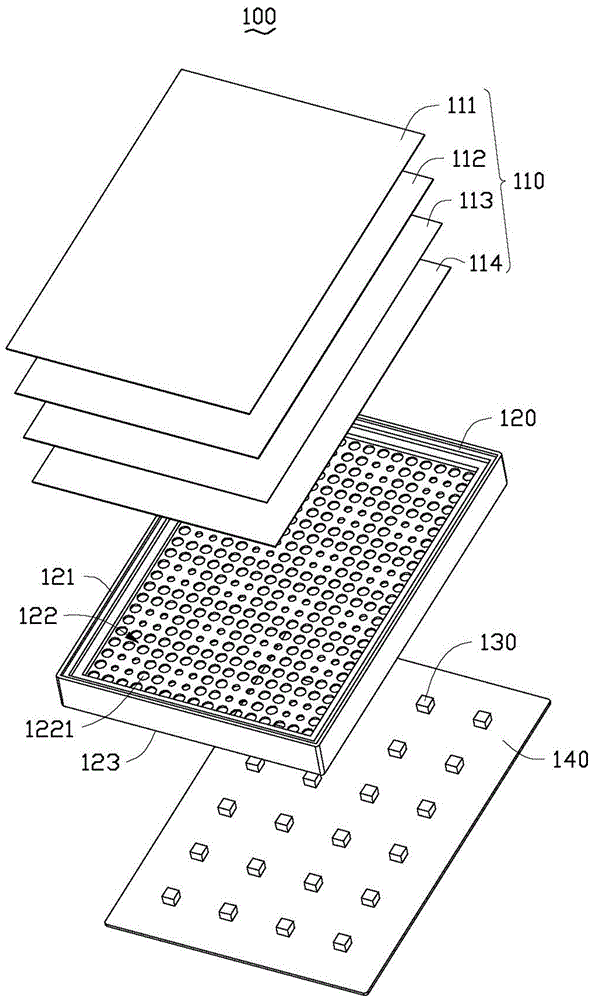

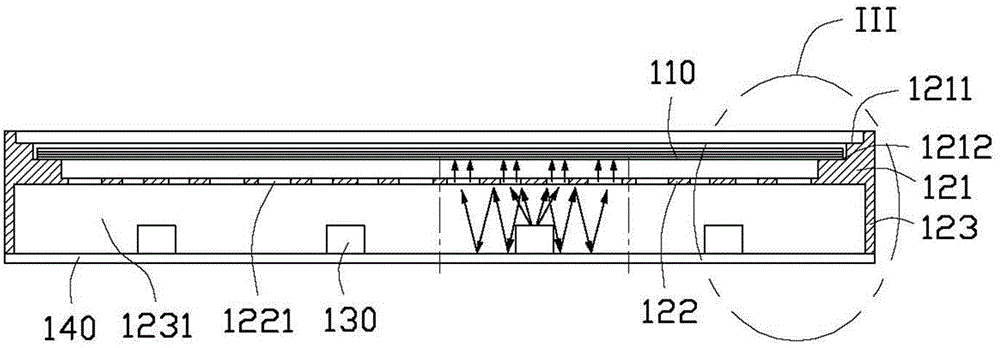

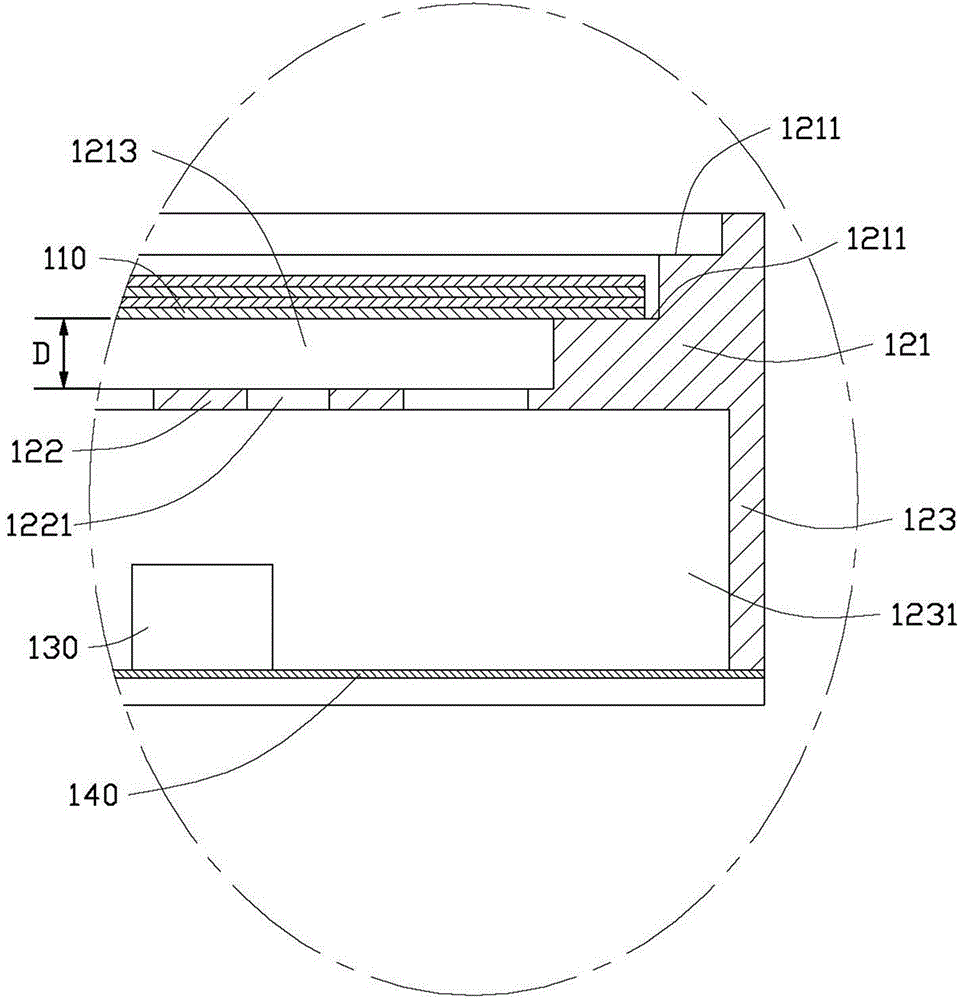

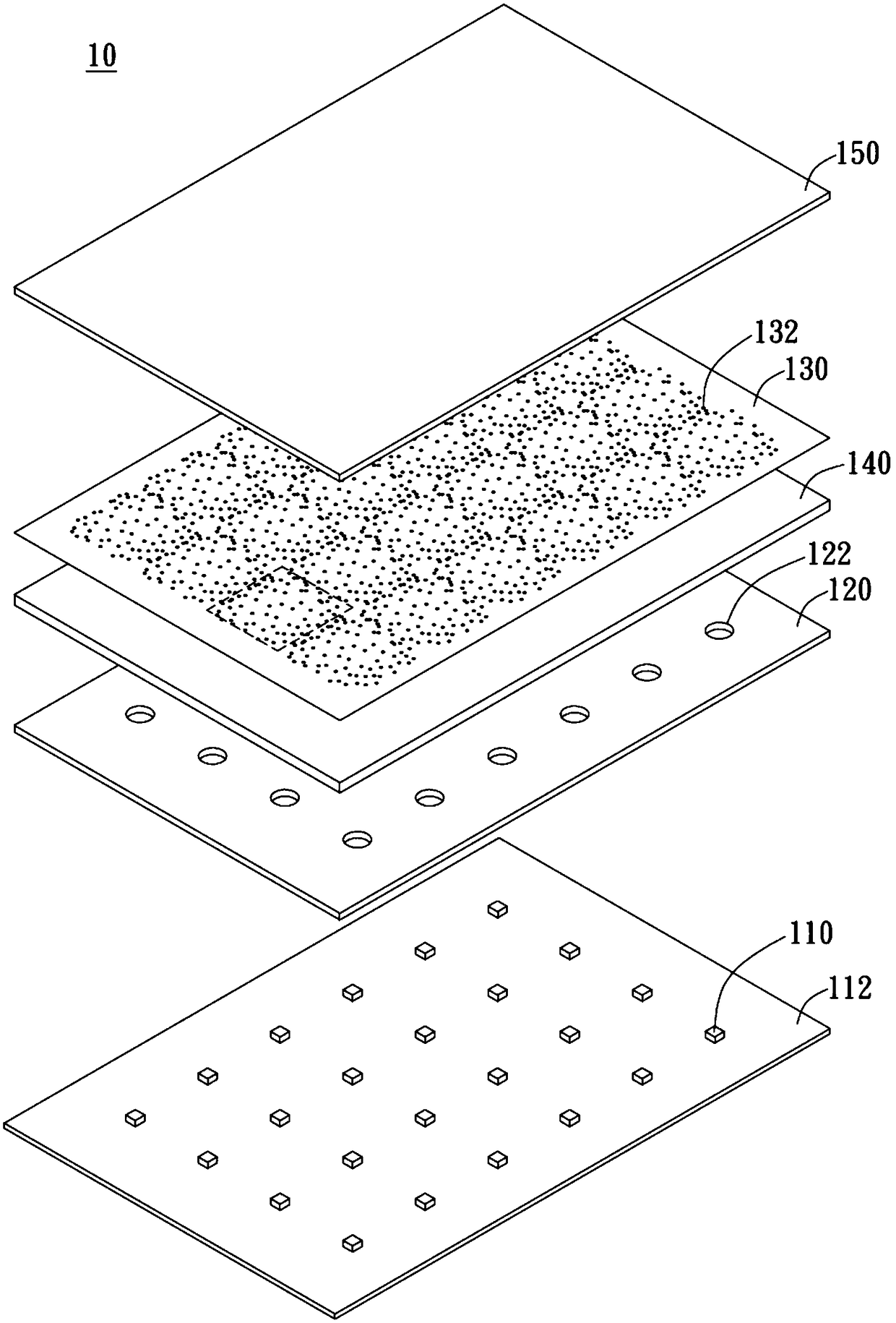

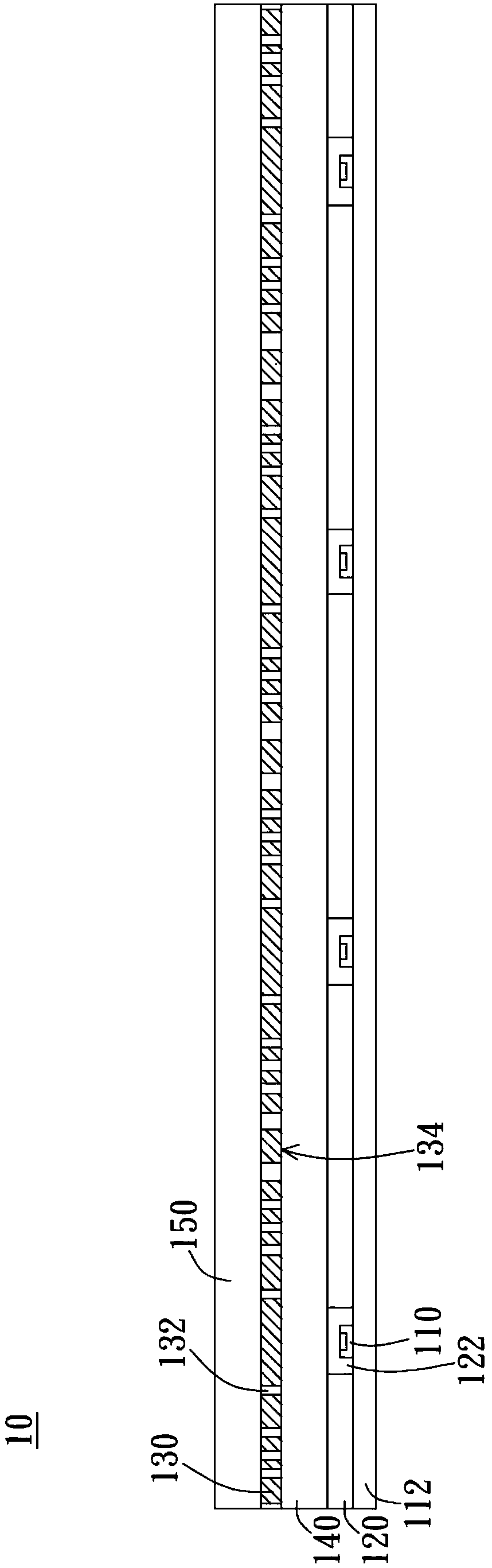

Display Device and Backlight Module Thereof

A display device includes a display panel and a backlight module disposed under the display panel. The display panel has a display area and a light-blocking layer disposed around the display area. The backlight module includes a plurality of light sources, a reflector disposed corresponding to the light sources, an optical modulation film disposed above the light sources and the reflector, a diffusion member sandwiched between the reflector and the optical modulation film, and a diffusion plate disposed on one side of the optical modulation film opposite to the diffusion member, wherein the optical modulation film is sandwiched between the diffusion plate and the diffusion member, and the diffusion member has a transmittance of 65%˜85%.

Owner:AU OPTRONICS CORP

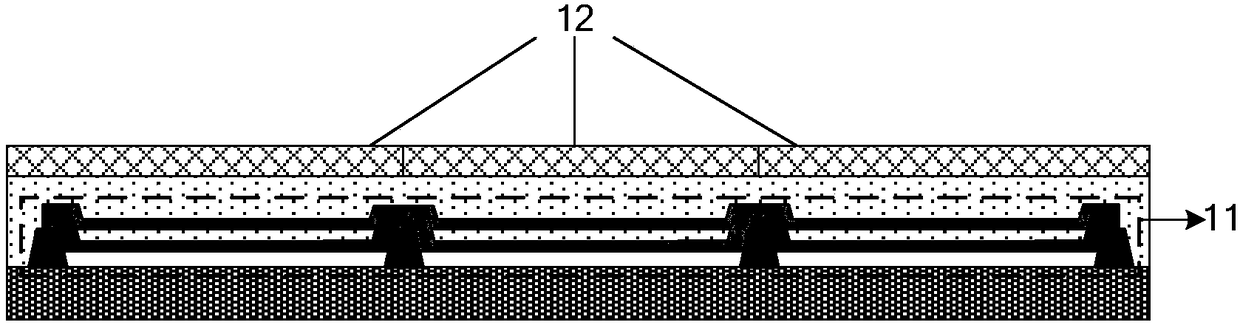

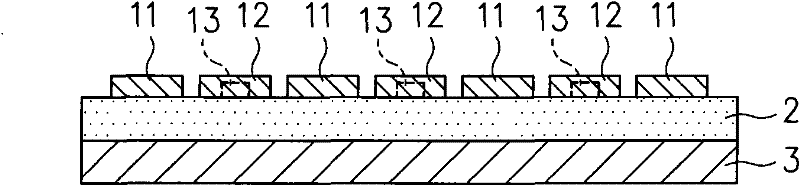

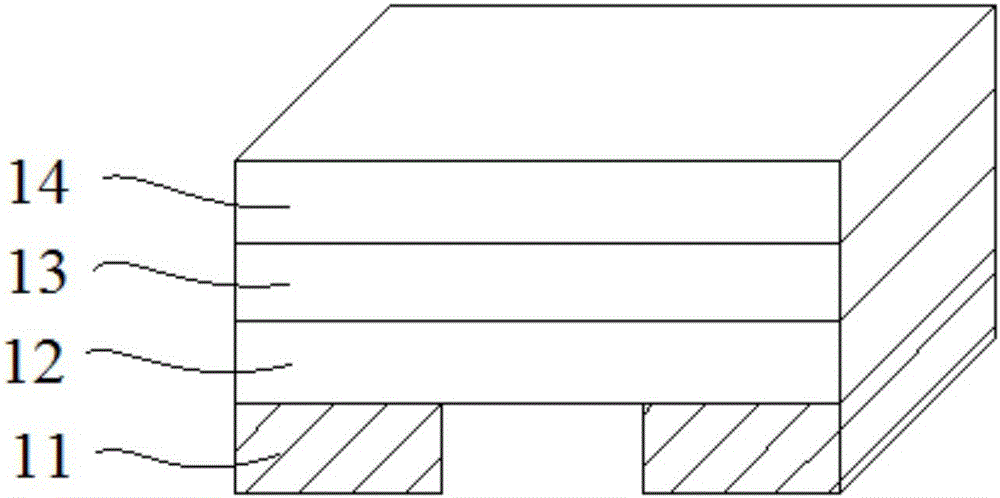

Backlight module and liquid crystal display

ActiveCN106773315AIncrease the mixing distanceUniform light distributionNon-linear opticsLiquid-crystal displayPrinted circuit board

The invention relates to the field of liquid crystal display technologies. The backlight module provided by the invention sequentially comprises a printed circuit board, a first reflection plate, LED light sources, light guide plates, a diffusion plate and an optical diaphragm from the bottom up. Each light guide plate is of a rectangular structure with thin periphery and thick center, and is buckled on the corresponding LED light source via a groove at the center, and bumps are arranged on a first light reflection plane and a second light reflection plane of the light guide plate, so that mixing distance of light rays entering the light guide plate is increased, and thus the light rays are more uniformly distributed, generation of a dark space is avoided, and thin design of the liquid crystal display is facilitated; the LED light source and the light guide plate are on one-to-one correspondence, regional dimming is facilitated, and becomes more accurate during rectangular light emitting surfaces formed by the light guide plates; meanwhile, a use ratio of the light sources is further improved due to the arrangement of a third reflection plate. According to the liquid crystal display including the backlight module provided by the invention, regional dimming can be accurately achieved, and the thin design is also achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

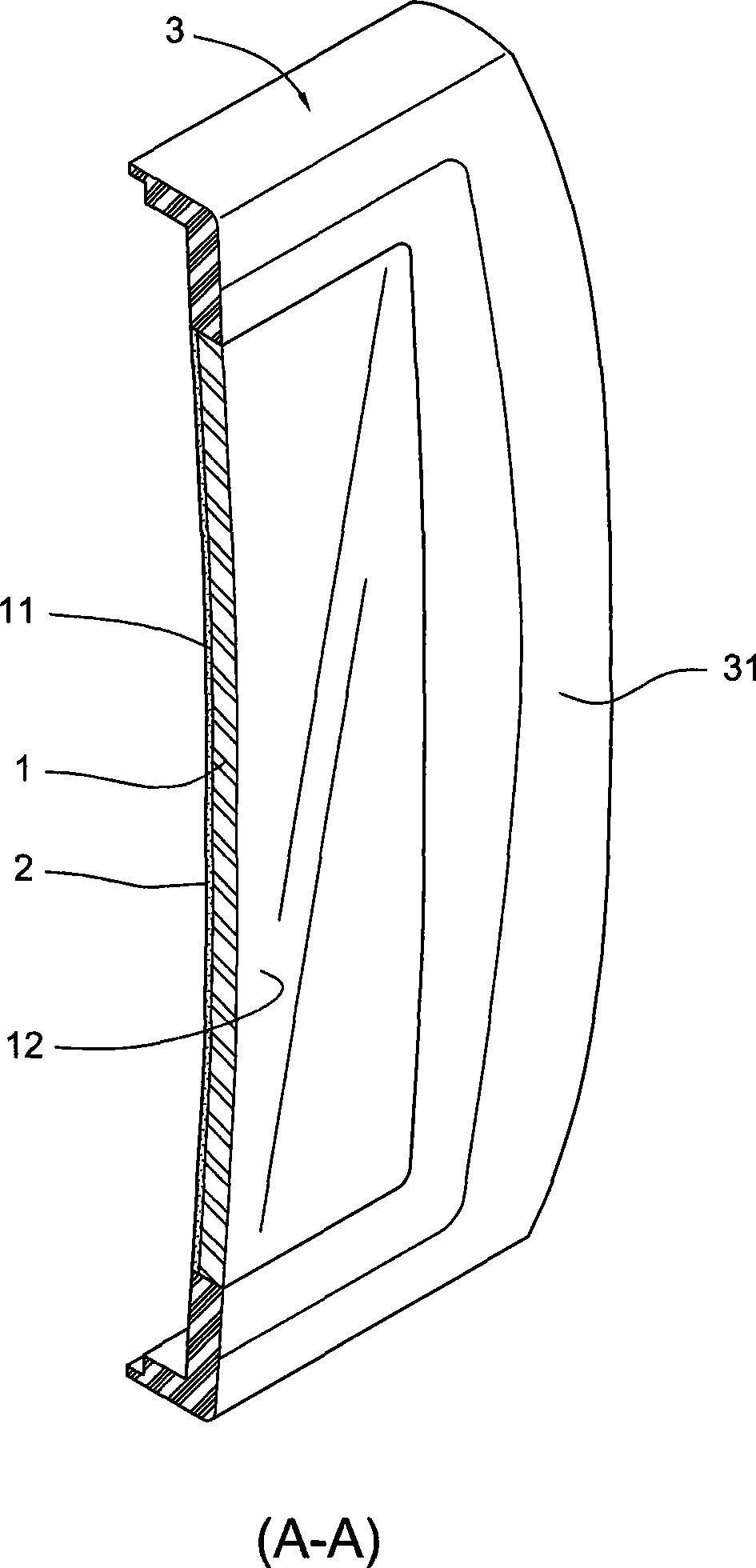

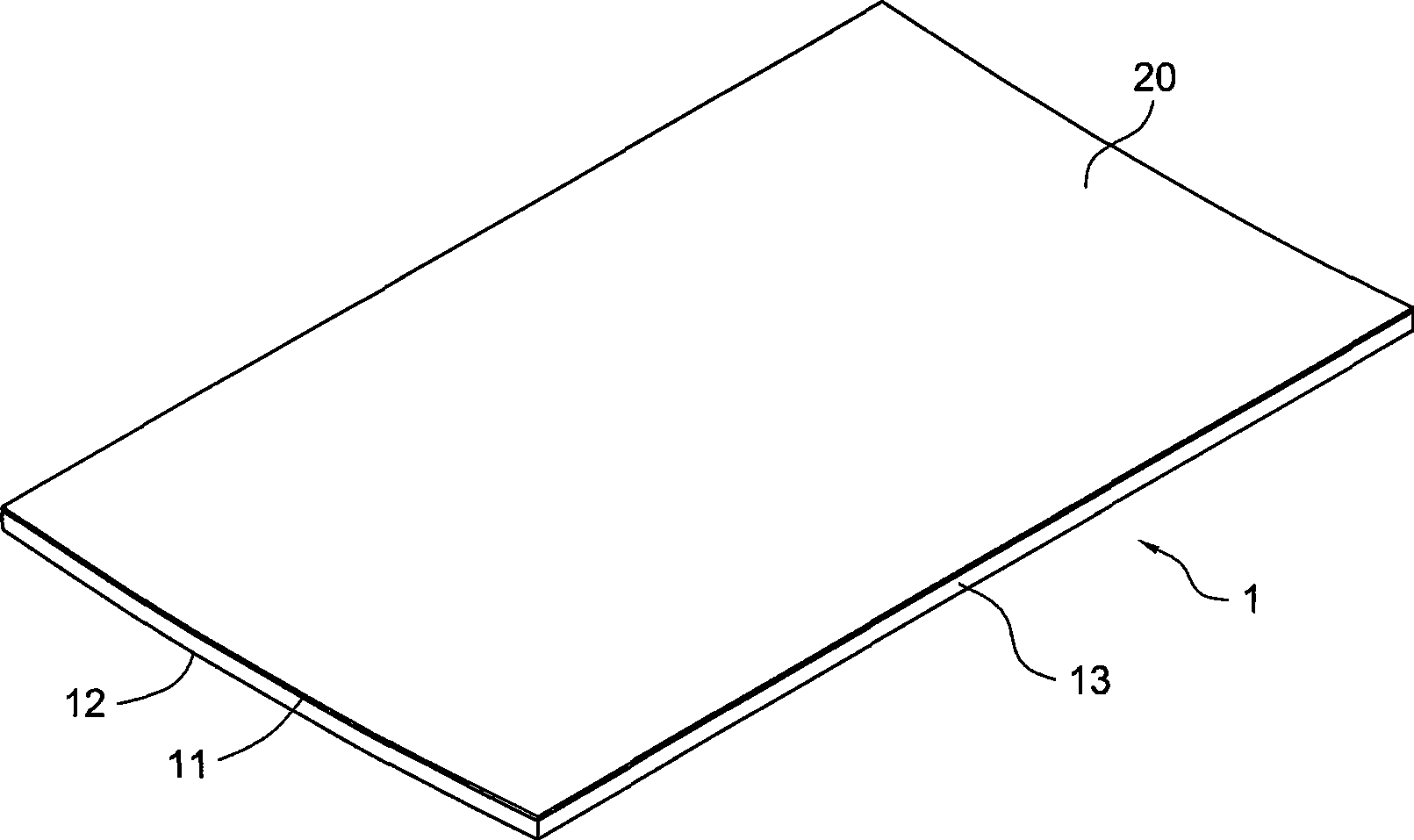

Touch control panel structure and manufacture method thereof

InactiveCN102207784ASimplify the fitting processSave production materialsInput/output processes for data processingInsulation layerElectrical conductor

The invention provides a touch control panel structure and a manufacture method thereof. In the invention, a conductive structure layer is formed on at least one adhesive layer; the conductive structure layer comprises at least one first conductor and at least one second conductor; and an insulation layer is arranged between the first conductor and the second conductor so that the first conductoris insulated from the second conductor. The purposes of saving production materials, reducing cost, improving product good rate, simplifying panel laminating procedure, attaching the touch control panel to object surfaces of arbitrary curved surfaces or plane surfaces, and facilitating design of thinned products and the like are achieved.

Owner:WINTEK CORP +1

Speaker device

InactiveCN104822112AImprove acoustic performanceImprove mid and high frequenciesLoudspeakersPiezoelectric/electrostrictive transducersIntegrated designEngineering

The invention discloses a speaker device, which comprises a vibration system, a magnetic circuit system and an auxiliary system for accommodating and fixing the magnetic circuit system and the vibration system. The vibration system comprises a centring disk. The centring disk comprises a first fixing portion, a second fixing portion disposed in the first fixing portion, and a connecting arm connecting the first fixing portion and the second fixing portion. The center position of the second fixing portion is provided with a piezoelectric patch, the centring disk is provided with a first bonding pad corresponding to the piezoelectric patch, and the piezoelectric patch is connected electrically with the first bonding pad. The second fixing portion is provided with an antenna circuit. According to the invention, a signal produced by the piezoelectric patch can effectively improve the medium-high frequency effects of the speaker device and the acoustic performance of the speaker device; the antenna circuit combines an antenna device with the speaker device integrally; and the speaker device has the advantages of excellent acoustic performance, high integrated design and multiple functions.

Owner:GOERTEK INC

Face light source backlight module and liquid crystal display panel

ActiveCN108732816AImprove light mixing uniformityStrong penetrating powerNon-linear opticsLiquid-crystal displayFluorescence

The invention provides a face light source backlight module and a liquid crystal display panel. The face light source backlight module comprises a Mini LED substrate, a plurality of Mini LED chips arranged on the Mini LED substrate at intervals and a fluorescent film covering the Mini LED chips, wherein a plurality of microstructures are arranged on the surface, away from one side of the Mini LEDchips, of the fluorescent film so that the Mini LED chips can achieve large-angle light emergence, the light mixing uniformity of the face light source backlight module is improved, the purpose of saving an optical film to achieve uniform light mixing is achieved, accordingly the penetration and brightness of a face light source are improved, and meanwhile thinning design of the face light sourcebacklight module is facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Backlight module and liquid crystal displayer

ActiveCN106842701AUniform light distributionImprove display qualityNon-linear opticsLiquid-crystal displayPrinted circuit board

The invention relates to the technical field of liquid crystal display, in particular to a backlight module and a liquid crystal displayer. The backlight module sequentially comprises a printed circuit board, a reflector plate, an LED light source and a diffusion plate from bottom to top. First protruding points are arranged on the light-in face, facing the LED light source, of the diffusion plate and around the projection, within the light-in face, of the LED light source. The first protruding points can conduct reflection diffusion on an illumination area, on the diffusion plate, of the LED light source, eliminate projection dark spaces and prevent light source gathering, so that the distribution of a light-emitting area on the diffusion plate is more uniform. Meanwhile, the LED light source can be independently controlled, local light control can be better achieved, and accordingly the display quality of a high-dynamic-comparison image is improved. The reflector plate can reflect leaking light again so that the light can irradiate the diffusion plate again, accordingly the utilization rate of the light source is increased, the light mixing distance is increased, and thinning design of the liquid crystal displayer is achieved easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

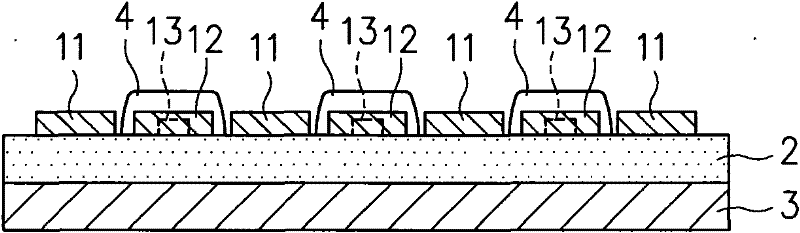

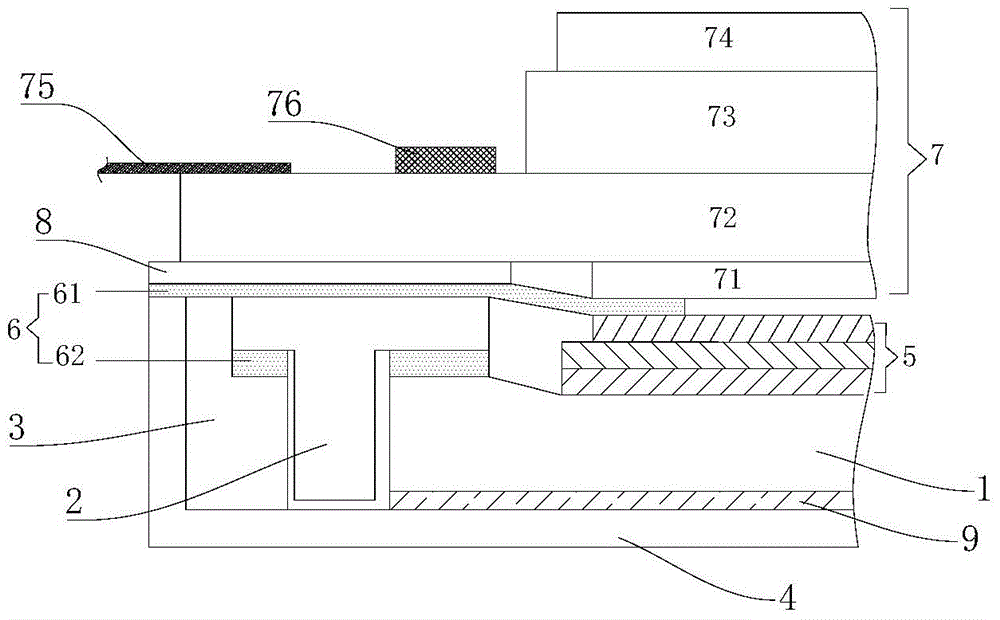

Backlight module

InactiveCN104913243AConducive to thin designFunctionLighting heating/cooling arrangementsReflectorsLiquid-crystal displayLight guide

The invention relates to the technical field of liquid crystal display and particularly provides a backlight module. The backlight module comprises a light guide plate, a light source component, an adhesive framework, an optical film, a panel component and a composite heat dissipation part, wherein the light guide plate, the light source component and the adhesive framework are arranged from inside to outside; the optical film is arranged on the upper surface of the light guide plate and is connected to the adhesive framework through an adhesive layer; the panel component is arranged above the optical film and corresponds to the adhesive layer; the composite heat dissipation part is arranged between the panel component and the adhesive layer, extends to the bottom of the light guide plate along the outer side of the adhesive framework and is connected to the light source component. The composite heat dissipation part is used for combining the reflection material with the heat dissipation material; the function of a reflection plate can be achieved; meanwhile, the heat dissipation function can also be achieved; the function of the protection film in the prior art is replaced; the structure of the backlight module is simplified; the thin design of the backlight module is facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

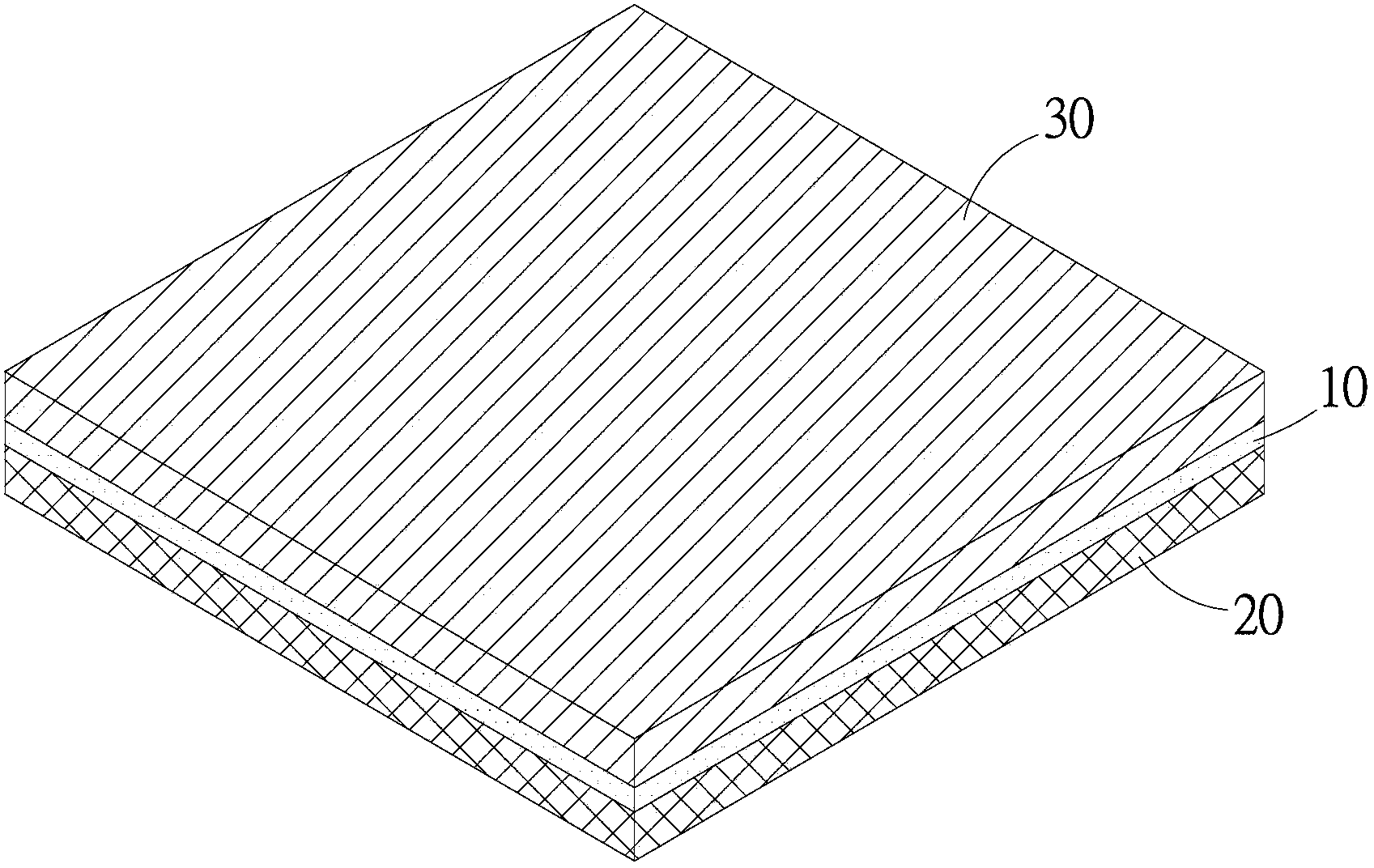

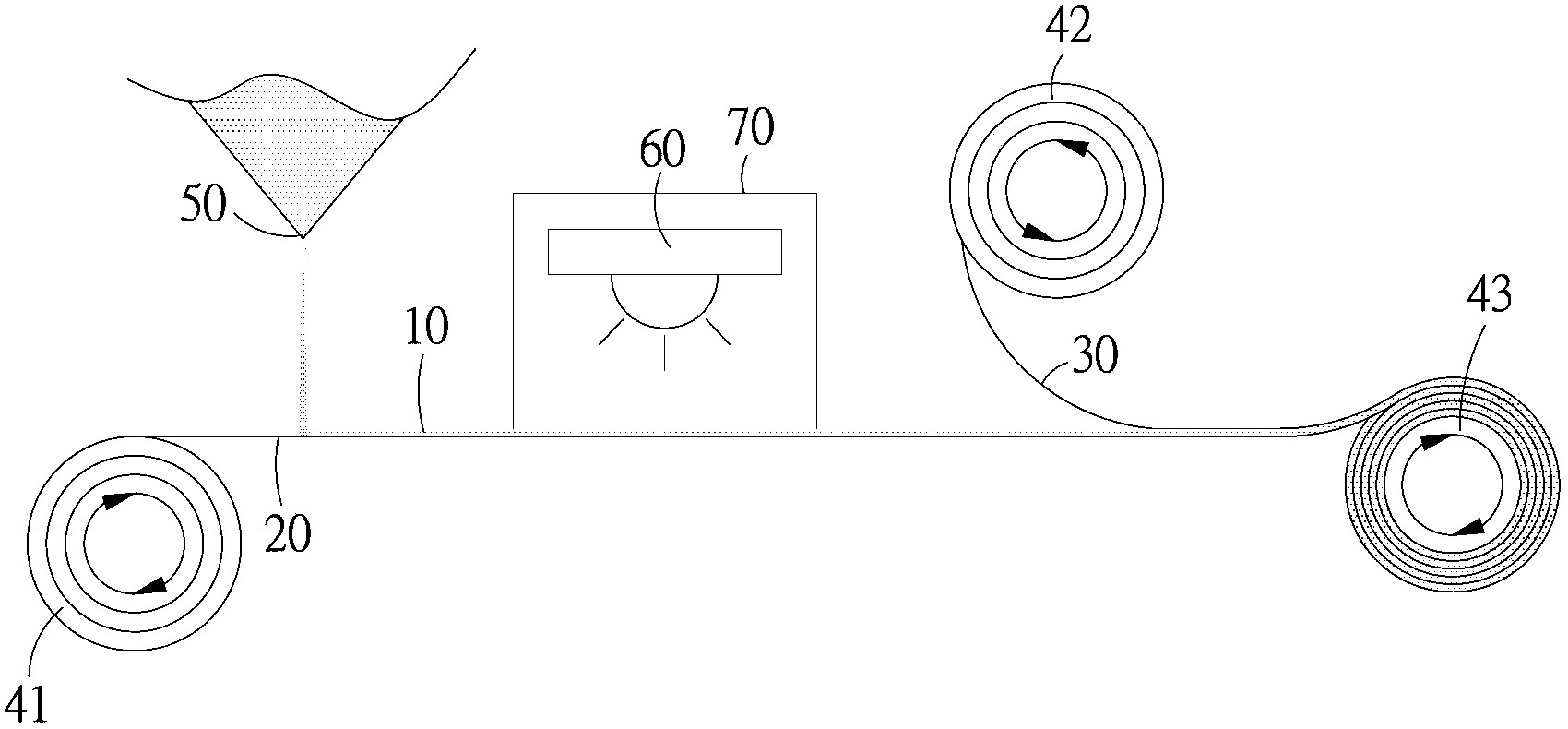

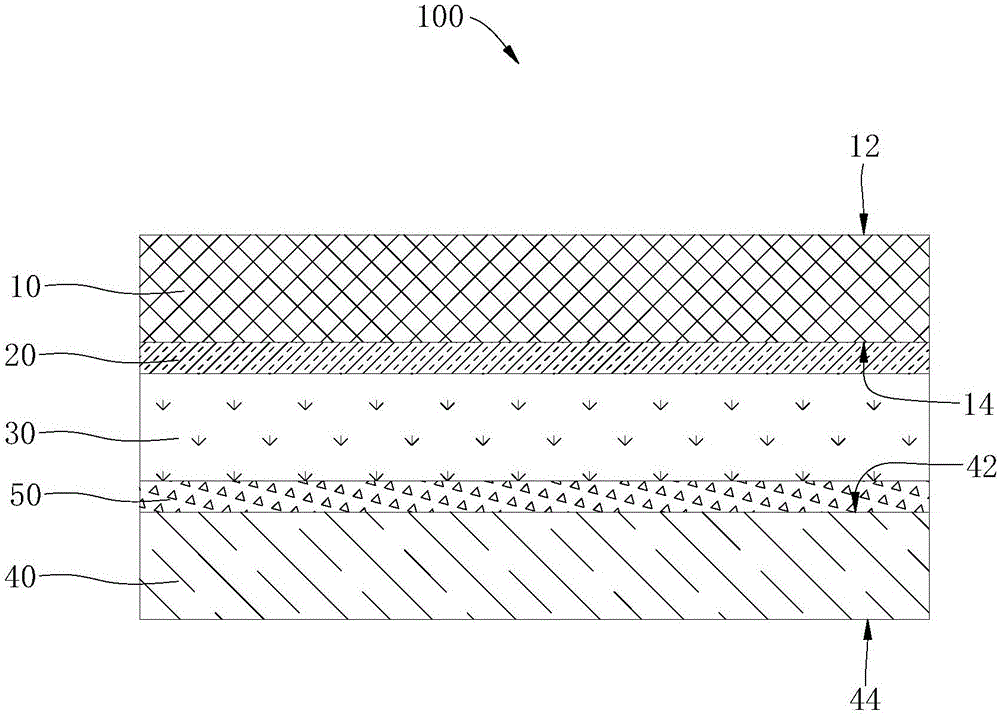

Base material-free optical adhesive tape and its manufacturing method

InactiveCN103450821AReduce thicknessConducive to thin designFilm/foil adhesivesPretreated surfacesPolymer chemistryAdhesive materials

The invention provides a base material-free optical adhesive tape and its manufacturing method. The method consists of: firstly adding a film-forming ingredient into a pre-synthetic adhesive material, conducting stirring to obtain a liquid optical adhesive, also providing a first release film transferred at a predetermined speed, when the first release film moves, coating a liquid optical adhesive with a predetermined thickness on the first release film at the same time, then carrying out UV illumination curing and maturation processing on the liquid optical adhesive on the first release film in order so as to form an optical film with a predetermined thickness, then providing a second release film and using it to cover the cured optical film, thus obtaining the base material-free optical adhesive tape that has a predetermined thickness optical film with both sides covered by the first release film and the second release film respectively.

Owner:YOUDING YONGAN OPTOELECTRONICS MATERIAL

Touch screen and electronic device

InactiveCN106527822AConducive to thin designInput/output processes for data processingCapacitanceElectricity

The invention discloses a touch screen which comprises a compound electrode layer, a reuse electrode layer and a piezoelectric film. The compound electrode layer comprises a plurality of induction electrodes and a plurality of first pressure induction electrodes, and the induction electrodes and the first pressure induction electrodes are alternately arranged. The reuse electrode layer comprises a plurality of reuse electrodes arranged at intervals, the reuse electrodes can serve as drive electrodes and can also serve as second pressure induction electrodes, the drive electrodes are used for forming first capacitors with the first induction electrodes and used for acquiring position information pressed on the touch screen, and the second pressure induction electrodes are used for forming second capacitors with the first pressure induction electrodes and used for acquiring pressing force information pressed on the touch screen. The piezoelectric film is arranged between the compound electrode layer and the reuse electrode layer, and charge generated when the piezoelectric film deforms is picked by the first pressure induction electrodes and the second pressure induction electrodes located at the two sides of the piezoelectric film in a coupling mode to be used for acquiring the pressing force information pressed on the touch screen. The invention further discloses an electronic device.

Owner:NANCHANG O FILM TECH CO LTD

Backlight module

InactiveCN104633521AConducive to thin designIncrease profitPoint-like light sourceLighting device detailsLight sourceOptical film

A backlight module includes an optical film, a light source panel, a number of light sources mounted on the light source panel, and a reflective frame positioned between the optical film and the light source panel. The reflective frame includes an upper frame, a lower frame, and a reflective plate positioned between the upper frame and the lower frame. The upper frame includes a receiving portion for receiving the optical film, the lower frame is connected with the light source panel, and the reflective plate defines a number of through holes. The reflective plate, the lower frame, and the light source panel cooperatively define a closed chamber.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU +1

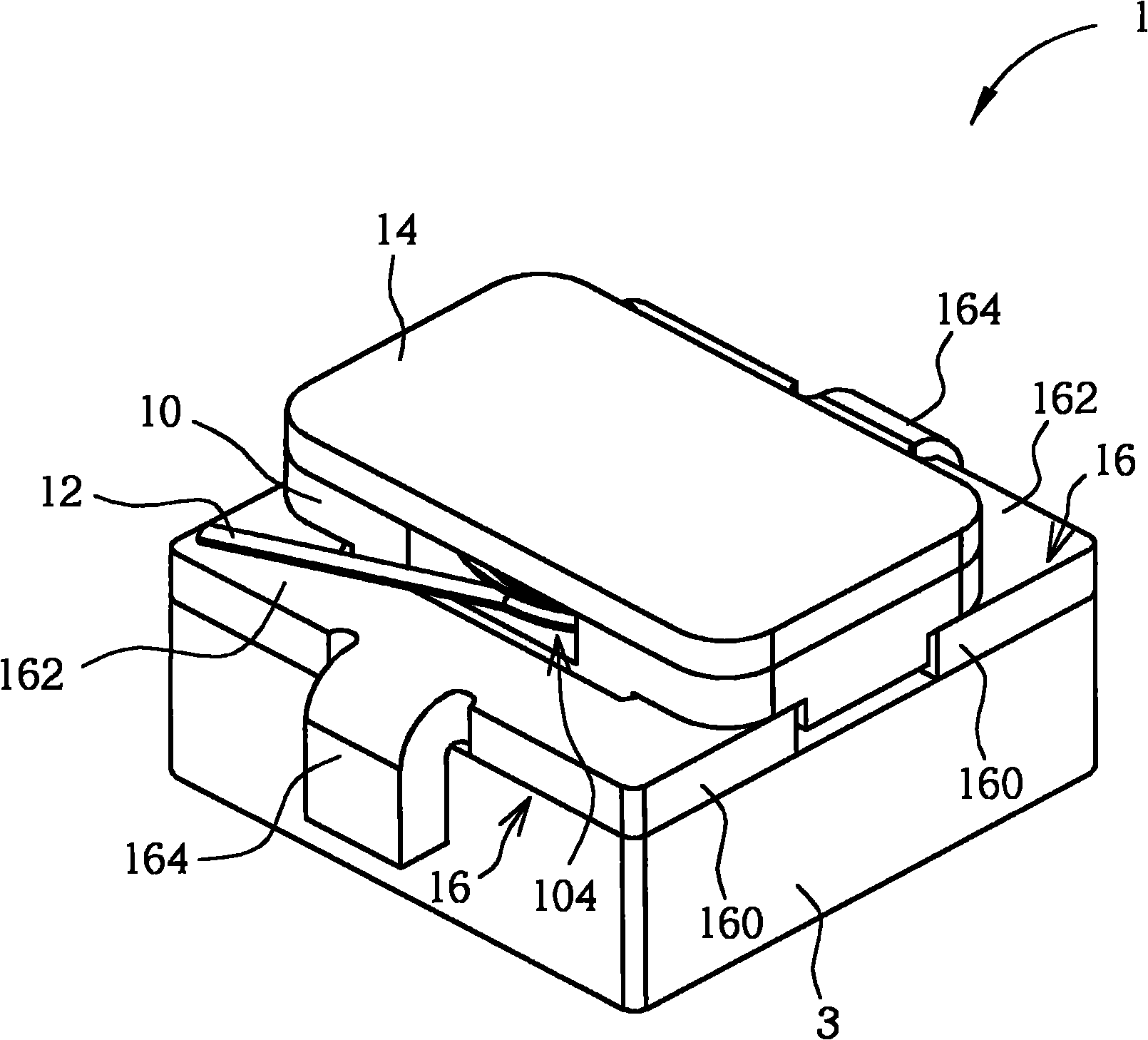

Inducer

ActiveCN102592781AConducive to thin designLower the altitudeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresIntegrated circuitEngineering

The invention discloses an inducer, which comprises a first core, a lead, a second core and a first lead frame. The first side of the first core is provided with a holding space, the second side of the first core is provided with a recess, and the first side is opposite to the second side. The first core is at the first height, the lead is arranged in the holding space, the second core is arranged on the first side of the first core and covers the holding space, and the first lead frame is provided with an embedded portion which is embedded in the recess and at the second height. The total height of the embedded portion and the first core is smaller than the total height of the first height and the second height after the embedded portion is embedded in the recess of the first core. The lead frame of the inducer is embedded in the first core, and when the inducer and an IC (integrated circuit) chip are integrated and packaged systemically, the integral height can be reduced effectively and thinning design of electronic products is benefited.

Owner:CYNTEC

Vibration sound-producing apparatus

ActiveUS20180184209A1Reduce occupancyConducive to thin designLoudspeaker transducer fixingLoudspeakersAcousticsMagnet

Disclosed is a vibration sound-producing apparatus. A sound output aperture of the vibration sound-producing apparatus is provided at a lateral surface. A diaphragm corresponds to the position of the sound output aperture. A flat sound coil is perpendicular to the diaphragm. A magnet is parallel to the sound coil. The vibrating direction of the sound coil avoids a thickness direction. The vibrating direction of the magnet and a mass block also avoids the thickness direction. The mass block is fixedly joined to a housing via a flexible piece. This facilitates reduced product thickness, increased product performance, and a simplified product production process. Therefore, the vibration sound-producing apparatus of the present invention has the advantages of a great thickness-reduced design, great performance, and simple assembly.

Owner:GOERTEK INC

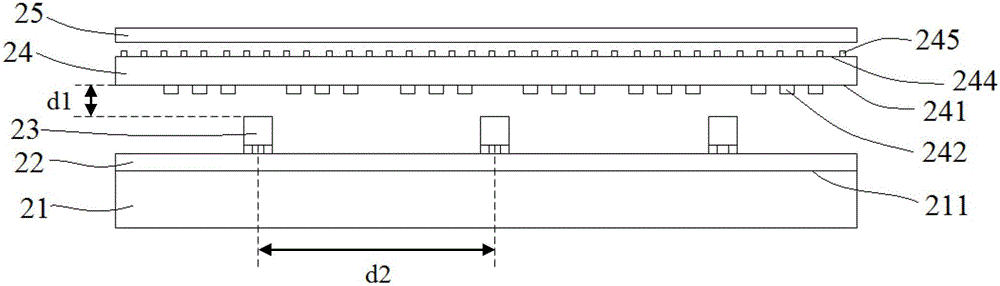

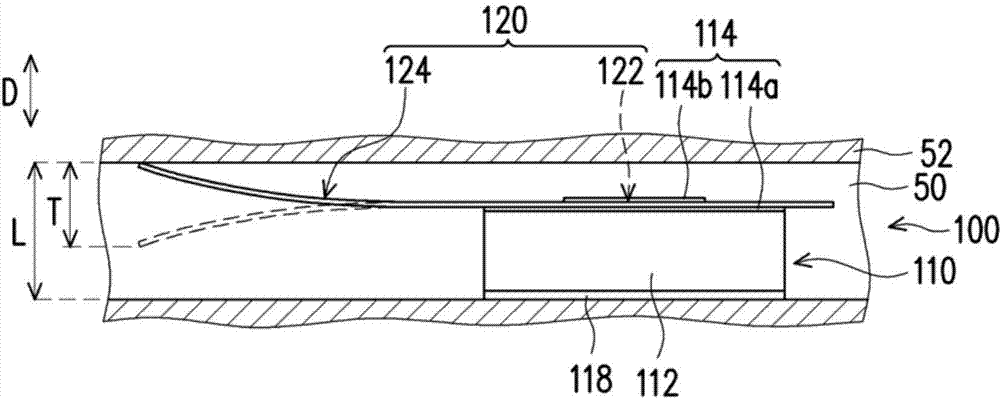

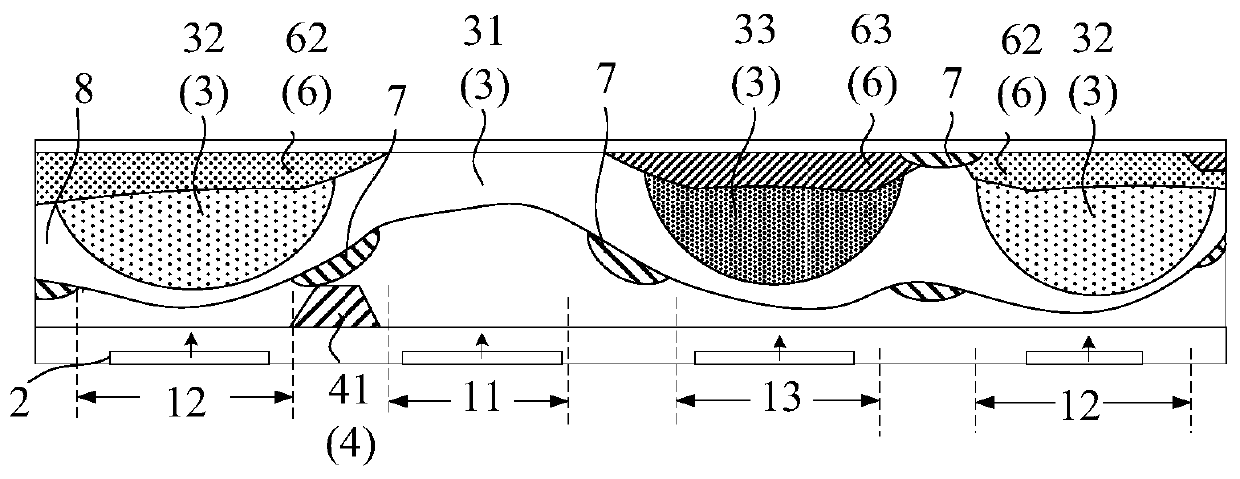

Display device and backlight module thereof

ActiveCN108761907ARealization of thin designFacilitate thinningNon-linear opticsDiffusionTransmittance

A display device includes a display panel and a backlight module disposed under the display panel. The display panel has a display area and a light shielding layer surrounding the display area. The backlight module includes a plurality of light sources, a reflective sheet corresponding to the plurality of light sources, an optical control film disposed above the plurality of light sources and thereflective sheet, a diffusion material layer interposed between the reflective sheet and the optical control film, and a diffusion plate disposed one side opposite to the diffusion material layer of the optical control film, wherein the optical control film has a plurality of light-emitting structures and is interposed between the diffusion plate and the diffusion material layer, and the diffusionmaterial layer has a transmittance of 65% to 85 %.

Owner:AU OPTRONICS CORP

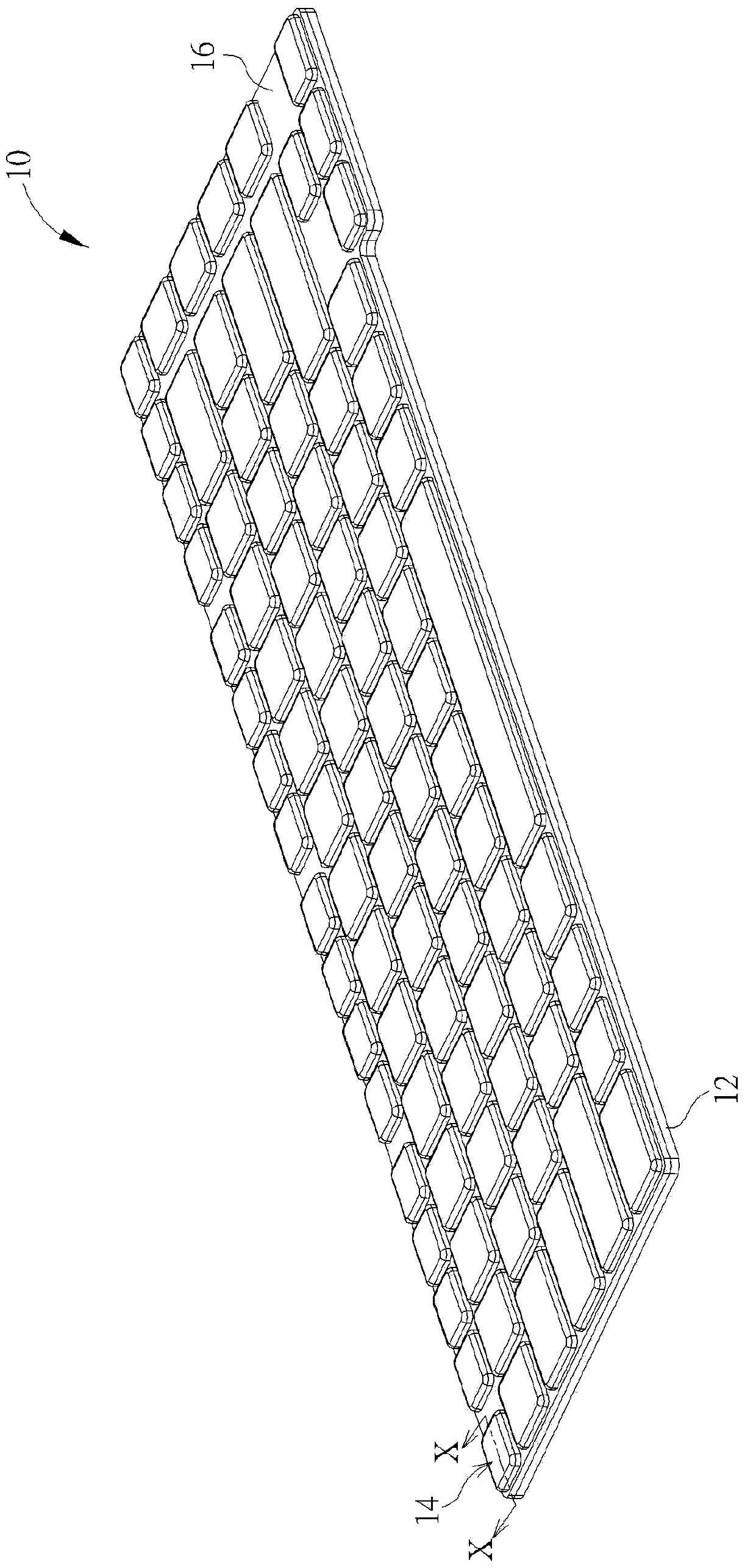

Keyboard

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Polarizer, preparation method thereof and display device

InactiveCN107037627AReduce thicknessAvoid scrappingNon-linear opticsInput/output processes for data processingDisplay devicePolarizer

The embodiment of the invention provides a polarizer, a preparation method thereof and a display device, and relates to the technical field of display. A touch electrode is arranged on the polarizer so that the problem that an existing touch control structure is difficult to rework can be solved. When structures like an OGS, a GG, a GF, a GFF and the like are applied to the display device, the thickness of the display device can be reduced. The polarizer comprises a polarizer body and also comprises a touch control structure manufactured on the polarizer body.

Owner:BOE TECH GRP CO LTD +1

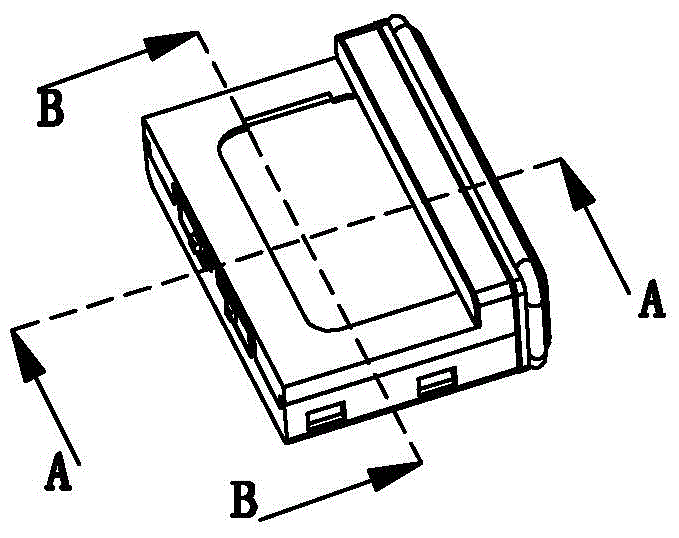

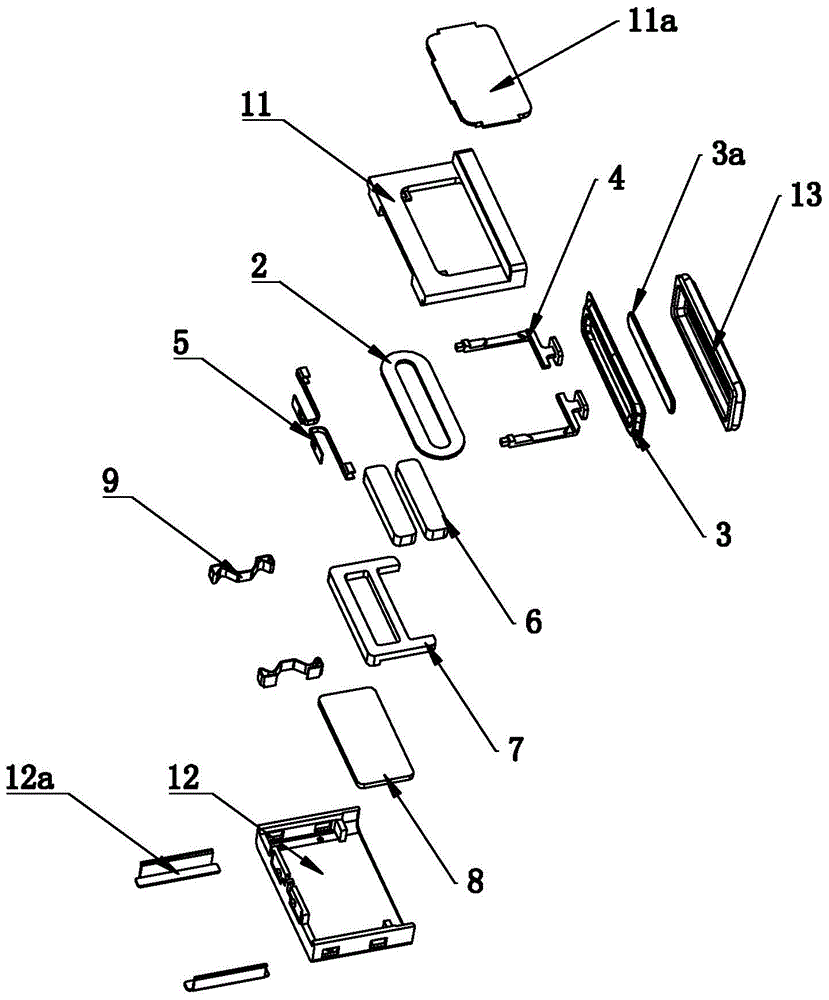

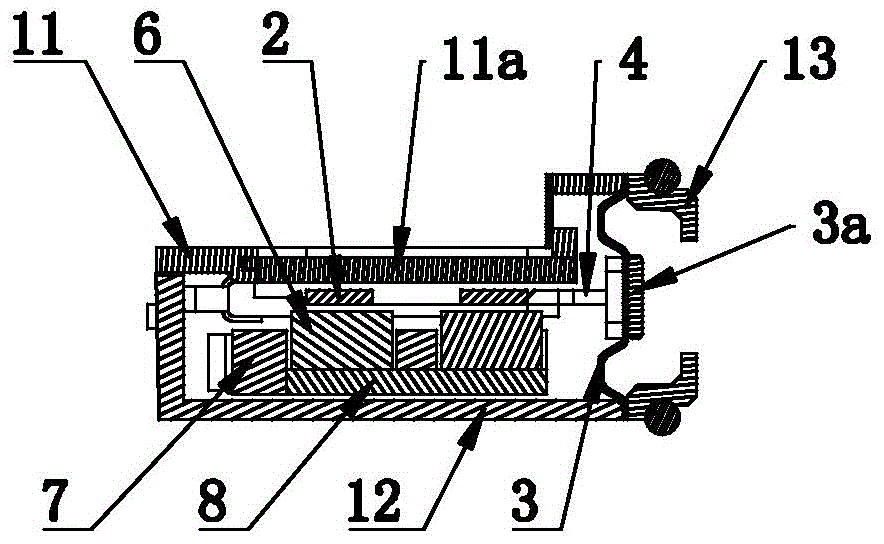

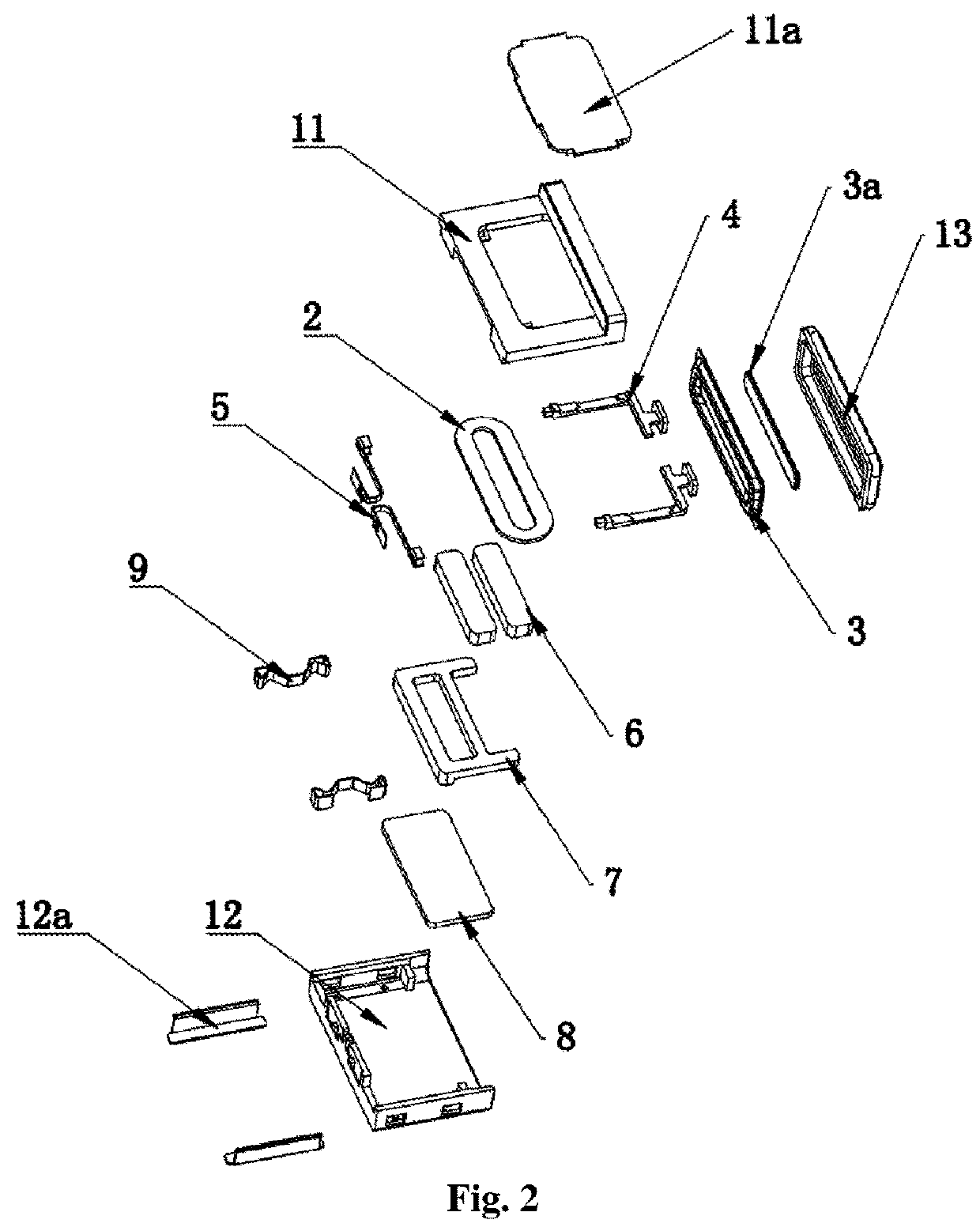

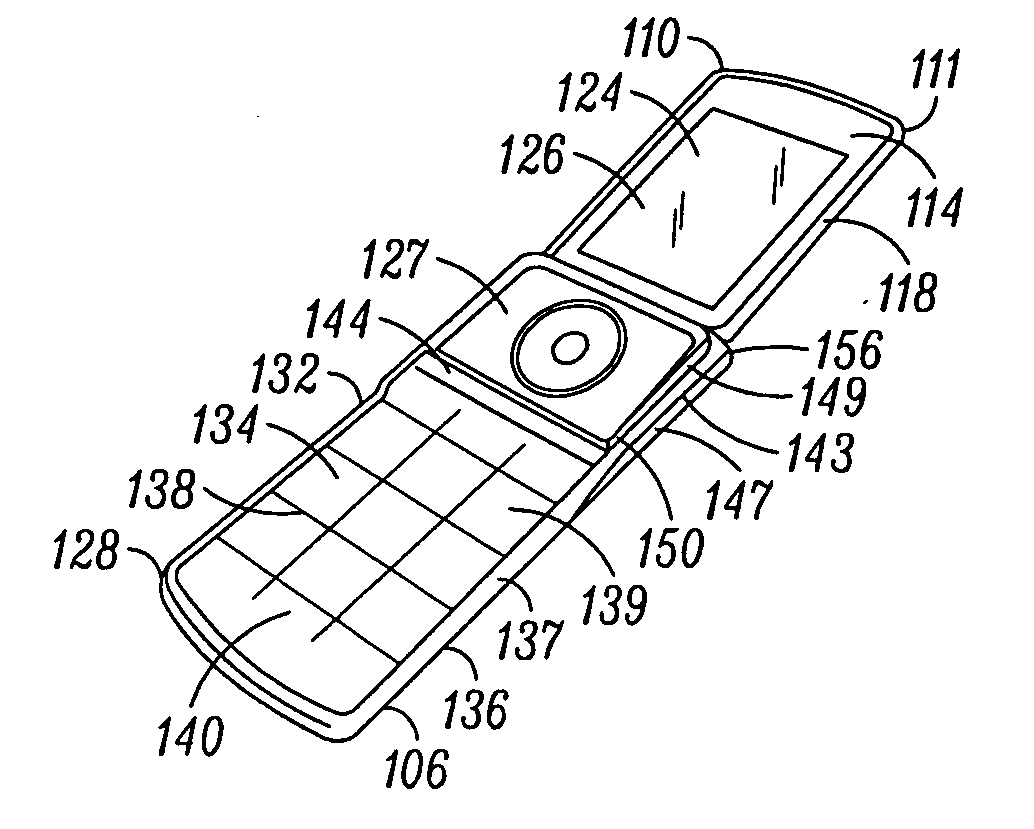

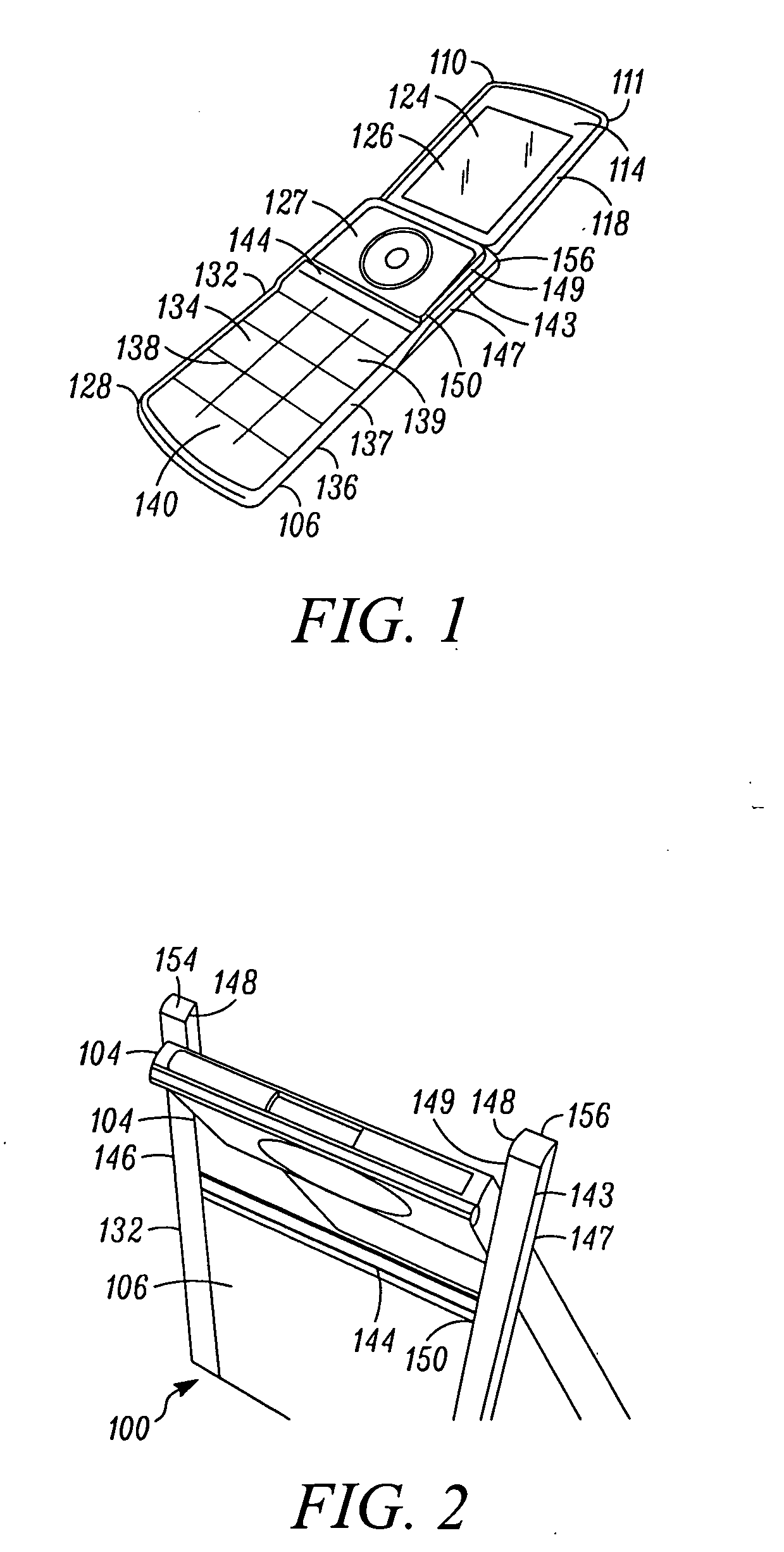

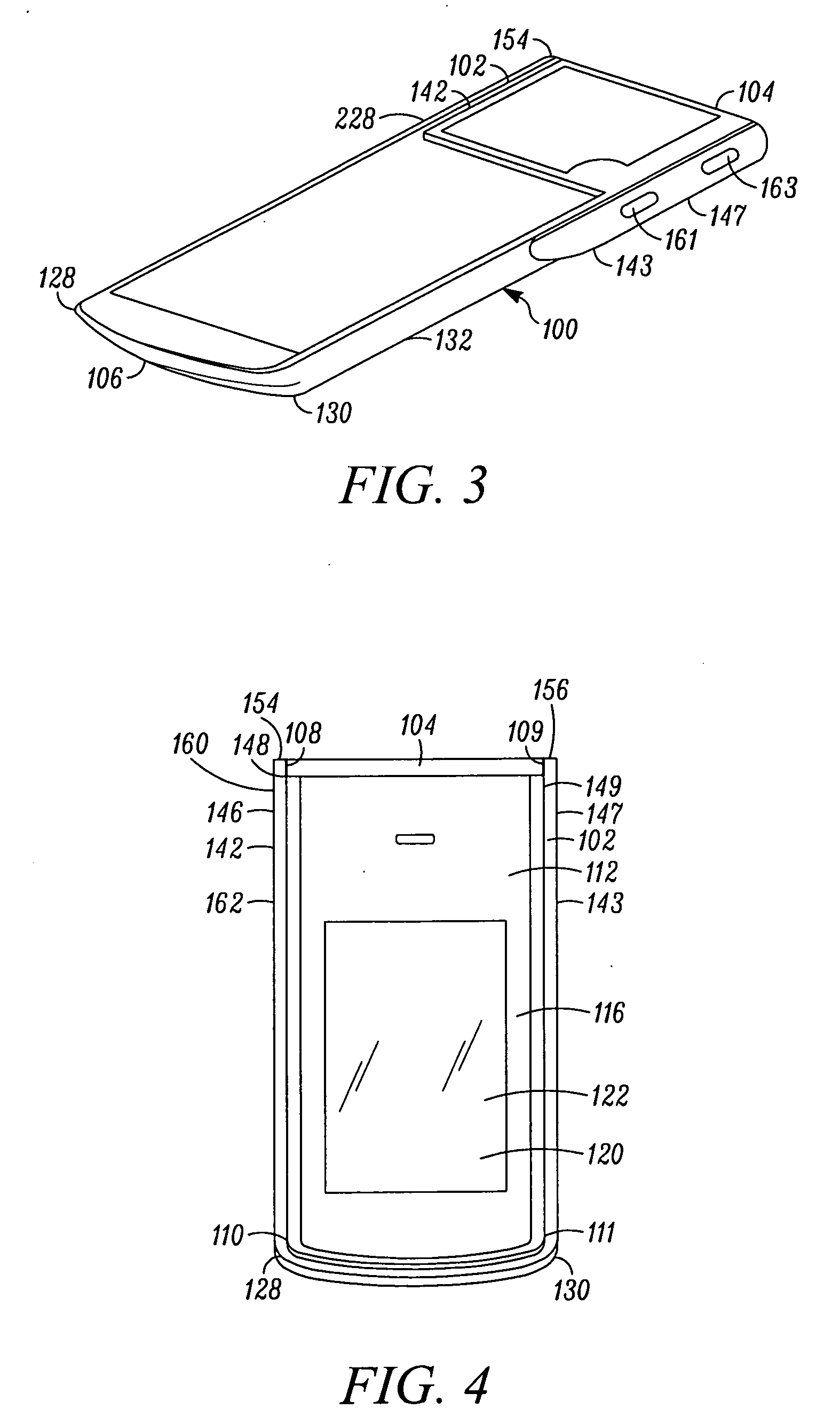

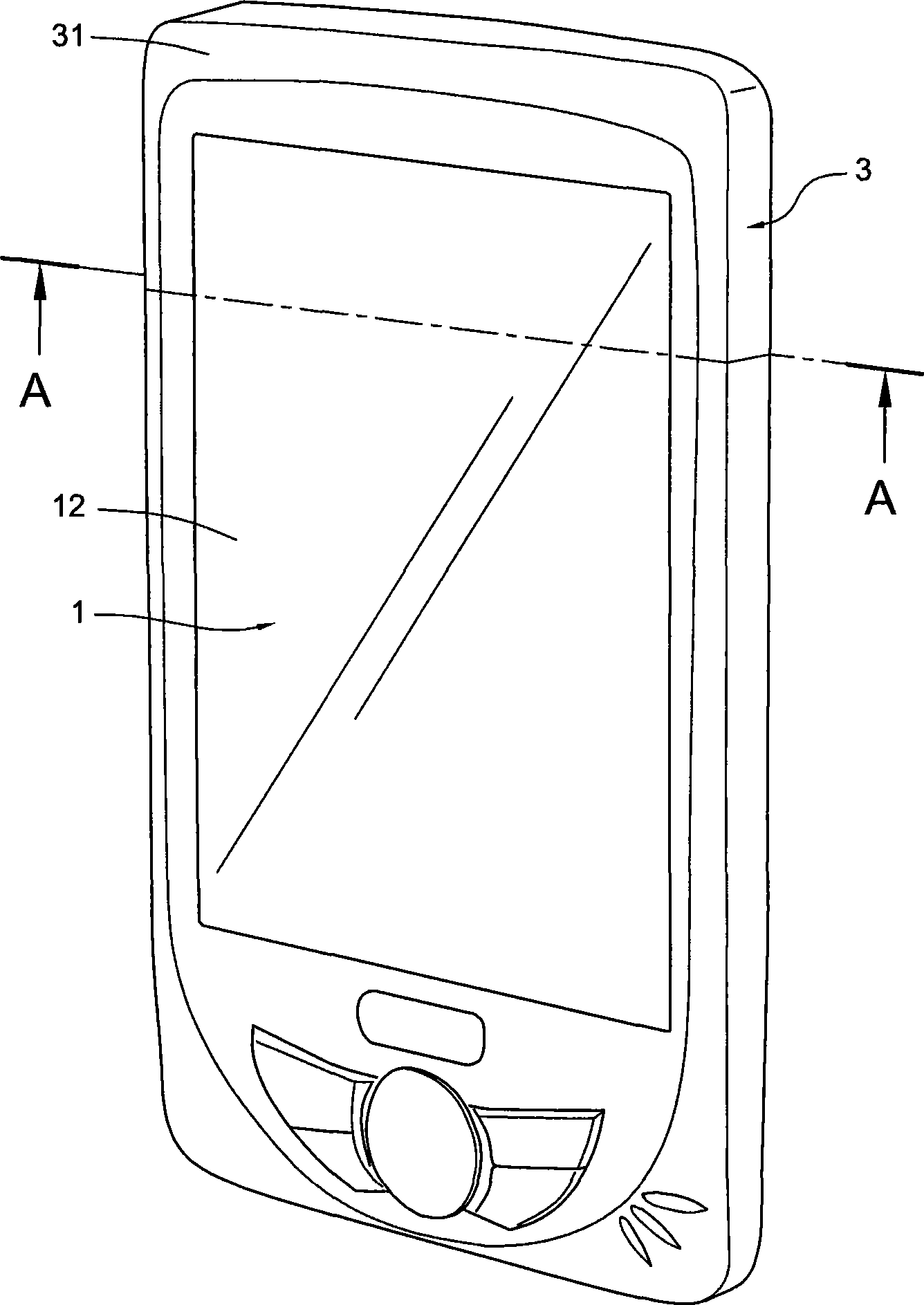

Goal Posts Side Key Implementation Scheme for Offset Hinge Clamshell Phone with Thickness Flip Hardware Compartment

InactiveUS20100188807A1Easy to useEasy to manufactureDigital data processing detailsSubstation equipmentCamMechanical engineering

A mobile phone or other electronic device is provided with side keys inside the goalpost compartment at a location offset from the axis of rotation to optimize the use of internal limited space inside the goalpost. In the preferred form, side keys comprise keycaps positioned in the goalpost area, while the switches are located inside the hardware compartment and engaged by the keycaps via a pin providing a cam.

Owner:GOOGLE TECH HLDG LLC

Display panel

ActiveCN106940605AConducive to thin designRealize the designInput/output processes for data processingComputer scienceSignal lines

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

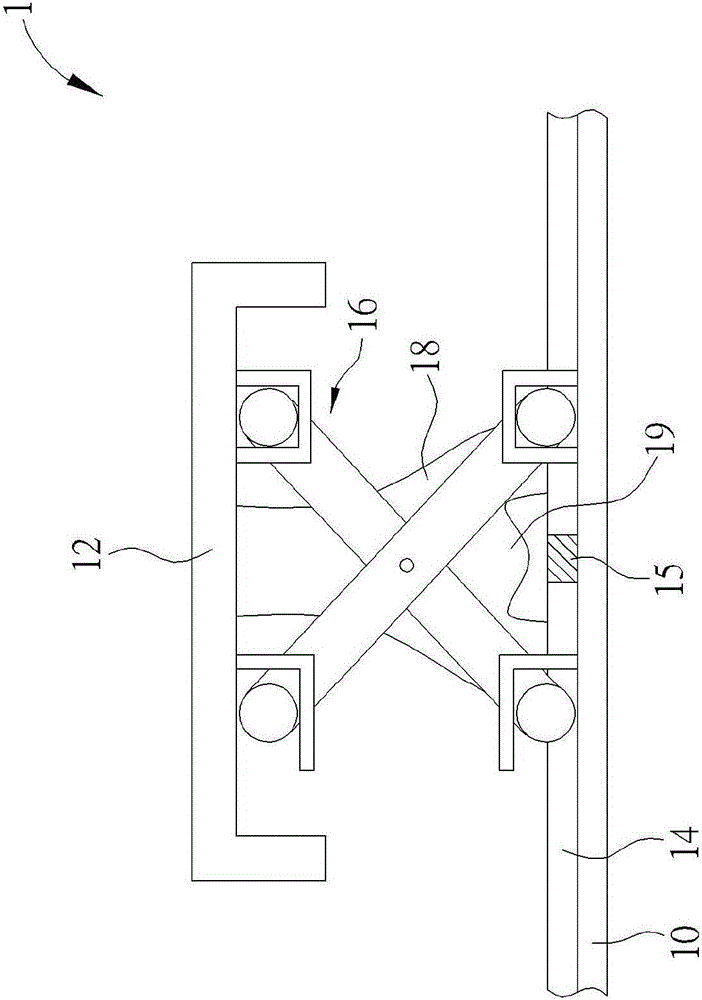

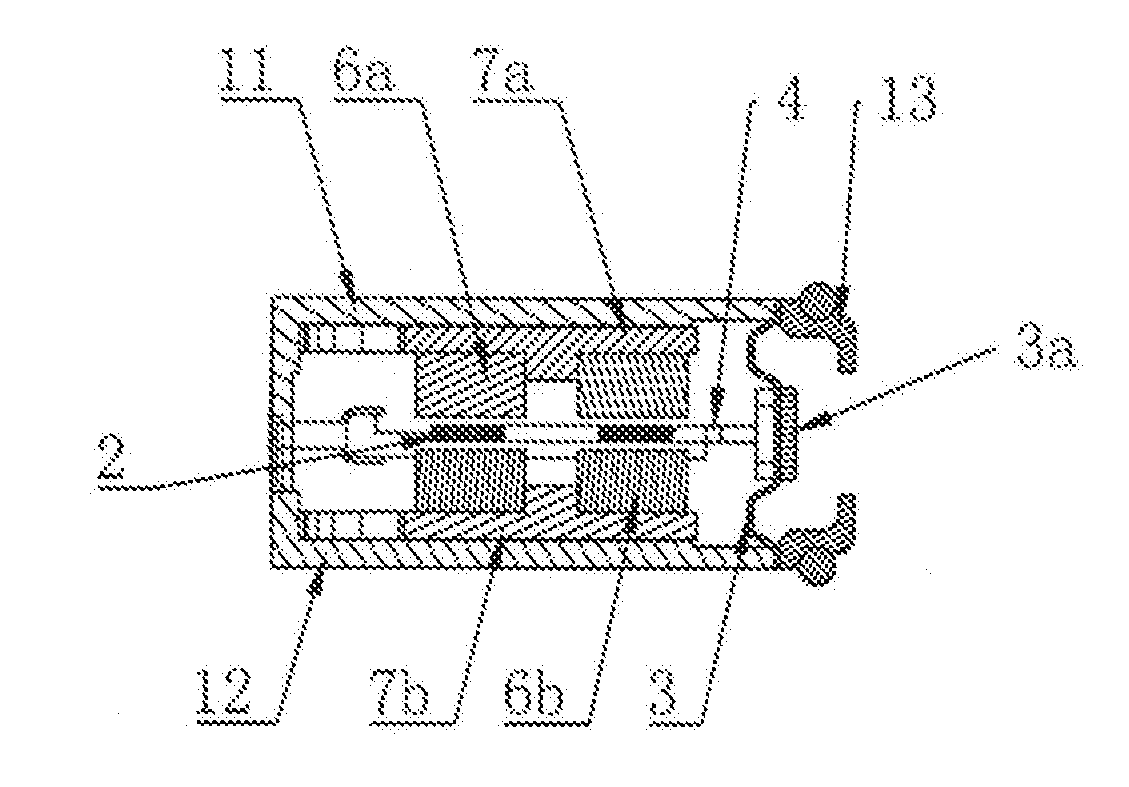

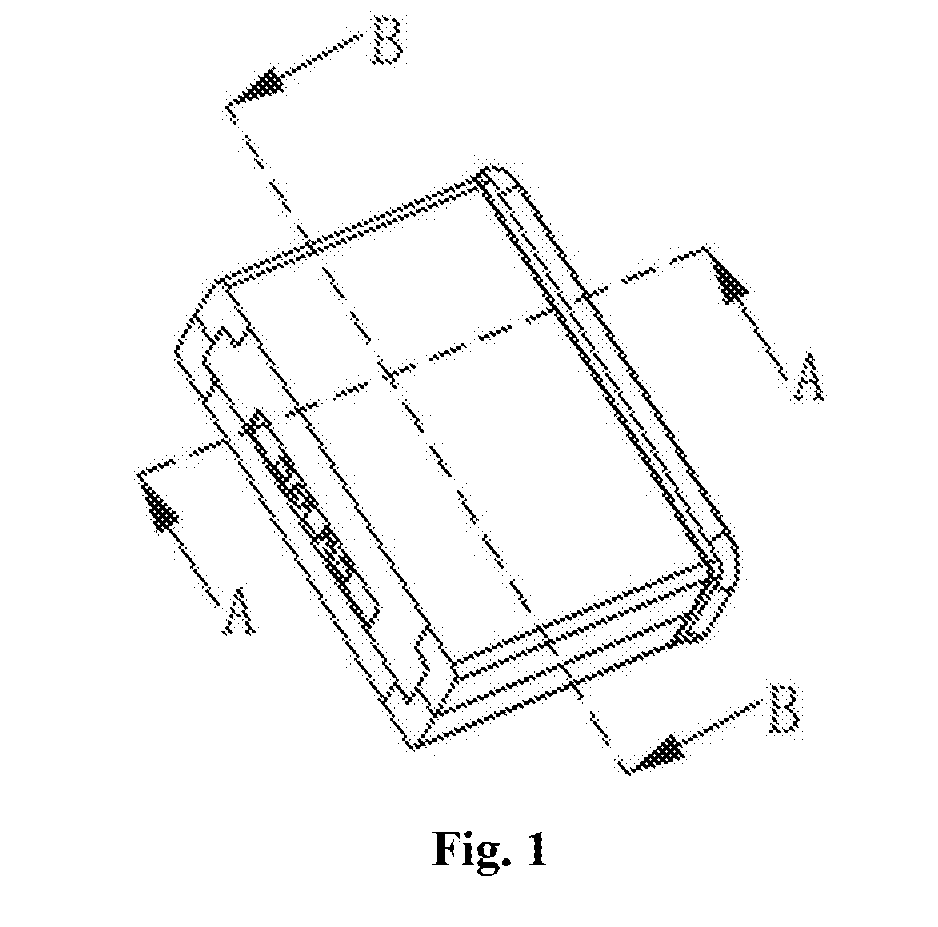

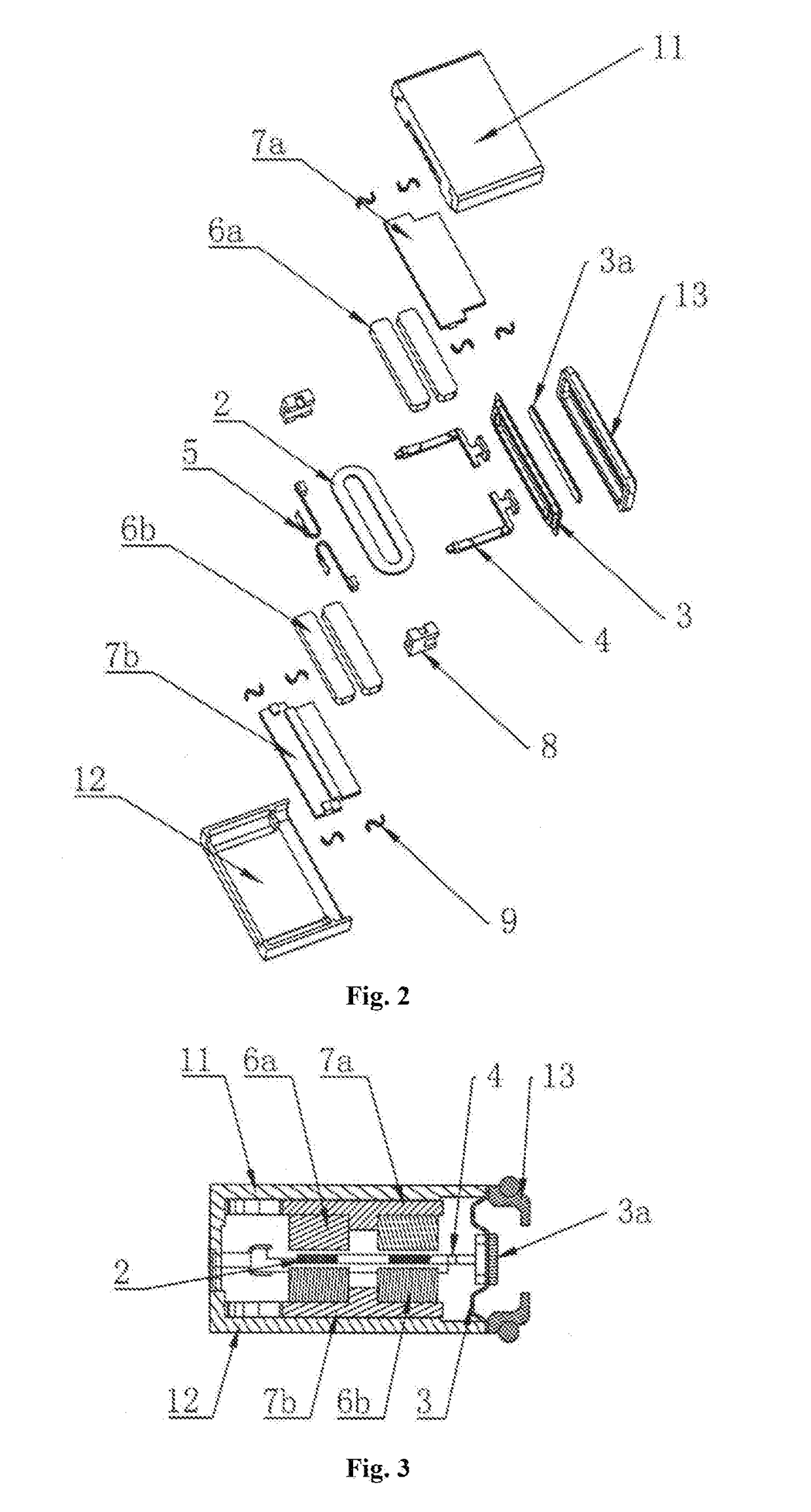

Key and keyboard with same

The invention relates to a key and a keyboard with the same. The key comprises a keycap, an upper cover, a switch unit electrically connected with a printed circuit board, an actuating part, an elastic part, a first supporting part, a second supporting part and a bottom plate part with first and second connecting structures, a lower cover, an abutting surface and a fixing seat, wherein the upper cover is provided with a sliding groove and sleeves the lower cover to form an accommodation space with the lower cover; the switch unit is arranged on the fixing seat and located in the accommodation space; the actuating part is abutted on the keycap and movably arranged in the sliding groove in a penetration manner; the elastic part is arranged in the accommodation space and abutted on the abutting surface and the actuating part; the first supporting part is movably connected to the first connecting structure and the keycap; the second supporting part is movably connected to the second connecting structure and the keycap; when the keycap is pressed, the actuating part moves downwards to trigger the switch unit; and when the keycap is released, the elastic part drives the actuating part to move upwards to drive the keycap to return. According to the key, the hand feeling of pressing can be improved and the phenomenon of circuit damage or continuous switch triggering due to improper pressing is avoided.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

In-mold moulding touch control module group and producing method thereof

ActiveCN101414235AEasy to implementImprove the efficiency of automated productionPhotomechanical apparatusInput/output processes for data processingIndium tin oxideEngineering

The invention discloses an in-mold forming touch control module comprising a perspective conductive carrier board and a molded shell body, a capacitive electrode layer which is a touch control sensing circuit made from indium tin oxide is arranged on one inner surface of the carrier board, the sensing circuit can be touched by one outer surface of the carrier board, and the shell body is coated and combined at the peripheral edges of the carrier board. The invention also comprises a production method of the in-mold forming touch control module, comprising the steps: the indium tin oxide is coated on the inner surface of the carrier board, the sensing circuit is formed by processing; the carrier board is arranged in a mold cavity, and molding material is injected in the mold cavity to form the molded shell body which is integratedly coated and combined at the peripheral edges of the carrier board, thereby improving the touch control sensitivity of the module and simplifying the process. The in-mold forming touch control module and the production method are conductive to the simple implementation in the environment of an injection molding machine which is provided with automatic loading and unloading devices and further conductive to enhancing the effectiveness of automatic production, compared with the prior art which adopts the layer iteration adhesion mode, the production method can effectively simplify the production process and reduce the working time and the cost.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Heat dissipation device and control method thereof

InactiveCN104717874AReduce weightConducive to thin designDigital data processing detailsFlexible member pumpsComputer moduleSoftware engineering

A heat dissipation device including a driving module and a heat dissipation sheet is provided. The heat dissipation sheet has a connection portion and a swing portion and is connected to the driving module by the connection portion. When the driving module receives an input voltage to drive the connection portion, the connection portion drives the swing portion to swing back and forth so as to generate a heat dissipation airflow.

Owner:WISTRON CORP

Light guide structure for implementing polarization collimation surface light sources

ActiveCN105511012AAchieving polarizationImplement featuresPlanar/plate-like light guidesLight guideSystem structure

The invention discloses a light guide structure for implementing polarization collimation surface light sources. The light guide structure comprises a light guide structure body, an incident polarization light source and a micro-lens array group. Light rays emitted by the incident polarization light source are reversely transmitted into a quarter-wave plate under the effects of concave dimming screen dots arranged at a light emergent surface, are modulated twice and are collimated by parabolic reflection micro-lenses, and the high-polarization collimation surface light sources in polarization states perpendicular to original polarization states can be ultimately formed at the light emergent surface. The light guide structure has the advantages that the efficient polarization collimation surface light sources can be implemented, the light guide structure is high in integration level, particularly suitable for application with requirements on surface light sources and favorable for thinning designs of system structures and is compact, and processing techniques are easy to implement.

Owner:FUZHOU UNIV

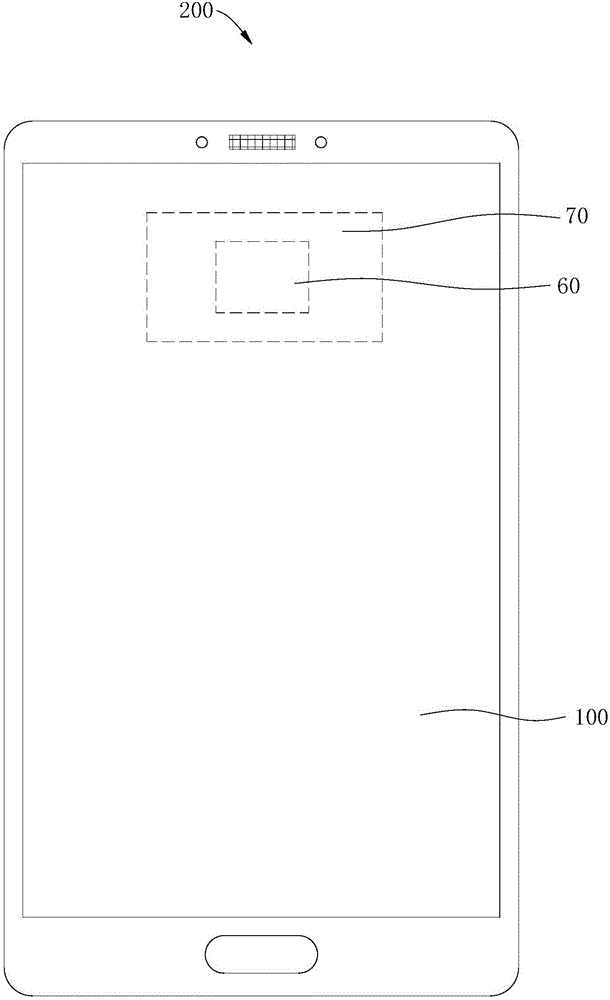

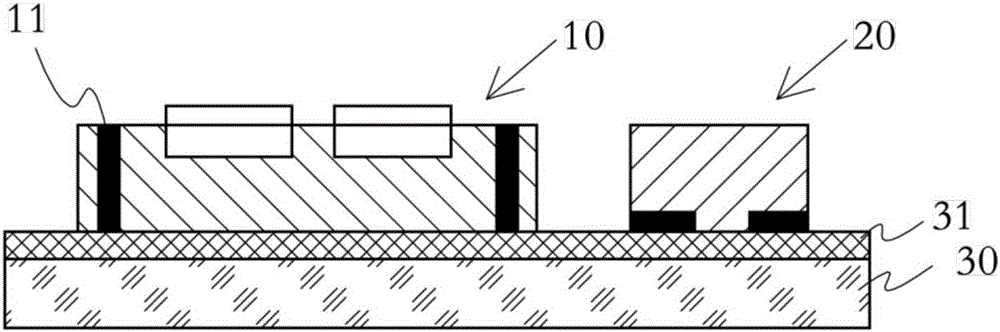

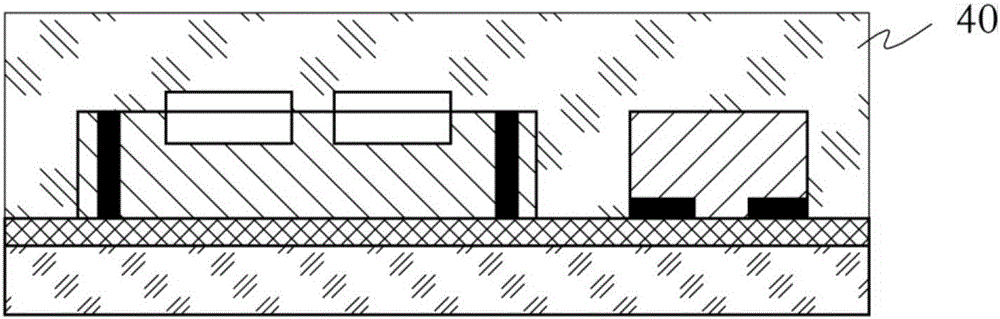

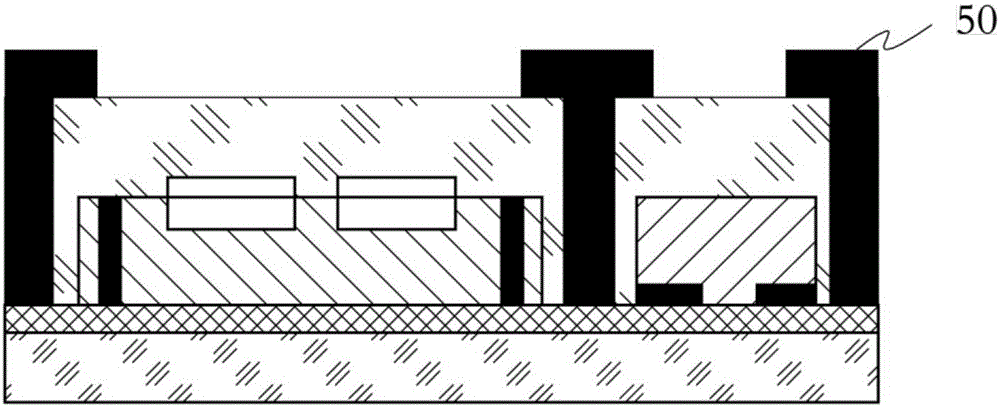

Ultra-thin ambient light and proximity sensor wafer level package and package method thereof

PendingCN106024649AConducive to thin designImprove routing densitySemiconductor/solid-state device detailsSolid-state devicesProximity sensorEngineering

The invention provides ultra-thin ambient light and proximity sensor wafer level package and a package method thereof. The method comprises the steps that a. a light-sensitive wafer with a silicon through-hole structure and a light-emitting wafer are placed on a forming carrier with a tape; b. the light-emitting wafer and the light-sensitive wafer are encapsulated by a light-transmitting material to form an optical cover; c. the optical cover is encapsulated by a non-light-transmitting material, and a light isolation belt is formed between the light-emitting wafer and the light-sensitive wafer to form a protection cover; d. the top of the protection cover is bonded to the processing fixture of an RDL wiring layer; e. the forming carrier and the tape are removed; and f. the RDL wiring layer is formed on the removed surface to realize the wafer level package. According to the invention, traditionally relying on the process of a PCB substrate is changed; the light-sensitive wafer with the silicon through-hole structure and the RDL wiring layer are combined to realize wafer level package; and thinning and efficient production are realized without the PCB substrate.

Owner:宁波德葳智能科技有限公司

Light guide plate and backlight module

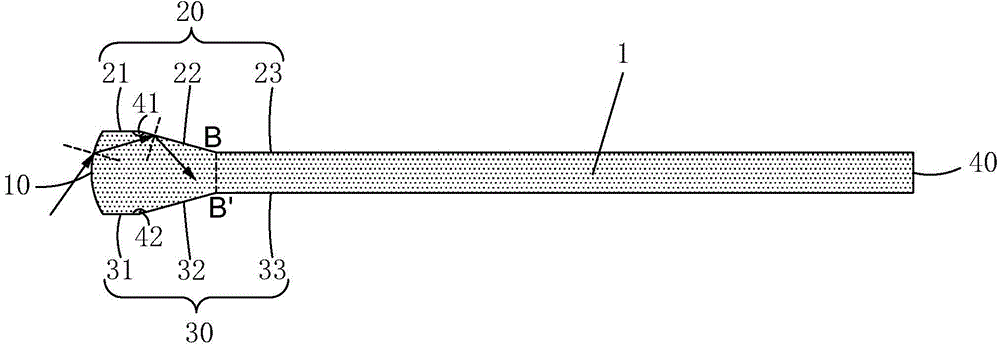

ActiveCN104808283AConducive to thin designThe overall thickness is thinPlanar/plate-like light guidesNon-linear opticsLight guideOptoelectronics

The invention provides a light guide plate and a backlight module. The light inlet surface of the light guide plate is arc-shaped; a first inclined surface and a second inclined surface are respectively arranged on the side, close to the light inlet surface, of the upper surface and the lower surface of the light guide plate, so that light at a large angle can be totally reflected at the first inclined surface and the second inclined surface after the gathering action of the arc-shaped light inlet surface, and enter the light guide plate; the light which enters the light guide plate is emitted out from a light outlet surface after being transferred and reflected; the light utilization rate is improved; the light coupling efficiency is improved. The light guide plate of the structure has a good converging effect on the light at various angles, so that the thickness of a light guide part of the light guide plate can be reduced without losing the light coupling efficiency; the thin-type design of the light guide plate is facilitated. The backlight module provided by the invention adopts the light guide plate of the special structure, so that the backlight module has a smaller thickness and a better light outlet effect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Display panel and display device

ActiveCN109801559APlay a supporting roleMaintain pressure resistanceNon-linear opticsIdentification meansColor filmDisplay device

An embodiment of the invention provides a display panel and a display device, relates to the technical field of display, and aims to improve the optical crosstalk problem among different-color subpixels in a quantum-dot display panel. The display panel comprises a backlight source, a quantum-dot color film layer and a retaining wall structure and is characterized in that the retaining wall structure only comprises a first retaining wall, and the projection, on the plane where the display panel is located, of the first retaining wall is only located between the first color subpixel area of thedisplay panel and a different-color subpixel area adjacent to the first color subpixel area; or the retaining wall structure comprises a first retaining wall and a second retaining wall, the projection, on the plane where the display panel is located, of the first retaining wall is located between the first color subpixel area of the display panel and a different-color subpixel area adjacent to the first color subpixel area, and the projection, on the plane where the display panel is located, of the second retaining wall is only located between the second color subpixel area of the display panel and the third color subpixel area of the display panel, and the height of the first retaining wall is larger than that of the second retaining wall.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Vibration sound-producing apparatus

ActiveUS20180146294A1Reduce occupancyBig spaceTransducer circuit dampingFrequency/directions obtaining arrangementsMagnetAcoustics

Disclosed is a vibration sound-producing apparatus. A sound output aperture is provided on a sidewall perpendicular to a thickness direction. A diaphragm is parallel to the plane on which the sound output aperture is located. A flat sound coil is perpendicular to the diaphragm. Two magnets parallel to the sound coil are arranged at either side of the sound coil. The vibrating direction of the sound coil avoids the thickness direction. The vibrating direction of an integral structure of the magnets and a magnetic conductor part also avoids the thickness direction. This facilitates a thickness-reduced design for a product, increases the space for vibration, and enhances product performance, meanwhile, the design of the two magnets effectively increases the strength of the magnetic field within the product, this further improving product performance. The vibration sound-producing apparatus of the present invention has the advantages of a great thickness-reduced design and great performance.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com