In-mold moulding touch control module group and producing method thereof

A touch module and in-mold molding technology, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as accumulation of dust, increased step thickness, complicated manufacturing process, etc., to reduce man-hour cost, improve efficiency, simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the structural composition and the effects that can be produced of the in-mold forming touch module and its production method of the present invention are described in detail as follows with preferred embodiments in conjunction with the accompanying drawings:

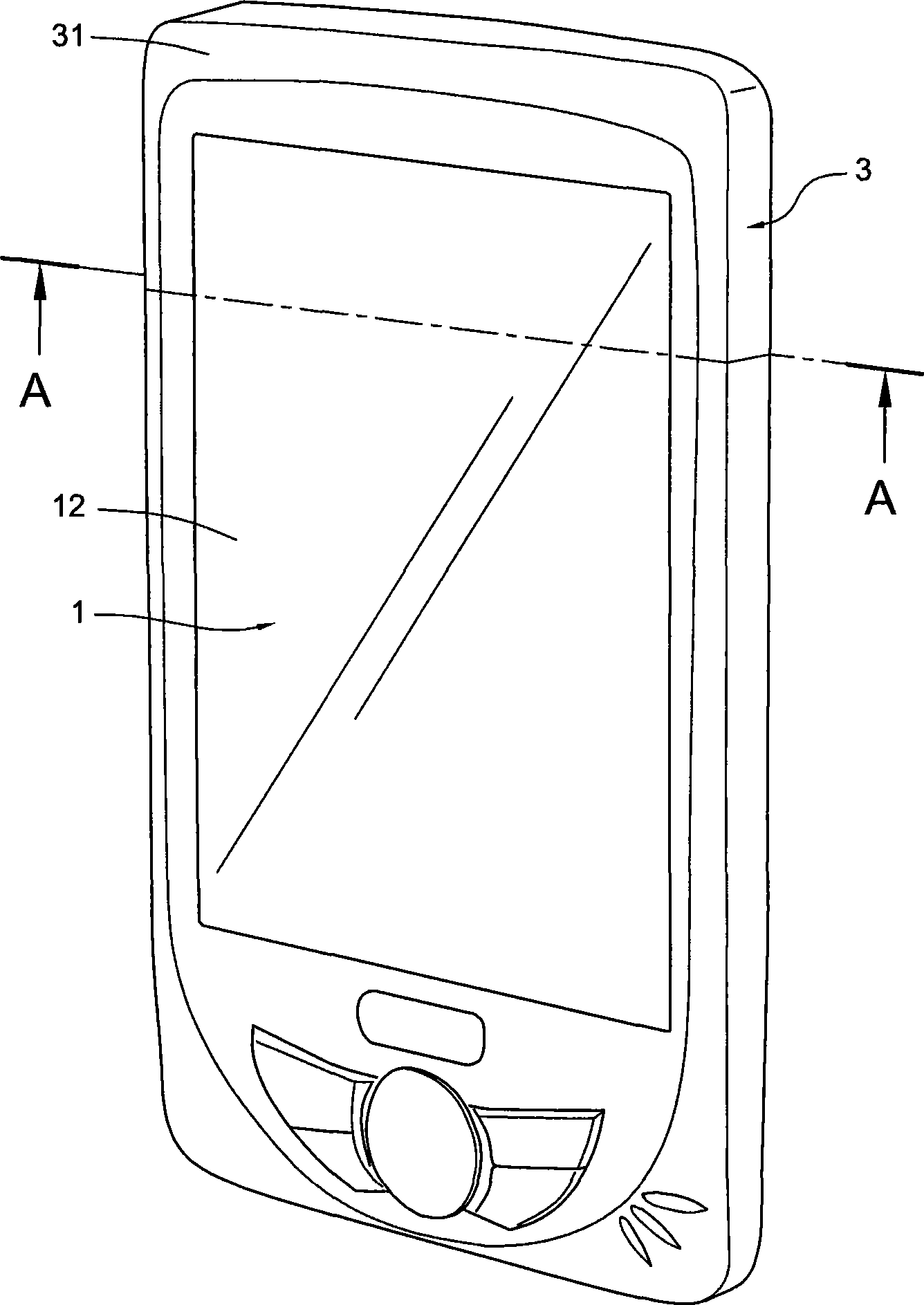

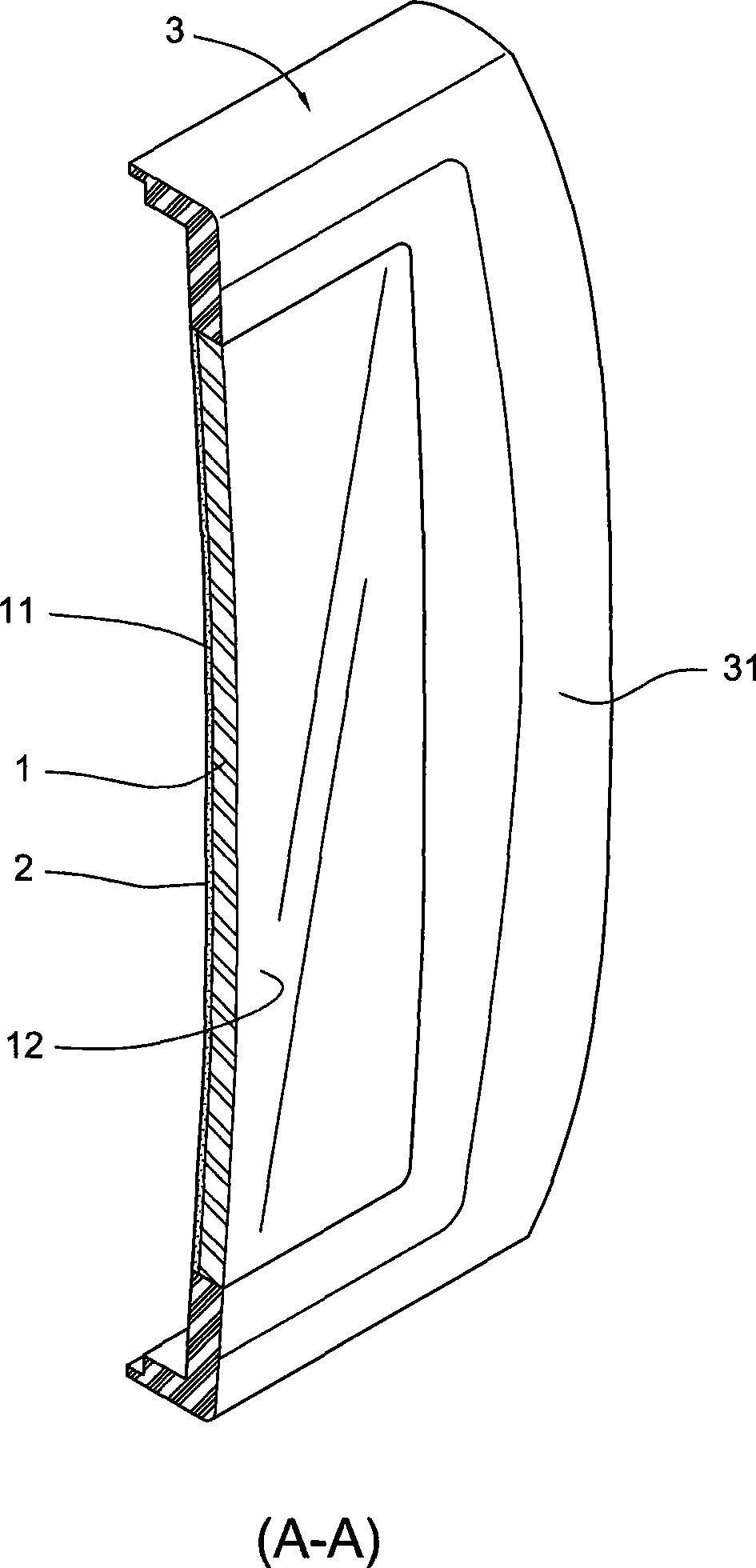

[0028] figure 1 It is a three-dimensional view of an electronic product housing with a touch module, figure 2 for figure 1 Three-dimensional cross-sectional view of the components. Depend on figure 1 with figure 2 It can be seen that the in-mold forming touch module of the present invention includes:

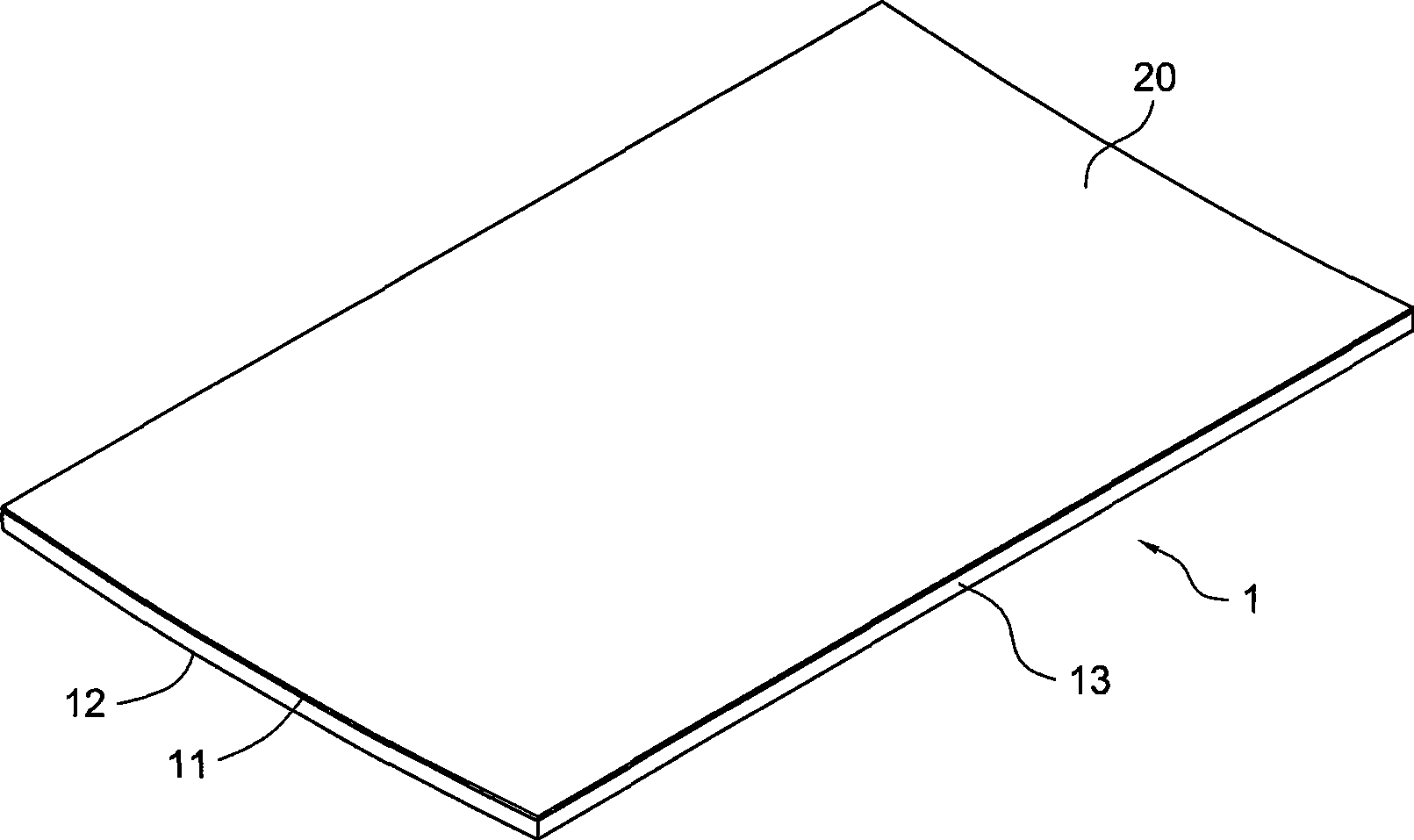

[0029] A see-through conductive carrier 1 has an inner surface 11 and an outer surface 12 (with Figure 8 As shown), there is a capacitive electrode layer 2 on the inner surface 11 (with Figure 4 shown), is a touch sensing circuit 21 made of indium tin oxide, and the outer surface 12 can be used to touch the sensing circuit 21;

[0030] A molded shell 3 is integrally covered and bonded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com