Patents

Literature

79results about How to "Eliminate Thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

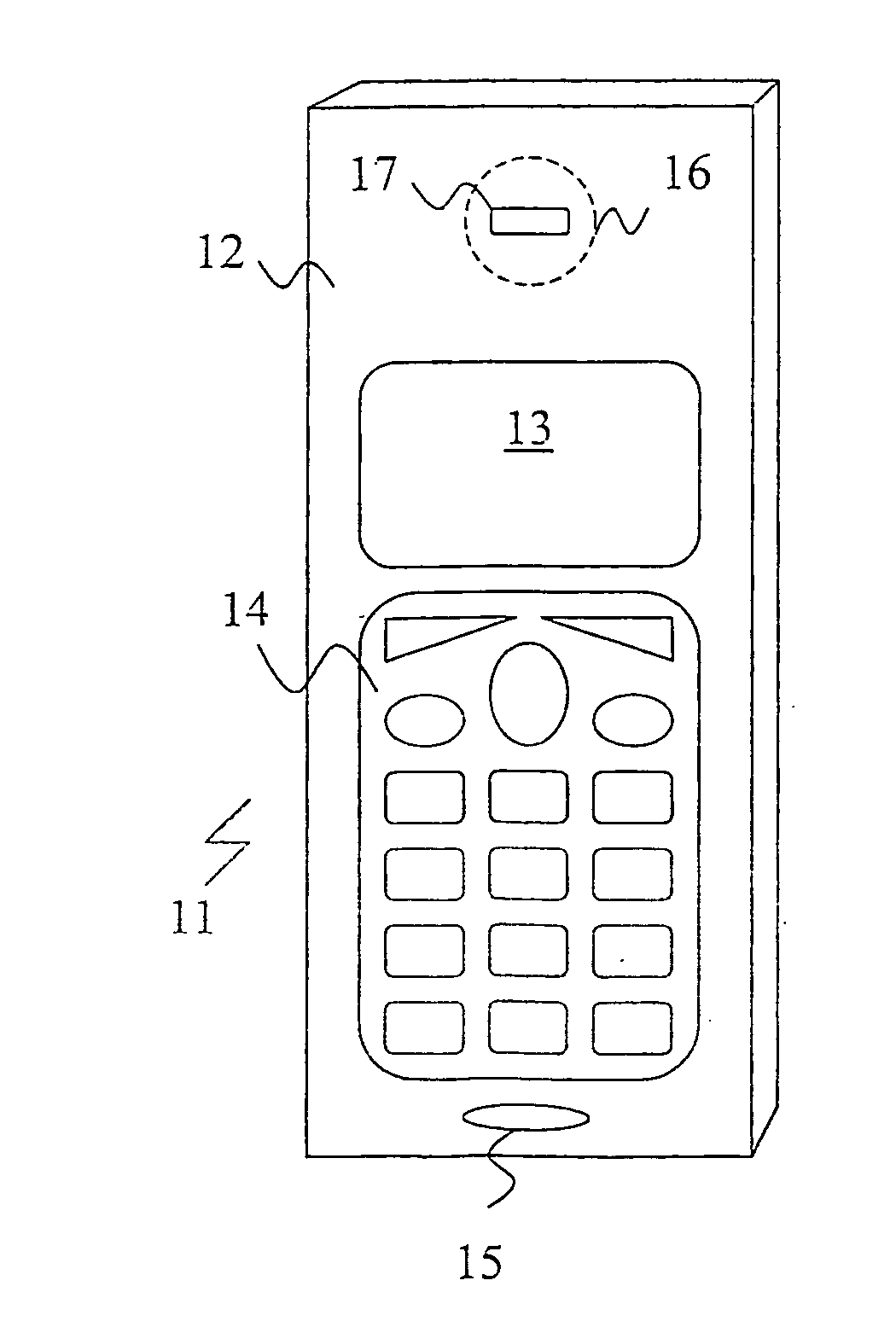

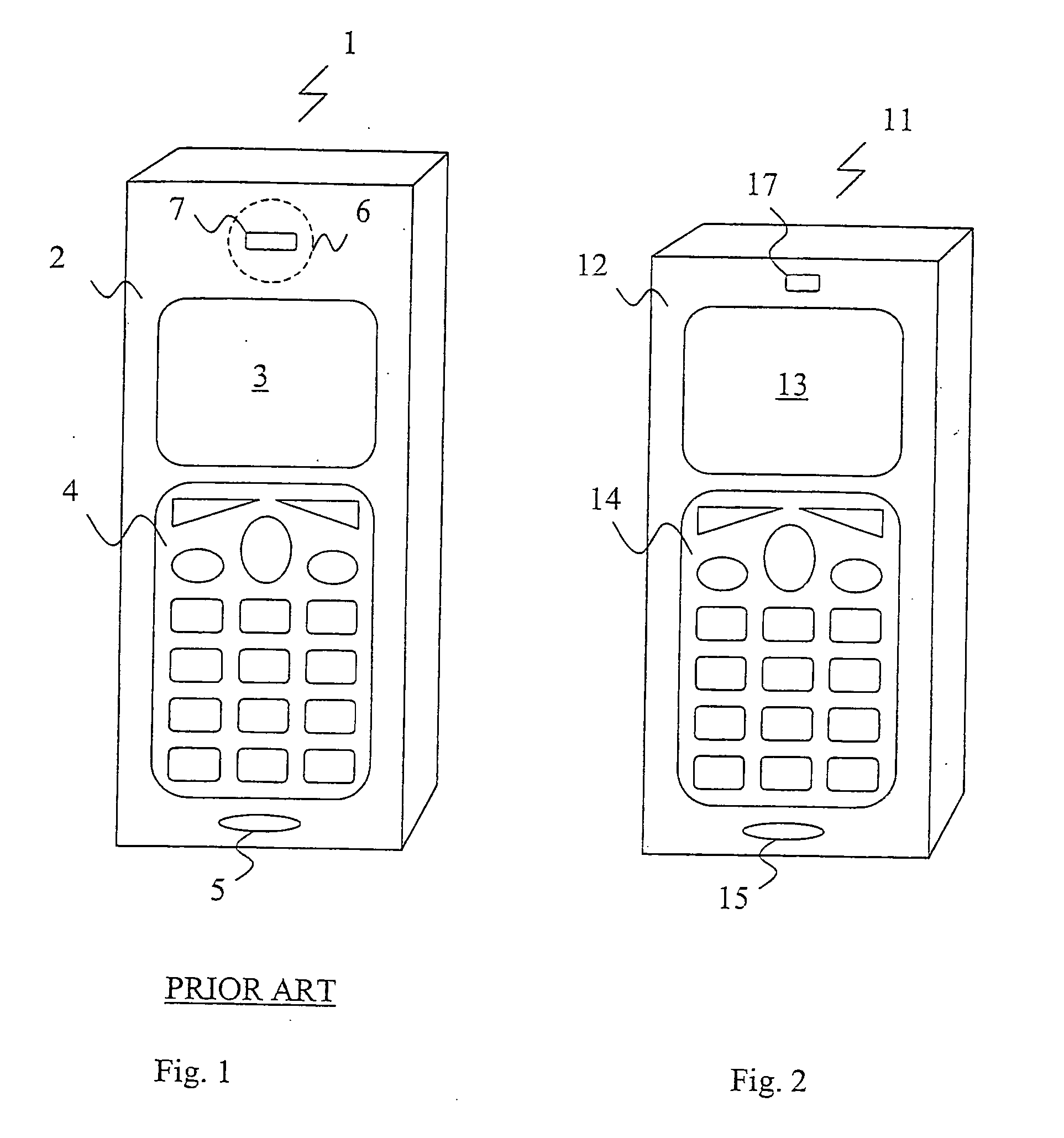

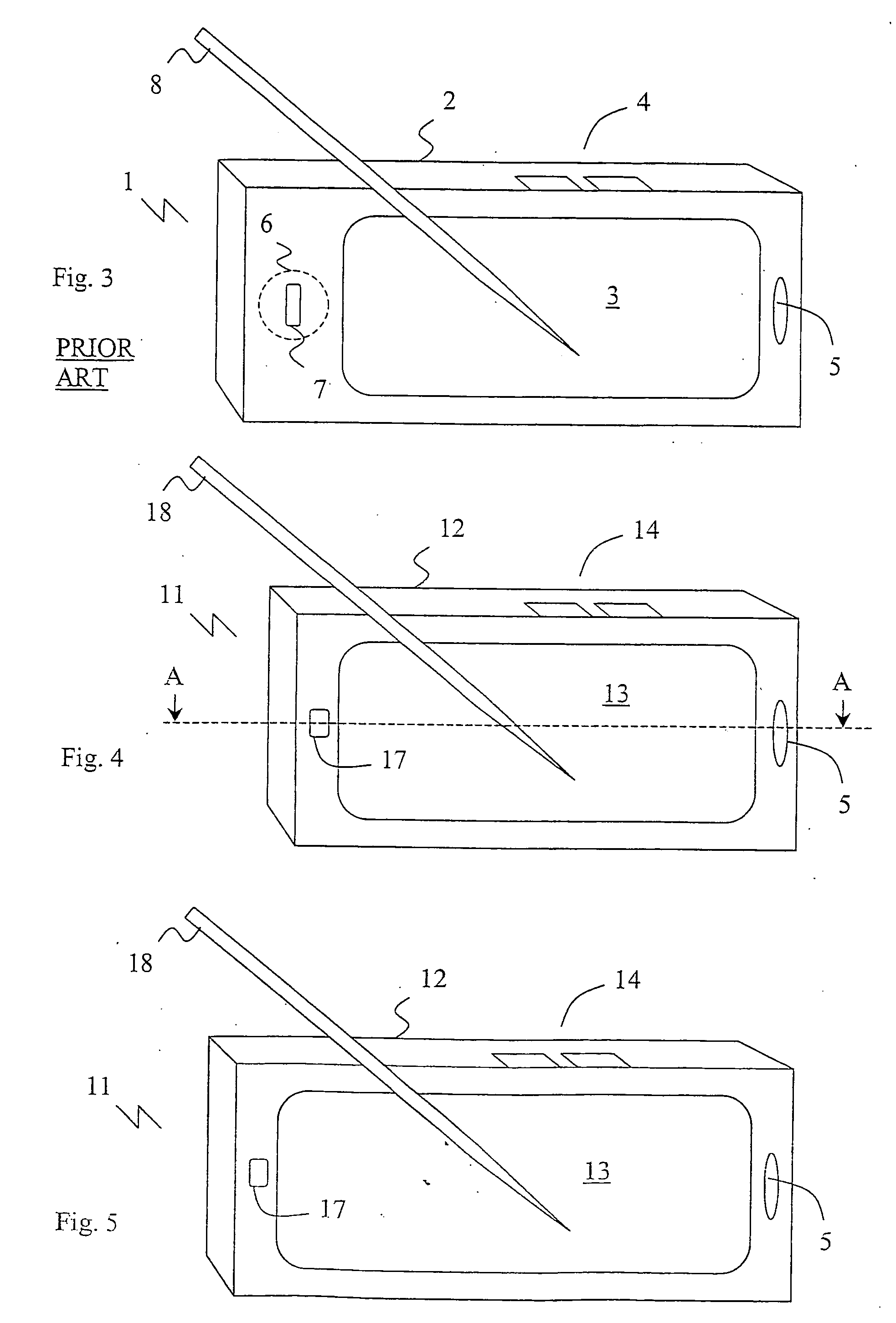

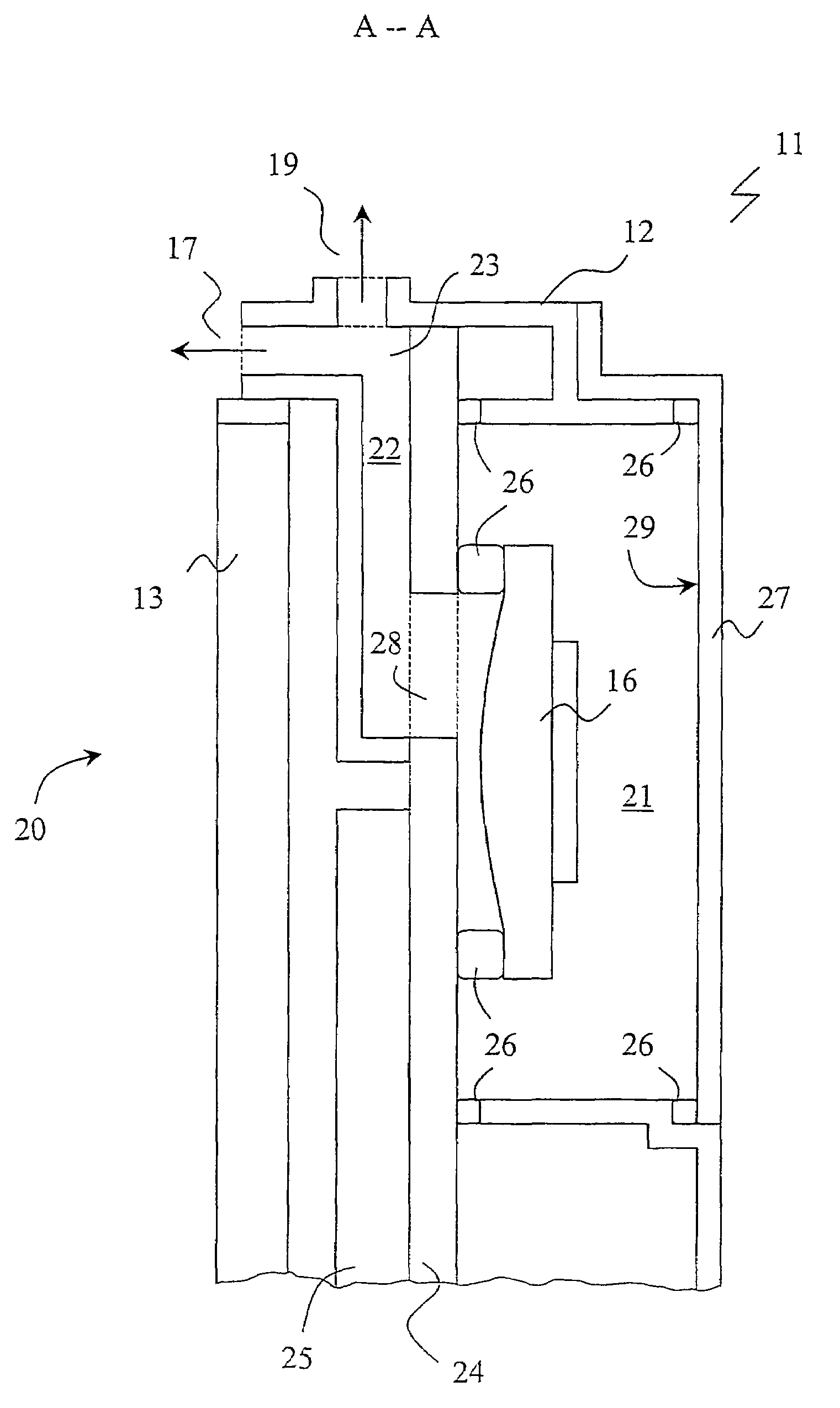

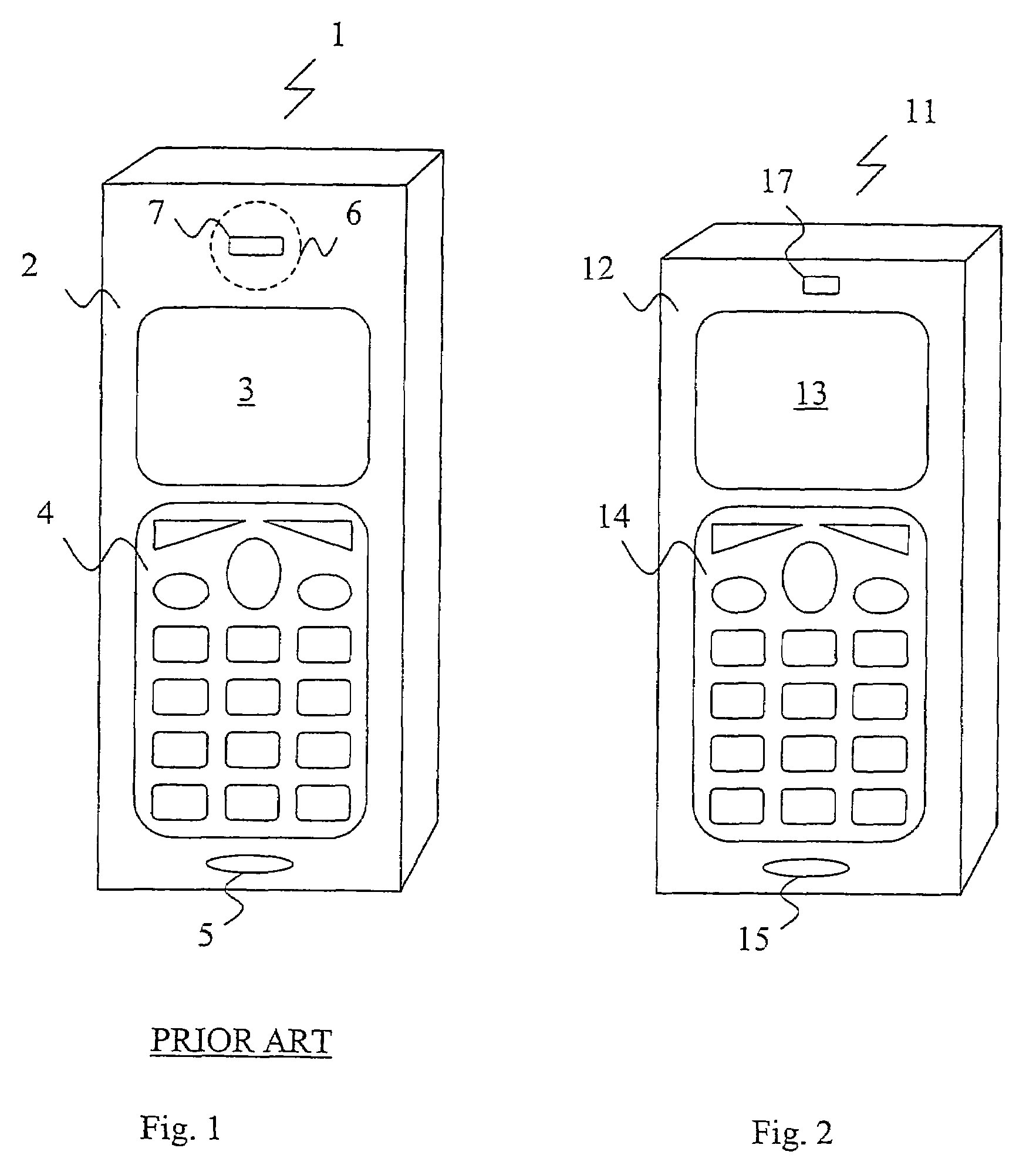

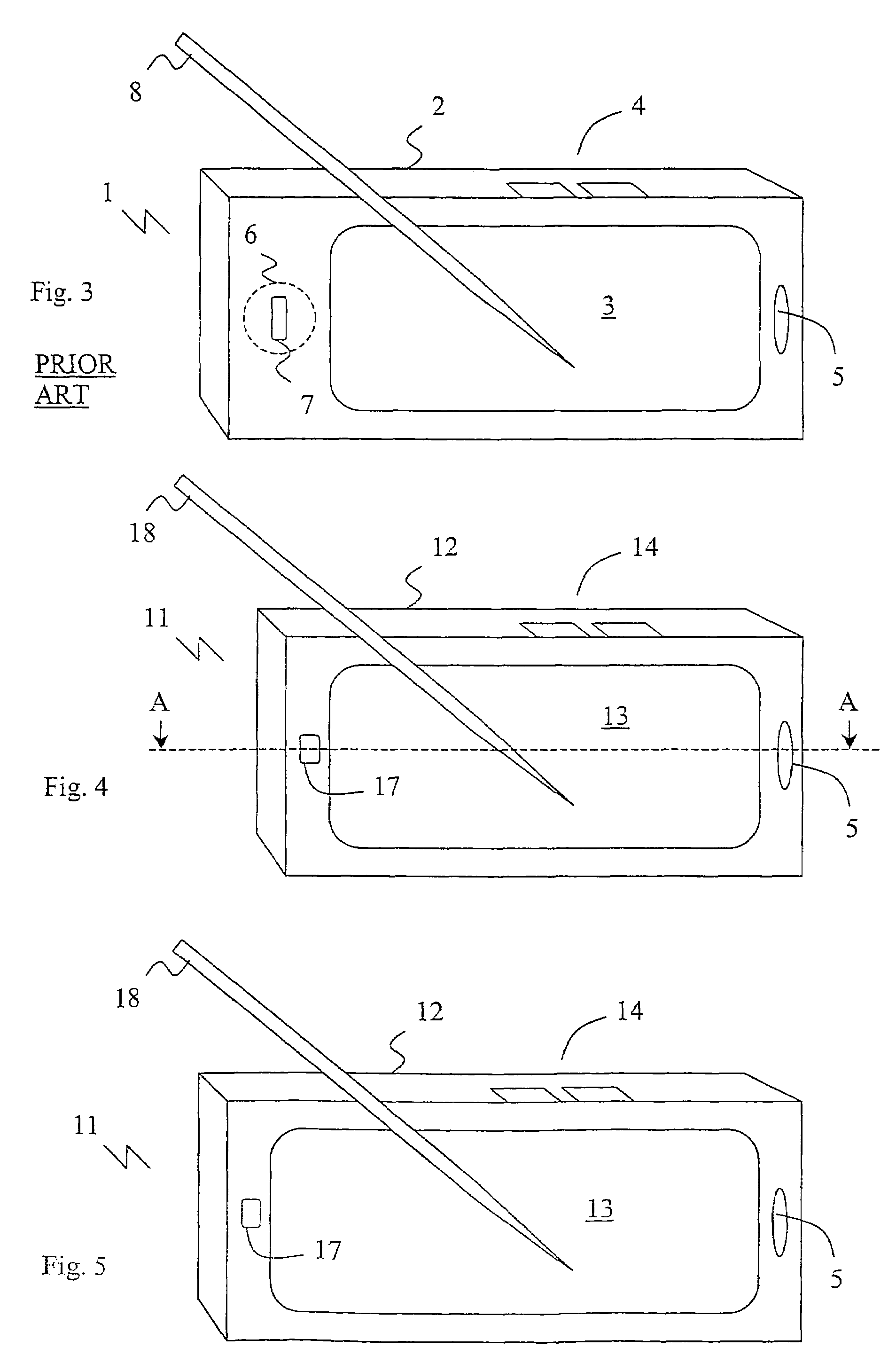

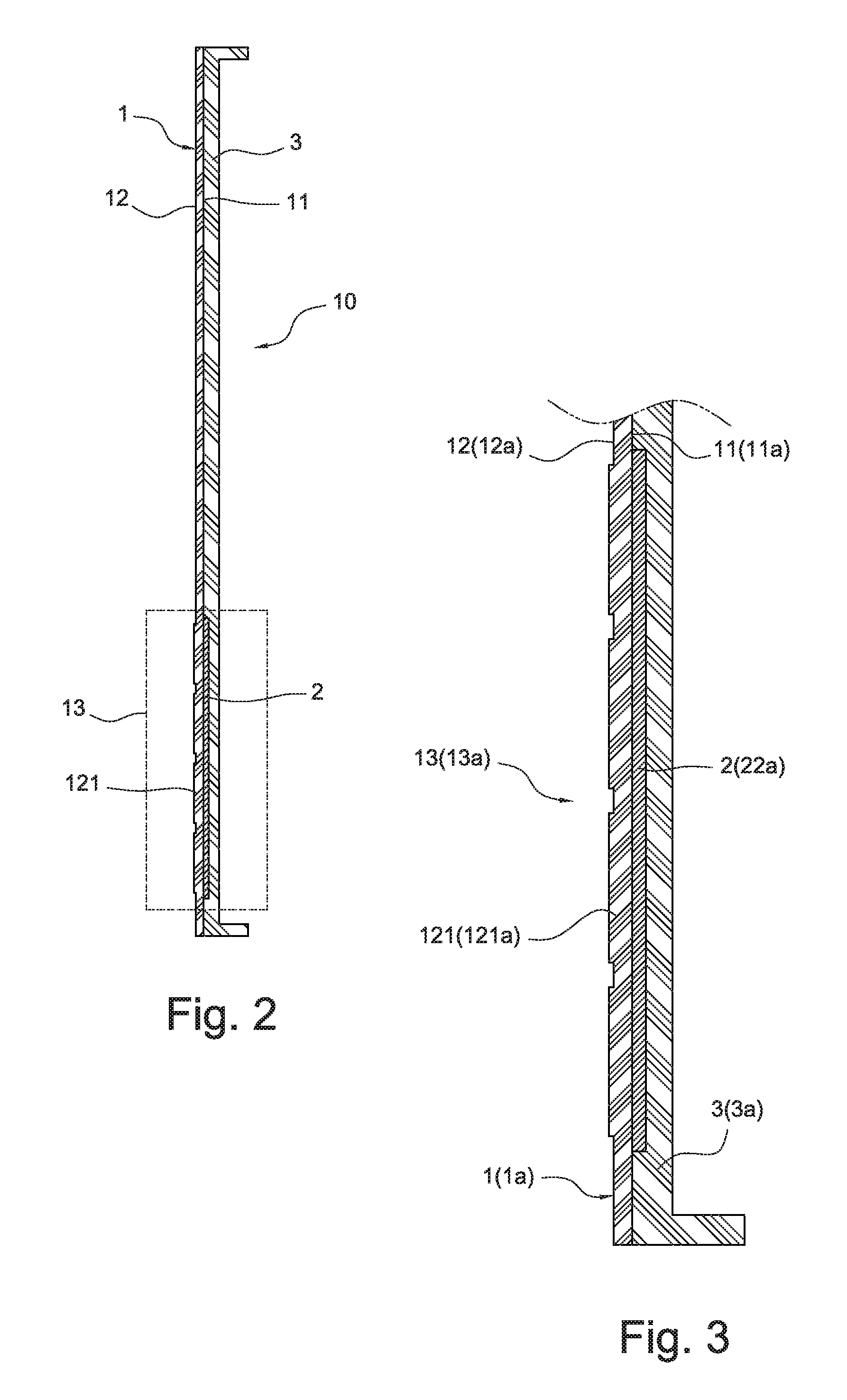

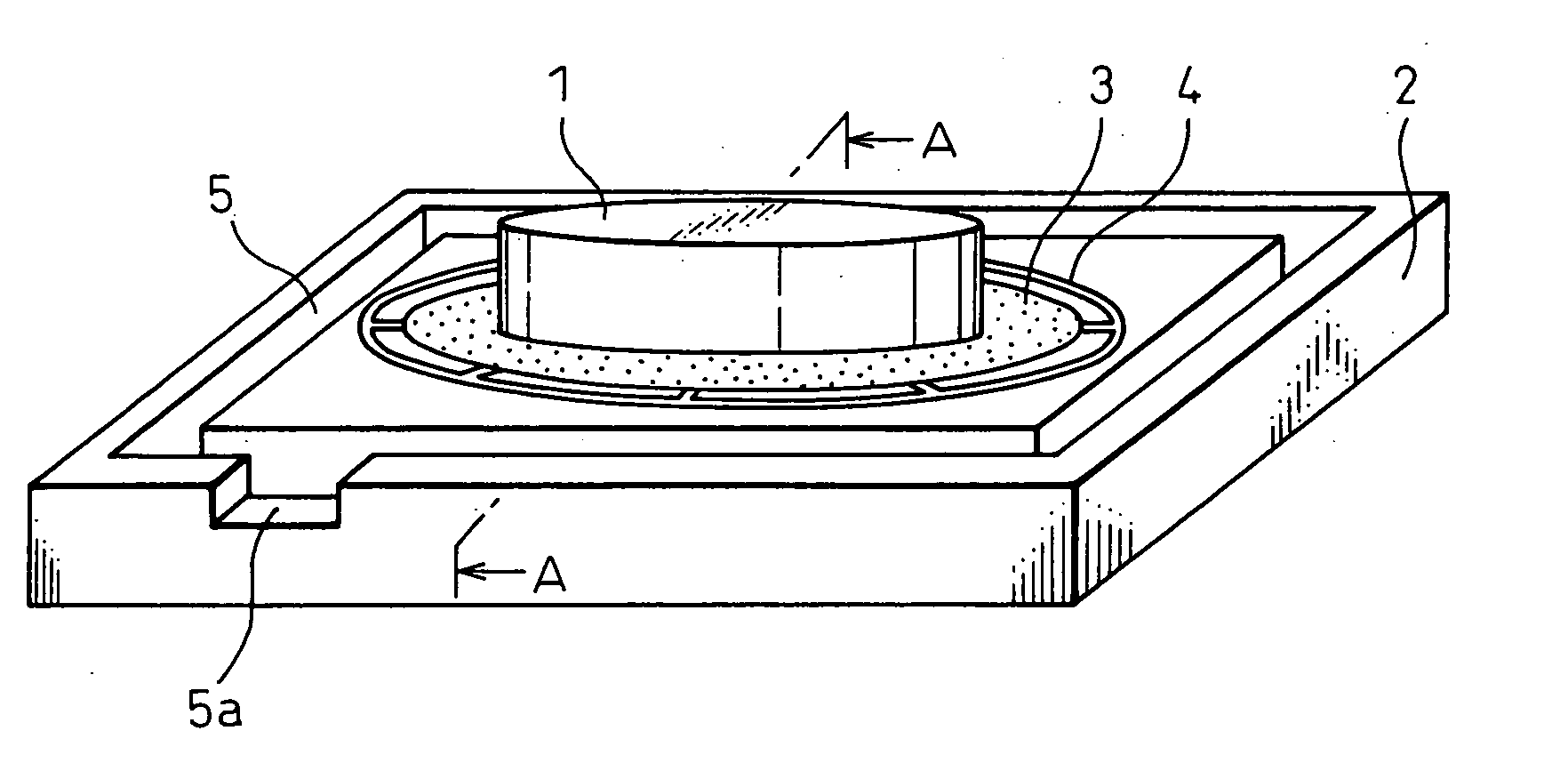

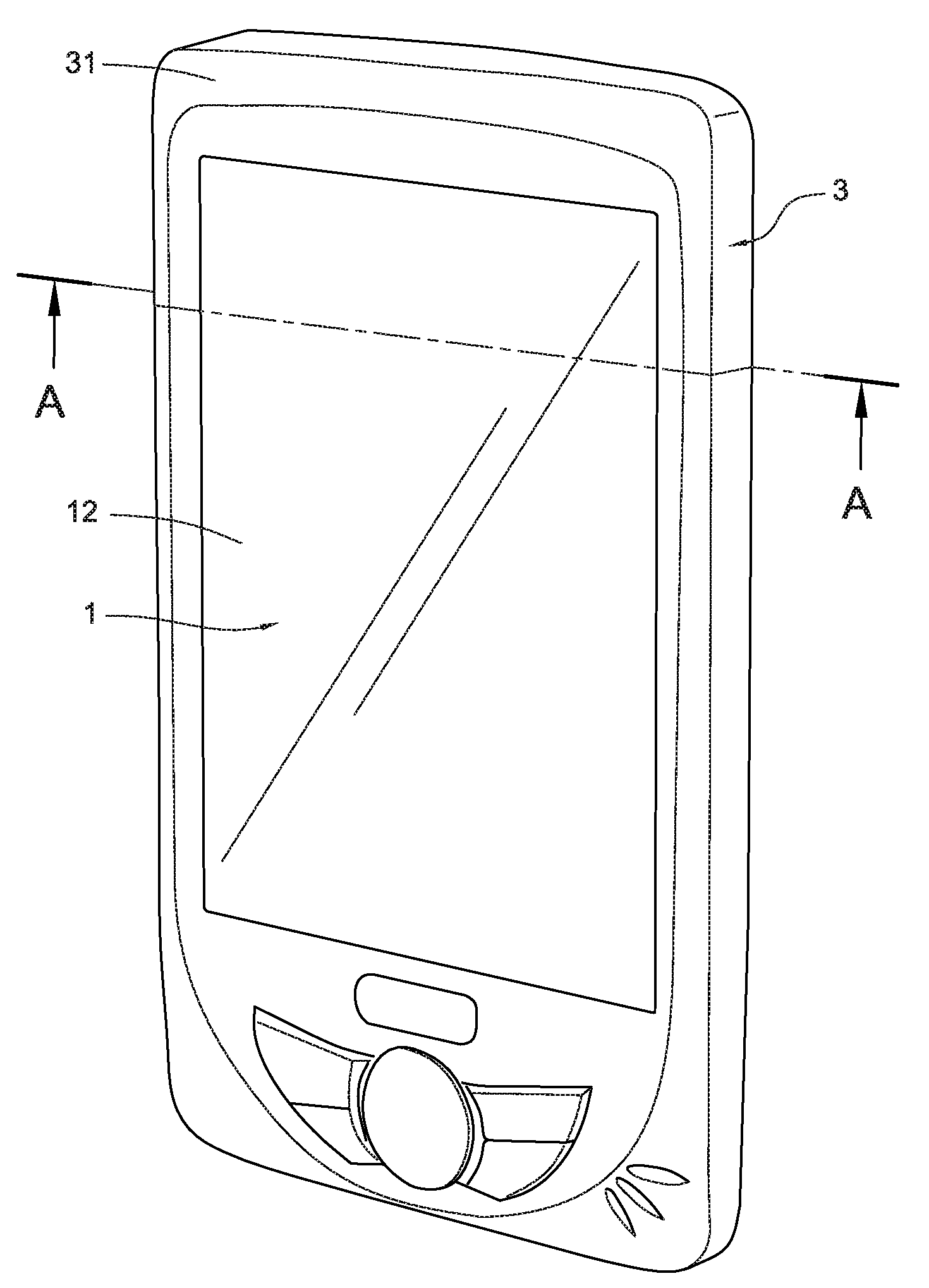

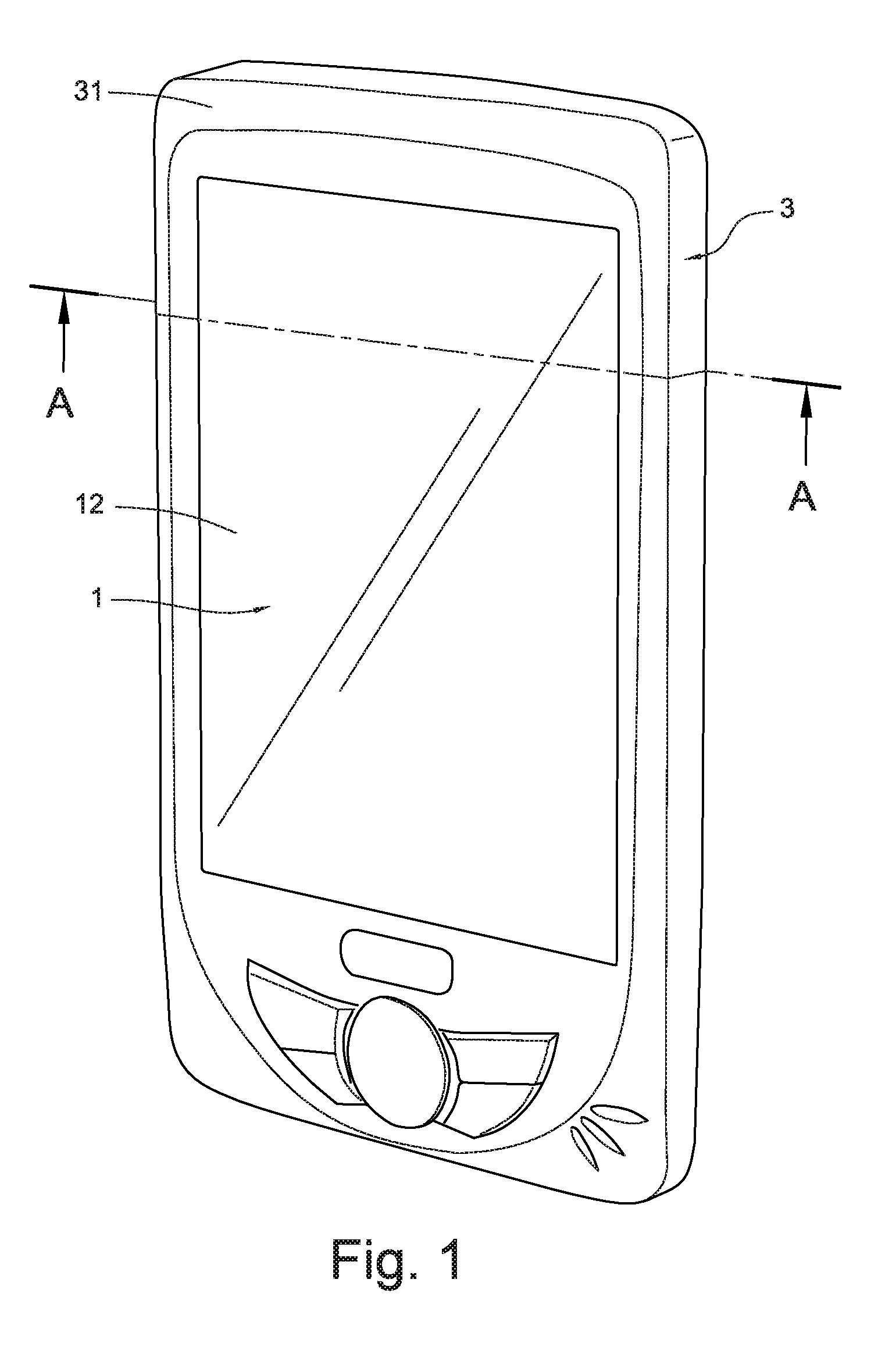

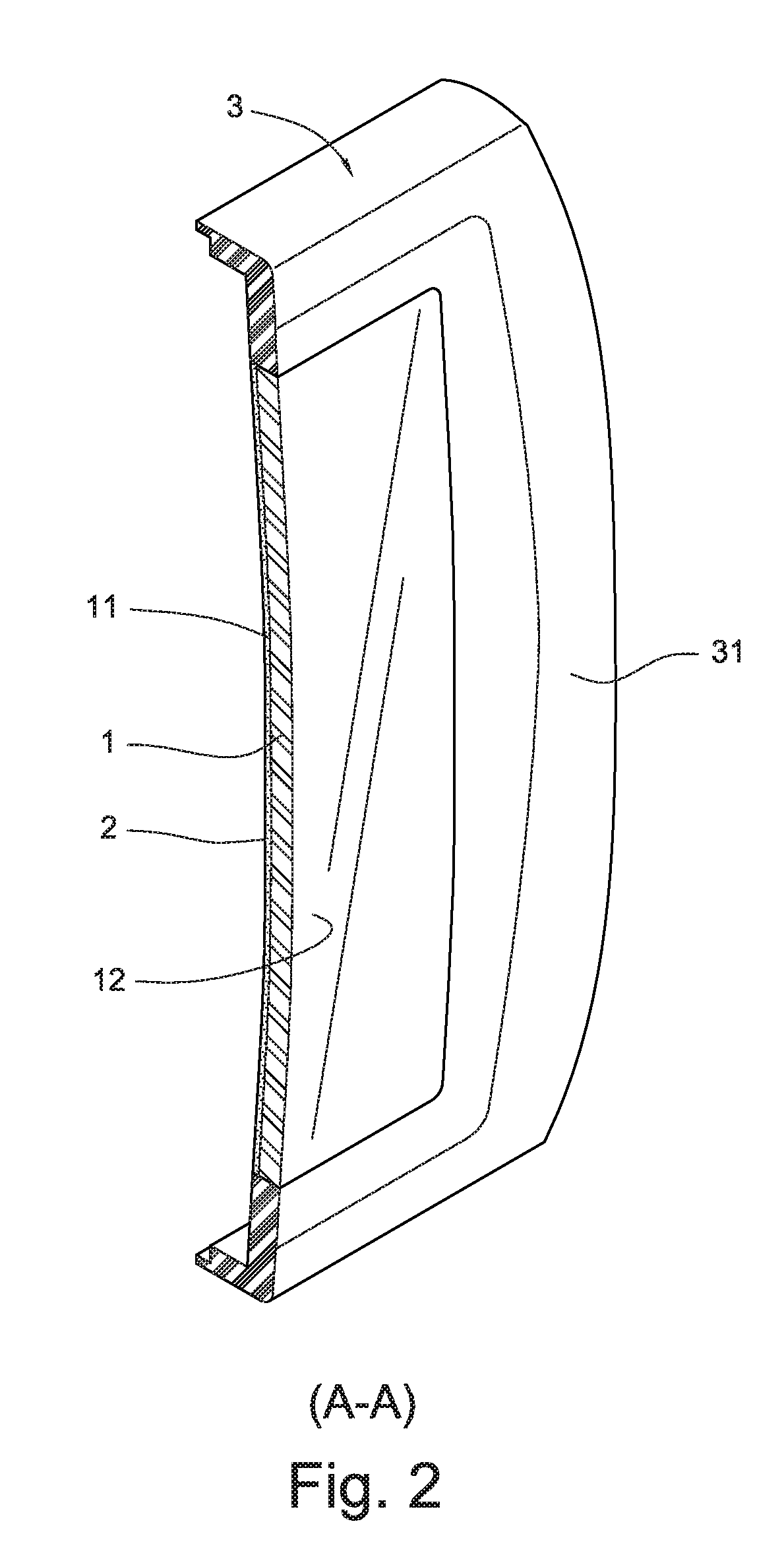

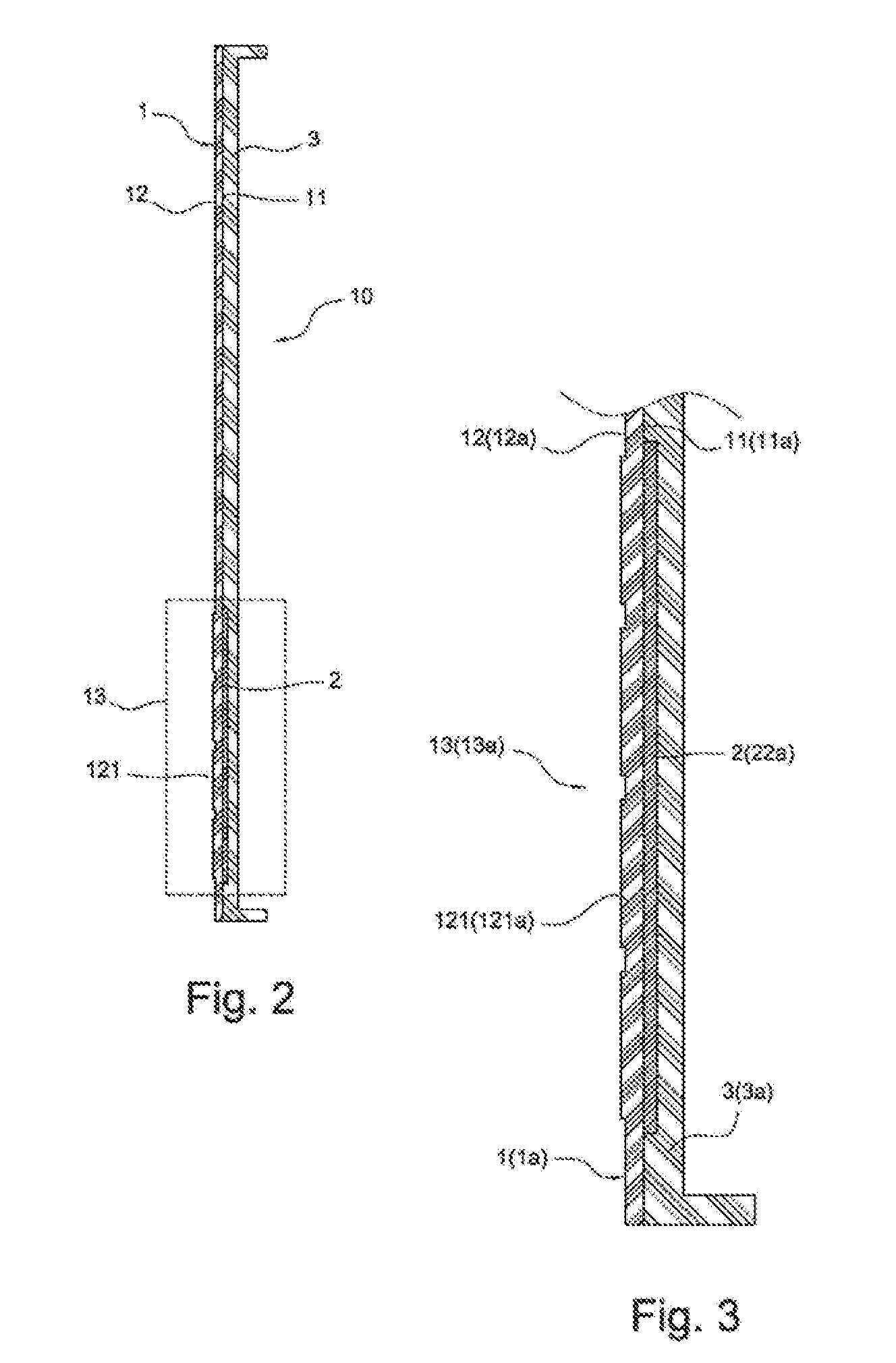

Speaker arrangement for communication terminal

InactiveUS20050233781A1Reduce decreaseGood resonance chamberLoudspeaker transducer fixingAntenna supports/mountingsEngineeringLoudspeaker

A communication terminal includes a housing carrying therein a radio antenna element, a speaker, and a chamber that acts as an electromagnetic resonance cavity for the antenna and as an acoustic resonance cavity for the speaker. The speaker is mounted inside the chamber and is coupled to the outside of the housing through a sound channel. The terminal includes a user interface on a front side of the housing and the speaker is placed behind the user interface as viewed from the front side, with the sound channel extending from a channel inlet at the speaker to a channel front outlet at the front side.

Owner:SONY ERICSSON MOBILE COMM AB

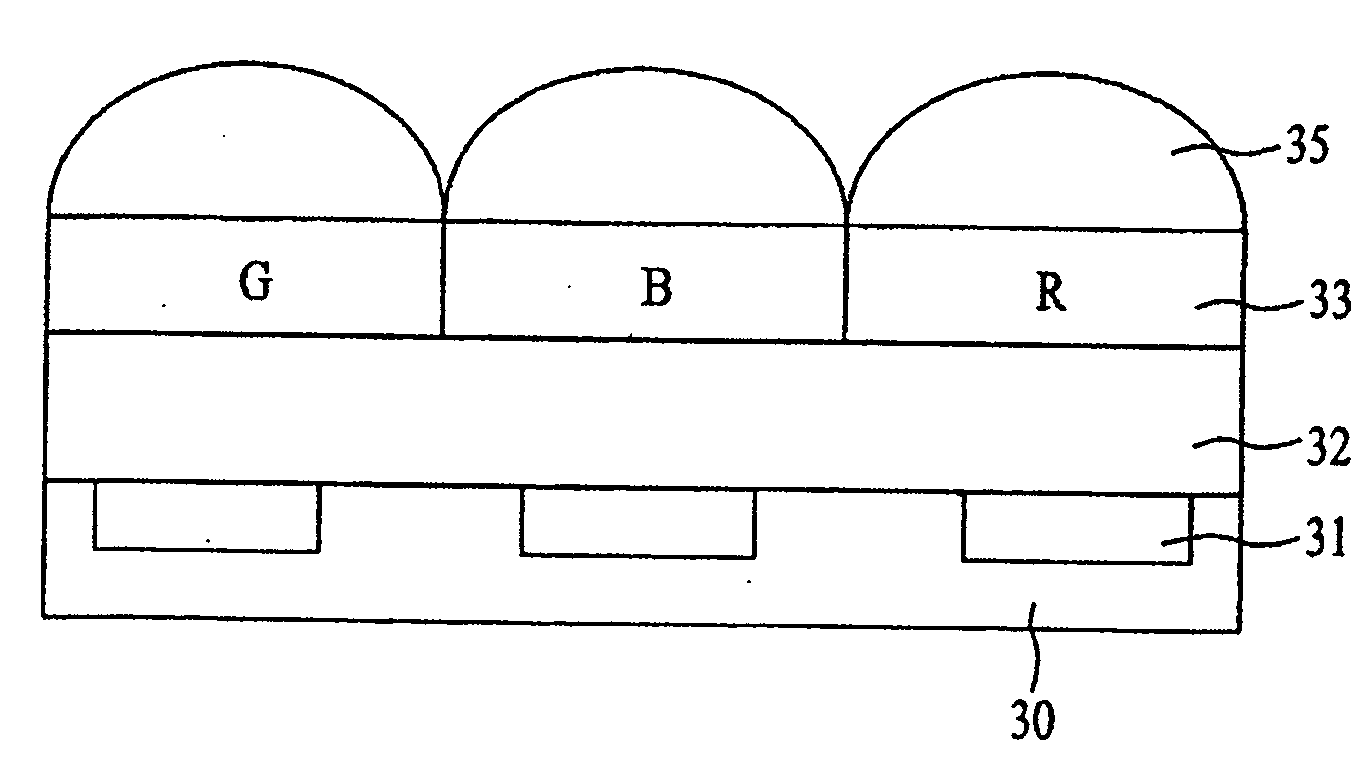

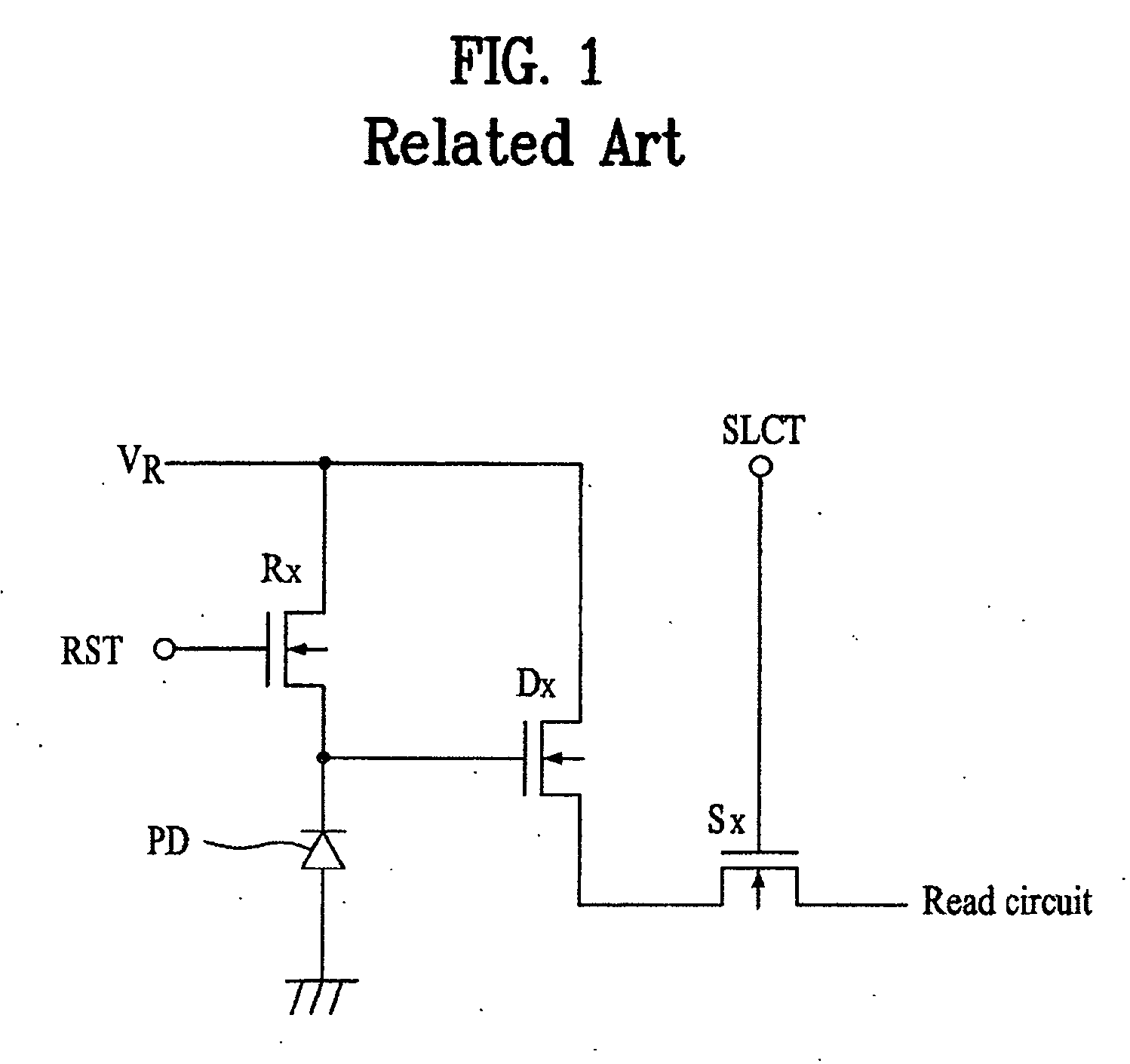

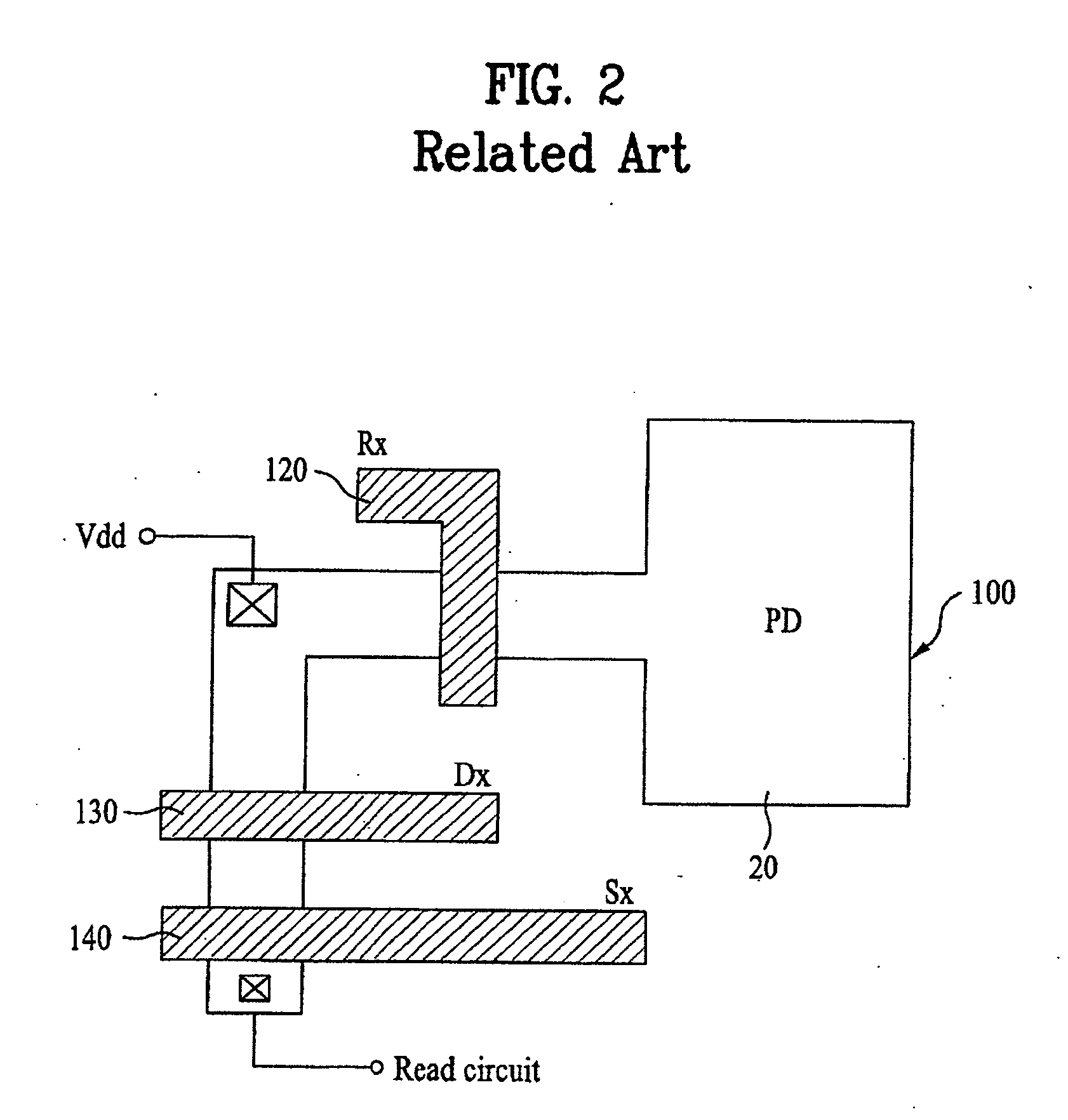

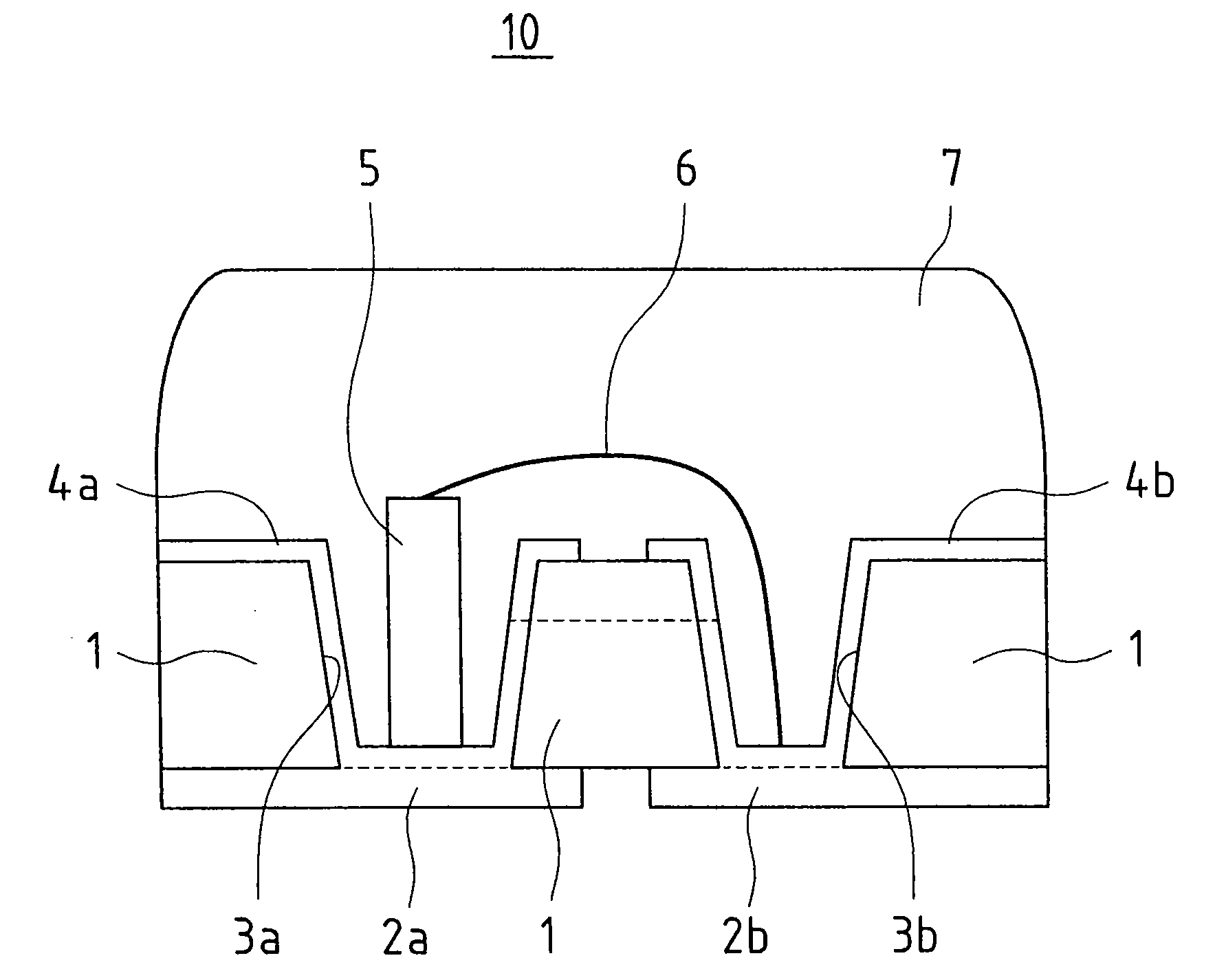

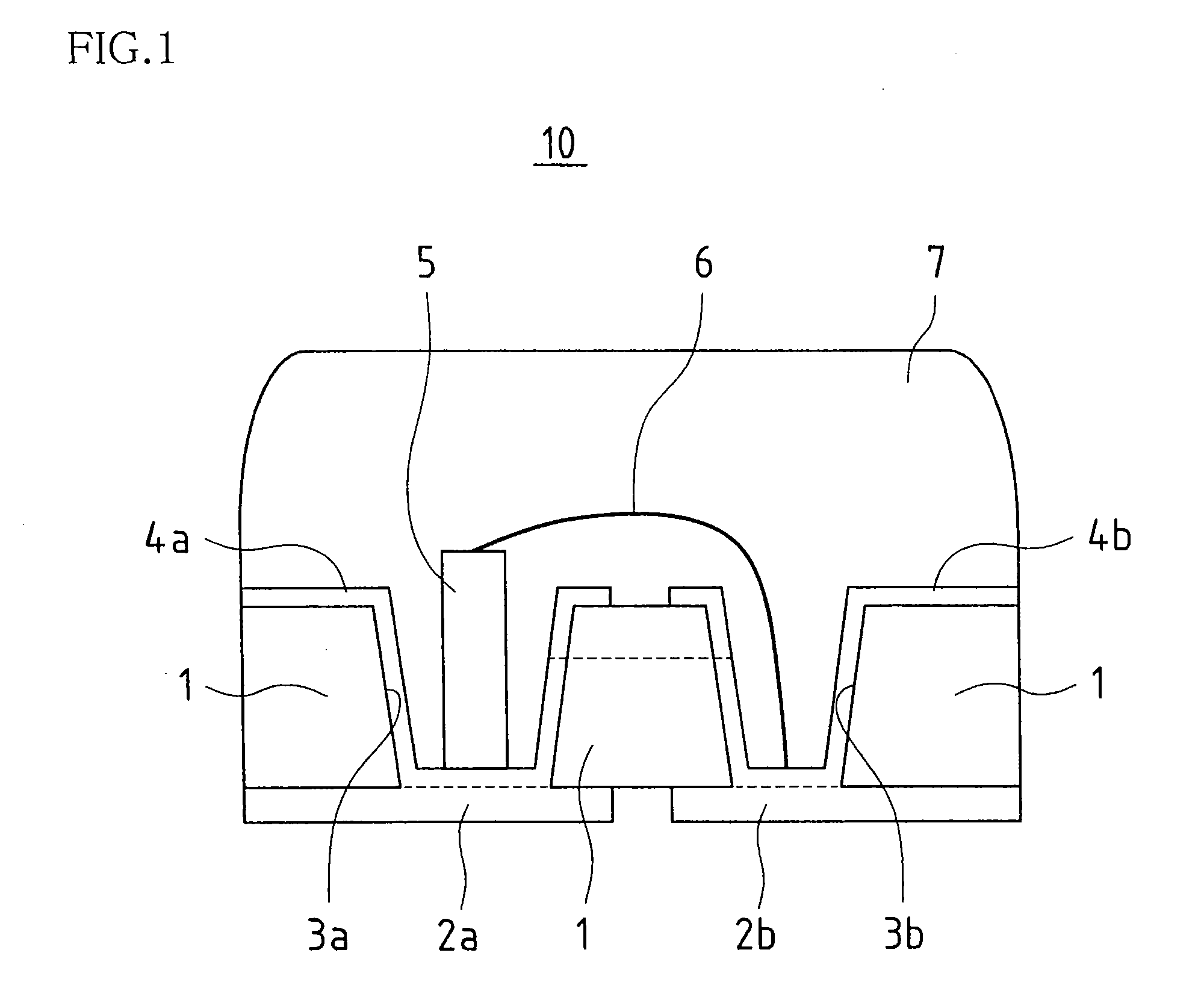

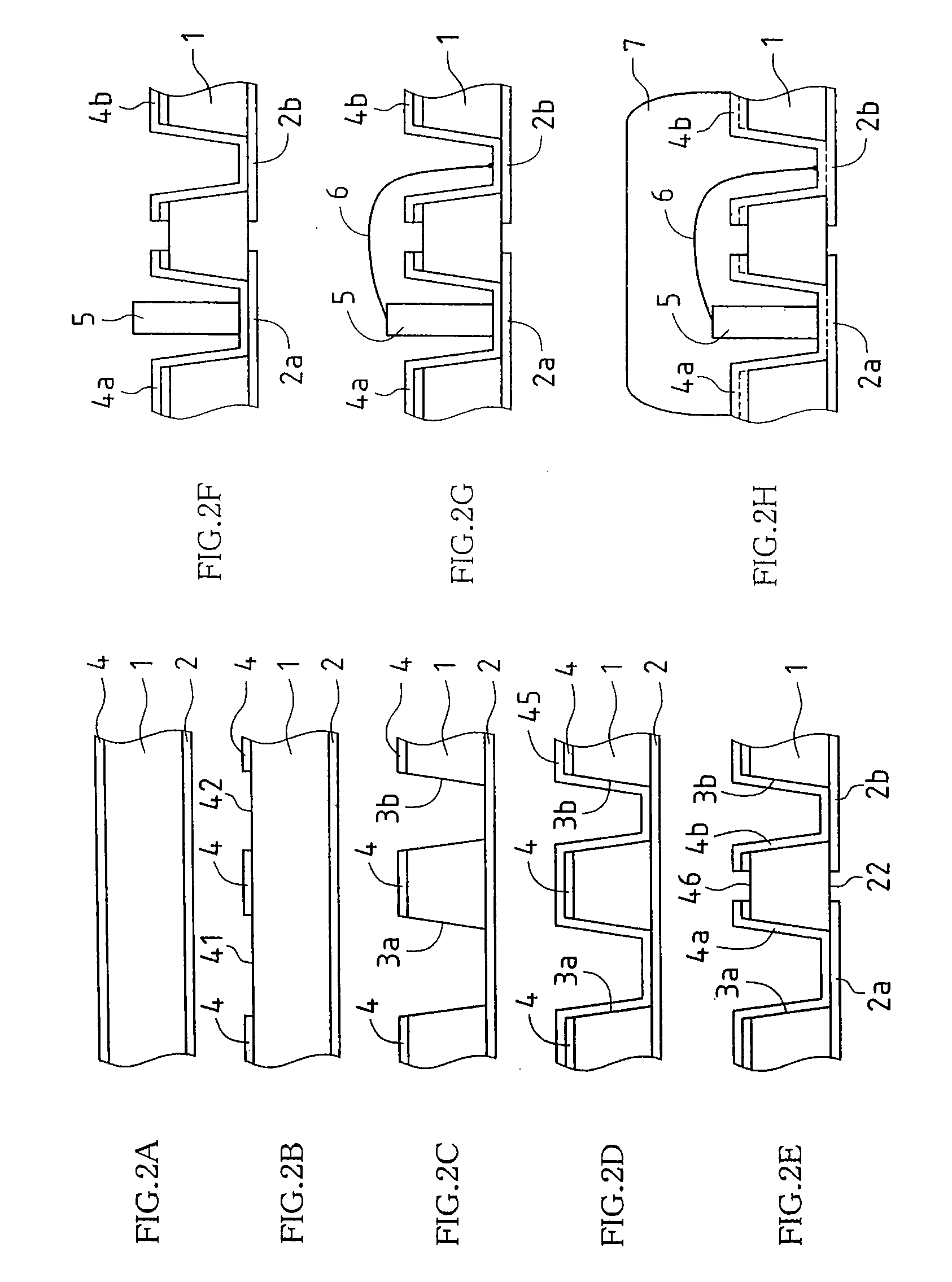

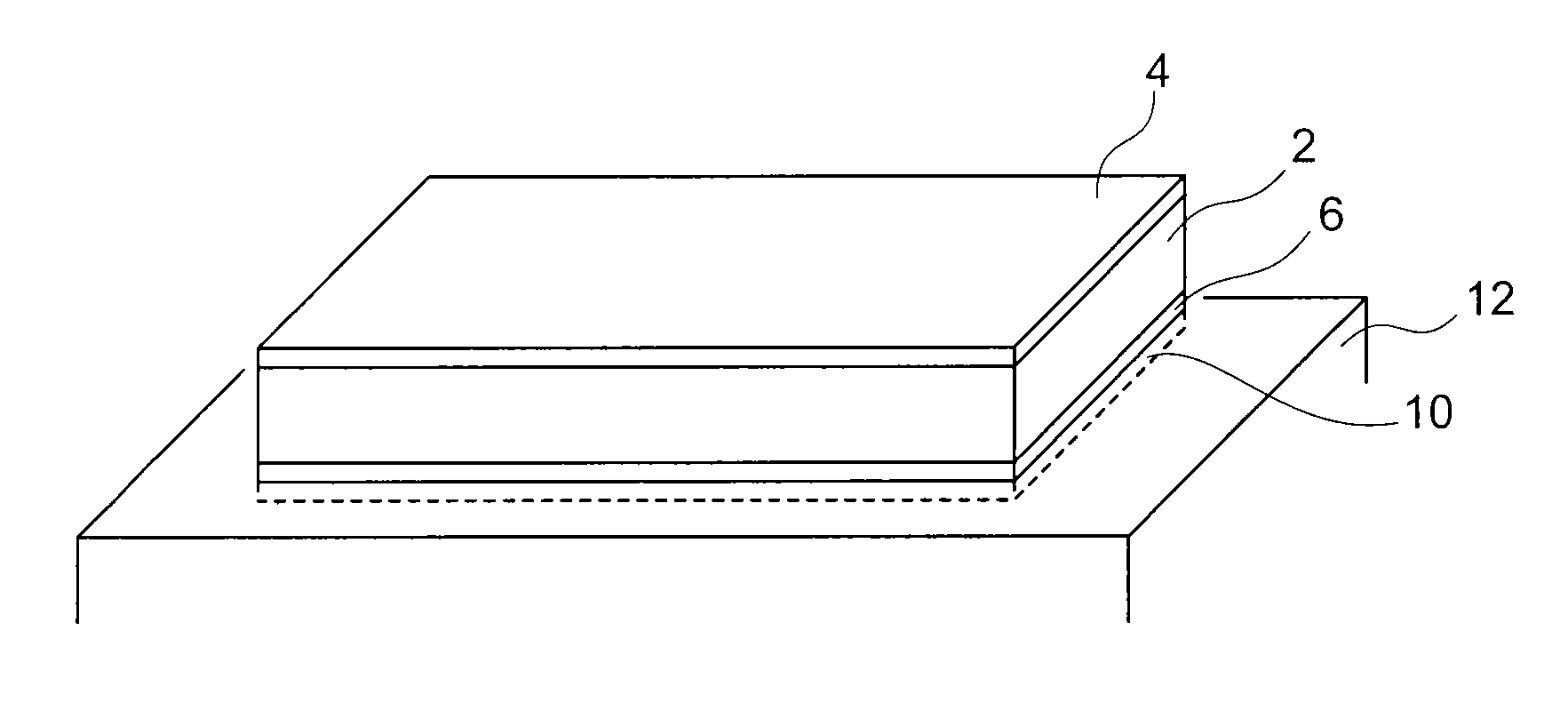

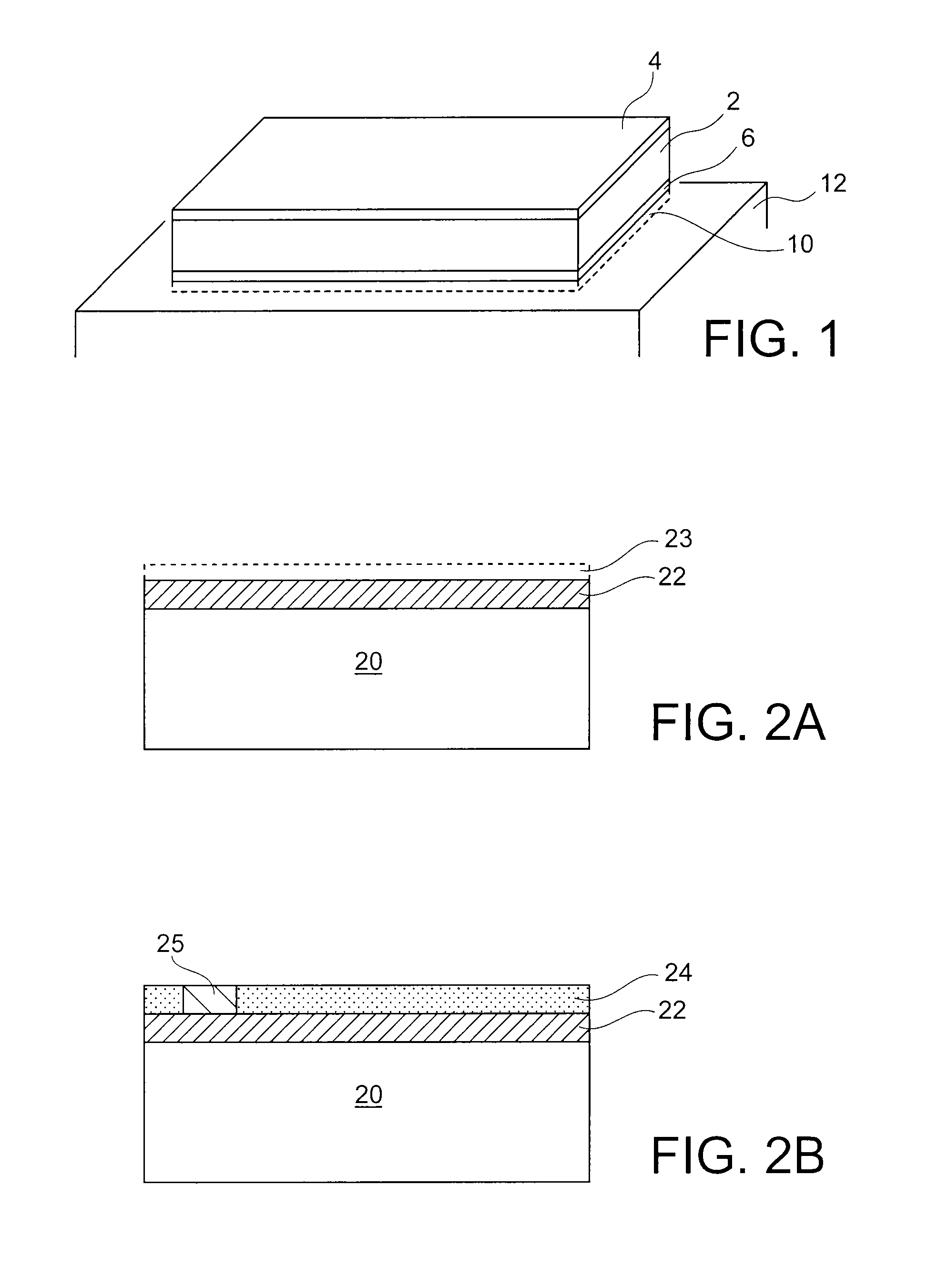

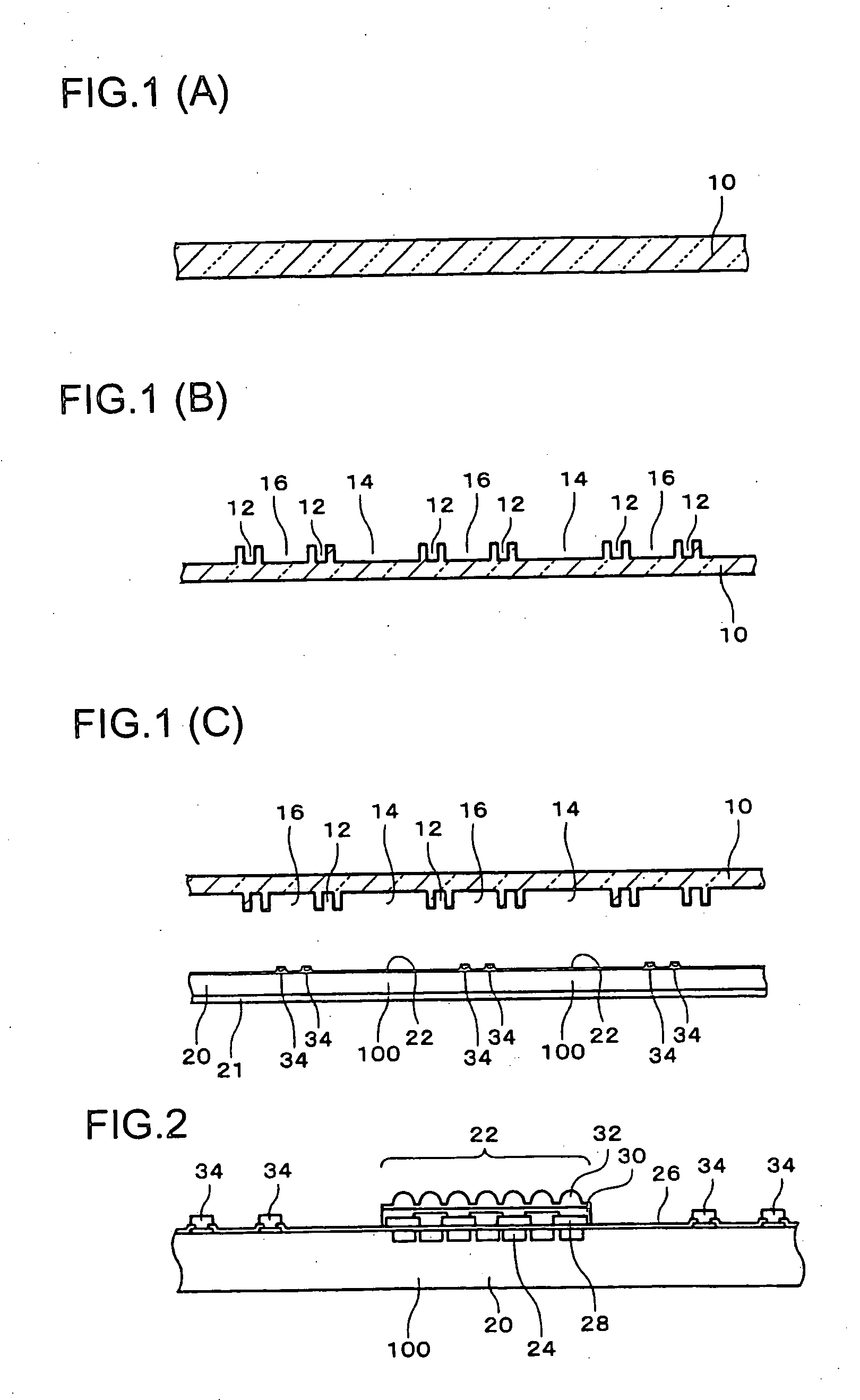

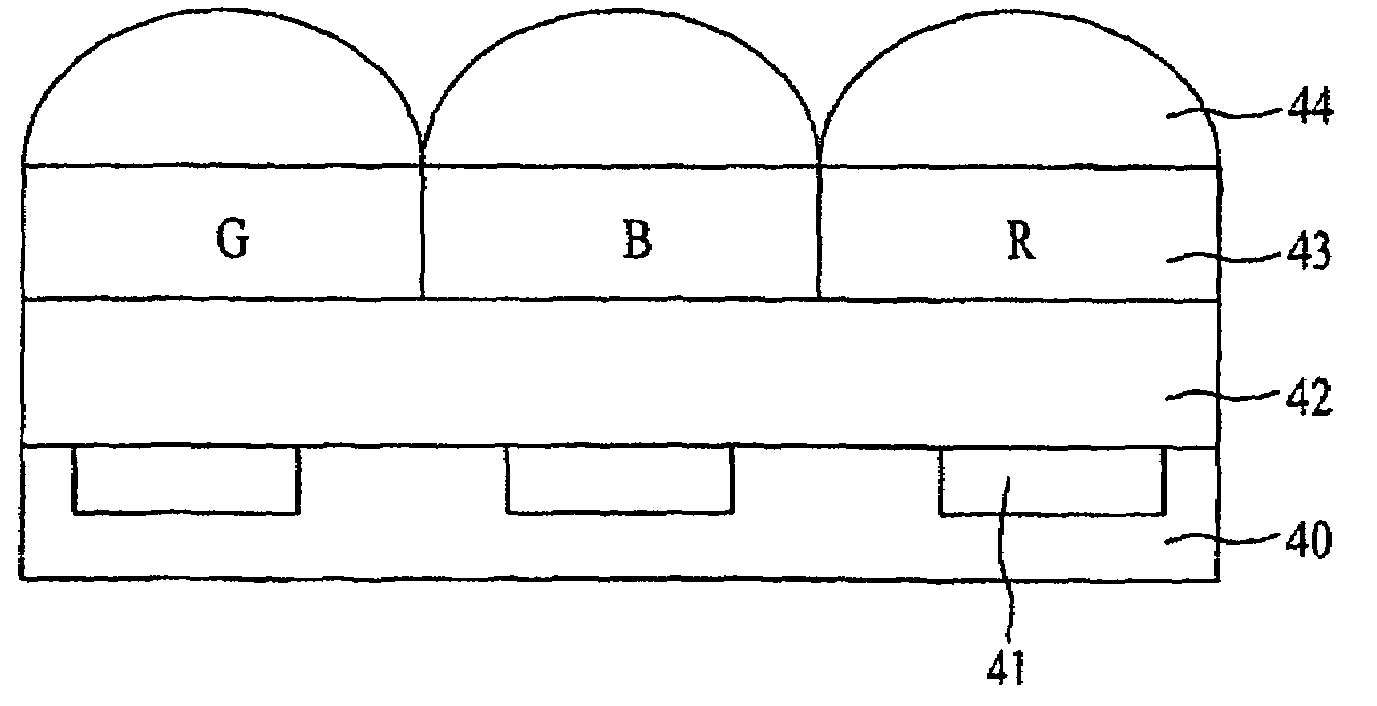

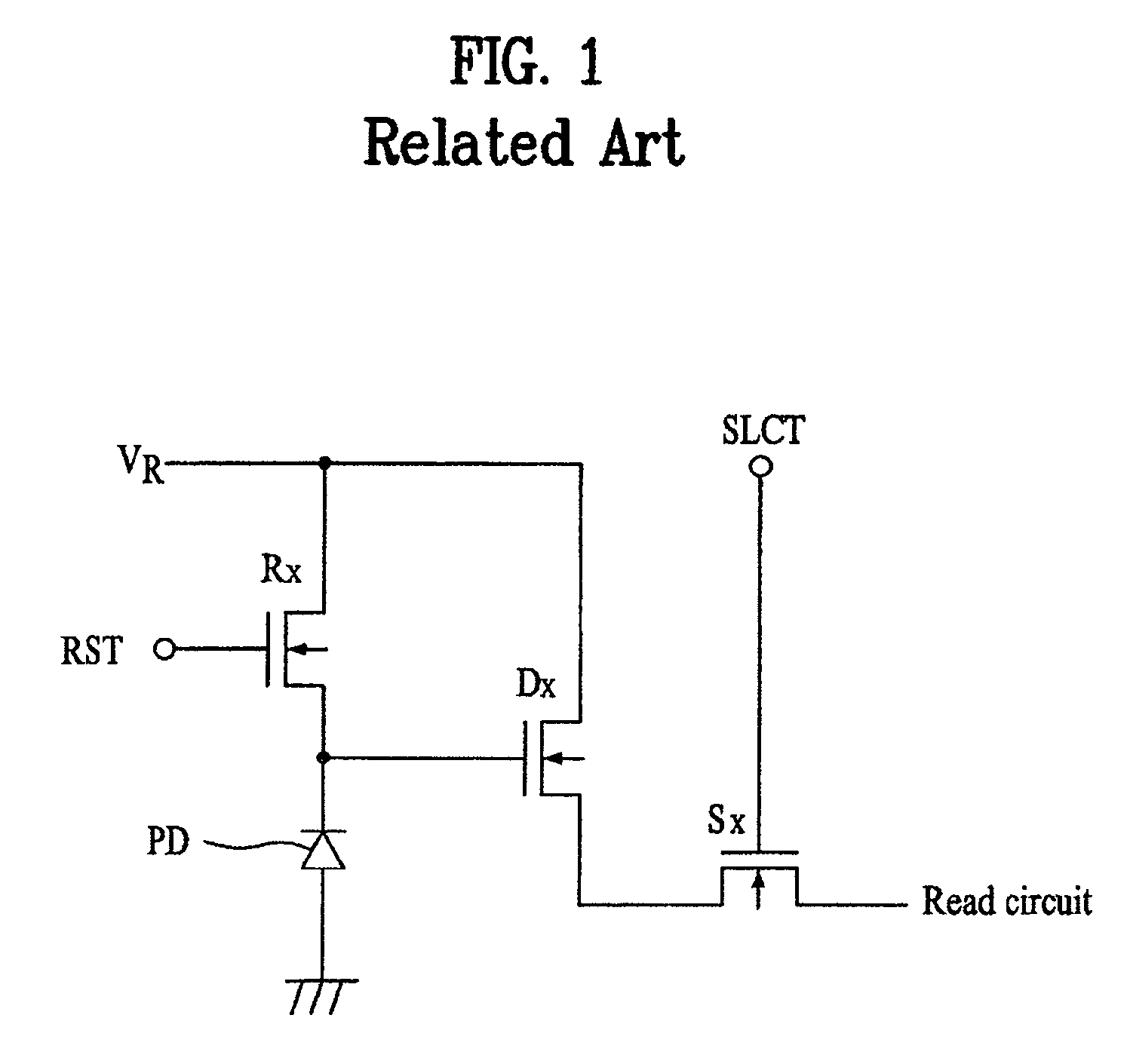

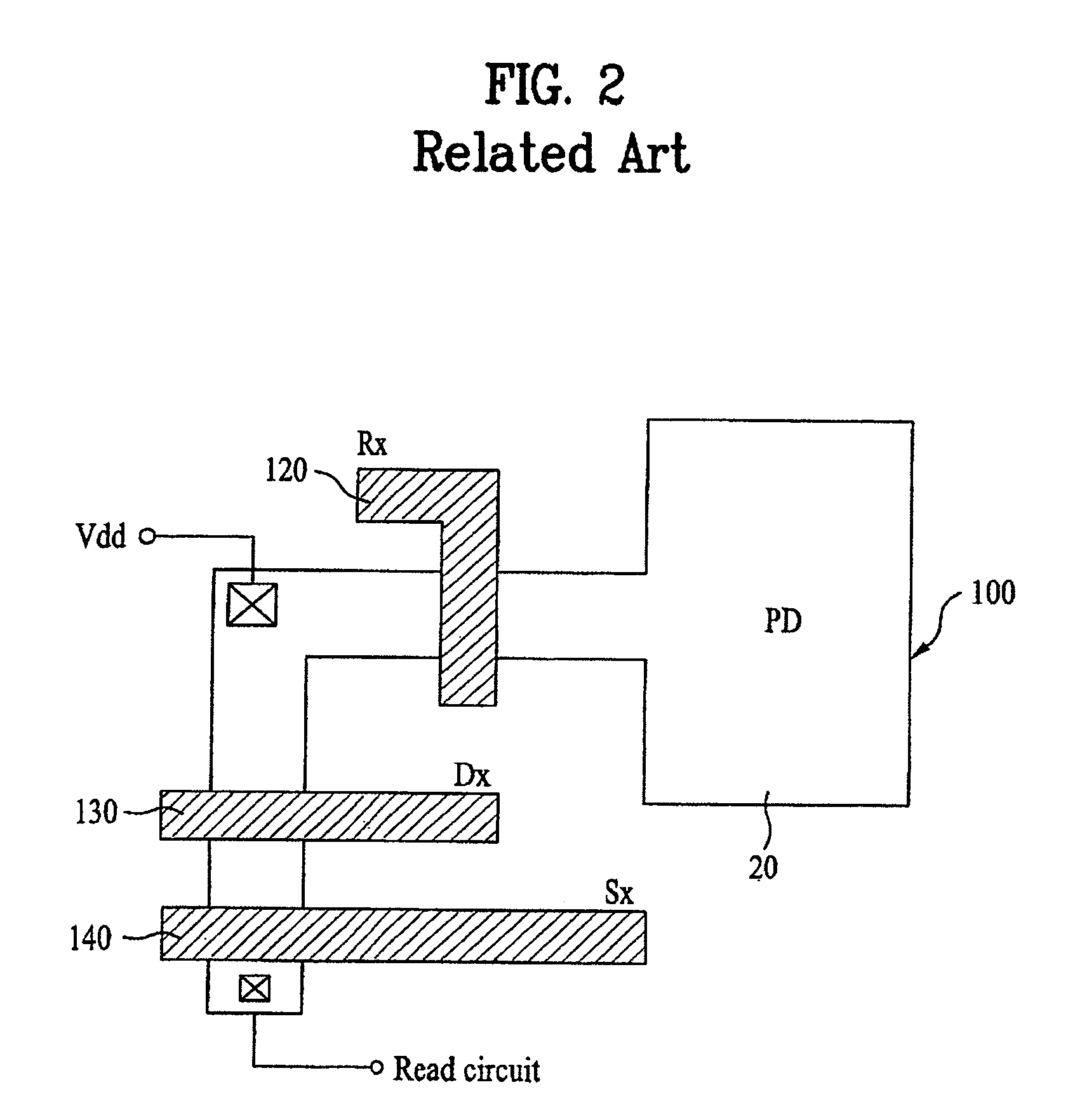

CMOS image sensor and method for fabricating the same

ActiveUS20060138500A1Good imaging propertiesEliminate ThicknessSolid-state devicesSemiconductor/solid-state device manufacturingCMOSInter layer

A CMOS image sensor and method for fabricating the same improve image characteristics by eliminating the thickness of a planarization layer. The CMOS image sensor includes a semiconductor substrate; a plurality of active devices, provided in a predetermined surface of the semiconductor substrate, for generating electrical charges according to an amount of incident light; an insulating interlayer formed on an entire surface of the semiconductor substrate including the plurality of active devices; a color filter layer formed on the insulating interlayer, the color filter layer comprised of red, green, and blue color filter patterns for respectively filtering light according to wavelength, the color filter patterns arranged to correspond to the plurality of active devices; and a plurality of microlenses formed on the color filter layer, wherein the color filter layer is planarized so that each color filter pattern of the color filter layer is imparted with an equal height for receiving the plurality of microlenses.

Owner:CONVERSANT INTPROP MANAGEMENT INC

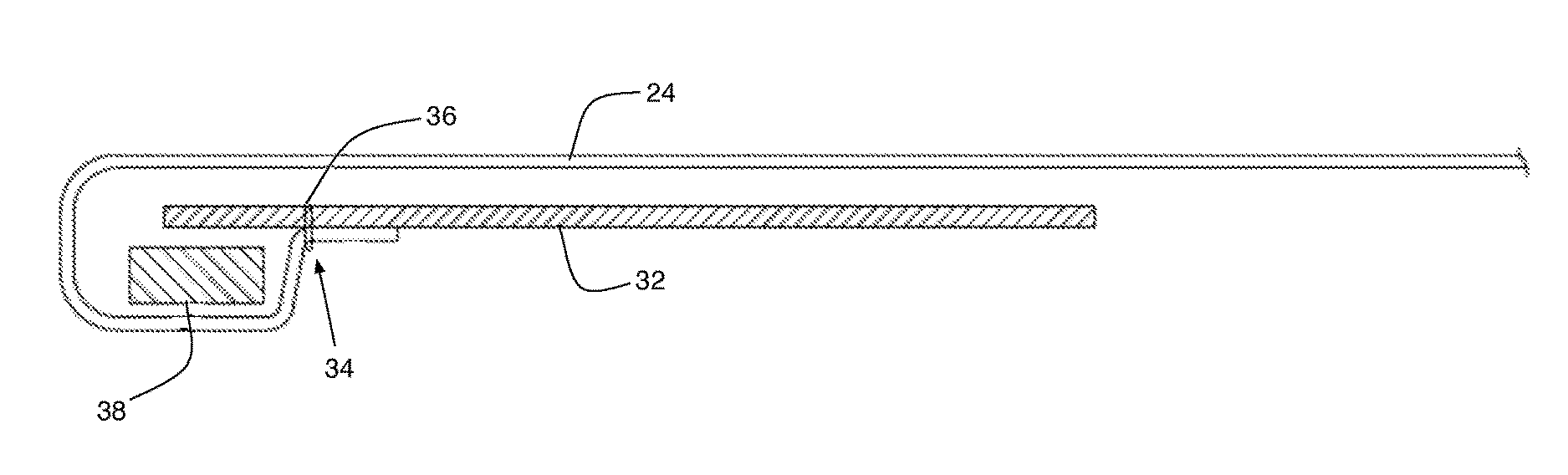

Speaker arrangement for communication terminal

InactiveUS7233678B2Good resonance chamberAffect antenna performanceLoudspeaker transducer fixingAntenna supports/mountingsEngineeringComputer terminal

A communication terminal includes a housing carrying therein a radio antenna element, a speaker, and a chamber that acts as an electromagnetic resonance cavity for the antenna and as an acoustic resonance cavity for the speaker. The speaker is mounted inside the chamber and is coupled to the outside of the housing through a sound channel. The terminal includes a user interface on a front side of the housing and the speaker is placed behind the user interface as viewed from the front side, with the sound channel extending from a channel inlet at the speaker to a channel front outlet at the front side.

Owner:SONY ERICSSON MOBILE COMM AB

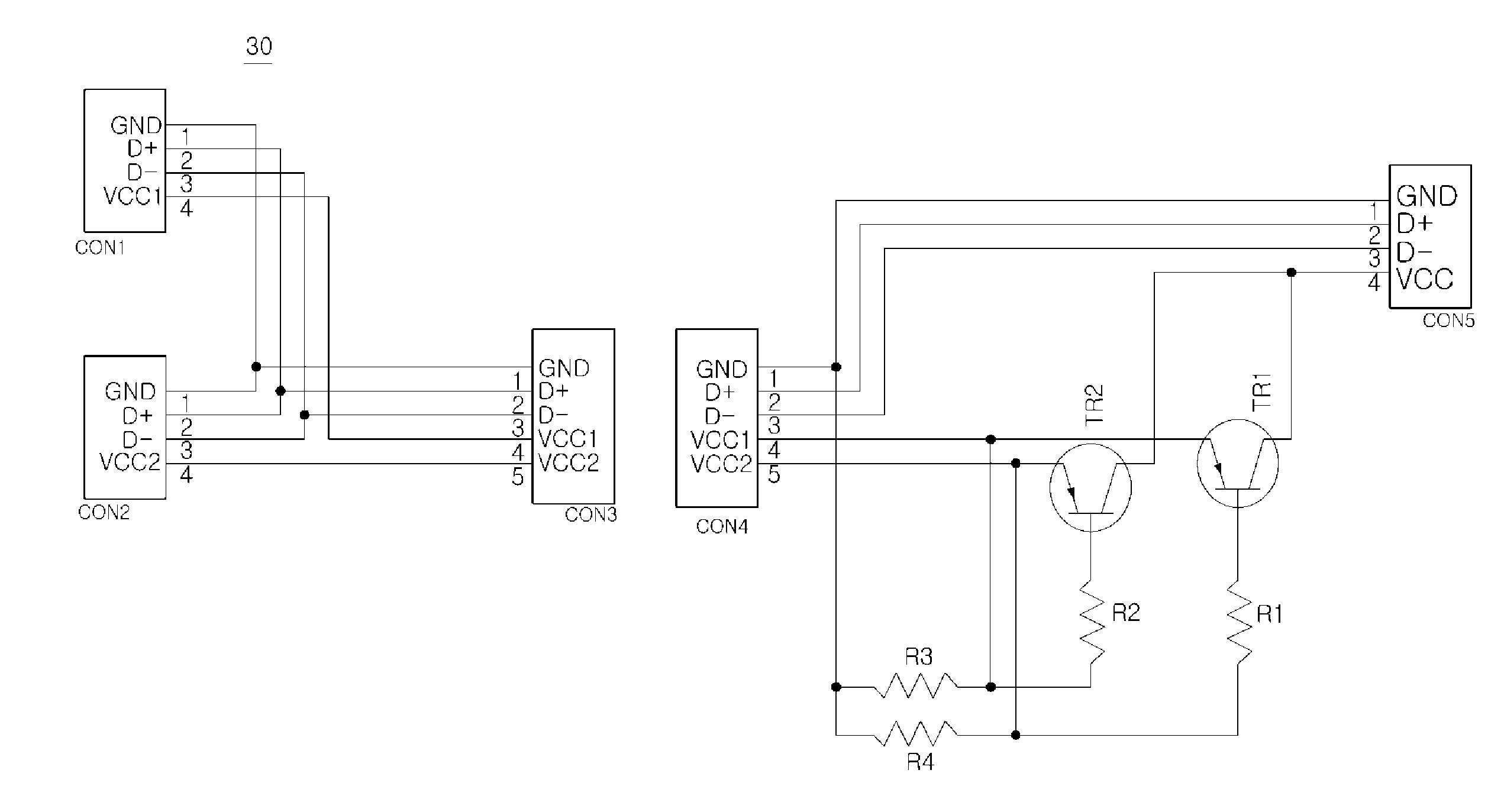

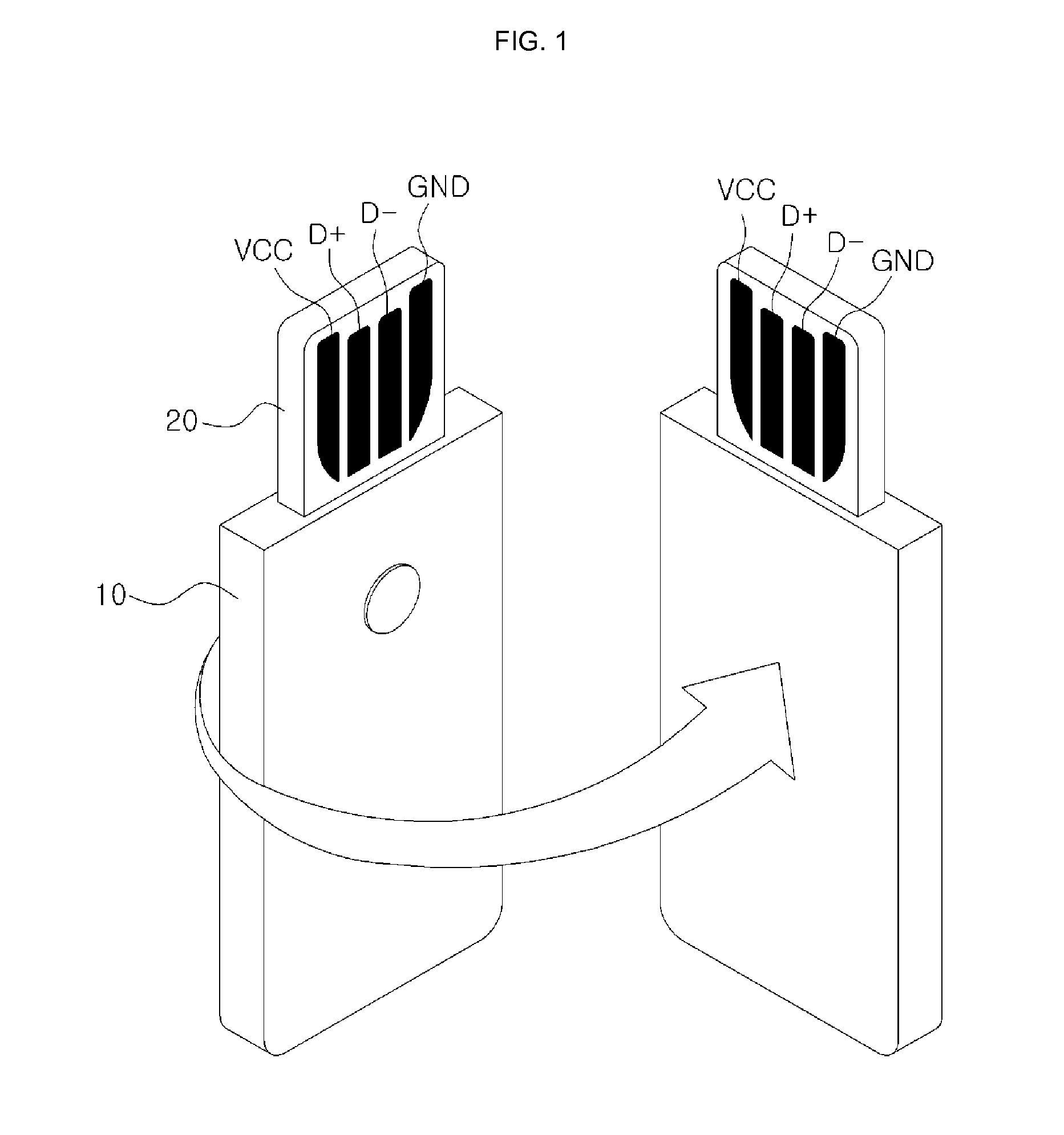

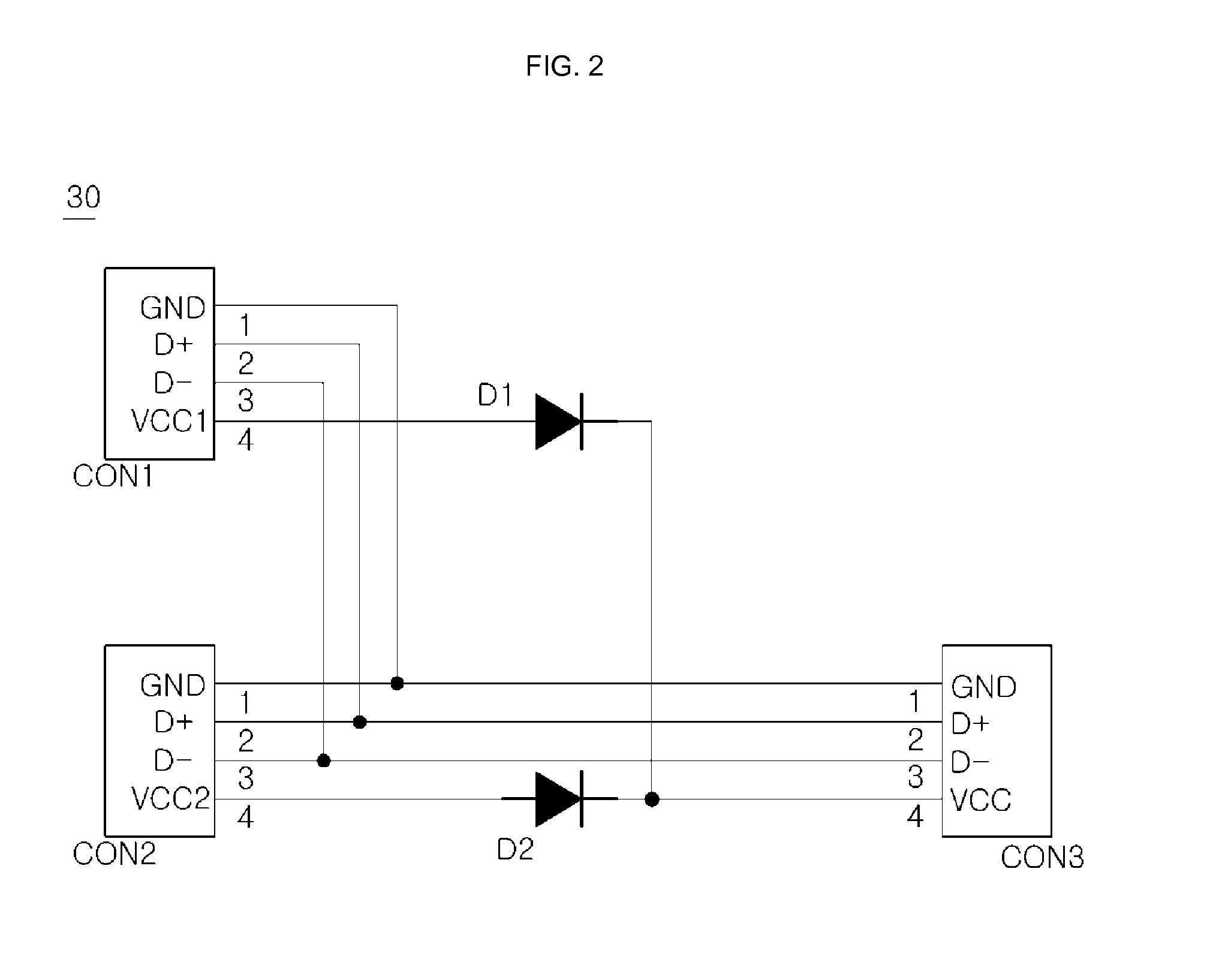

Bidirectional plug having short circuit prevention circuit

InactiveUS20110136381A1Reduce manufacturing costEliminate ThicknessIncorrect coupling preventionTwo-part coupling devicesEngineeringCommunication device

Disclosed herein is a bidirectional plug having a short circuit prevention circuit. The bidirectional plug includes a body part, a terminal part, connecting terminals, and a short circuit prevention circuit. The terminal part is connected to one end of the body part, and is inserted into an interface port of a communication device. The connecting terminals are respectively provided on two opposite surfaces of the terminal part, and make contact with a connecting pin provided in the interface port regardless of a direction from which the terminal part is inserted. The short circuit prevention circuit prevents a remaining connecting terminal, provided on a surface of the terminal part which is not in contact with a connecting pin, from making electrical contact with a tension ground pin provided in the interface port.

Owner:CLEAR ELECTRONICS INC

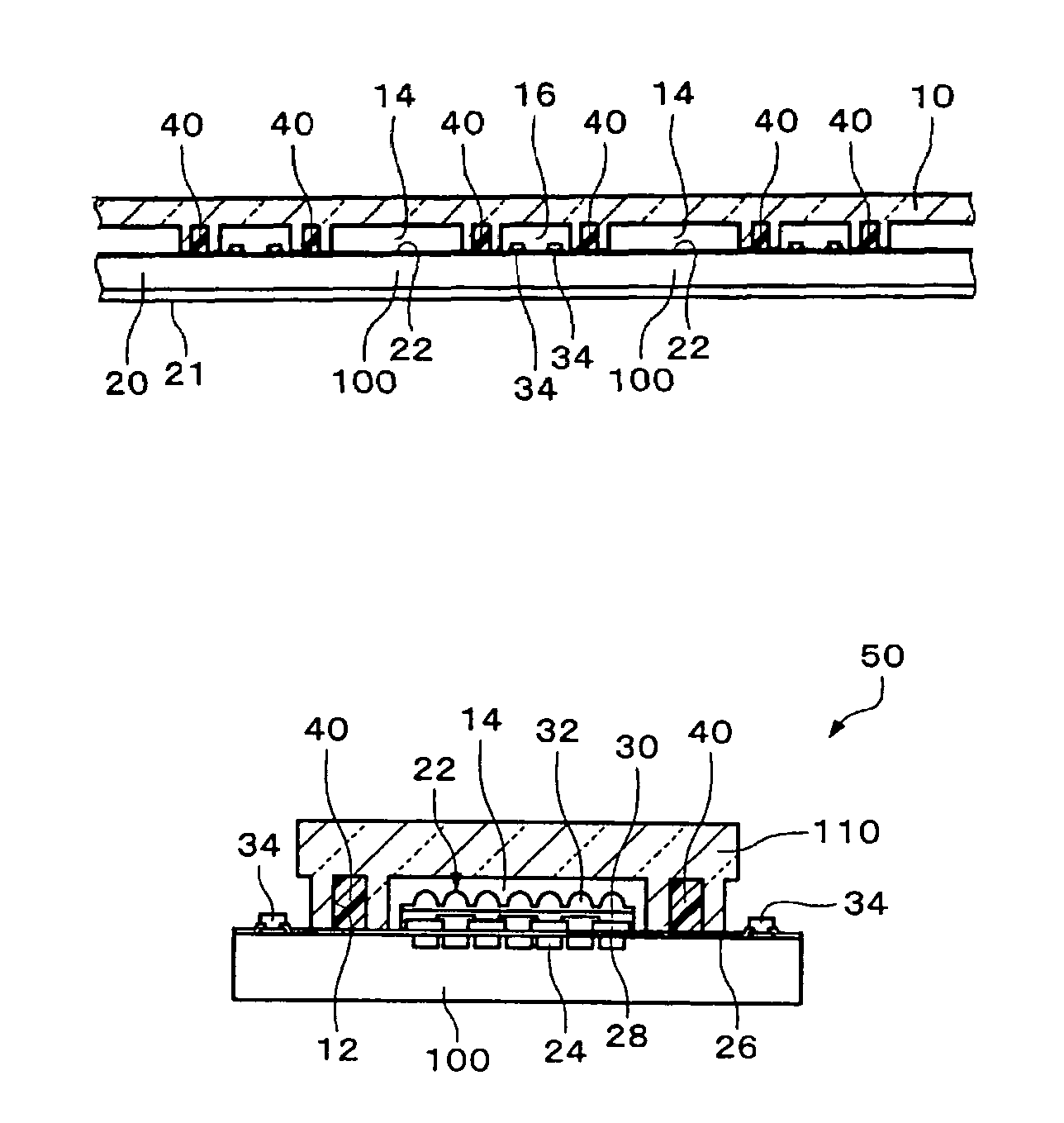

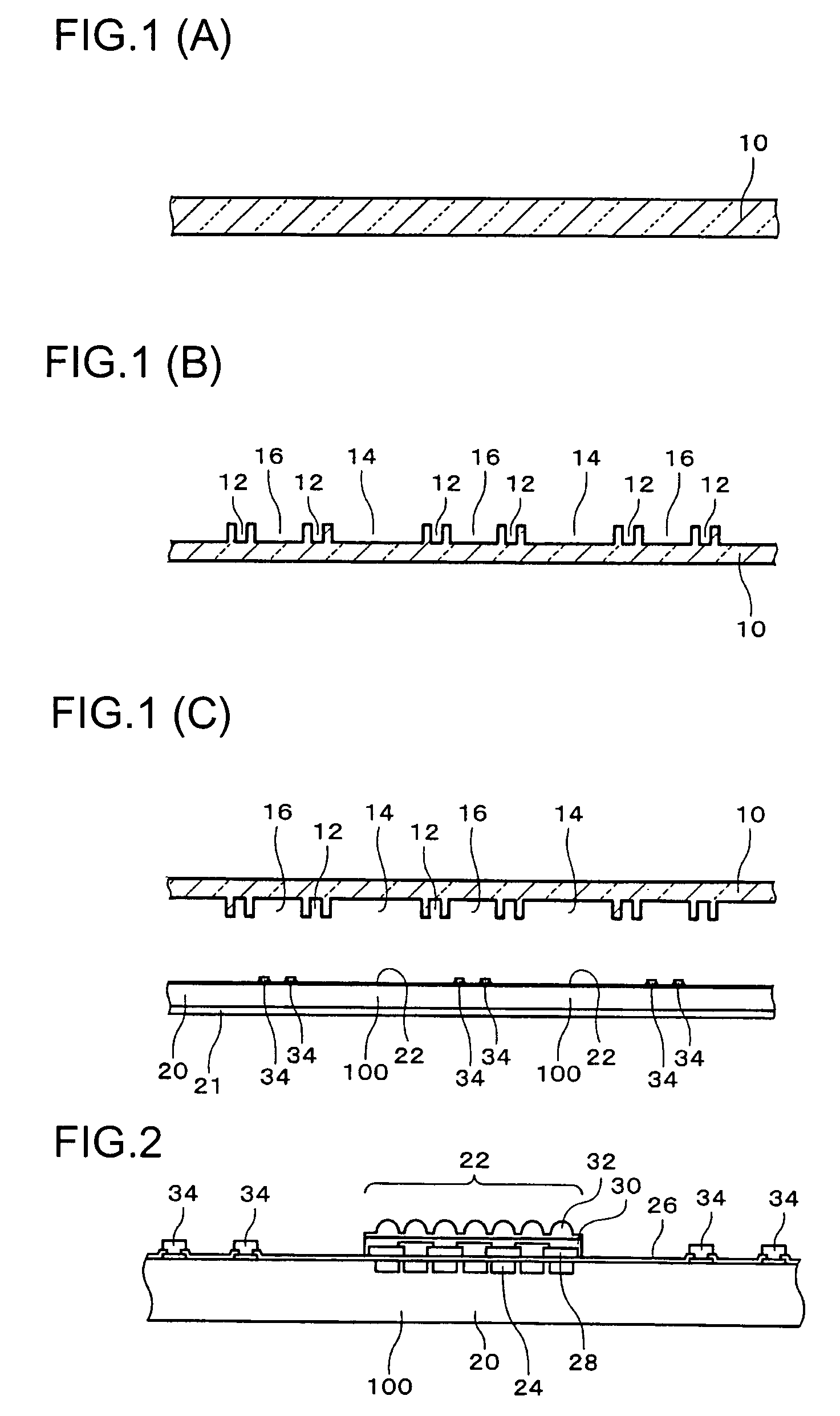

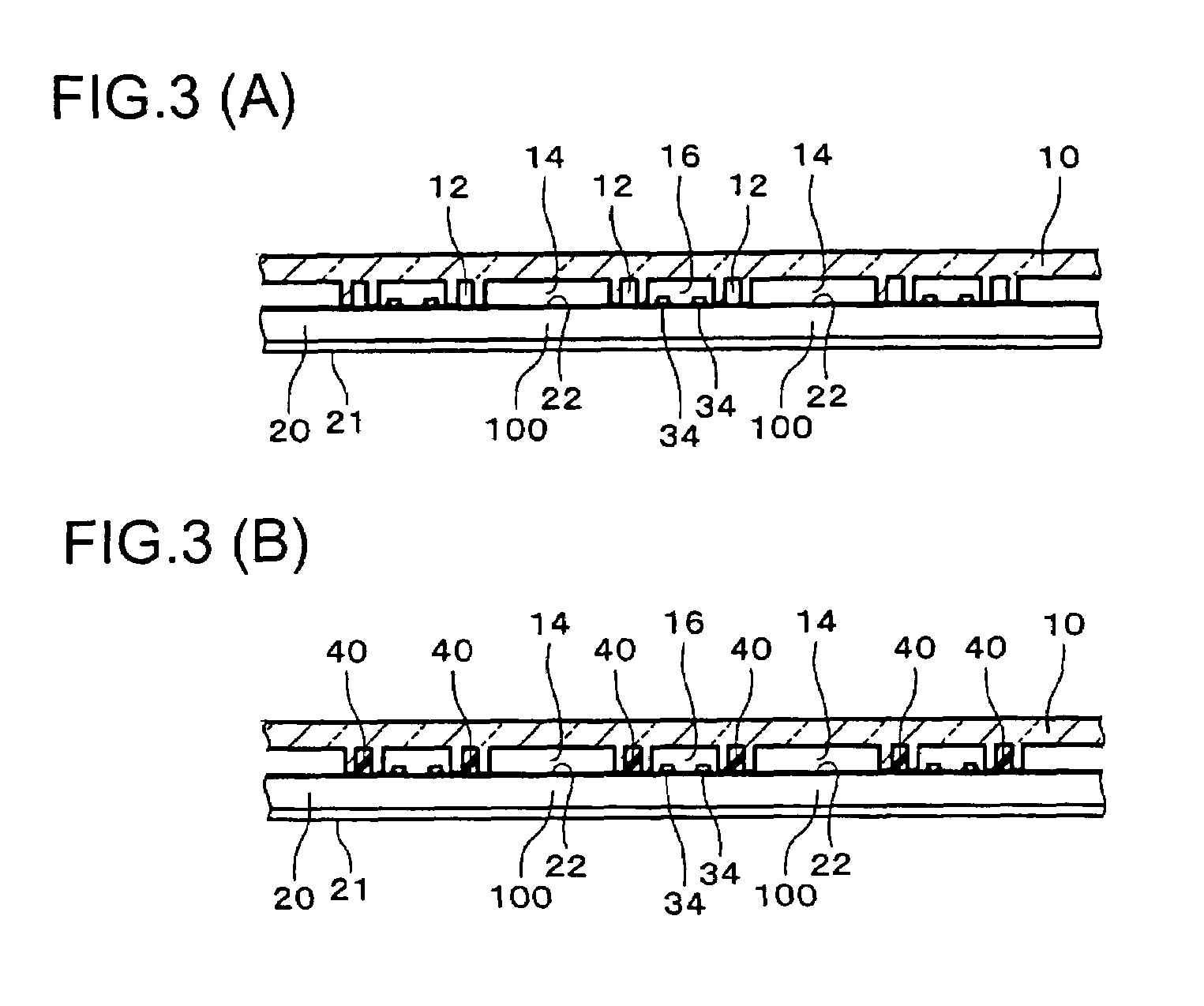

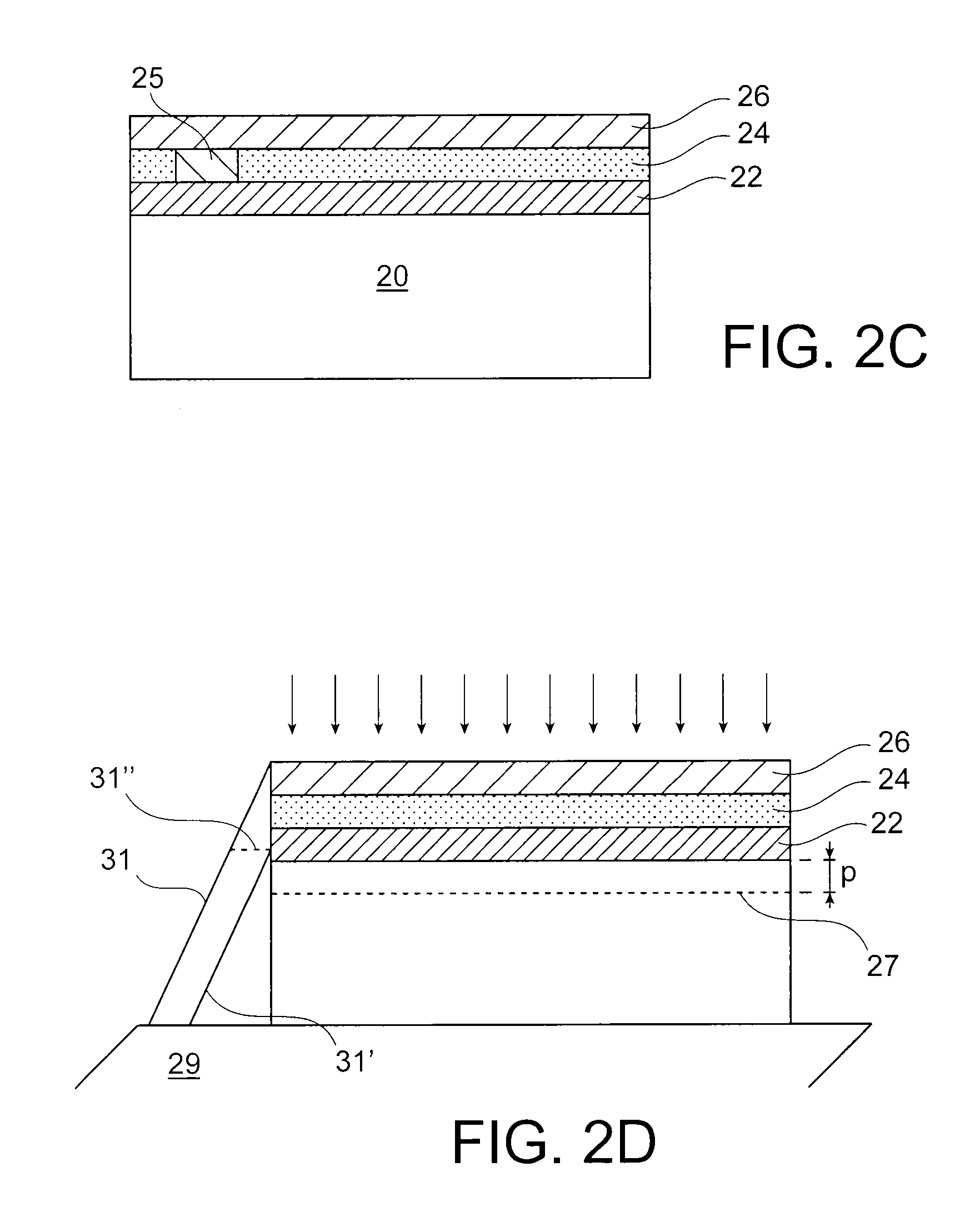

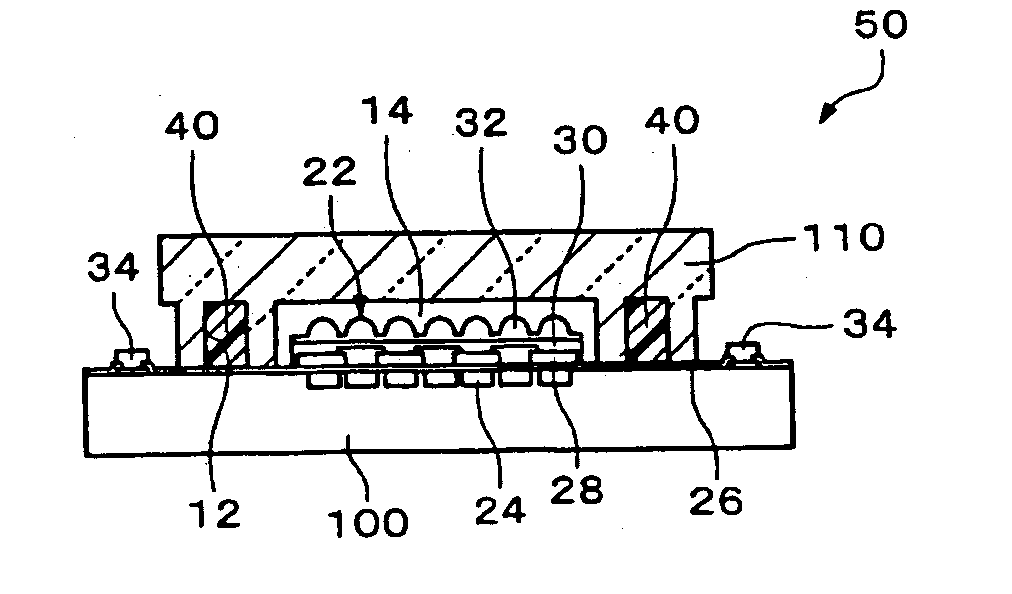

Semiconductor device, method of manufacturing the same, cover for semiconductor device, and electronic equipment

InactiveUS6982470B2Eliminate ThicknessHigh precisionTelevision system detailsSemiconductor/solid-state device detailsAdhesiveEngineering

A method of manufacturing a semiconductor device includes (a) fixing a cover onto a semiconductor substrate so as to place a surface of the cover that includes a portion defining a first opening, face to face on a surface of the semiconductor substrate that includes an electrode and (b) applying an adhesive to the inside of the first opening.

Owner:SEIKO EPSON CORP

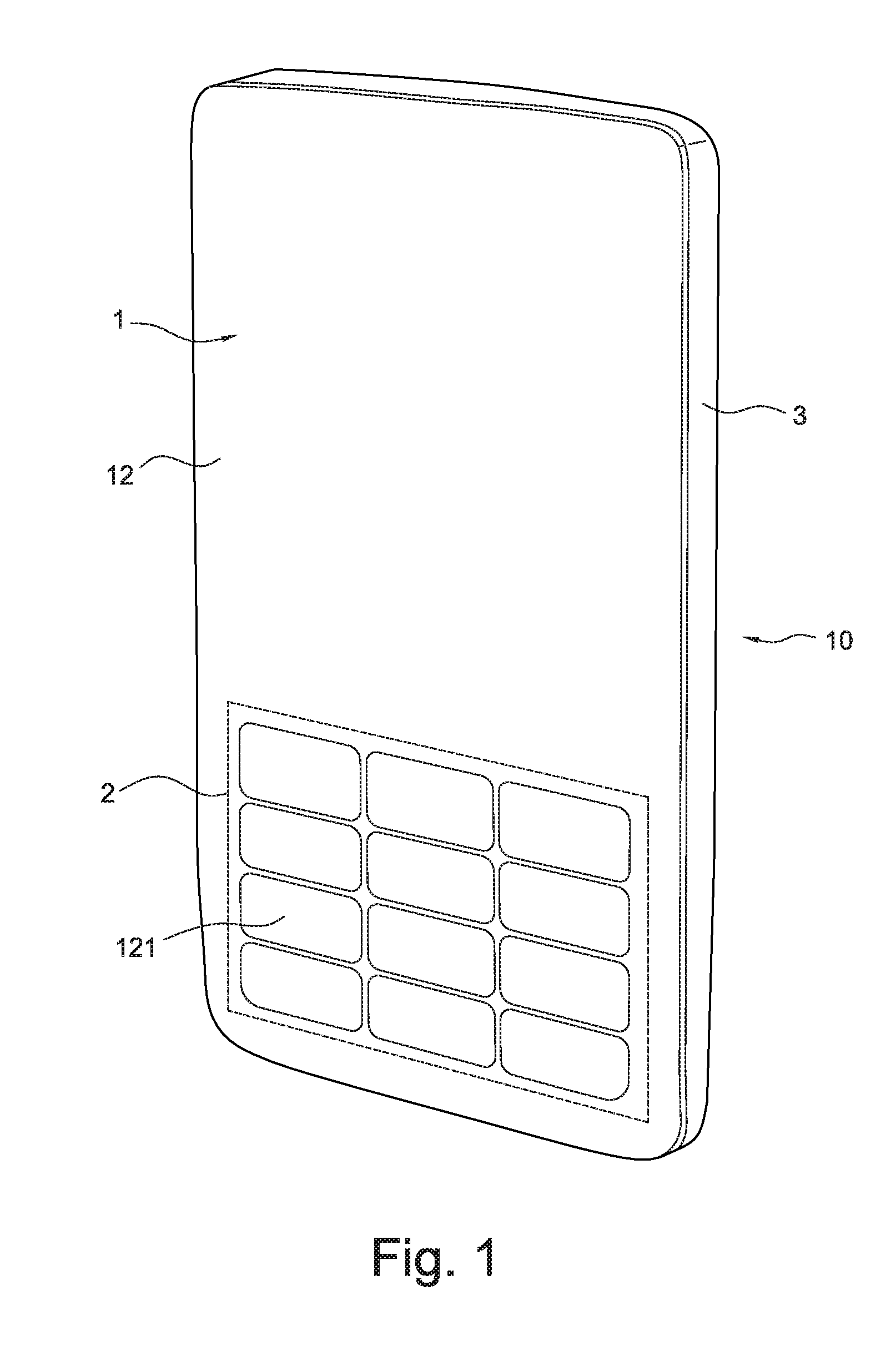

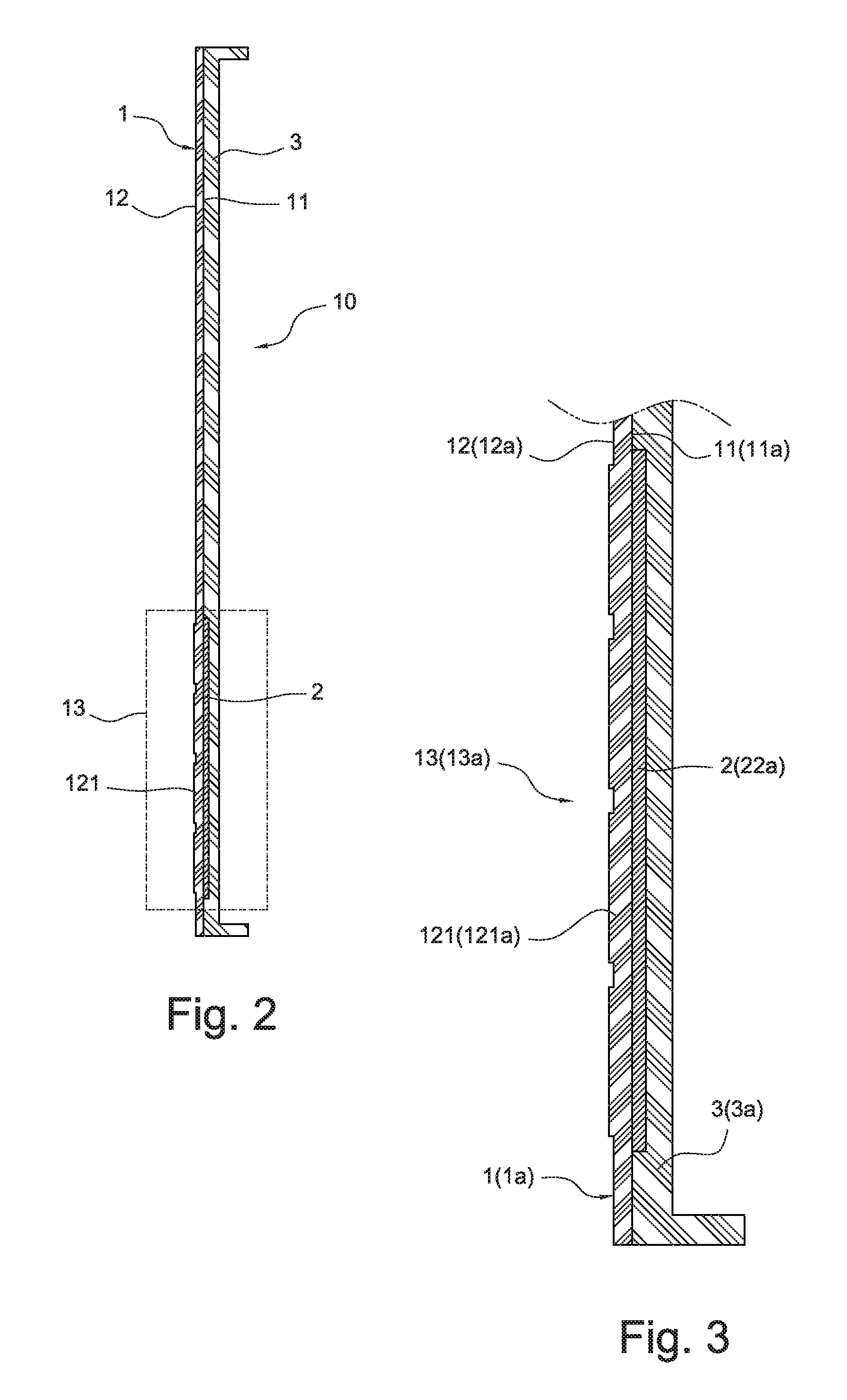

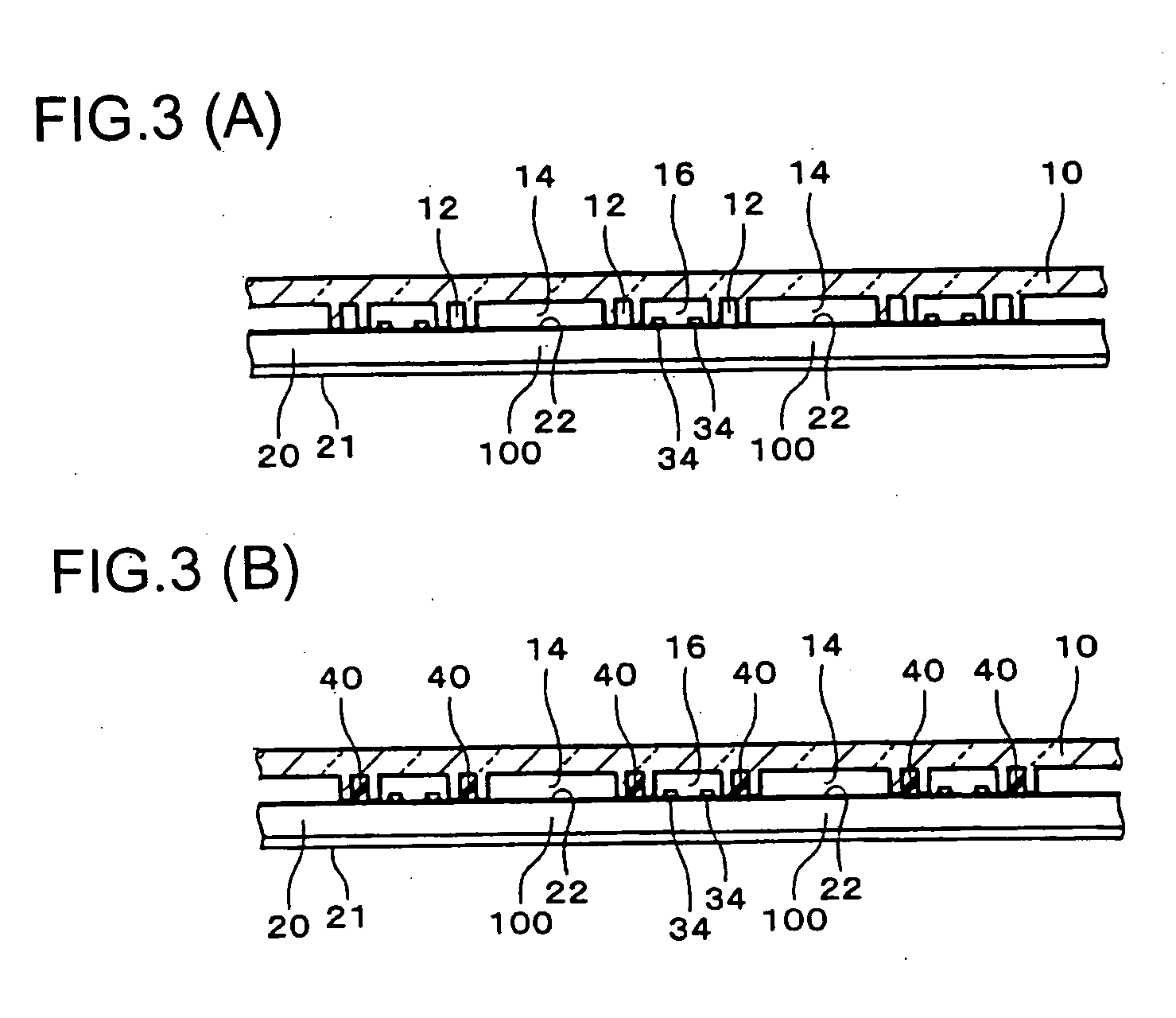

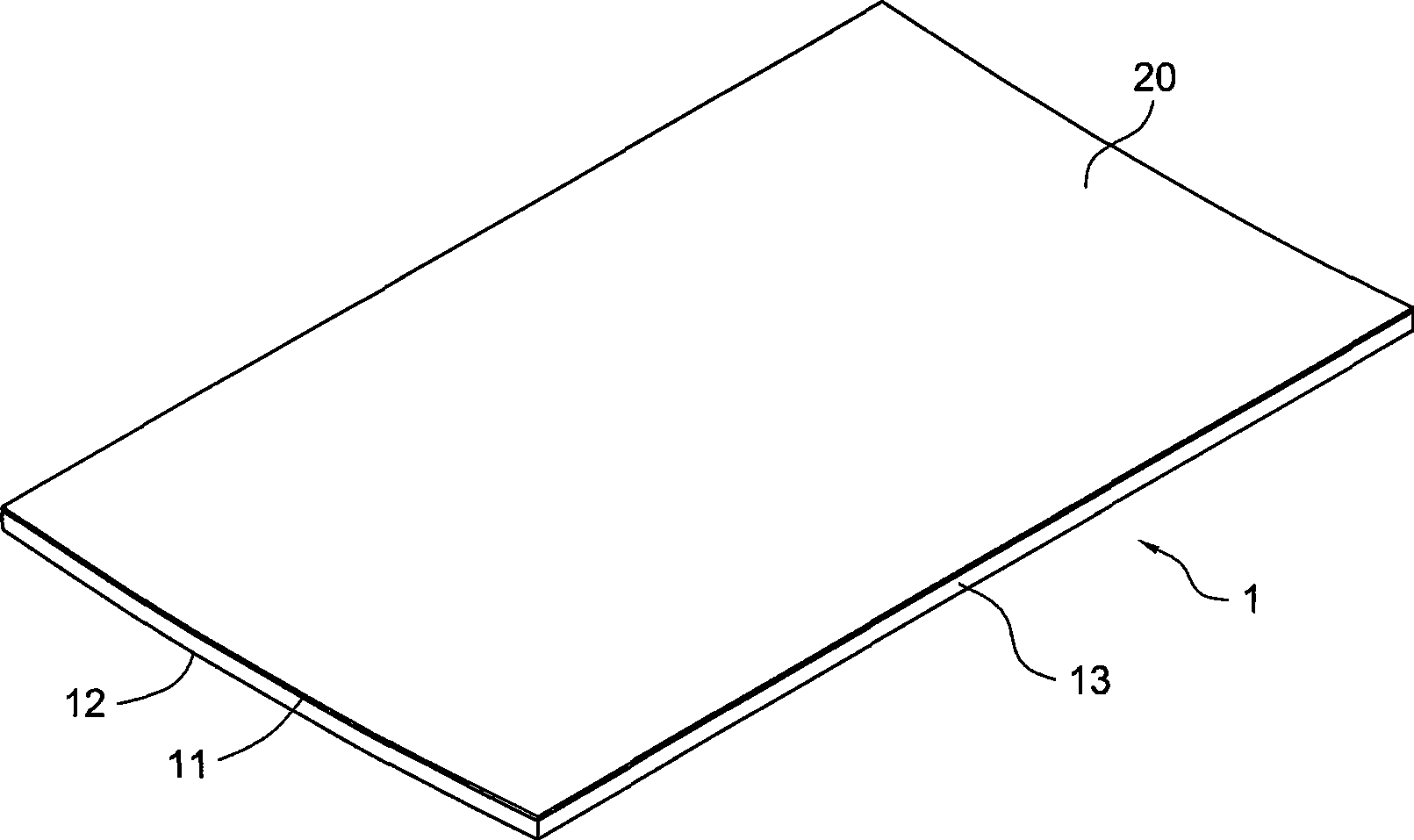

In-mould molding touch module and method for manufacturing the same

ActiveUS7977953B2Thin thicknessEliminate ThicknessResistance/reactance/impedenceCasings with display/control unitsEngineeringPlastic film

An in-mold molding touch module includes a plastic film, a touch circuit and a molding rind. The plastic film includes an inner surface and an outer surface for handling and touching. At least one region of the inner surface and a corresponding region of the outer surface define a touch area. The touch circuit is arranged on the inner surface in the touch area. The molding rind is integrated on the inner surface by an in-mold injecting mode to contain the touch circuit for forming a one-piece body. In addition, the invention also provides a method for manufacturing an in-mold molding touch module.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Chip-type LED and method of manufacturing the same

ActiveUS20090014749A1Reduce manufacturing costEasy to preparePrinted circuit aspectsSolid-state devicesEngineeringCapacitor

An embodiment of the present invention has an insulating substrate in which a first concave hole for mounting an LED chip and a second concave hole for connecting a metallic small-gauge wire are formed, where a metallic sheet that serves as a first wiring pattern is formed at a portion that includes the first concave hole, a metallic sheet that serves as a second wiring pattern is formed at a portion that includes the second concave hole, an LED chip is mounted upon the metallic sheet inside the first concave hole, the LED chip is electrically connected to the metallic sheet inside the second concave hole via a metallic small-gauge wire, and the chip-type LED is sealed with a clear resin.

Owner:SHARP KK

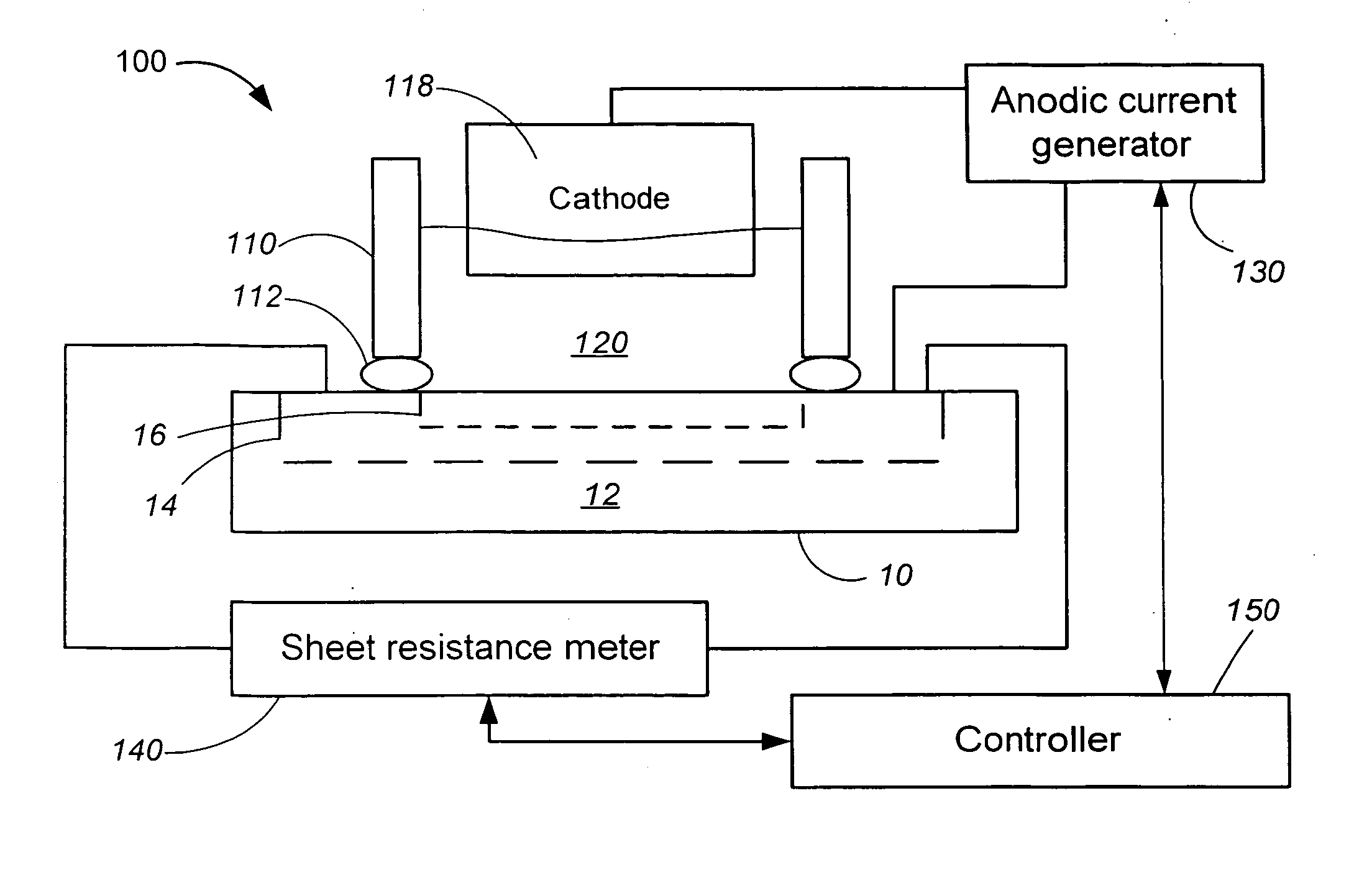

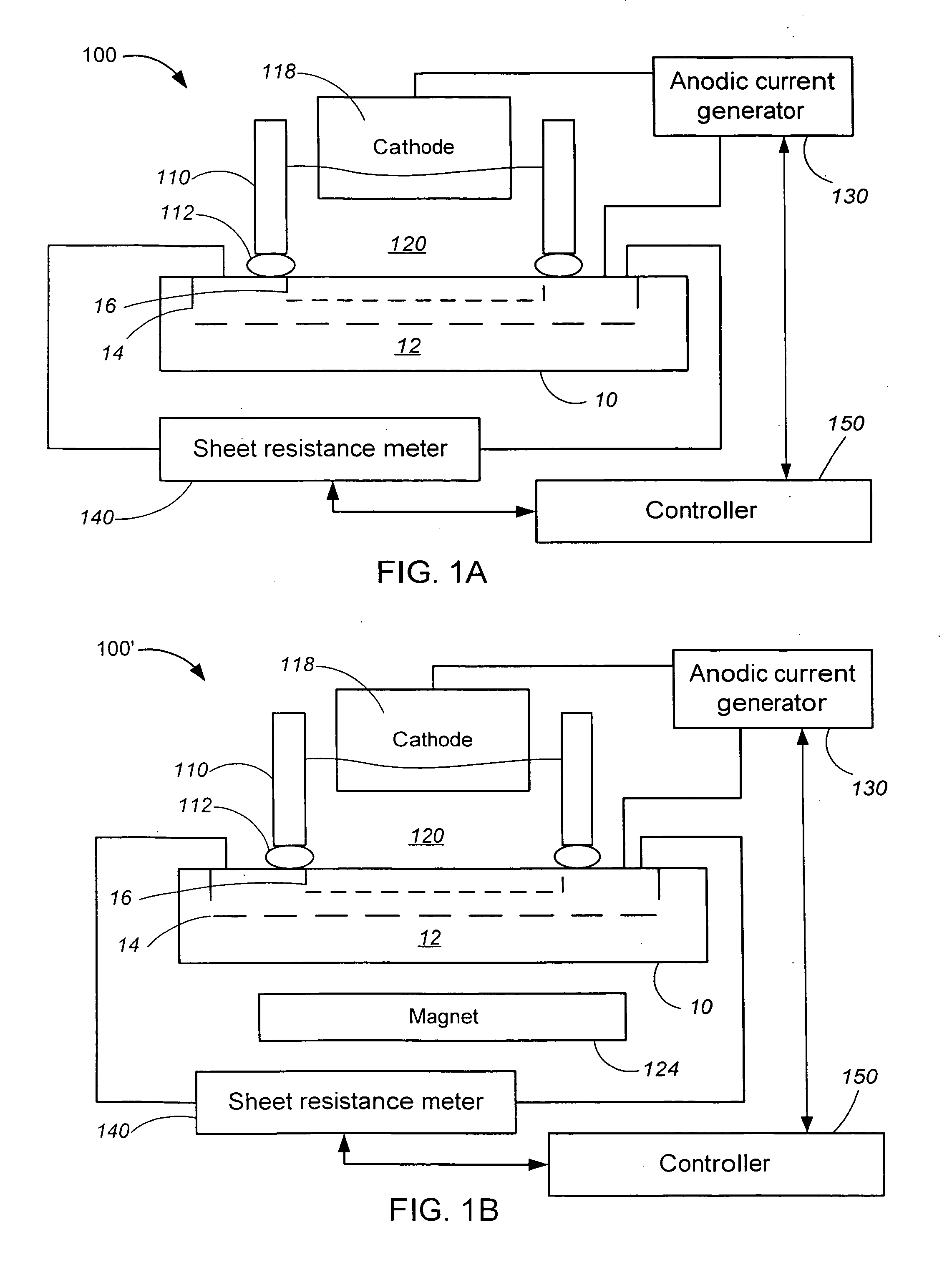

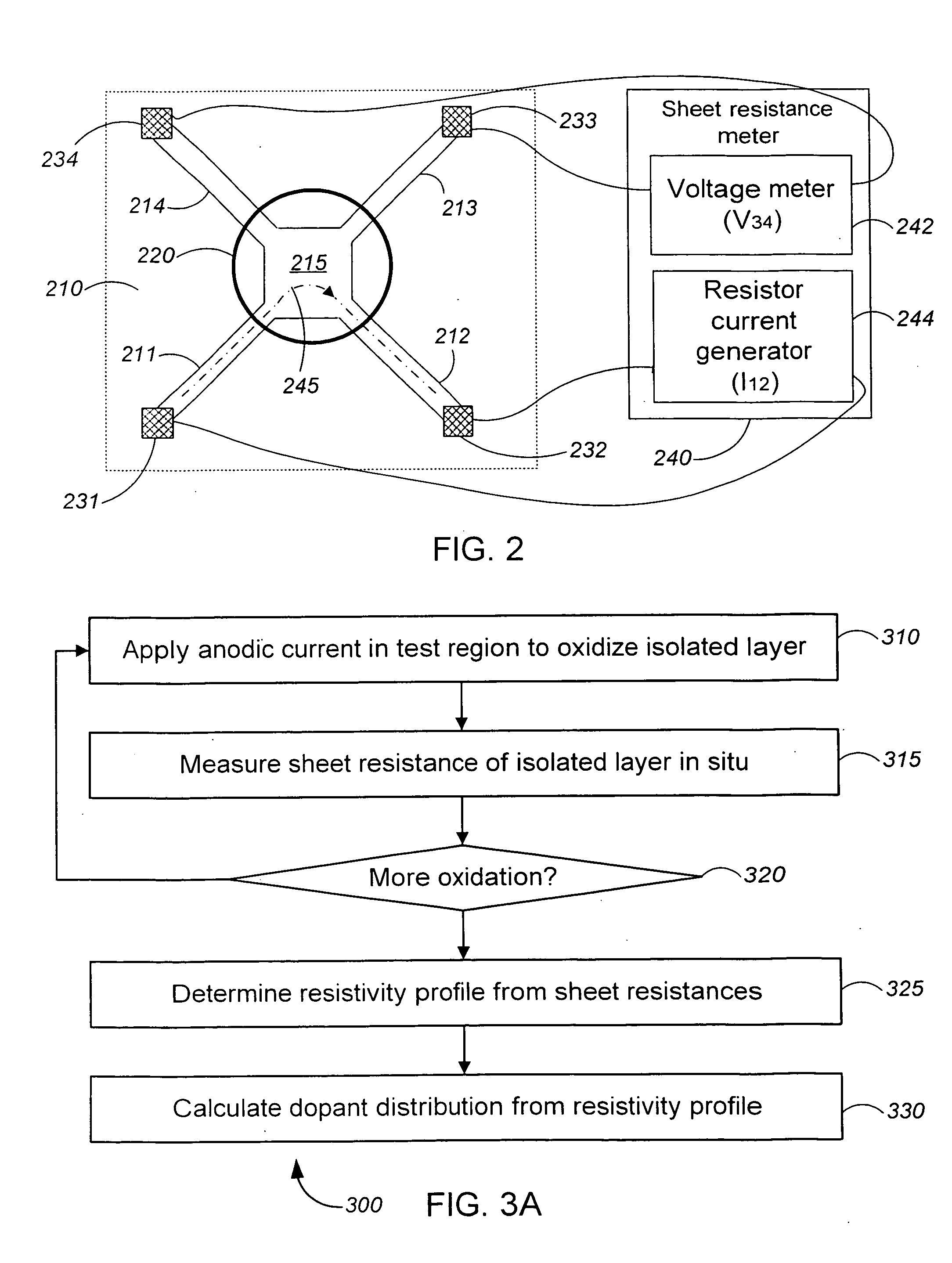

In situ determination of resistivity, mobility and dopant concentration profiles

ActiveUS20050052191A1Accurate measurementEliminate ThicknessSemiconductor/solid-state device testing/measurementElectronic circuit testingSheet resistanceElectrical resistance survey

The present invention provides techniques for an in-situ measurement of resistivity profiles and dopant concentration distributions in semiconductor structures, such as shallow junctions. A substrate with a resistor test structure having a conduction circuit may be placed at a measurement station, surface layers may be successively removed from the conduction circuit at the measurement station, a sheet resistance of the conduction circuit may be measured at the measurement station after the removal of each surface layer to generate a plurality of sheet resistance measurements, and the resistivity profile may be calculated from the plurality of sheet resistance measurements.

Owner:ACTIVE LAYER PARAMETERICS

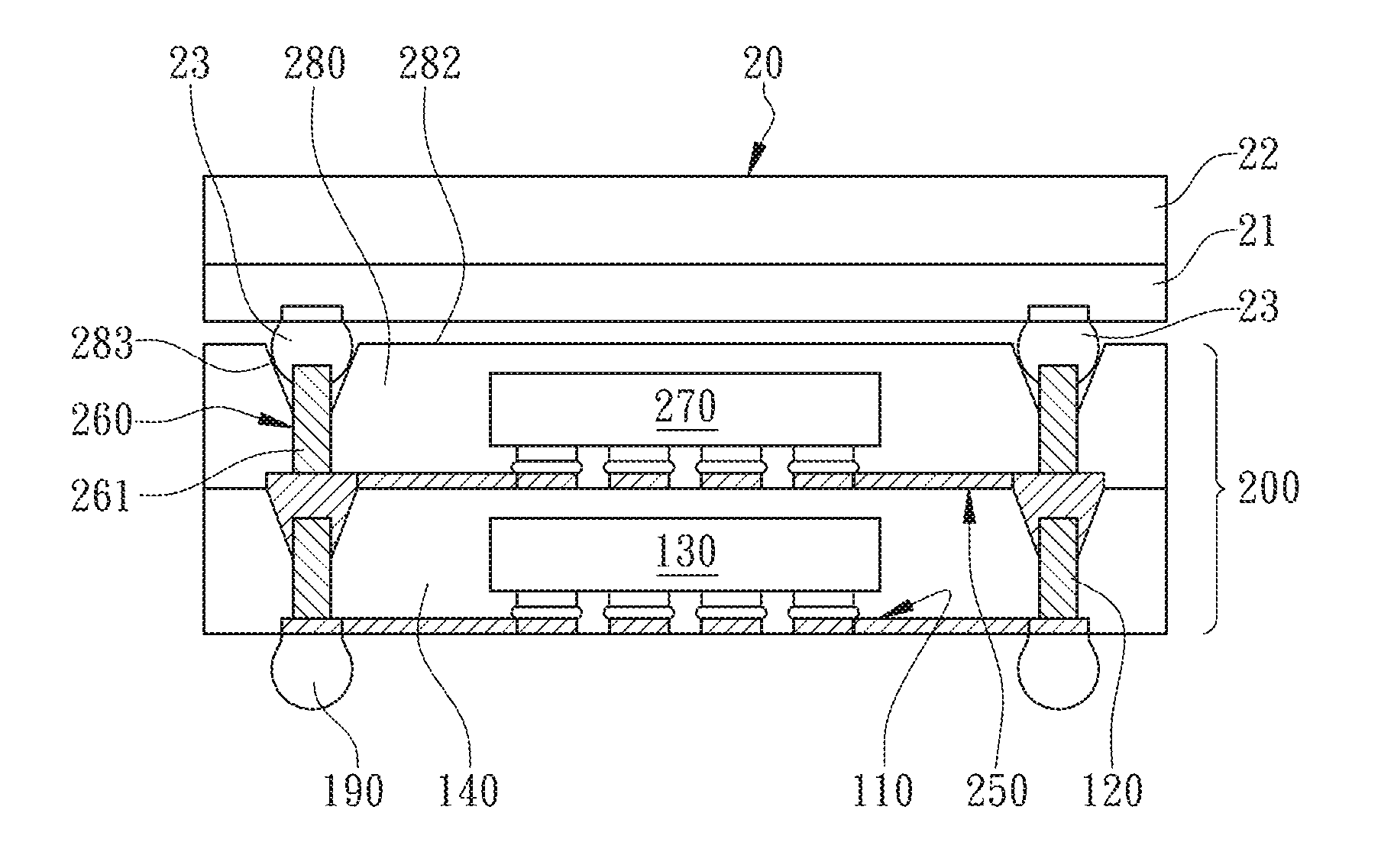

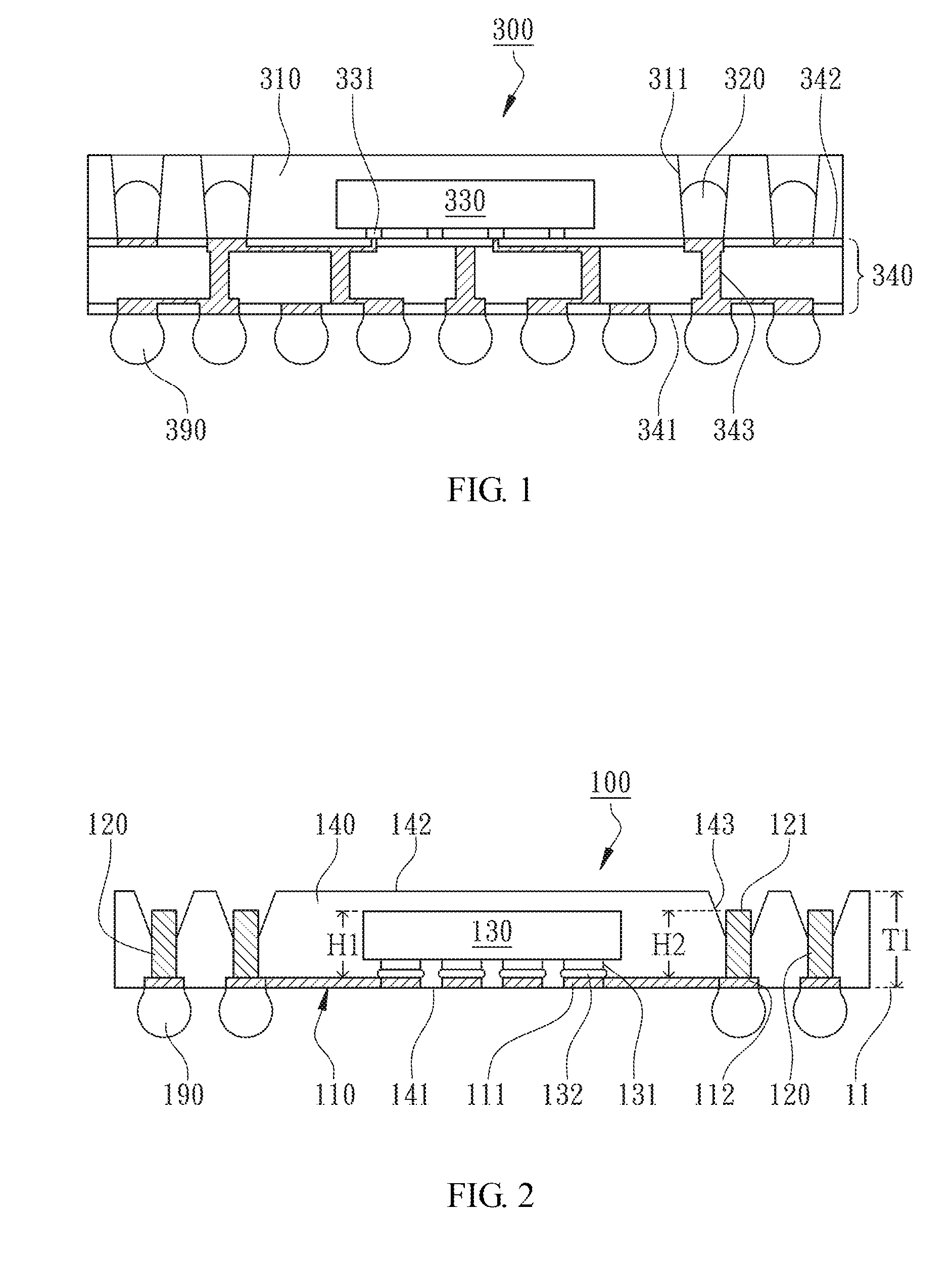

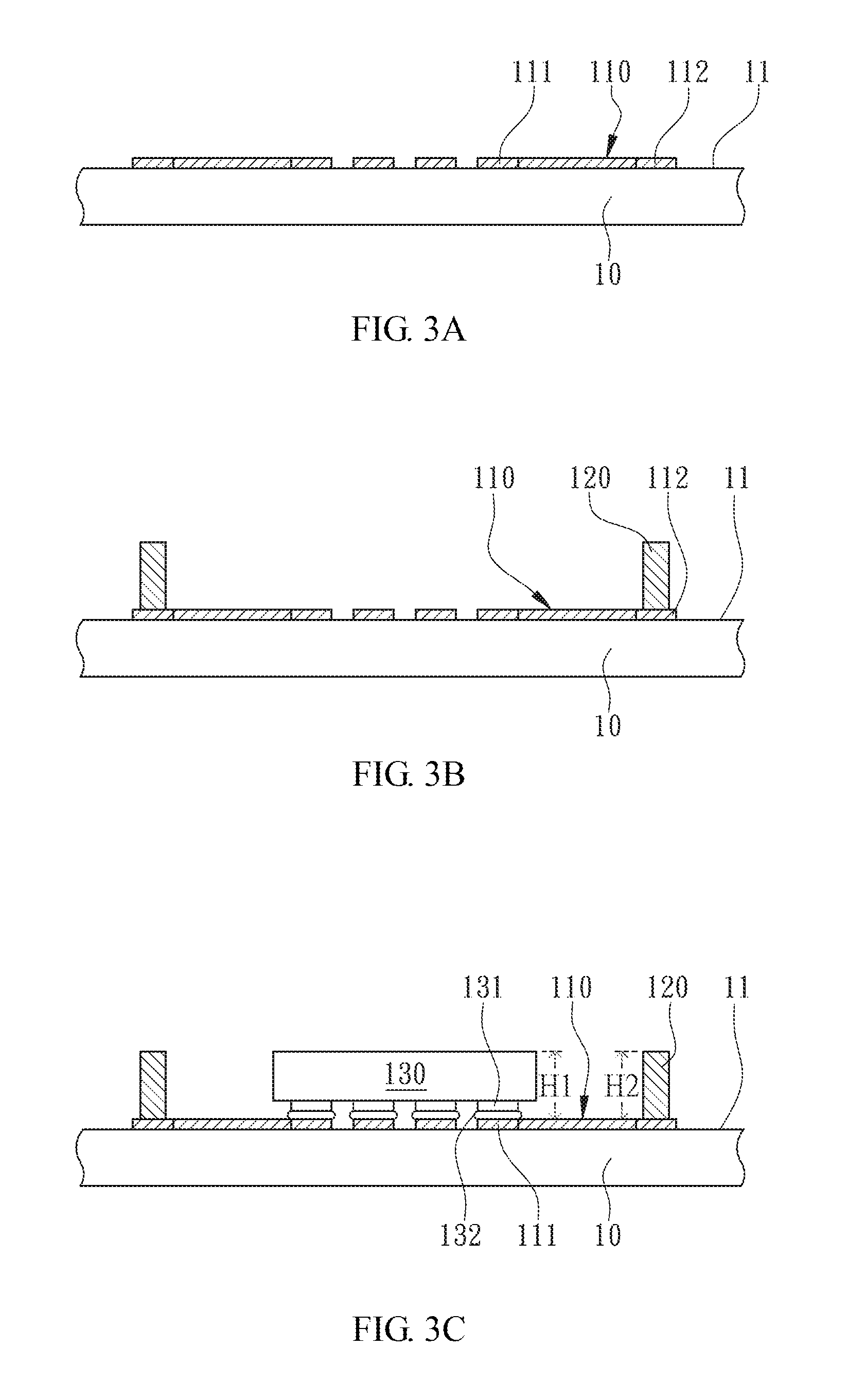

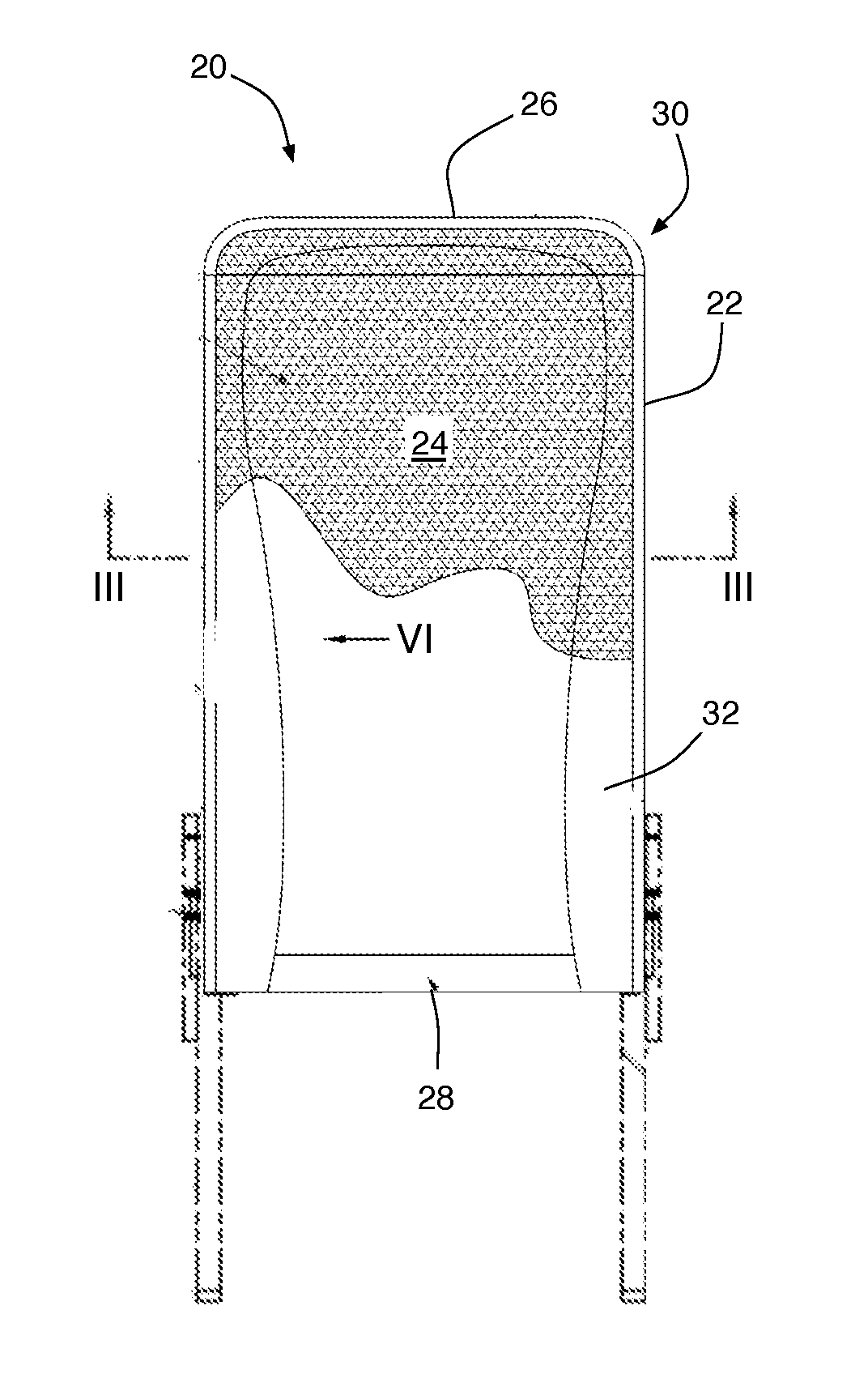

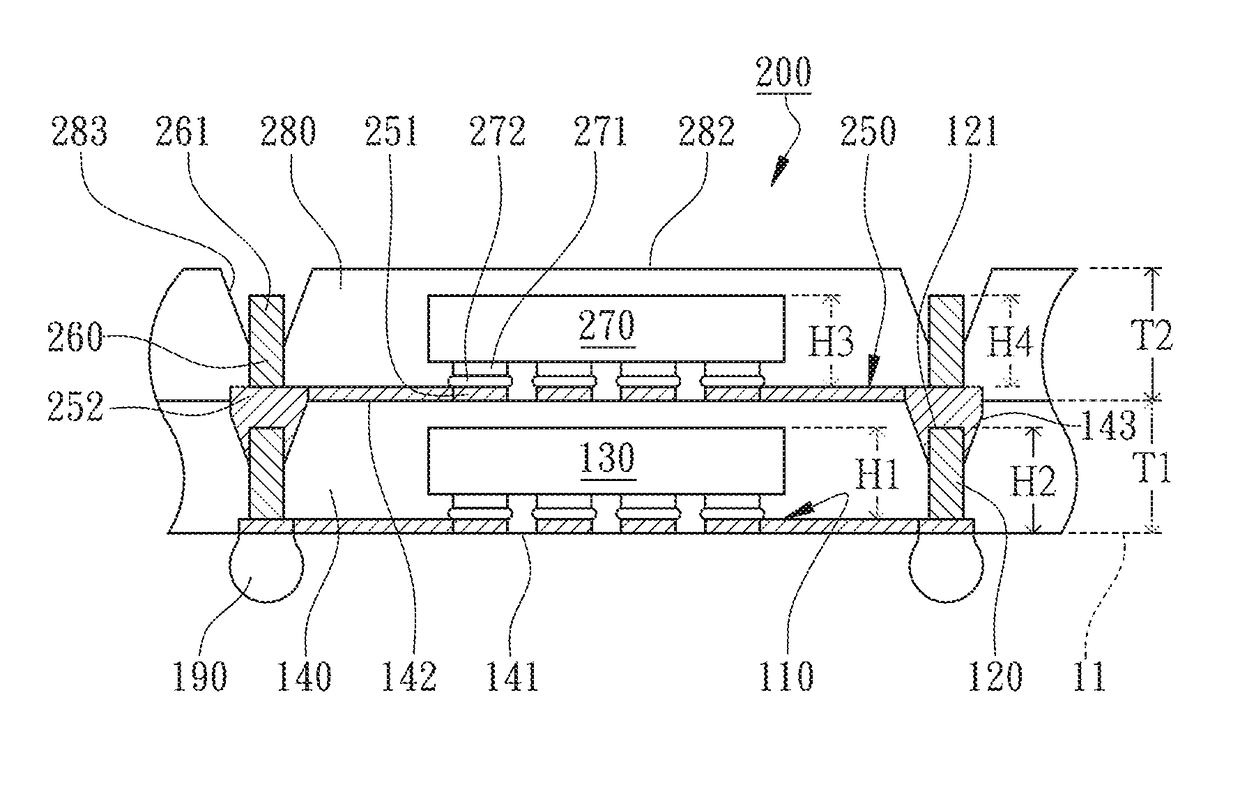

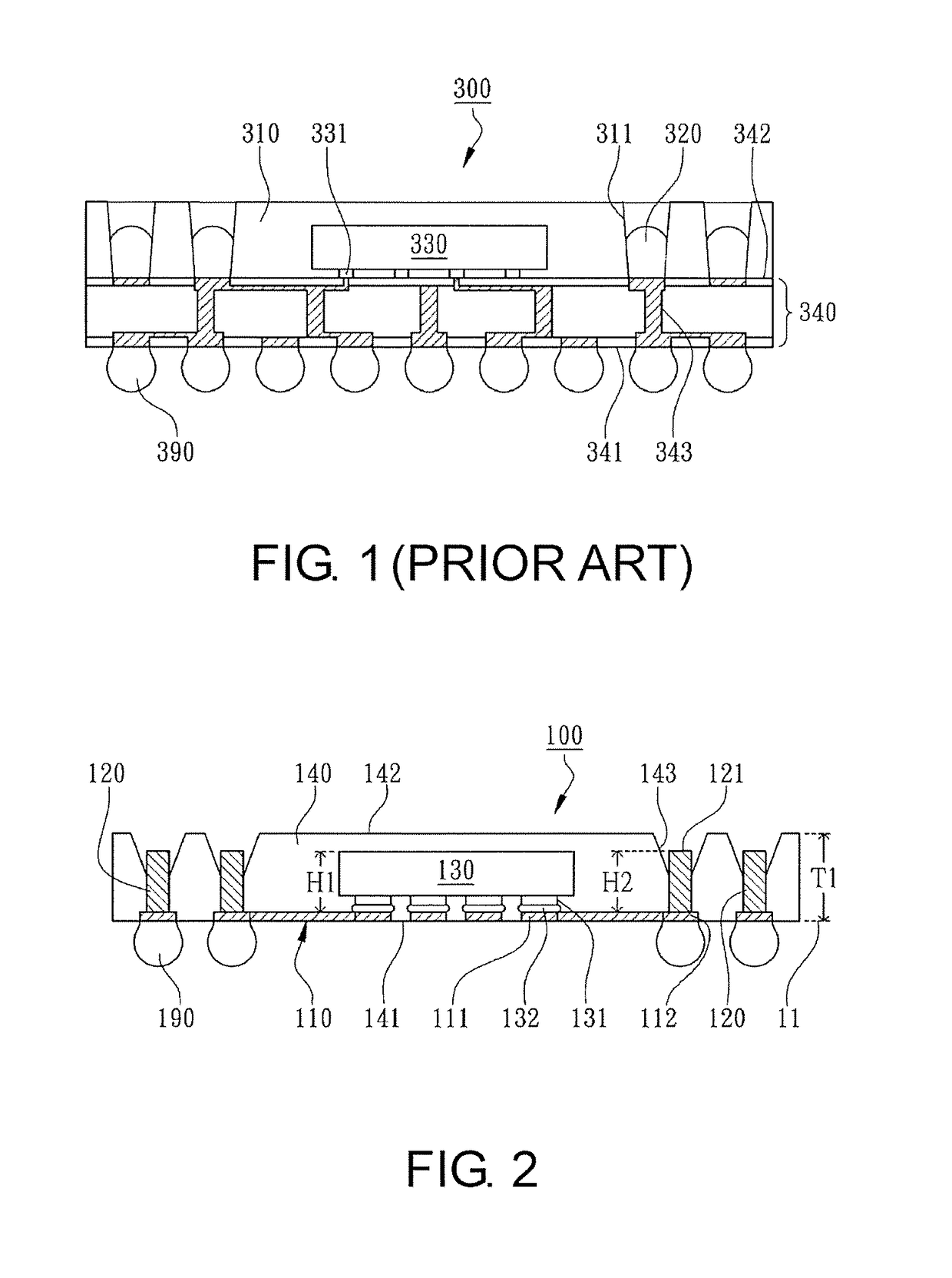

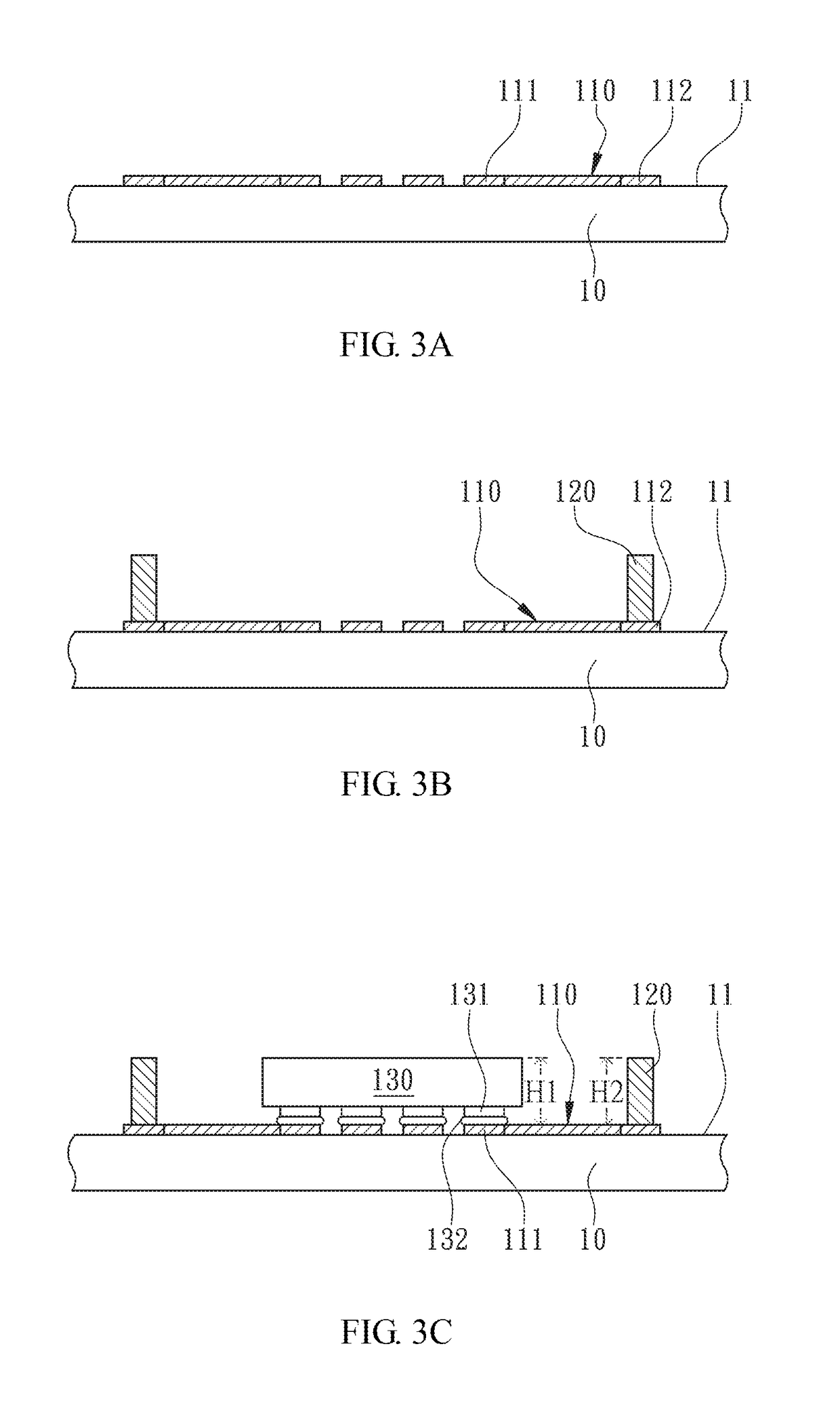

Semiconductor package with pillar-top-interconnection (PTI) configuration and its mis fabricating method

ActiveUS20170053898A1Small footprintEliminate gapsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageInterconnection

Disclosed is a semiconductor package with Pillar-Top-Interconnection (PTI) configuration, comprising a redistribution layer (RDL) formed on a carrier plane, a plurality of metal pillars disposed on the RDL, a chip bonded onto the RDL, and a molding core. The molding core is formed on the carrier plane and has a bottom surface defined by the carrier plane so that the RDL is embedded inside the molding core. The package thickness of the molding core is greater than the chip-bonding height of the chip so that the chip is completely embedded inside the molding core. The metal pillars are encapsulated at the peripheries of the molding core with a plurality of pillar top portions exposed from the molding core. The exposed pillar top portions are reentrant from a top surface of the molding core and uneven. Accordingly, it realizes the effects of ultra-thin and smaller footprint POP stacked assembly with fine pitch vertically electrical connections in POP structure. Also, it is possible to achieve zero spacing between POP stacked assembly.

Owner:POWERTECH TECHNOLOGY

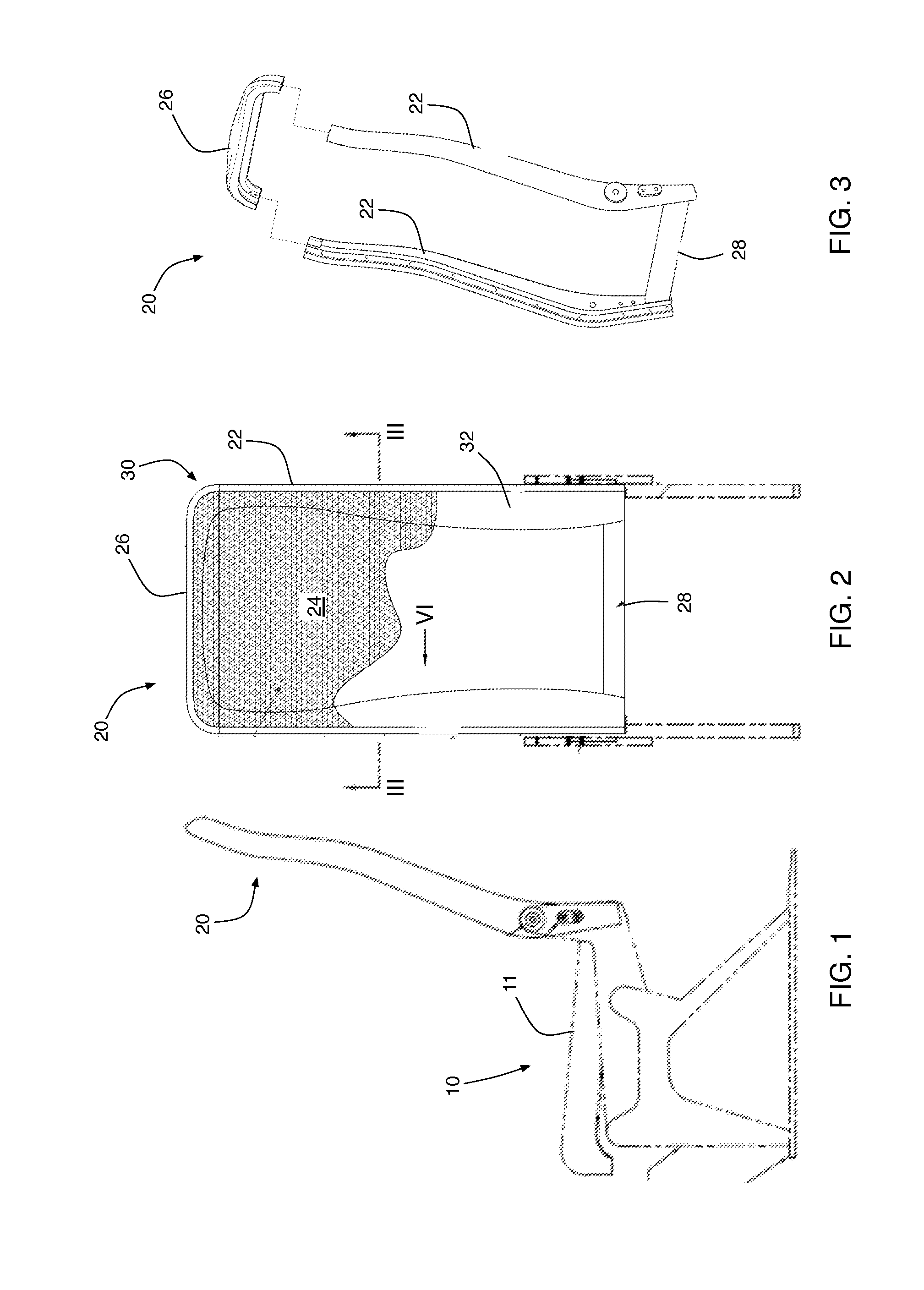

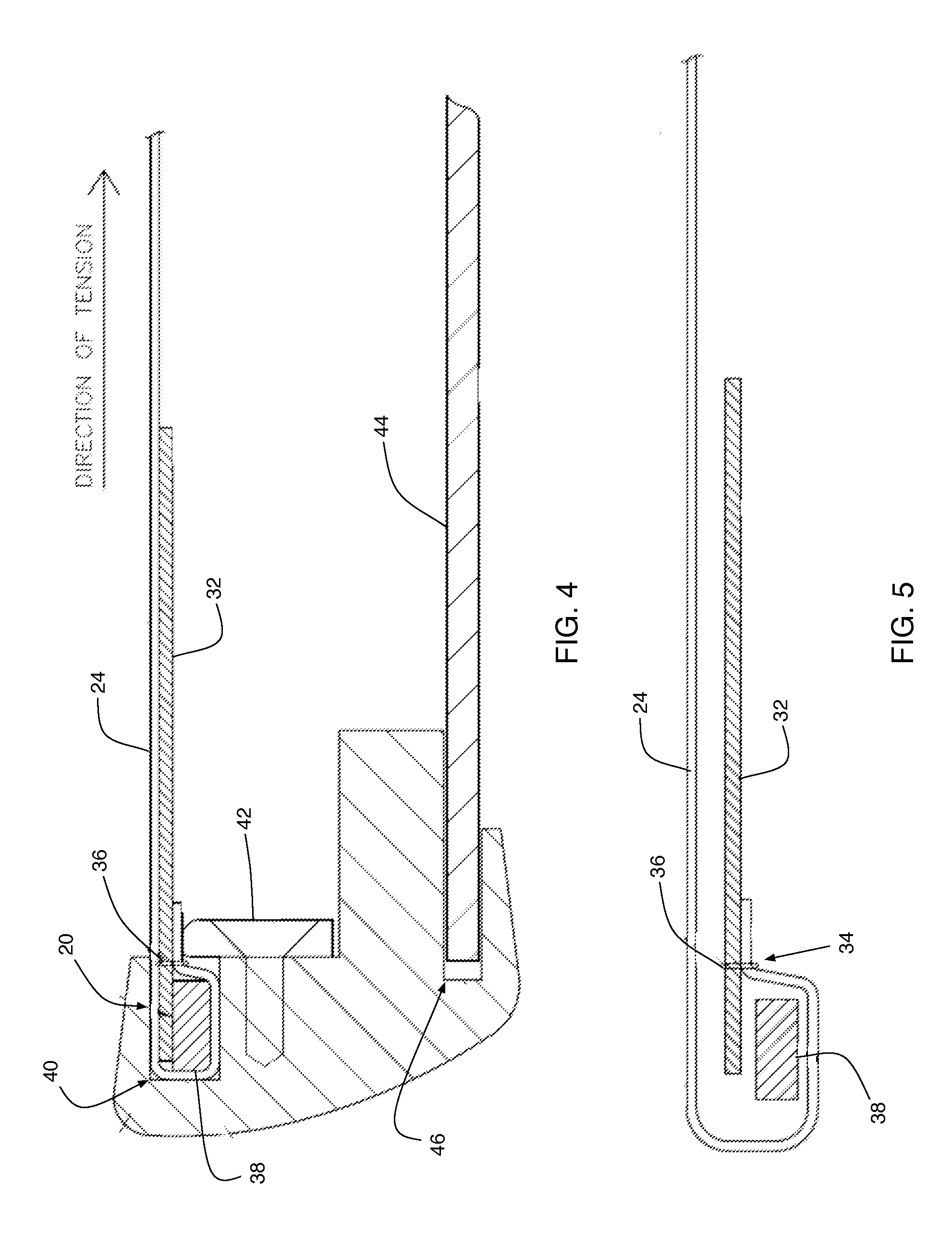

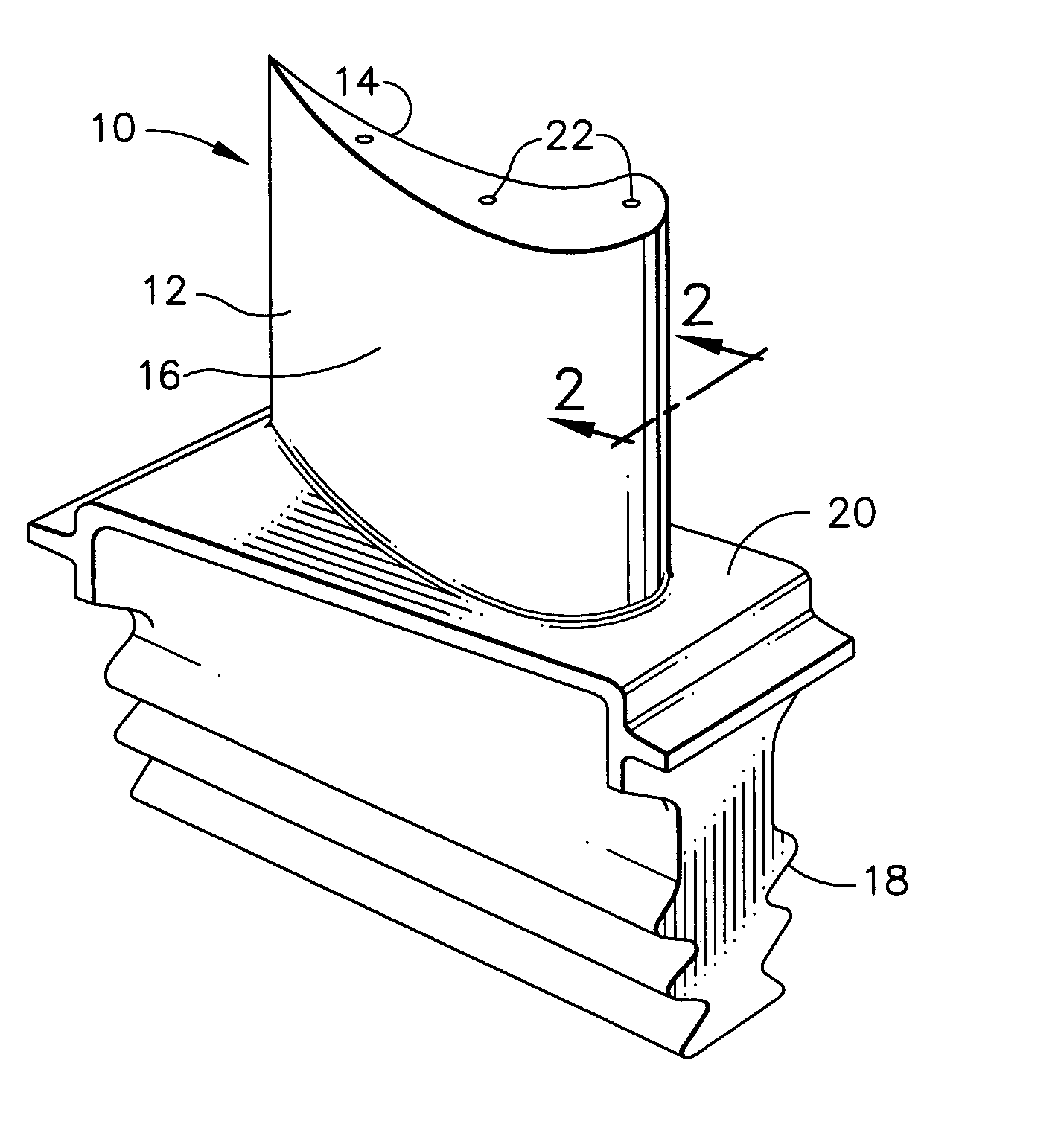

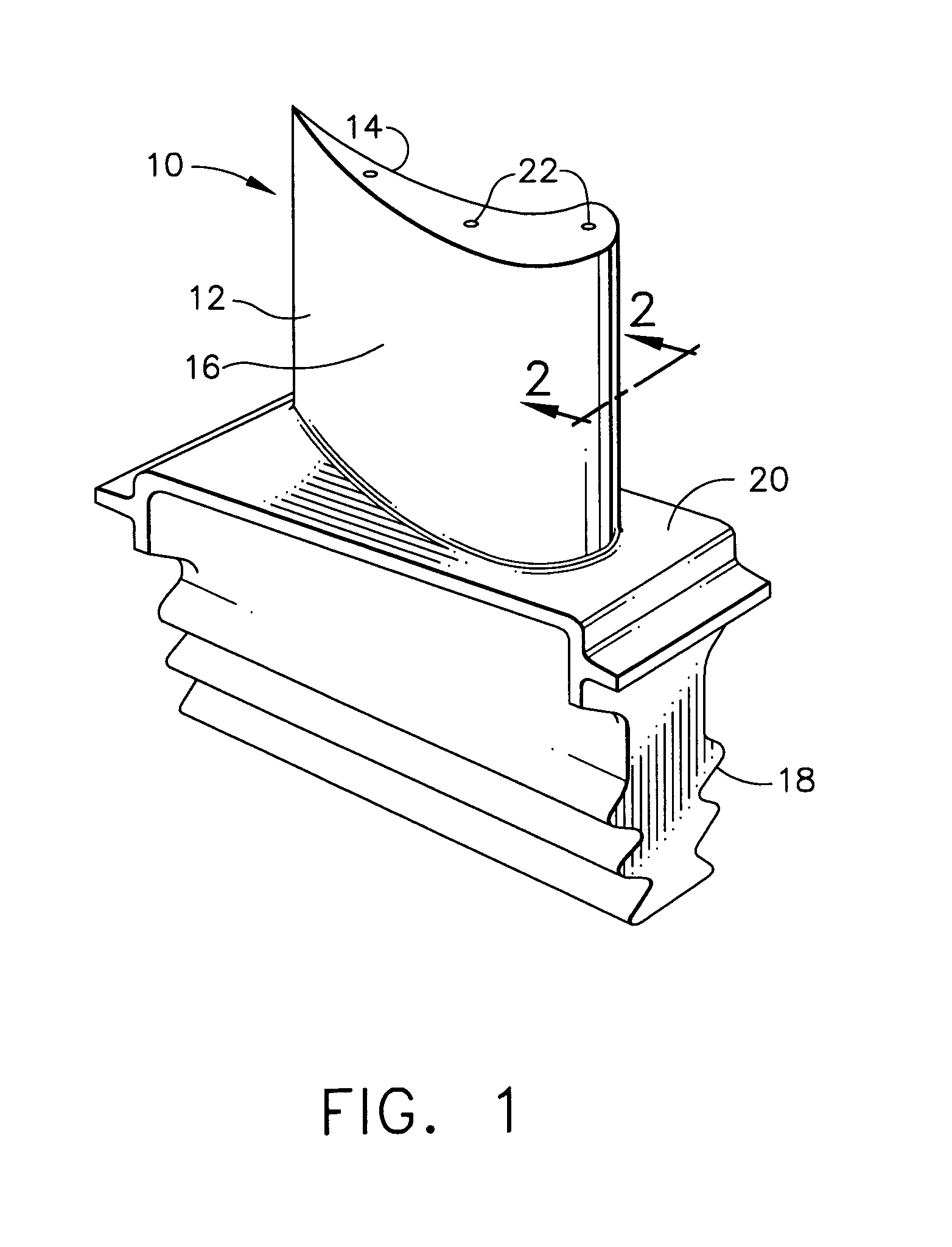

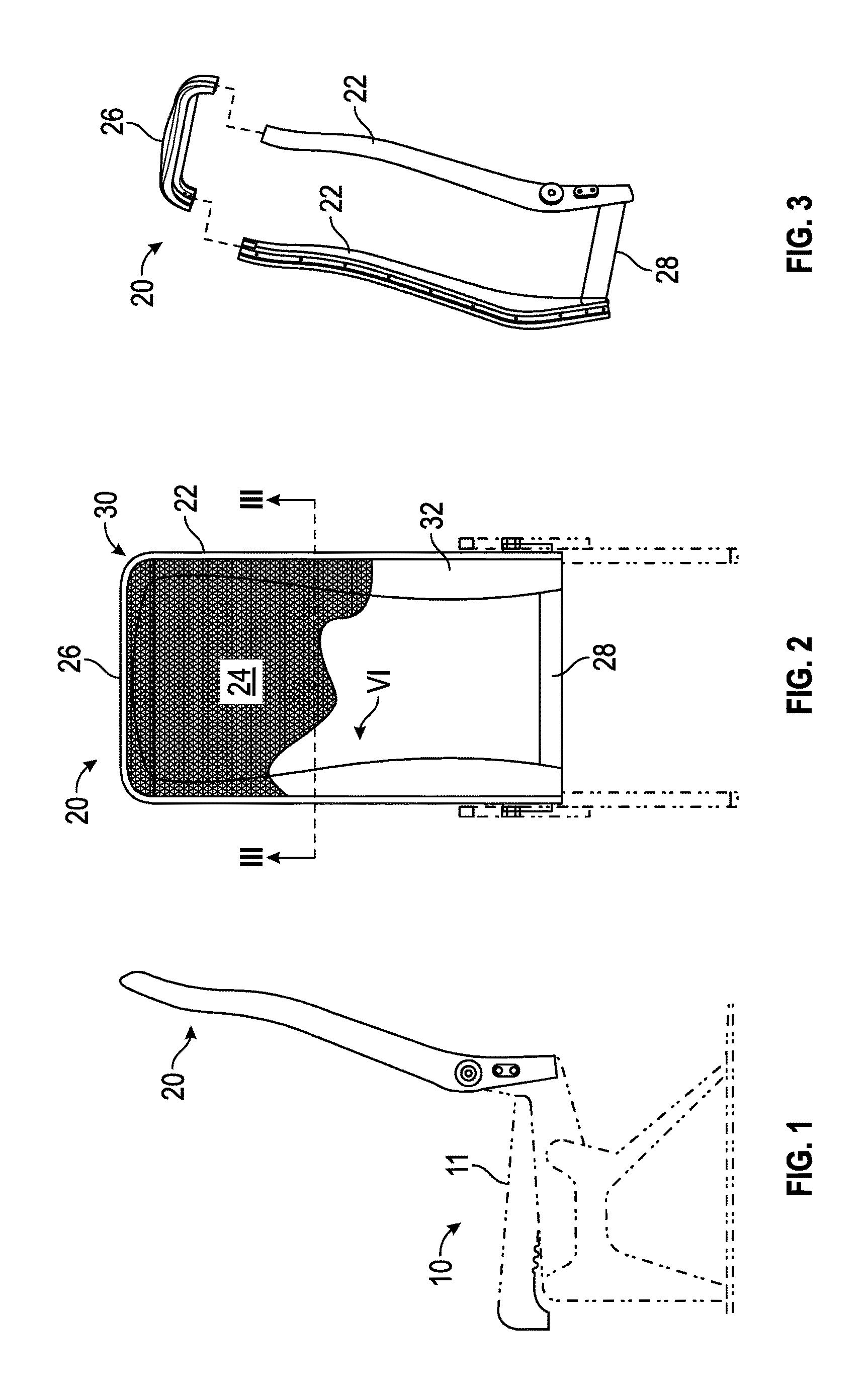

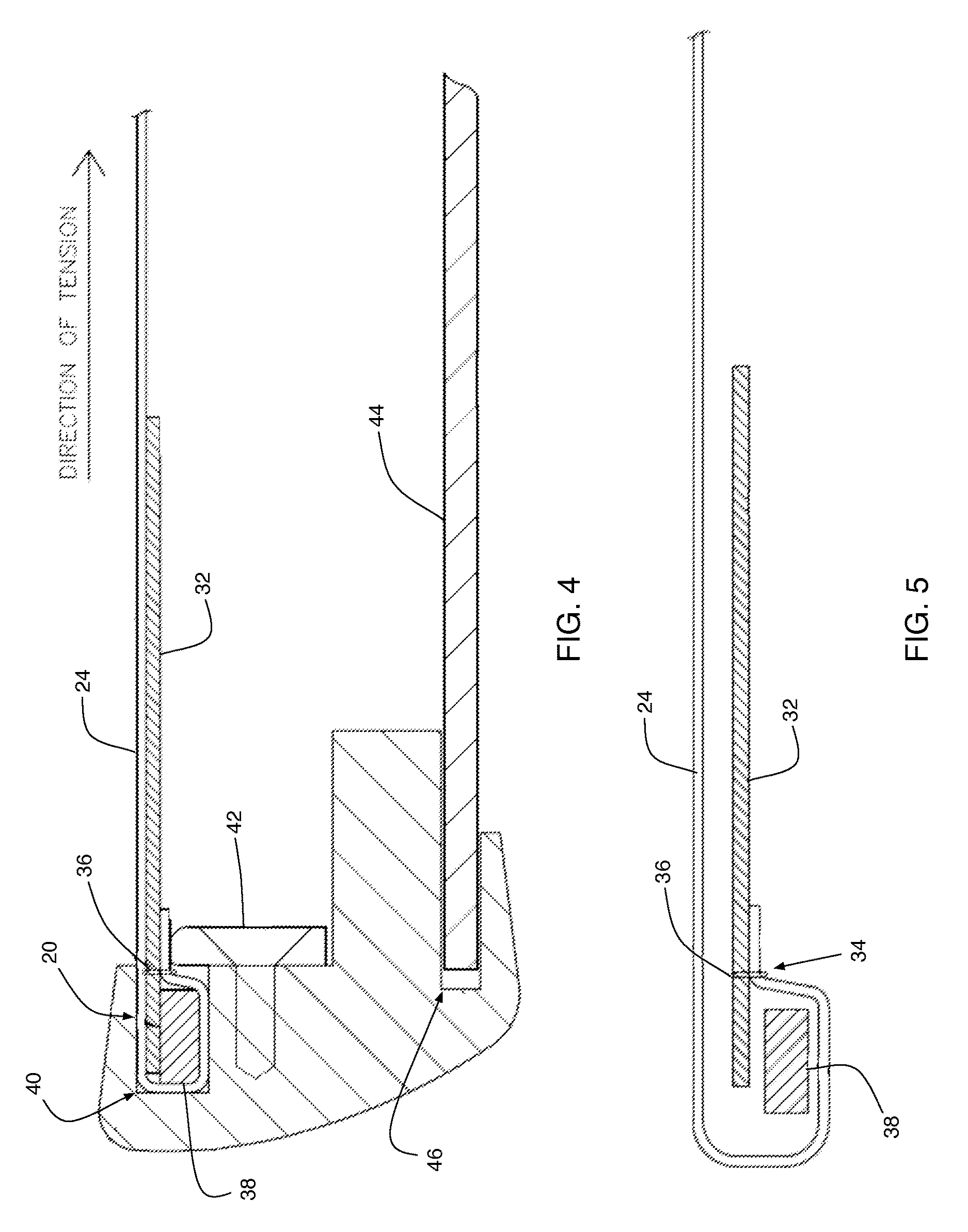

Aircraft seat back assembly

The seat back portion of a passenger aircraft seat is built of an elastomer mesh type diaphragm without conventional cushions or dress covers, in order to maximize space available to the passenger while reducing costs and weight. The diaphragm is attached and tensioned into a structural frame, which also supports a slide-in rear shroud closeout. The frame is designed to remain exposed, showing a decorative finish.

Owner:FRANKLIN PRODS

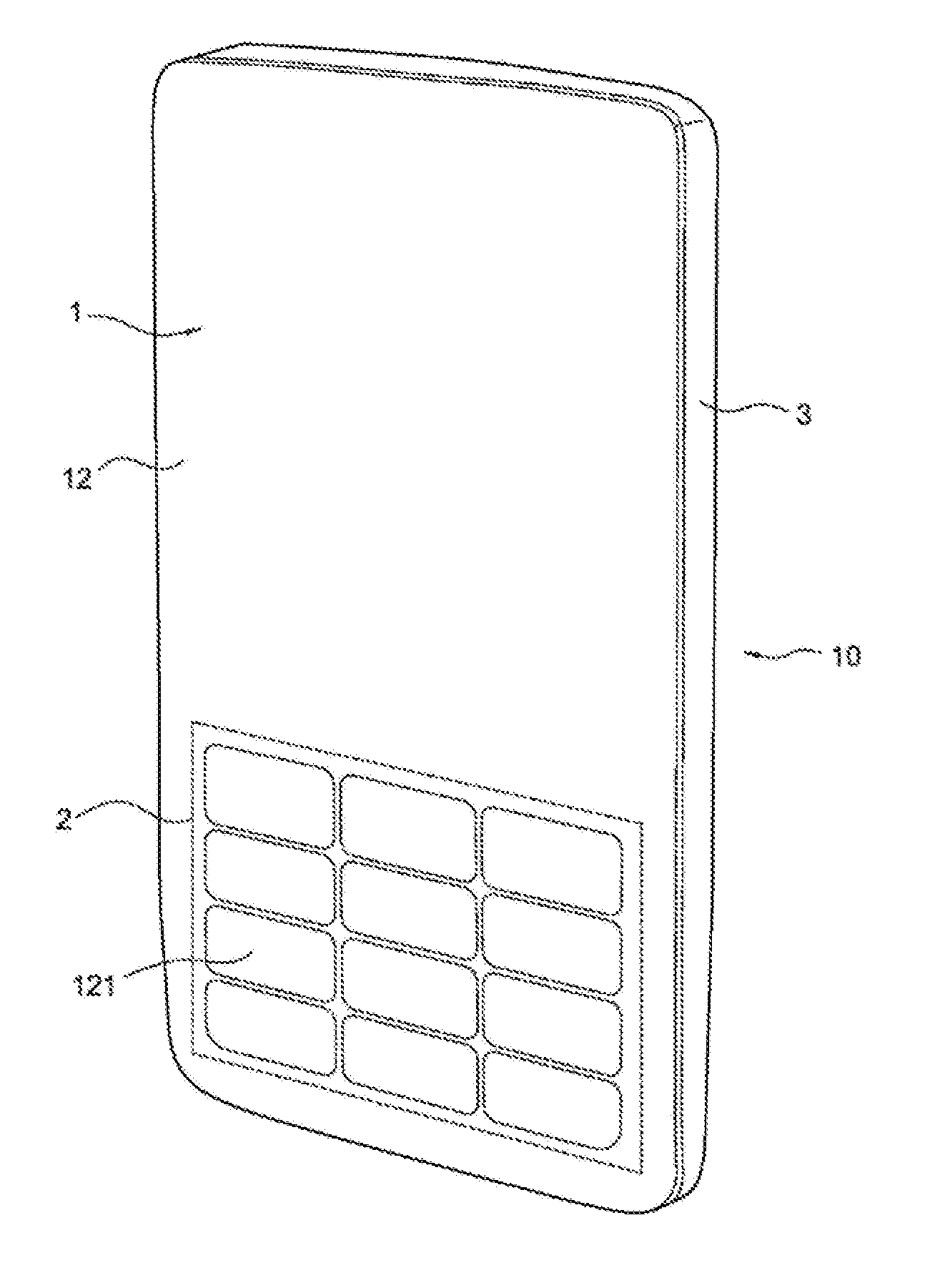

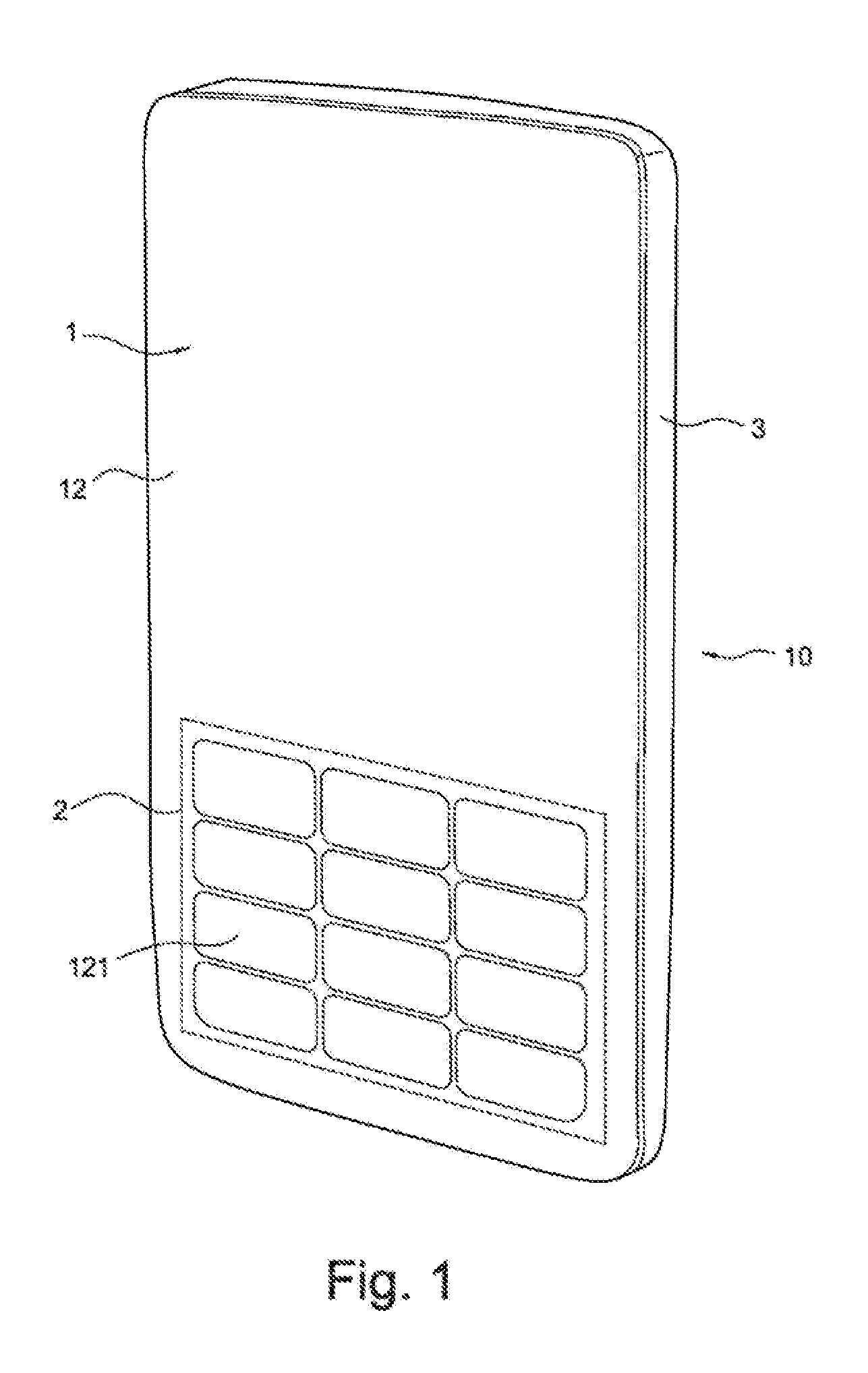

In-mould molding touch module and method for manufacturing the same

ActiveUS20090101489A1Thin thicknessEliminate ThicknessCasings with display/control unitsElectronic switchingEngineeringPlastic film

An in-mould molding touch module includes a plastic film, a touch circuit and a molding rind. The plastic film includes an inner surface and an outer surface for handling and touching. At least one region of the inner surface and a corresponding region of the outer surface define a touch area. The touch circuit is arranged on the inner surface in the touch area. The molding rind is integrated on the inner surface by an in-mould injecting mode to contain the touch circuit for forming a one-piece body. In addition, the invention also provides a method for manufacturing an in-mould molding touch module.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

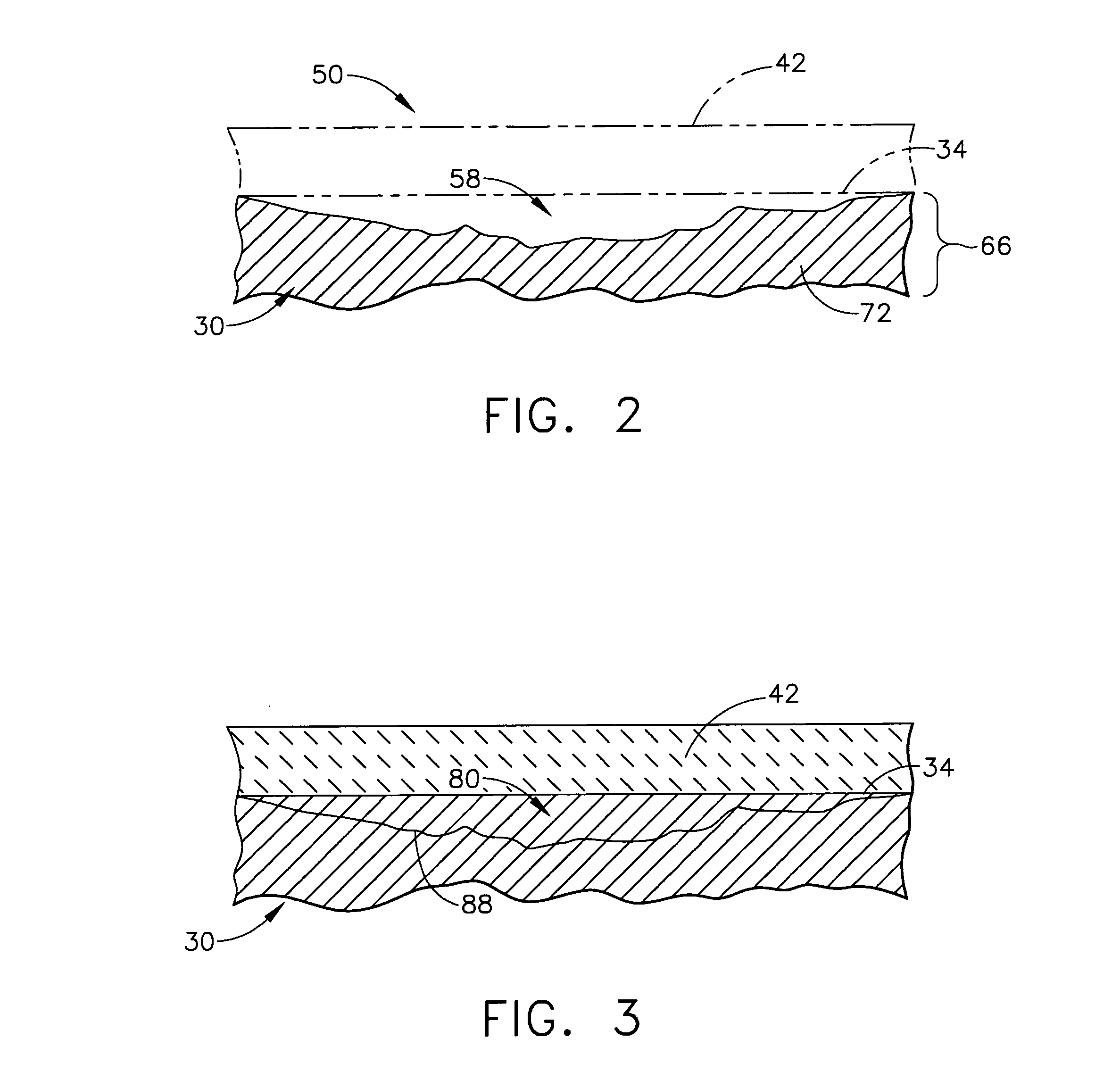

Method for restoring portion of turbine component

InactiveUS20070039176A1Eliminate ThicknessEffectively restore the removed wall thickness of the repaired airfoilBlade accessoriesMachines/enginesTurbineMaterials science

A method for restoring a removed portion of the airfoil wall of a turbine component. This method comprises the following steps: (a) providing a turbine component comprising an airfoil having a metal substrate with a wall thickness, wherein a portion of the wall thickness has been removed so as to provide a residual wall thickness; (b) providing a metal composition that at least substantially matches that of the residual wall thickness; and (c) applying the metal composition to the residual wall thickness such that the metal composition: (1) is adhered to the residual wall thickness; and (2) at least substantially restores the removed wall thickness. Also provided is a method for restoring a removed portion of the airfoil wall of a previously repaired turbine component.

Owner:GENERAL ELECTRIC CO

Method for implanting a piezoelectric material

ActiveUS20130111719A1Eliminate ThicknessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksMetalElectrical contacts

A method of producing a structure made of a piezoelectric material, including: a) production of a stack including at least one metal layer and at least one conductive layer on a substrate made of piezoelectric material, wherein at least one electrical contact is established between the conductive layer and a metal element outside the stack; b) an ionic and / or atomic implantation, through the conductive layer and the metal layer; c) transfer of the substrate onto a transfer substrate, followed by fracturing of the transferred piezoelectric substrate, in an embrittlement area.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

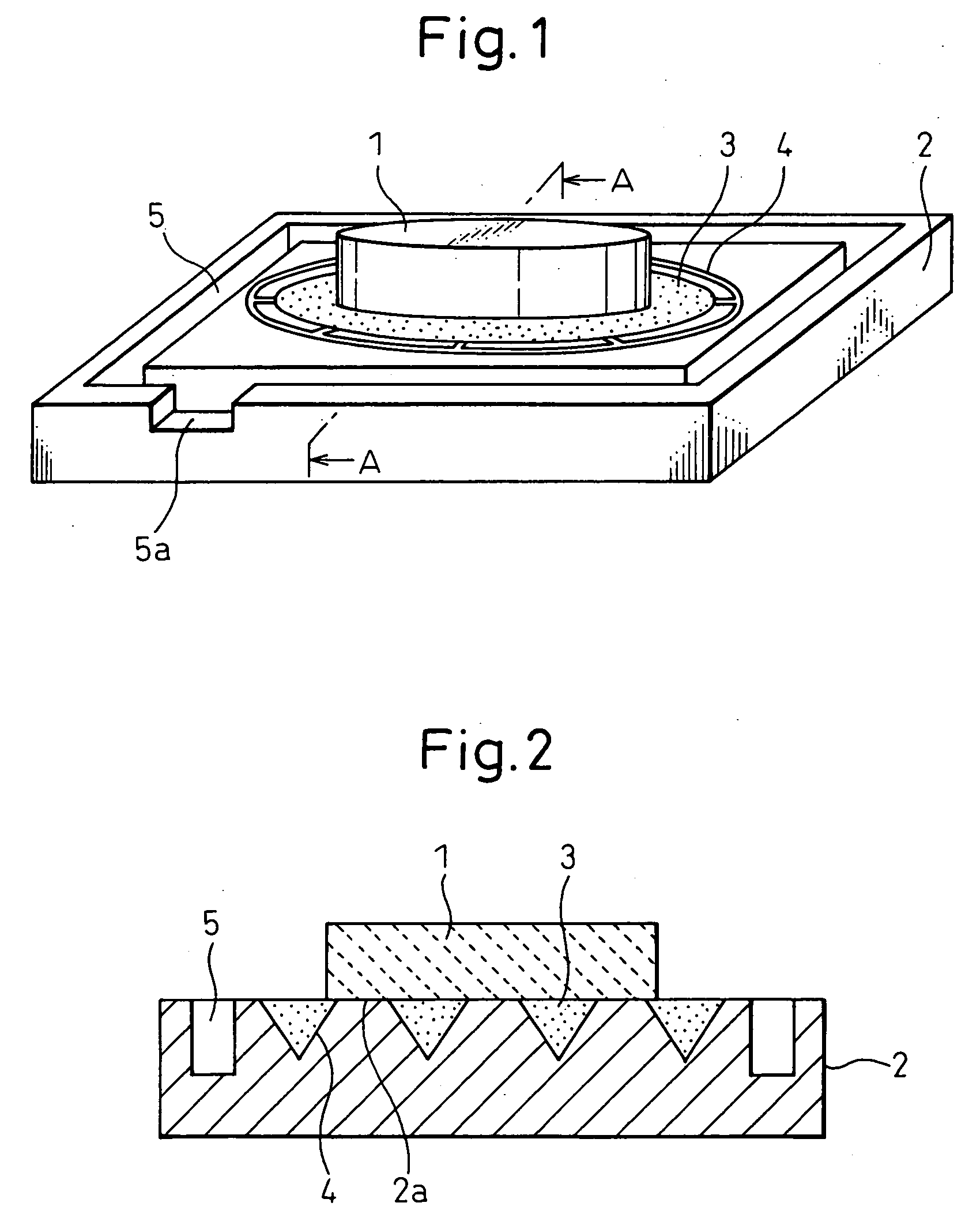

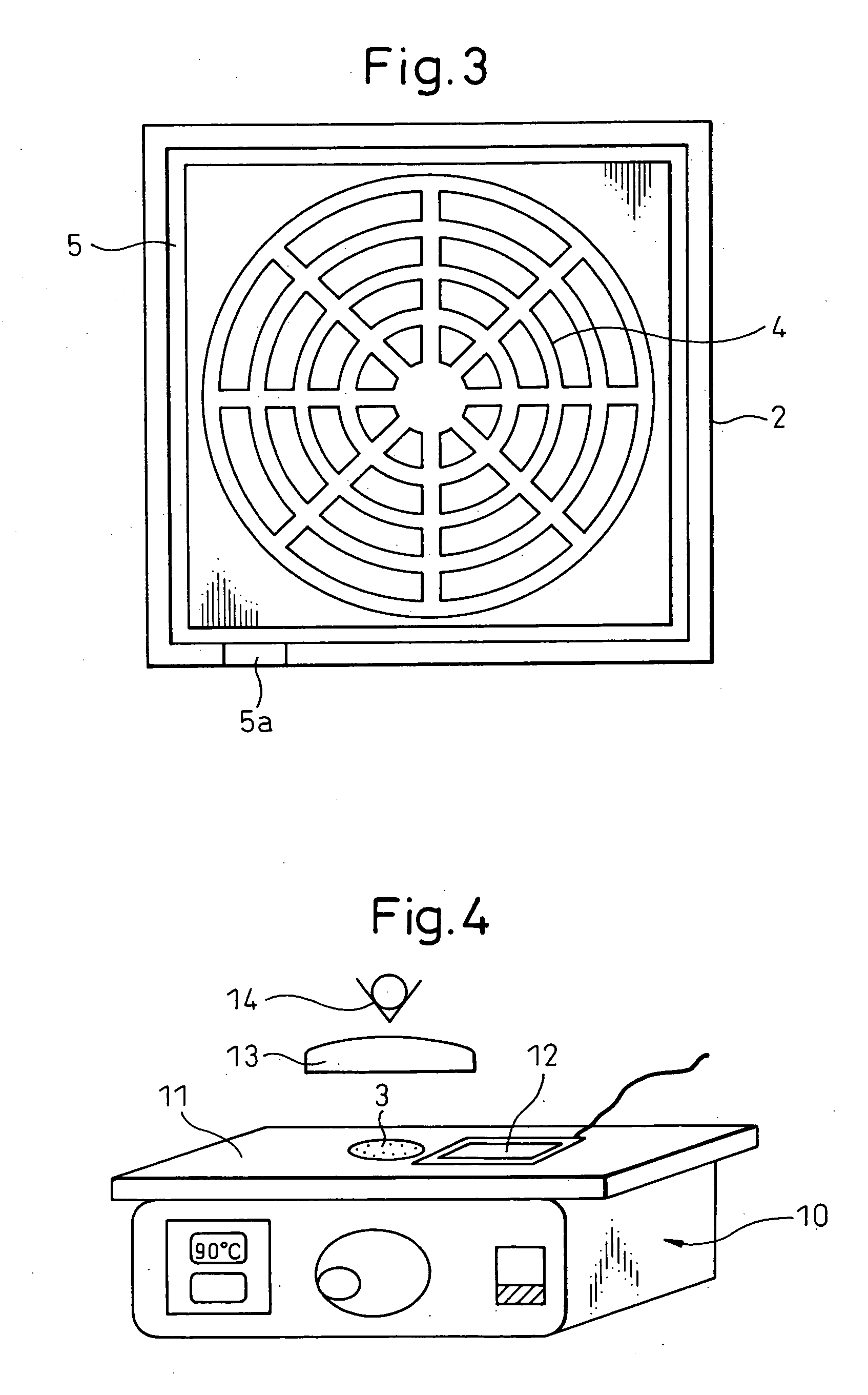

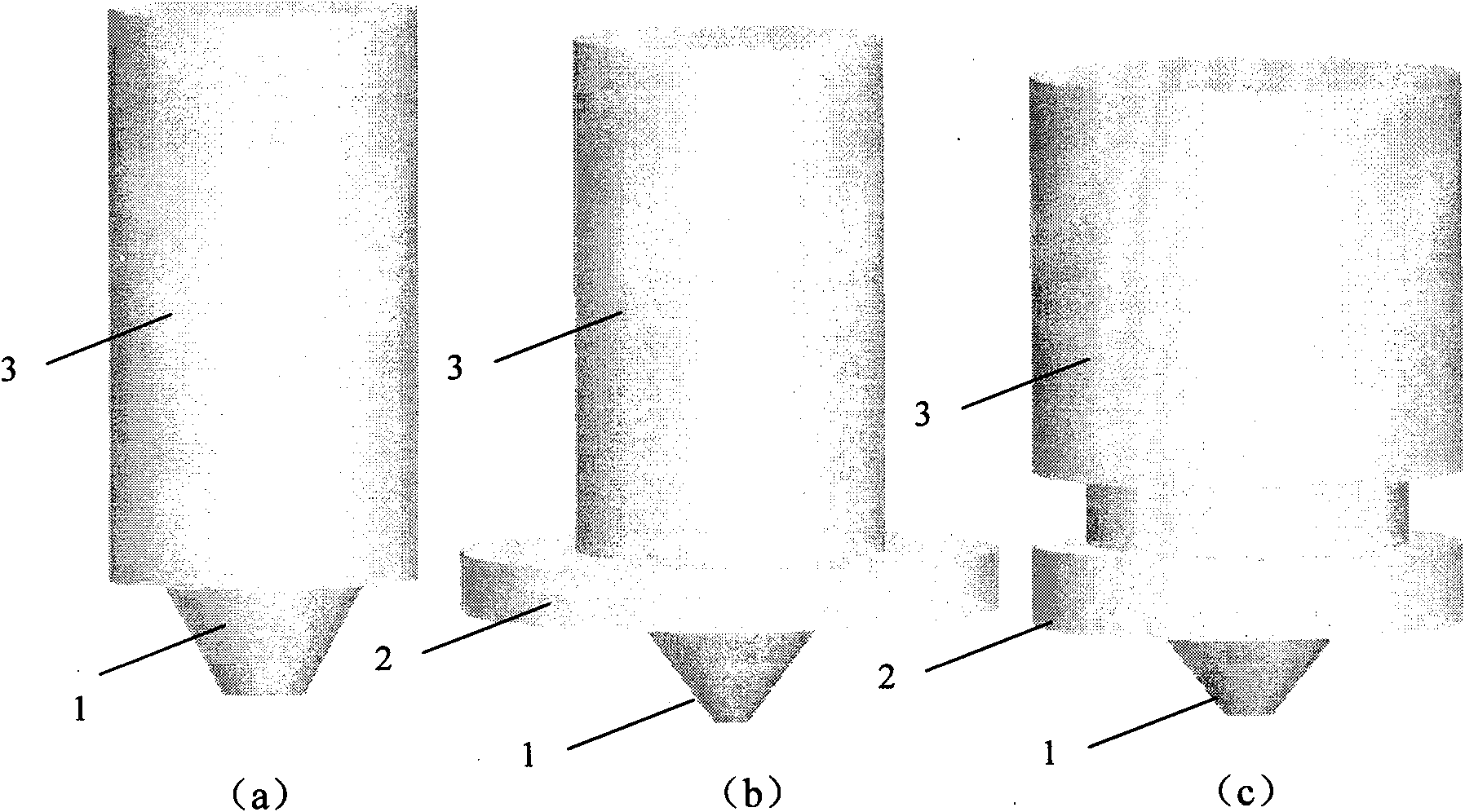

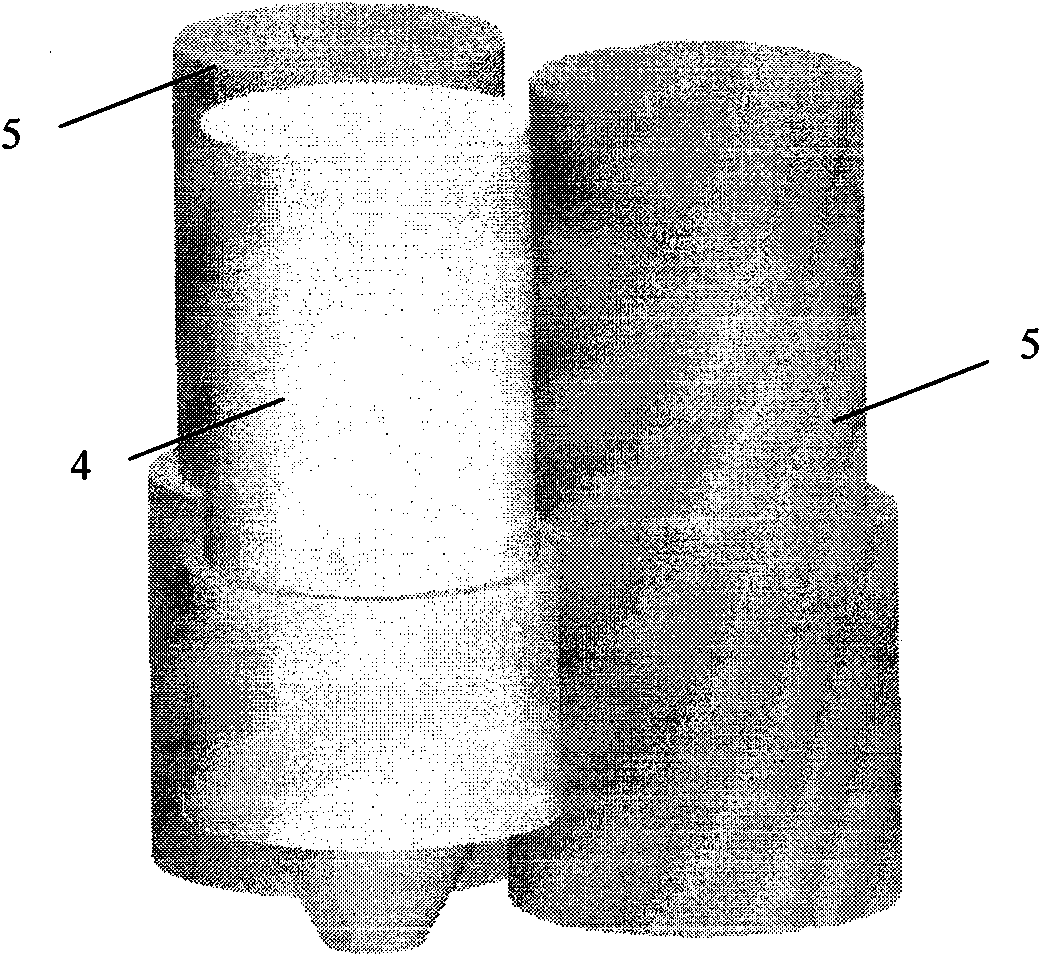

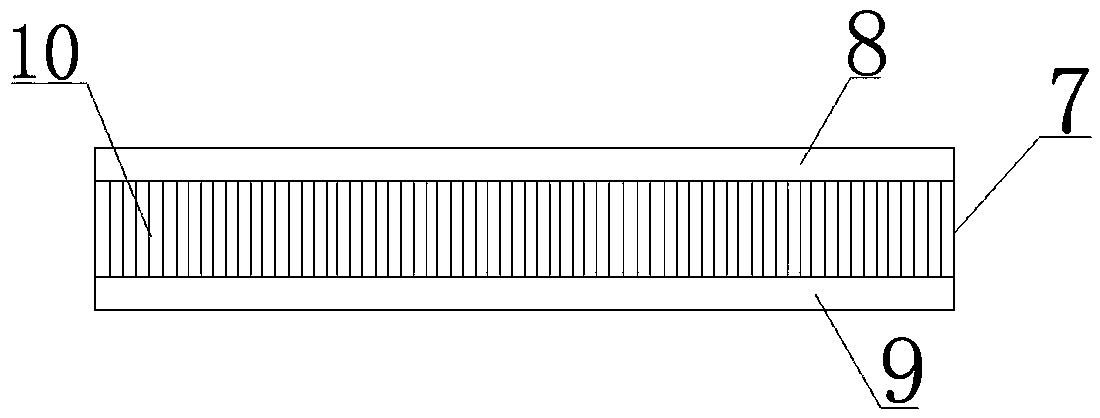

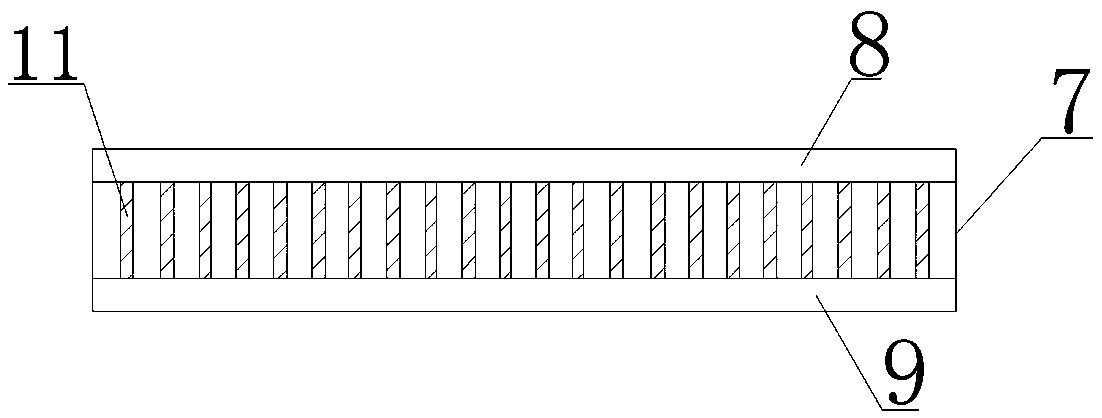

Fusion/coagulation work fixing agent and machining method using the same

InactiveUS20050269022A1Improve workabilityImprove parallelismLamination ancillary operationsOptical surface grinding machinesEngineeringMachining

A fusion / coagulation work fixing agent and a machining method are disclosed. The workability of the machining method is improved using the fusion / coagulation work fixing agent (3) which utilizes the fusion and coagulation of itself to fix a work (1). The difference between the fusion start temperature and the fusion end temperature of the fusion / coagulation work fixing agent (3) is not more than 2° C.

Owner:DENSO CORP

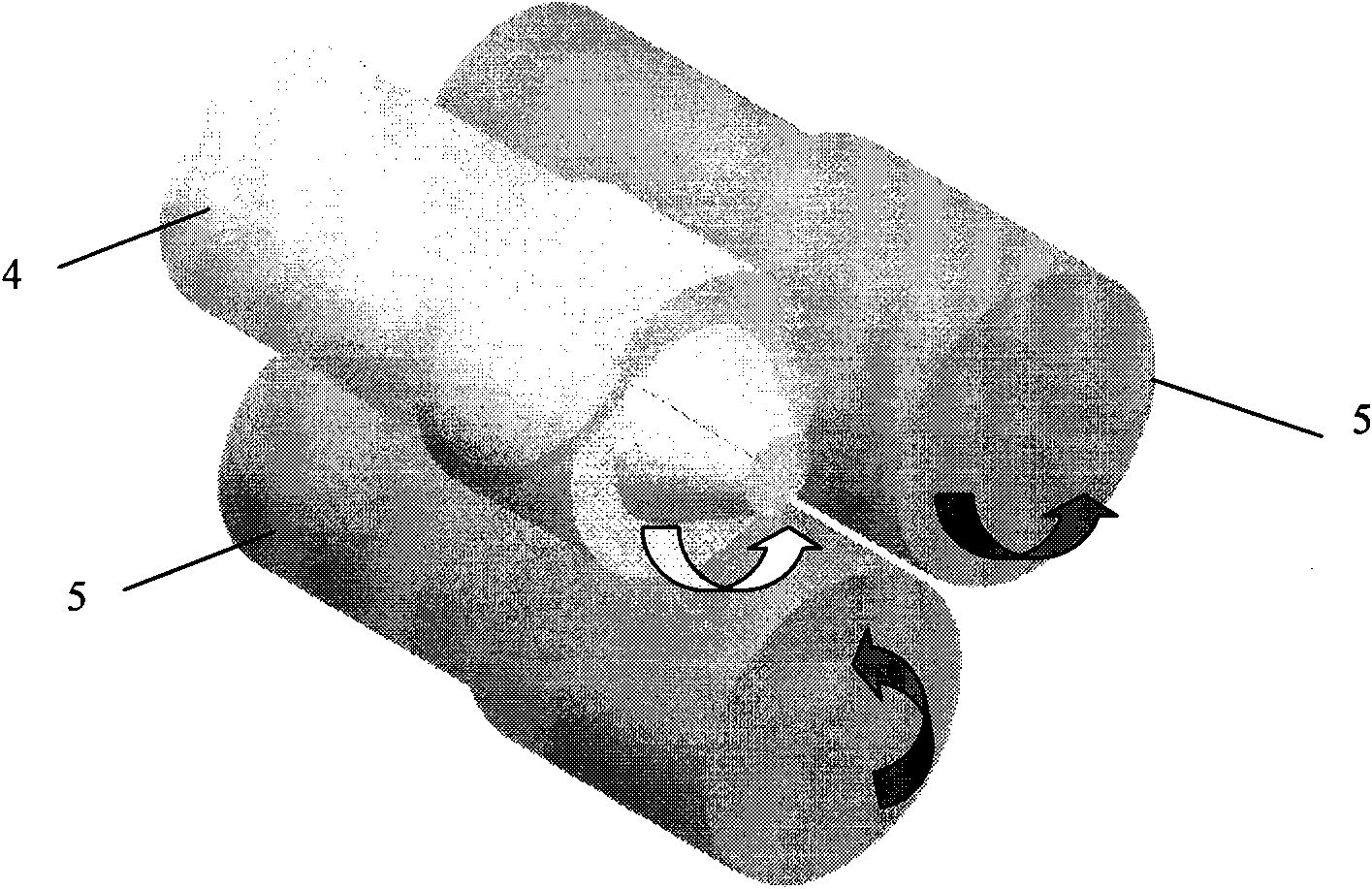

Multi-legged friction-stir welding method for improving properties of welding seam

InactiveCN101559534AUniform transitionEliminate thickness differencesNon-electric welding apparatusStress concentrationEngineering

The invention discloses a multi-legged friction-stir welding method for improving properties of a welding seam. After the welding seam is formed by stir welding by a front stirring head, the welding seam and a mother plate are rotated and squeezed by a back stirring head. The multi-legged stirring head can not only ensure smooth welding process, but also carry out rotation and squeeze to the welding seam, and smooth transition is realized between the welding seam and the mother plate so as to reduce stress concentration to the lowest or even zero. By adopting the multi-legged stirring head, smooth transition can be realized between the welding seam and the mother plate, thus eliminating the thickness difference which is peculiar to FSW.

Owner:UNIV OF SCI & TECH BEIJING

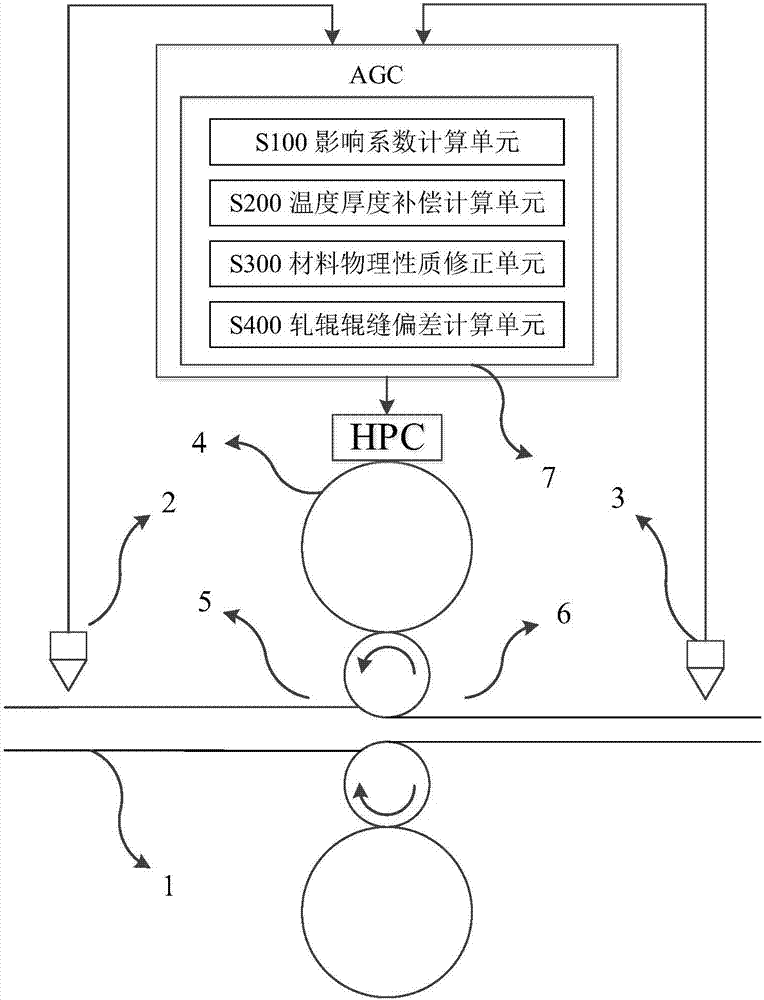

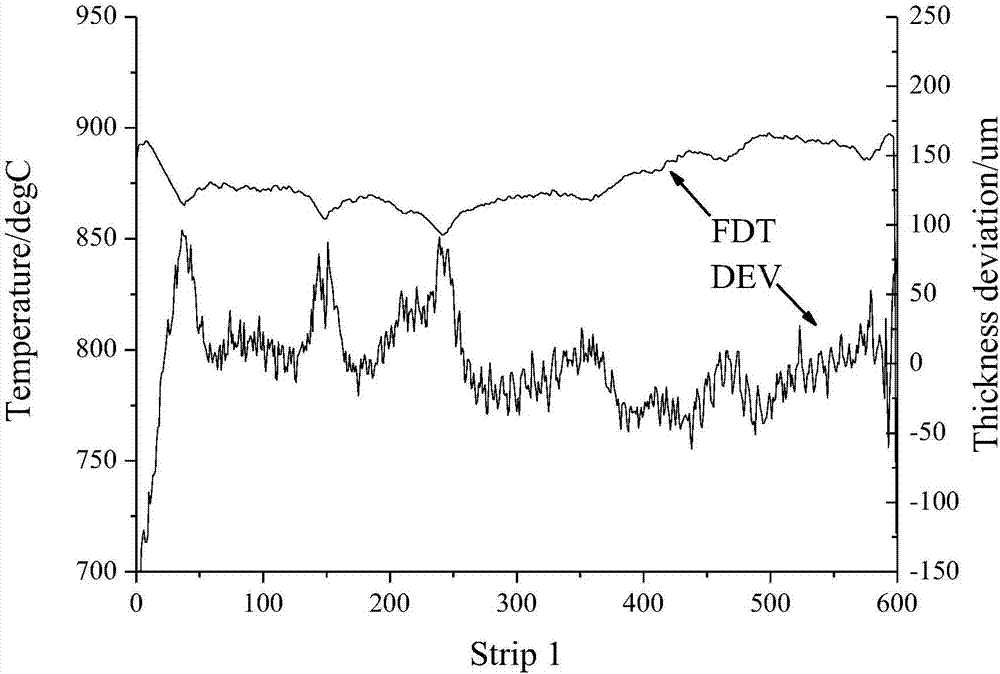

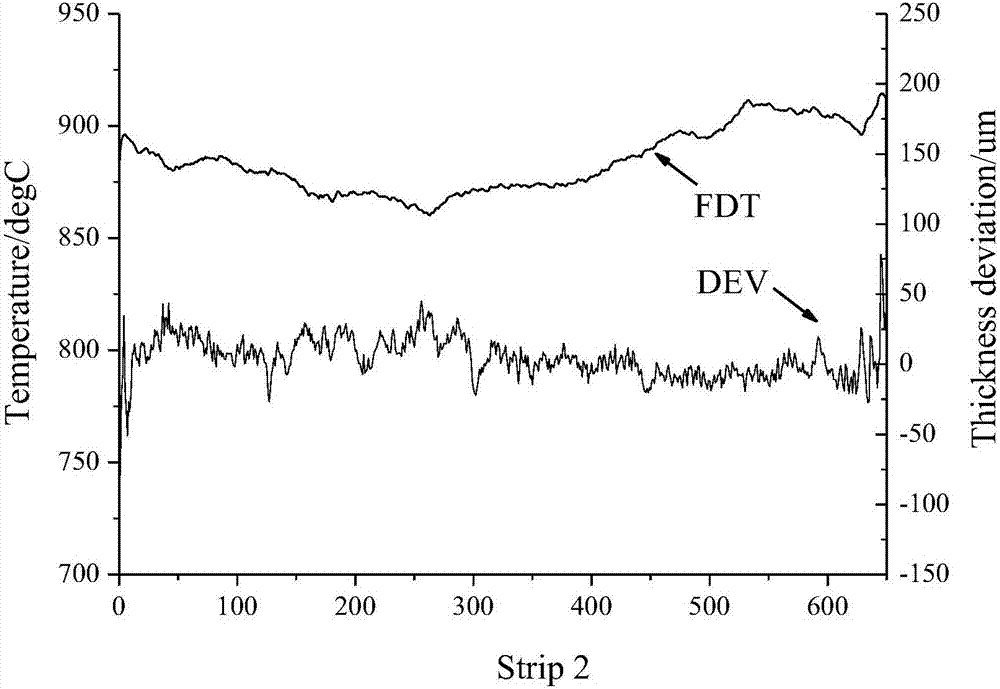

Online control system capable of improving rolled piece thickness control precision

ActiveCN106984651AImprove thickness control accuracyEliminate ThicknessRoll mill control devicesMetal rolling arrangementsControl systemMachining

The invention provides an online control system capable of improving the rolled piece thickness control precision. According to the system, a rolling mill rack inlet side rolled piece temperature measuring device and a rolling mill outlet side rolled piece thickness measuring device are used for carrying out compensation calculation on a roller gap in real time, specifically, according to measured data of the rolled piece temperature measuring device and the rolled piece thickness measuring device, the influence coefficient of the rolled piece plastic machining temperature relative to the rolled piece thickness changes is calculated, and therefore the increasing and decreasing value, generated by temperature changes of a rolled piece, of the rolling mill outlet side rolled piece thickness is calculated; meanwhile, the material physical property correction value is used for compensating for the influence of the machining temperature on the rolled piece physical property, and through the roller gap deviation calculation result, the roller gap is subject to real-time compensation control; the problem that due to rolled piece plastic machining temperature unevenness, the thickness control precision is poor is solved, and the thickness control precision of different thickness specifications can be improved by 2% or above.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

In-mould molding touch module and method for manufacturing the same

InactiveUS20090090000A1High transparencyImprove heat resistancePrinted circuit assemblingCasings with display/control unitsTouch SensesEngineering

An in-mould molding touch module includes a transparent conducting substrate and a molding rind. The transparent conducting substrate has an inner surface and an outer surface. The inner surface has a capacitive electrode layer formed thereon. The capacitive electrode layer is a touch sense circuit made of ITO, and the outer surface is configured for touching the touch sense circuit. The molding rind is integrated to contain a periphery of the transparent conducting substrate by an in-mould injecting mode.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Aircraft seat back assembly

ActiveUS9580175B2Easy to combineIncrease spacingSeating arrangementsWeight reductionElastomerBack rests

The seat back portion of a passenger aircraft seat is built of an elastomer mesh type diaphragm without conventional cushions or dress covers, in order to maximize space available to the passenger while reducing costs and weight. The diaphragm is attached and tensioned into a structural frame, which also supports a slide-in rear shroud closeout. The frame is designed to remain exposed, showing a decorative finish.

Owner:FRANKLIN PRODS

Semiconductor device, method of manufacturing the same, cover for semiconductor device, and electronic equipment

InactiveUS20050255627A1Eliminate ThicknessHigh precisionTelevision system detailsSemiconductor/solid-state device detailsDevice materialAdhesive

A method of manufacturing a semiconductor device includes (a) fixing a cover onto a semiconductor substrate so as to place a surface of the cover that includes a portion defining a first opening, face to face on a surface of the semiconductor substrate that includes an electrode and (b) applying an adhesive to the inside of the first opening.

Owner:SEIKO EPSON CORP

In-mold moulding touch control module group and producing method thereof

ActiveCN101414235AEasy to implementImprove the efficiency of automated productionPhotomechanical apparatusInput/output processes for data processingIndium tin oxideEngineering

The invention discloses an in-mold forming touch control module comprising a perspective conductive carrier board and a molded shell body, a capacitive electrode layer which is a touch control sensing circuit made from indium tin oxide is arranged on one inner surface of the carrier board, the sensing circuit can be touched by one outer surface of the carrier board, and the shell body is coated and combined at the peripheral edges of the carrier board. The invention also comprises a production method of the in-mold forming touch control module, comprising the steps: the indium tin oxide is coated on the inner surface of the carrier board, the sensing circuit is formed by processing; the carrier board is arranged in a mold cavity, and molding material is injected in the mold cavity to form the molded shell body which is integratedly coated and combined at the peripheral edges of the carrier board, thereby improving the touch control sensitivity of the module and simplifying the process. The in-mold forming touch control module and the production method are conductive to the simple implementation in the environment of an injection molding machine which is provided with automatic loading and unloading devices and further conductive to enhancing the effectiveness of automatic production, compared with the prior art which adopts the layer iteration adhesion mode, the production method can effectively simplify the production process and reduce the working time and the cost.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

CMOS image sensor and method for fabricating the same

ActiveUS7341885B2Good imaging propertiesEliminate ThicknessSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A CMOS image sensor and method for fabricating the same improve image characteristics by eliminating the thickness of a planarization layer. The CMOS image sensor includes a semiconductor substrate; a plurality of active devices, provided in a predetermined surface of the semiconductor substrate, for generating electrical charges according to an amount of incident light; an insulating interlayer formed on an entire surface of the semiconductor substrate including the plurality of active devices; a color filter layer formed on the insulating interlayer, the color filter layer comprised of red, green, and blue color filter patterns for respectively filtering light according to wavelength, the color filter patterns arranged to correspond to the plurality of active devices; and a plurality of microlenses formed on the color filter layer, wherein the color filter layer is planarized so that each color filter pattern of the color filter layer is imparted with an equal height for receiving the plurality of microlenses.

Owner:CONVERSANT INTPROP MANAGEMENT INC

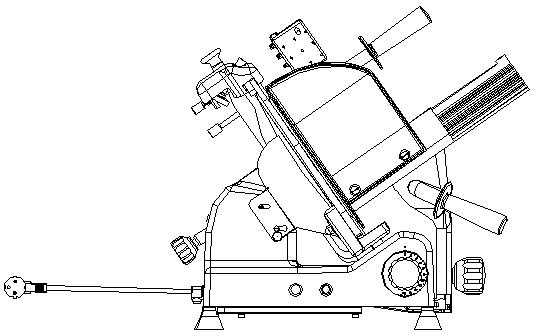

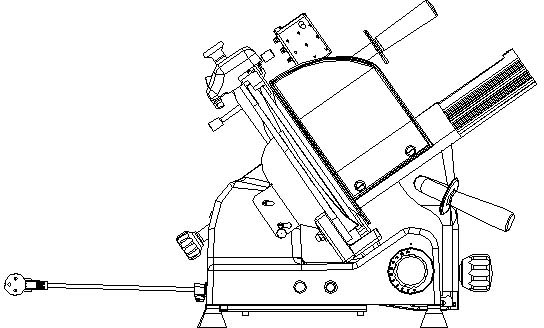

Thickness adjusting device of slicing machine

The invention discloses a thickness adjusting device for a slicing machine, which comprises a handle, a graduated disk, a sizing plate slide, a transmission mechanism and a gap elimination mechanism. The transmission mechanism comprises a gear shaft, a rack and a nut. One end of the gear shaft is connected with the handle in a threaded mode, the toothed end of the gear shaft is meshed with the rack in such way that the graduated disk sleeved on the nut is tightly pressed on the inner end face of the handle through the nut, and the rack is fixed on the sizing plate slide through a fastening screw. The gap elimination mechanism is sleeved on the gear shaft and comprises an eccentric sleeve, an eccentric sleeve screw and a spring. The eccentric sleeve mounted on a top is sleeved in the middle of the gear shaft and fastened through the eccentric sleeve screw, and the spring is sleeved on the gear shaft and tightly pressed to the right end face of the eccentric sleeve. Thickness adjustment is achieved by the aid of the gear shaft and the rack, the eccentric sleeve is used to adjust a gap between a gear and the rack generated due to machining errors, the spring is used to eliminate backlashes among teeth, and accordingly, the actual thickness of each slice is consistent to gradation of the graduated disk.

Owner:ANHUI HUALING KITCHEN EQUIP

In-mould molding touch module and method for manufacturing the same

ActiveUS20110186422A1Thin thicknessEliminate ThicknessCasings with display/control unitsVacuum evaporation coatingThin membranePlastic film

An in-mould molding touch module includes a plastic film, a touch circuit and a molding rind. The plastic film includes an inner surface and an outer surface for handling and touching. At least one region of the inner surface and a corresponding region of the outer surface define a touch area. The touch circuit is arranged on the inner surface in the touch area. The molding rind is integrated on the inner surface by an in-mould injecting mode to contain the touch circuit for forming a one-piece body. In addition, the invention also provides a method for manufacturing an in-mould molding touch module.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

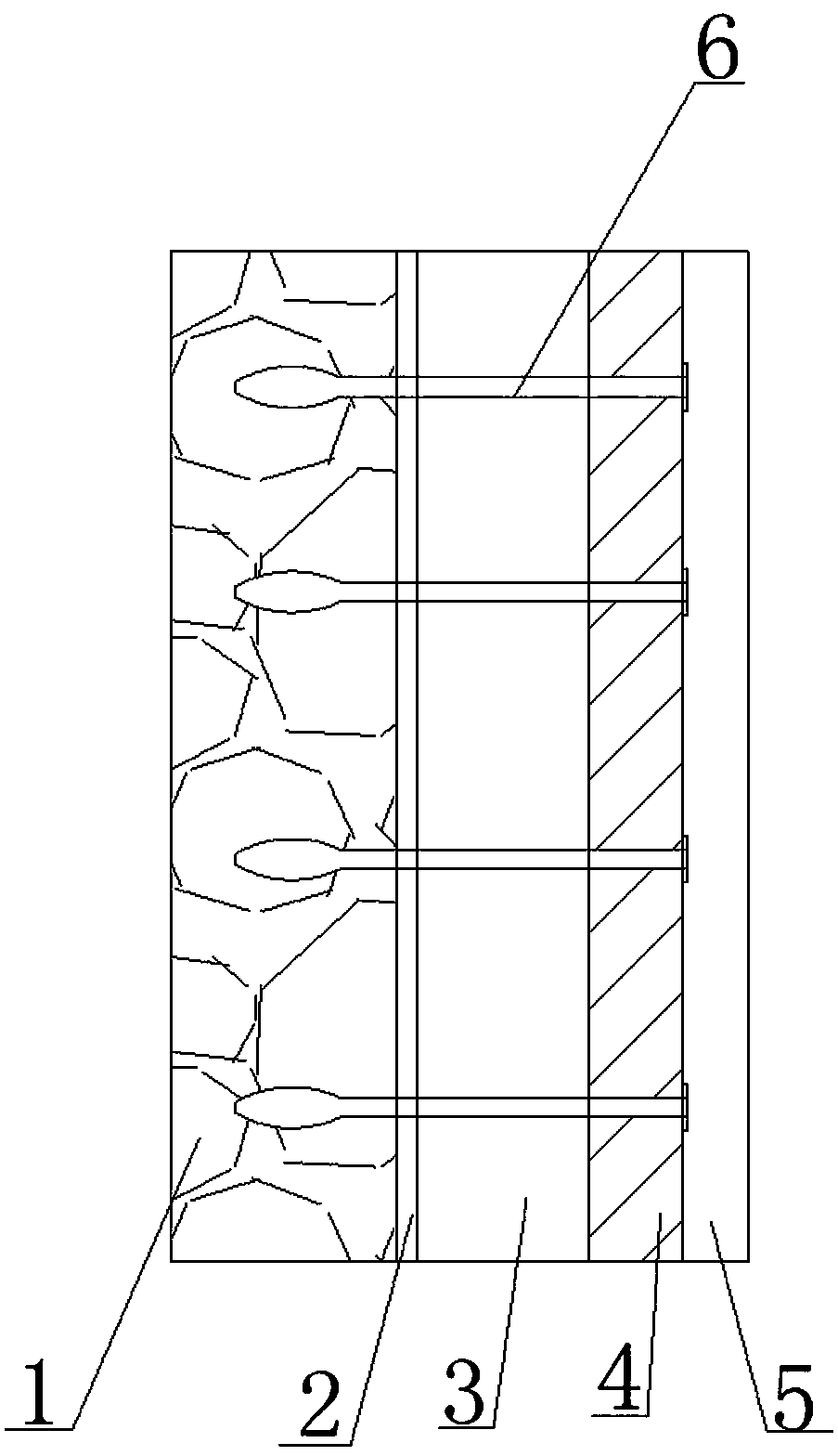

Lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof

PendingCN110258867AReduce manual labor intensityEnhanced deformation stressWallsClimate change adaptationInsulation layerManufacturing technology

The invention belongs to a lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof. The lightweight dismantle-free heat insulation template integrated composite heat insulation system comprises a cast-in-place concrete base wall body, a heat insulation template inner protective layer, an organic heat insulation material layer, seamed reinforced glass wool or a rock wool board inorganic material insulation layer, and a polymer mortar layer are sequentially arranged on the outer side of the cast-in-place concrete base wall body, and are fixedly mounted and connected with the cast-in-place concrete base wall body through pre-embedded anchoring connecting parts, and the outer surface of the seamed reinforced glass wool or the rock wool board inorganic material insulation layer is coated with the polymer mortar layer. The lightweight dismantle-free heat insulation template integrated composite heat insulation system has the advantages that structure design is reasonable, the lightweight, high intensity and low heat conductivity performance are achieved, the comprehensive cost can be lowered, the load of buildings is relieved, the whole thickness of the mortar layer on the outer surface of the wall body is advantageously controlled, and the safety of anti-cracking, anti-falling-off and anti-fire is improved.

Owner:河南省澳科保温节能材料技术开发有限公司

Ellipsoidal anisotropy friction simple pendulum support

InactiveCN111021238AHigh design strengthIncreased durabilityBridge structural detailsProtective buildings/sheltersEngineeringMechanical engineering

The invention discloses an ellipsoidal anisotropy friction simple pendulum support which comprises an upper base plate the top surface of which is a plane and the bottom surface of the which is an ellipsoidal concave surface; a lower base plate the bottom surface of which is a plane and the top surface of which is a concave spherical curved surface; a hinge sliding block arranged between the upperbase plate and the lower base plate, wherein the top surface of the hinge sliding block is an ellipsoidal convex surface matched with the ellipsoidal concave surface, and the bottom surface of the hinge sliding block is a convex spherical curved surface matched with the concave spherical curved surface. According to the ellipsoidal anisotropy friction simple pendulum support, the lower portion ofthe hinge sliding block and a groove in the upper portion of the lower base plate are spherical surfaces, and the hinge sliding block rotates in any horizontal direction through the spherical surfaces; a vertical rotating gap is formed between the hinged sliding block and a groove in the upper portion of the lower base plate, vertical rotation of the hinged sliding block is achieved when the upper base plate of the support swings horizontally, then anisotropic seismic mitigation and absorption design in the longitudinal and transverse bridge directions of a bridge is achieved, and the performance of the support is good under a rapid shearing friction test with the speed larger than or equal to 500 mm / s.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT +1

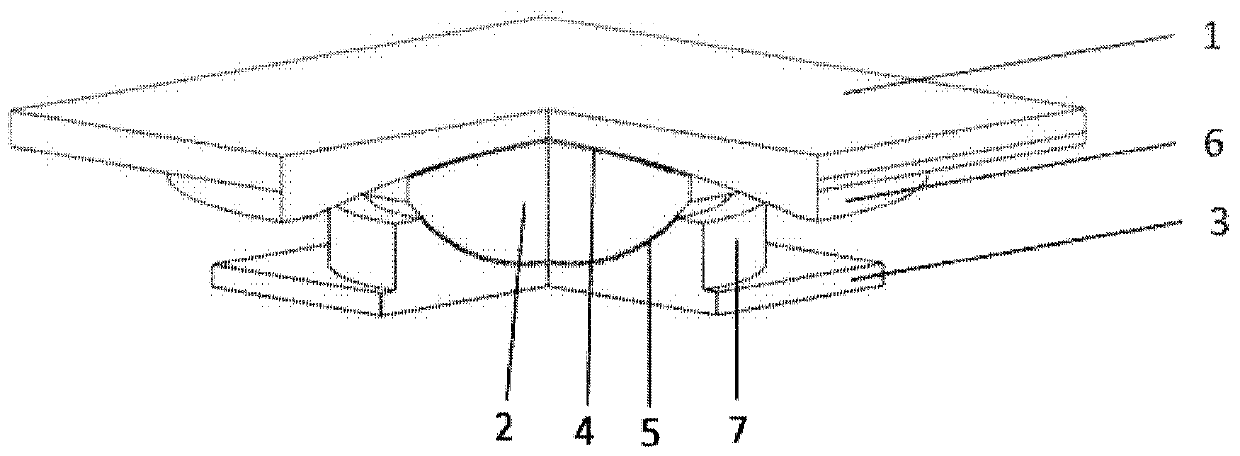

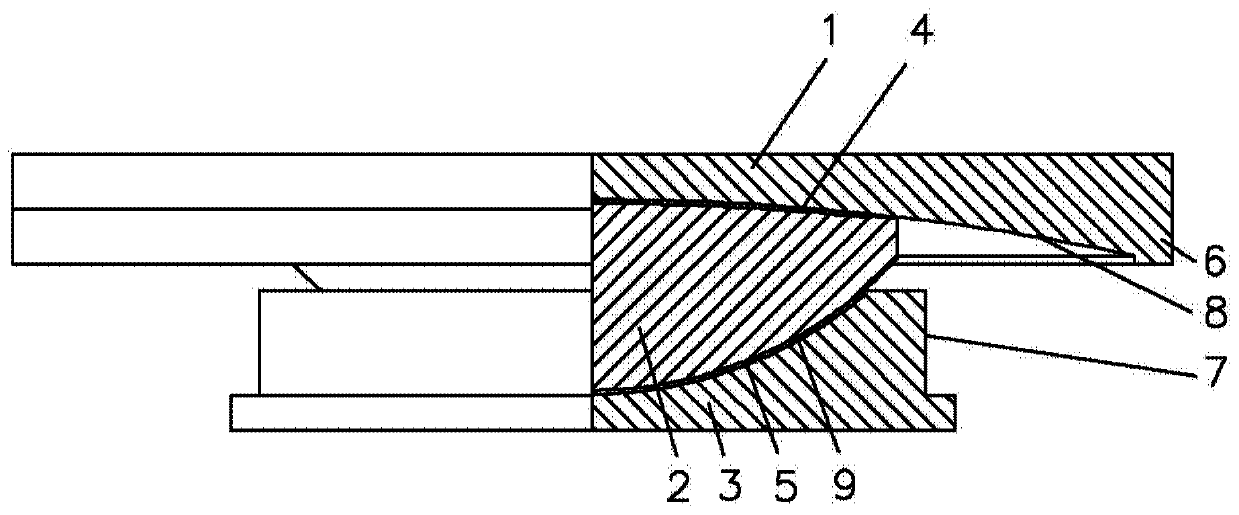

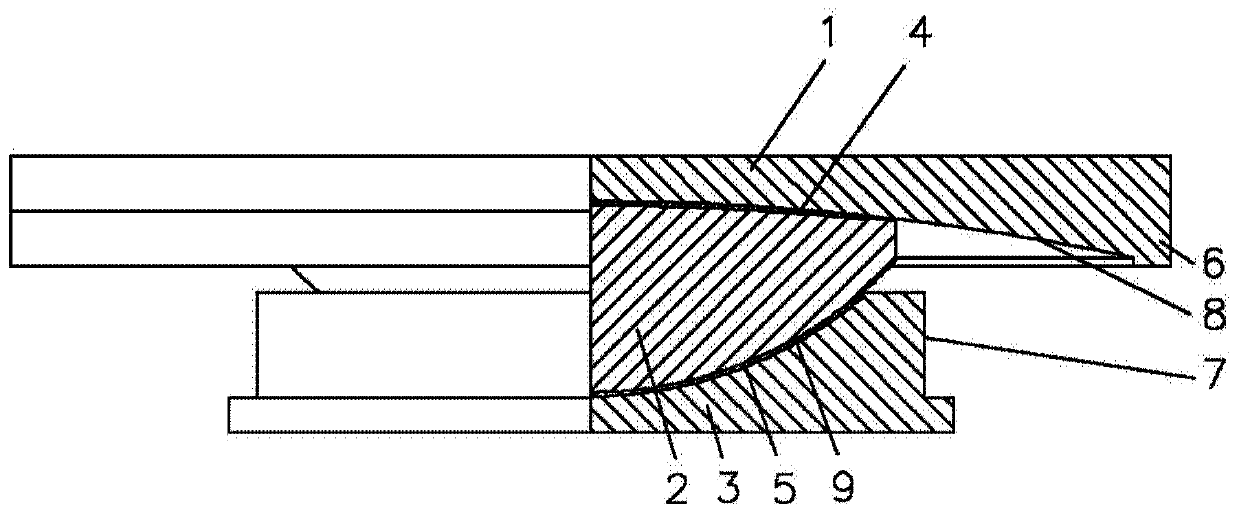

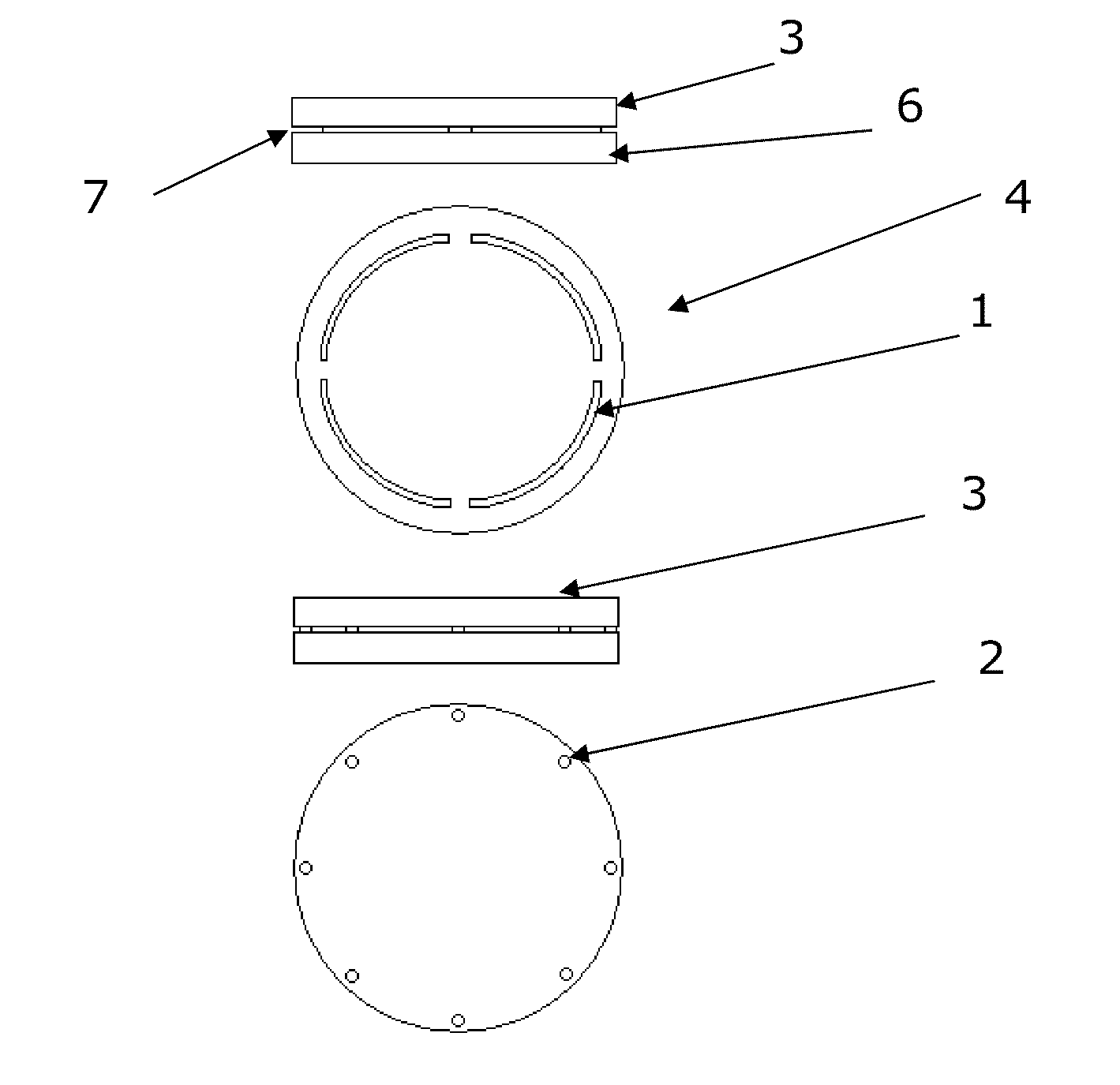

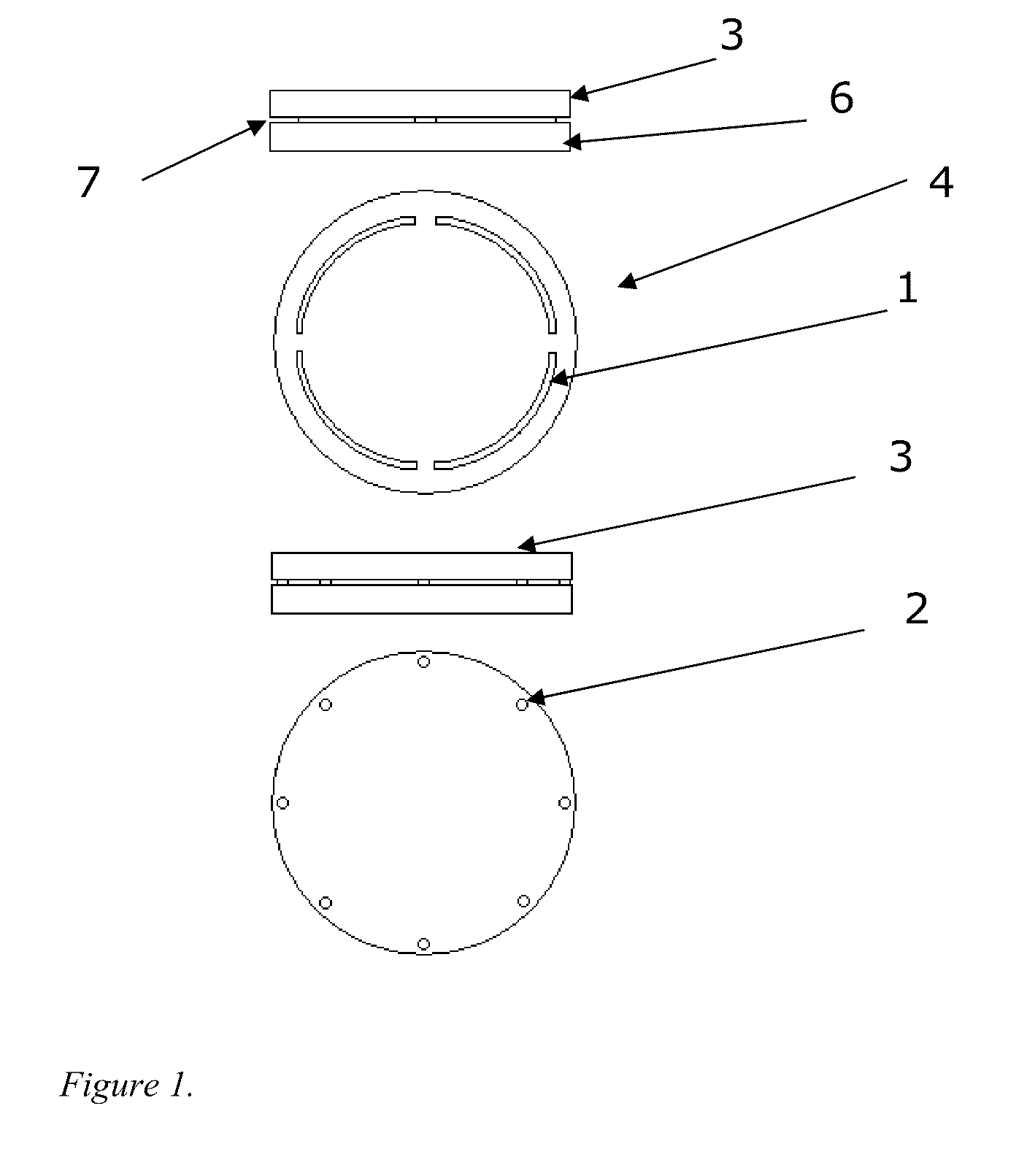

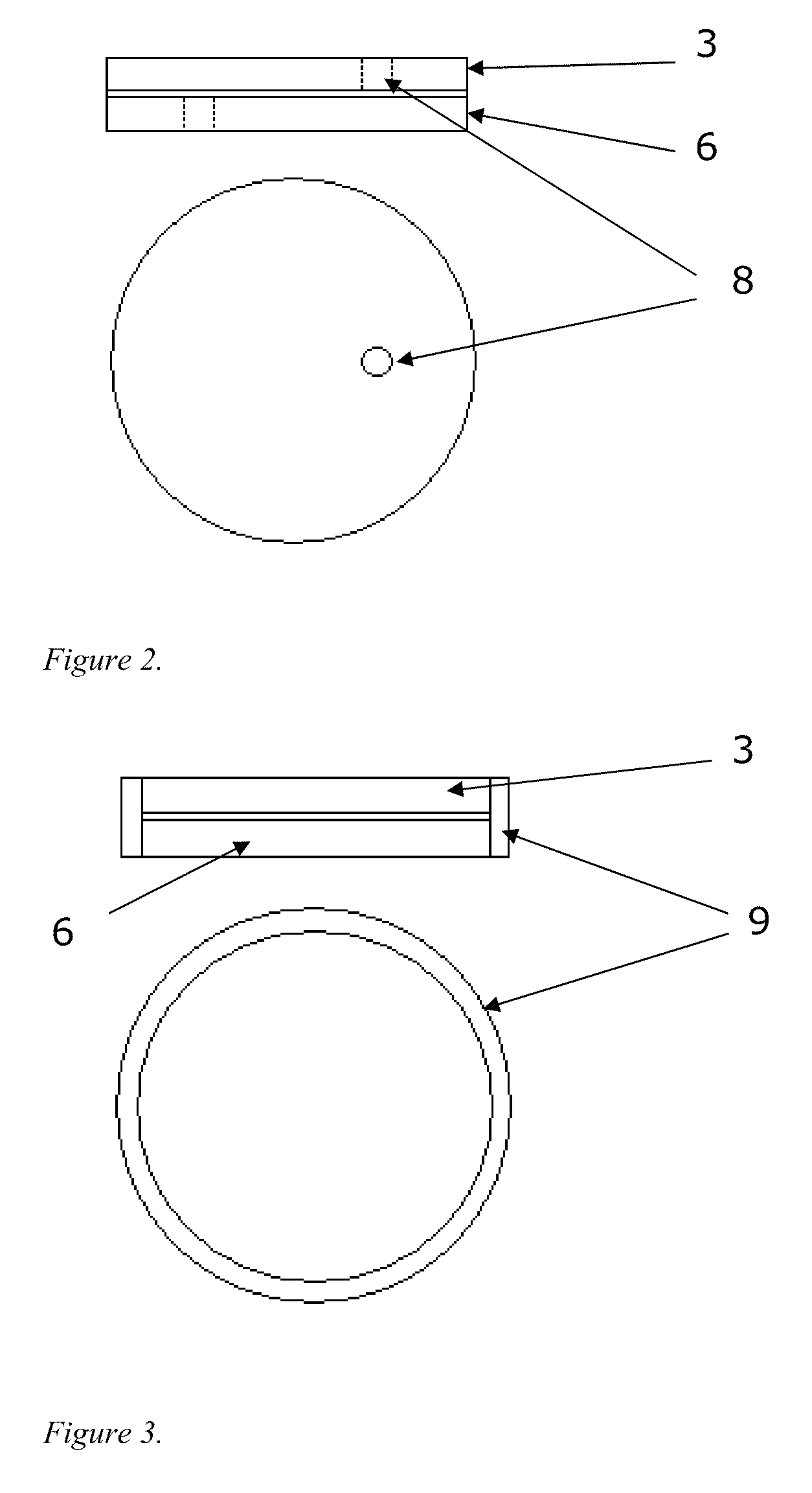

Cell for confinement of very small volumes of soft matter and fluids

InactiveUS20100139420A1Eliminate structureEliminate ThicknessMaterial nanotechnologyMaterial analysis by optical meansNanobatteriesNanocell

The present invention relates to a nanocell, and method for manufacturing same, for holding small volumes of soft matter confined in a gap of order 1 micrometer or smaller and measurement systems using the same. The nanocell comprise:a first structure (3) with a substantially flat surface in one direction;a second structure (6) with a substantially flat surface in one direction; andat least one spacer (1, 2);wherein said substantially flat surface of each first and second structure face each other and are separated by the at least one spacer and the two surfaces and the spacer together define a volume (7) between them for holding said soft matter or fluid, and the distance defined by the spacer between said surfaces of the first and second structure is less than 1 micrometer; the volume between the surfaces of the first and second structures and the spacer is in the range between 1 femto liters and 1 micro liters.

Owner:OHLSSON GABRIEL JOHN SIMON +3

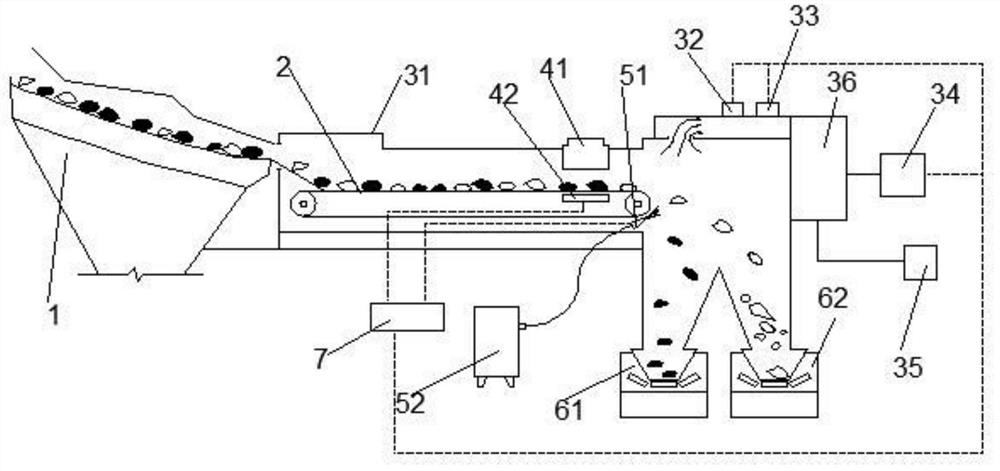

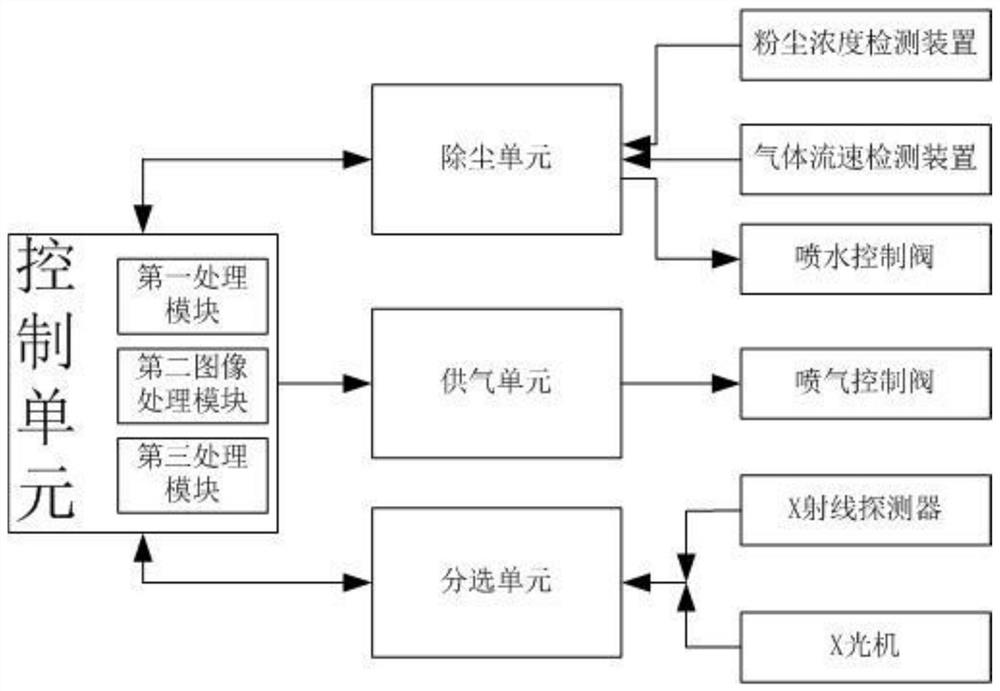

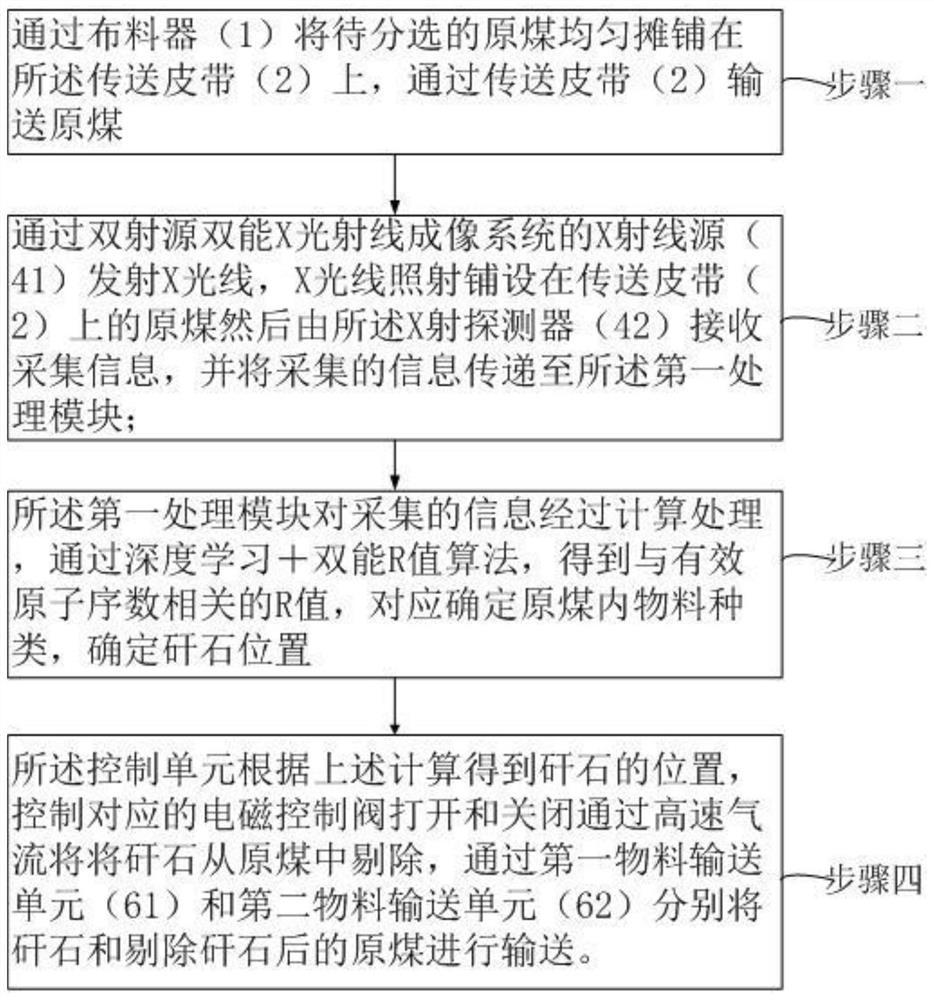

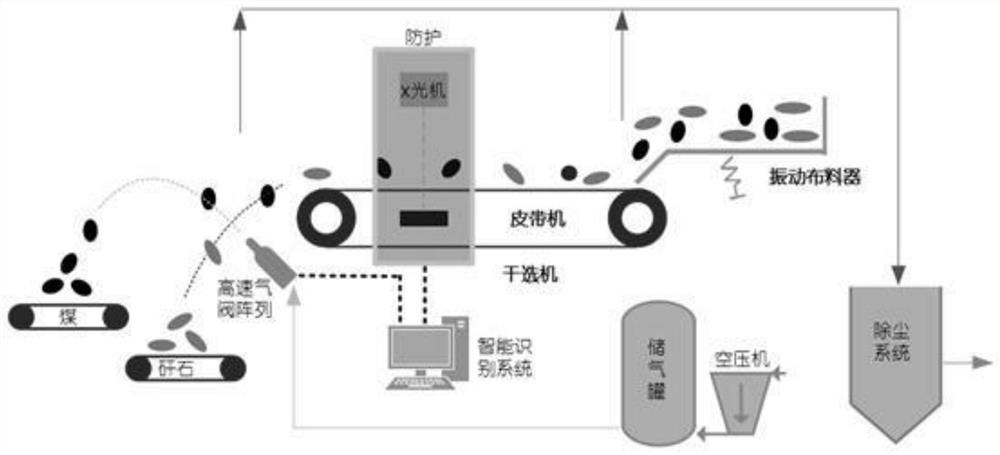

Intelligent mining coal gangue sorting device and recognition method thereof

ActiveCN113941515AImprove sorting performanceConserve waterSolid waste managementUsing liquid separation agentCoal gangueProcess engineering

The invention provides an intelligent mining coal gangue sorting device which comprises a distributing device, a conveying belt and at least two distributing conveying belts arranged at the tail end of the conveying belt. The intelligent mining coal gangue sorting device is characterized by further comprising a control system, a dual-radiation-source dual-energy X-ray system arranged on the conveying belt, a high-precision air valve removing system, a first material conveying unit and a second material conveying unit, wherein the high-precision air valve removing system, the first material conveying unit and the second material conveying unit are arranged at the discharging end of the conveying belt, the control system comprises a first processing module connected with the dual-radiation-source dual-energy X-ray system and a control unit connected with the high-precision air valve removing system, the first processing module is used for collecting imaging information of the dual-radiation-source dual-energy X-ray system and analyzing and processing the imaging information, and the control unit can control the high-precision air valve removing system to work according to the processing result of the first processing module. According to the intelligent mining coal gangue sorting device, the raw coal is screened through a dual-energy X-ray imaging recognition method, the influence of density, thickness and other parameters on screening can be eliminated, the excellent recognition effect is achieved, and the sorting performance of the sorting device is improved.

Owner:河南中平自动化股份有限公司

Semiconductor package with Pillar-Top-Interconnection (PTI) configuration and its MIS fabricating method

ActiveUS9825005B2Small footprintEliminate gapsSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor package

Disclosed is a semiconductor package with Pillar-Top-Interconnection (PTI) configuration, comprising a redistribution layer (RDL) formed on a carrier plane, a plurality of metal pillars disposed on the RDL, a chip bonded onto the RDL, and a molding core. The molding core is formed on the carrier plane and has a bottom surface defined by the carrier plane so that the RDL is embedded inside the molding core. The package thickness of the molding core is greater than the chip-bonding height of the chip so that the chip is completely embedded inside the molding core. The metal pillars are encapsulated at the peripheries of the molding core with a plurality of pillar top portions exposed from the molding core. The exposed pillar top portions are reentrant from a top surface of the molding core and uneven. Accordingly, it realizes the effects of ultra-thin and smaller footprint POP stacked assembly with fine pitch vertically electrical connections in POP structure. Also, it is possible to achieve zero spacing between POP stacked assembly.

Owner:POWERTECH TECHNOLOGY

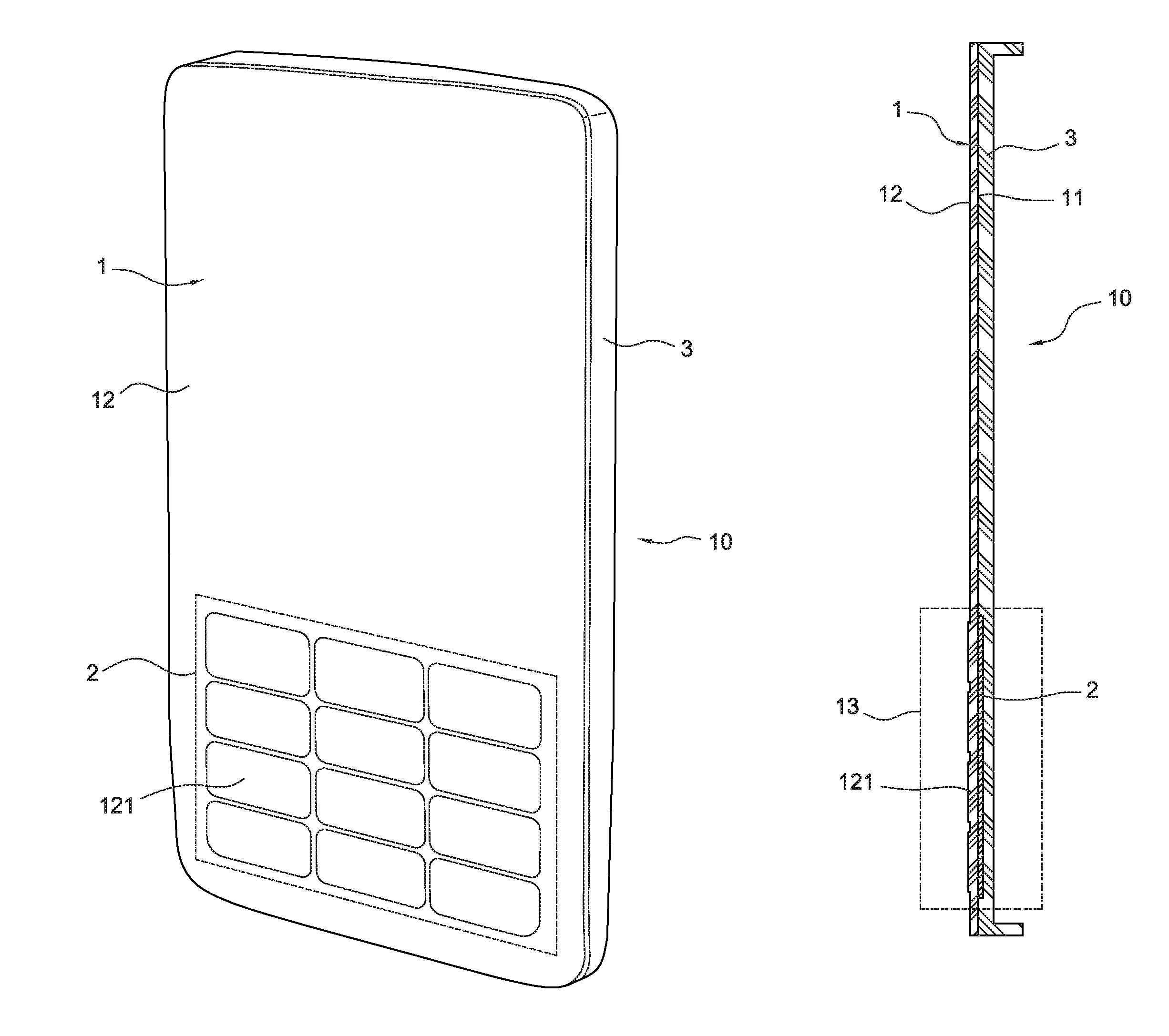

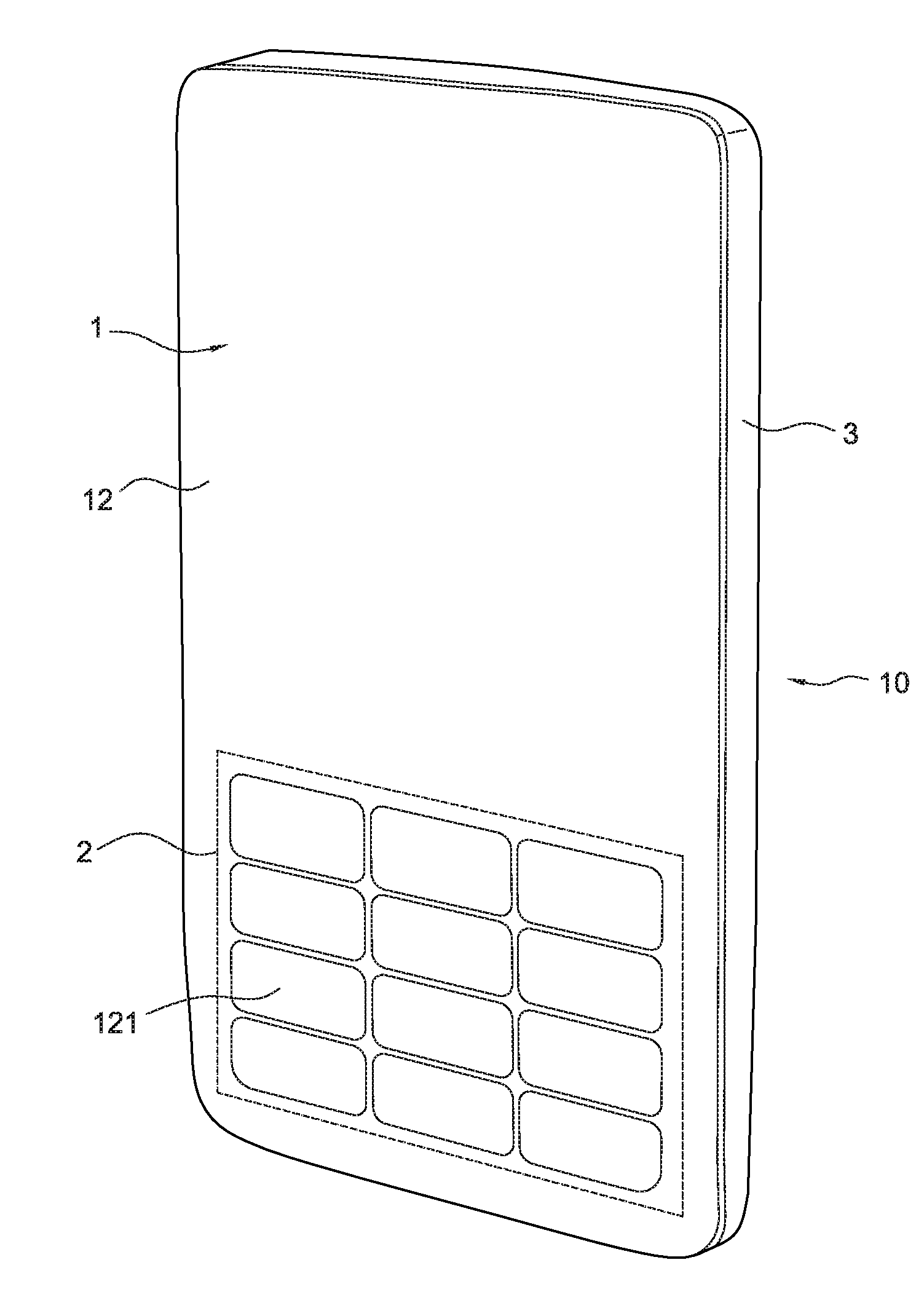

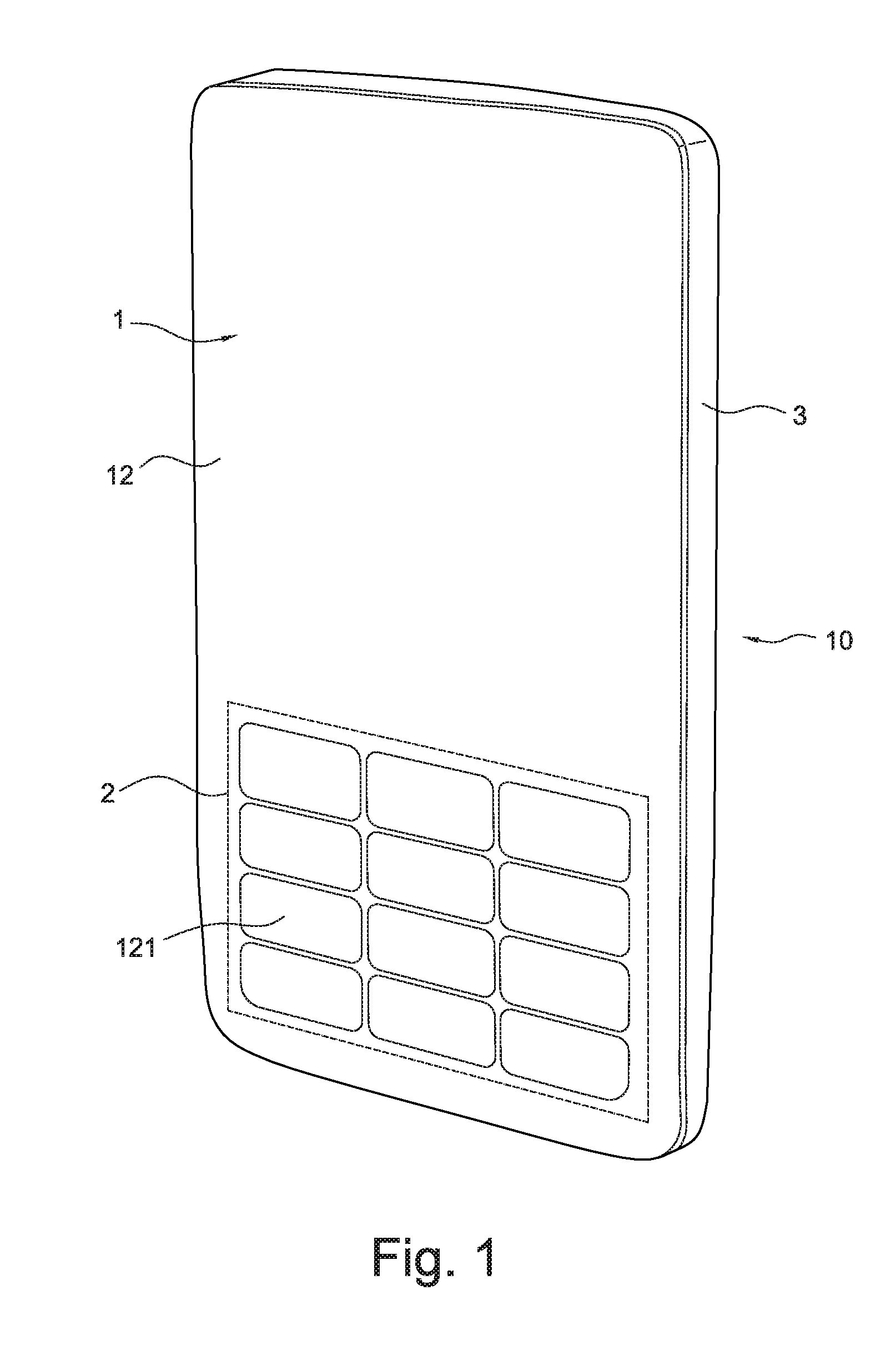

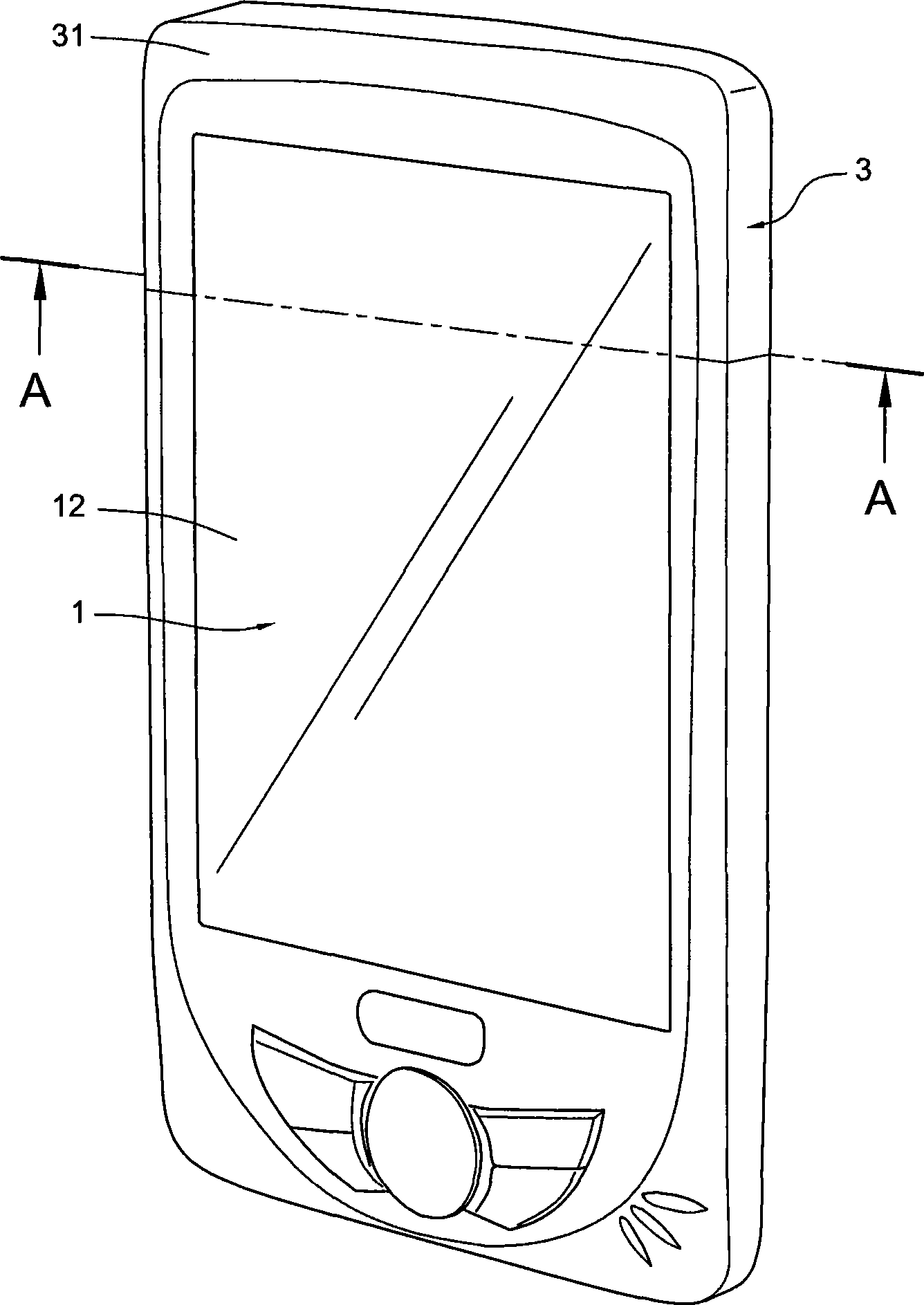

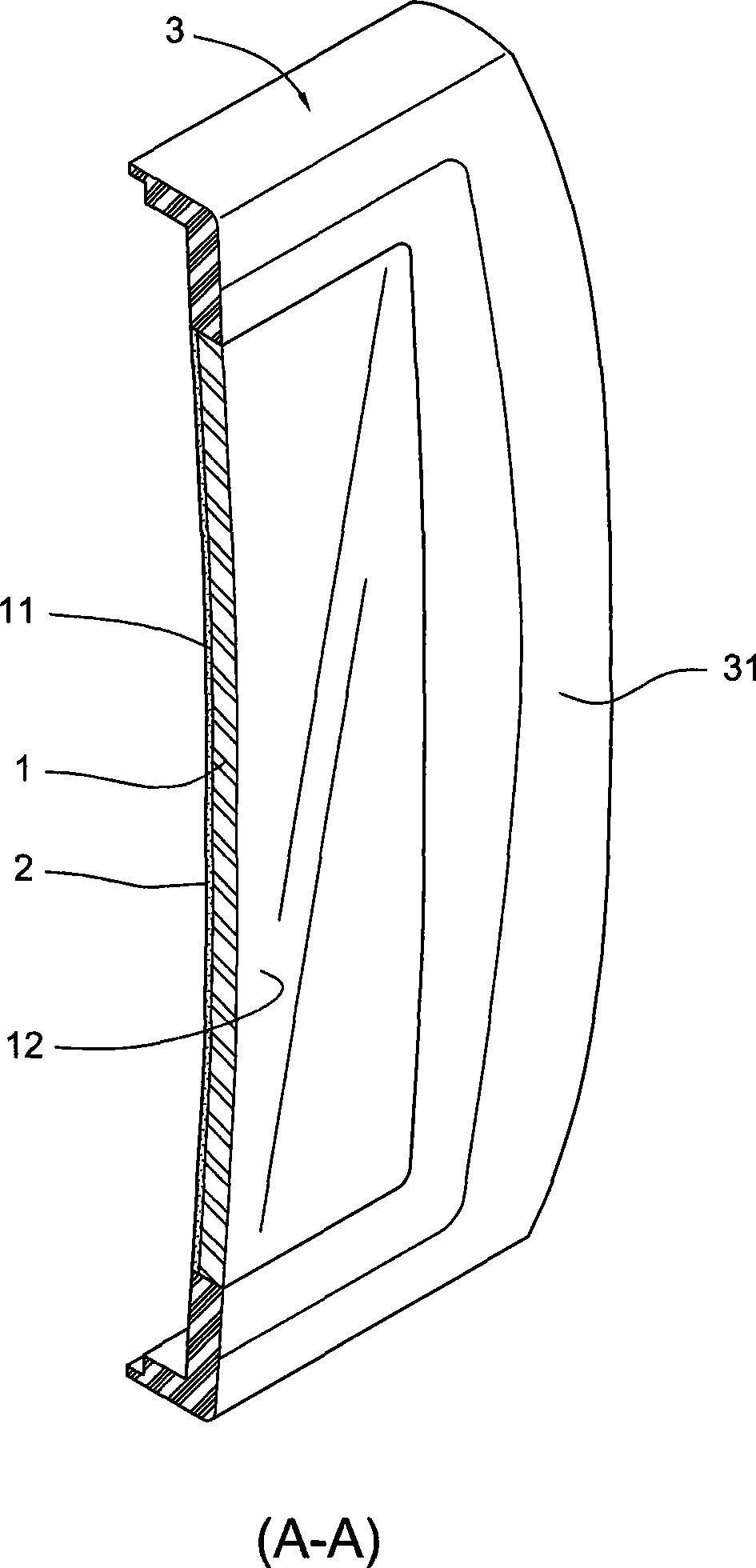

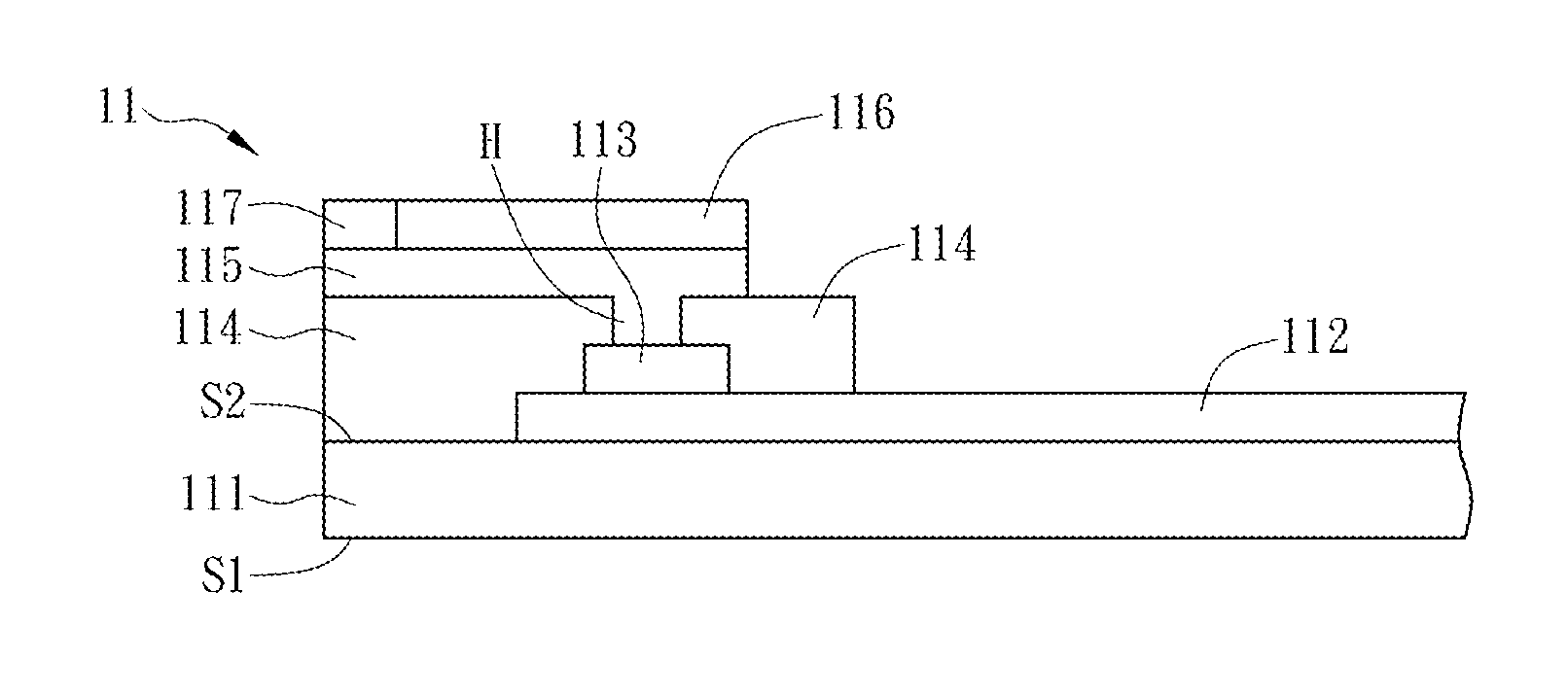

Portable Electronic Device

ActiveUS20130285978A1Eliminate ThicknessThin typeDigital data processing detailsInput/output processes for data processingComputer moduleEngineering

A portable electronic device includes a touch control module and a processing module. The touch control module has a substrate, a transparent conductive layer, a conductive decoration pad, a decoration layer and a non-transparent conductive layer. The transparent conductive layer is disposed on the substrate. The conductive decoration pad is disposed on the transparent conductive layer. The decoration layer is disposed on the conductive decoration pad and the transparent conductive layer, and has an opening. The non-transparent conductive layer is disposed on the decoration layer and electrically connected with the transparent conductive layer via the opening. The processing module is electrically connected with the touch control module.

Owner:WISTRON CORP

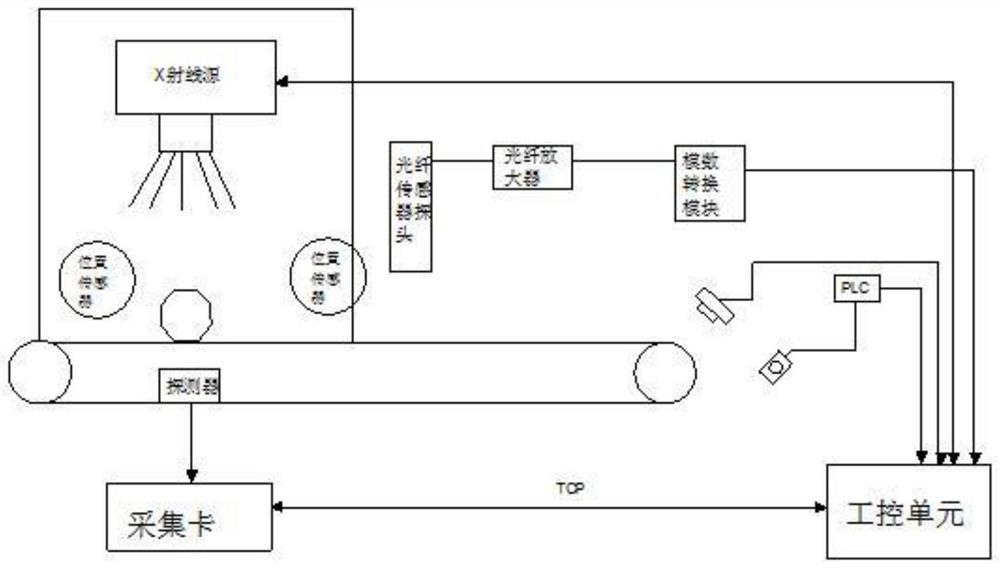

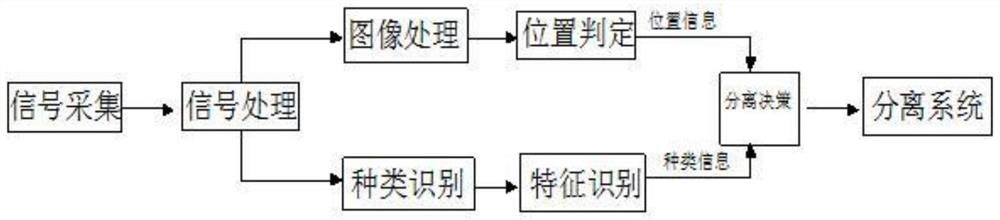

Coal gangue device utilizing dual-energy dual-machine X-rays and identification method thereof

PendingCN113926737AEliminate densityEliminate ThicknessImage enhancementImage analysisThermodynamicsImaging processing

The invention relates to a coal gangue device utilizing dual-energy dual-machine X-rays. The coal gangue device comprises a belt, an X-ray source and an air valve, a detector matched with the X-ray source is arranged on the belt in a manner of corresponding to the lower portion of the X-ray source, the air valve is arranged at the output end of the belt, and the detector is connected to an industrial control unit through an acquisition card; and the industrial control unit comprises a type identification module and an image processing module, the image processing module obtains the position and boundary information of materials and extracts high and low energy transmission data of the materials, and the type identification module performs a type identification algorithm on the high and low energy transmission data to obtain type information of the materials. According to the coal gangue device and the identification method thereof, double-radiation-source double-energy X-ray imaging is adopted, the composition proportion of substances can be accurately distinguished, the types of the materials can be correspondingly determined, double-energy imaging is related to the atomic sequences of the substances and is irrelevant to the particle size of raw coal, and an excellent identification effect is achieved.

Owner:河南中平自动化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com