Online control system capable of improving rolled piece thickness control precision

A technology of thickness control and control system, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as unconsidered, inapplicable thickness control, and poor control accuracy of strip thickness at the exit side of the rolling mill, to achieve Improving control precision, eliminating standard control thickness deviation, direct and effective effect of adapting to the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

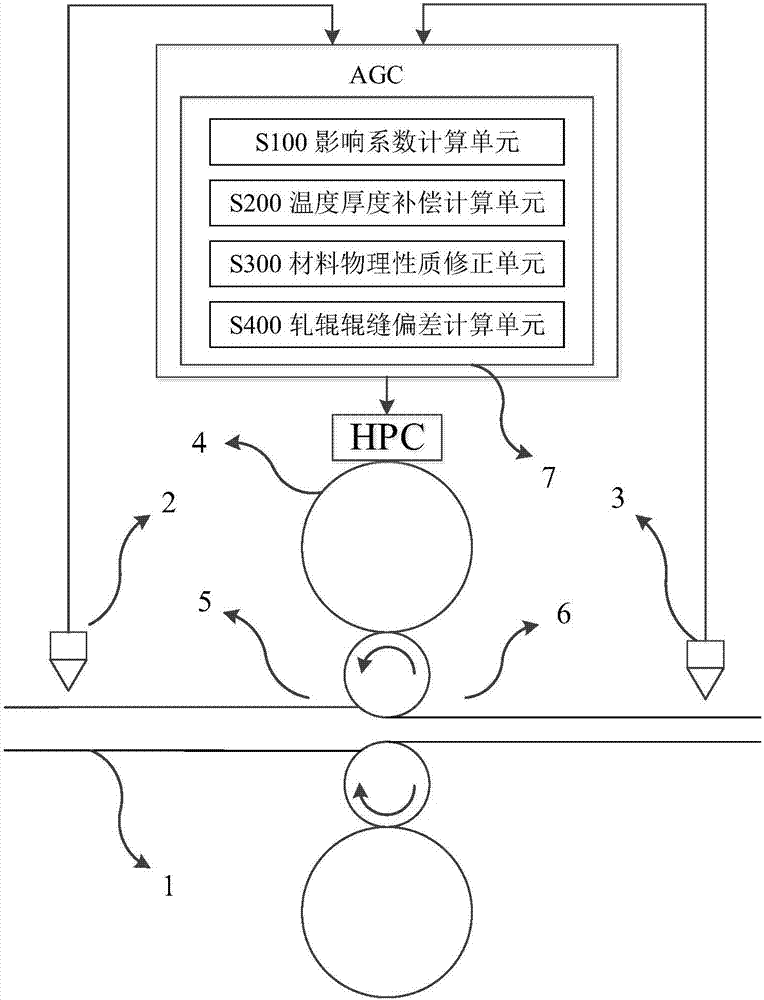

[0033] figure 1 It is the equipment device and control flow chart of the present invention. It can be seen that the online control system for improving the thickness control accuracy of the rolled piece in the present invention includes: the rolled piece 1, at least one rolling mill 4, the rolling piece temperature measuring device 2 on the entrance side of the rolling mill, and the rolling mill exit. The rolled piece thickness measuring device 3 and the rolled piece thickness automatic control device 7 on the side 6; the rolled piece thickness automatic control device 7 includes: an influence coefficient calculation unit S100 for calculating the plastic working temperature change rate and thickness fluctuation influence coefficient, and calculating the plastic working temperature devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com