Preparation method of X-ray multilayer film reflector

A multi-layer film and X-ray technology, applied in the application of diffraction/refraction/reflection processing, coating, radiation/particle treatment, etc., can solve the problems that are difficult to prepare multi-layer film mirrors with higher periodic thickness and small size, and achieve The effect of small roughness, clear interface and less diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

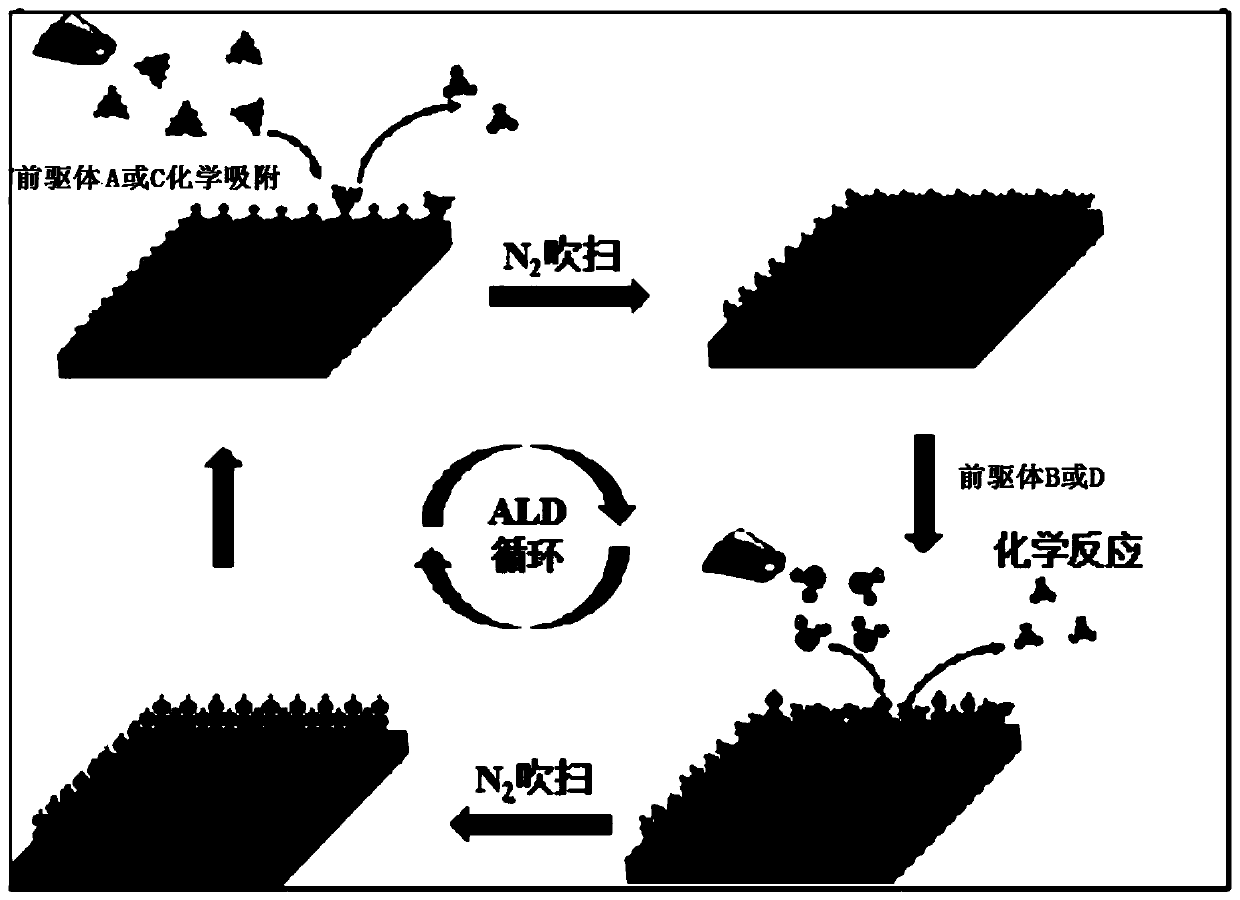

[0037] The invention provides a kind of preparation method of X-ray multilayer film reflector, comprises the following steps:

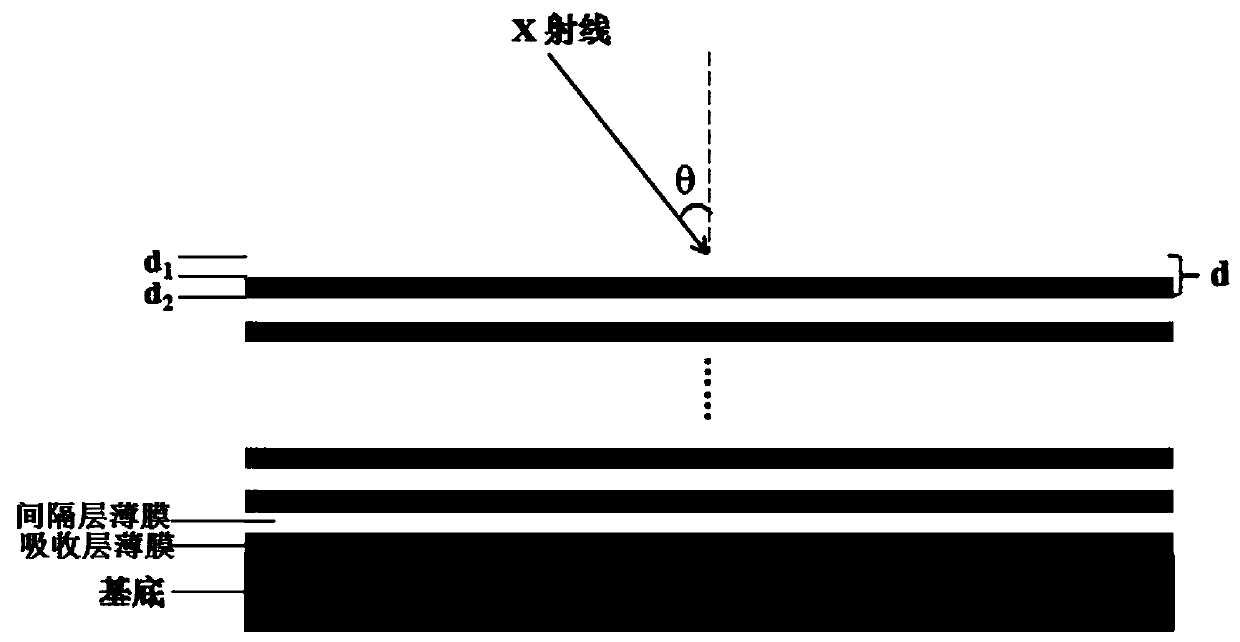

[0038] (1) according to the wavelength of X-ray and the angle of incidence, determine the periodic thickness of multilayer film reflector; The period of described multilayer film reflector is counted with the period of double-layer film, and described double-layer film is spacer layer thin film and Absorbing layer film; the periodic thickness is the thickness of the double-layer film;

[0039](2) according to the maximization of the X-ray reflectivity, determine the thickness ratio of the spacer layer film and the absorption layer film and the period number of the double-layer film;

[0040] (3) According to the thickness ratio determined in the step (2) and the periodic thickness determined in the step (1), obtain the thickness of the spacer layer film and the thickness of the absorption layer film, then determine according to the thickness and depos...

Embodiment 1~8

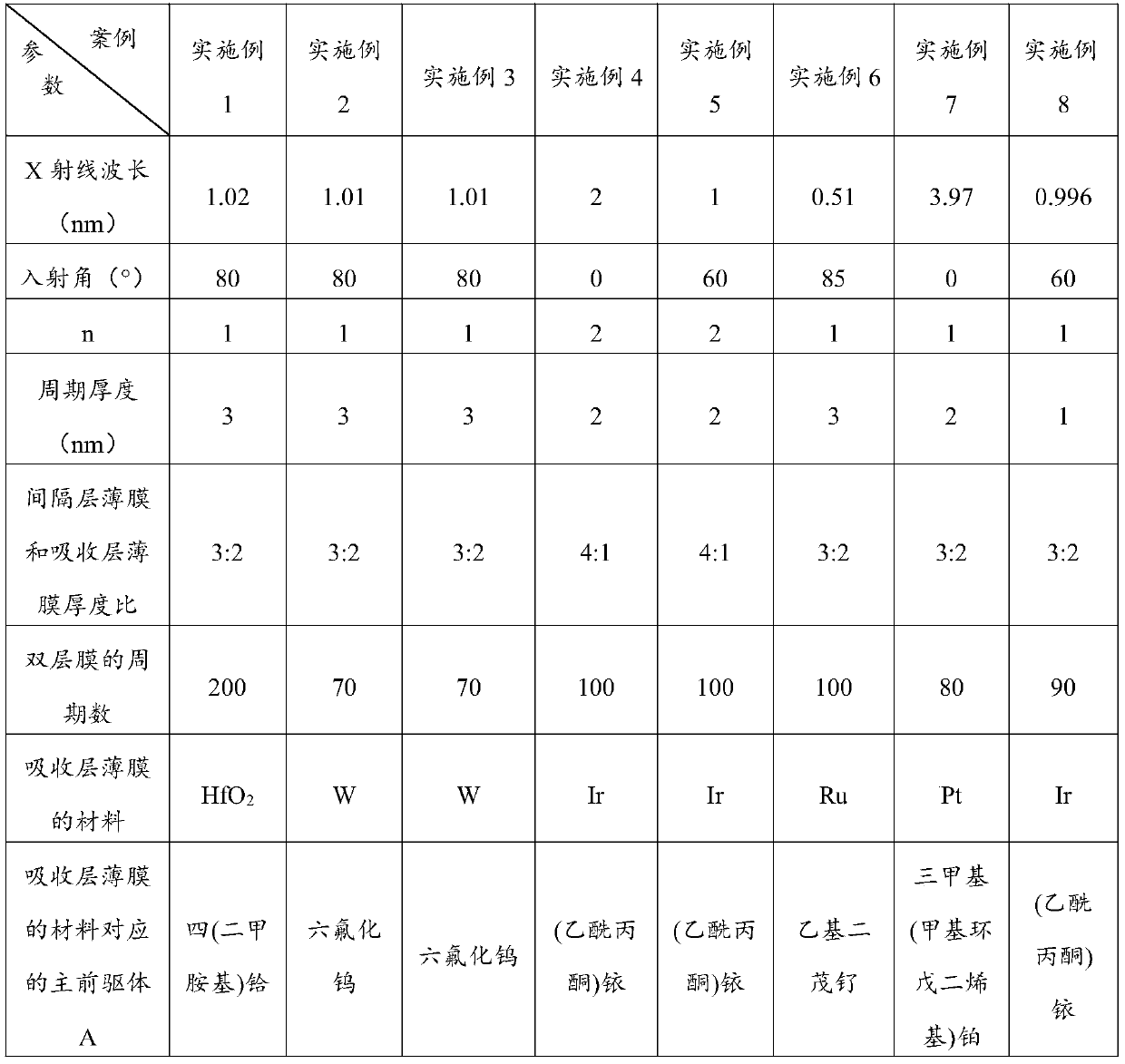

[0066] According to the parameters listed in Table 1, different X-ray multilayer film mirrors are prepared according to the following methods:

[0067] (1) according to the wavelength of X-ray and the angle of incidence, according to formula d=nλ / (2cosθ), determine the period thickness of multilayer reflector; The double-layer film is respectively a spacer layer film and an absorption layer film; the periodic thickness is the thickness of the double-layer film;

[0068] (2) According to the maximization of the X-ray reflectivity, determine the thickness ratio of the spacer layer film and the absorber layer film and the cycle number of the double-layer film, and the specific data are shown in Table 1;

[0069] (3) According to the thickness ratio of the spacer layer film and the absorber layer film and the periodic thickness of the multilayer film reflector, obtain the thickness of the spacer layer film and the thickness of the absorber layer film, then according to the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com