Thickness adjusting device of slicing machine

A technology of thickness adjustment and slicing machine, which is applied in metal processing and other directions, and can solve problems such as difficult manufacturing, thickness deviation, and processing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

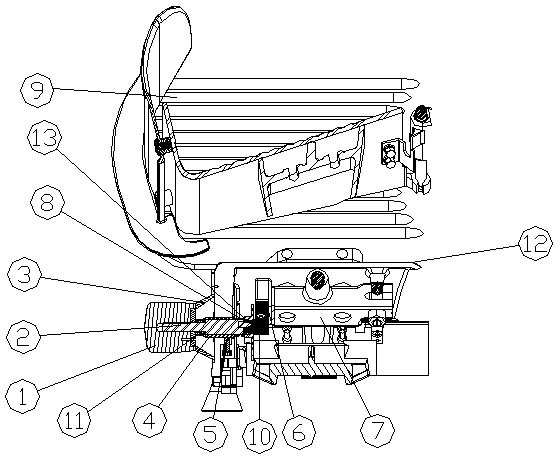

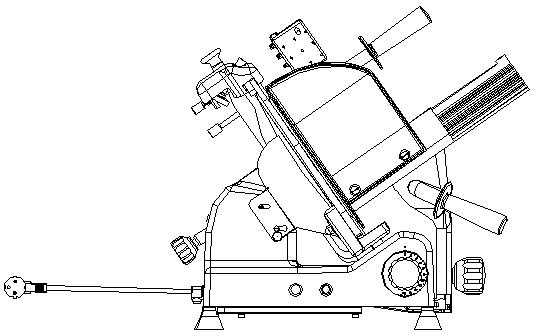

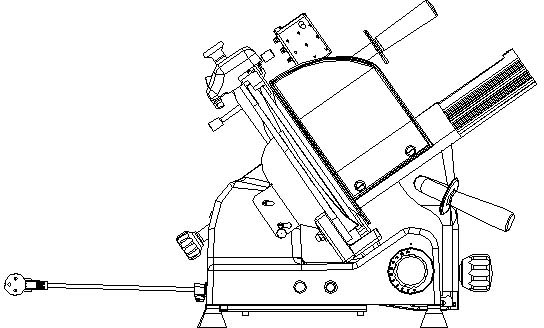

[0012] Below in conjunction with accompanying drawing this device is described in further detail:

[0013] From figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the thickness adjusting device of the slicer of the present invention includes the handle 1, the dial 3, the sliding seat 7 of the scale plate, and also includes a transmission mechanism and a gap elimination mechanism.

[0014] The transmission mechanism includes a gear shaft 2, a rack 6, and a nut 11; one end of the gear shaft 2 is connected to the handle 1 through threads, and the dial 3 set on it is tightly pressed on the inner end surface of the handle 1 through the nut 11. The tooth end of the shaft 2 meshes with the rack 6, and the rack 6 is fixed on the sliding seat 7 of the scale plate through the fixing screw 10; the gap elimination mechanism is sleeved on the gear shaft 2.

[0015] When operating the device, the rotary handle 1 drives the gear shaft 2 and the dial 3 to rotate, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com