Multi-legged friction-stir welding method for improving properties of welding seam

A technology of friction stir welding and welding method, which is applied in the direction of welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of increasing industrial production costs, increasing processing procedures, etc., to reduce residual stress, improve weld performance, grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

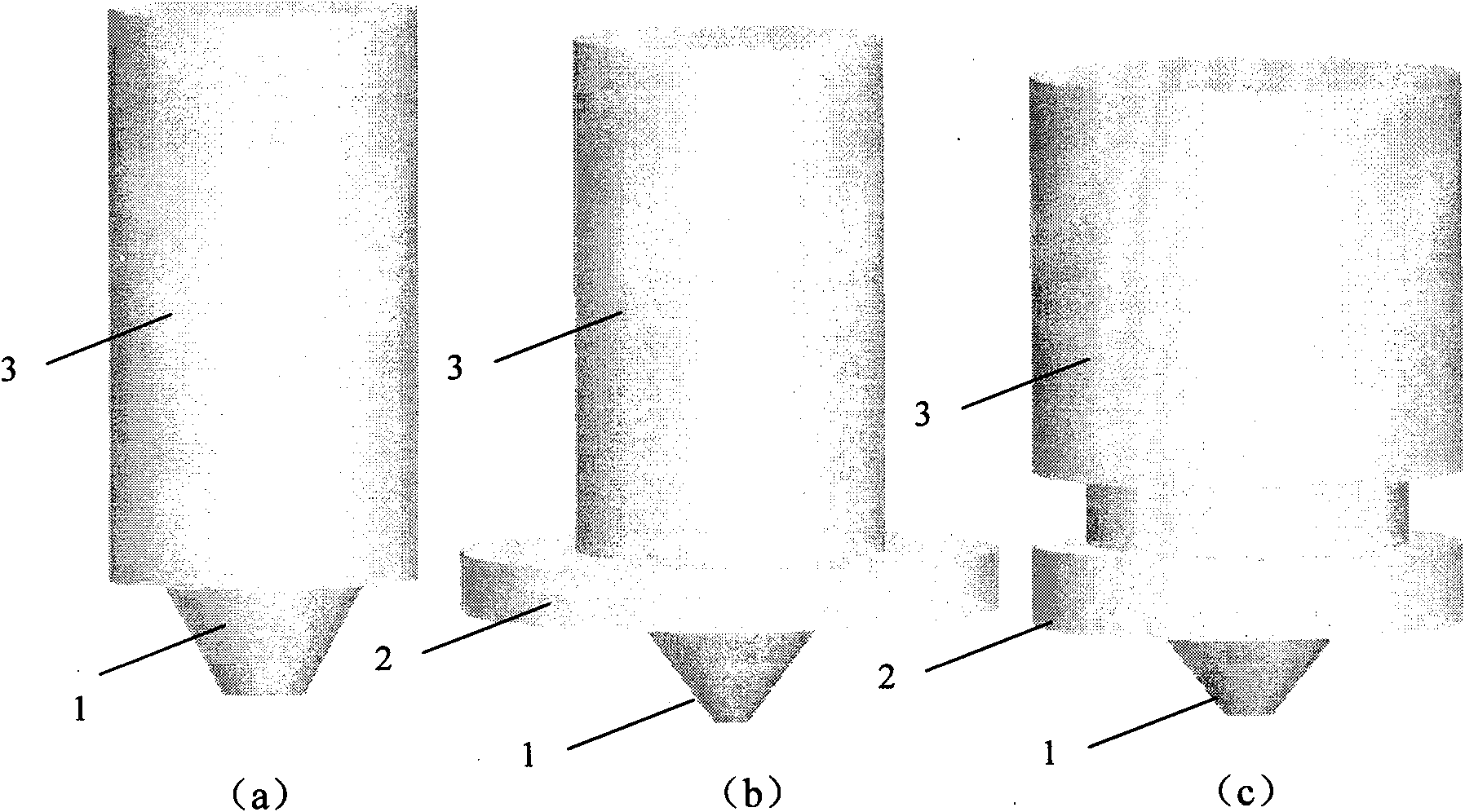

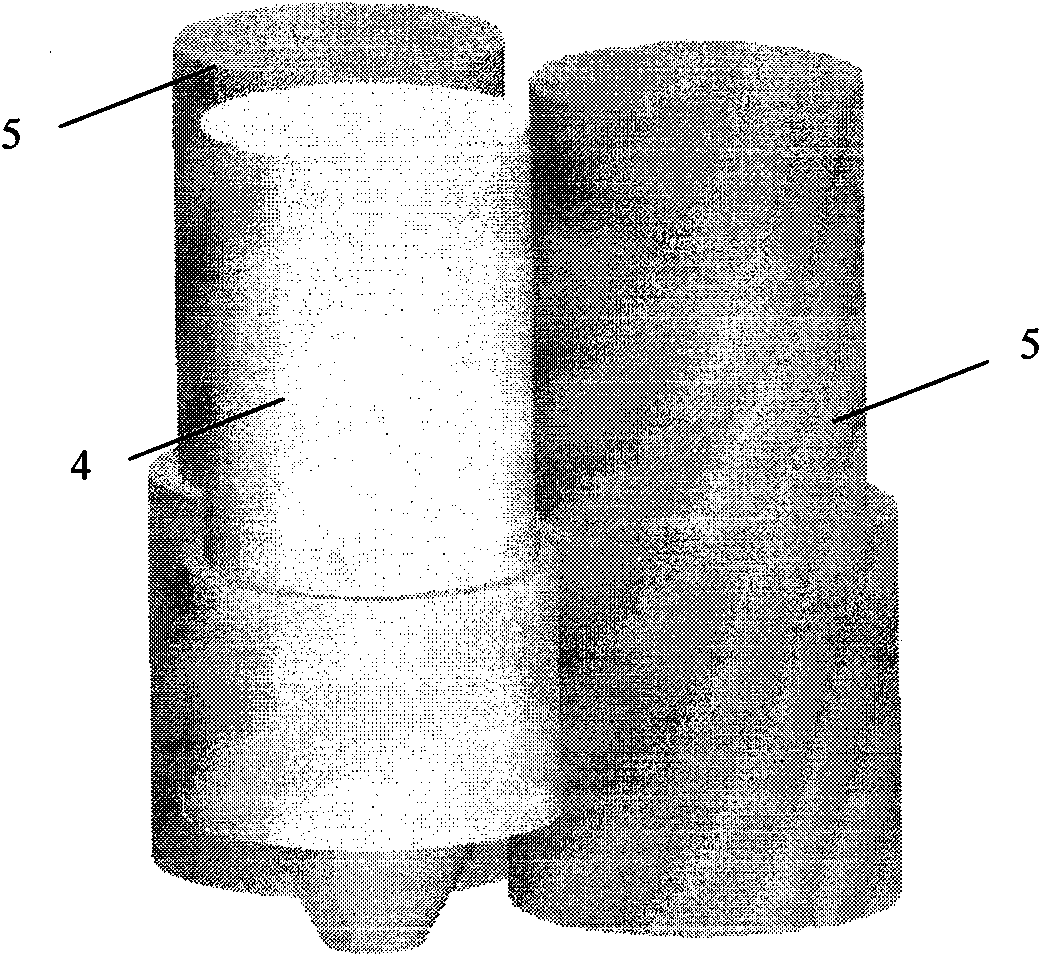

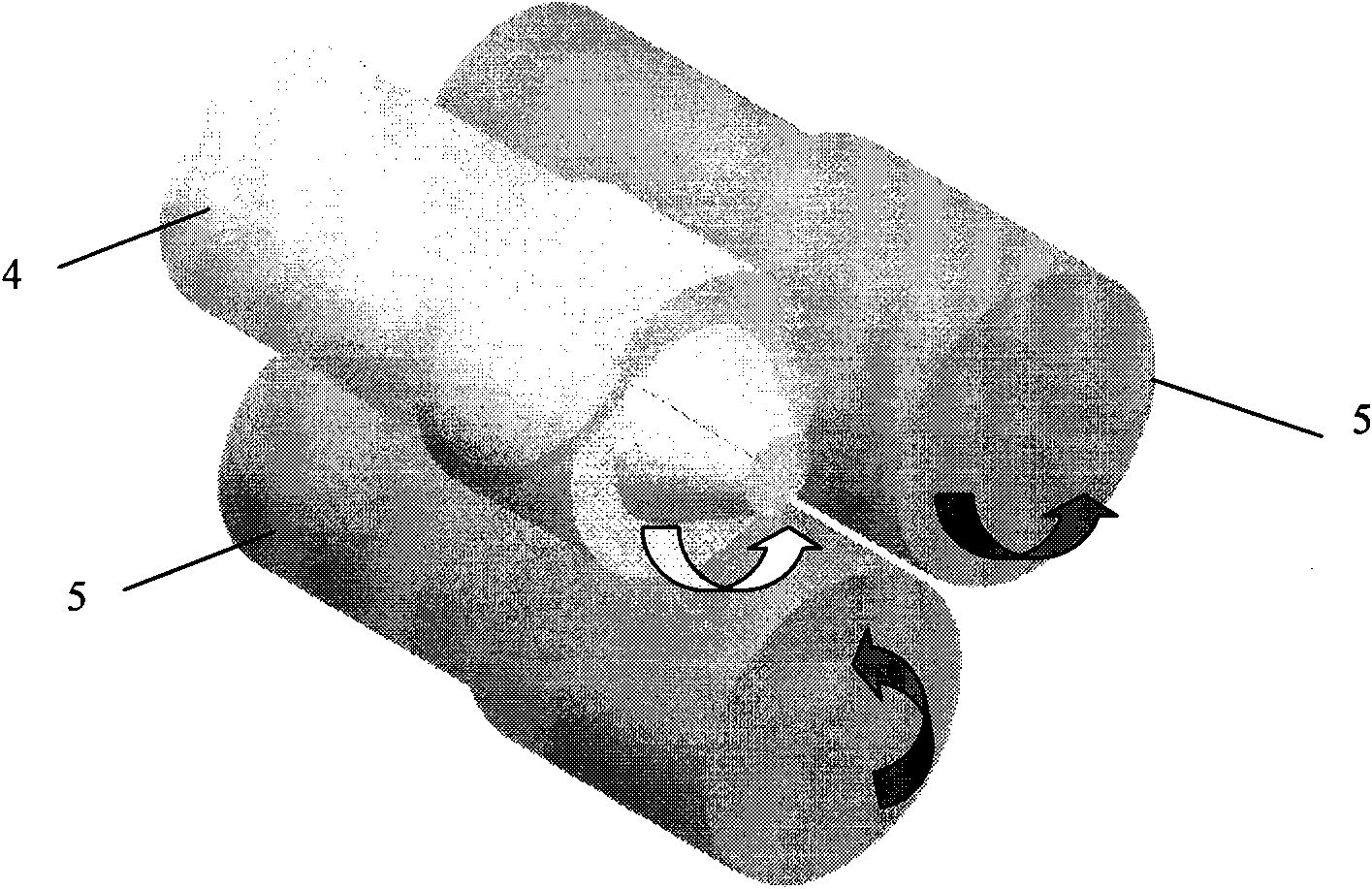

[0017] Such as figure 2 and image 3 As shown, the multi-legged friction stir welding stirring head that can improve the weld performance of the present invention includes at least one front stirring head 4 for stirring welding to form a weld seam and at least one behind the front stirring head 4 The rear stirring head 5 is used for rotating and extruding the weld seam and base metal. In this embodiment, there is one front stirring head 4 and two rear stirring heads 5 . The two rear stirring heads 5 are arranged symmetrically behind the front stirring head 4 . The front stirring head 4 includes a stirring probe 1 , a shaft shoulder 2 and a clamping part 3 , and the rear stirring head 5 has no stirring probe and only includes a shaft shoulder 2 and a clamping part 3 .

[0018] When performing friction stir welding, the welding seam is formed by stirring welding with the front stirring head 4 , and then the welding seam and the base material are rotated and extruded by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com