Patents

Literature

504 results about "Capacitive electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

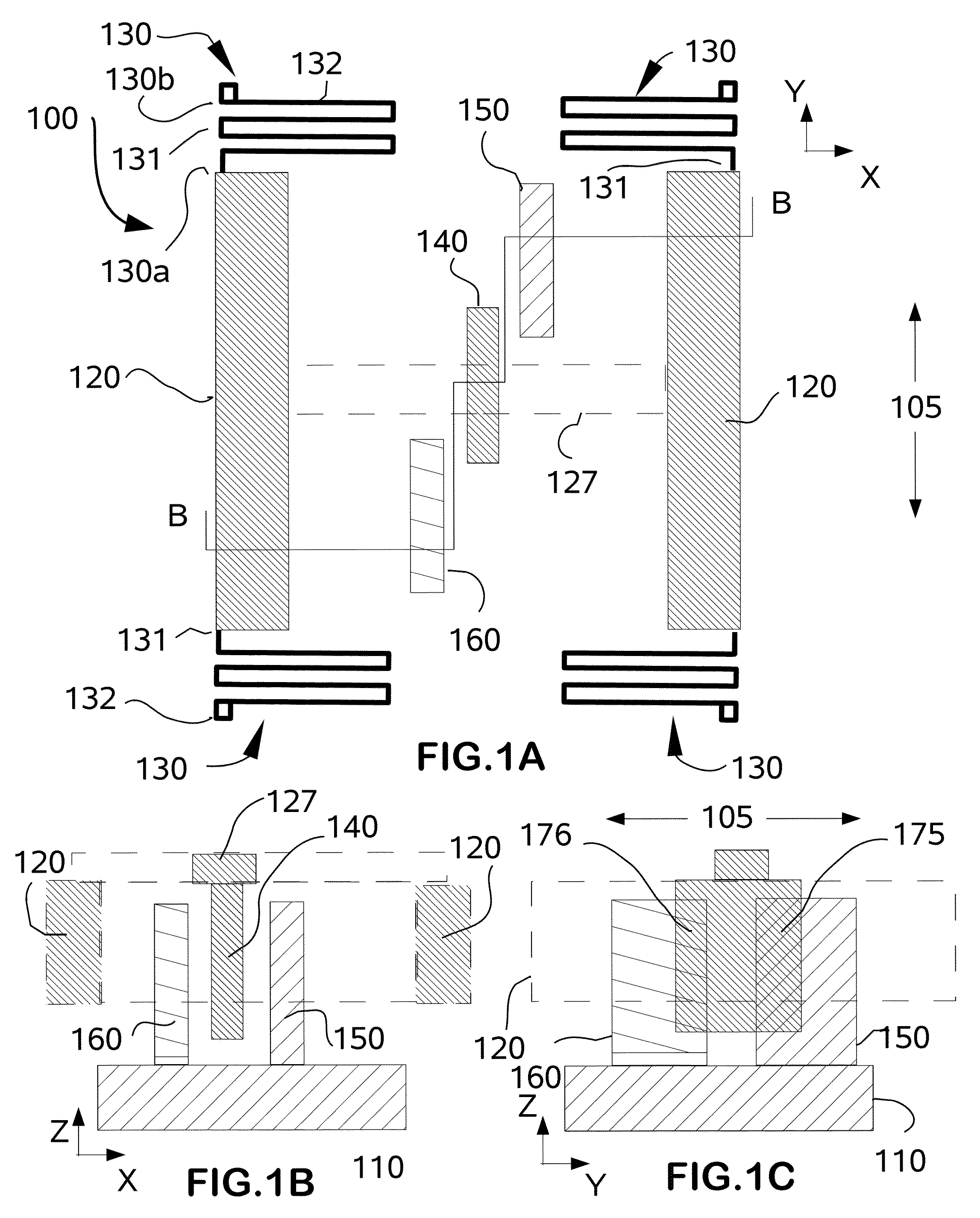

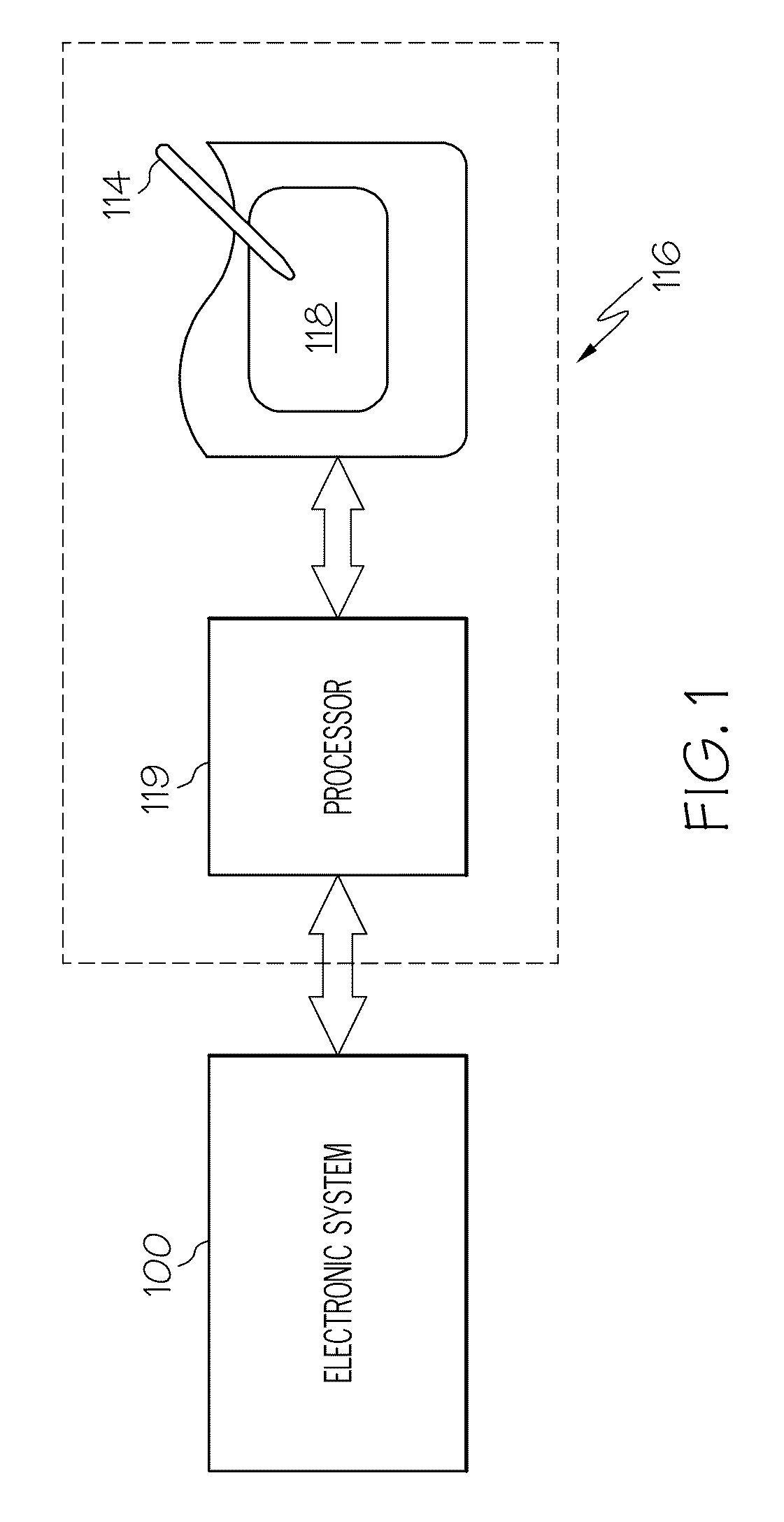

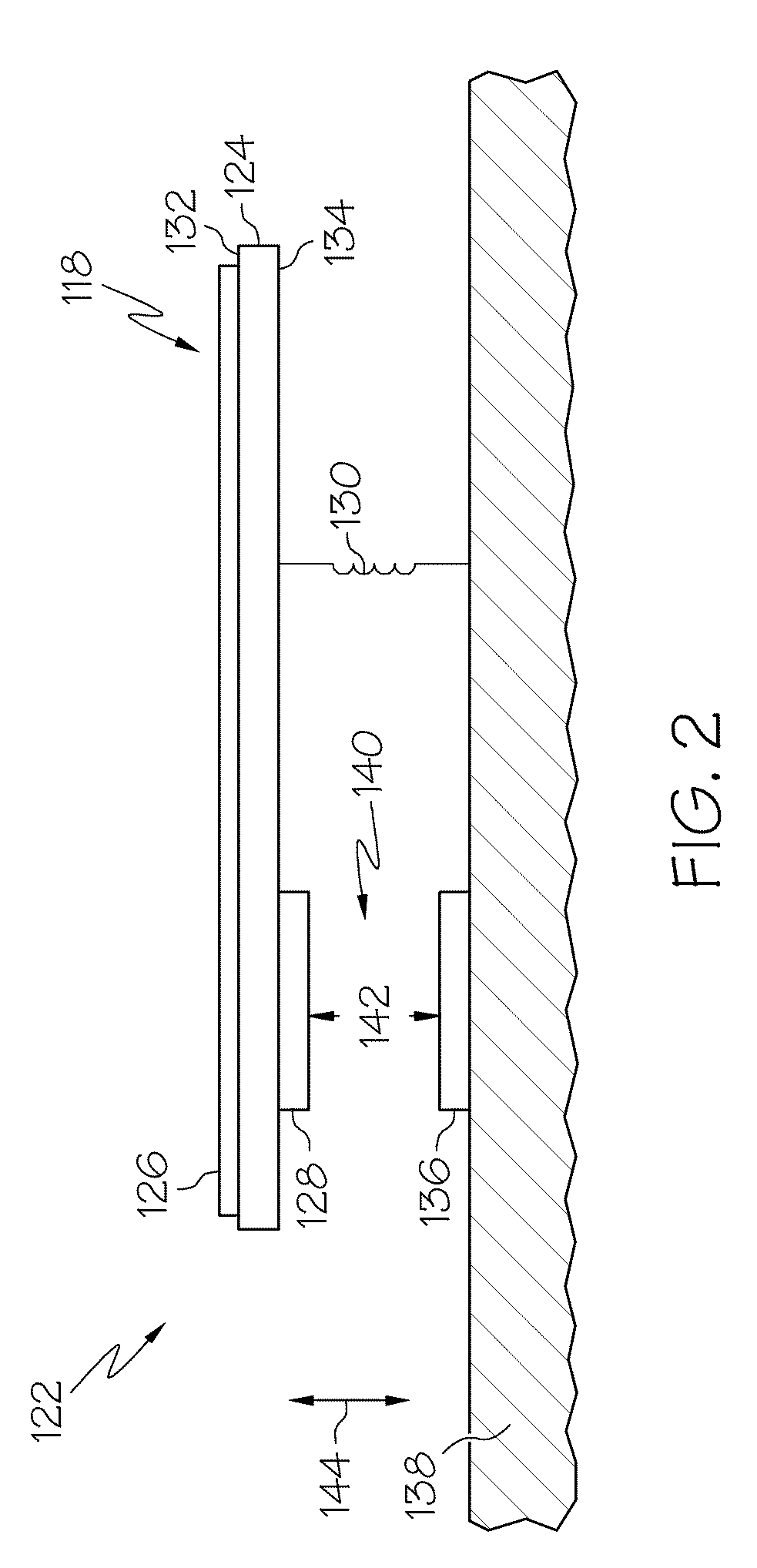

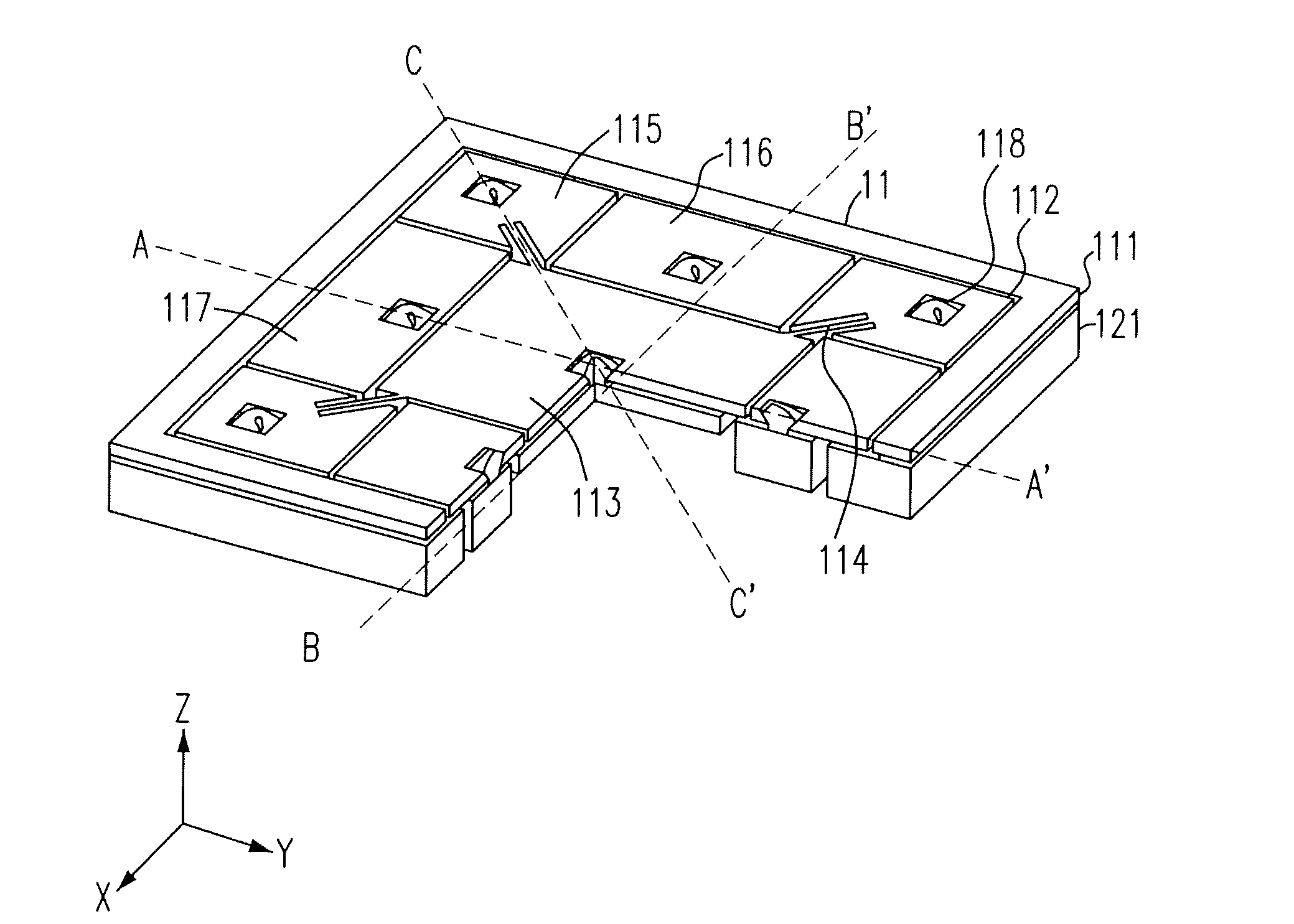

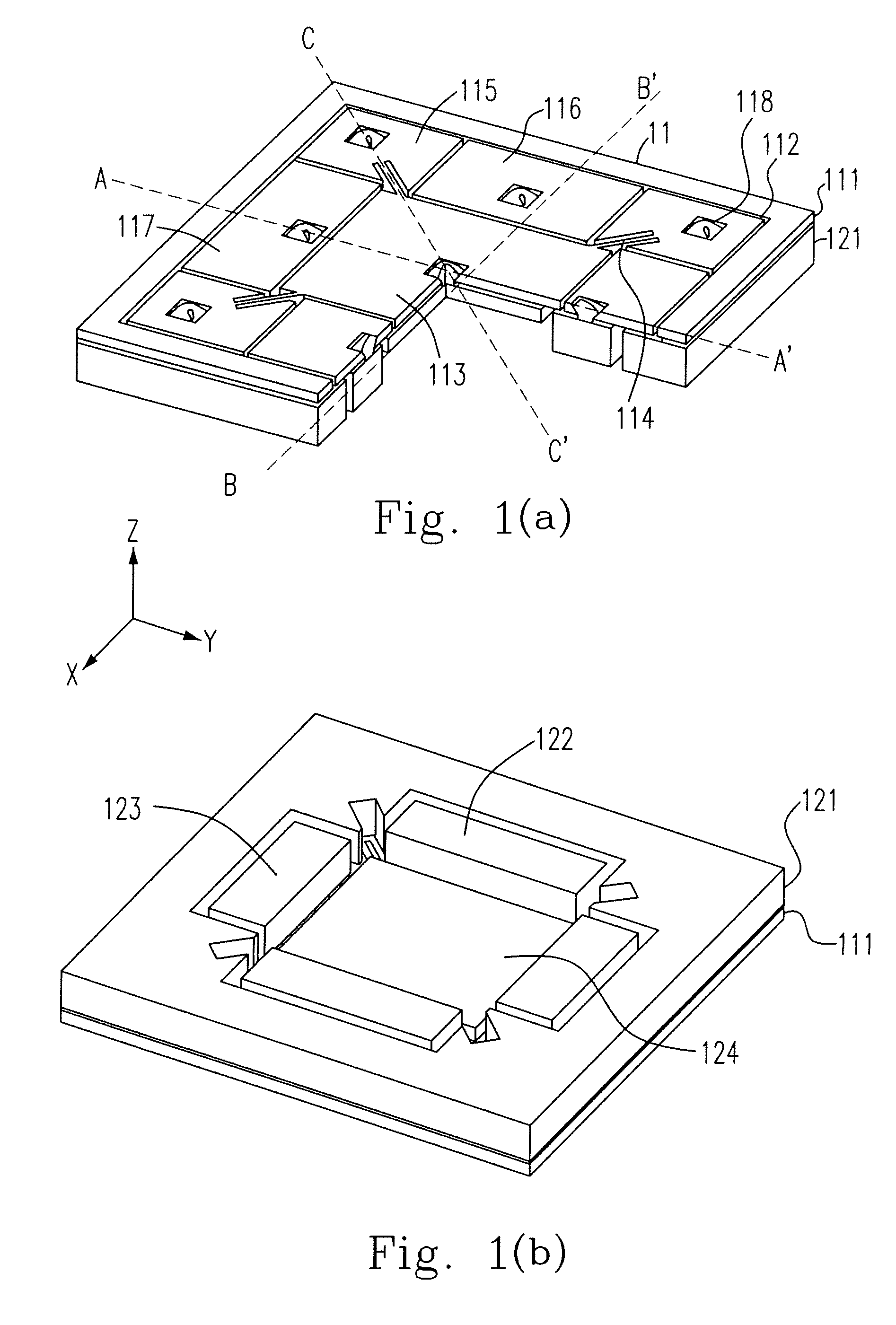

Input device with capacitive force sensor and method for constructing the same

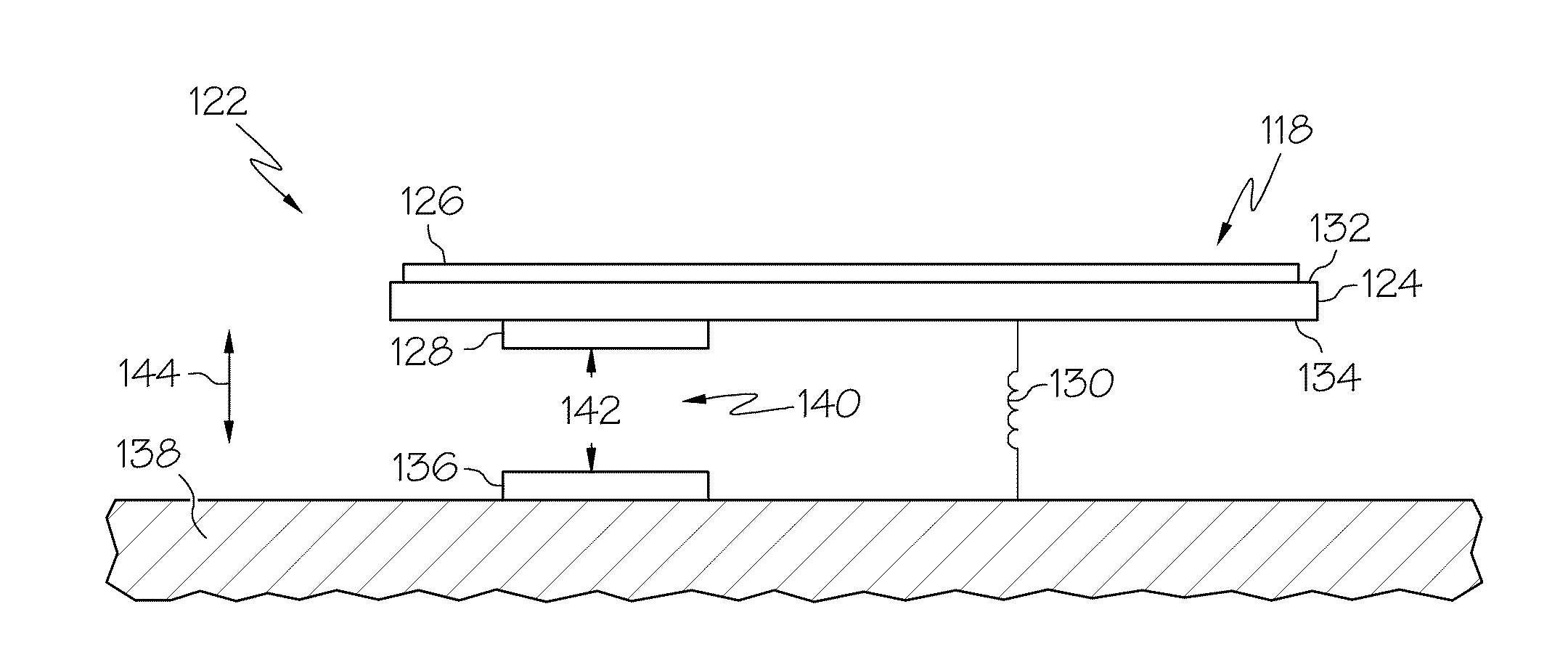

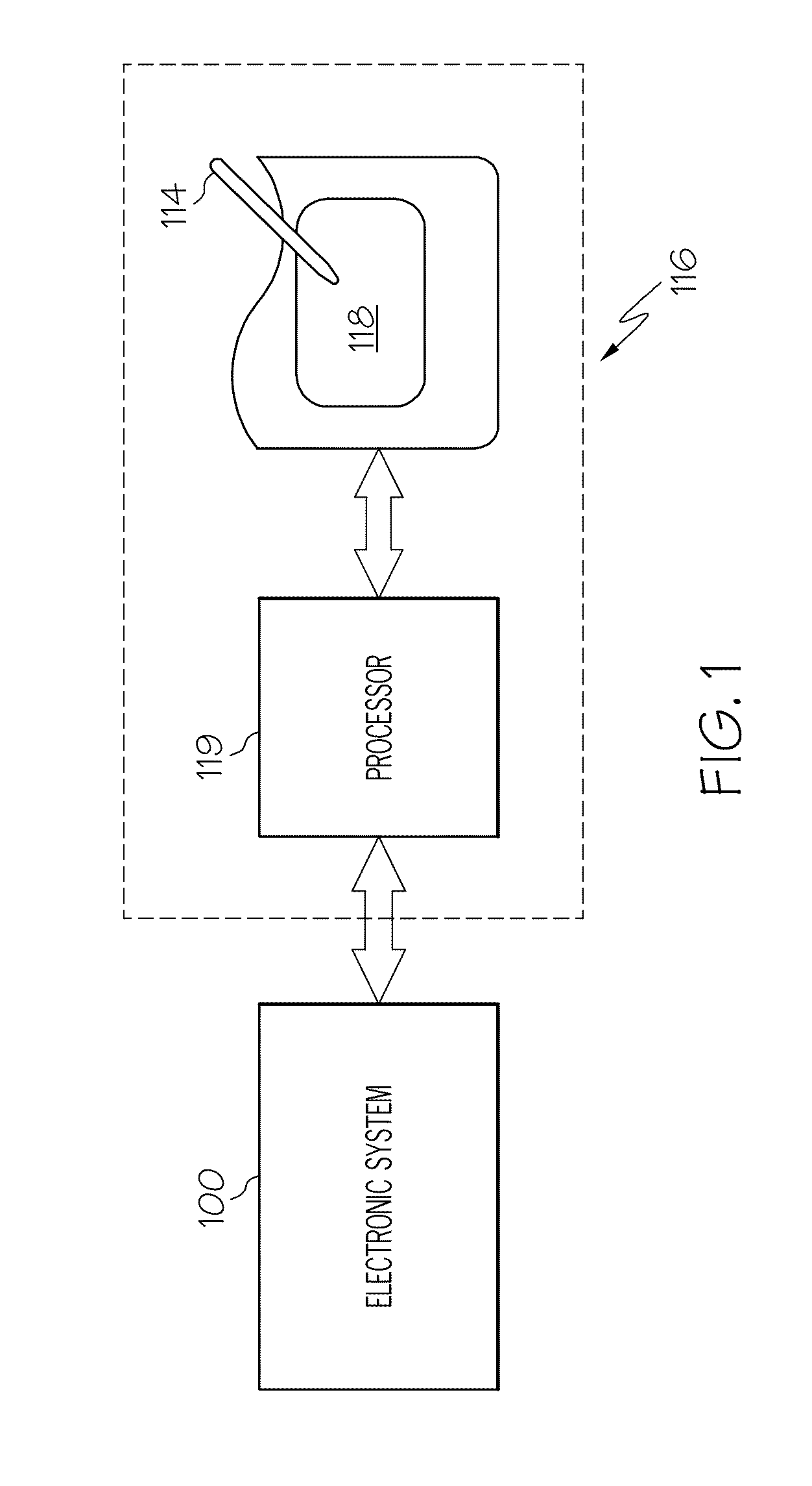

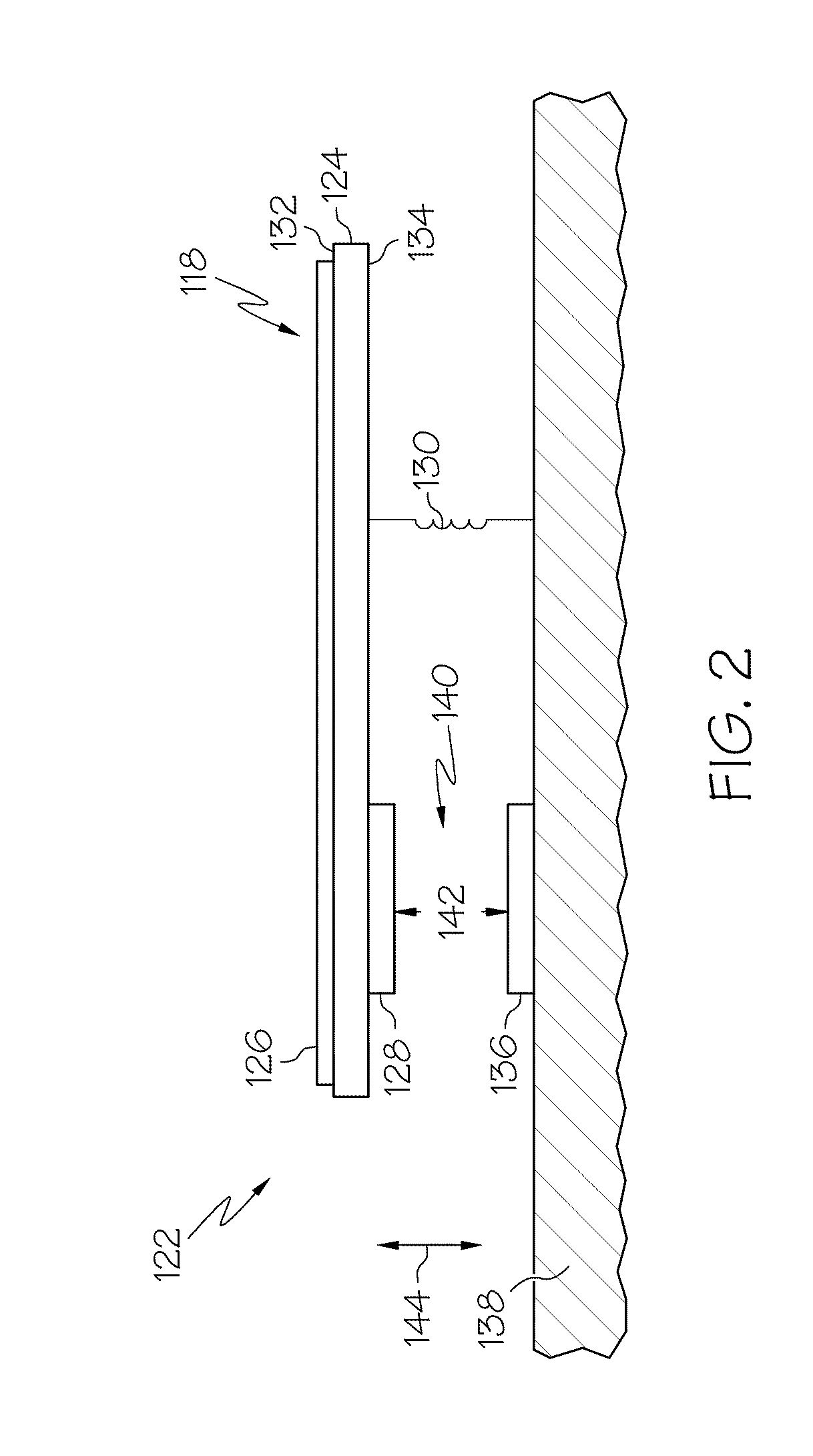

Input devices which include a capacitive force sensor, along with methods of making and using such, are provided. The input device includes a structural component having first and second substantially opposing sides, a plurality of sensor electrodes located on the first side of the structural component, the plurality of sensor electrodes configured to capacitively sense positional information associated with user input in a sensing region, a first capacitive electrode located on the second side of the structural component, the first capacitive electrode being configured to capacitively couple to a second capacitive electrode that is separated from the first capacitive electrode by a gas and moveable relative to the first capacitive electrode, and a biasing member configured to be physically coupled to the structural component such that a force associated with the user input causes a change in a separation distance between the first and second capacitive electrodes based on the force.

Owner:SYNAPTICS INC

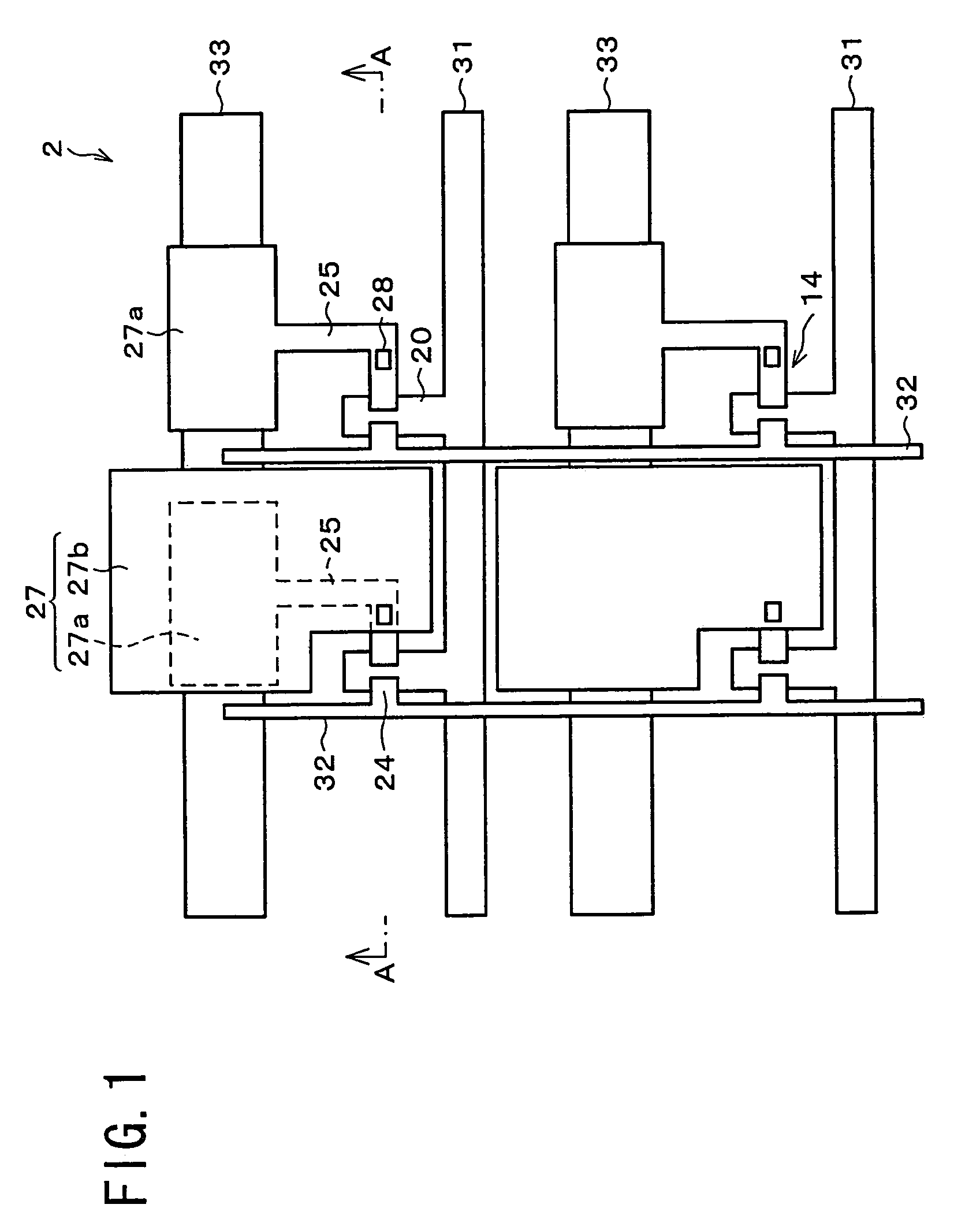

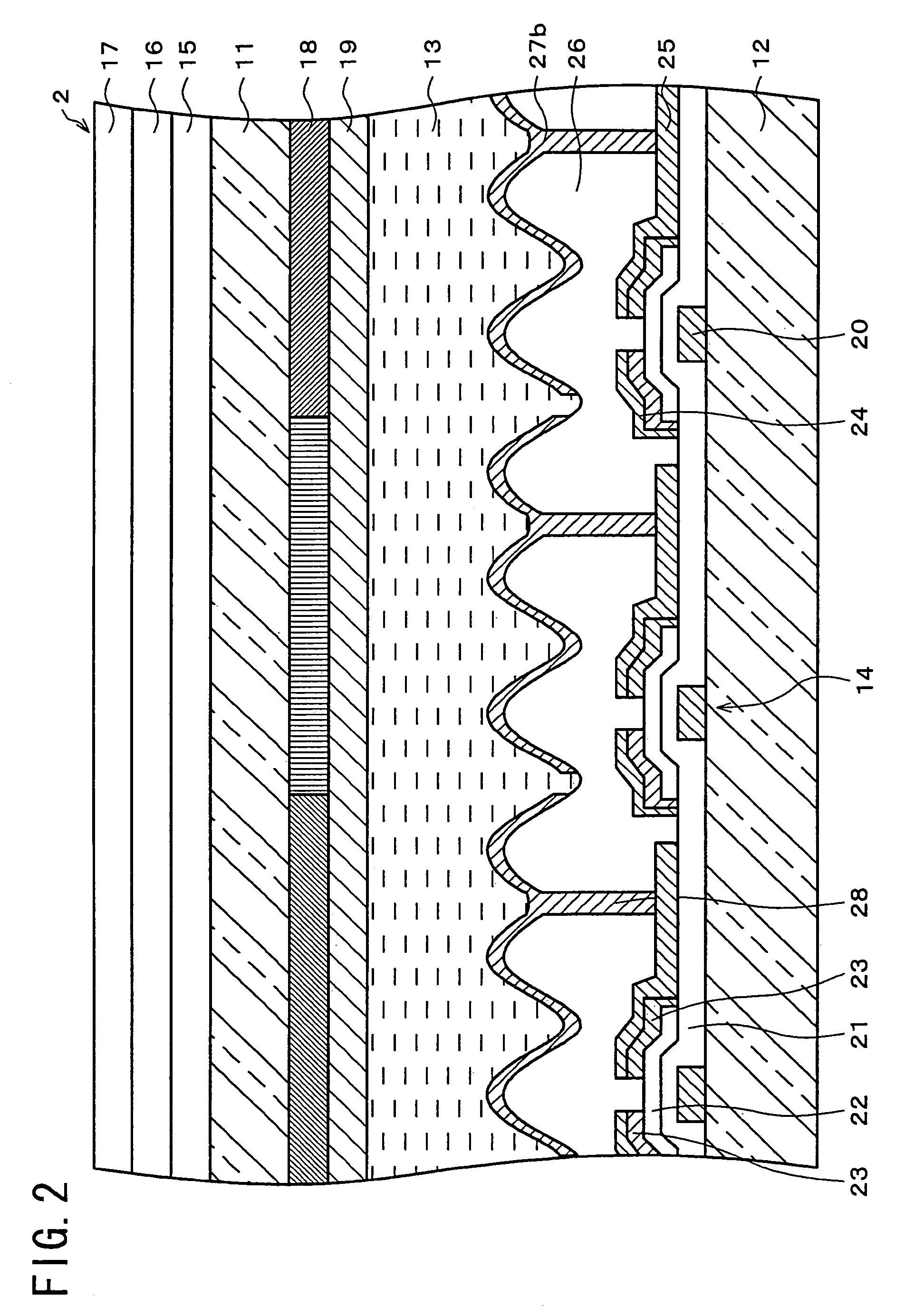

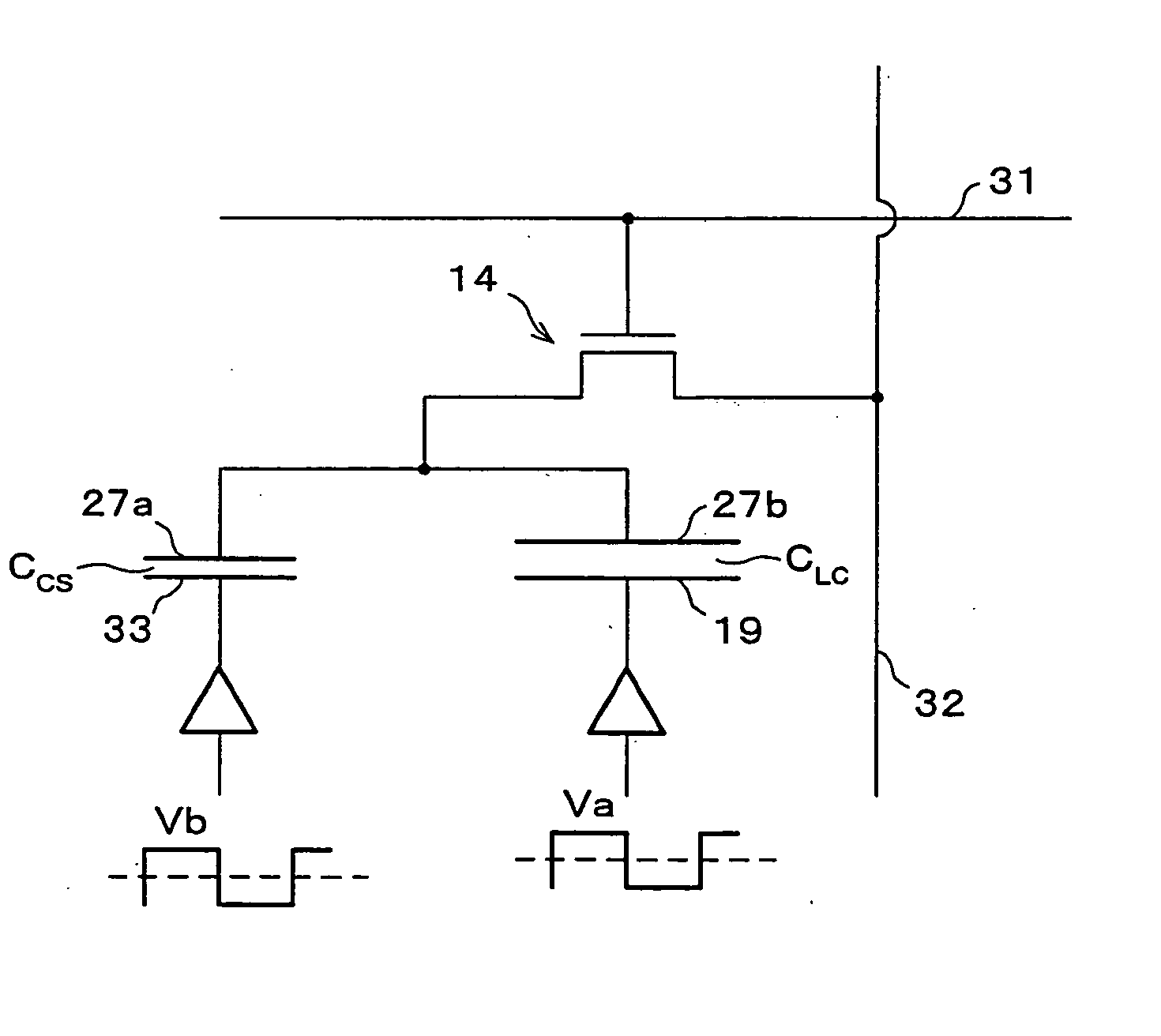

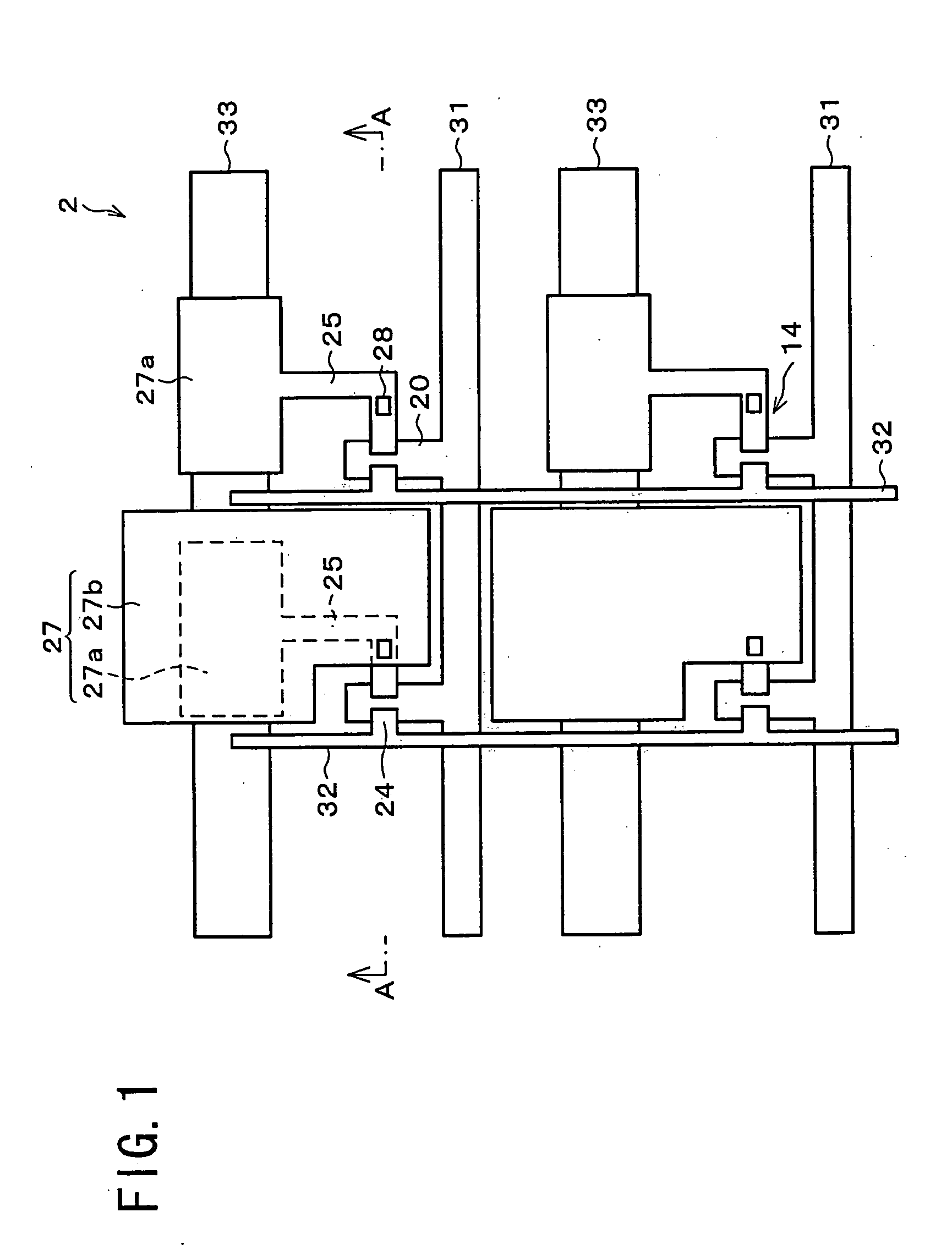

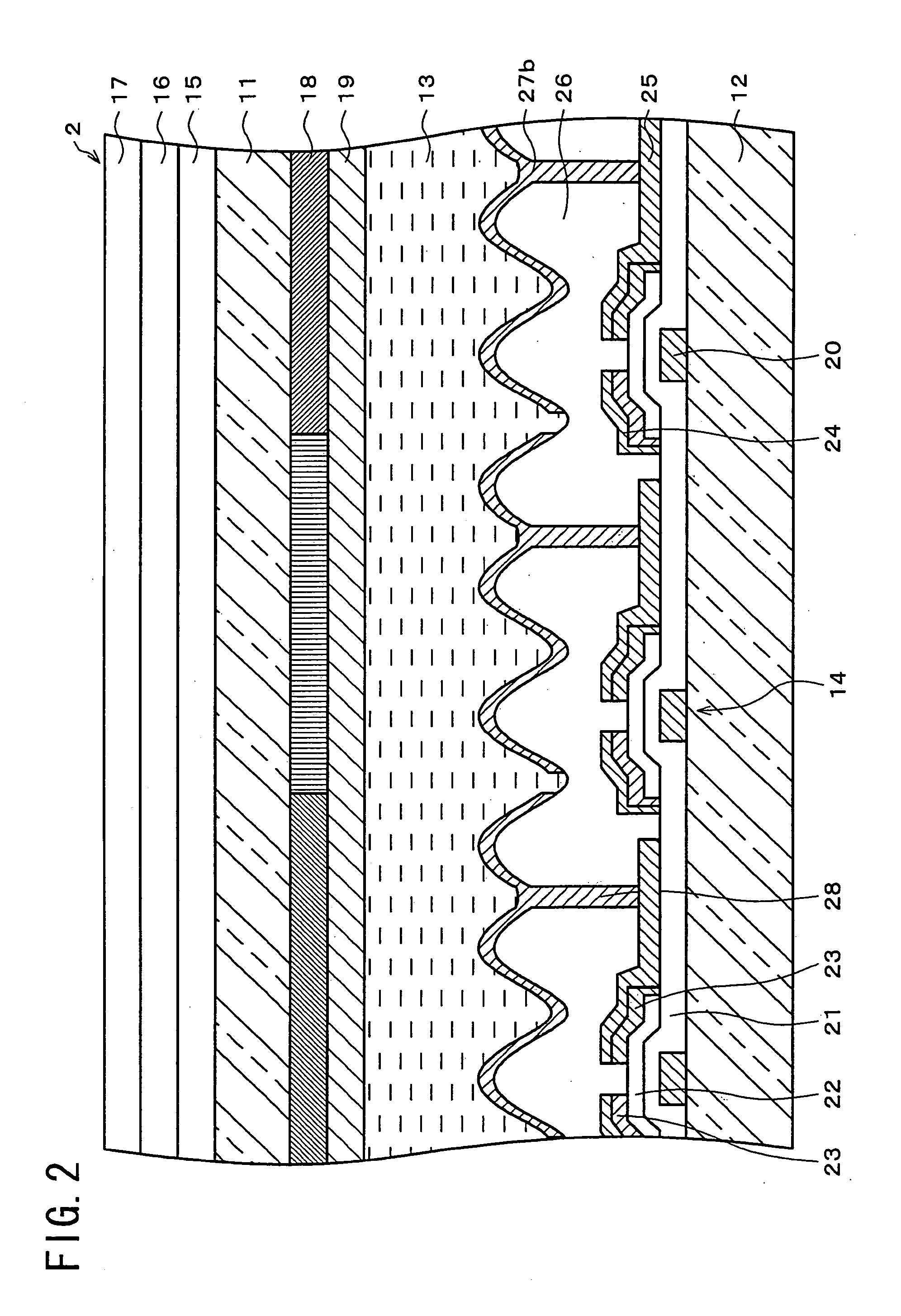

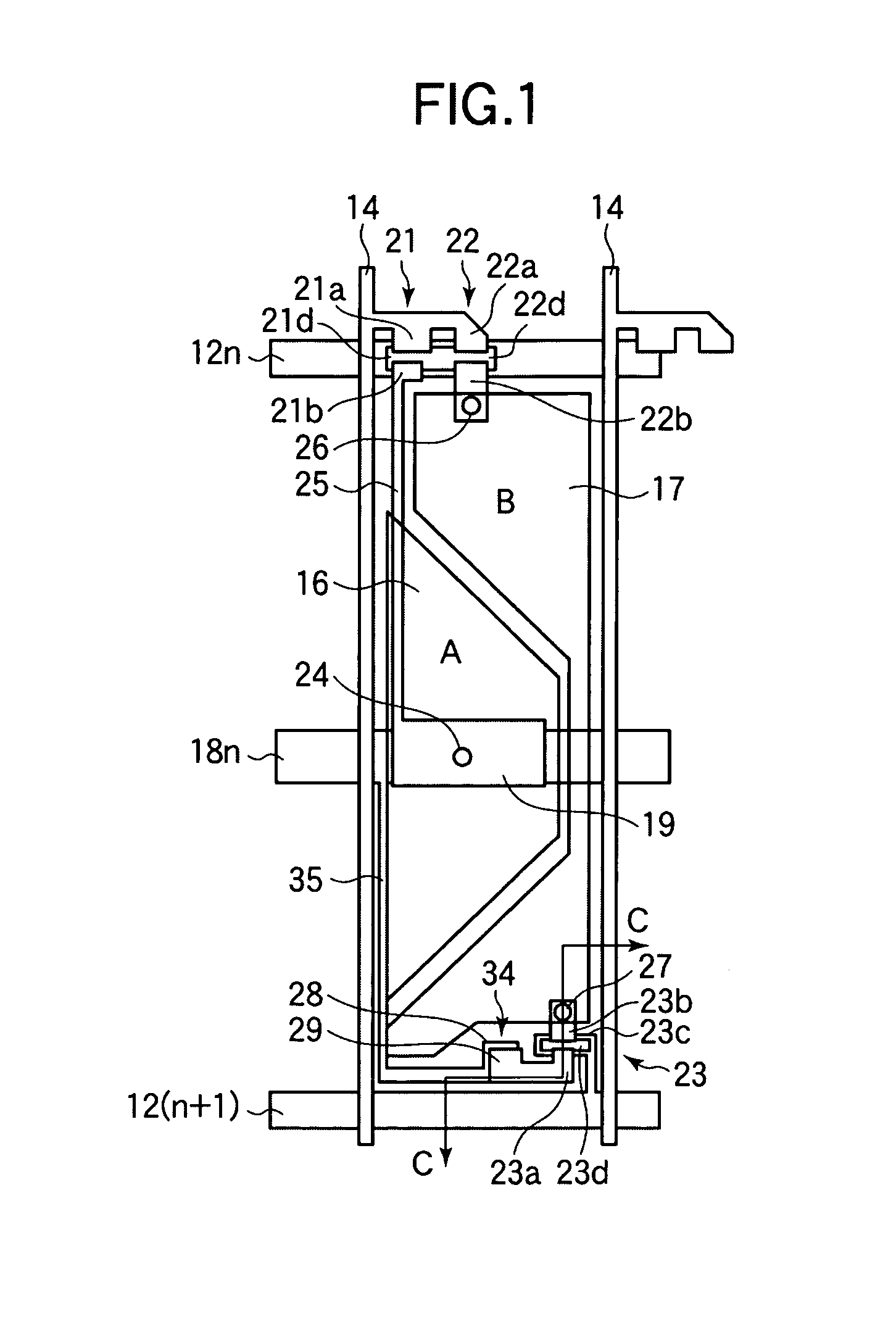

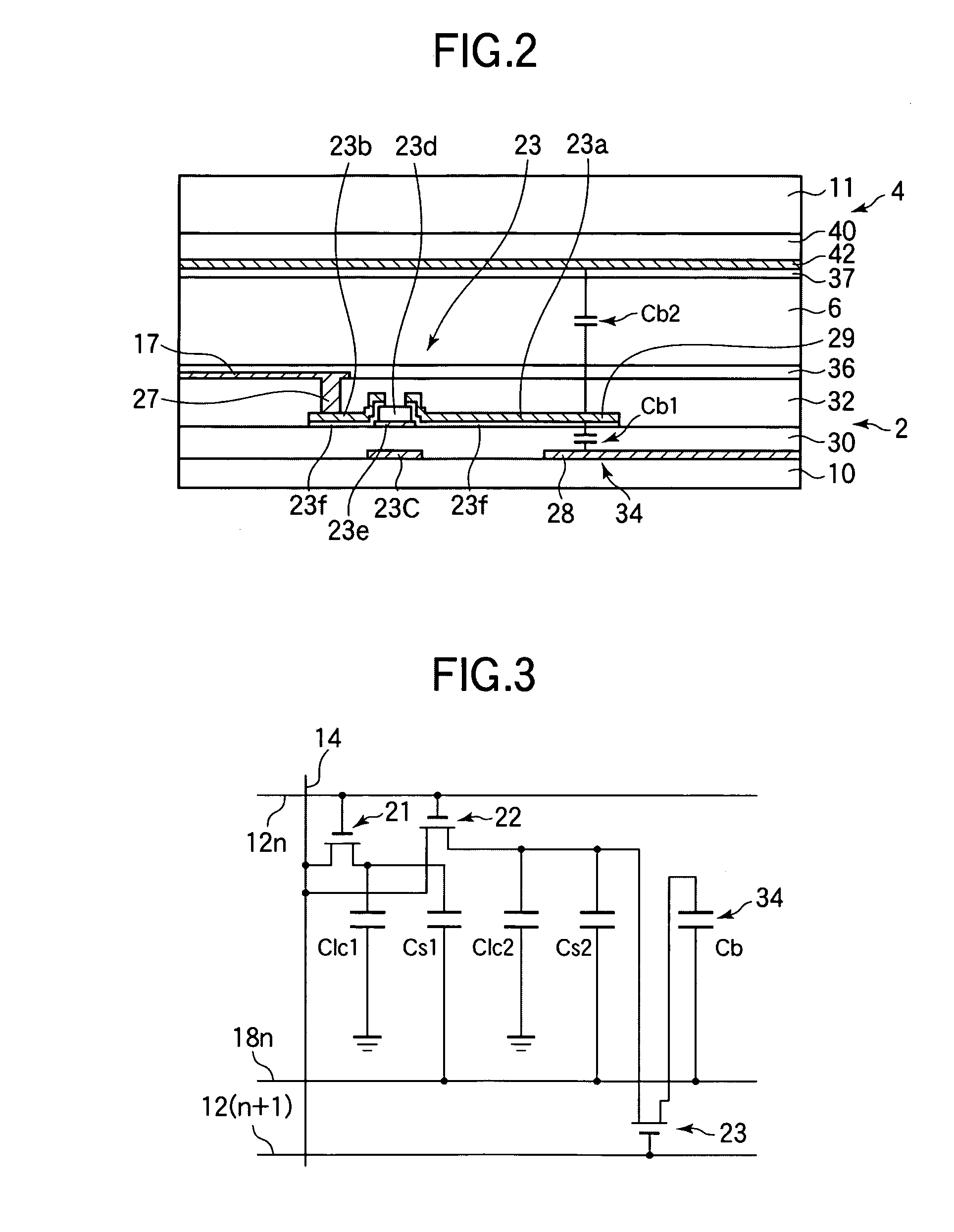

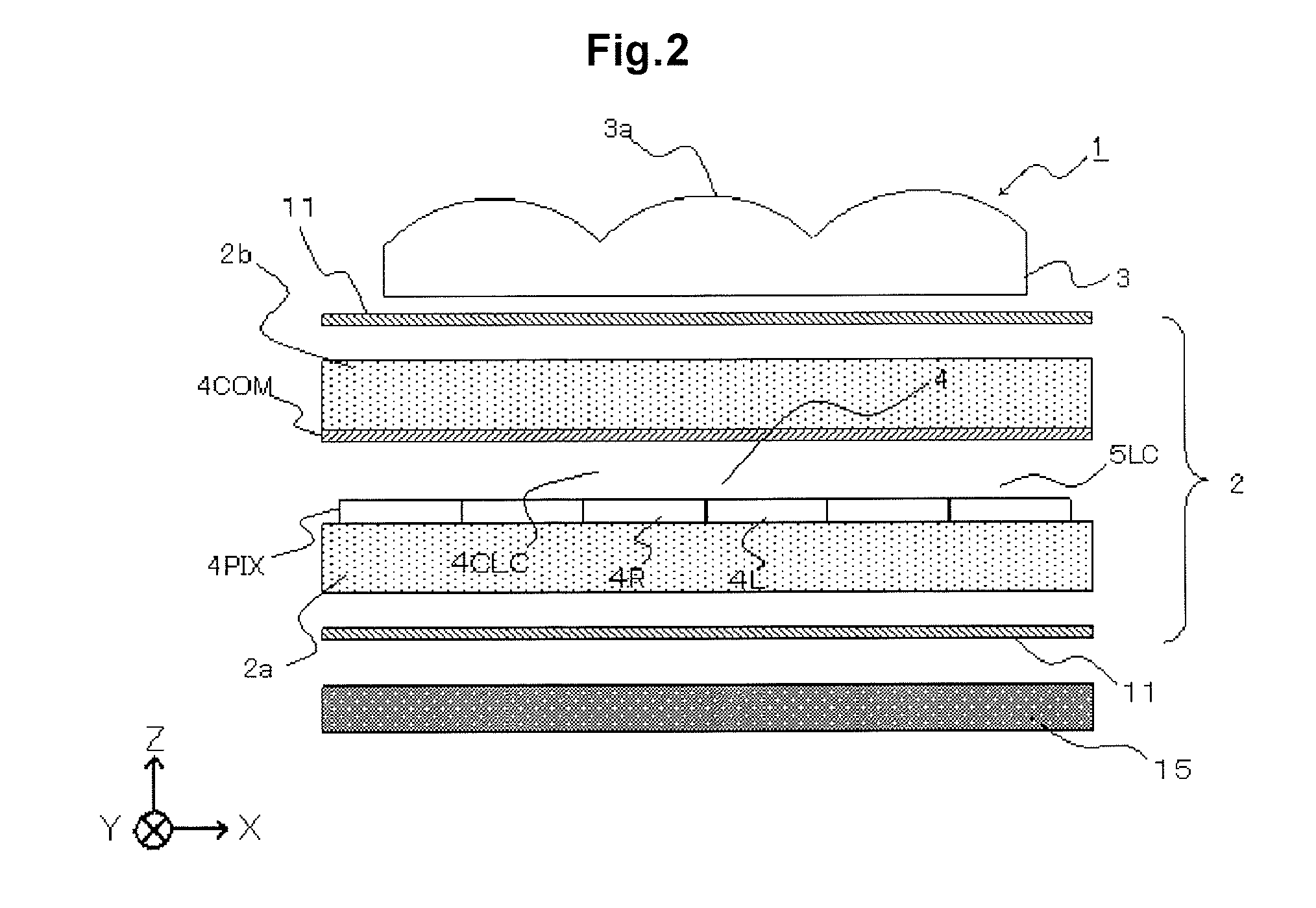

Display device, method of driving same and electronic device mounting same

InactiveUS7286108B2Potential fluctuationSuppress noiseStatic indicating devicesNon-linear opticsCapacitanceData signal

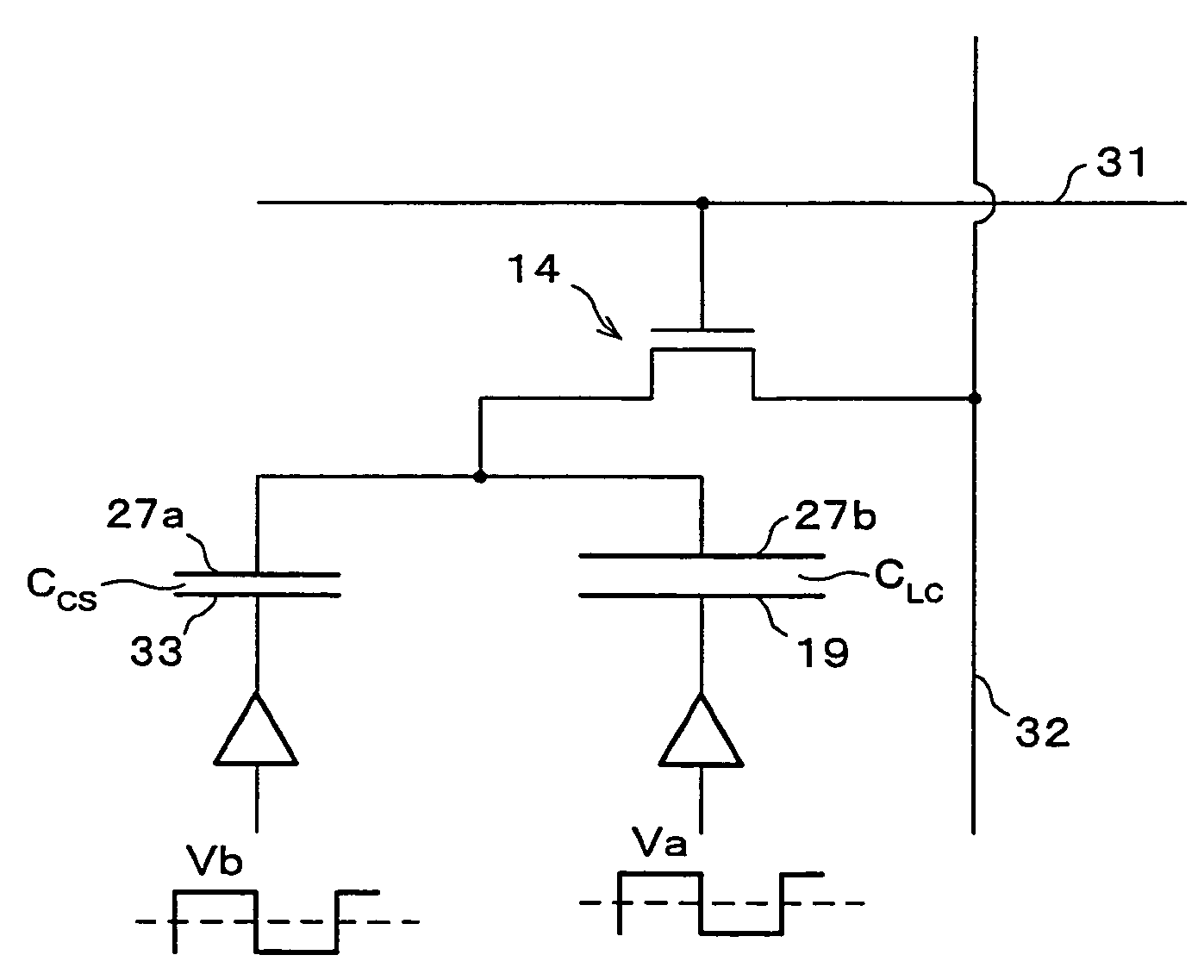

A liquid crystal panel (2) includes scanning signal lines (31) for supplying scanning signals to gate electrodes (20) of TFTs (14), and data signal lines (32) for supplying data signals to data electrodes (24) of TFTs. The liquid crystal panel further includes auxiliary capacitive electrode pads (27a) for use in forming auxiliary capacitance and an auxiliary capacitive lines (33) so as not to generate a capacitive bond with the scanning signal lines. The liquid crystal panel is driven at a rewriting frequency of a screen of not more than 30 Hz. As a result, the liquid crystal panel can be driven at a low consumption power while maintaining a desirable display quality of the liquid crystal panel.

Owner:SHARP KK

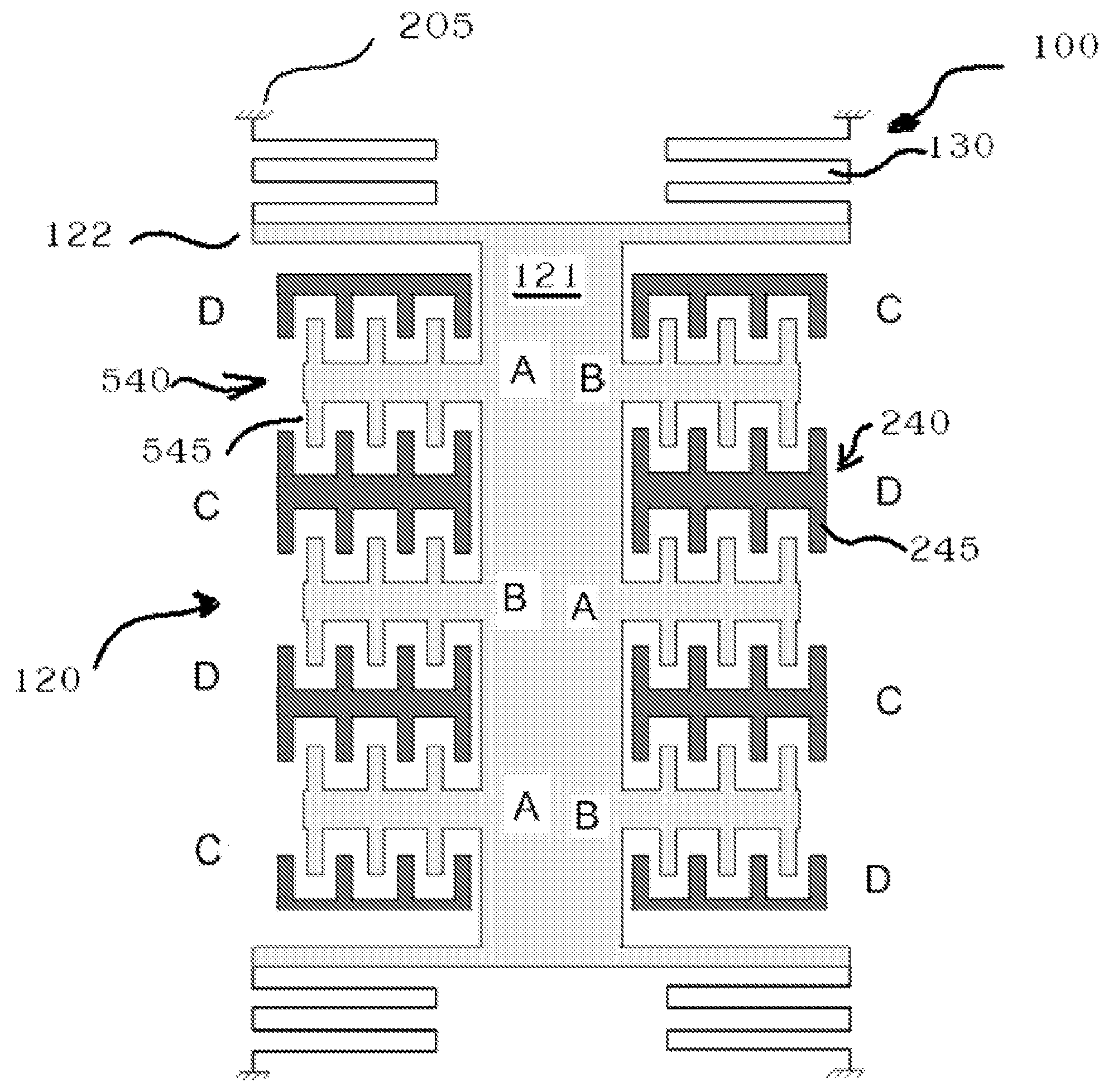

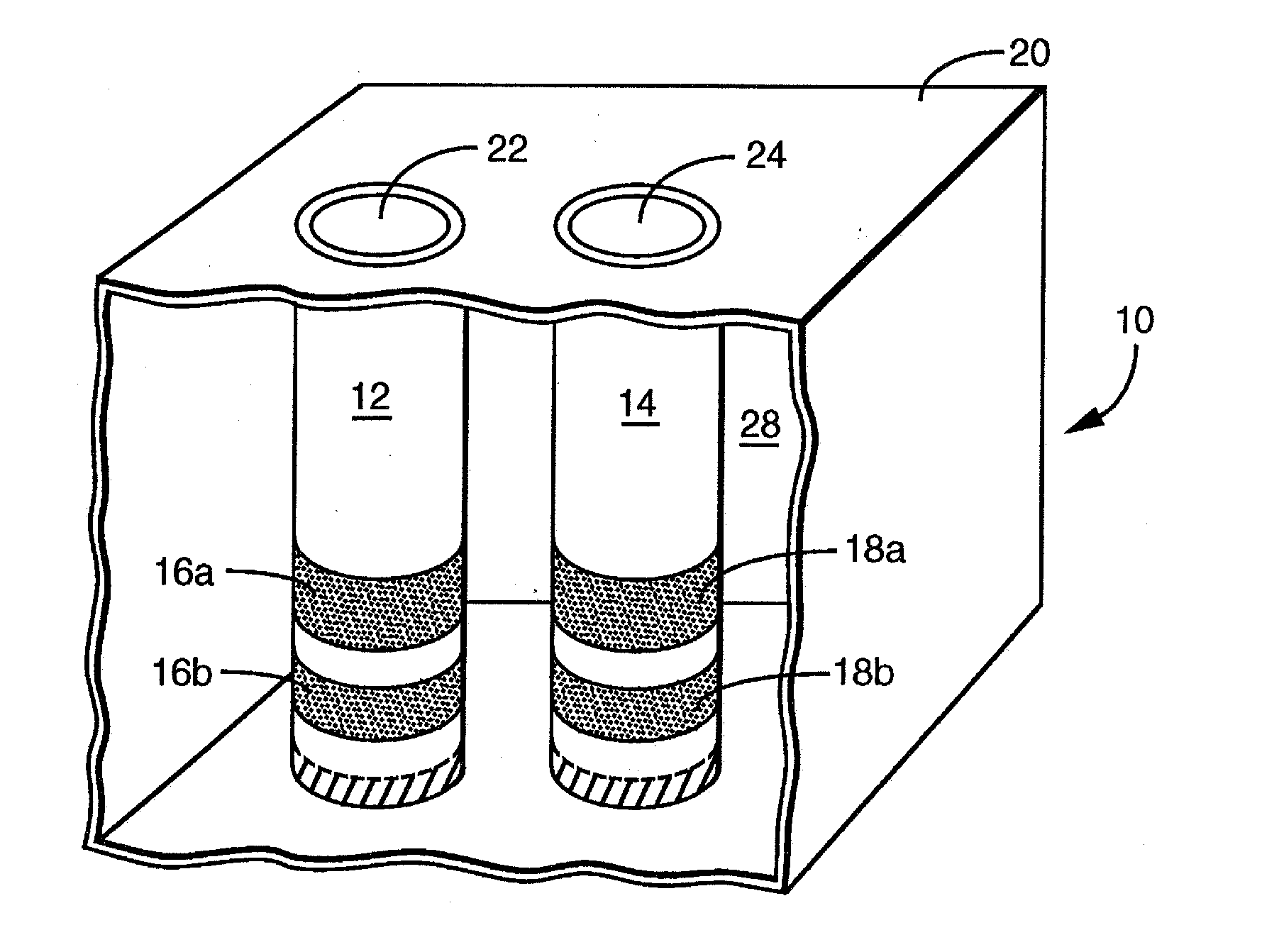

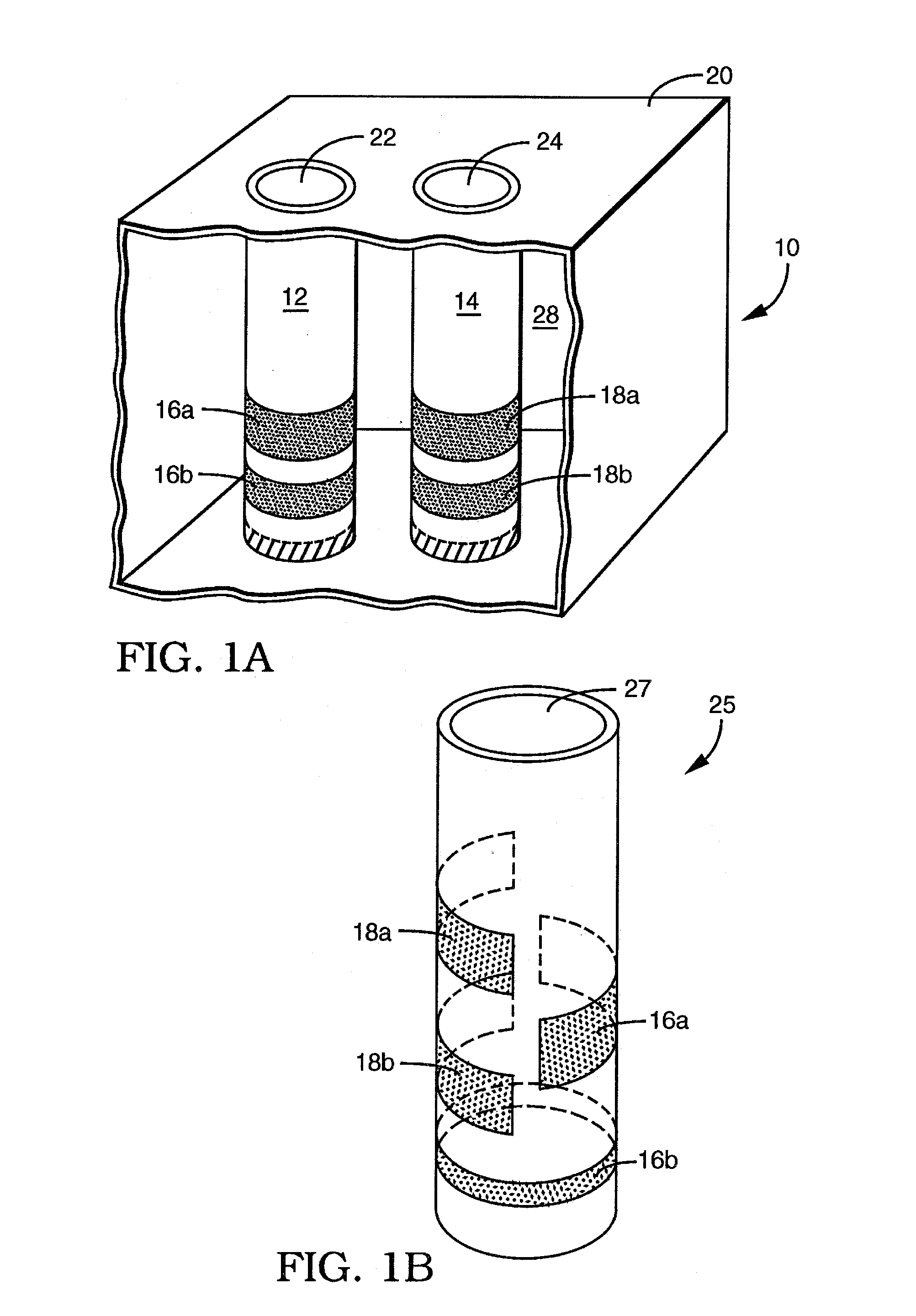

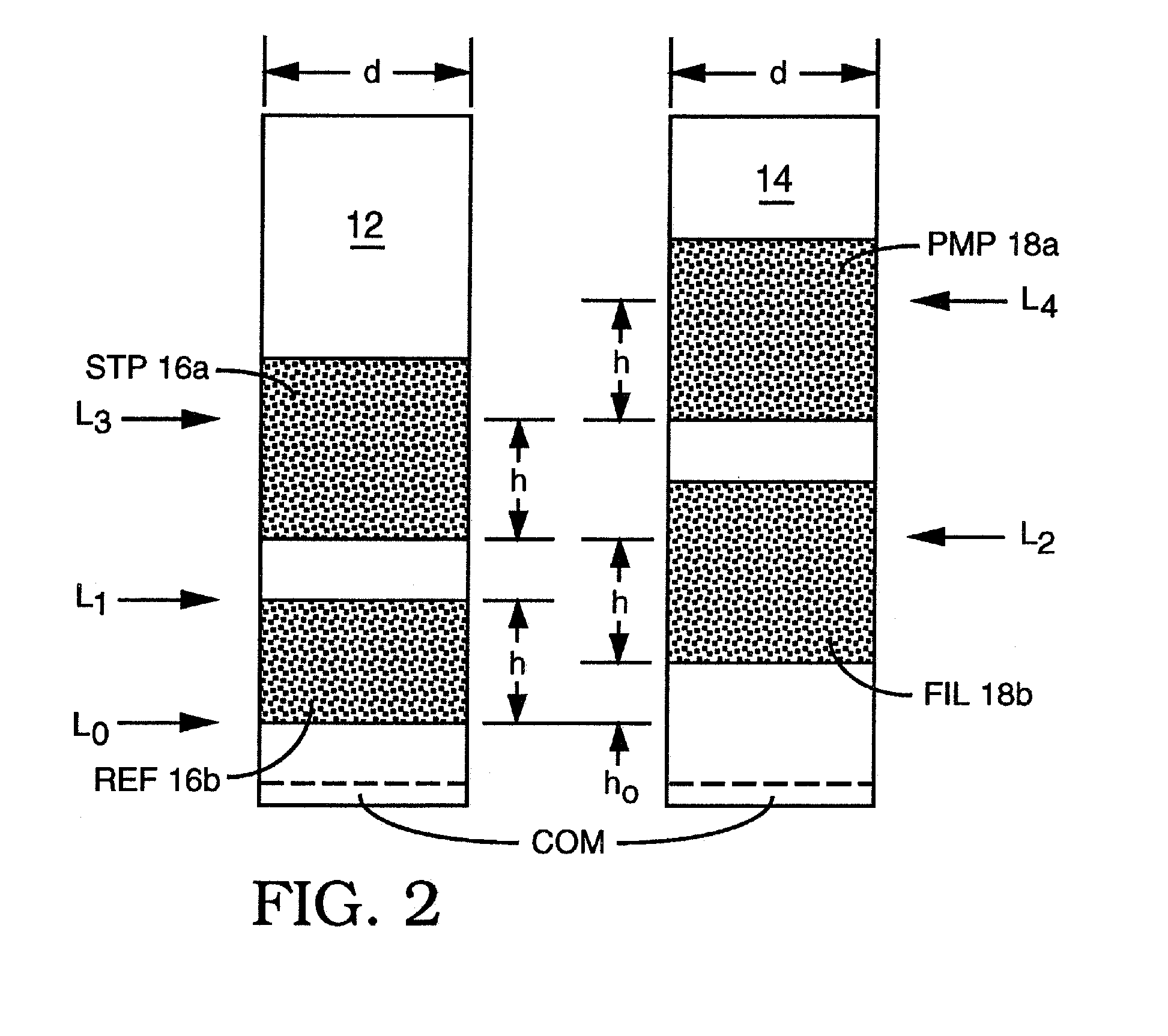

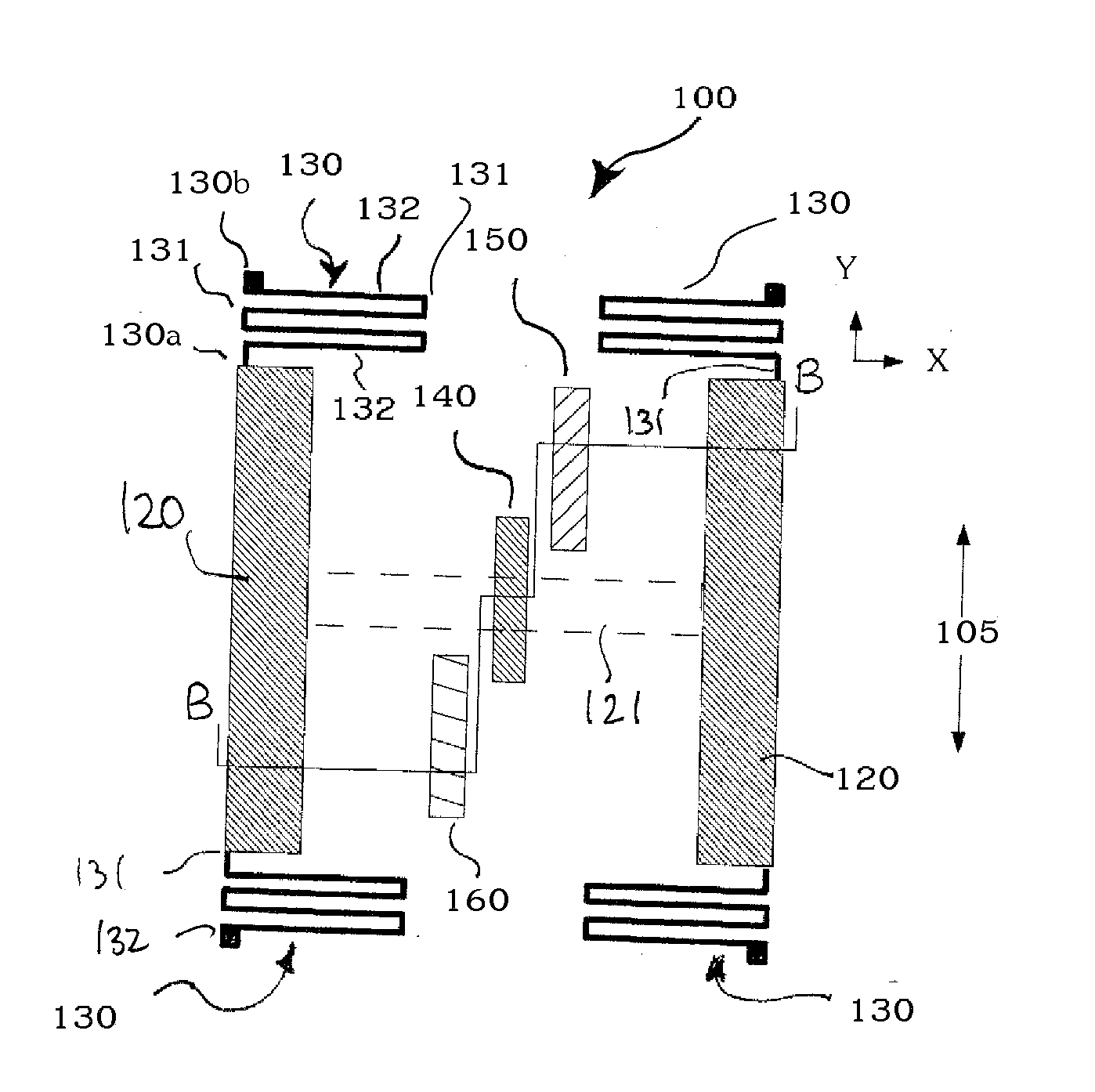

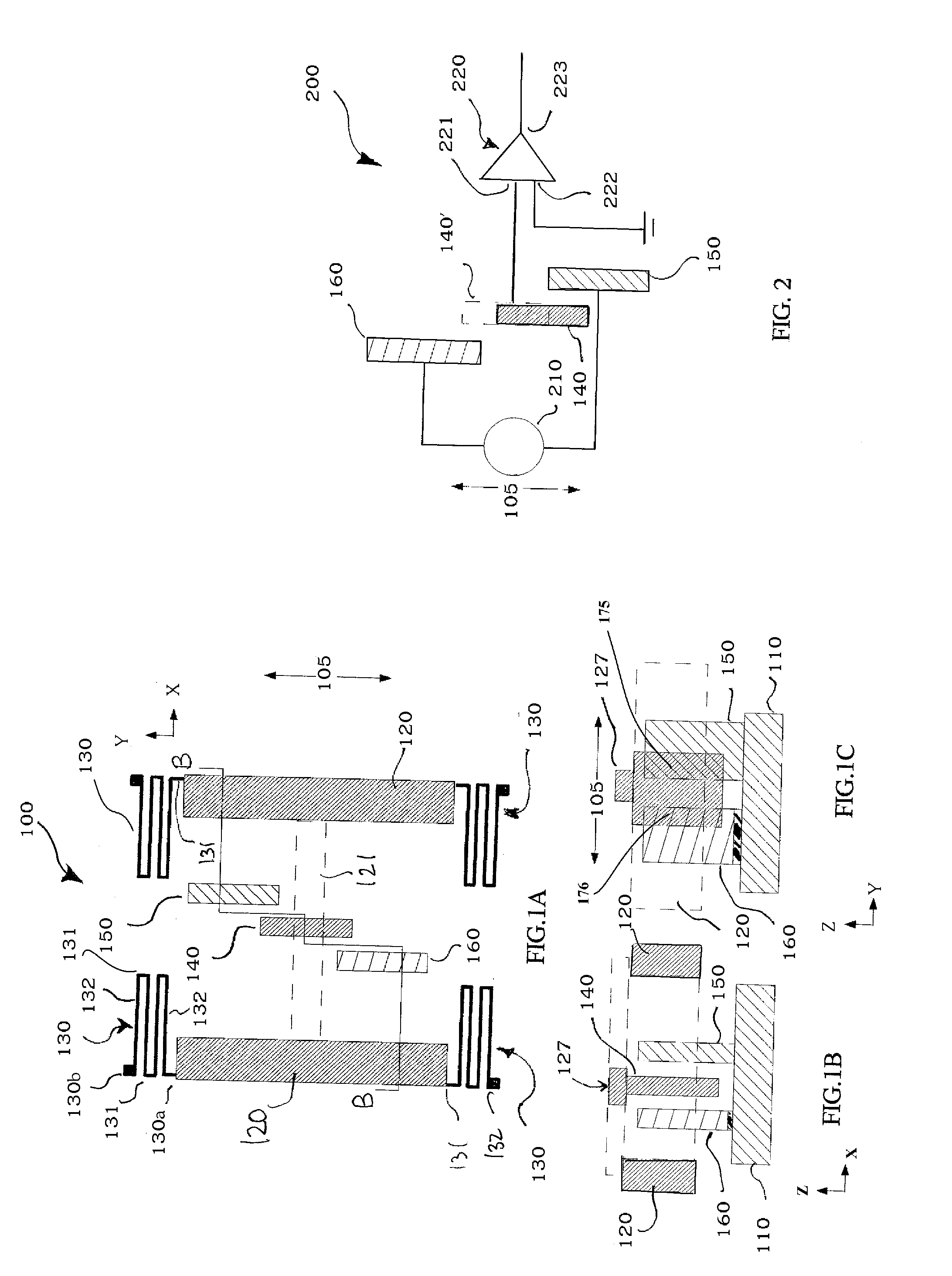

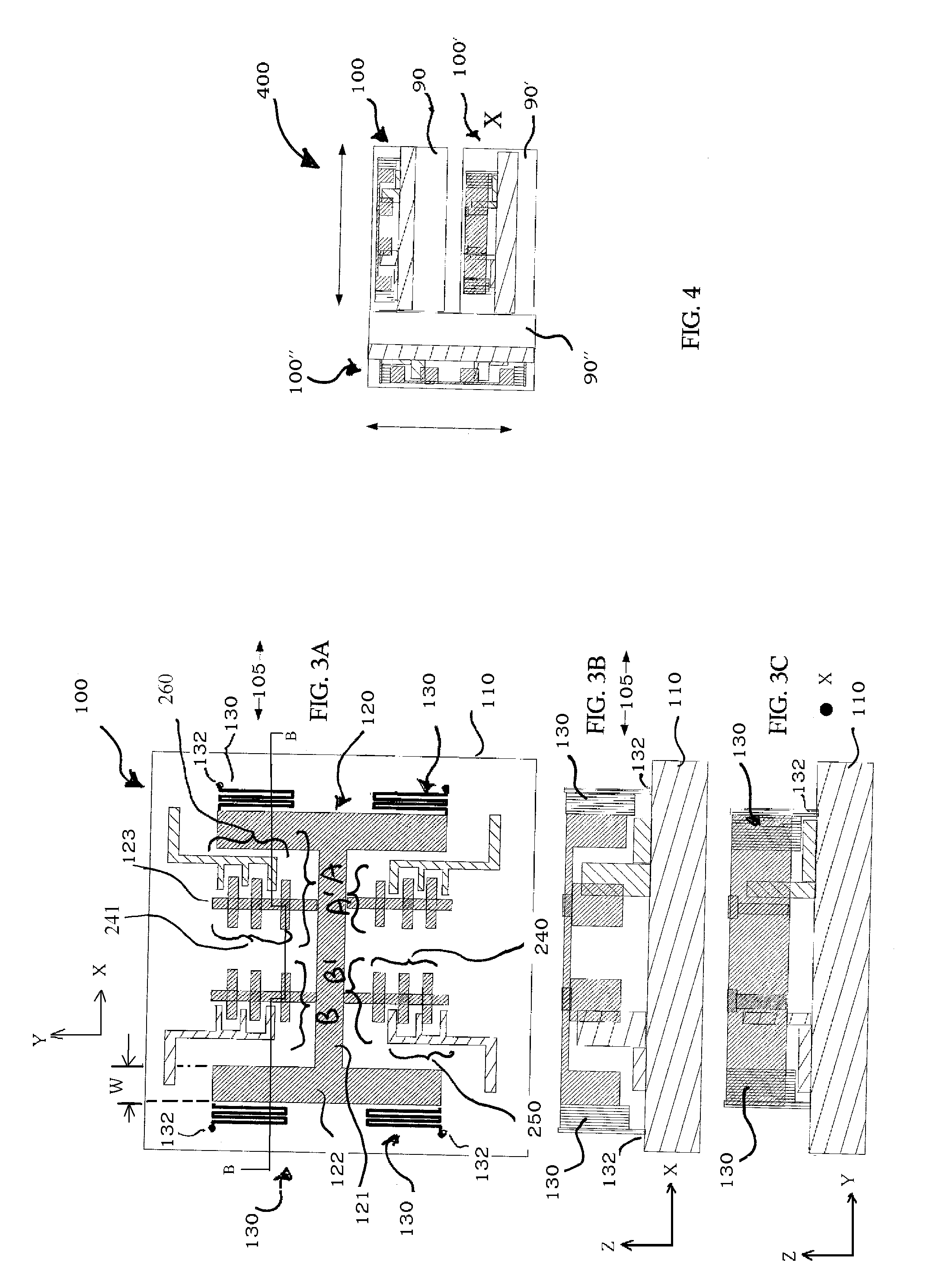

Accelerometer

ActiveUS7617729B2Cancel noiseQuality improvementAcceleration measurementCapacitanceClassical mechanics

An accelerometer is fabricated as a MEMS device and includes an array of capacitive electrode plates mechanically coupled to a common proof mass.The proof mass is constrained to move or vibrate in the plane parallel to the first array of plates. The capacitance between the first array of plates is measured with respect to additional arrays of capacitive plates inter-digitated in a comb like pattern.

Owner:PHYSICAL LOGIC LTD

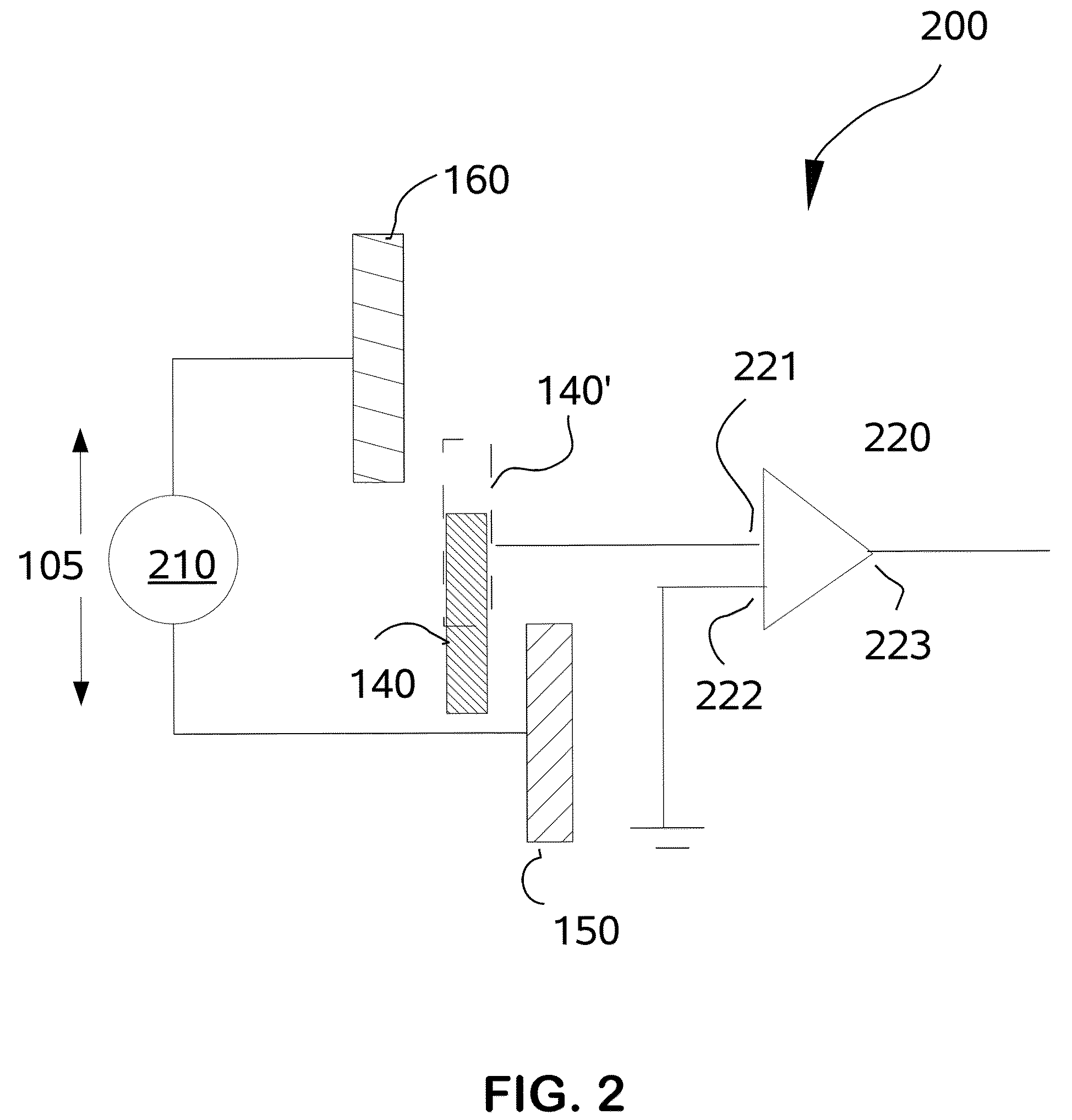

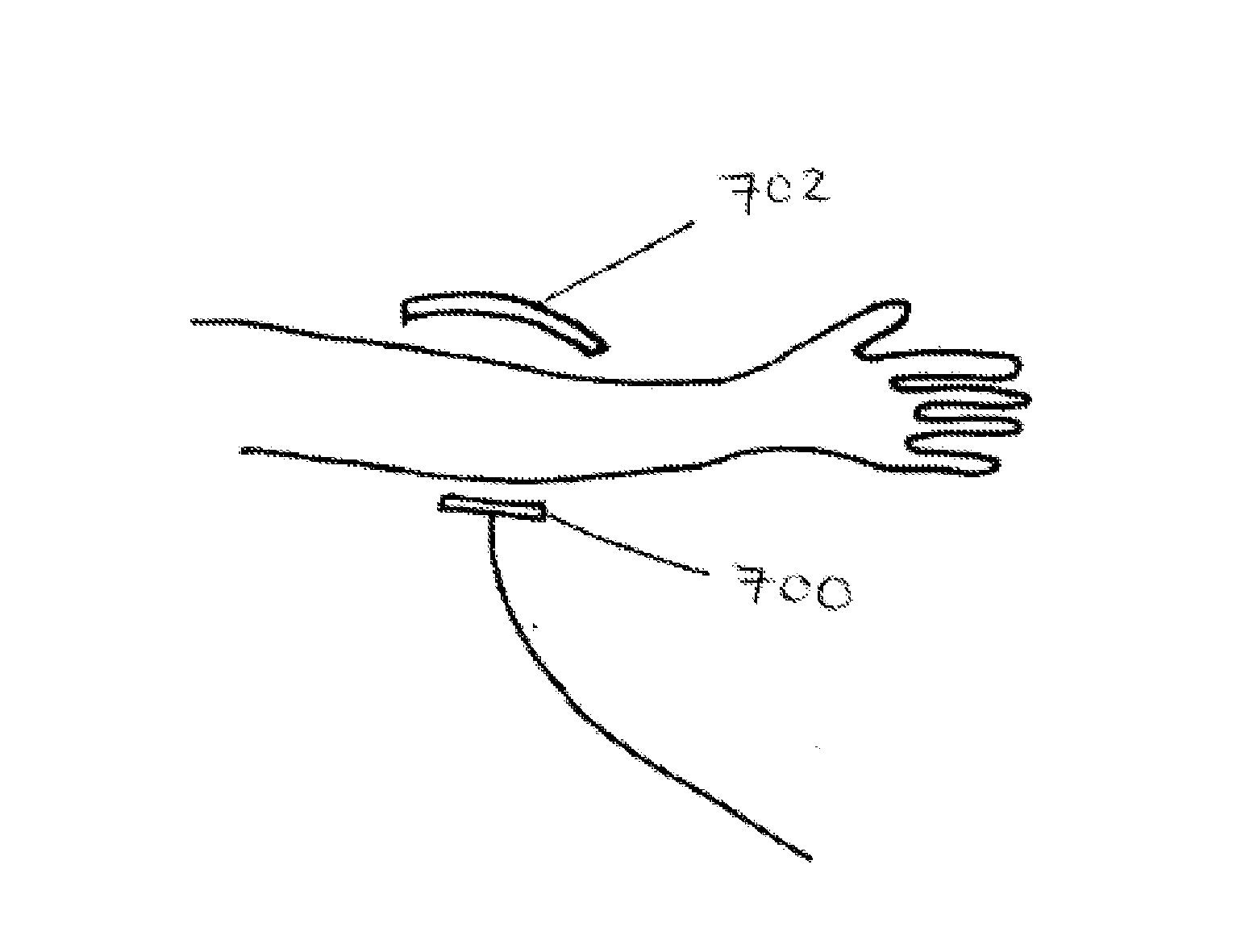

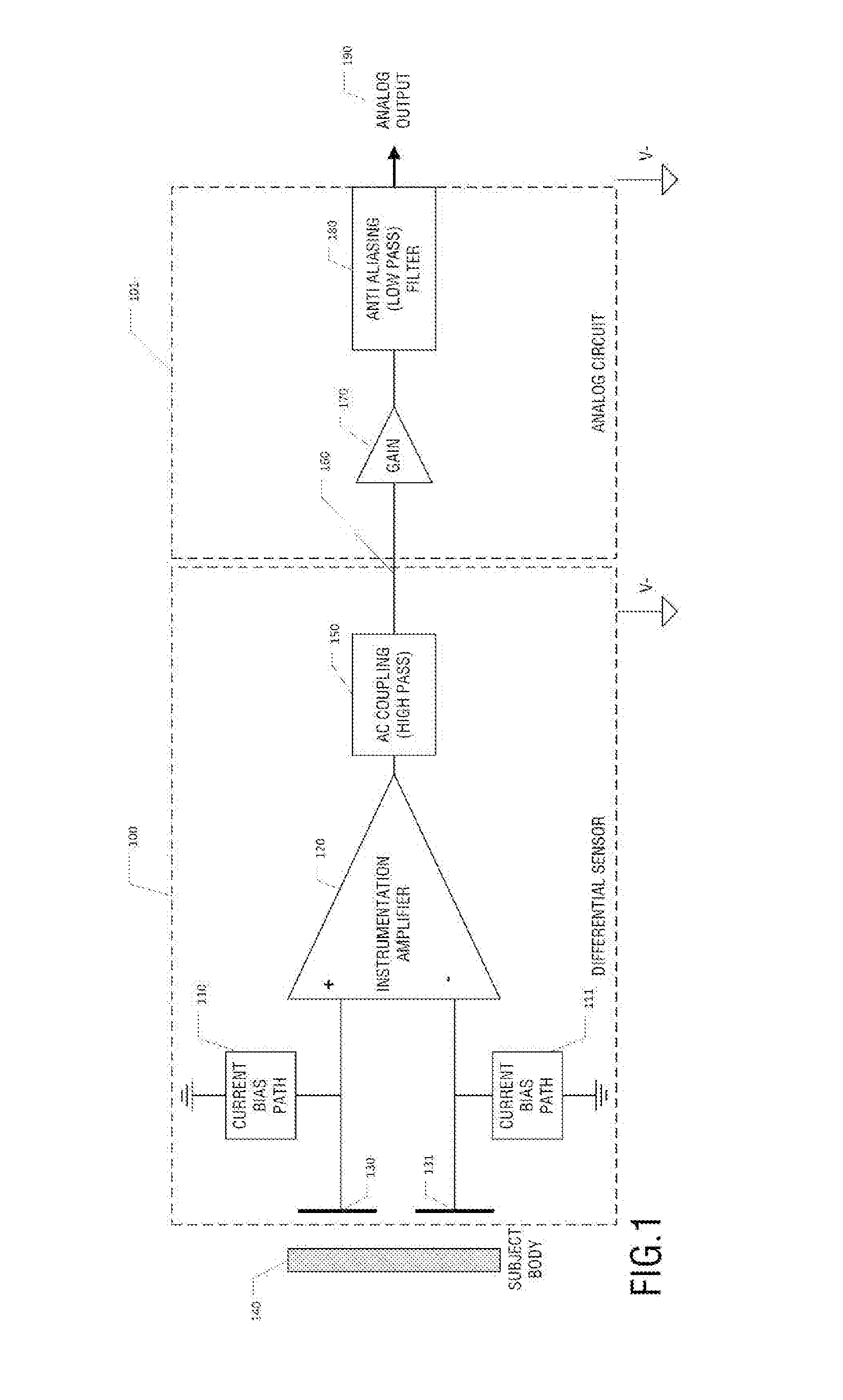

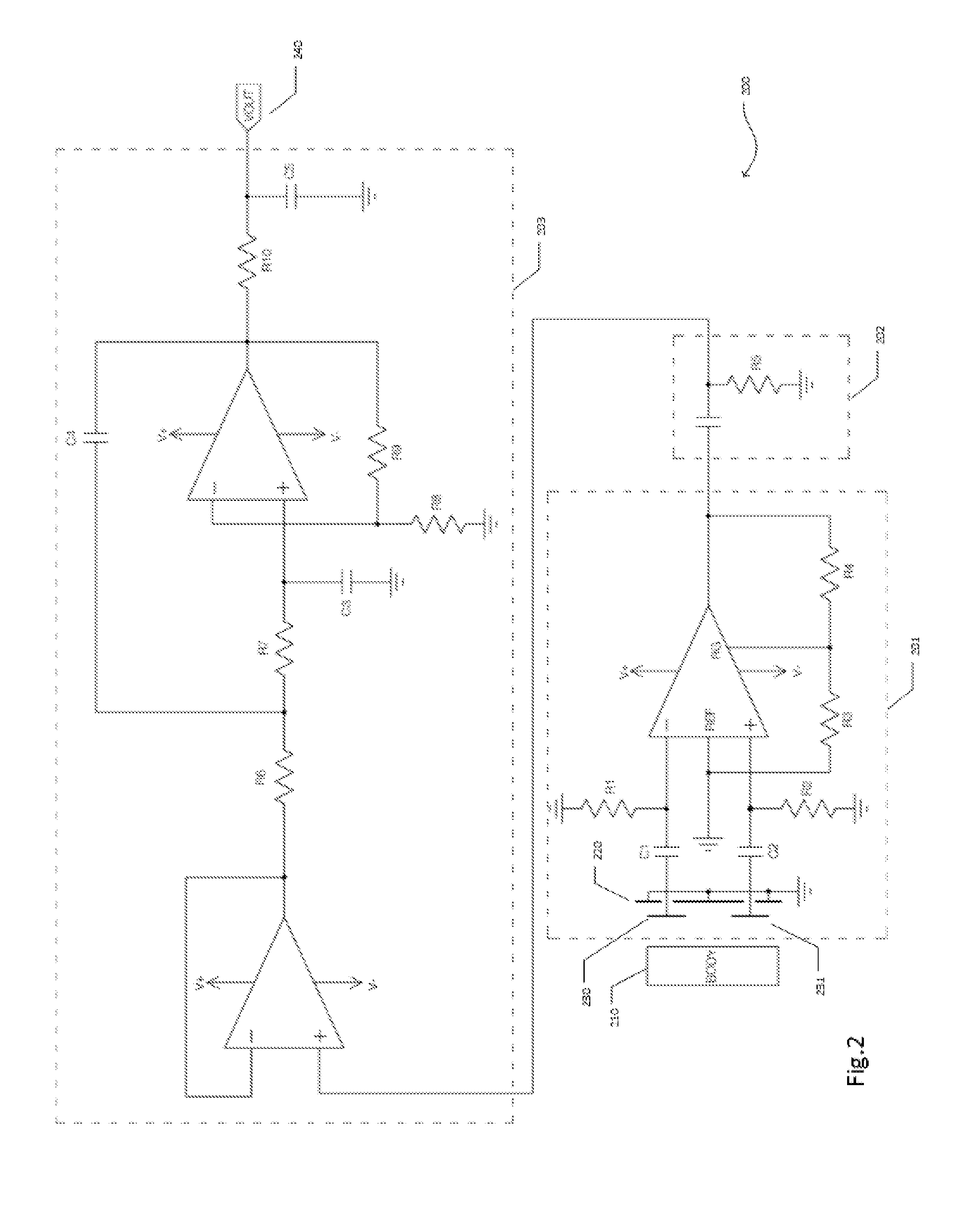

Differential non-contact biopotential sensor

InactiveUS20140249397A1Reduce the environmentReduce ambient noiseElectromyographySensorsLow noiseDifferential signaling

A differential non-contact sensor system for measuring biopotential signals is described. The sensor is a low-noise, non-contact capacitive sensor system to measure electrical voltage signals generated by the body comprising two capacitive electrodes and outputting a differential signal.

Owner:THALMIC LABS

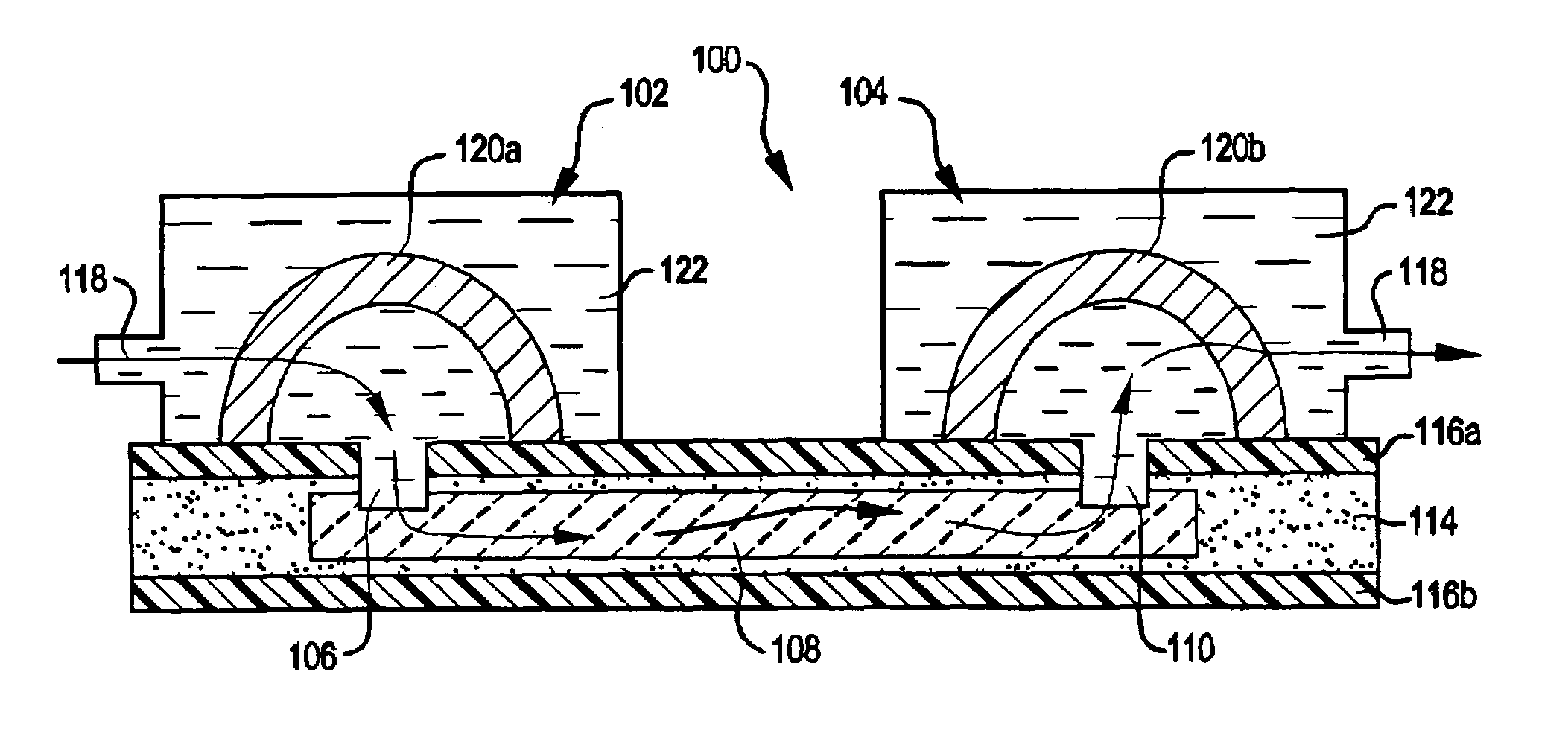

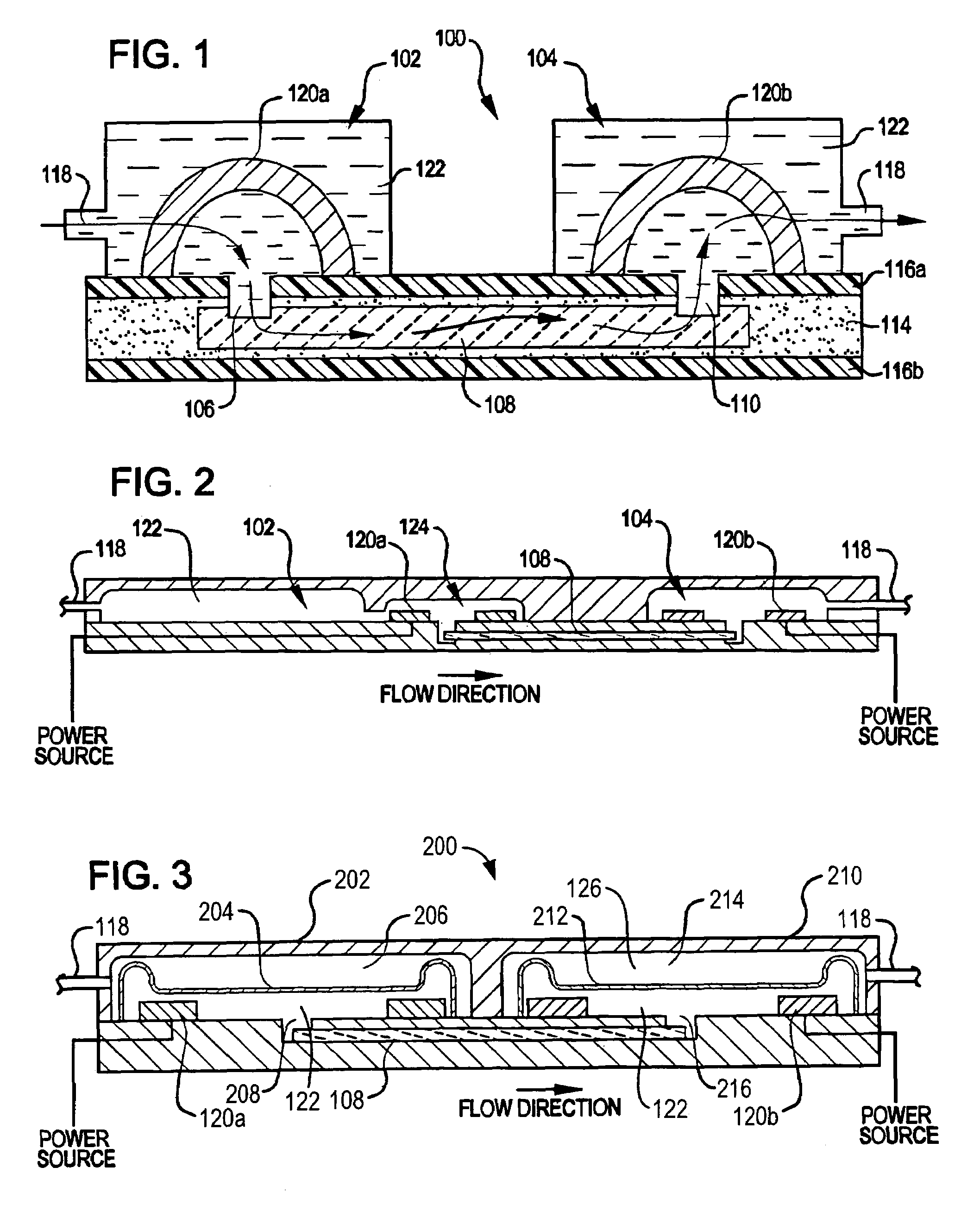

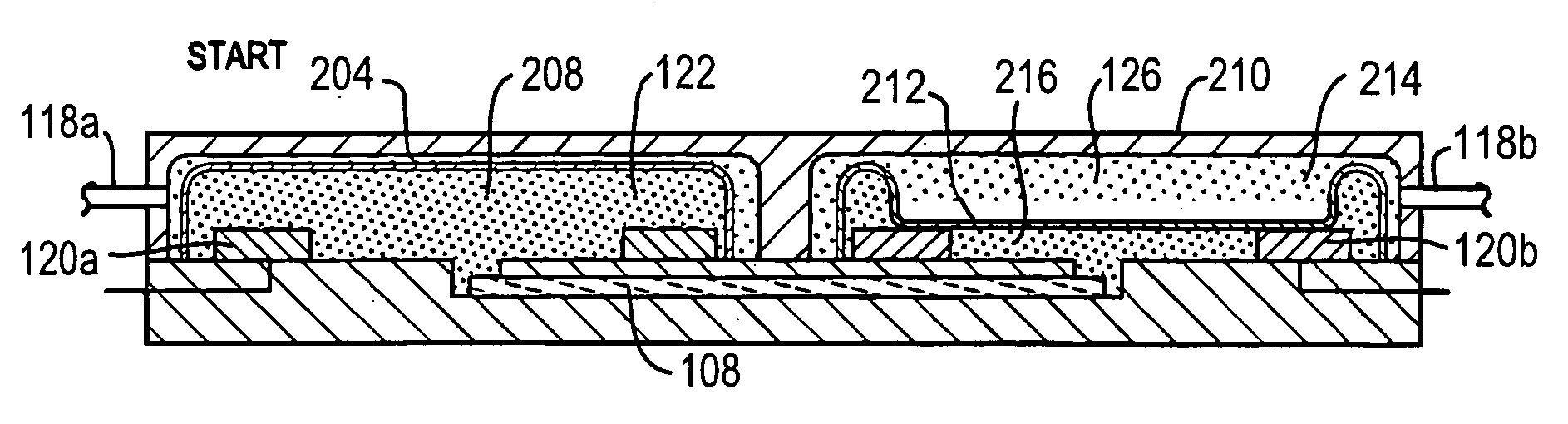

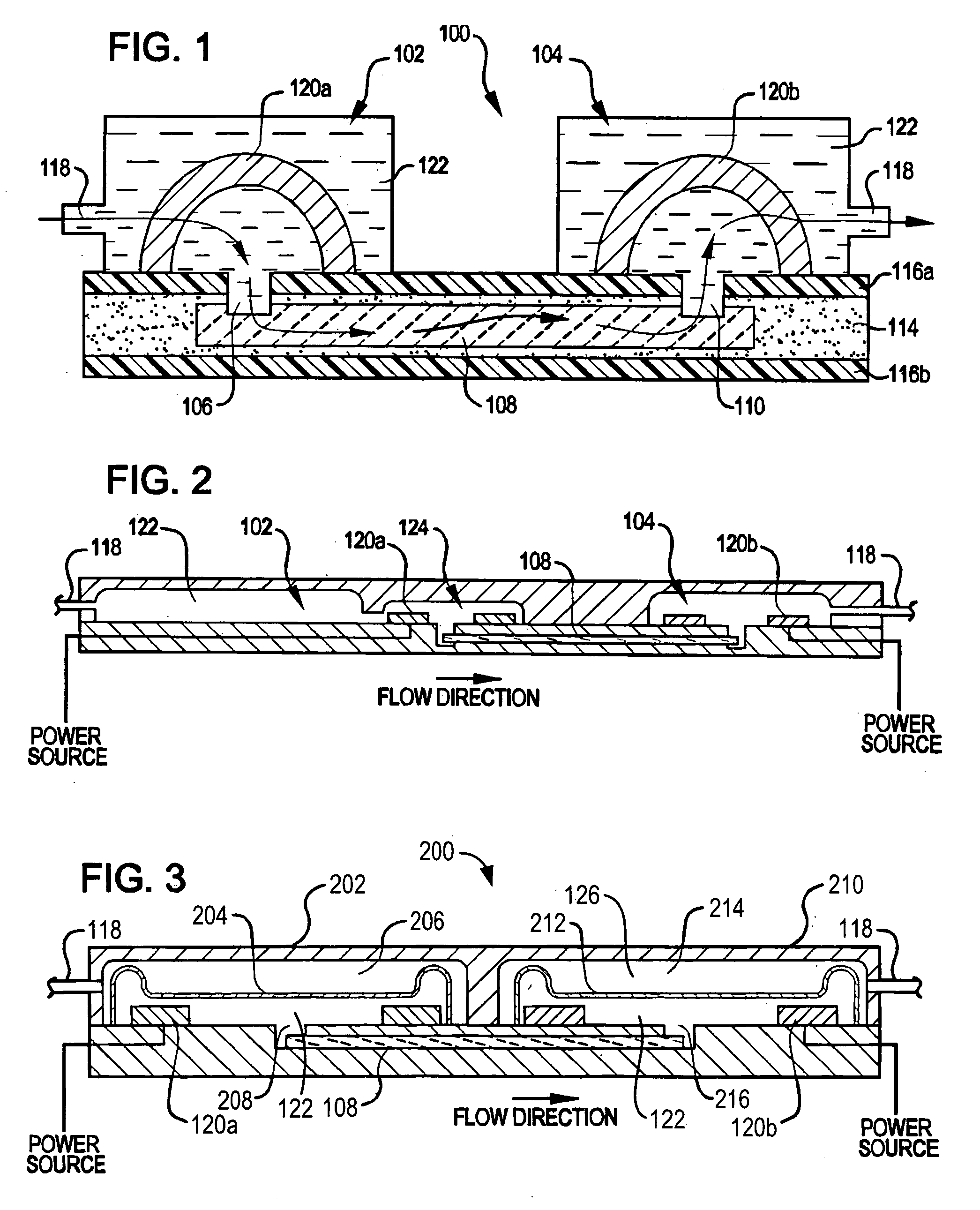

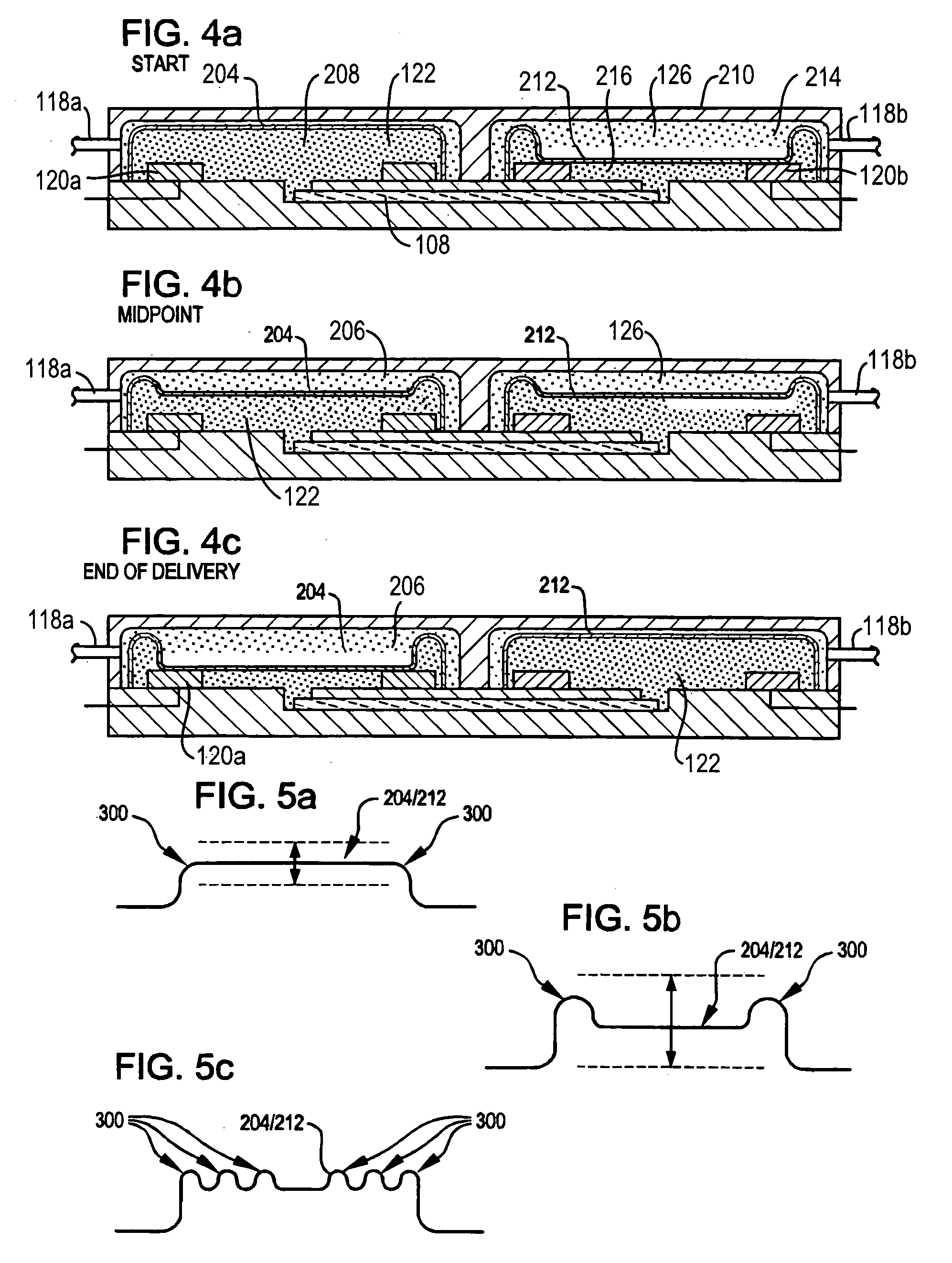

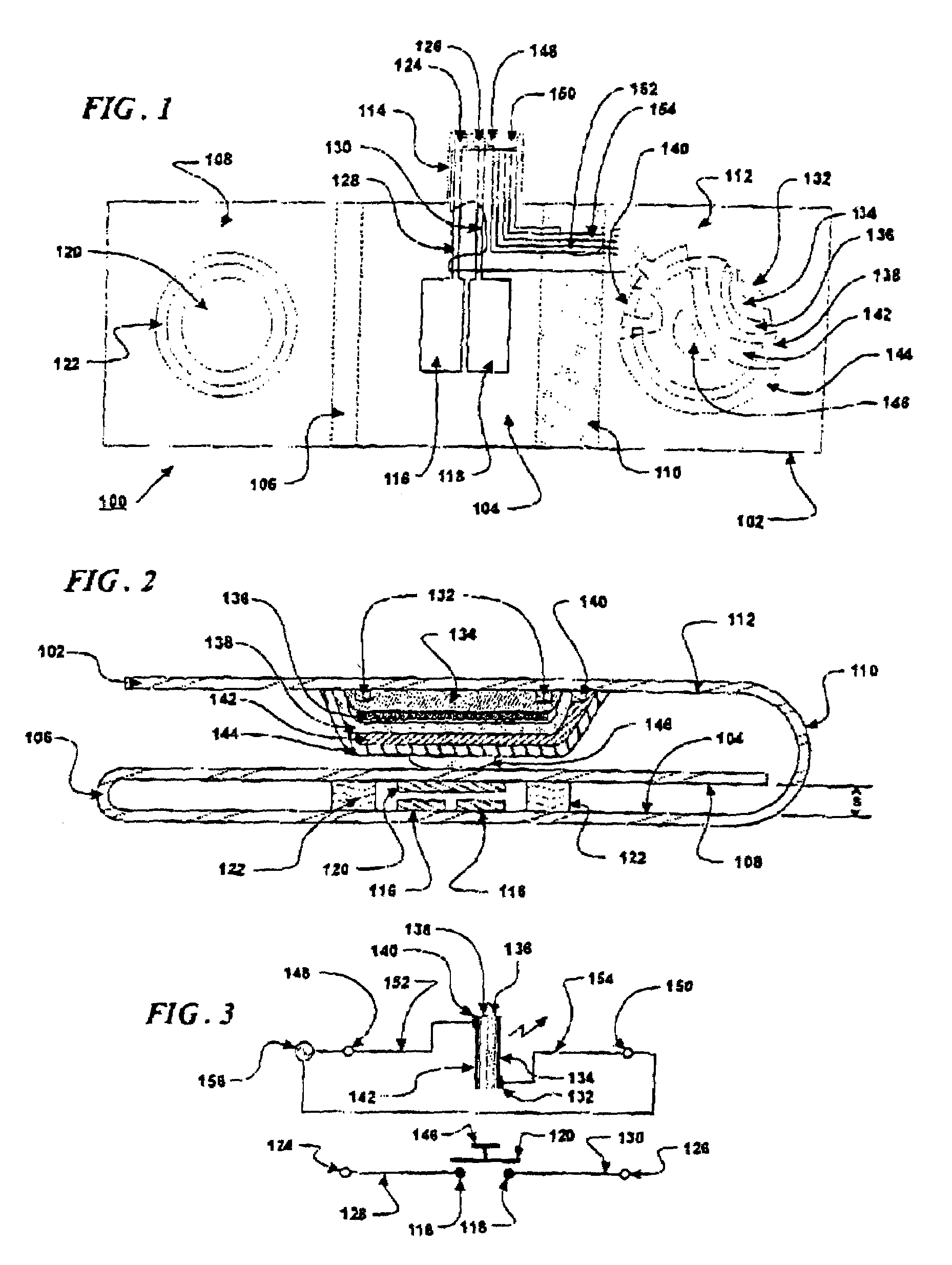

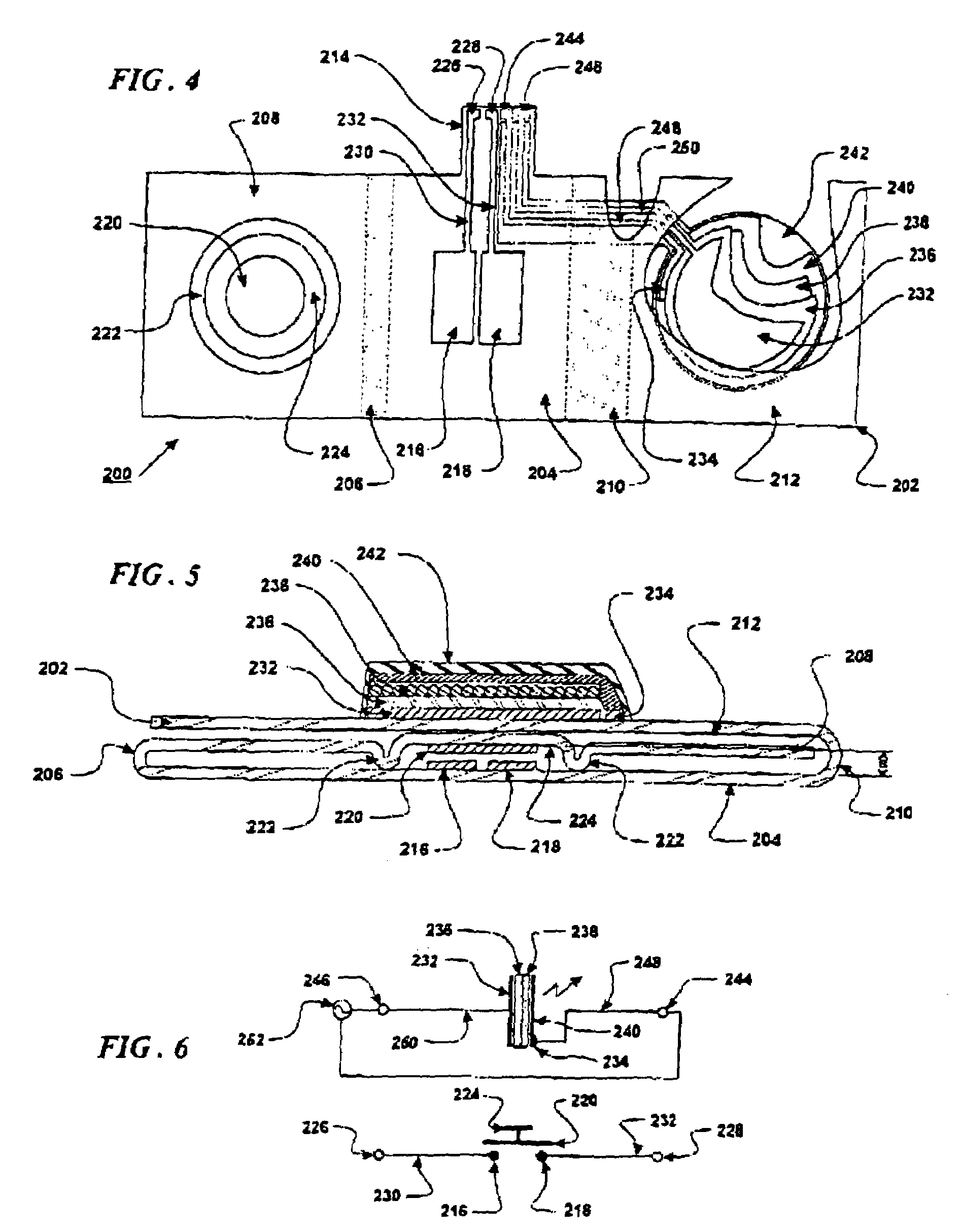

Electrokinetic delivery systems, devices and methods

InactiveUS7517440B2Efficient and reliable and highly movementSludge treatmentVolume/mass flow measurementElectricityCapacitance

A method of pumping fluid including the steps of providing an electrokinetic pump comprising a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2 and being connectable to a power source, a porous dielectric material disposed between the electrodes and a reservoir containing pump fluid; connecting the electrodes to a power source; and moving pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump. The invention also includes an electrokinetic pump system having a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2; a porous dielectric material disposed between the electrodes; a reservoir containing pump fluid; and a power source connected to the electrodes; the electrodes, dielectric material and power source being adapted to move the pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump.

Owner:TELEFLEX LIFE SCI PTE LTD

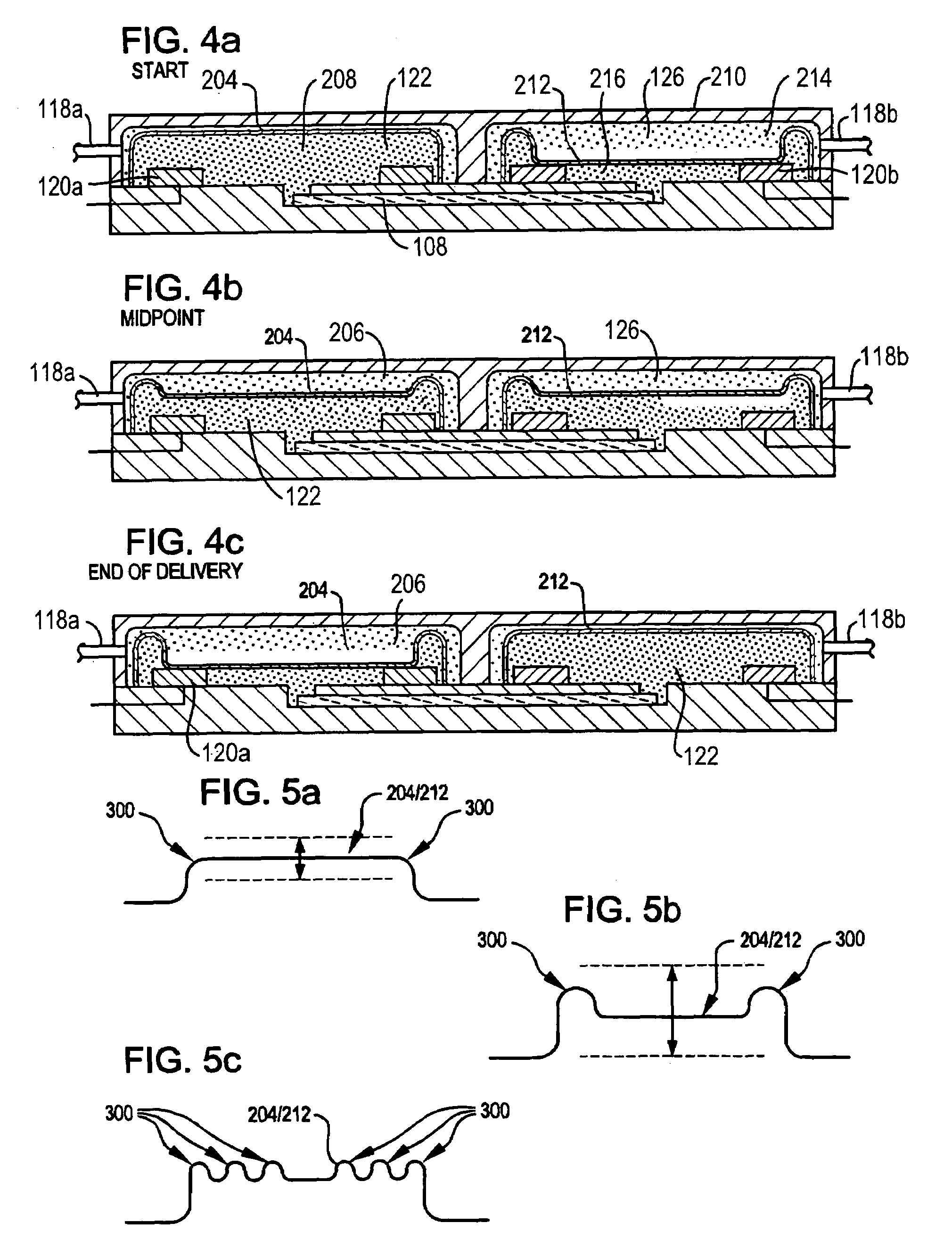

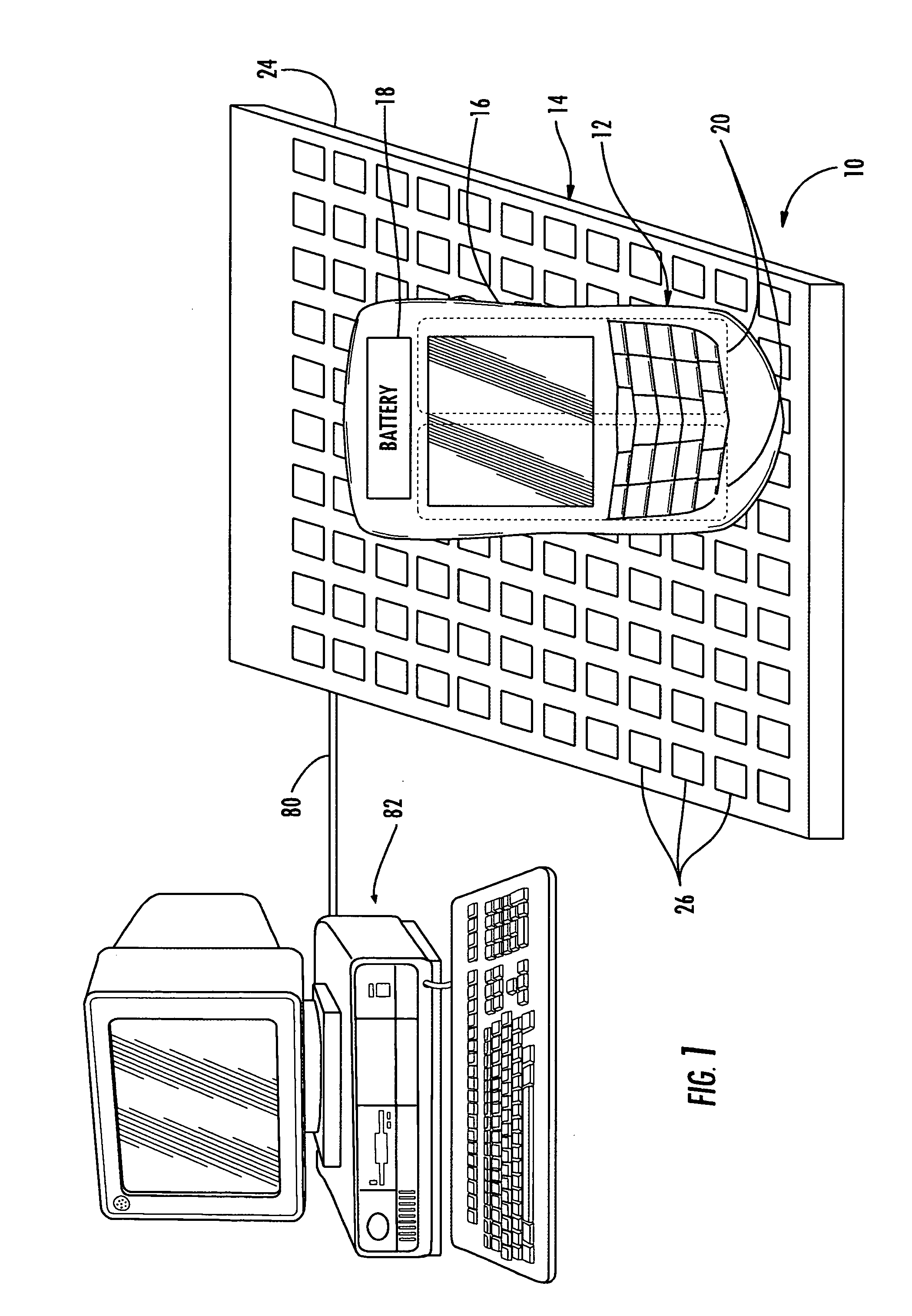

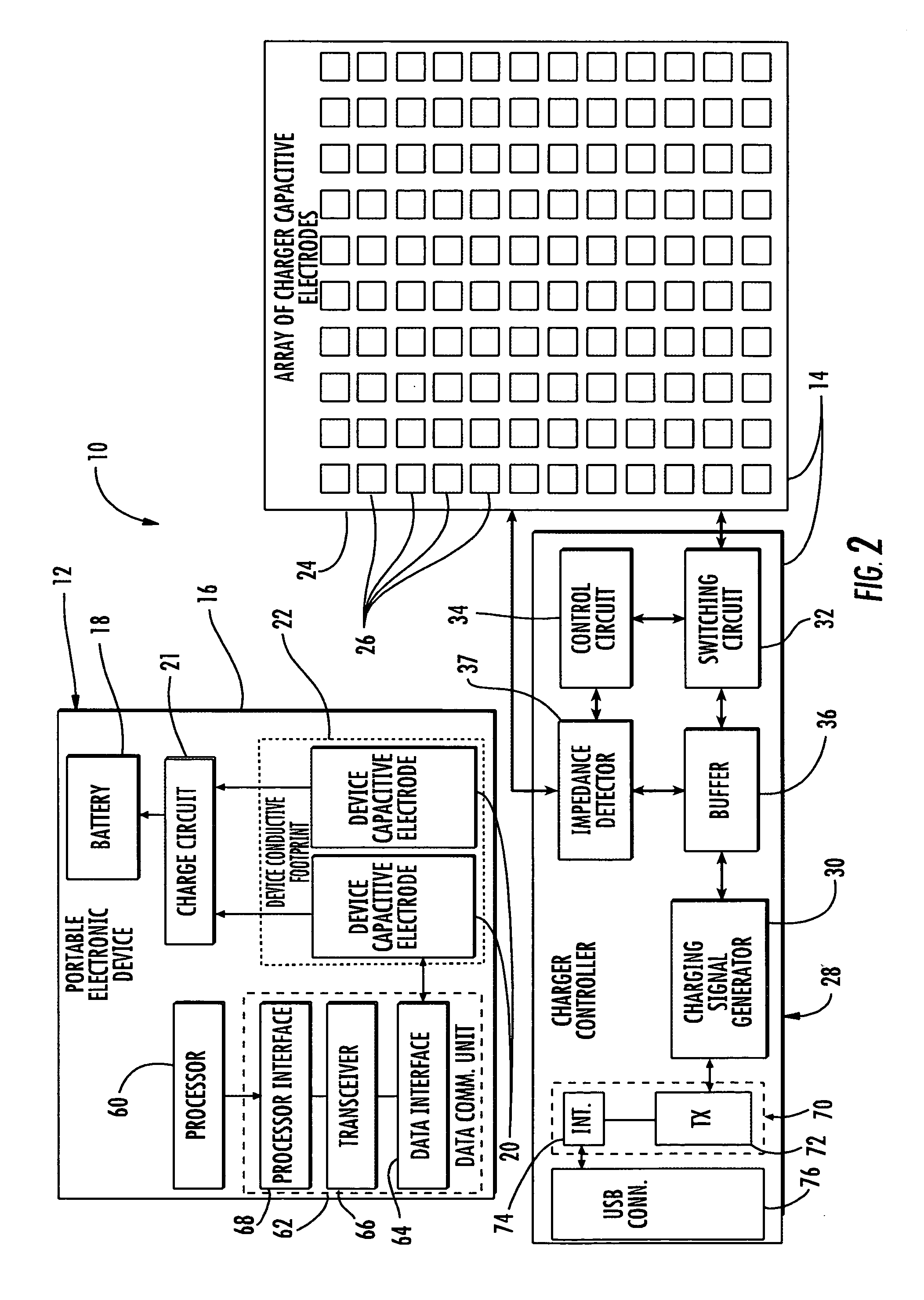

Portable electronic device and capacitive charger providing data transfer and associated methods

ActiveUS20070126393A1Batteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCommunication unit

The electronic apparatus includes a portable electronic device and a charger for capacitively charging the portable electronic device when the portable electronic device is temporarily placed adjacent the charger. The portable electronic device includes a device data communication unit and an associated battery, and a pair of device capacitive electrodes, defining a device conductive footprint, to receive a charging signal to charge the battery. The charger includes a base having an area larger than the device conductive footprint and able to receive the portable electronic device thereon in a plurality of different positions, and an array of charger capacitive electrodes carried by the base. A charger controller selectively drives only the charger capacitive electrodes within the device conductive footprint with a charging signal to capacitively charge the battery. A charger data communication unit communicates with the device data communication unit via the charger capacitive electrodes and device capacitive electrodes, e.g. by modulating data onto the charging signal.

Owner:MALIKIE INNOVATIONS LTD

Electrokinetic delivery systems, devices and methods

InactiveUS20050247558A1Efficient and reliable and highly movementSludge treatmentVolume/mass flow measurementElectricityCapacitance

A method of pumping fluid including the steps of providing an electrokinetic pump comprising a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2 and being connectable to a power source, a porous dielectric material disposed between the electrodes and a reservoir containing pump fluid; connecting the electrodes to a power source; and moving pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump. The invention also includes an electrokinetic pump system having a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2; a porous dielectric material disposed between the electrodes; a reservoir containing pump fluid; and a power source connected to the electrodes; the electrodes, dielectric material and power source being adapted to move the pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump.

Owner:TELEFLEX LIFE SCI PTE LTD

Capacitive touch switch and domestic appliance provided with such switch

InactiveUS20090090611A1Increasing the thicknessControl thicknessElectronic switchingElectric switchesLight guideEngineering

A capacitive touch switch having a printed circuit board and capacitive electrode provided on a surface of the printed circuit board is disclosed. The printed circuit board is interposed between a transparent planar light guide and the electrode, the planar light guide being attached to a first face of a transparent cover whose second face is adapted to be touched by the user, a light source being connected to the printed circuit board and being able to convey light to the planar light guide.

Owner:WHIRLPOOL CORP

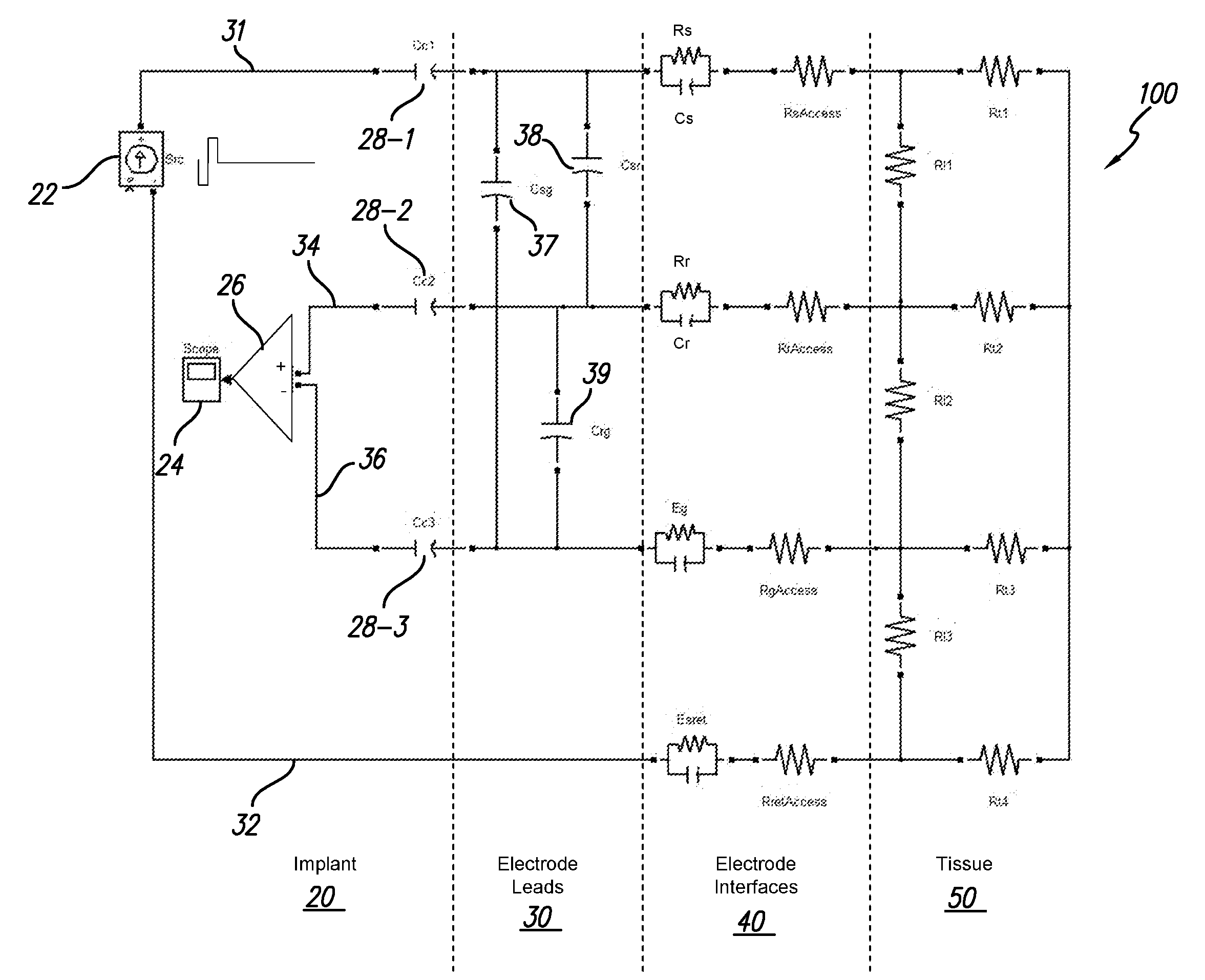

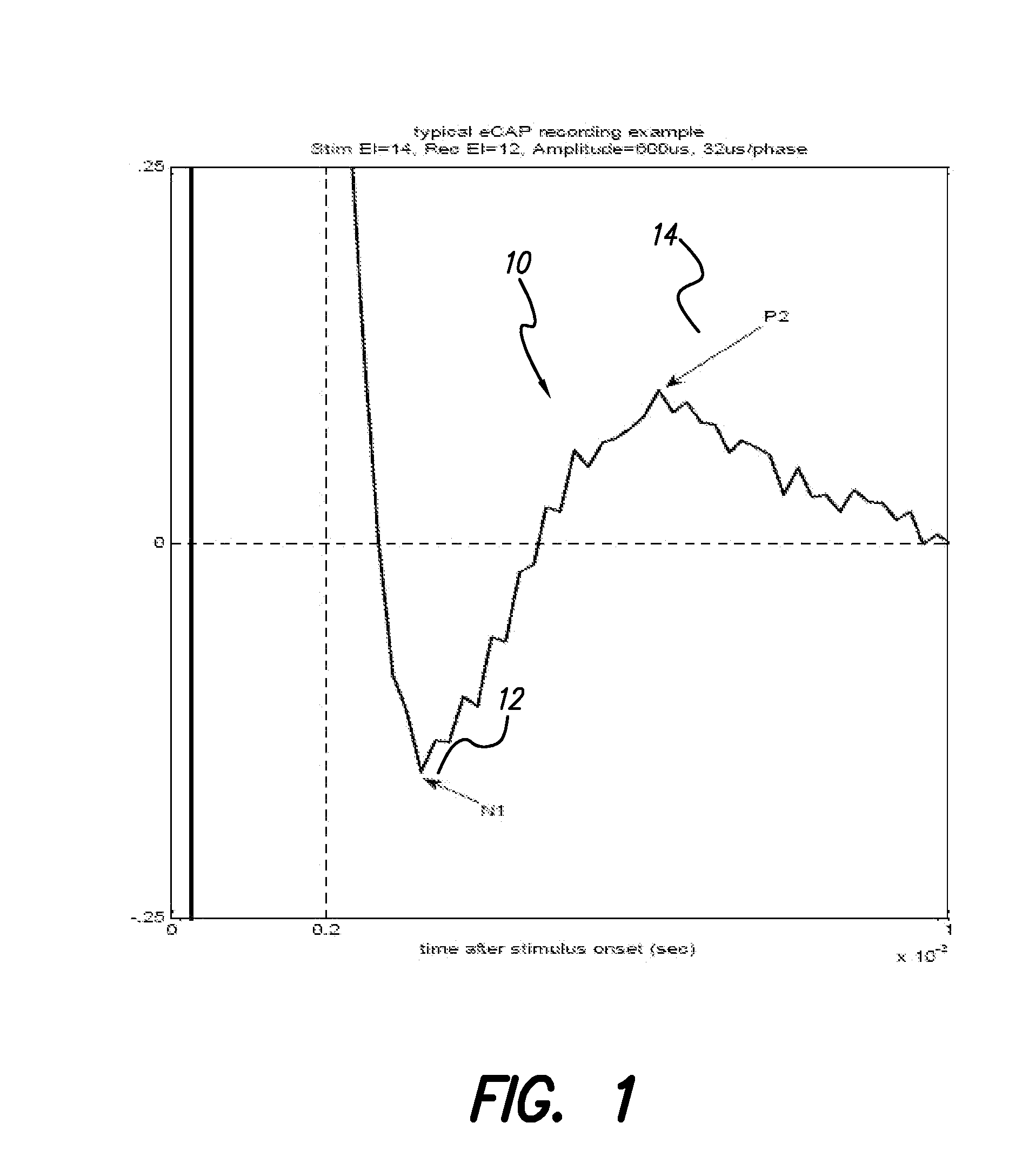

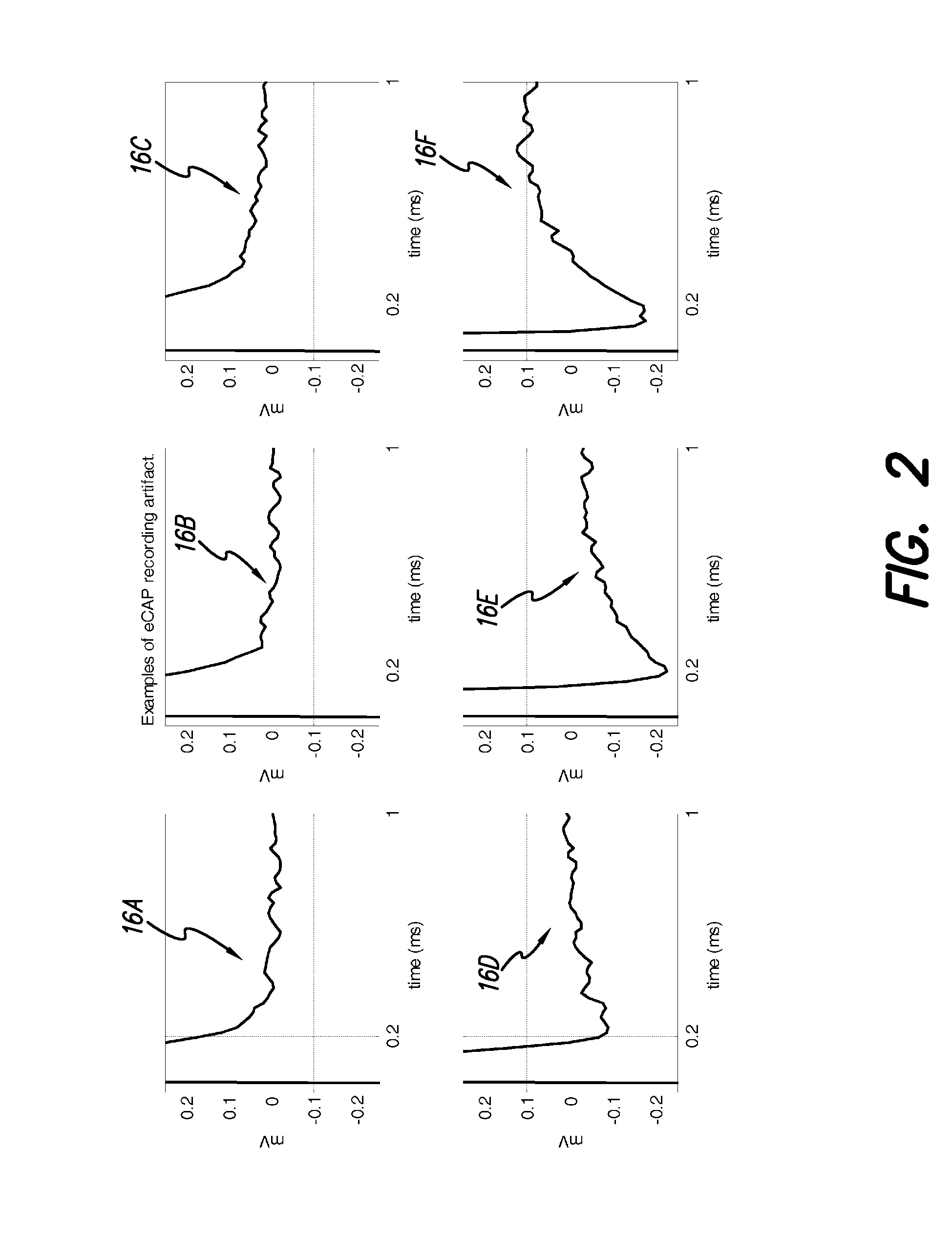

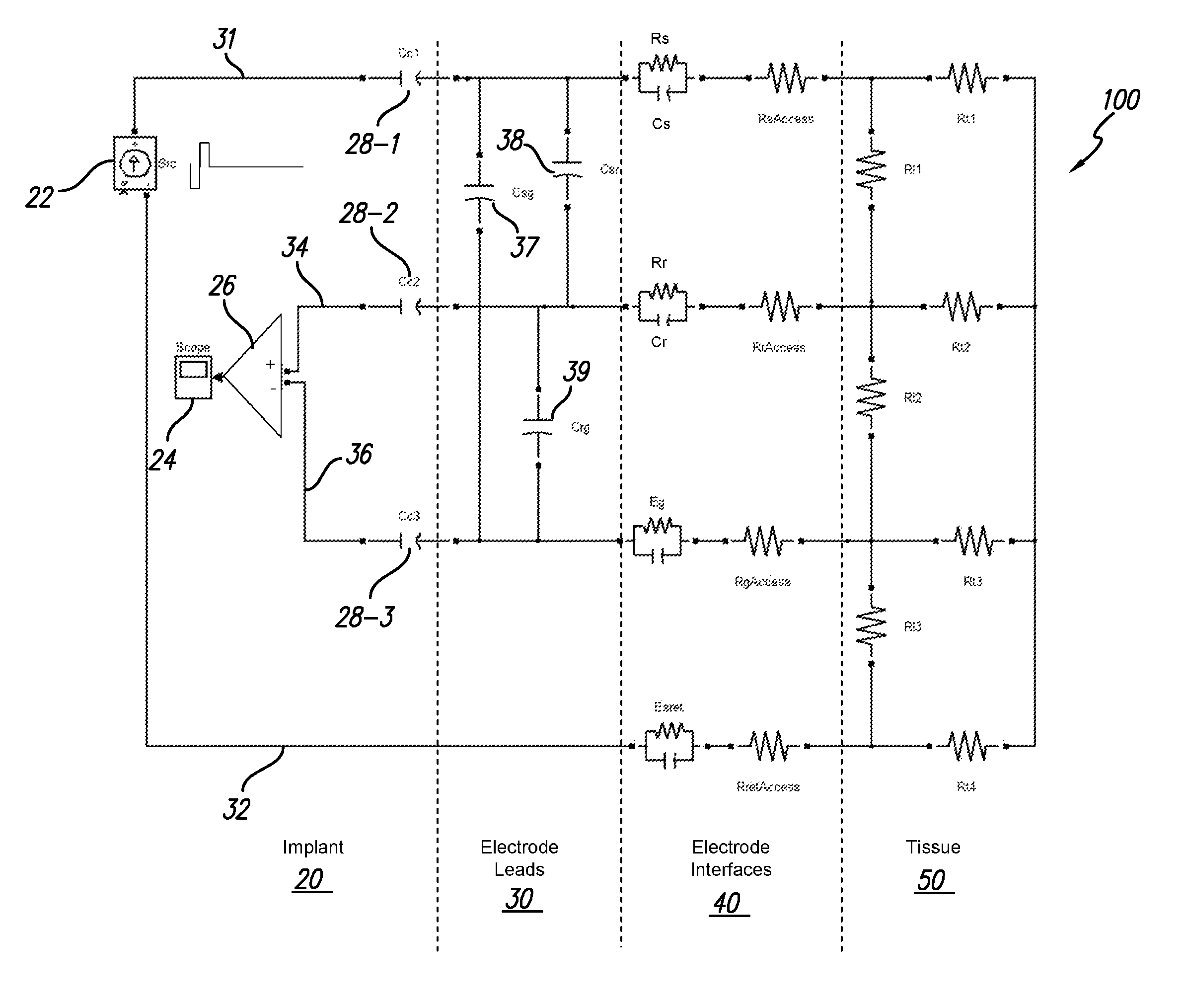

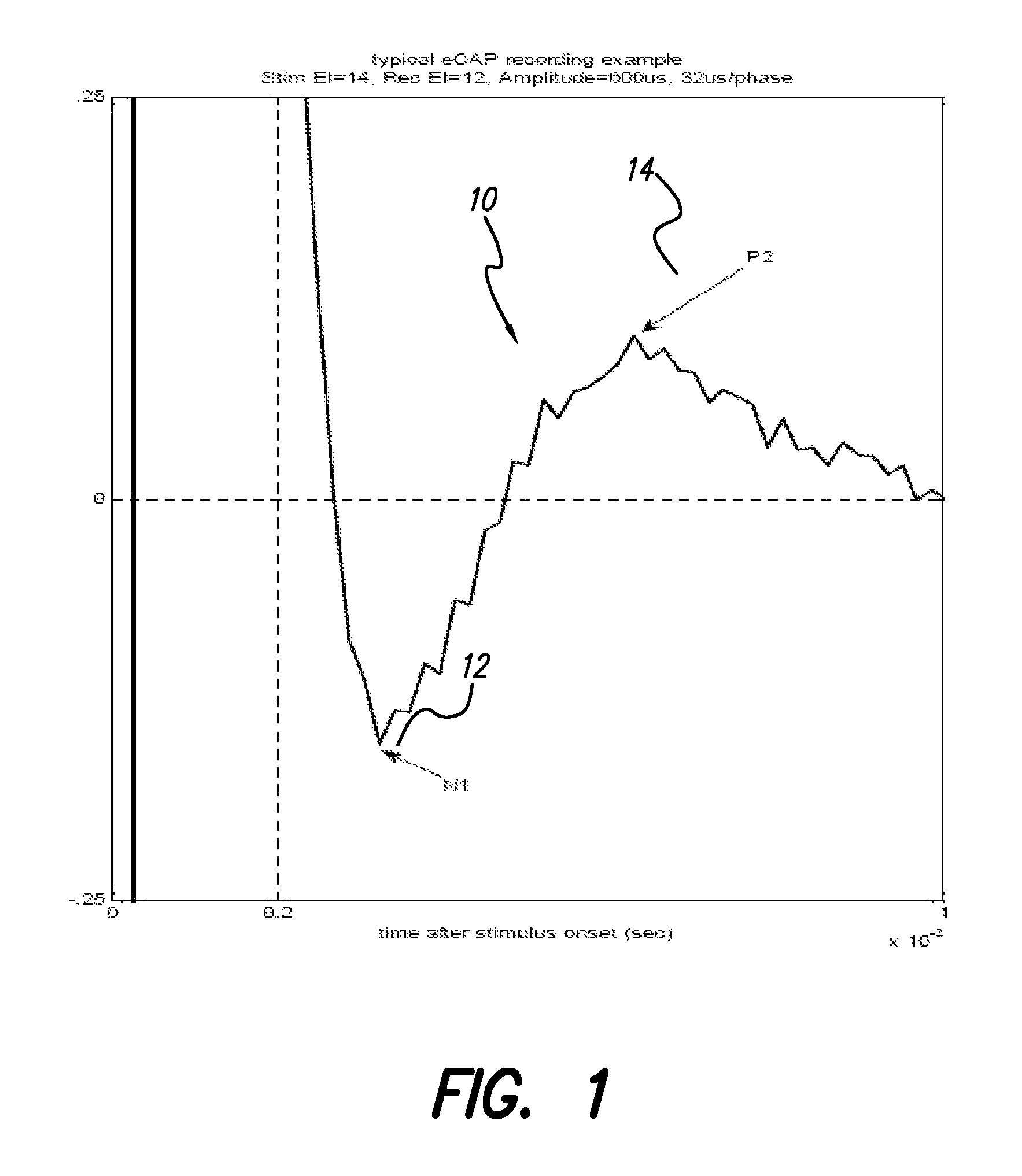

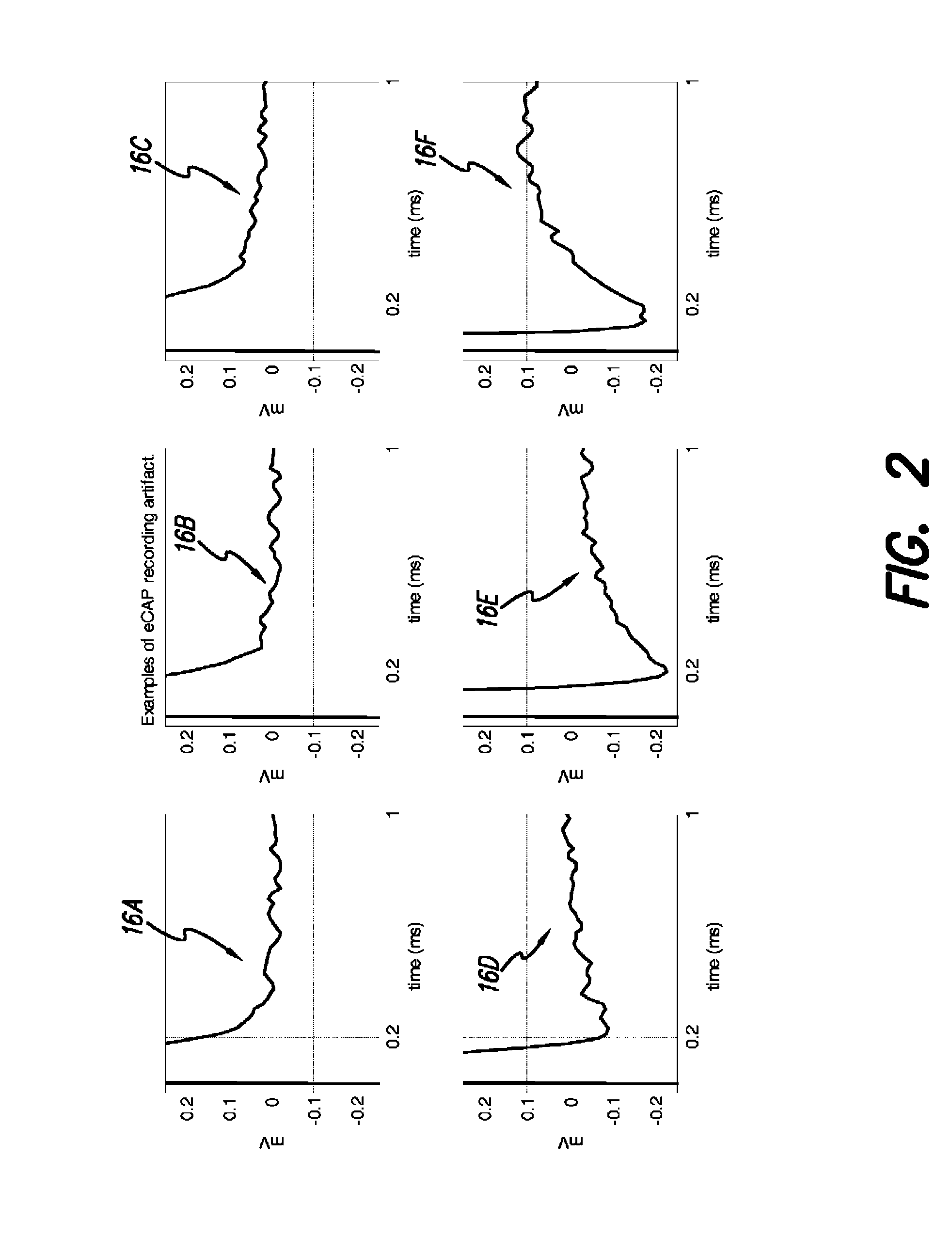

Removing Artifact in Evoked Compound Action Potential Recordings in Neural Stimulators

The accuracy of neural response recordings in neural stimulators, e.g., cochlear implants, is often degraded by a recording artifact. An idealized electrical-equivalent model of a neural stimulator is created to study, measure and compensate for artifact evoked compound action potential (eCAP). Using this model, the artifact is shown to occur even when the electrical components that make-up the neural stimulator are ideal. The model contains parasitic capacitances between the electrode wires. The model demonstrates that these small parasitic capacitances provide a current path during stimulation which can deposit charge on the electrode-tissue interfaces of the recording electrodes. The dissipation of this residual charge and the charge stored across the stimulating electrode is seen as the recording artifact. The proposed solution for eliminating the artifact problem is realized by utilizing a capacitive electrode material, e.g., TiO2, Ta2O5, or other dielectric coatings or films, instead of Faradaic electrode material, e.g., Platinum (Pt), Pt—Ir alloy or similar alloys, on the neural stimulator electrode lead.

Owner:ADVNACED BIONICS LLC

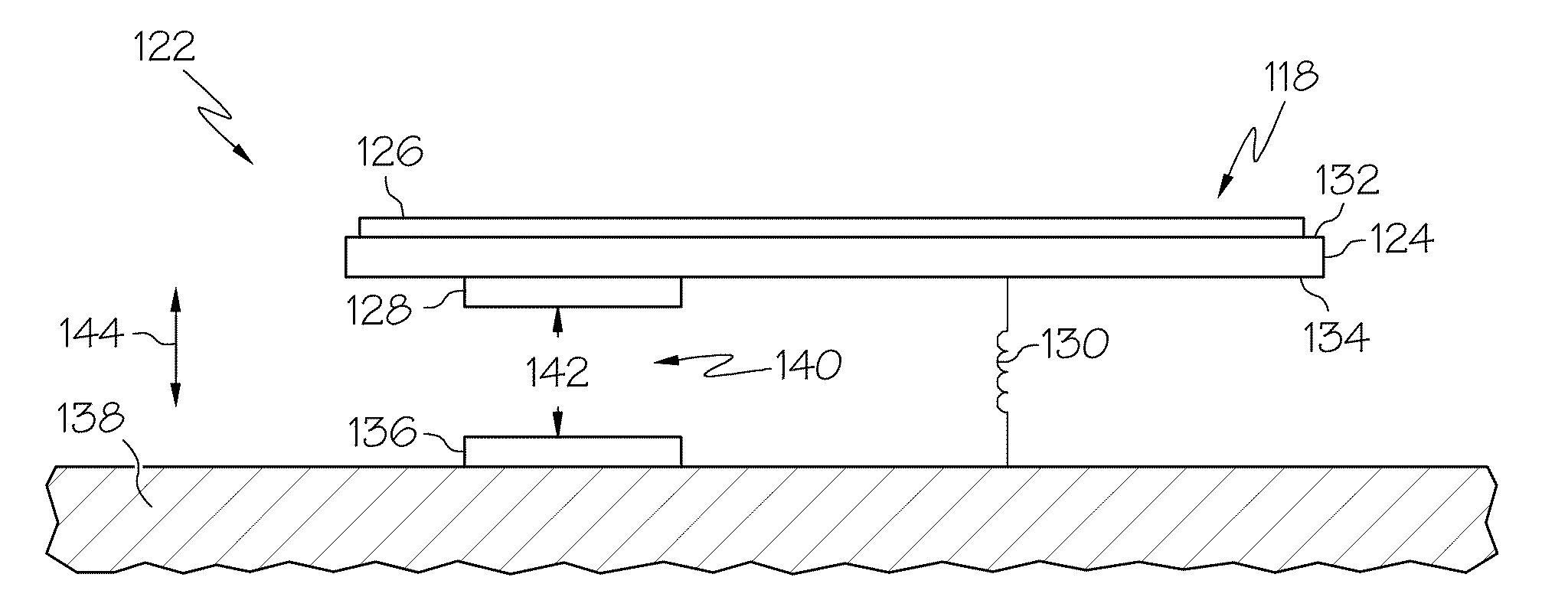

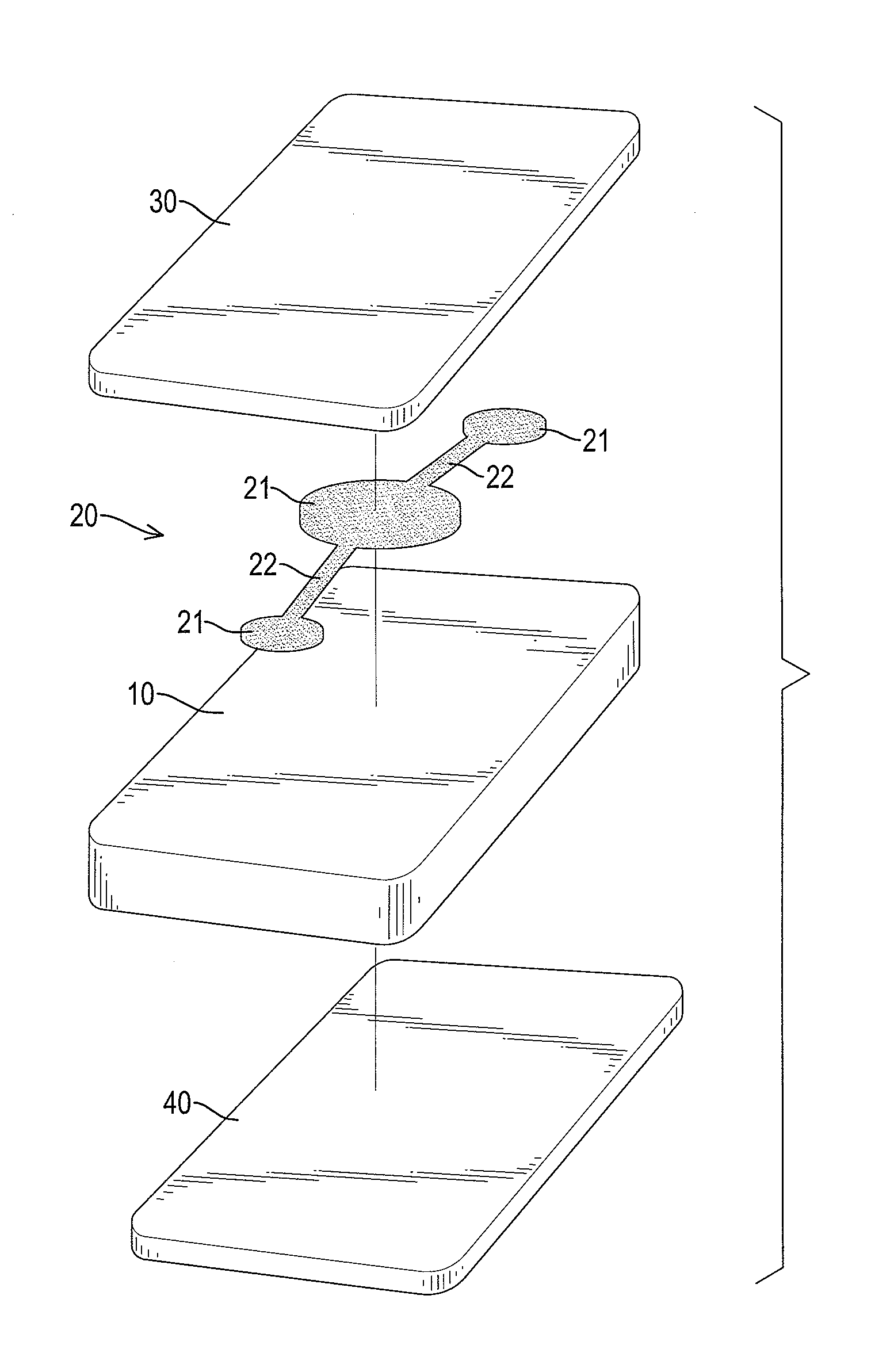

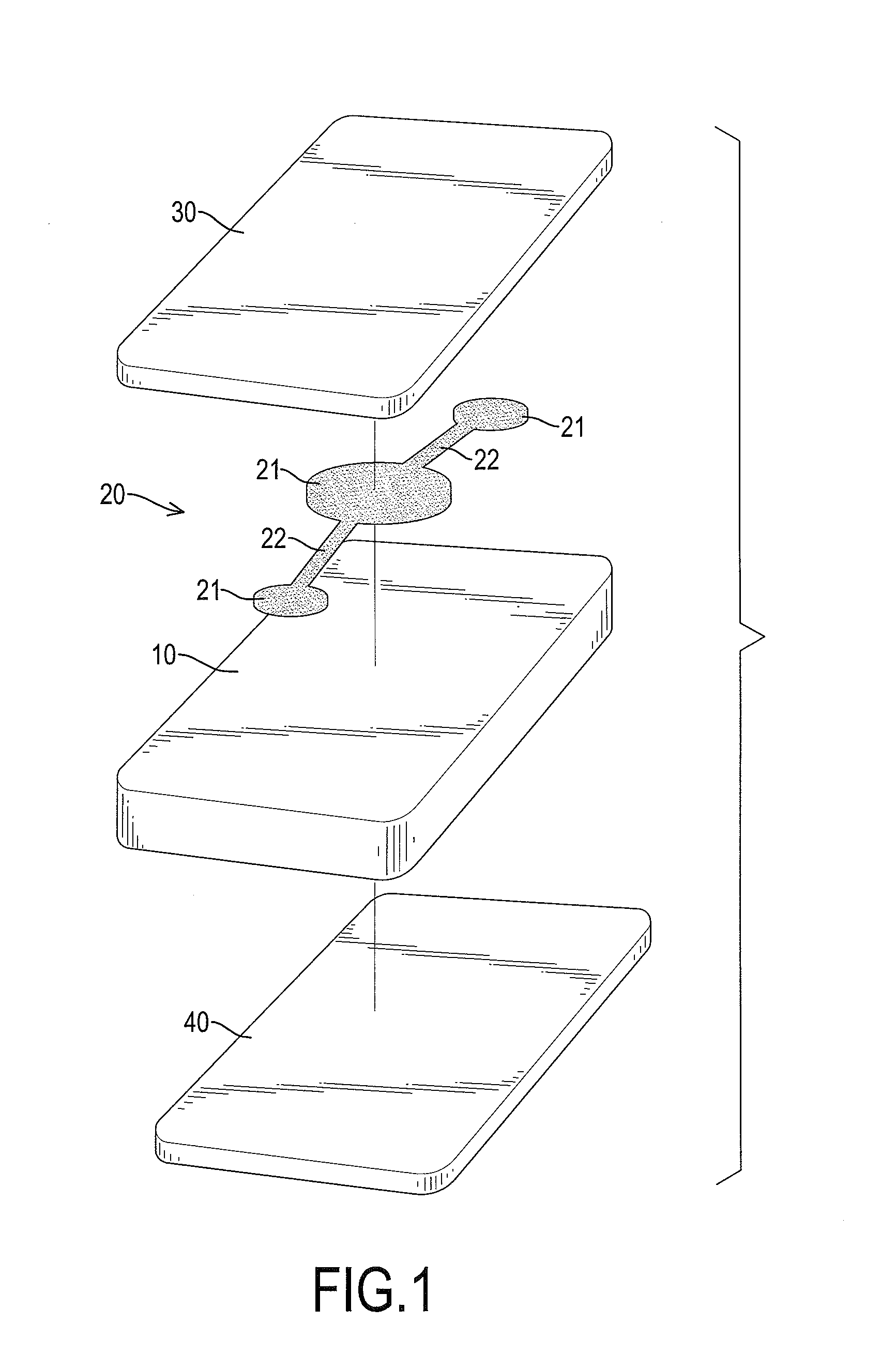

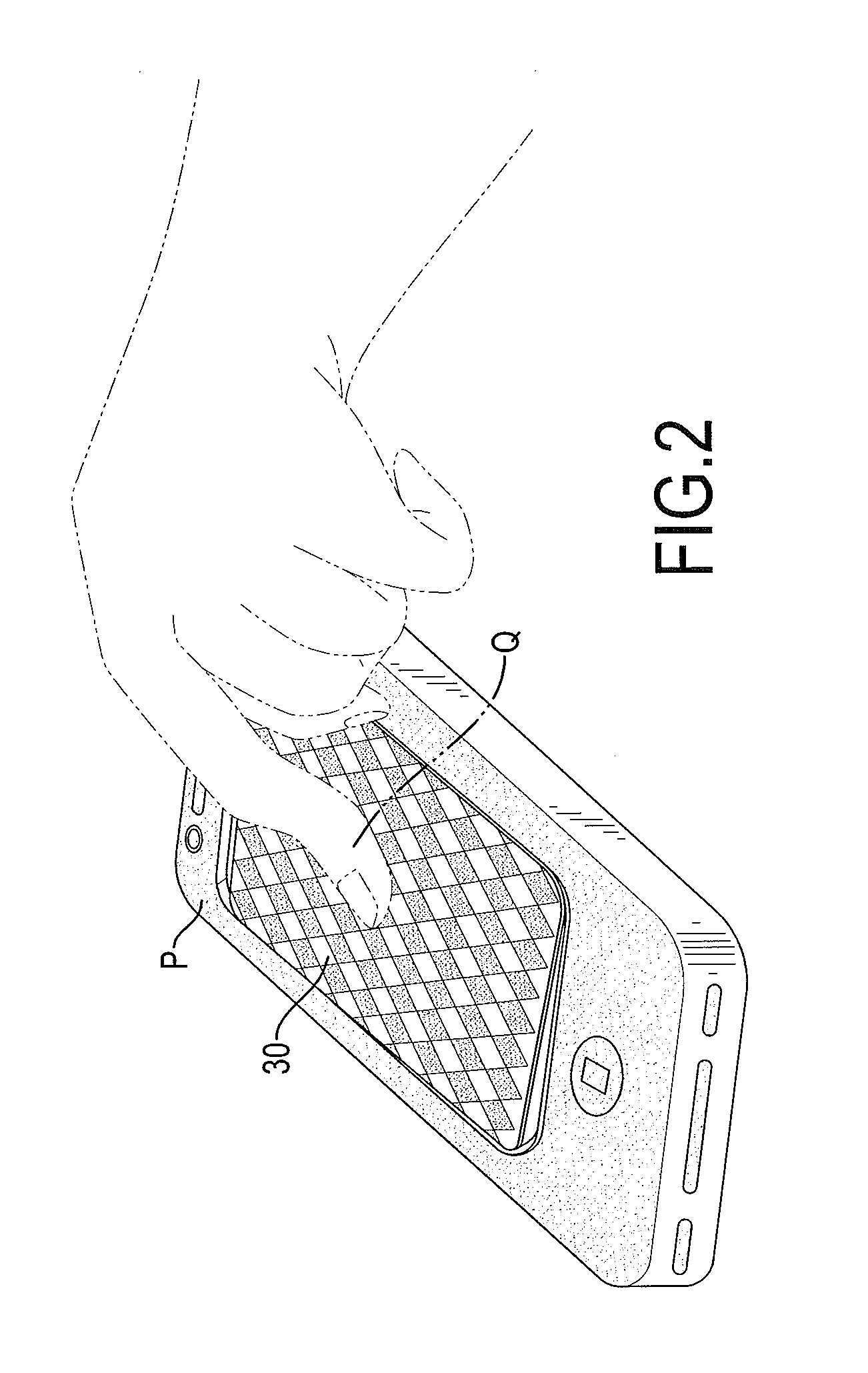

Input device with capacitive force sensor and method for constructing the same

Input devices which include a capacitive force sensor, along with methods of making and using such, are provided. The input device includes a structural component having first and second substantially opposing sides, a plurality of sensor electrodes located on the first side of the structural component, the plurality of sensor electrodes configured to capacitively sense positional information associated with user input in a sensing region, a first capacitive electrode located on the second side of the structural component, the first capacitive electrode being configured to capacitively couple to a second capacitive electrode that is separated from the first capacitive electrode by a gas and moveable relative to the first capacitive electrode, and a biasing member configured to be physically coupled to the structural component such that a force associated with the user input causes a change in a separation distance between the first and second capacitive electrodes based on the force.

Owner:SYNAPTICS INC

Display device, method of driving same and electronic device mounting same

InactiveUS20050140632A1Reduce power consumptionIncreased power consumptionStatic indicating devicesNon-linear opticsCapacitanceDisplay device

A liquid crystal panel (2) includes scanning signal lines (31) for supplying scanning signals to gate electrodes (20) of TFTs (14), and data signal lines (32) for supplying data signals to data electrodes (24) of TFTs. The liquid crystal panel further includes auxiliary capacitive electrode pads (27a) for use in forming auxiliary capacitance and an auxiliary capacitive lines (33) so as not to generate a capacitive bond with the scanning signal lines. The liquid crystal panel is driven at a rewriting frequency of a screen of not more than 30 Hz. As a result, the liquid crystal panel can be driven at a low consumption power while maintaining a desirable display quality of the liquid crystal panel.

Owner:SHARP KK

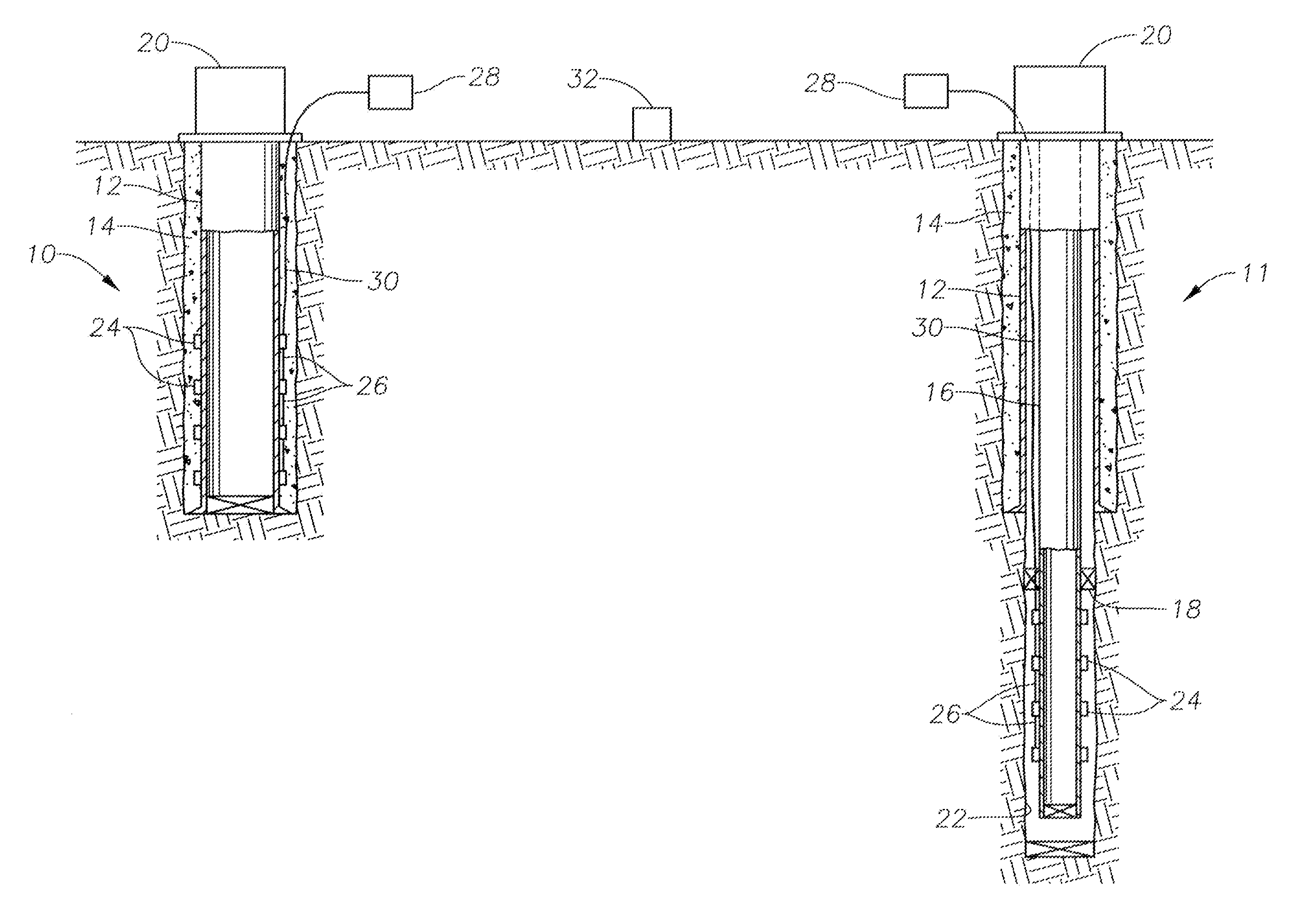

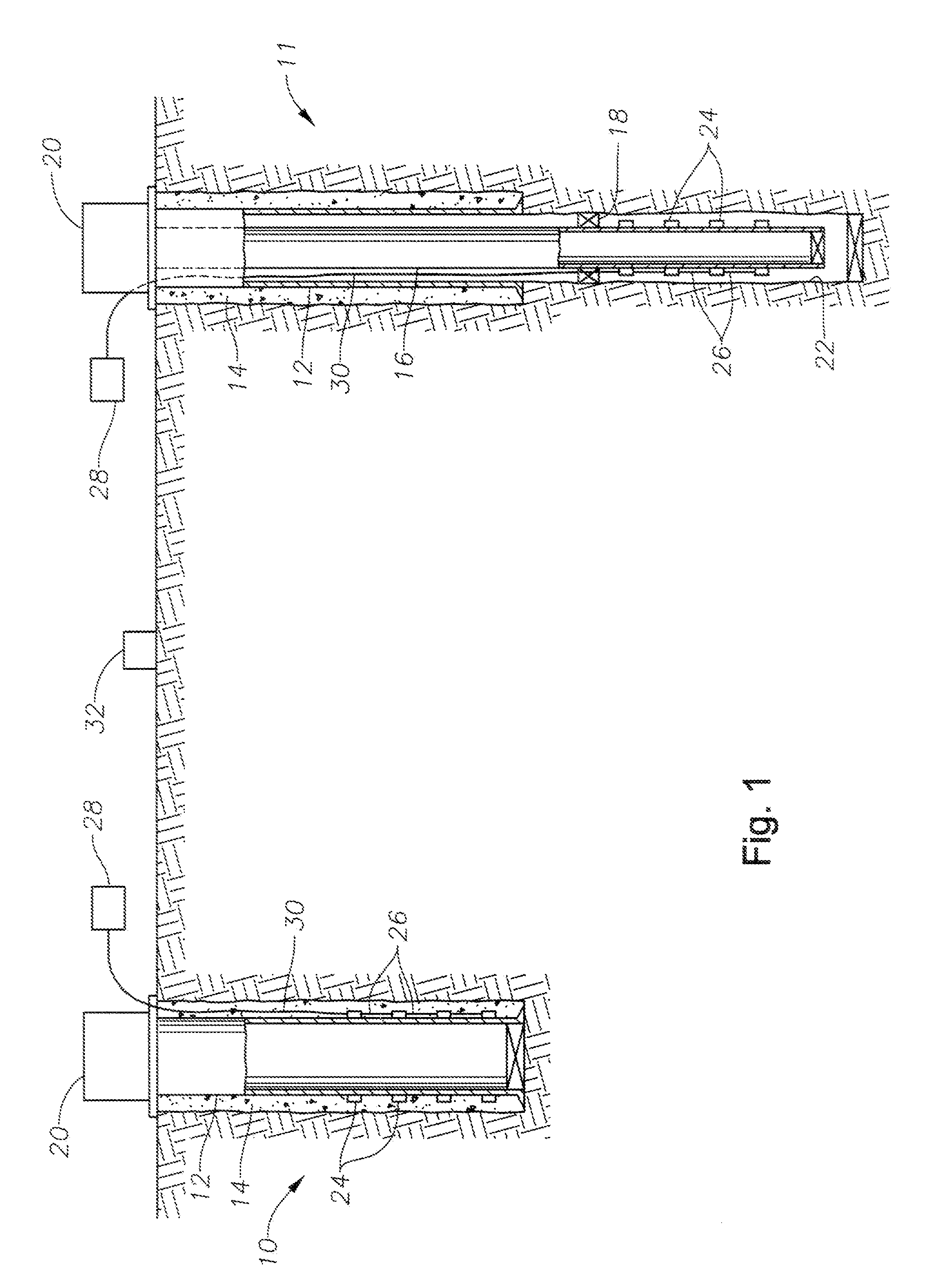

Wireless swimming pool water level system

InactiveUS7318344B2Increase surface areaPreserves watertight integrityLevel controlMachines/enginesTimerDevice failure

A wireless (e.g., radio) system and method for automatic water level maintenance of, e.g., a swimming pool utilizing capacitive liquid level sensing. A reference electrode allows water level sensing independent of the water chemistry or temperature. Capacitive electrodes having areas larger than the reference electrode sense various liquid levels when the liquid covers an area of any sensing electrode equal to the area of the reference electrode. Averaging is incorporated to filter out effects of wind or other disturbances. Upon sensing a given condition, the transmitter transmits a sensed condition to a remote receiver for control of valves and pumps for changing the water level in the pool. The receiver includes safety timers for filling and emptying to protect against equipment failure or communications faults. User selectable identification allows identical such radio systems to operate within proximity to each other. Power saving features are used to extend battery life.

Owner:HEGER RES

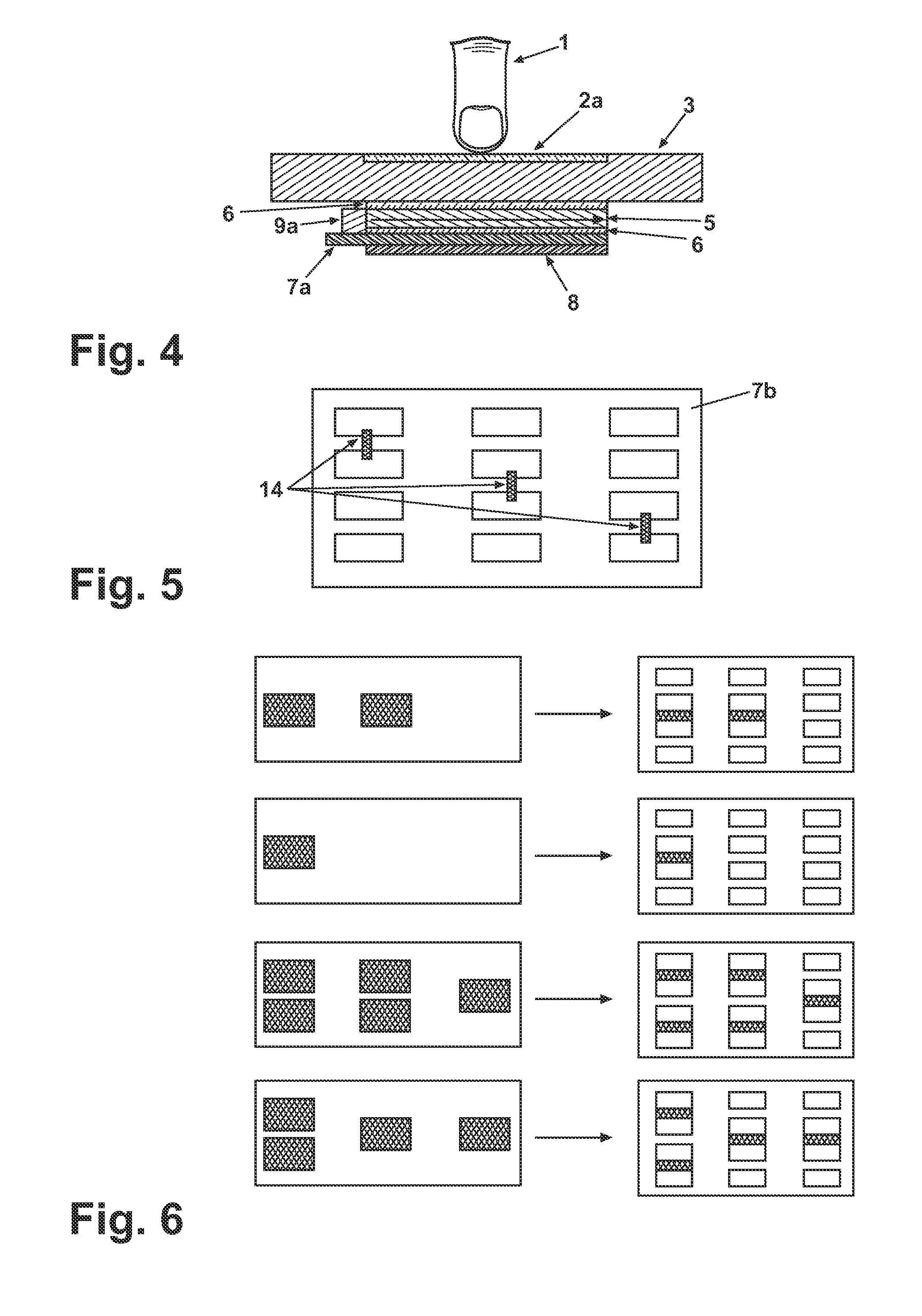

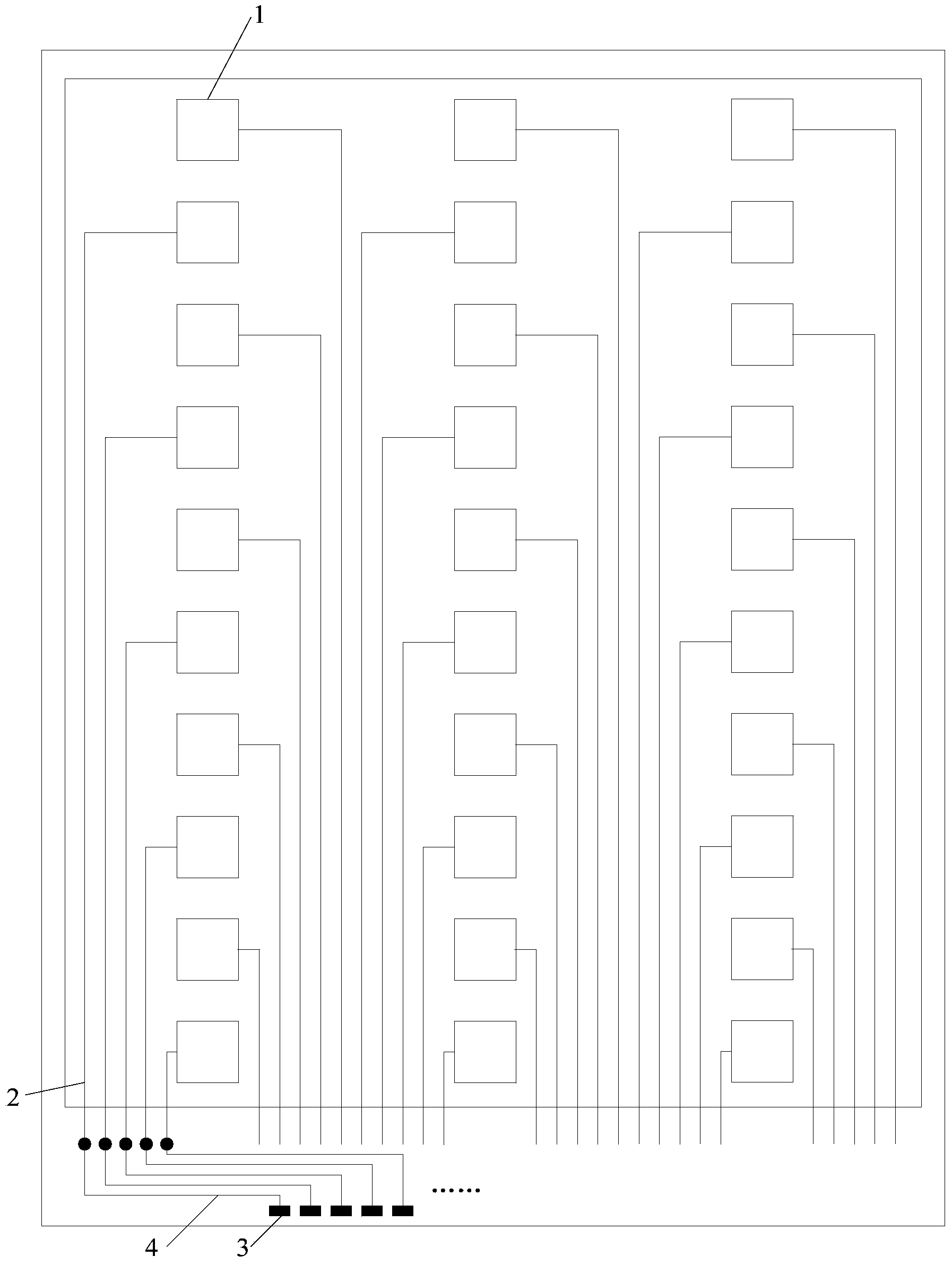

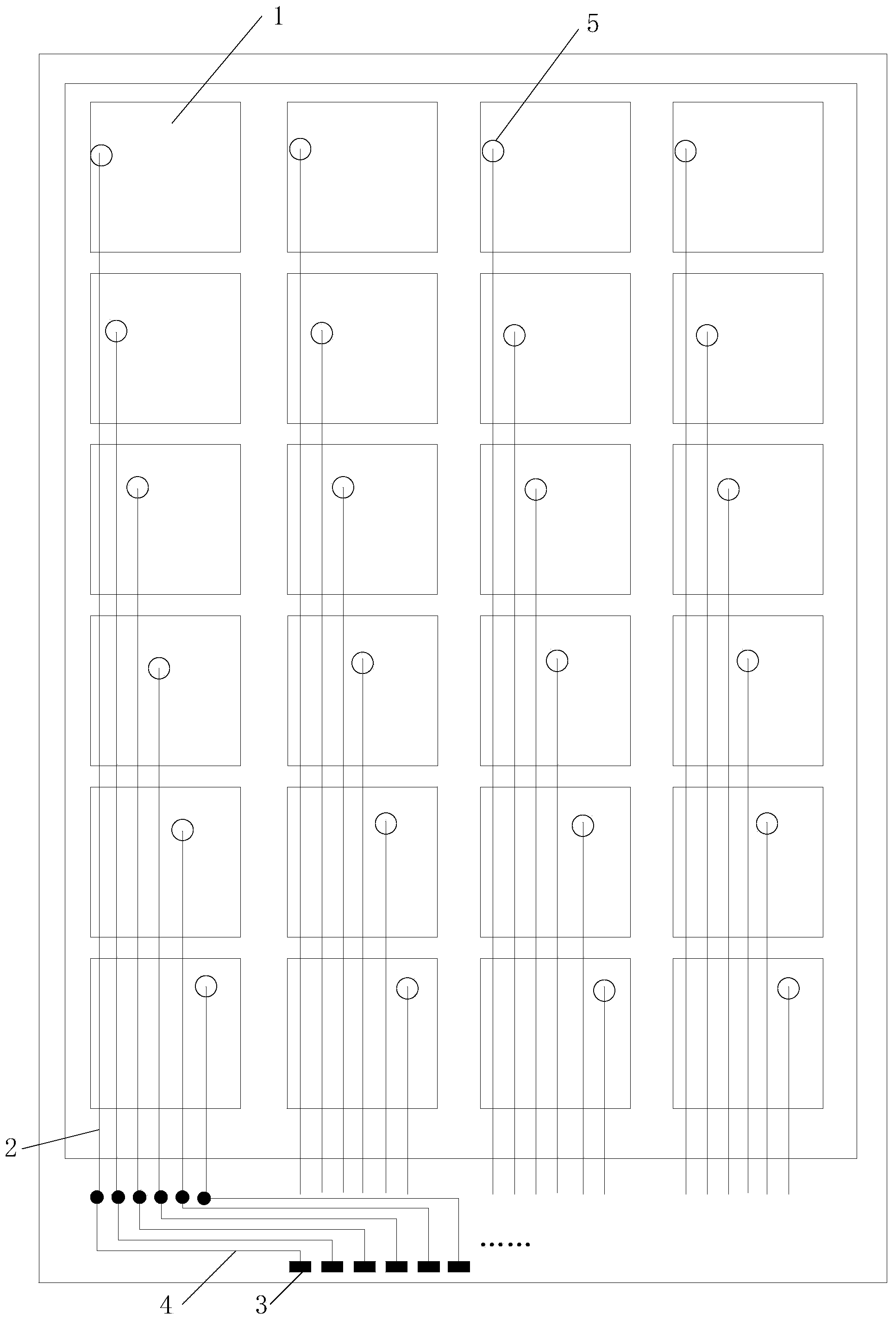

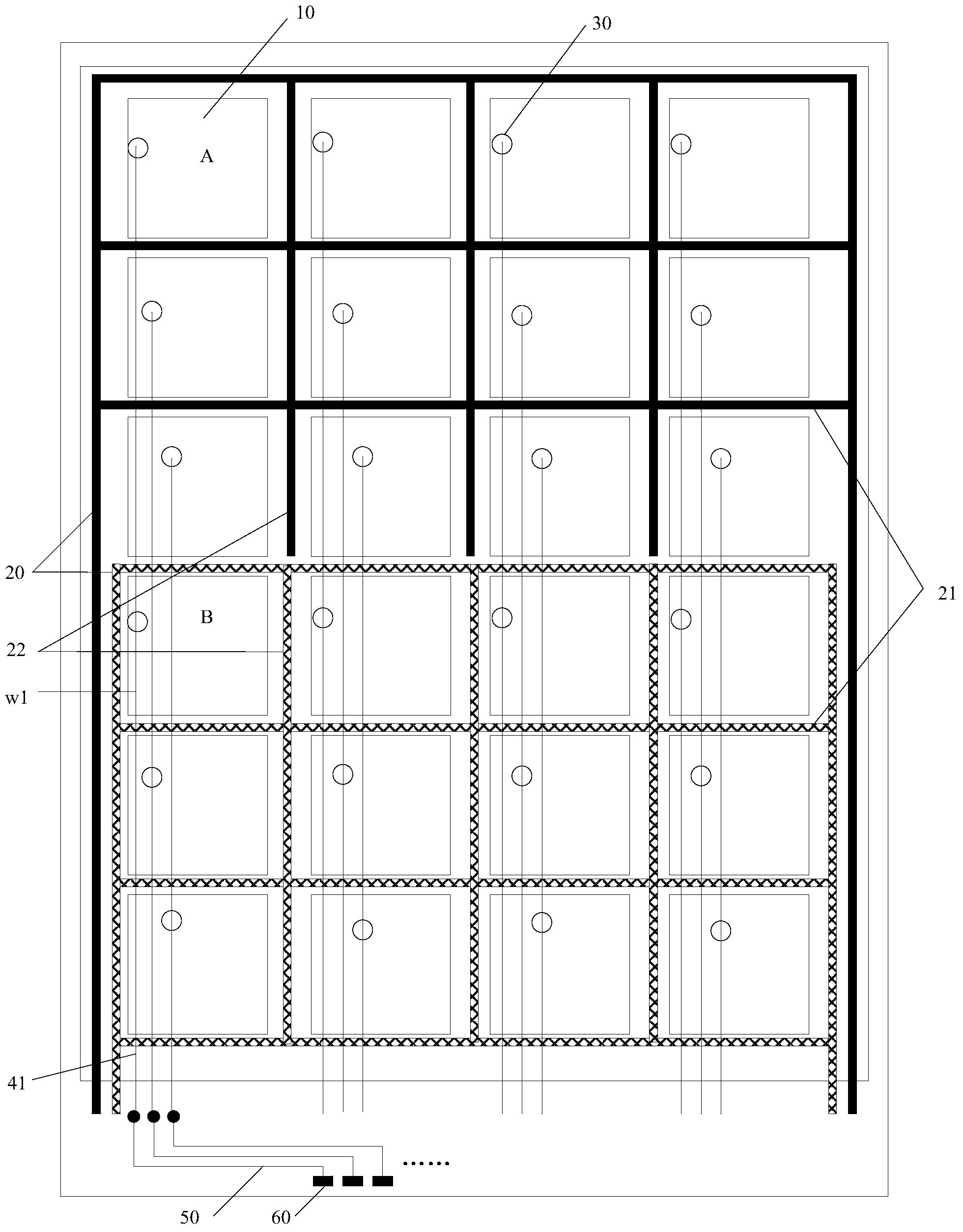

Capacitive touching structure, embedded touch screen, display device and scanning method of display device

ActiveCN104035639AReduce in quantityReduction is not conducive to narrow bezel designNon-linear opticsInput/output processes for data processingCapacitanceDisplay device

The invention relates to the technical field of touching, in particular to a capacitive touching structure, an embedded touch screen, a display device and a scanning method of the display device. The number of wires in the self-capacitance touching structure is decreased, and the probability of occurrence of the problems that the narrow frame design is not facilitated and a touch blind area is large is decreased to a certain degree. The capacitive touching structure comprises a plurality of self-capacitance electrodes which are arranged on the same layer, area electrodes, first wires, second wires and touch detection chips, wherein the self-capacitance electrodes are located in at least two areas contained by the surface of a film where the self-capacitance electrodes are located respectively; the area electrodes are located in the areas respectively, and the area electrodes and the self-capacitance electrodes are located on the same layer; the first wires are connected with the self-capacitance electrodes, and each first wire is connected with at least two self-capacitance electrodes which are located in different areas respectively; the second wires are connected with the area electrodes, and the area electrodes located in the areas are electrically connected with the different second wires; the touch detection chips are connected with the first wires and the second wires.

Owner:BOE TECH GRP CO LTD +1

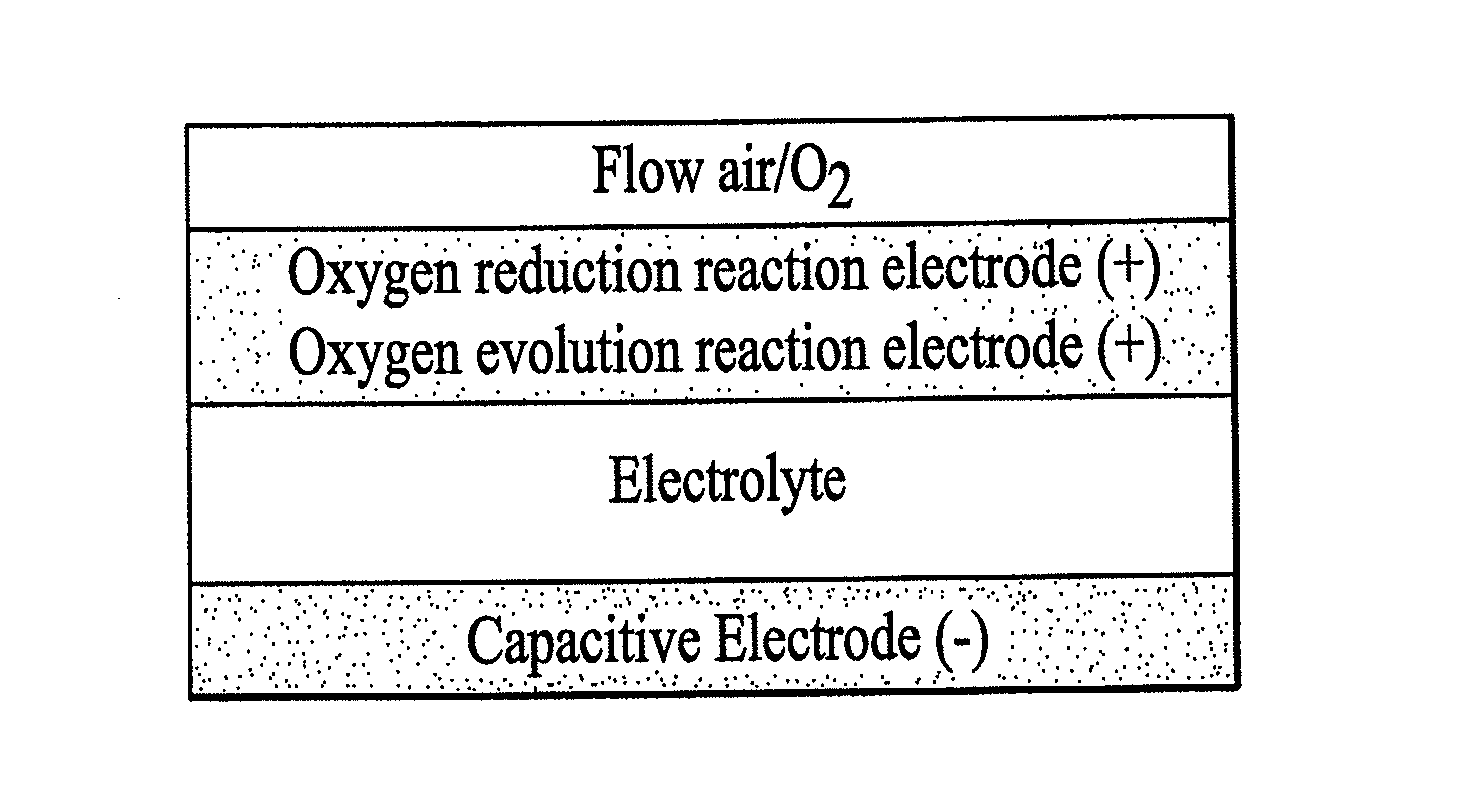

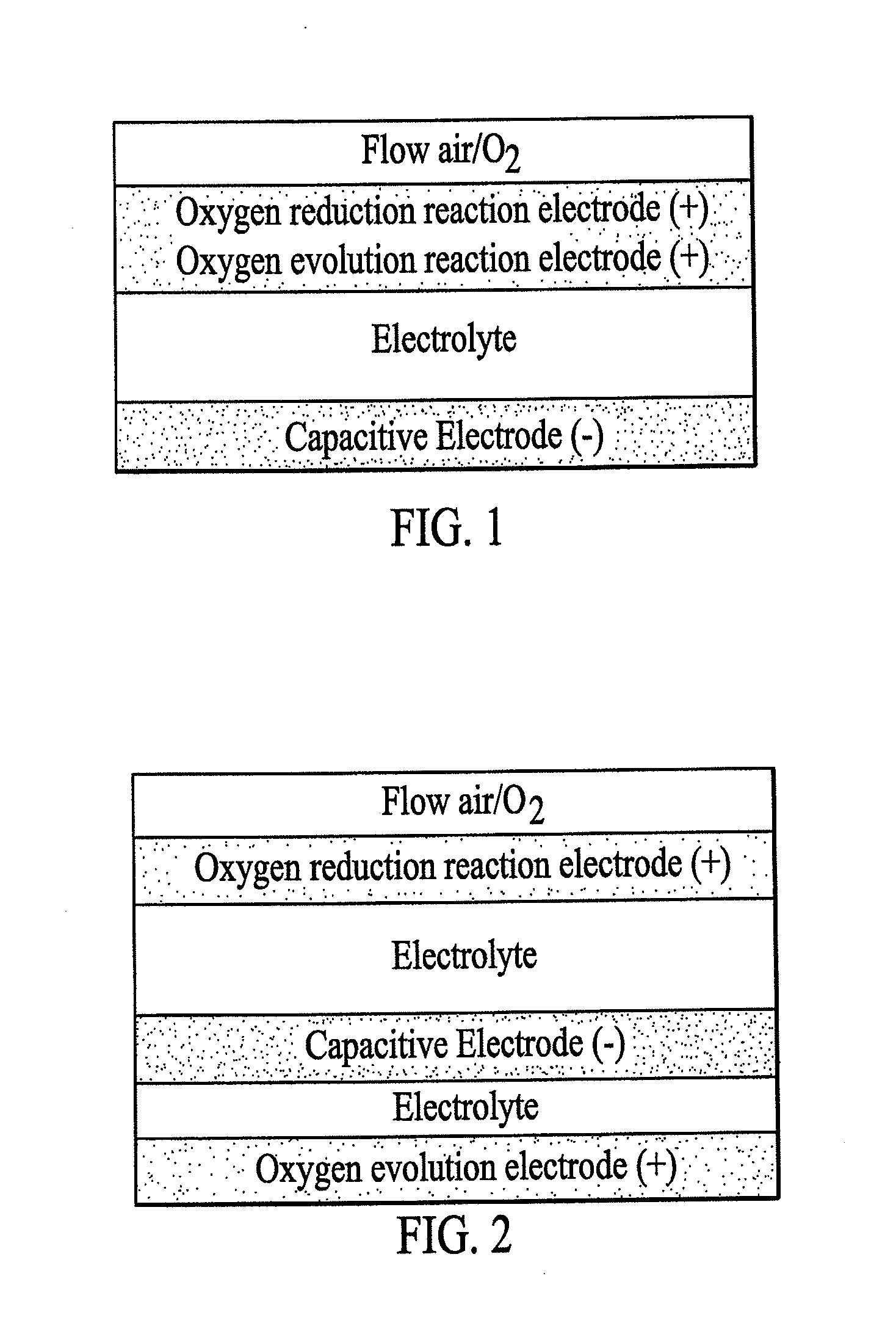

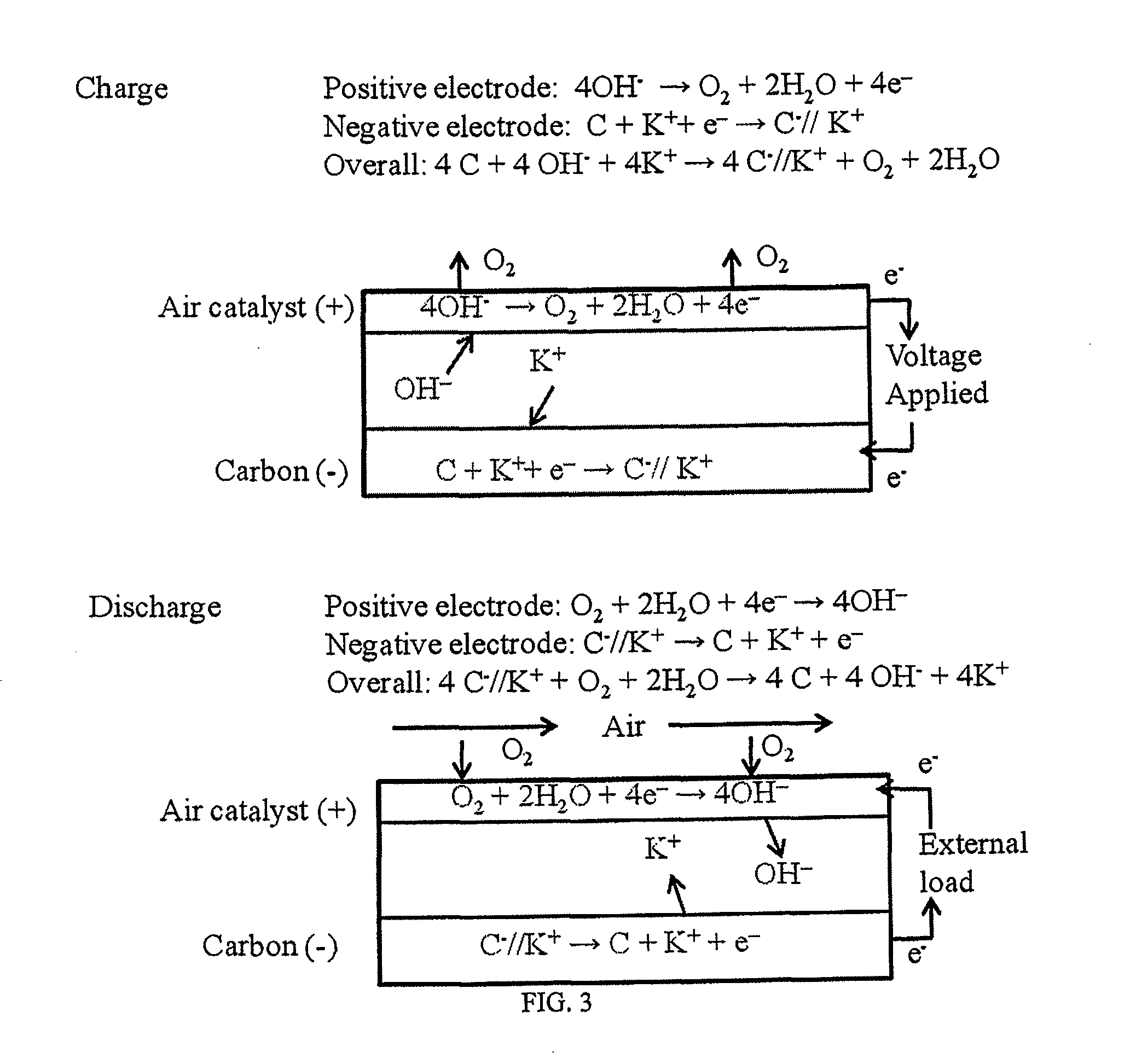

Rechargeable electrochemical energy storage device

InactiveUS20120140378A1Increase energy densityReduce weightFuel and primary cellsFuel and secondary cellsFuel cellsHybrid system

A rechargeable energy storage device is disclosed. In at least one embodiment the energy storage device includes an air electrode providing an electrochemical process comprising reduction and evolution of oxygen and a capacitive electrode enables an electrode process consisting of non-faradic reactions based on ion absorption / desorption and / or faradic reactions. This rechargeable energy storage device is a hybrid system of fuel cells and ultracapacitors, pseudocapacitors, and / or secondary batteries.

Owner:IMRA AMERICA

Removing artifact in evoked compound action potential recordings in neural stimulators

Owner:ADVNACED BIONICS LLC

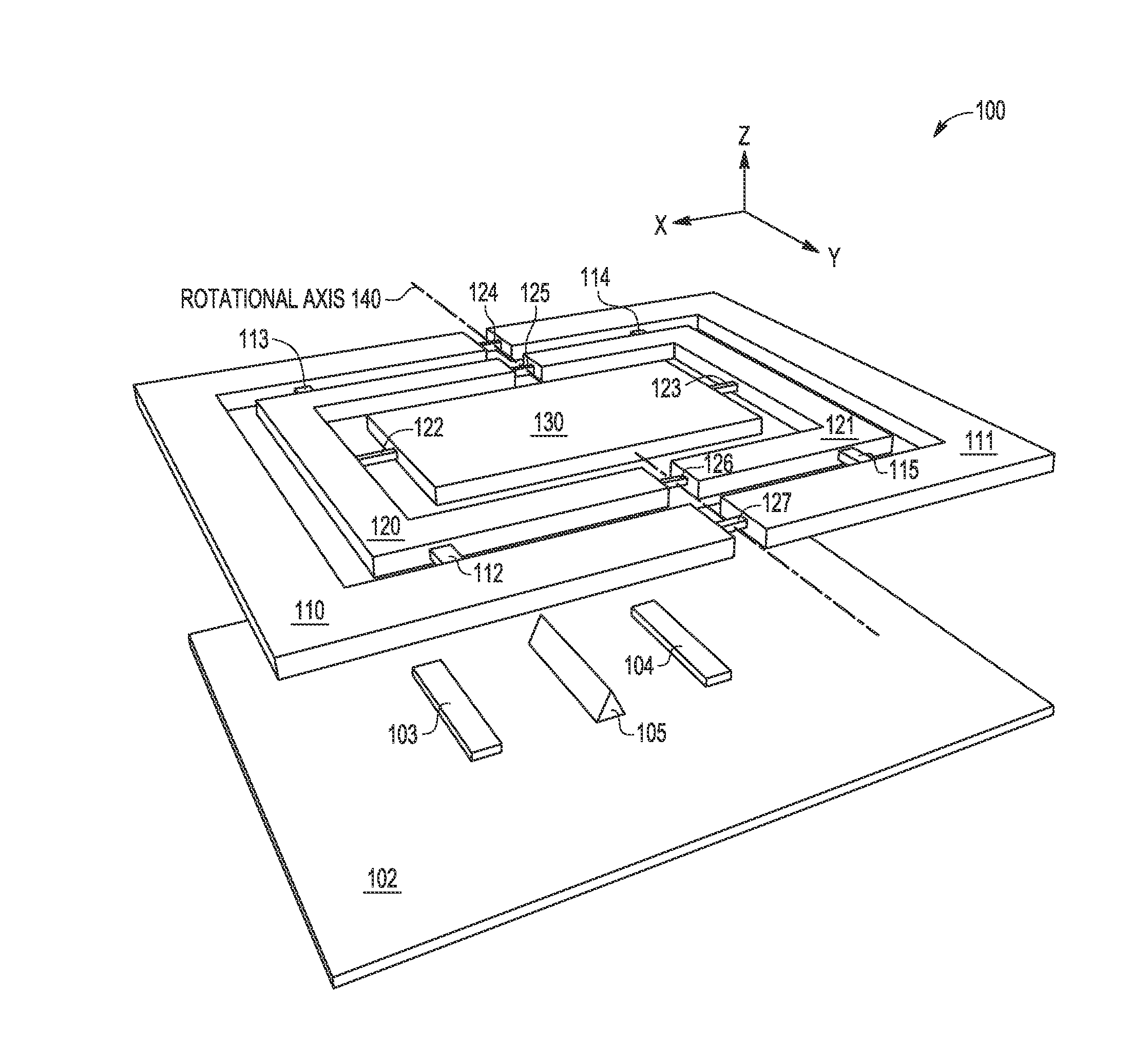

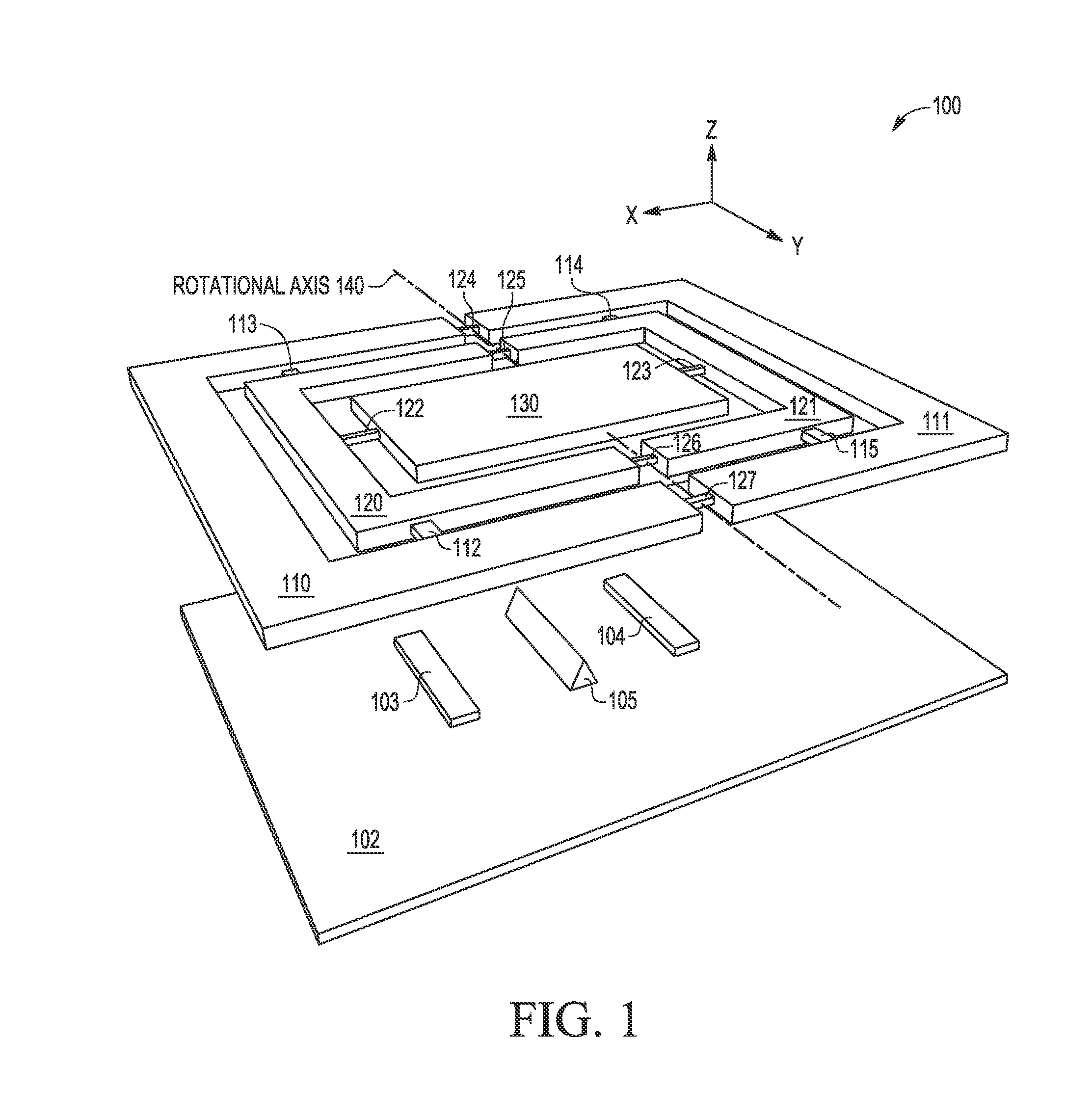

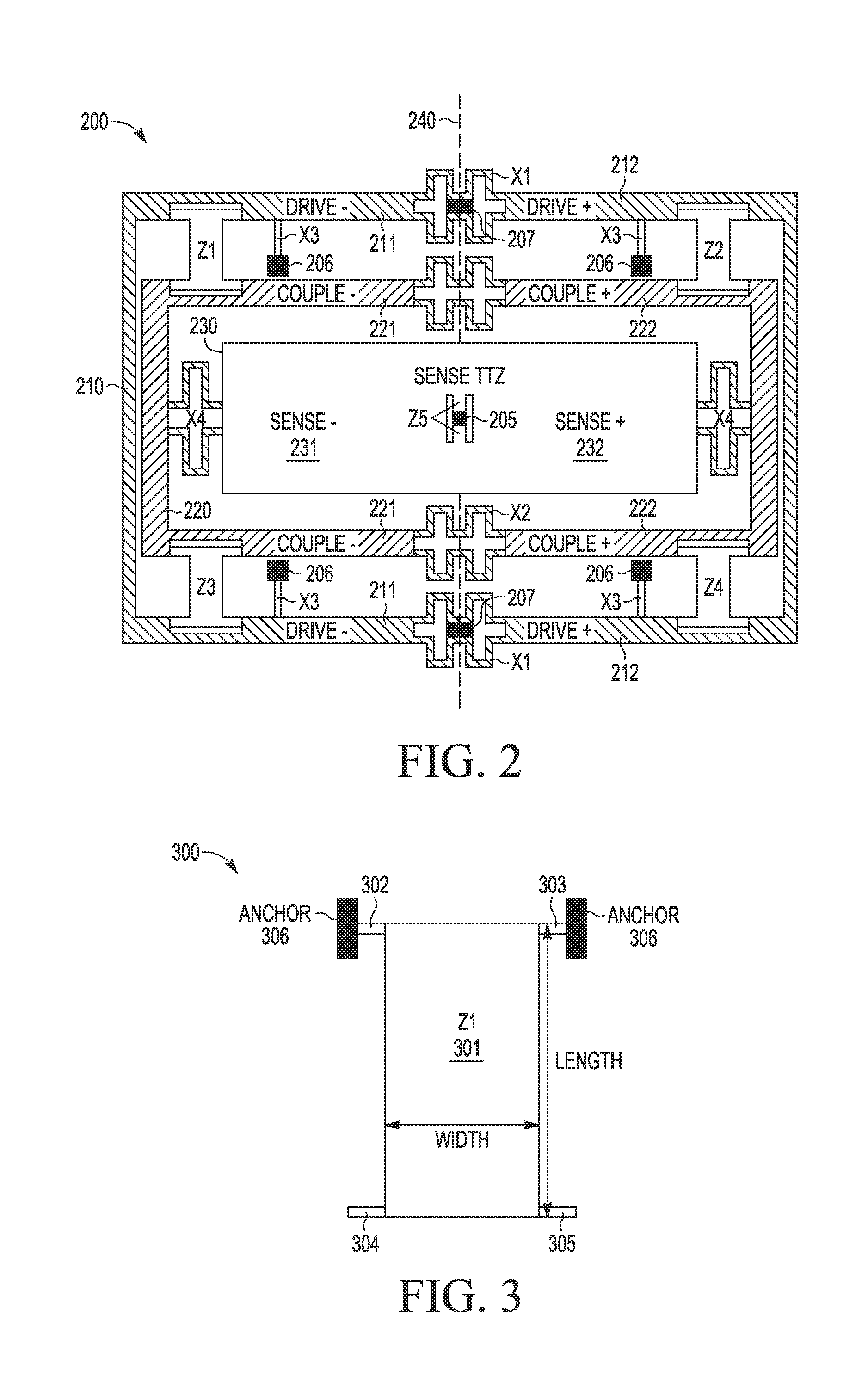

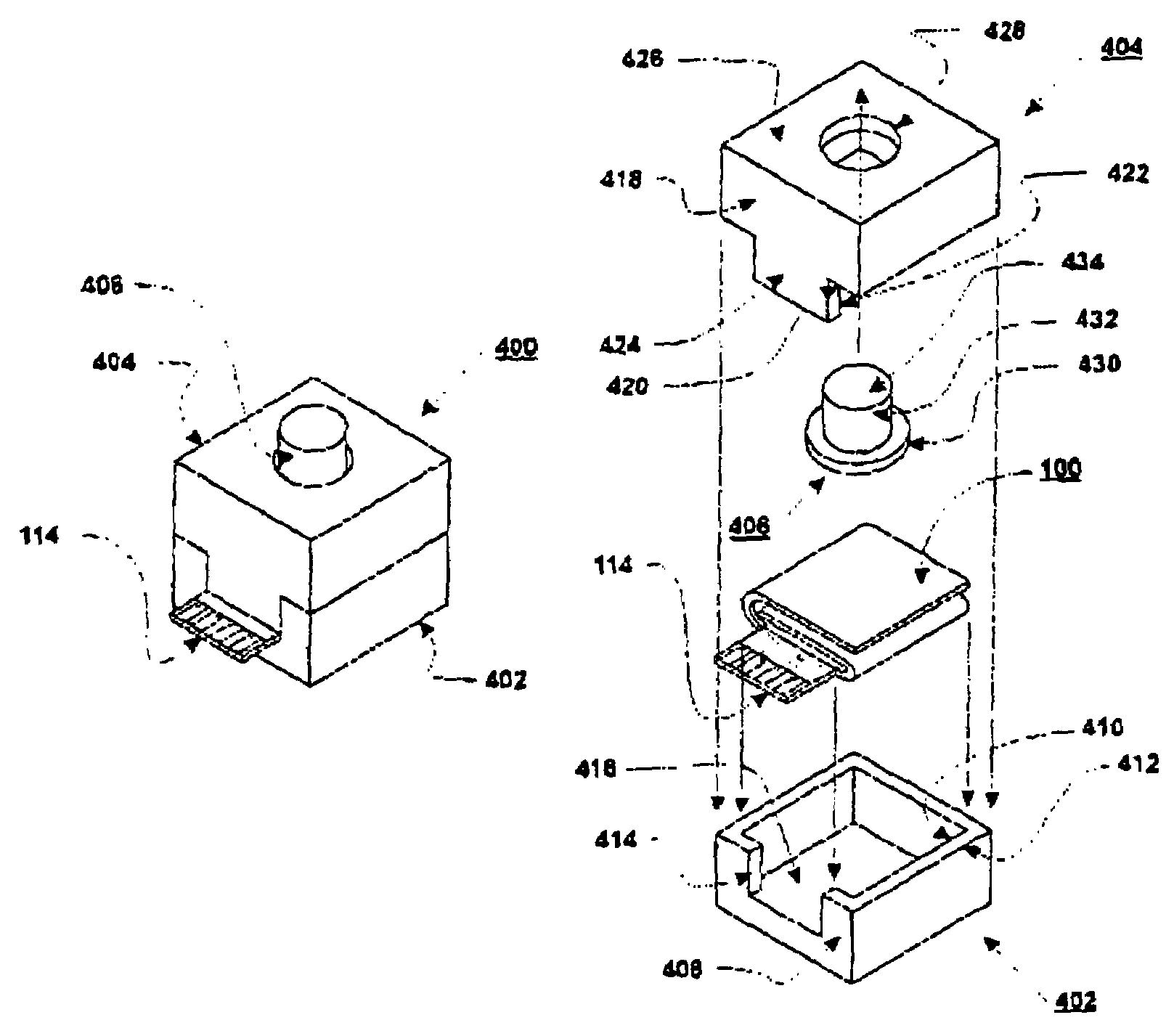

Fully Decoupled Lateral Axis Gyroscope with Thickness-Insensitive Z-Axis Spring and Symmetric Teeter Totter Sensing Element

ActiveUS20130180332A1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeTransverse axis

A micro-electromechanical systems (MEMS) transducer (400) is adapted to use lateral axis vibration of the drive mass (210) to generate non-planar oscillations of a coupling mass (220) in response to Coriolis forces created from in-plane rotational acceleration, which in turn generate non-planar motions of a symmetric teeter-totter sense mass (230) which are detected as a capacitive difference signal by capacitive electrodes (403, 404) formed on the substrate (402) below the sense mass (230).

Owner:NXP USA INC

Capacitive Card for a Capacitive Touch Screen

A capacitive card for a capacitive touch screen has a substrate and a capacitive layer. The substrate has a surface. The capacitive layer is securely formed on the surface of the substrate and has multiple capacitive electrode areas and at least one circuit connected with the capacitive electrode areas. Because the capacitive card in accordance with the present invention is capacitive, the capacitive touch screen can read the configuration of the capacitive electrode areas and execute a specific program.

Owner:DAGI CORP

Method for manufacturing low cost electroluminescent (EL) illuminated membrane switches

InactiveUS7255622B2Precise positioningLegendsVessels or leading-in conductors manufactureMetal foilMembrane switch

A method for manufacturing low cost electroluminescent (EL) illuminated membrane switches is disclosed. The method includes the steps of die cutting, embossing or chemically etching the metal foil surface of a metal foil bonded, light transmitting flexible electrical insulation to simultaneously form one or more front capacitive electrodes, membrane switch contacts and electrical shunt, electrical distribution means and electrical terminations that together form a flexible printed circuit panel. This continuous flexible printed circuit substrate is then used with a precisely positioned indexing system.

Owner:NOVATECH ELECTRO LUMINESCENT

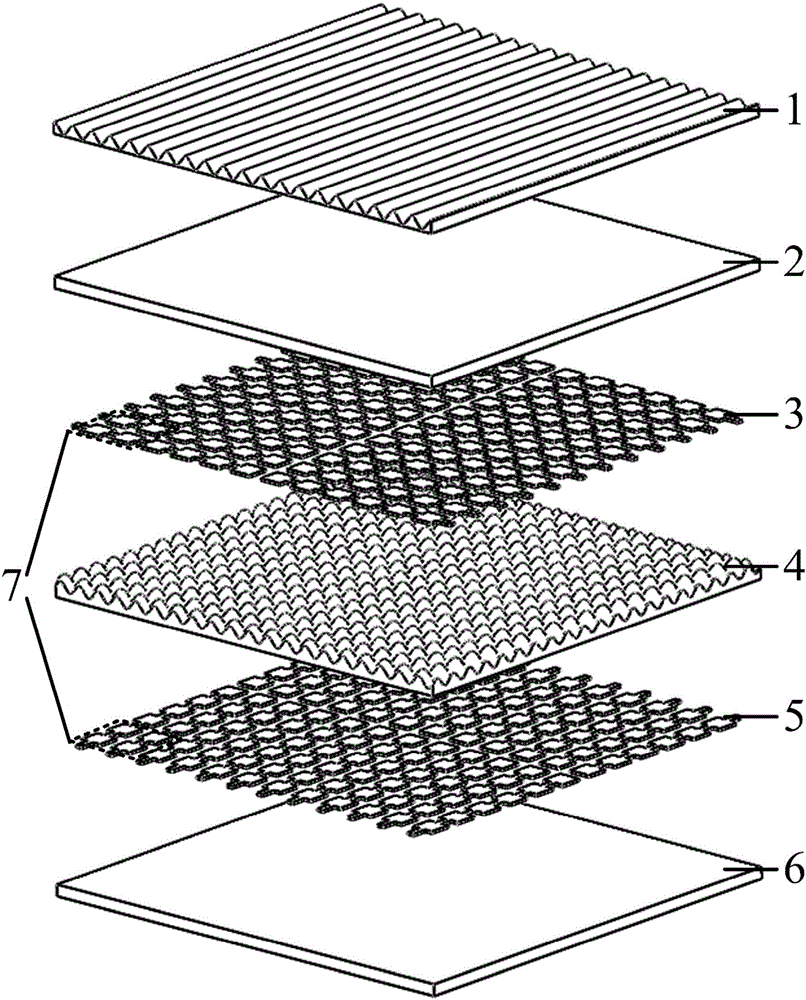

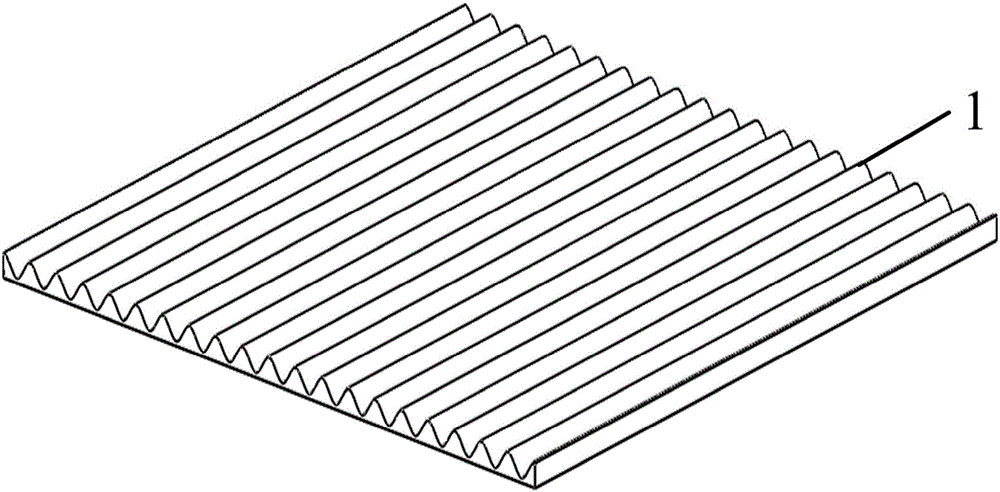

Capacitive touch sensor having patterned microstructure array

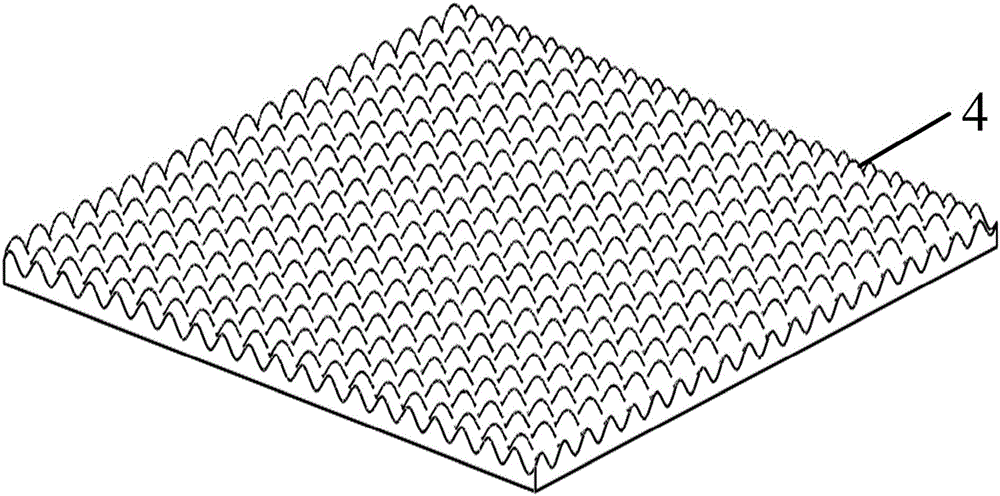

PendingCN106706176AHigh sensitivitySolve the problem of high-sensitivity real-time detectionForce measurementCapacitancePole piece

The invention discloses a capacitive touch sensor having a patterned microstructure array. The capacitive touch sensor is formed by fingerprint-shaped surface micro-protrusion, an upper capacitive electrode substrate, an upper capacitive electrode, a two-dimensional sine micro-protrusion dielectric layer, a lower capacitive electrode and a lower capacitive electrode substrate which are laminated from the top to the bottom in turn. The fingerprint-shaped surface micro-protrusion is used for receiving external force stimulation. The upper and lower capacitive electrode substrates are used as structural support. The series connection direction of the electrode pole pieces of the upper and lower capacitive electrodes are orthogonally arranged, and the upper and lower capacitive electrodes and the two-dimensional sine micro-protrusion dielectric layer form the capacitor body of the sensor together. After the upper surface of the fingerprint-shaped surface micro-protrusion is affected by external force stimulation, the change of capacitance is sensed by the capacitor body and the size and the direction of the force are acquired through conversion. The problem of high sensitivity real-time detection of the sensor for multidimensional force can be solved, and the sensor can be applied to the field of artificial limbs and surgical manipulators having high requirement of sensitivity.

Owner:ZHEJIANG UNIV

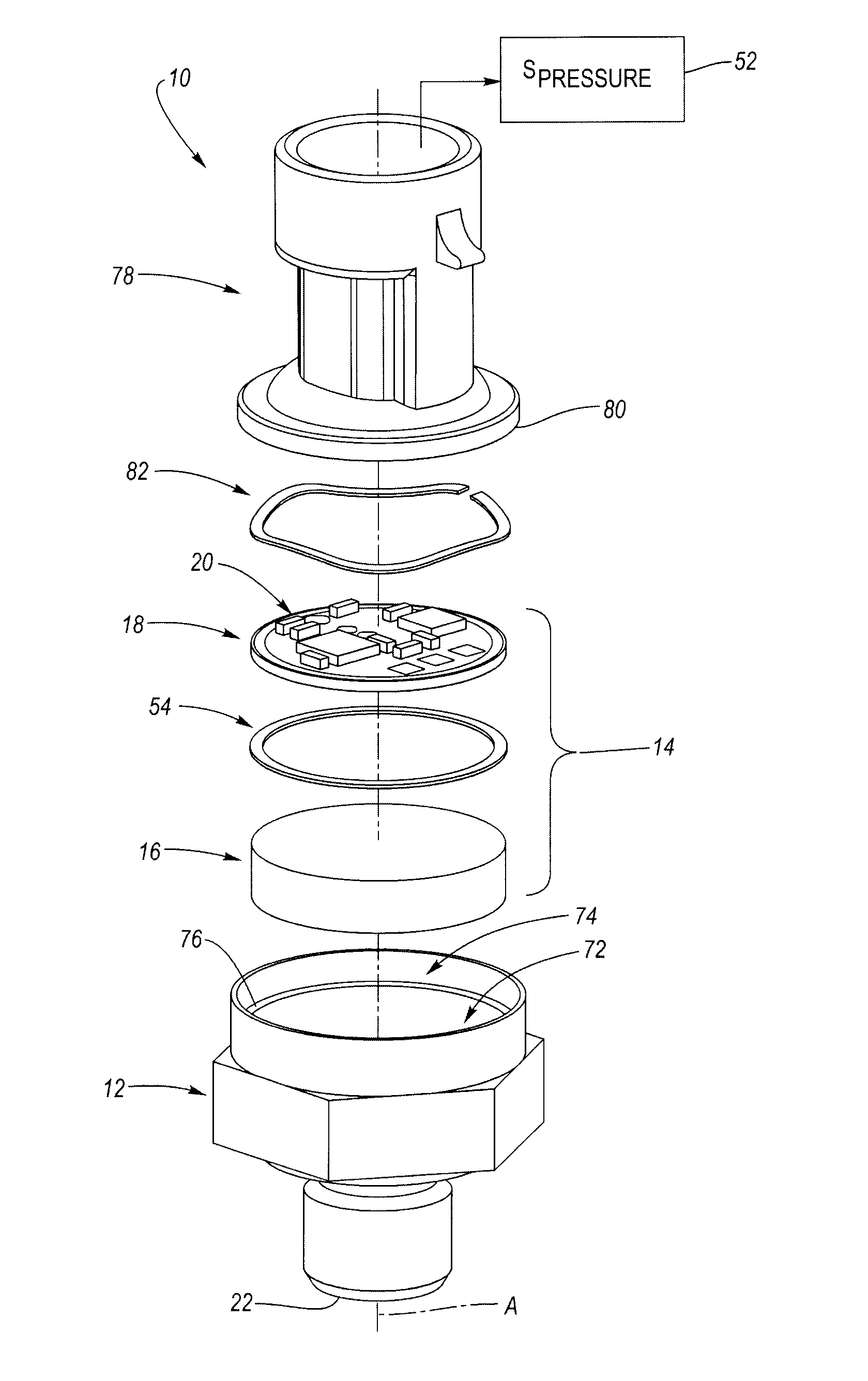

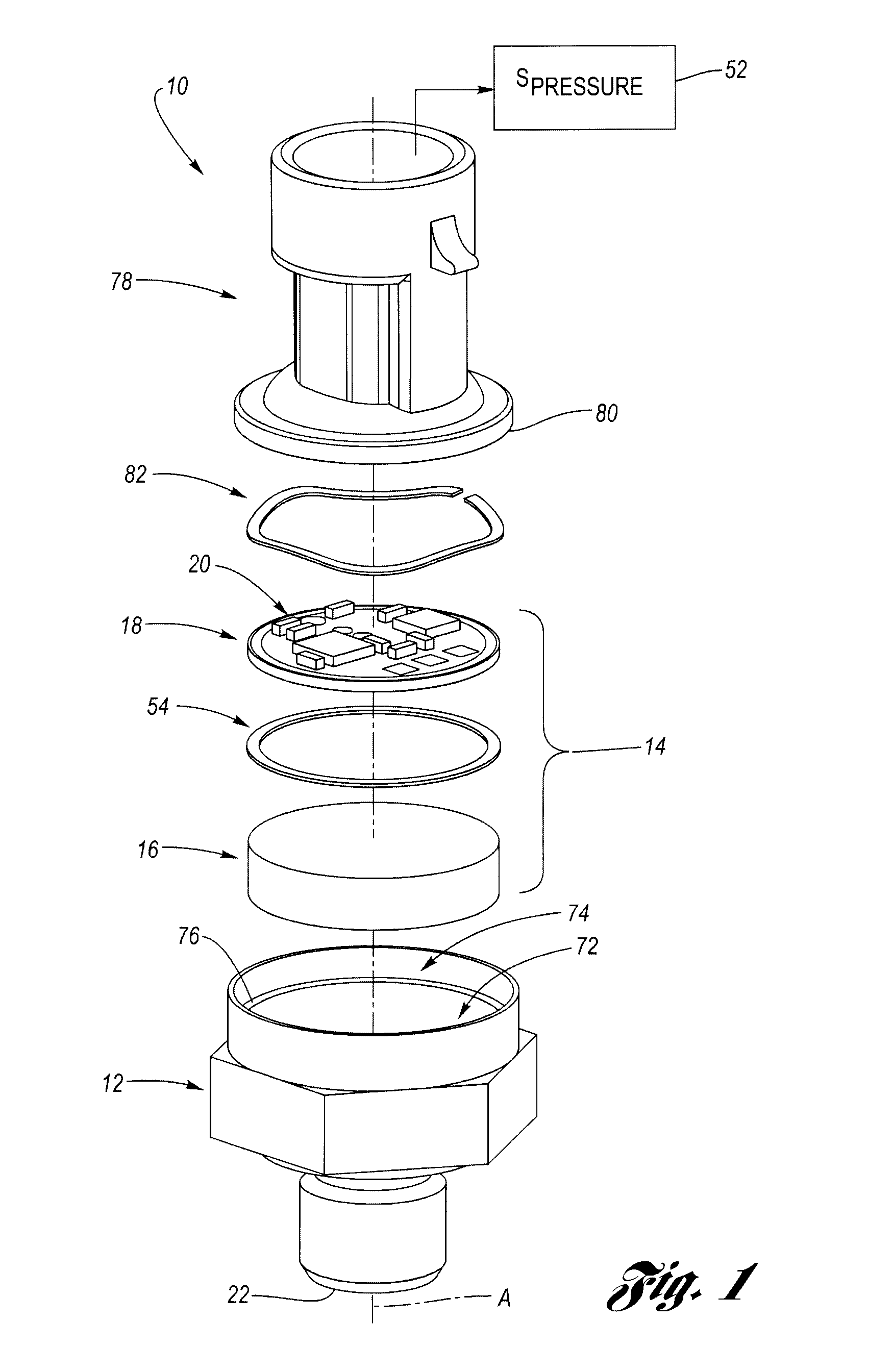

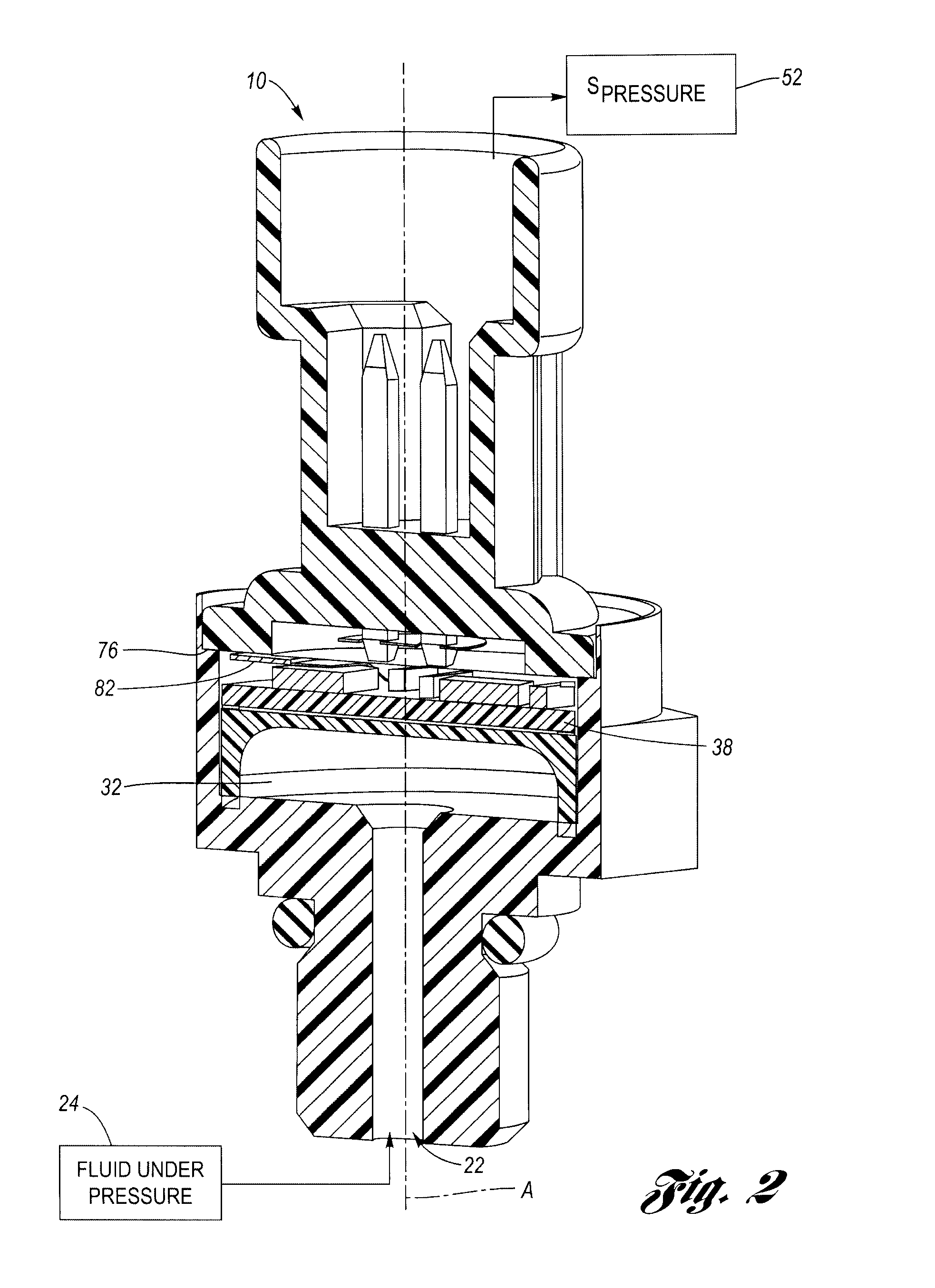

Capacitive pressure sensor

InactiveUS7383737B1Easy to processSimplify the assembly processFluid pressure measurement using capacitance variationCapacitive pressure sensorEngineering

A capacitive pressure sensor includes a electrically conductive, generally piston shaped diaphragm with a flexible base wall configured to deflect under pressure. The diaphragm is generally U-shaped in cross section. The base wall includes an upper, flat sensing surface which acts as a capacitive electrode. The diaphragm further includes a step around a radially-outermost perimeter which is elevated from the flat sensing surface. A sensing electrode body is located on top of the step and creates a capacitive sensing cavity between the sensing surface and the bottom surface of the electrode body. On the bottom surface of the electrode body is formed a center, circular electrode and a ring electrode that surrounds the center electrode. The center electrode and the sensing surface form a variable capacitor which changes with pressure and the ring electrode and the sensing surface form a reference capacitor. A circuit determines a differential capacitance between the variable capacitor and the reference capacitor and generates a pressure signal indicative of the fluid pressure applied to the diaphragm. A spring ring holds the sensing electrode body against the diaphragm when assembled. The diaphragm can be a machined metal part or a sheet metal cup. The sensing electrodes and signal generating circuit can take the form of a hybrid circuit.

Owner:DELPHI TECH INC

3-Axis Accelerometer With Gap-Closing Capacitive Electrodes

ActiveUS20100212425A1Precise definitionAcceleration measurement in multiple dimensionsElectricityThree axis accelerometer

Disclosed is a novel three-axis capacitive-type accelerometer implemented on SOI wafer. The accelerometer consists of four springs, one proof mass, four pairs of gap-closing sensing electrodes (each pair of gap-closing sensing electrode containing one movable electrode and one stationary electrode), and several metal-vias as the electrical interconnections. The movable electrodes are on the proof mass, whereas the stationary electrodes are fixed to the substrate. The three-axis accelerometer has five merits. (1) The sensitivity of the accelerometer is improved since the proof-mass is increased by containing both device and handling silicon layers; (2) The sensitivity is also improved by the gap-closing differential capacitive sensing electrodes design; (3) The parasitic capacitance at bond pad is reduced by the existing of metal-vias between the device Si layer and handling Si layer; (4) The sensing gap thickness is precisely defined by the buried oxide of SOI wafer; (5) The stationary sensing electrodes anchored to the substrate also act as the limit stops to protect the accelerometer.

Owner:NATIONAL TSING HUA UNIVERSITY

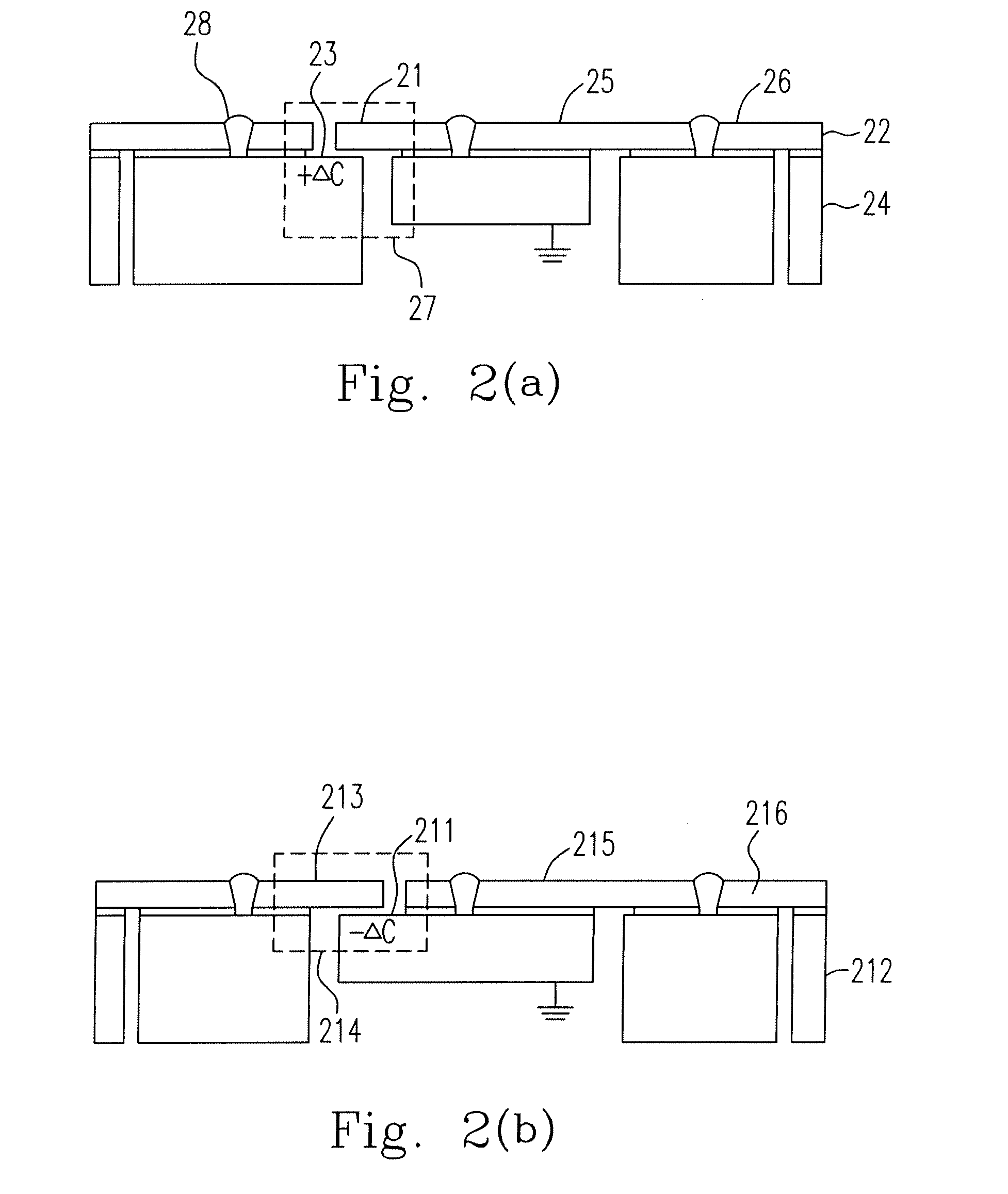

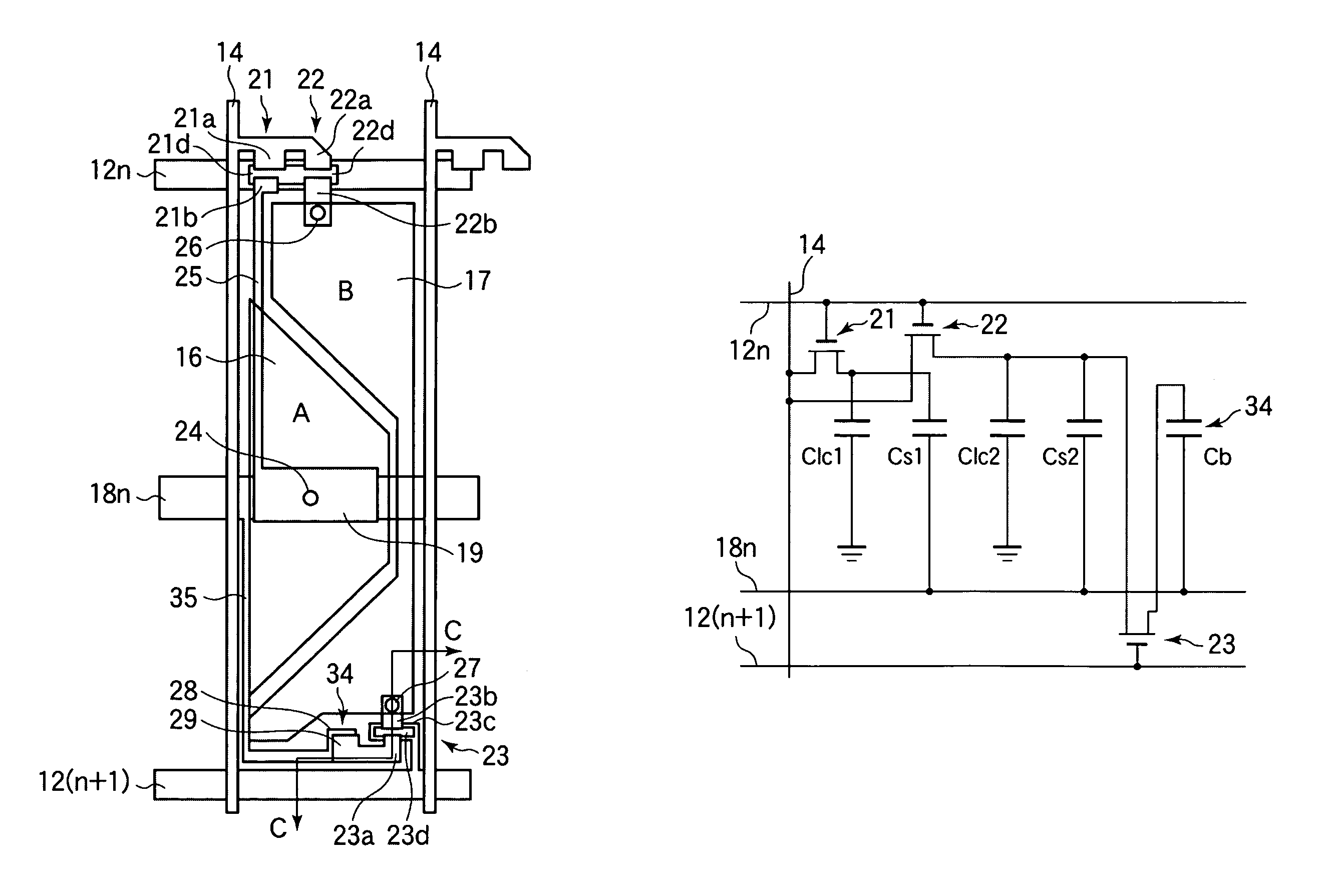

LCD device comprising an overlap between the first and second buffer capacitance electrodes

InactiveUS7834949B2Improve display characteristicsSolid-state devicesNon-linear opticsCapacitanceLiquid-crystal display

A liquid crystal display device is provided with first and second TFTs each having a gate electrode connected to an nth gate bus line and a drain electrode connected to a drain bus line; a first pixel electrode connected to a source electrode of the first TFT; a second pixel electrode connected to a source electrode of the second TFT; a third TFT having a gate electrode connected to an (n+1)th gate bus line and a source electrode connected to the second pixel electrode; and a buffer capacitance portion having a buffer capacitance electrode which is formed in the same layer as the first and second pixel electrodes and is connected to a drain electrode of the third TFT and a buffer capacitance electrode connected to a storage capacitance bus line. The buffer capacitance portion establishes capacitive coupling.

Owner:SHARP KK

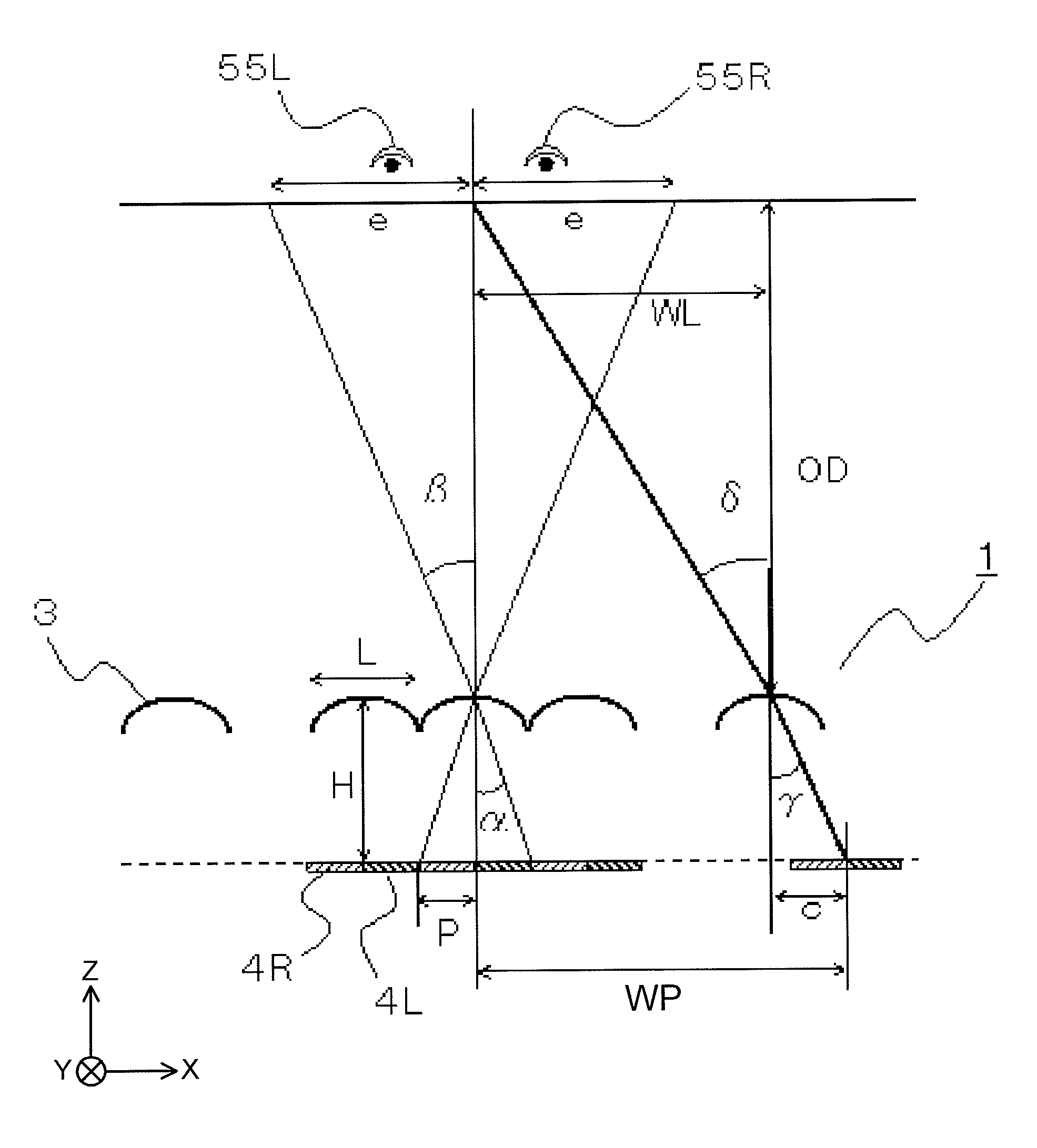

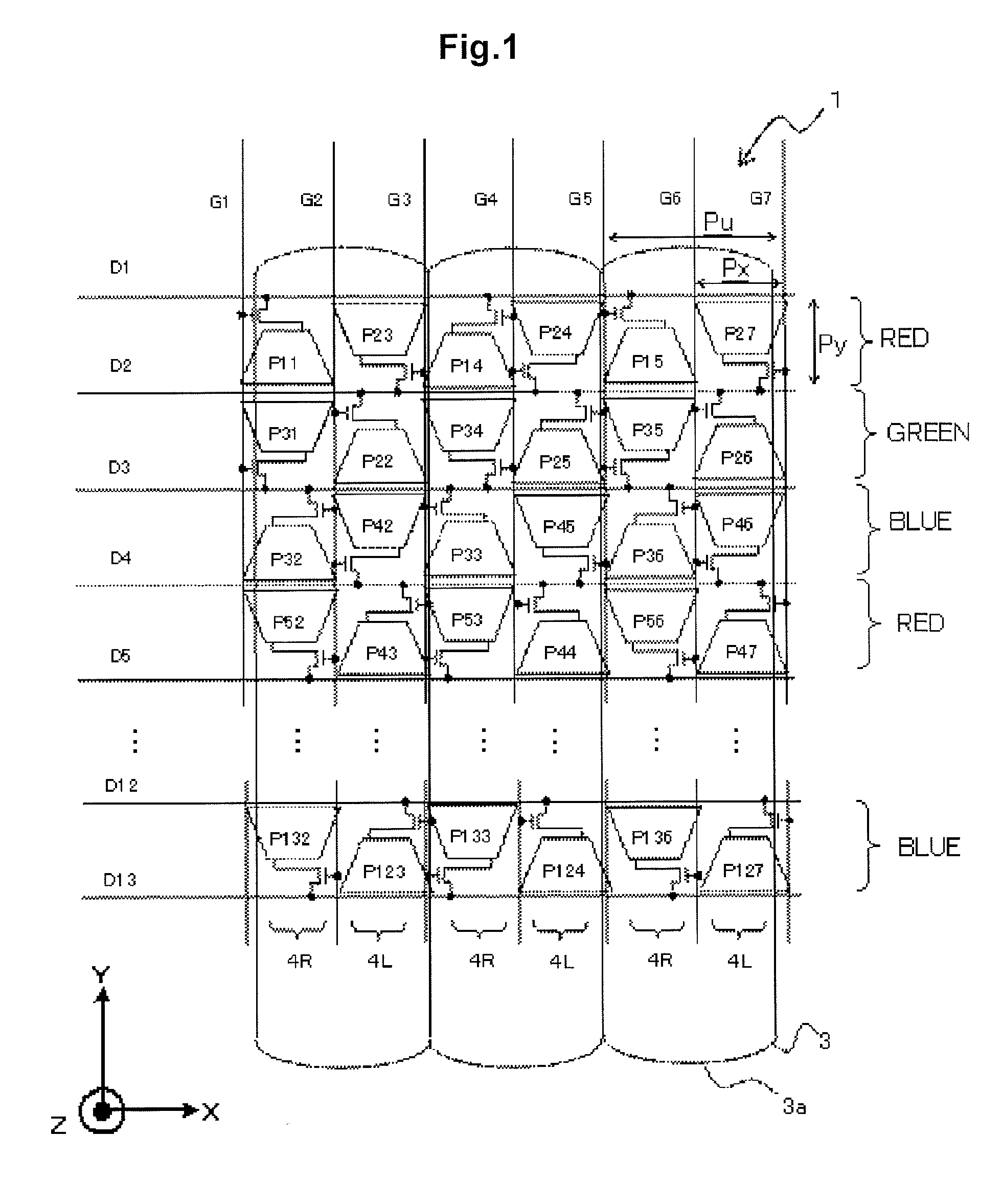

Image display device, driving method of image display device and terminal device

ActiveUS20110304601A1Improved aperture ratioPotential fluctuation be reduceCathode-ray tube indicatorsNon-linear opticsData linesComputer graphics (images)

An image display device includes a display element having a unit of display comprising sub pixels displaying images for first and second view points, respectively, and an optical unit that distributes lights emitted from respective sub pixels into different directions. When a region surrounded by a data line, a gate line and a storage capacitor electrode in the sub pixel is defined as an aperture, the sub pixels form a base unit that is an adjoining pixel pair including two sub pixels arranged via a data line therebetween. The two sub pixels have switching elements connected to the data line between the two sub pixels and controlled by different gate lines. When virtual lines each evenly dividing a width of the sub pixel in the first direction into K+1 pieces are presumed, K number of storage capacitor lines are each arranged across at least one virtual line in the aperture.

Owner:NEC LCD TECH CORP

Accelerometer

ActiveUS20070193355A1Quality improvementIncrease capacityAcceleration measurementCapacitanceCapacitive electrodes

An accelerometer is fabricated as a MEMS device and includes an array of capacitive electrode plates mechanically coupled to a common proof mass. The proof mass is constrained to move or vibrate in the plane parallel to the first array of plates. The capacitance between the first array of plates is measured with respect to additional arrays of capacitive plates inter-digitated in a comb like pattern.

Owner:PHYSICAL LOGIC LTD

Apparatus and Method for Multi-Component Wellbore Electric Field Measurements Using Capacitive Sensors

ActiveUS20120293179A1High sensitivityAchieving Reliability RequirementsElectric/magnetic detection for well-loggingSurveyCapacitanceEngineering

A method and apparatus is provided for collecting reservoir data. The method includes providing one or more electromagnetic sources for generating an electromagnetic field in a reservoir and providing one or more electromagnetic sensors equipped with capacitive electrodes. The electromagnetic source is located separately from the electromagnetic sensor. The electromagnetic sensor may either be located within a well or at the surface, is capable of measuring the electromagnetic field in three dimensions, and may be isolated from the well fluids. The data collected by the electromagnetic sensors can be used to create a model of the oil reservoir, including the water saturation.

Owner:SAUDI ARABIAN OIL CO

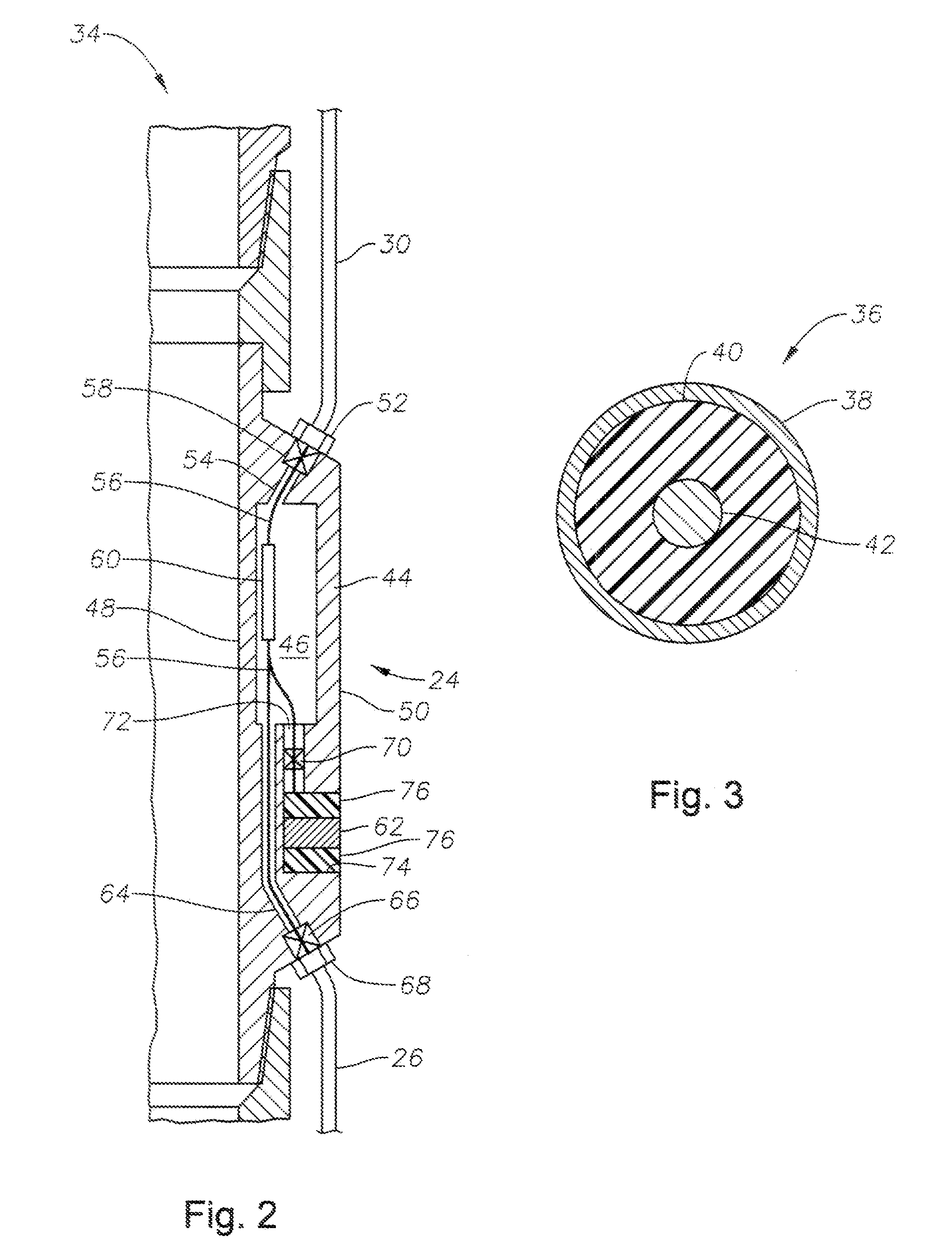

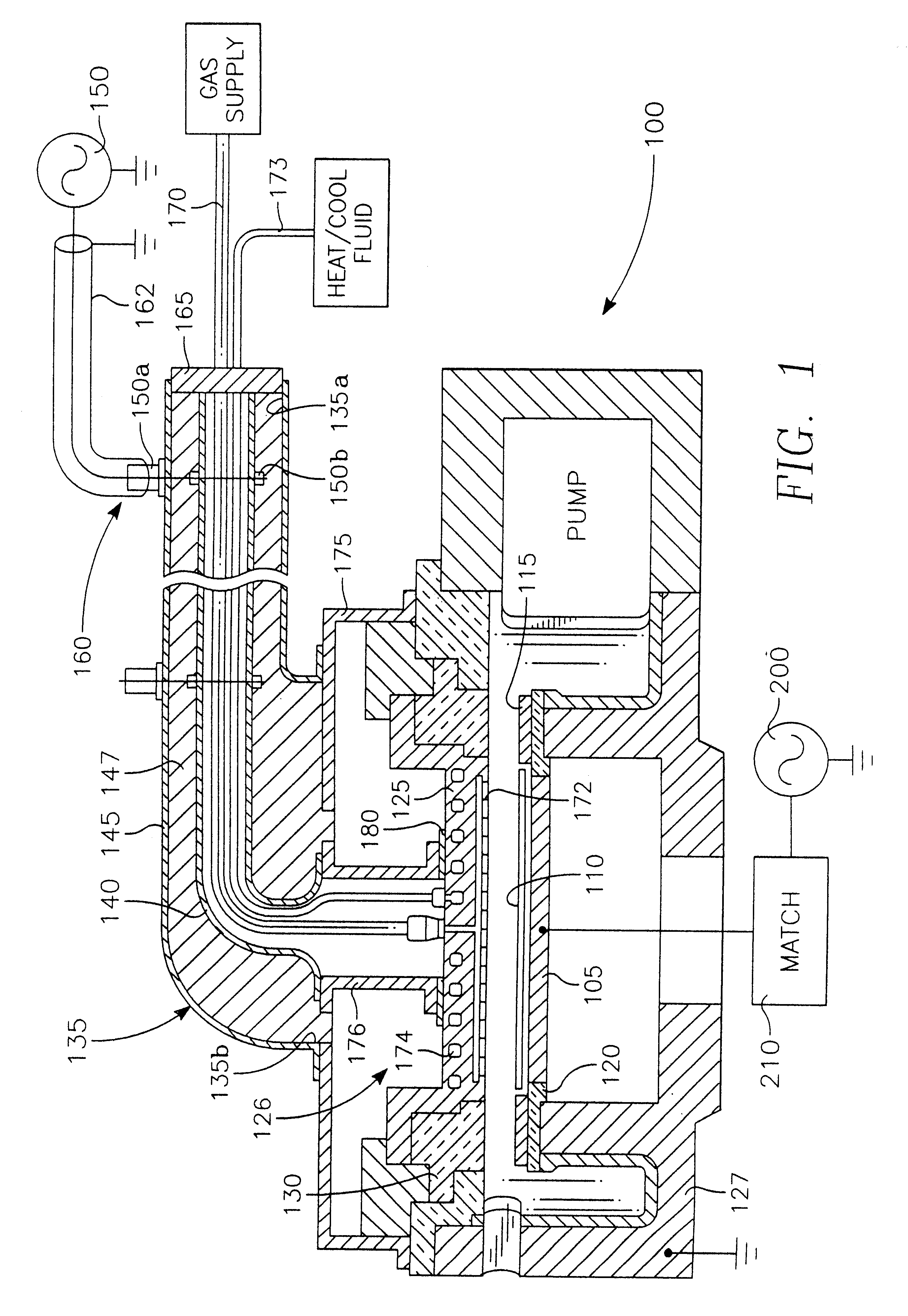

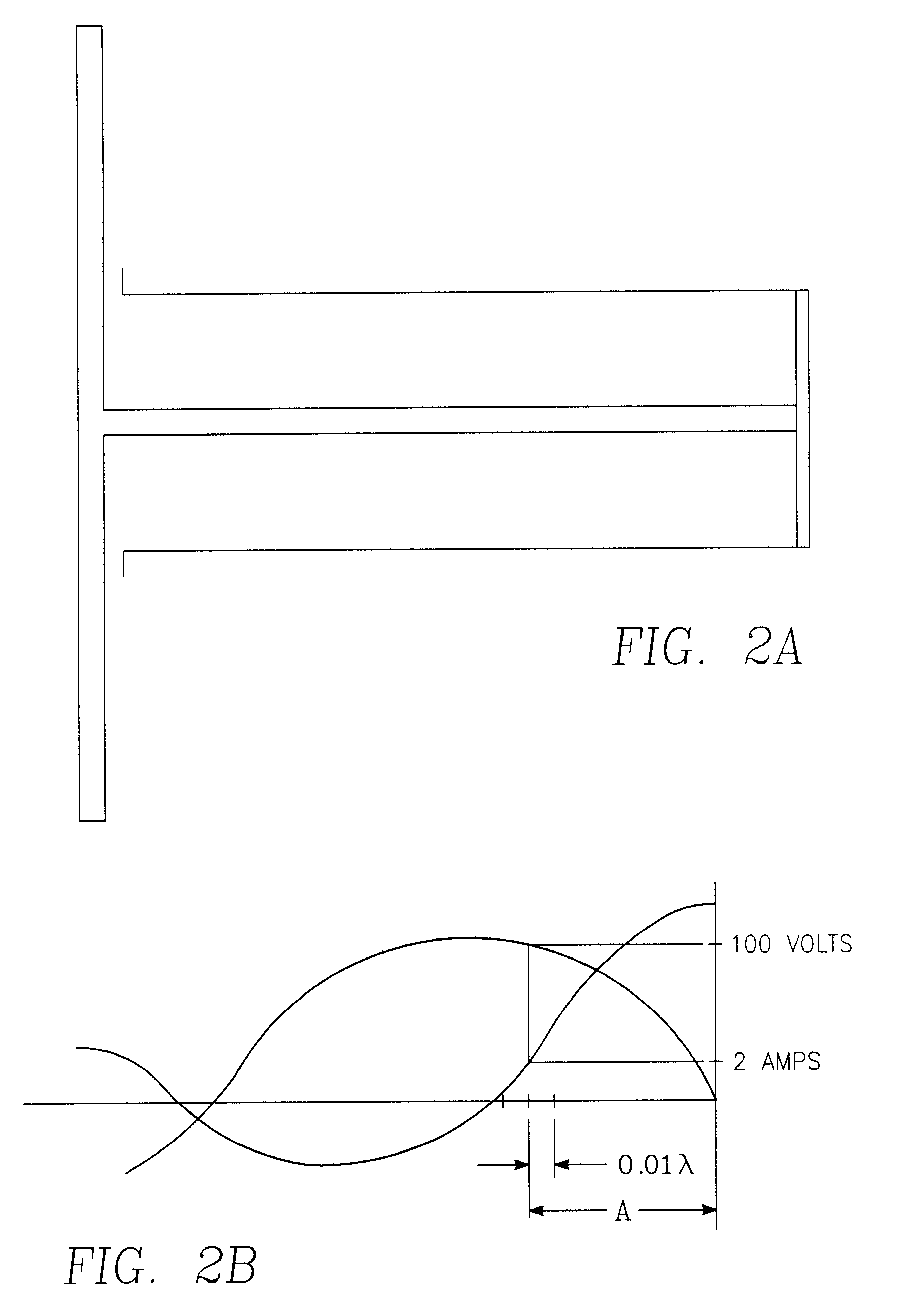

Plasma reactor with overhead RF electrode tuned to the plasma

InactiveUS6838635B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitancePlasma density

In accordance with one aspect of the invention, a plasma reactor has a capacitive electrode driven by an RF power source, and the electrode capacitance is matched at the desired plasma density and RF source frequency to the negative capacitance of the plasma, to provide an electrode plasma resonance supportive of a broad process window within which the plasma may be sustained.

Owner:APPLIED MATERIALS INC

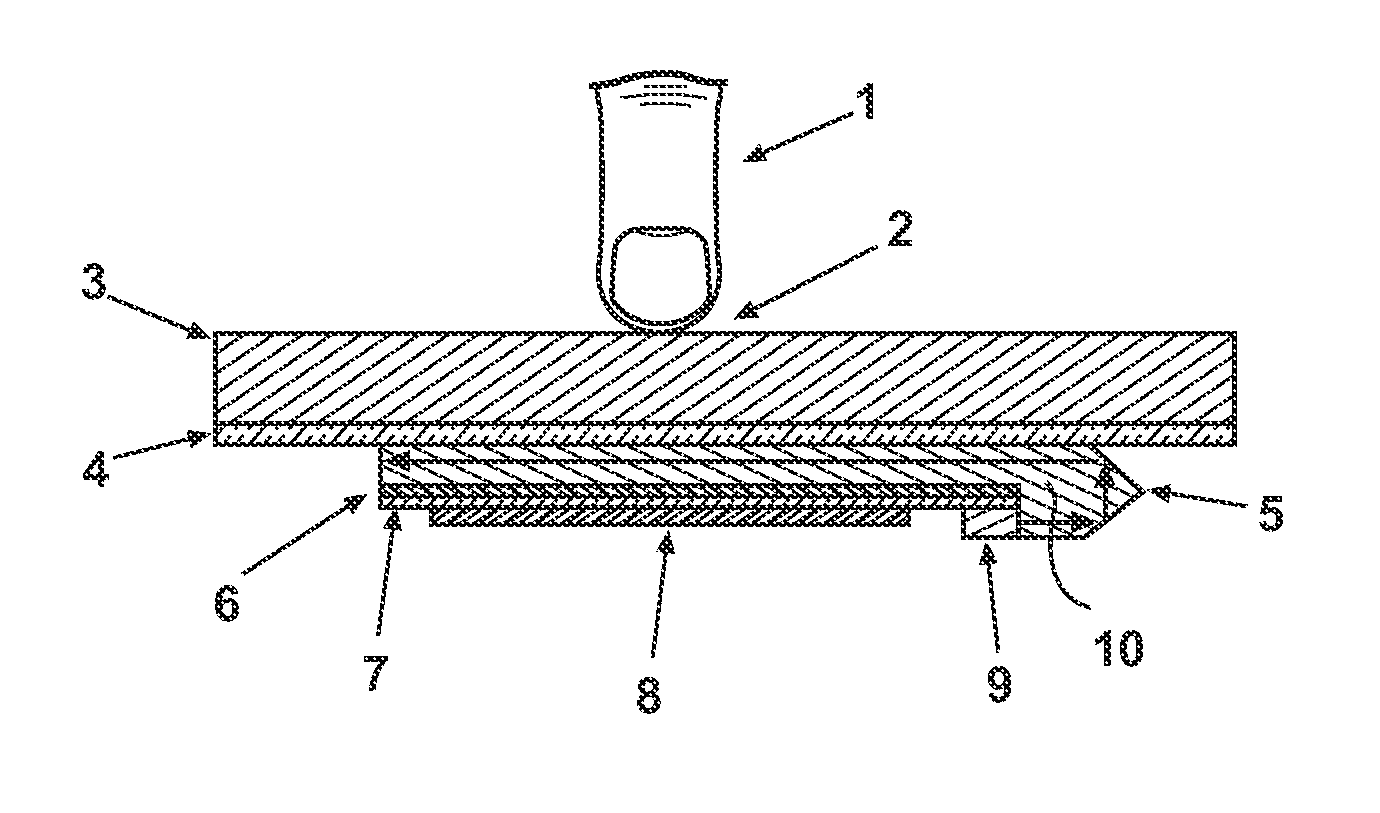

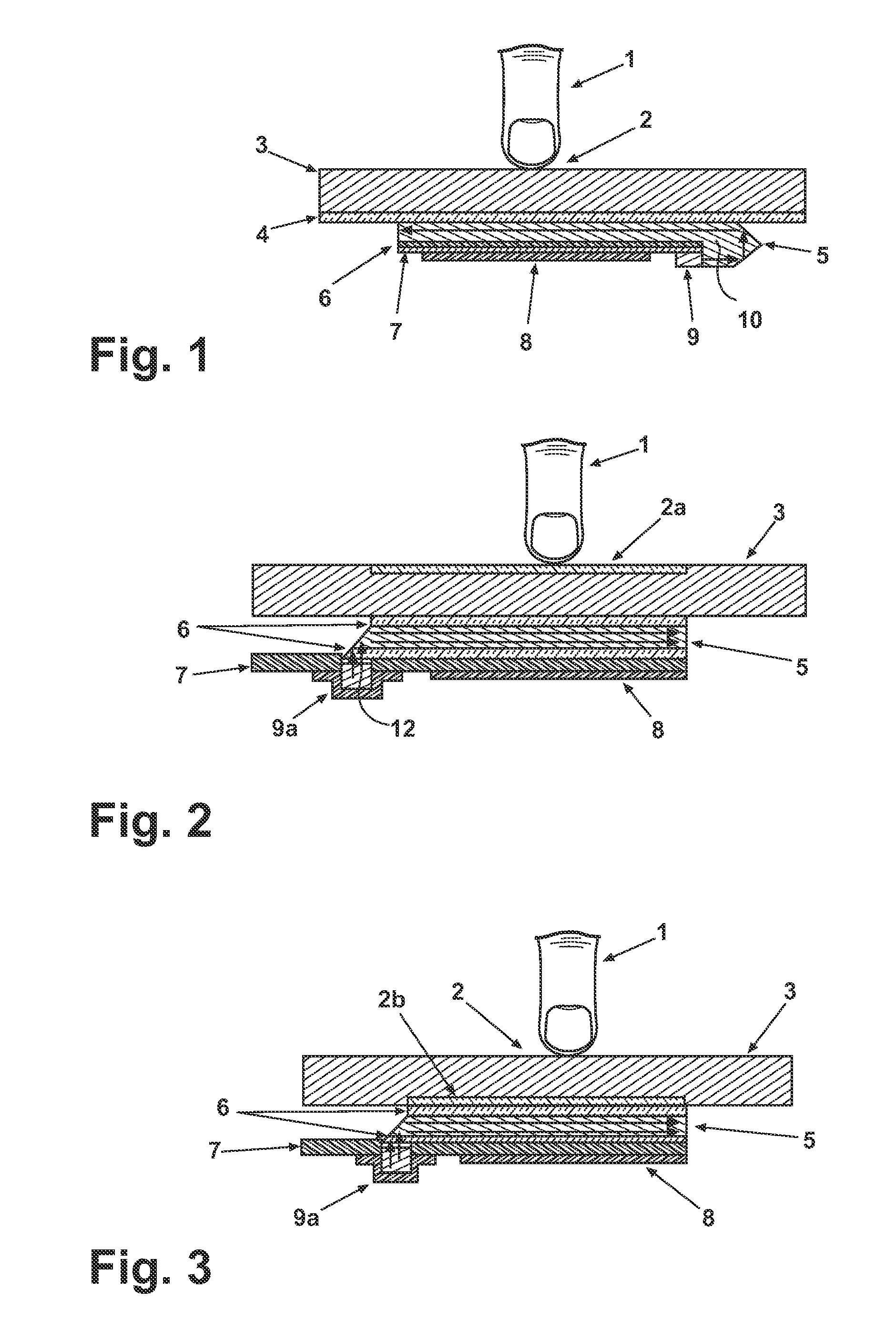

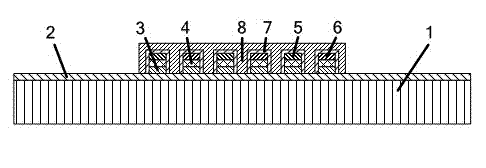

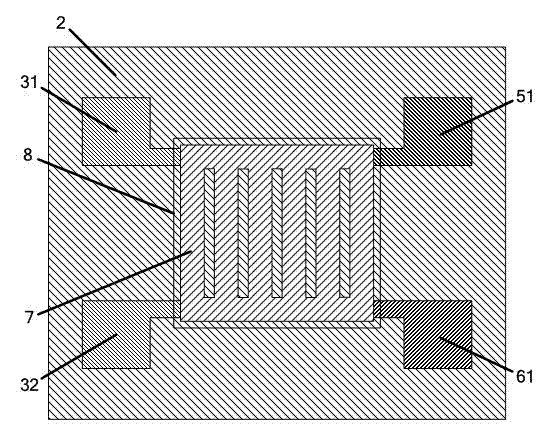

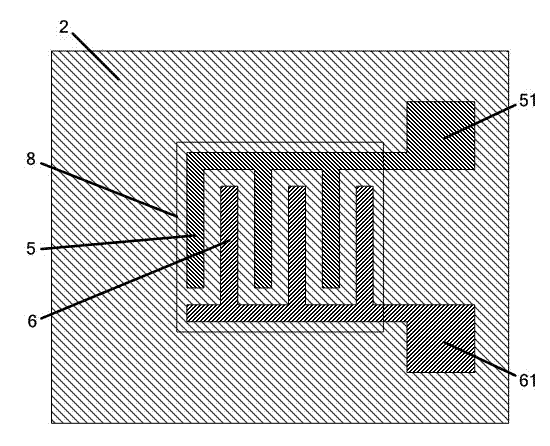

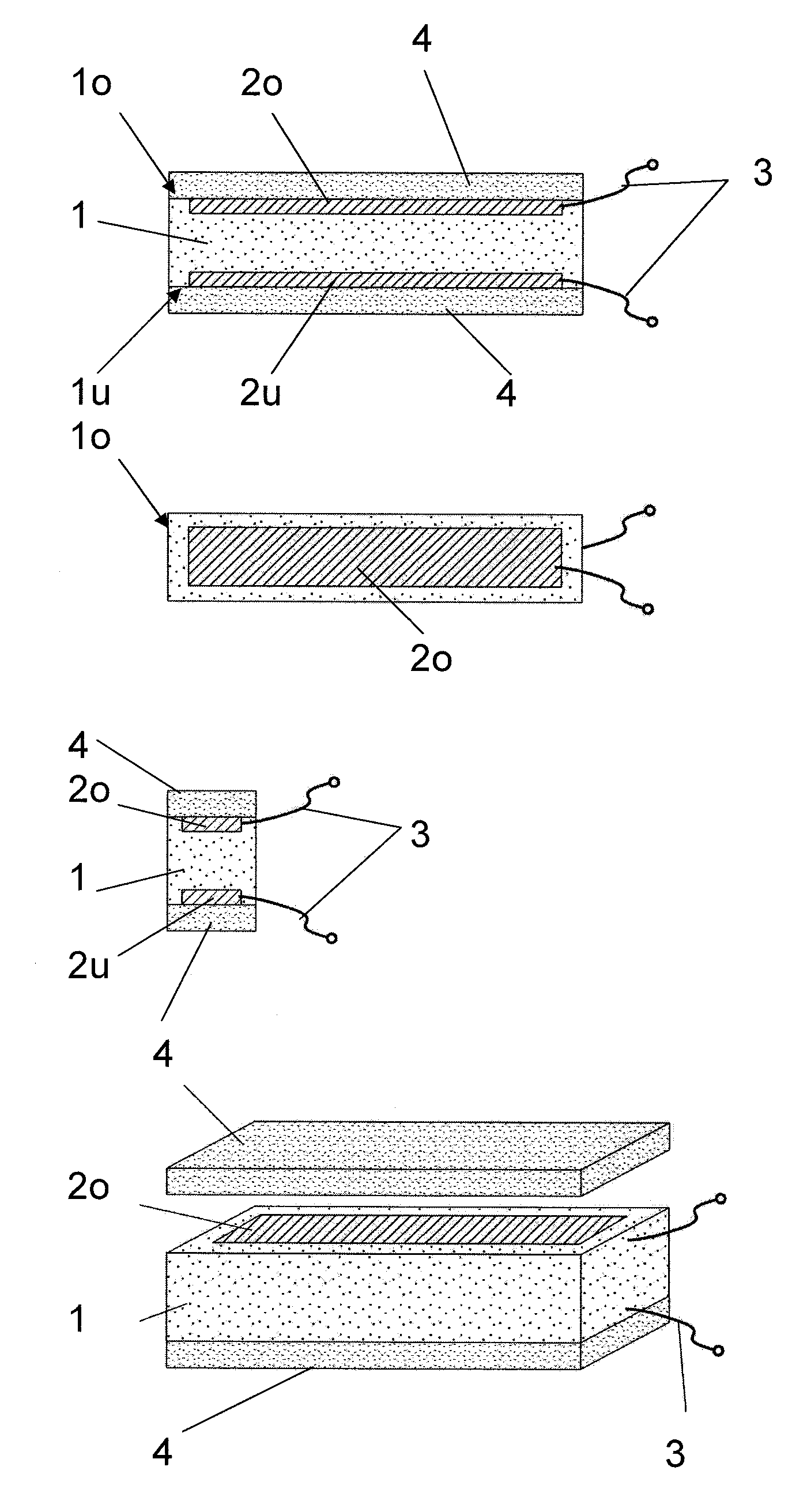

Capacitive relative humidity sensor based on graphene oxide

InactiveCN102253091AHigh sensitivityQuick responseTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceEngineering

The invention discloses a capacitive relative humidity sensor based on graphene oxide. The humidity sensor is characterized by comprising a substrate (1), an oxide layer (2), a heating strip (3) and an insulating layer (4) that are successively arranged on the substrate (1) from bottom to up. The humidity sensor also comprises a first capacitance electrode (5), a second capacitance electrode (6), passivation layers (7) and humidity sensitive mediums (8). The first capacitance electrode (5) and the second capacitance electrode (6) are arranged on the insulating layer (4) respectively and are equipped with a passivation layer (7) respectively; and the sensitive mediums (8) are arranged between the first capacitance electrode (5) and the second capacitance electrode (6), and also arranged above the first capacitance electrode (5) and the second capacitance electrode (6). According to the invention, sensor reliability is increased; technology steps are simple; and graphene oxide is employed as the humidity sensitive medium. Therefore, the sensor has advantages of high sensitivity, fast response speed and low hysteresis.

Owner:SOUTHEAST UNIV

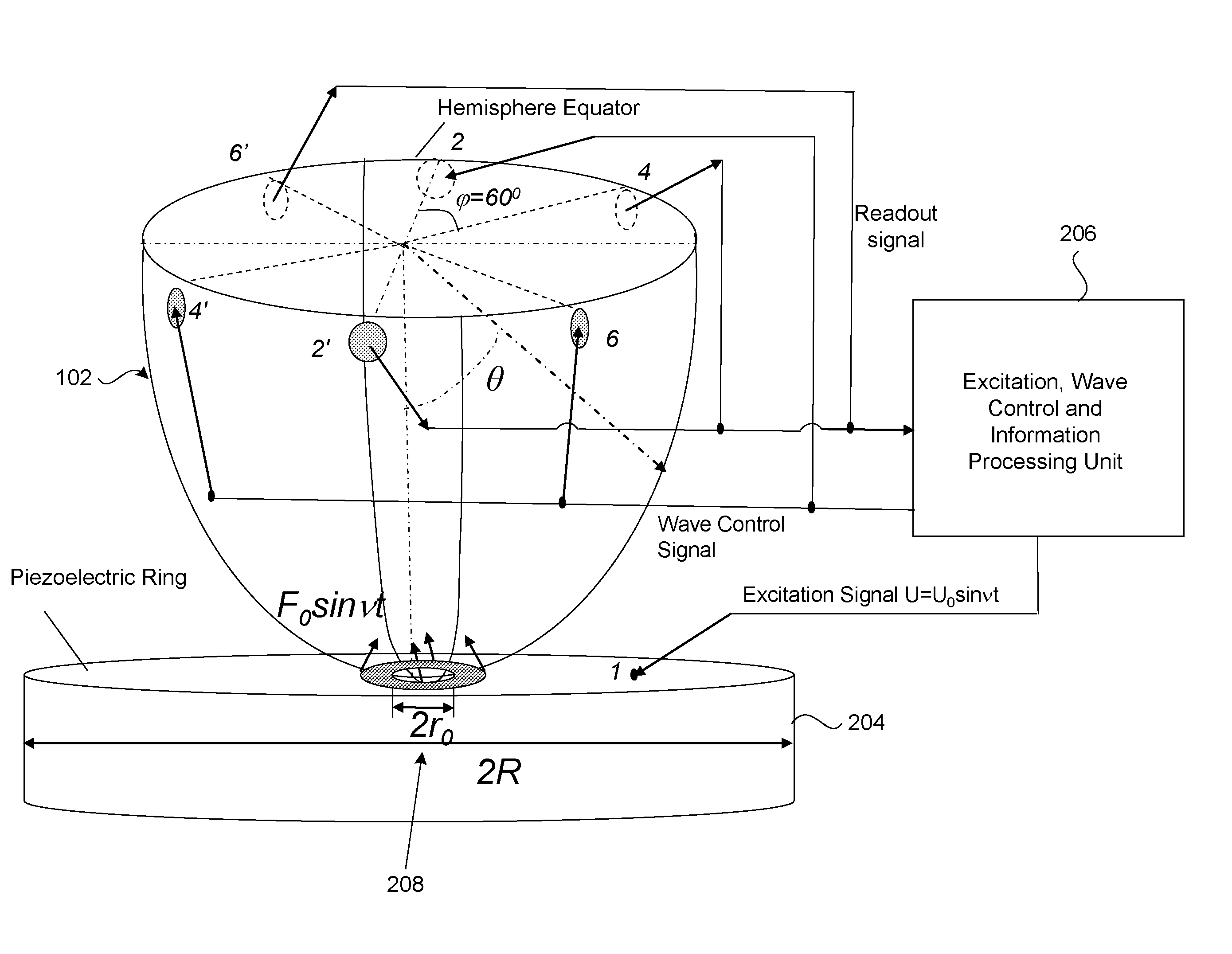

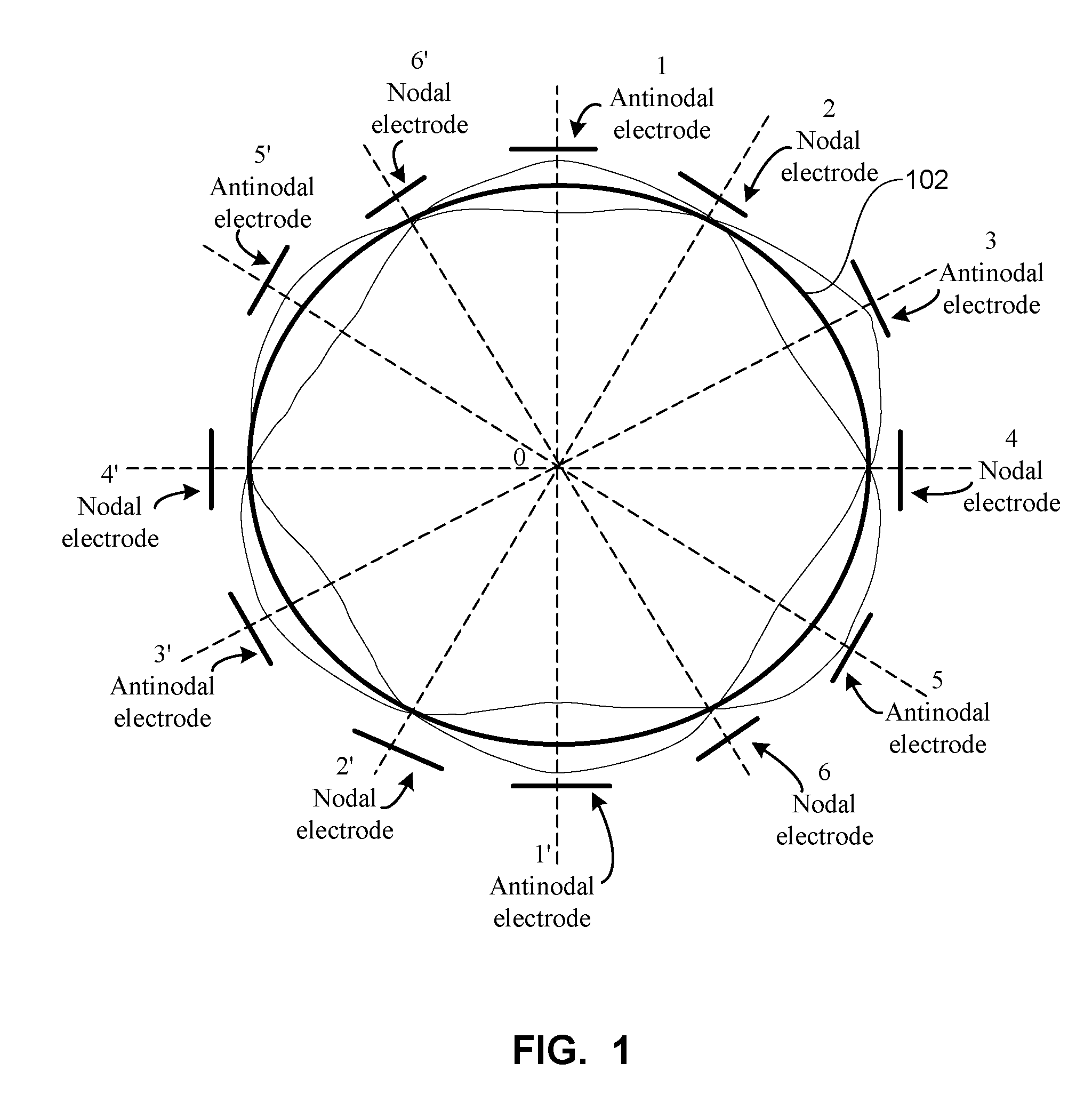

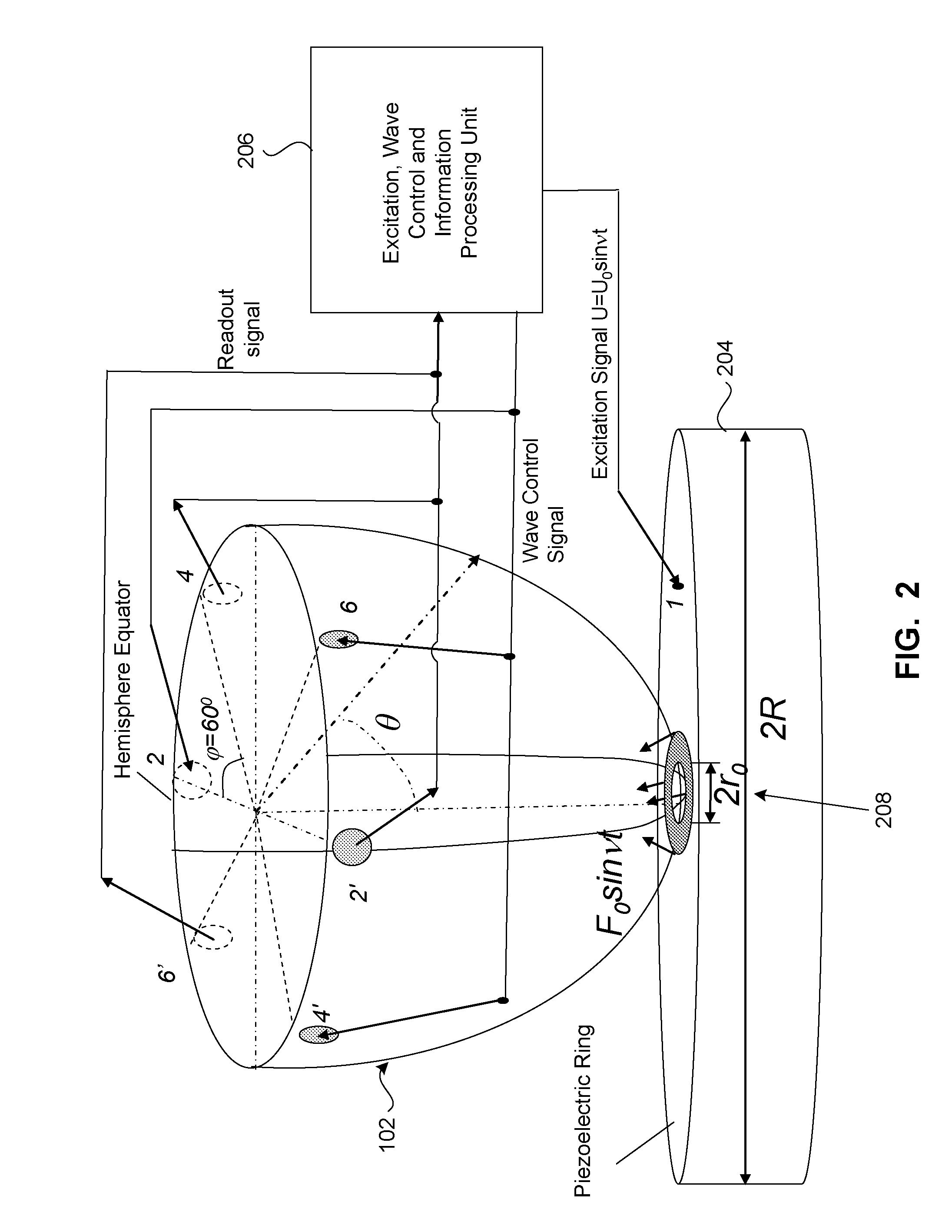

Stemless hemispherical resonator gyroscope

InactiveUS7281426B1Improve accuracyEliminate disadvantagesAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsConductive coatingAngular velocity

A vibrational gyroscope includes a piezoelectric ring having a central opening, and a hemispherical resonator having a central opening and mounted over the opening of the central opening of the piezoelectric ring. A plurality of electrodes delivers a voltage to the piezoelectric ring. A plurality of electrodes provides signal readout that corresponds to angular velocity. The hemispherical resonator can be glued to the piezoelectric ring. The hemispherical resonator preferably vibrates in the third vibration mode. A plurality of capacitive electrodes can be located at nodes and at antinodes of the vibration of the hemispherical resonator, and provide a signal readout that corresponds to the angular velocity. The piezoelectric ring is segmented, non-segmented, or includes an outer segmented portion and an inner non-segmented portion. The inner non-segmented portion can be used to excite the resonator into a vibration mode, and the outer segmented portion provides a readout signal and is used to adjust the vibration of the resonator. The piezoelectric ring includes a conductive coating used to conduct excitation voltage to the piezoelectric ring.

Owner:INNALABS

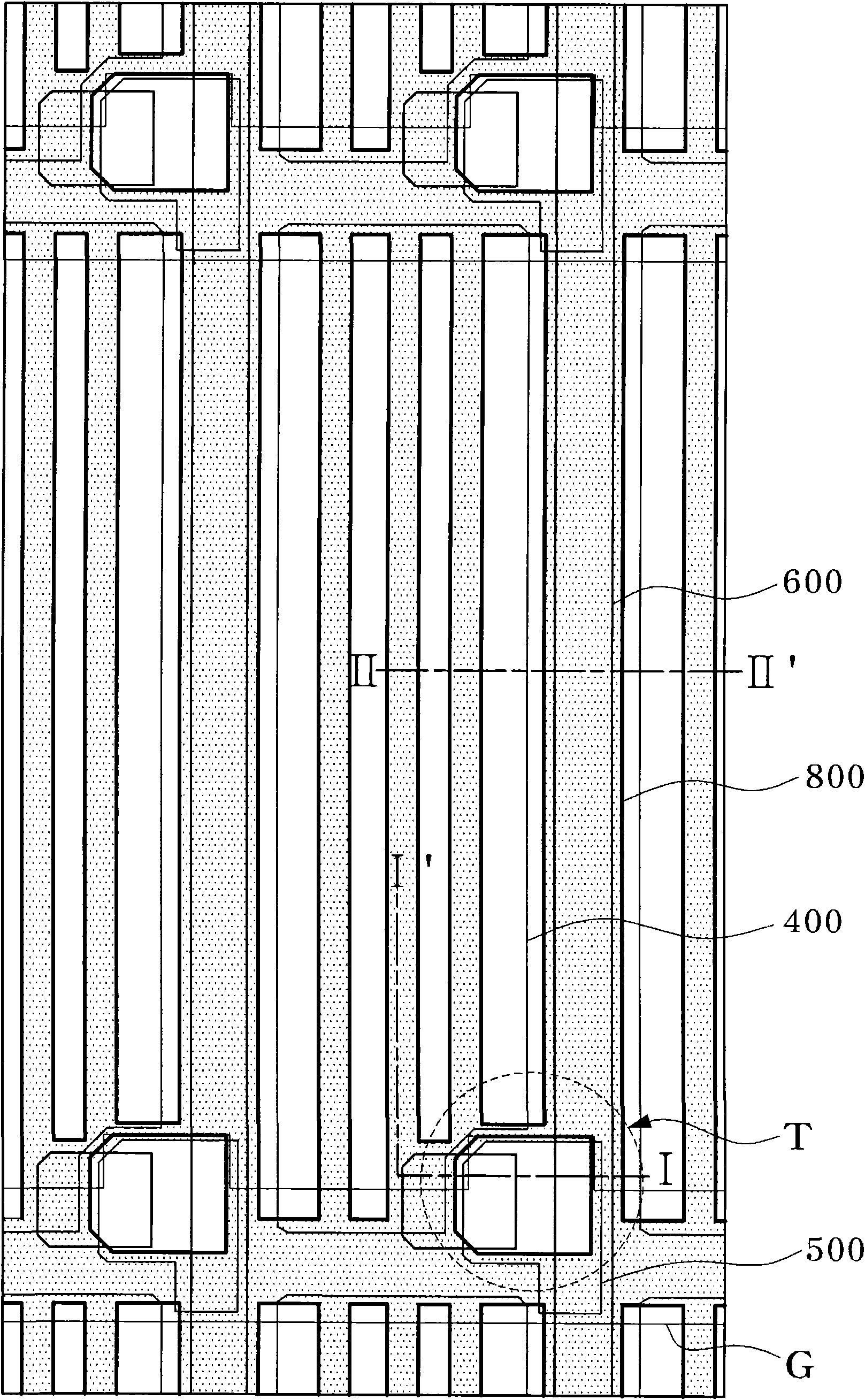

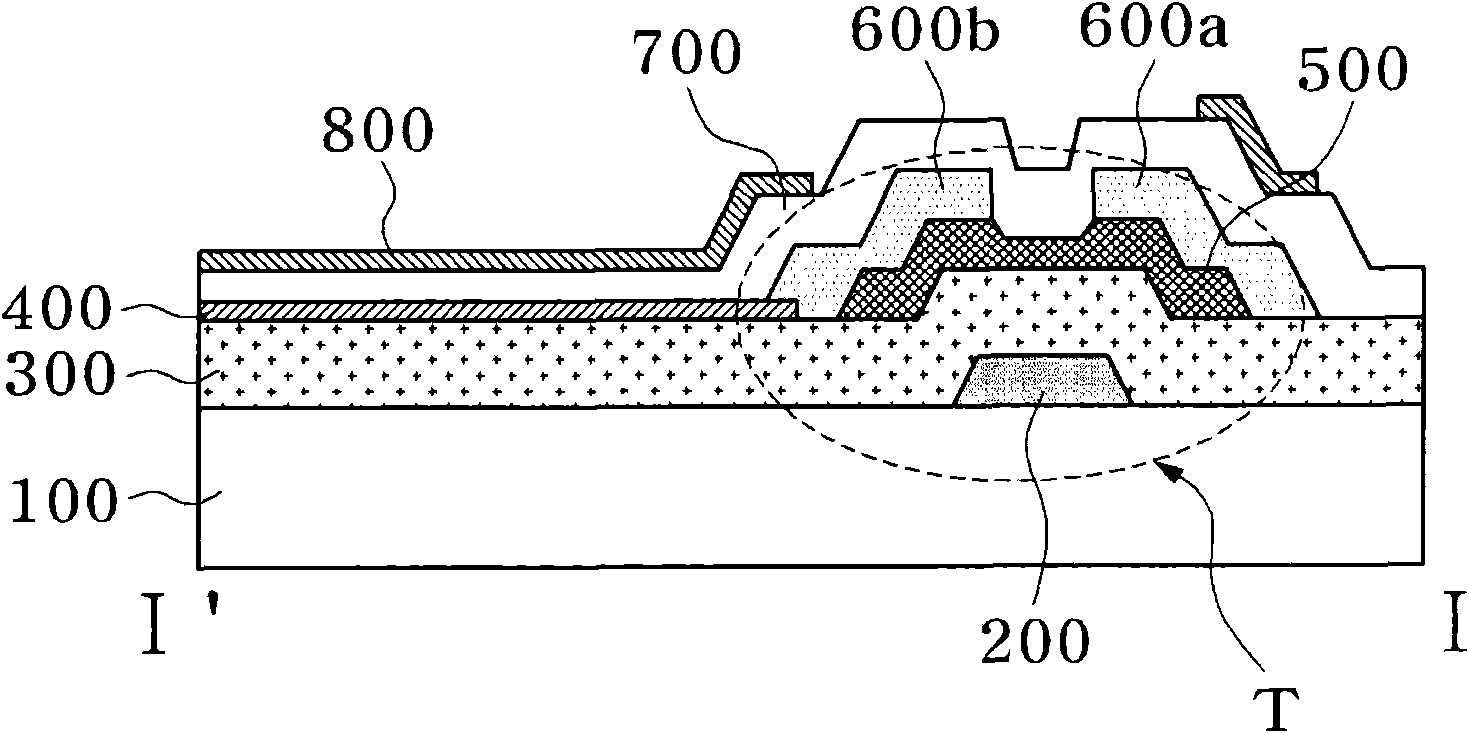

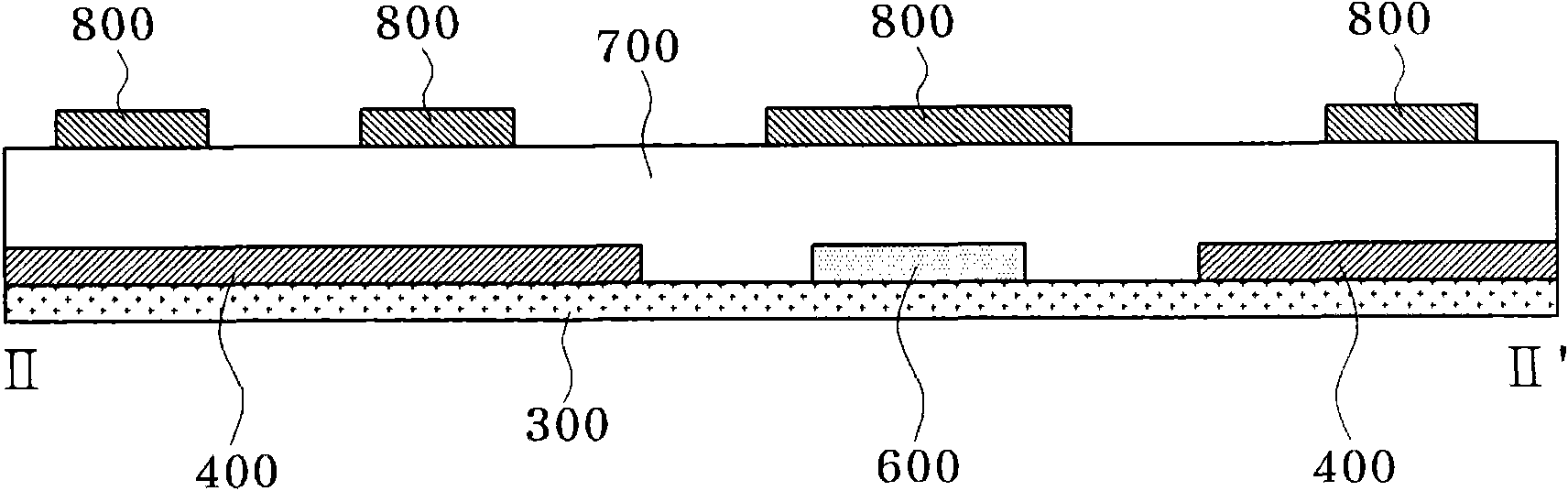

Fringe field switching mode liquid crystal display device and method of fabricating the same

InactiveCN102033365ASolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLiquid-crystal display

Provided is a fringe field switching (FFS) mode liquid crystal display device (LCD) and a method of fabricating the same that are capable of effectively improving image quality by reducing loads of gate lines and data lines and increasing a conventional storage capacitance. The LCD includes a lower substrate, an upper substrate, and a liquid crystal layer disposed between the substrates, the lower substrate including unit pixel regions defined by gate lines and data lines formed to intersect each other and switching devices disposed on intersections of the gate and data lines, the LCD also comprises: a transparent pixel electrode disposed in the pixel region and a transparent common electrode spaced apart from and overlapping the transparent pixel electrode in a predetermined region with an insulating layer interposed therebetween, and a transparent auxiliary capacitive electrode spaced apart from and overlapping the transparent pixel electrode in a predetermined region with the gate insulating layer interposed therebetween, wherein the transparent auxiliary capacitive electrode is electrically connected to a common bus line formed on a non-display region of an outer periphery of the lower substrate through a contact hole, and the common bus line is connected to the transparent common electrode.

Owner:HYDIS TECH CO LTD

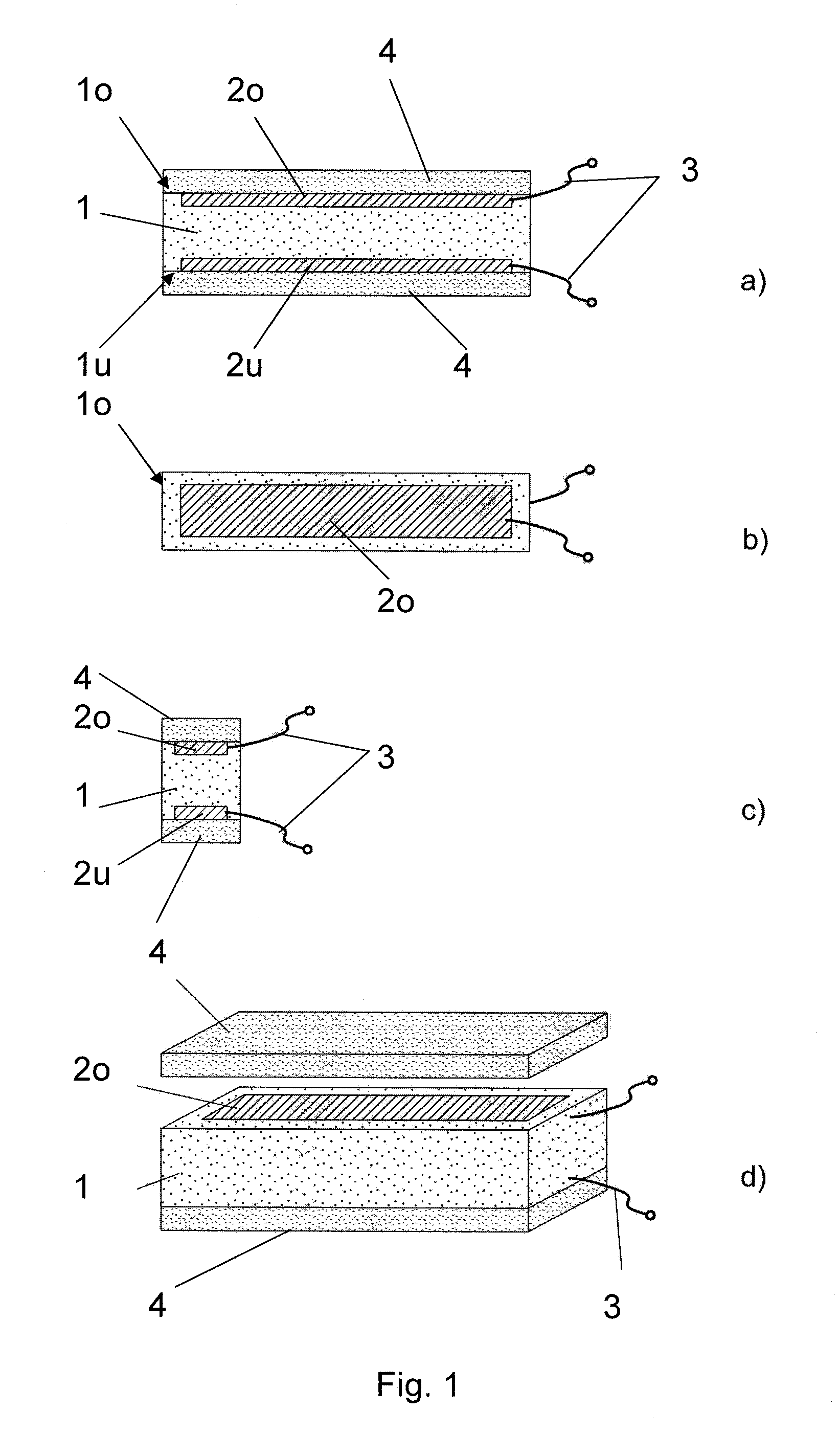

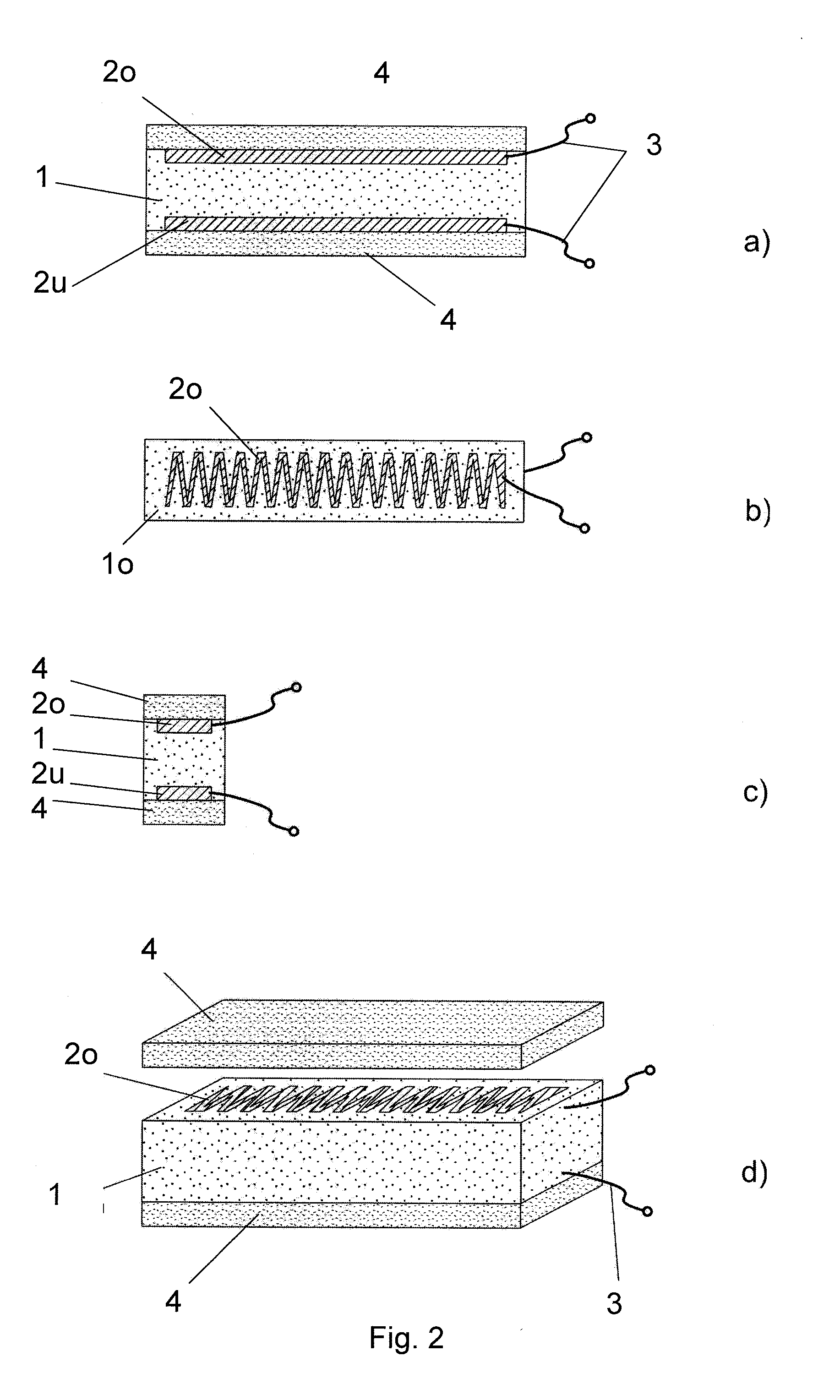

Implantable device for detecting a vessel wall expansion

InactiveUS20130041244A1Improve signal qualityAvoid influenceCapacitor with electrode distance variationForce measurementCapacitanceConductive polymer

An implantable device is described for detecting an expansion which is an elastic deformation of an intracorporeal vessel wall. The device comprises a support structure which contains dielectric polymer, has surface elasticity and can be applied directly or indirectly to the vessel wall, which provides at least one capacitive electrode arrangement, of which the assignable electrical capacitance can be influenced by an elastic deformation of the support structure. The electrode arrangement includes at least two electrodes each consisting of an electrically conductive polymer. The electrodes each define at least one side an intermediate space that influences the electrical capacitance of the electrode arrangement. The space is filled with the dielectric polymer of the support structure.

Owner:ALBERT LUDWIGS UNIV FREIBURG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com