Fringe field switching mode liquid crystal display device and method of fabricating the same

A mode and substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as increase, image quality reduction, and voltage retention rate reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example Embodiment

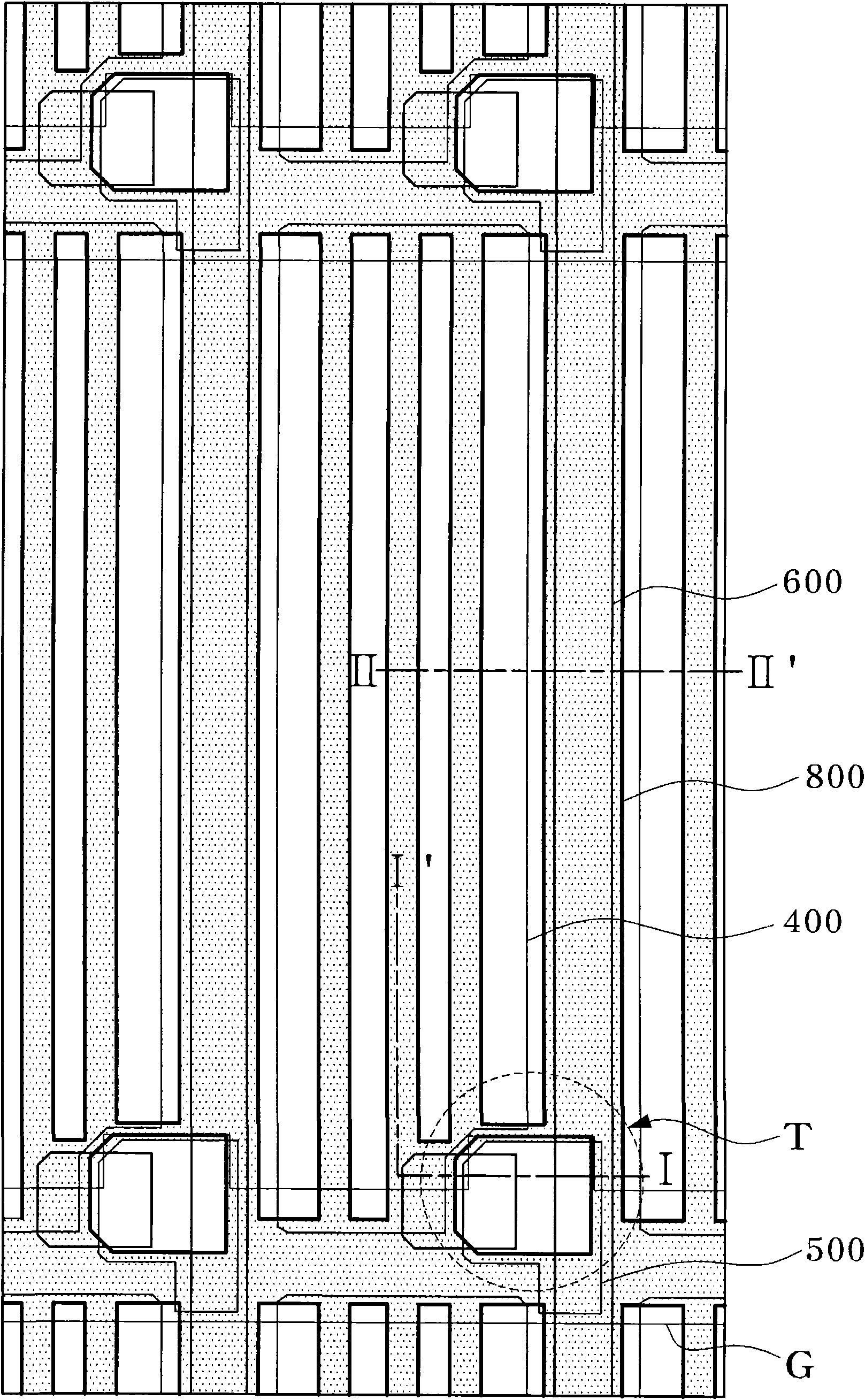

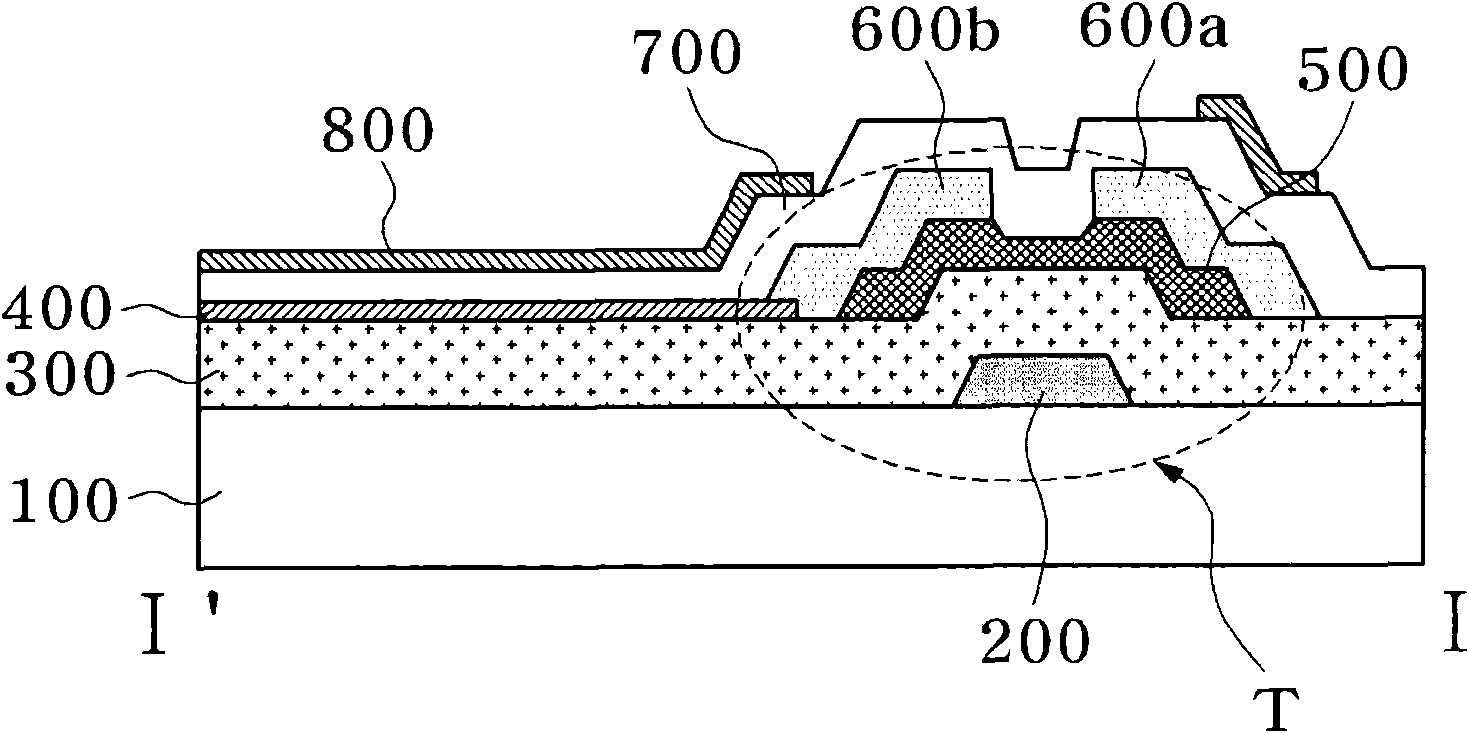

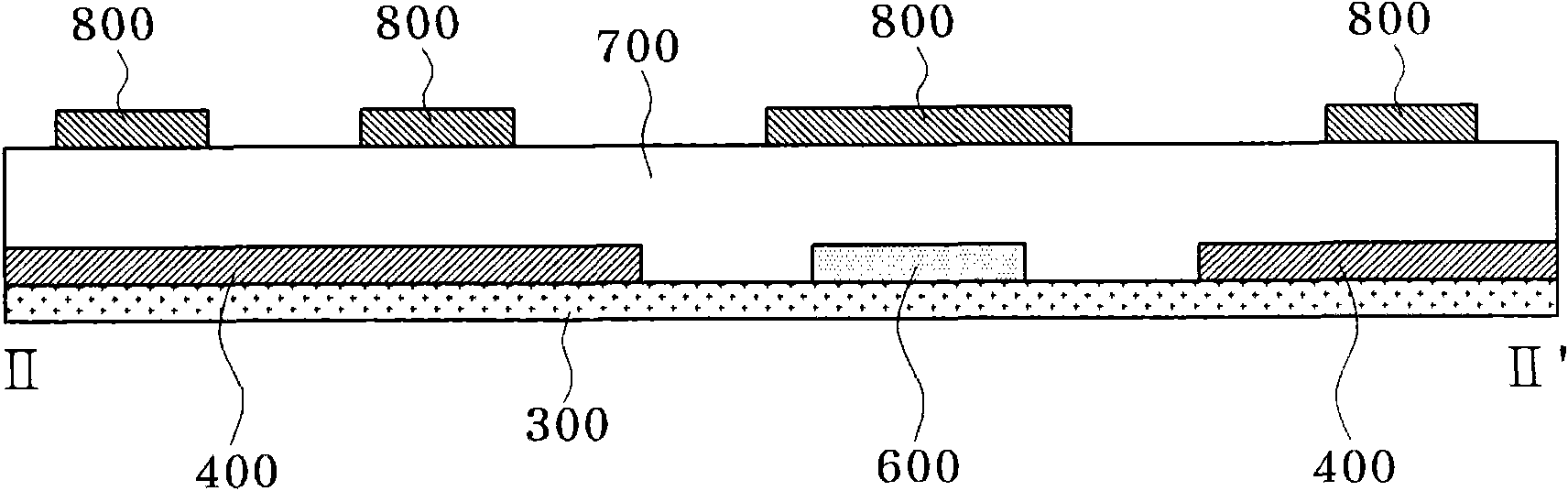

[0050] Figure 4 is a plan view of a part of the pixel region of the lower substrate of the FFS mode LCD according to the first exemplary embodiment of the present invention; Figure 5 to Figure 8 Formed for sequential display Figure 4 A plan view of the various layers shown and steps for overlapping the layers; Figure 9 for Figure 4 The sectional view taken along the line A-A'; Figure 10 for Figure 4 The sectional view taken along the line B-B'; Figure 11 is the plan view of FFS mode LCD, which shows Figure 4 part of the layer shown; Figure 12 for Figure 11 The sectional view taken along the line C-C'; Figure 13 is an equivalent circuit diagram showing a liquid crystal cell of an FFS mode LCD according to a first exemplary embodiment of the present invention.

[0051] see Figure 4 to Figure 13 , the lower substrate applied to the first exemplary embodiment of the present invention has a structure in which gate lines G and data lines 600 formed of an opaqu...

no. 2 example Embodiment

[0077] Figure 15 is a plan view of a part of a pixel region of a lower substrate of an FFS mode LCD according to a second exemplary embodiment of the present invention; Figure 16 to Figure 21 is a plan view sequentially showing the steps of forming the layers and overlapping the layers; Figure 32 for Figure 15 The cross-sectional view taken along the line D-D'.

[0078] The structure of the lower substrate applied to the second exemplary embodiment of the present invention is similar to the structure of the lower substrate applied to the above-mentioned first exemplary embodiment, for the convenience of explanation, for the same elements as in the first exemplary embodiment, The same reference numerals and names as in the first exemplary embodiment will be used.

[0079] Furthermore, the main explanation will be related to Figure 4 The difference of the lower substrate of the FFS mode LCD according to the first exemplary embodiment of the present invention is shown, t...

no. 3 example Embodiment

[0094] Figure 22 is a plan view of a part of a pixel region of a lower substrate of an FFS mode LCD according to a third exemplary embodiment of the present invention, Figure 33 then Figure 22 Sectional view taken along the line E-E' of .

[0095] see Figure 22 and Figure 33 , comparing the lower substrate of the FFS mode LCD device according to the third exemplary embodiment of the present invention with the lower substrate of the FFS mode LCD device according to the second exemplary embodiment of the present invention described above, the difference is only in the The arrangement position of the common line 900 which reduces the resistance, and the FFS mode LCD device according to the third exemplary embodiment of the present invention is the same as that of the FFS mode LCD device according to the second exemplary embodiment of the present invention in structure and its manufacturing method. Therefore, for its detailed description, refer to the second exemplary emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com