Capacitive touching structure, embedded touch screen, display device and scanning method of display device

An embedded touch screen and capacitive technology, which is applied in the fields of electrical digital data processing, optics, instruments, etc., can solve the problems of large touch blind area, unfavorable narrow frame design, and a large number of peripheral traces, etc., to reduce the number of traces , Reduce the effect of relatively large touch blind area and the reduction of the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

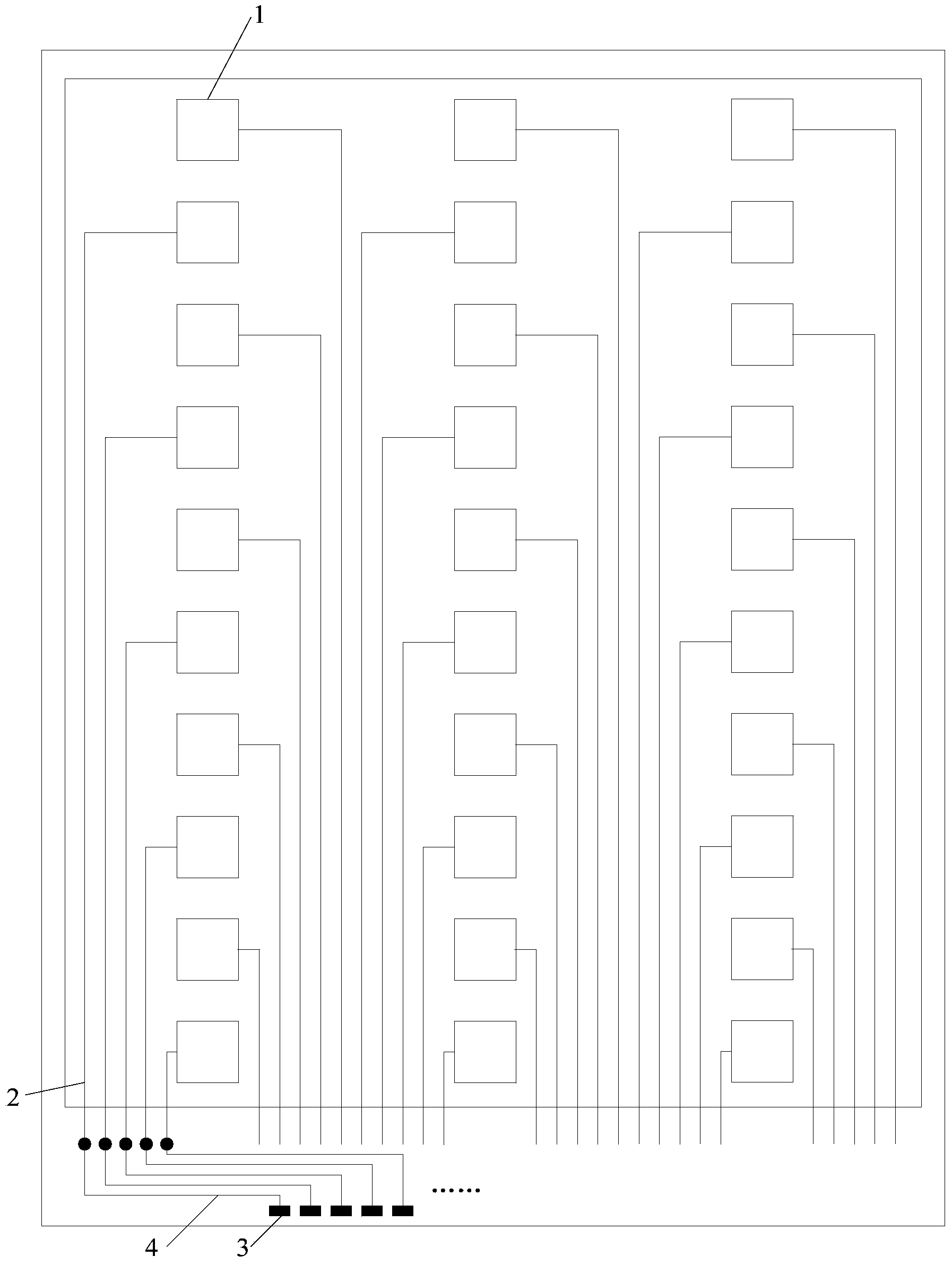

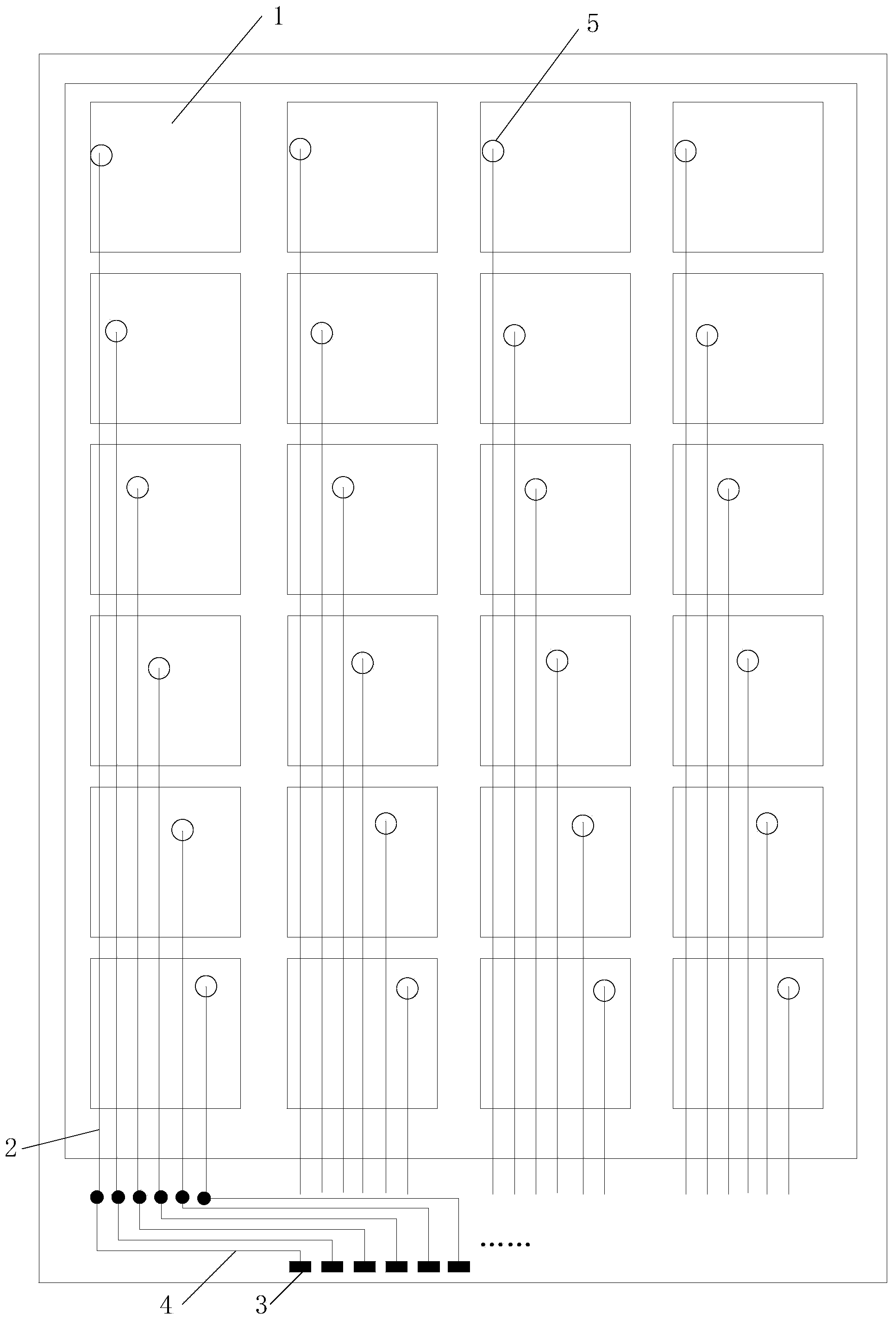

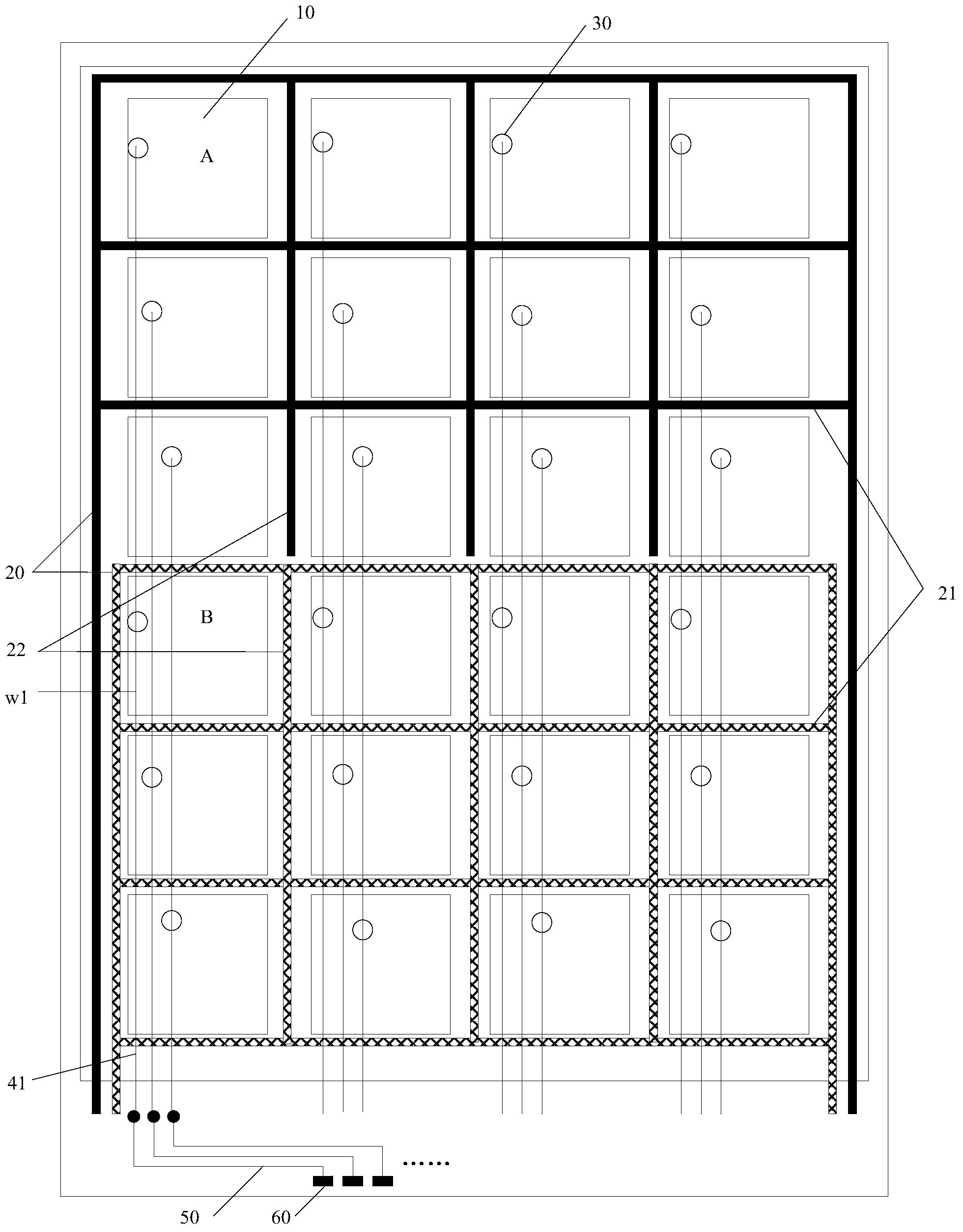

[0165] In the first embodiment of the present invention, the combination of image 3 , the structure of the capacitive touch structure is introduced in detail.

[0166] like image 3 As shown, the capacitive touch structure applied to the touch screen includes:

[0167] A plurality of self-capacitance electrodes 10 arranged on the same layer and insulated from each other in a matrix form are respectively located in the upper and lower regions that are not equally divided along the horizontal direction included on the surface of the film layer where the self-capacitance electrodes 10 are located; in, image 3 The description will be made by taking 16 self-capacitance electrodes 10 in 4 rows and 4 columns in the upper region and 12 self-capacitance electrodes 10 in 3 rows and 4 columns in the lower region;

[0168] A regional electrode 20 located in each of the regions, the regional electrode 20 located in the upper region is arranged on the same layer as the self-capacitance...

Embodiment 2

[0178] In the second embodiment of the present invention, the combination of image 3 , the touch principle of the capacitive touch structure applied to the touch screen in the embodiment of the present invention is introduced in detail.

[0179] 1. Single touch.

[0180] 1. The touch point is located at image 3 in the upper region shown.

[0181] Such as Figure 4 shown in the image 3 Point P1 in the upper area shown partially overlaps the regional electrode pad1, self-capacitance electrode A, self-capacitance electrode B, self-capacitance electrode E, and self-capacitance electrode F in the upper area; P1 point overlaps with the self-capacitance electrode The overlapping area of A is S1, the overlapping area of P1 point and self-capacitance electrode B is S4, the overlapping area of P1 point and self-capacitance electrode E is S2, and the overlapping area of P1 point and self-capacitance electrode F The area is S3, where S2>S1>S3>S4;

[0182] when the finger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com