Capacitive relative humidity sensor based on graphene oxide

A humidity sensor, relative humidity technology, applied in material capacitance, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the thickness of the comb-shaped electrode Large size, small size of the micro-sensor, slow sensor response, etc., to achieve the effect of good long-term stability, simple process steps and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

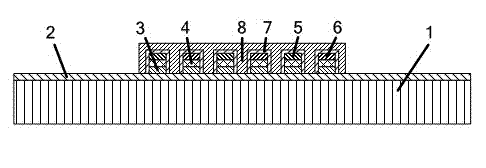

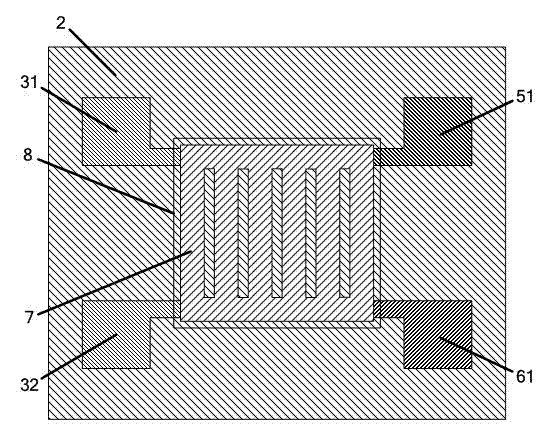

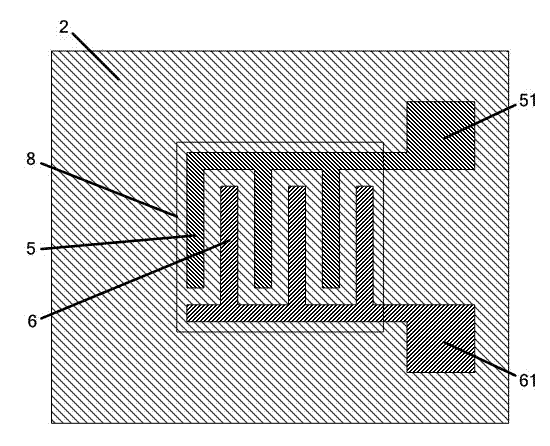

[0016] The invention is a capacitive relative humidity sensor based on graphene oxide, which is composed of a substrate, an oxide layer, a heating strip, an insulating layer, a capacitor electrode, a passivation layer, and a humidity sensitive medium. The oxide layer is arranged on the substrate and heated The strip is arranged on the oxide layer, the capacitor electrode is arranged above the heating strip, an insulating layer is arranged between the capacitor electrode and the heating strip, the capacitor electrode is drawn out from the electrode lead, the heating strip is drawn out from the heating strip lead, the capacitor electrode is a comb-shaped electrode and Arranged in a staggered manner, the heating strips are in a comb-like parallel structure. A passivation layer is provided on the capacitor electrodes. The humidity sensitive medium is arranged between and ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com