Backlight module

A backlight module and light source assembly technology, which is applied in electric light sources, lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as poor heat conduction, and achieve the effect of simplifying the structure and facilitating thin design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

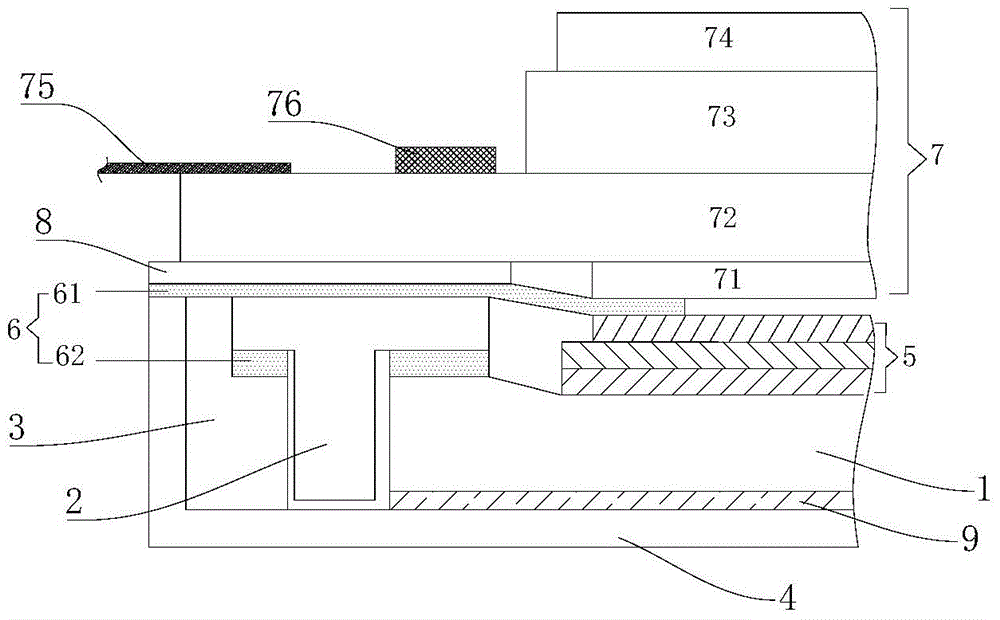

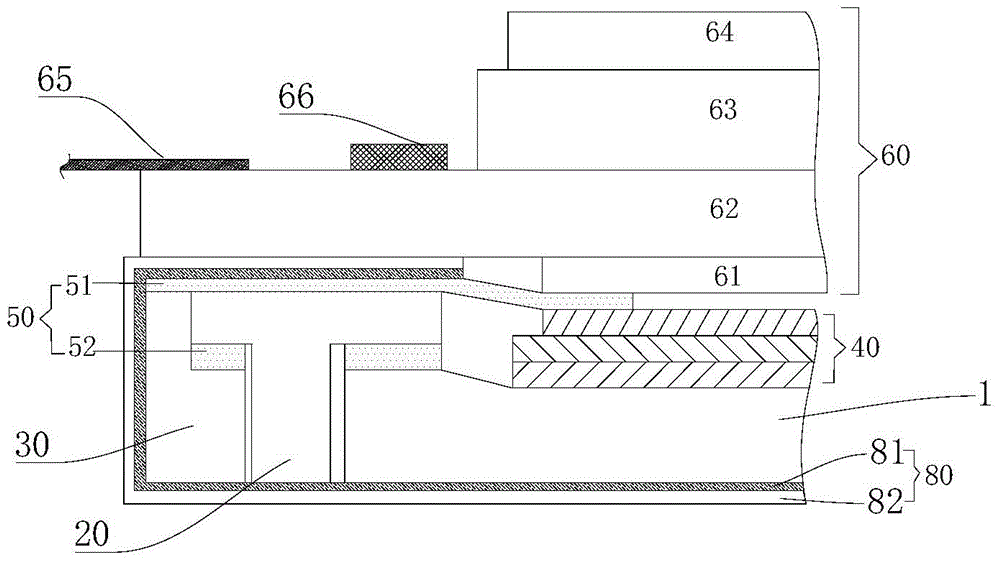

[0023] Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

[0024] The backlight module provided in this example, such as figure 2 As shown, it includes: a light guide plate 10 , a light source assembly 20 , and a plastic frame 30 installed from inside to outside;

[0025] Specifically, the optical film 40 is disposed on the upper surface of the light guide plate 10 , and is sequentially connected to the light source assembly 20 and the plastic frame 30 through the adhesive layer 51 . Wherein, the light source assembly 20 is fixed between the plastic frame 30 and the light guide plate 10 through the adhesive layer 52 . Those skilled in the art are well aware that the adhesive layer 50 used to fix the light source assembly 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com