Touch control panel structure and manufacture method thereof

A technology for a touch panel and a manufacturing method, which are applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of consuming a lot of production materials, increasing the thickness of steps, and defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

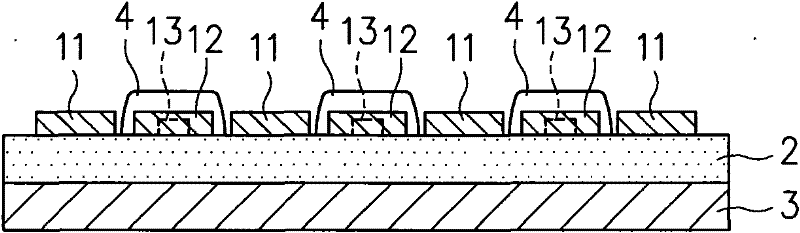

[0044] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only auxiliary explanations to facilitate the understanding of the review committee, but the technical means of this case are not Not limited to the figures listed.

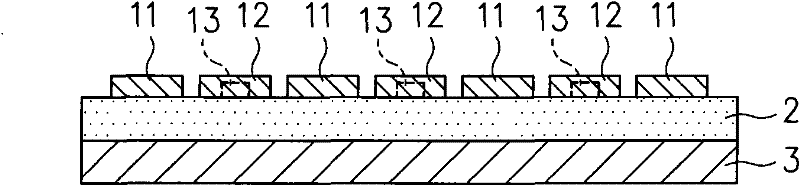

[0045] see Figure 1 to Figure 7 A schematic flow chart showing the forming process of the first embodiment of the touch panel structure of the present invention is shown.

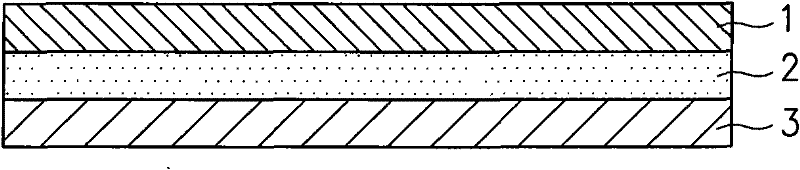

[0046] First, if figure 1 As shown, a transparent conductive film 1 is prepared. One side of the transparent conductive film 1 is provided with an adhesive layer 2. The adhesive layer 2 is a transparent photosensitive adhesive. The transparent conductive film 1 is not provided on the adhesive layer 2. A release film 3 is provided on one side of the transparent conductive film 1, and then patterning processes such as wet etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com