A method and device for rapid calibration and focus positioning of the focus plane of a microscopic imaging system

A technology of microscopic imaging and calibration methods, applied in microscopes, instruments, optics, etc., can solve the problems of low precision and large error of focusing algorithm, and achieve the effect of reducing cumulative errors, reducing errors, and simplifying the fitting of surface equations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

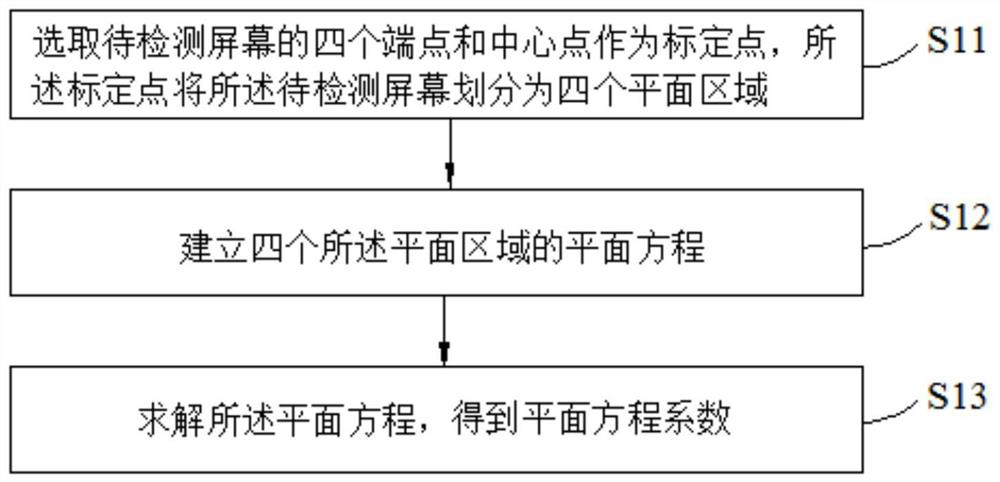

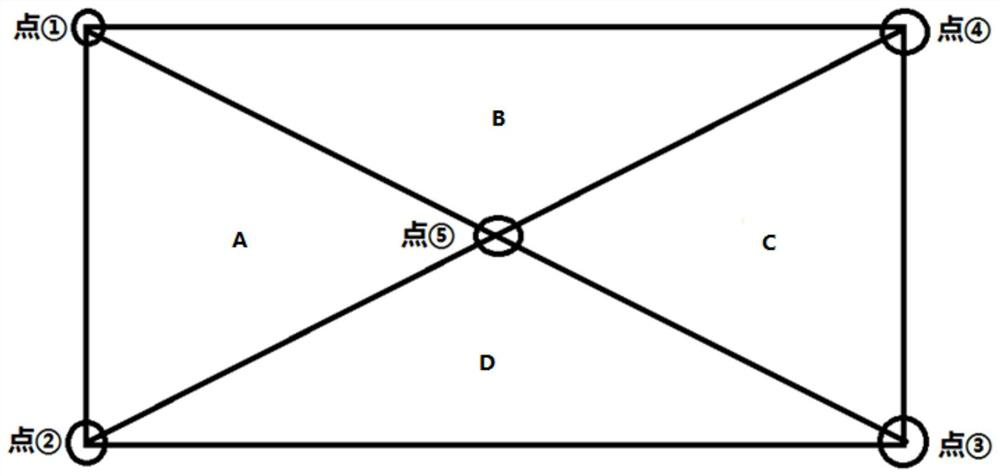

[0088] For the first step, see figure 2 , move the microscopic imaging system so that the center of the field of view of the microscopic imaging system is aligned with the position of the end point ① of the screen to be tested for image acquisition, and a series of image acquisitions are performed according to a fixed pulse interval, and the definition of each image is calculated to make the image clear The position with the highest resolution is used as the focusing surface. If the highest resolution image is in the first or last image, then enlarge the pulse jump range and re-acquire and calculate until convergence (the highest resolution image is not in the first or last image) Zhang), and record the converged coordinates (x_①, y_①, z_①) as the first point of calibration.

[0089] The second step is to move the microscopic imaging system so that the center of the field of view of the microscopic imaging system is aligned with the end point ② of the screen to be tested for ...

Embodiment 2

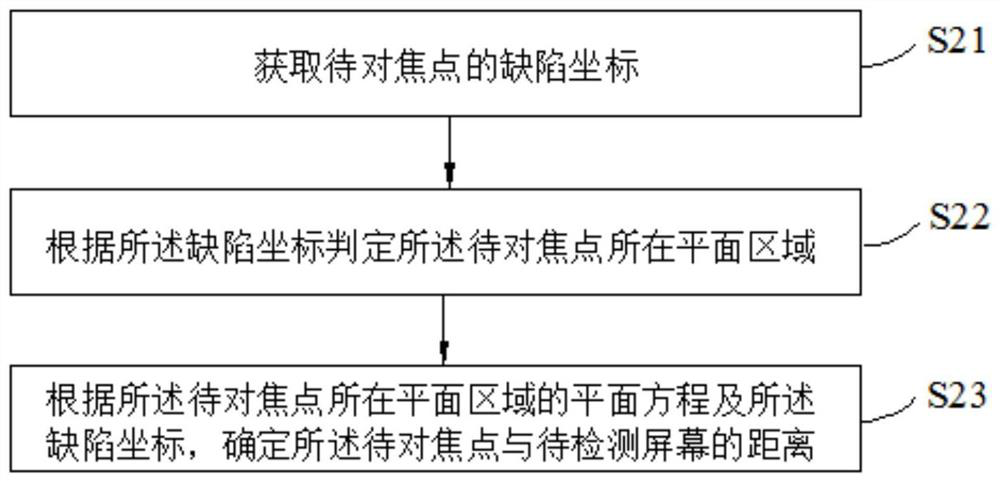

[0107] The first step is to obtain the defect coordinates (x, y) of the point to be focused;

[0108] The second step is to determine which plane area (x, y) the focus point (the point mapped by the center of the field of view of the microscopic imaging system at the imaging position of the mobile phone screen) (x, y) belongs to, for example, it belongs to the A plane area;

[0109] In the third step, according to the plane equation of the plane where the focus point is located and the defect coordinates, that is, the defect coordinates (x, y) are substituted into the plane equation of the A plane area, and the z value is calculated, that is, the distance between the focus point and the defect coordinate is determined. The distance of the screen to be detected.

[0110] It can be seen from the above technical solutions that the embodiment of the present application provides a focus positioning method for a microscopic imaging system, which includes obtaining the defect coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com