Backlight module and liquid crystal displayer

A backlight module, one-sided technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of unsatisfactory local light control effect, affecting the quality of display products, uneven light and shade of diffuser plate, etc., to improve display quality, Realize the effect of thin design and improved brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described in detail below in conjunction with the accompanying drawings. The words "up", "down", "left" and "right" are all relative to the directions shown in the drawings and should not be construed as limiting the present invention.

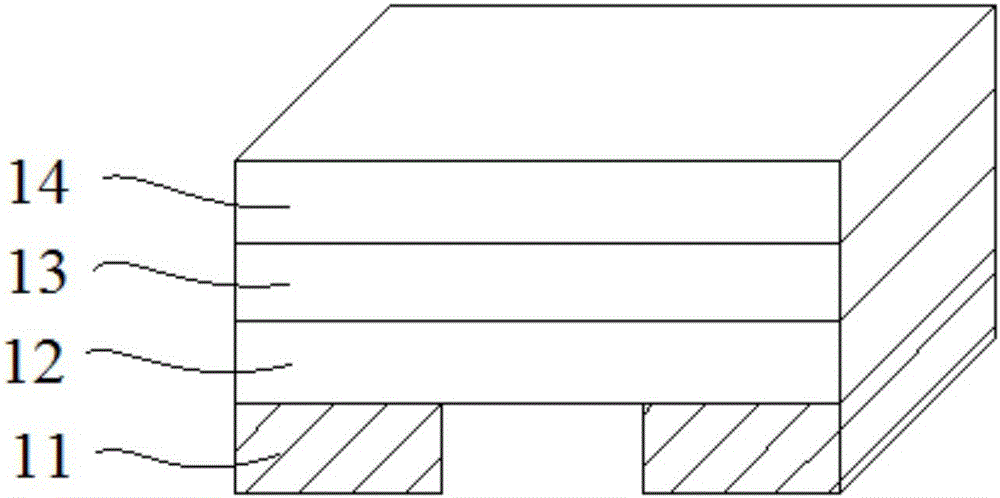

[0027] figure 1 It is a structural schematic diagram of a four-sided light-emitting LED in the prior art. Usually, a four-sided light-emitting LED is connected to a printed circuit board through a metal electrode 11, and the working mode of the four-sided light-emitting LED is controlled through the printed circuit board.

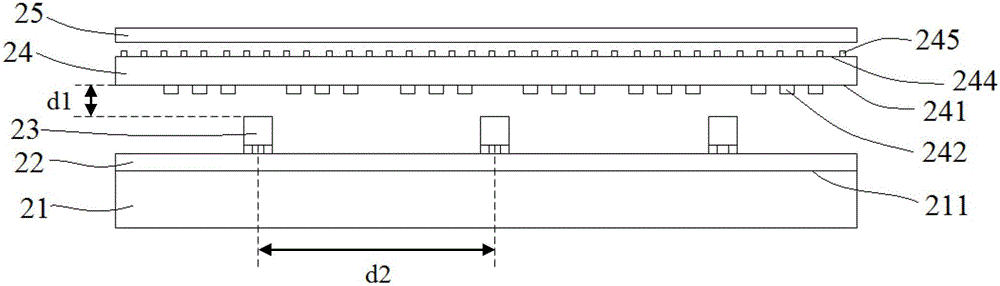

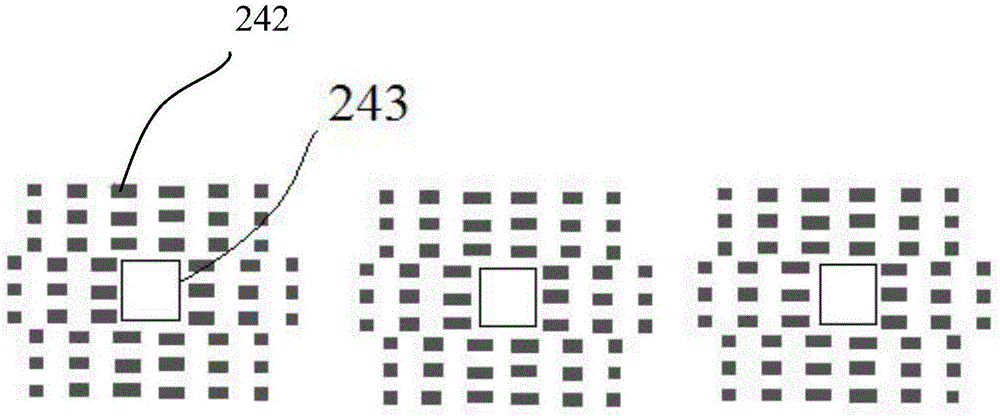

[0028] figure 2 It is a schematic structural diagram of the backlight module 20 proposed by the present invention, from figure 2It can be seen from the figure that the backlight module includes a printed circuit board 21, a reflective sheet 22, an LED light source 23, and a diffuser plate 24 from bottom to top, wherein the reflective sheet 22 is arranged on the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com