Patents

Literature

555results about How to "Facilitate thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

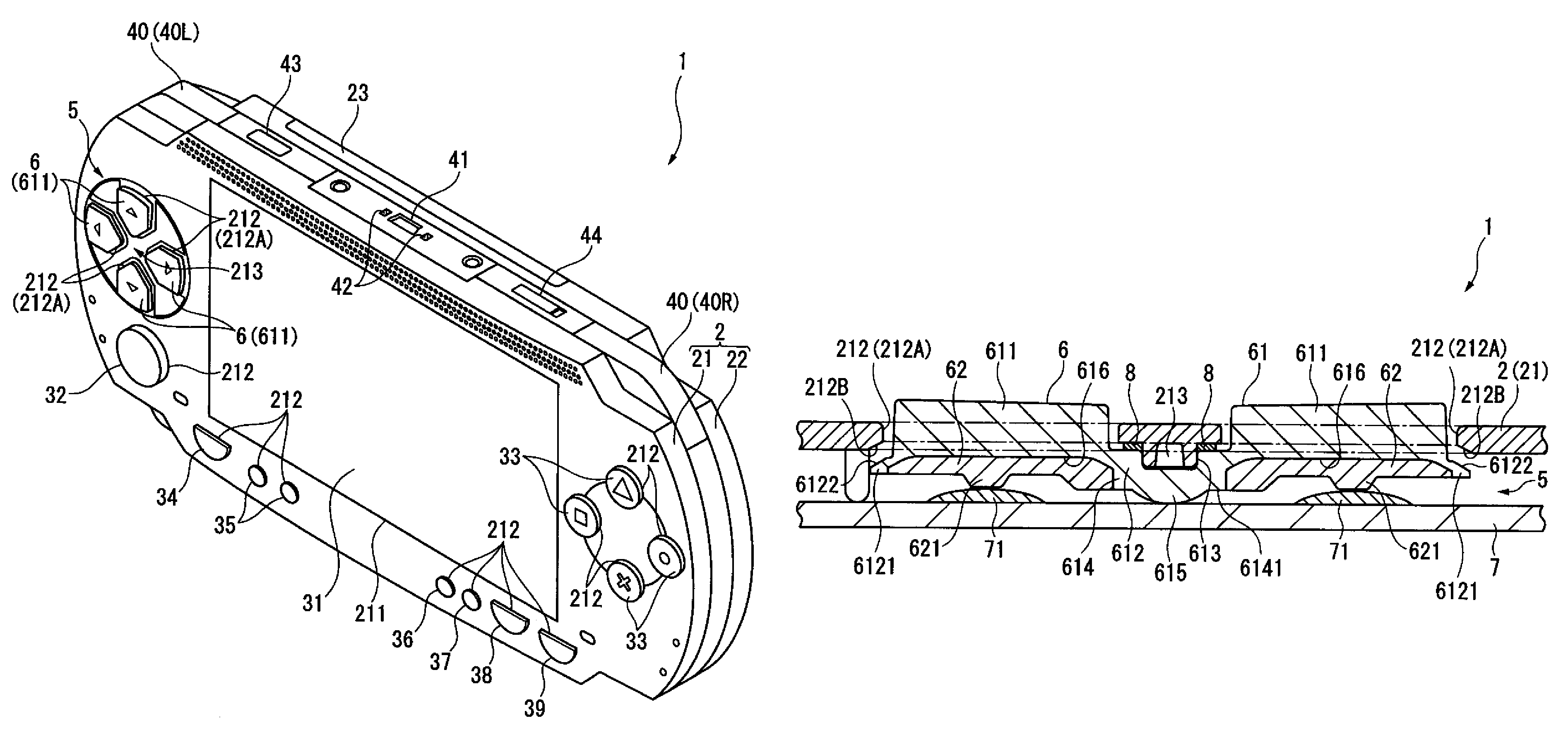

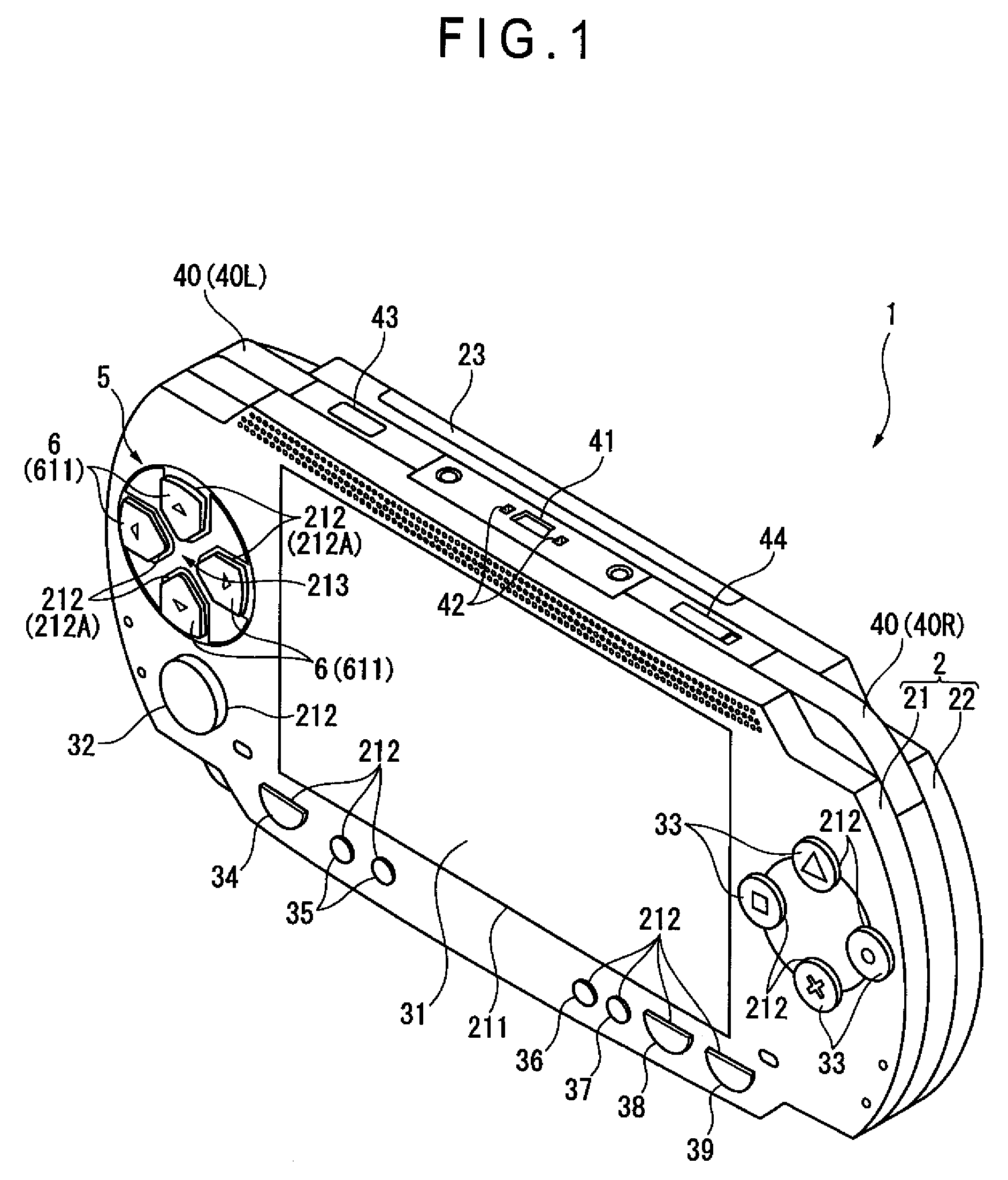

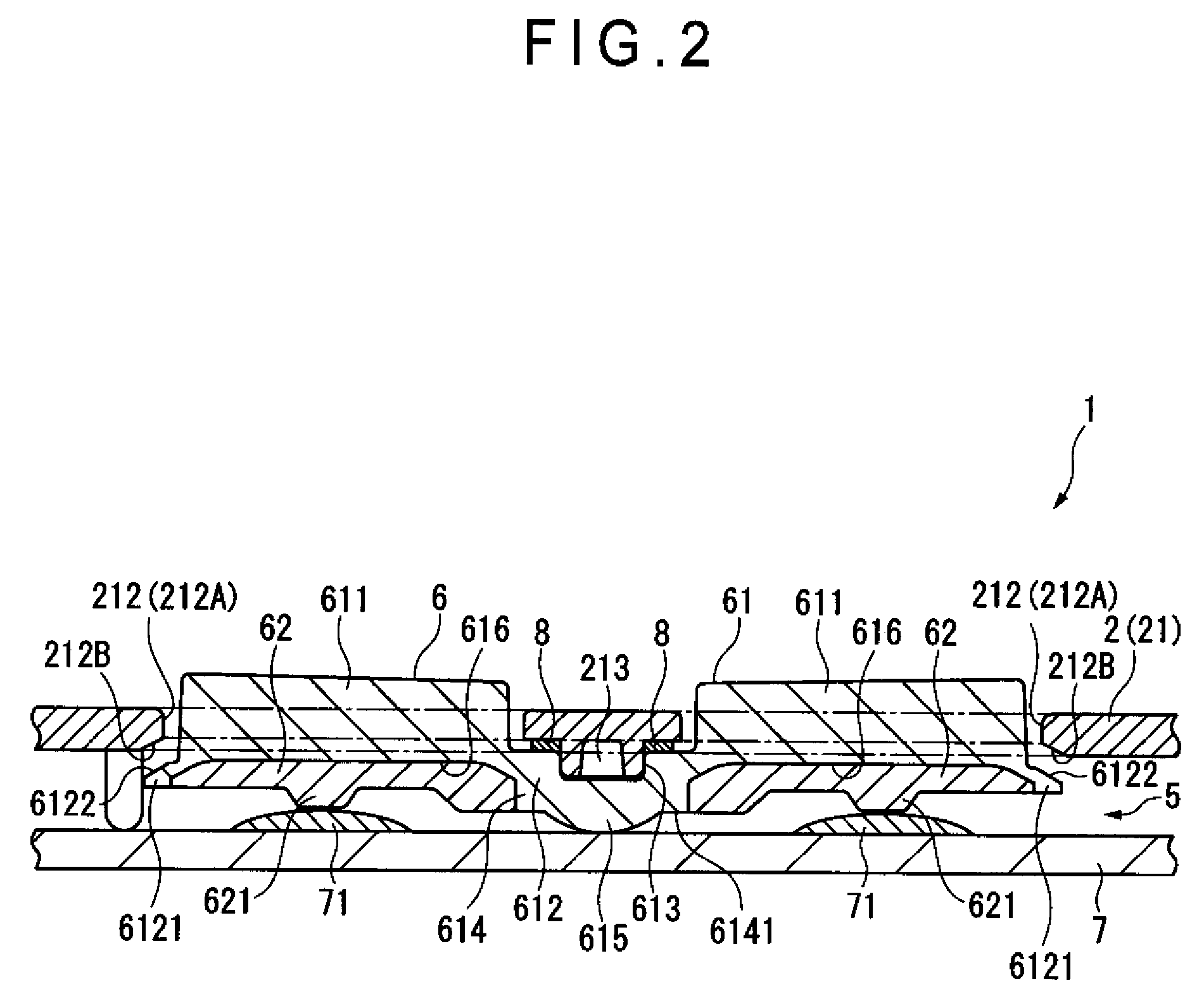

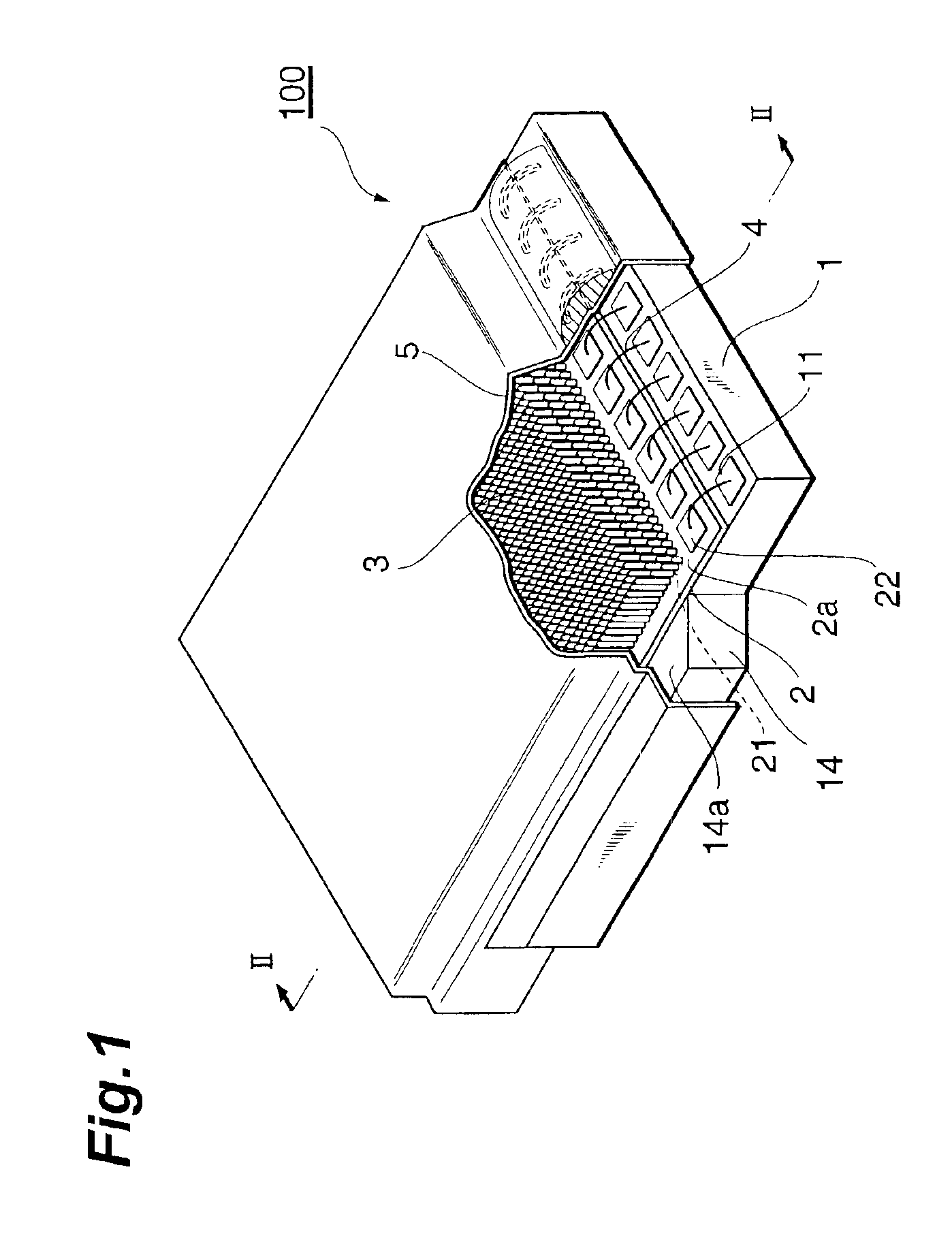

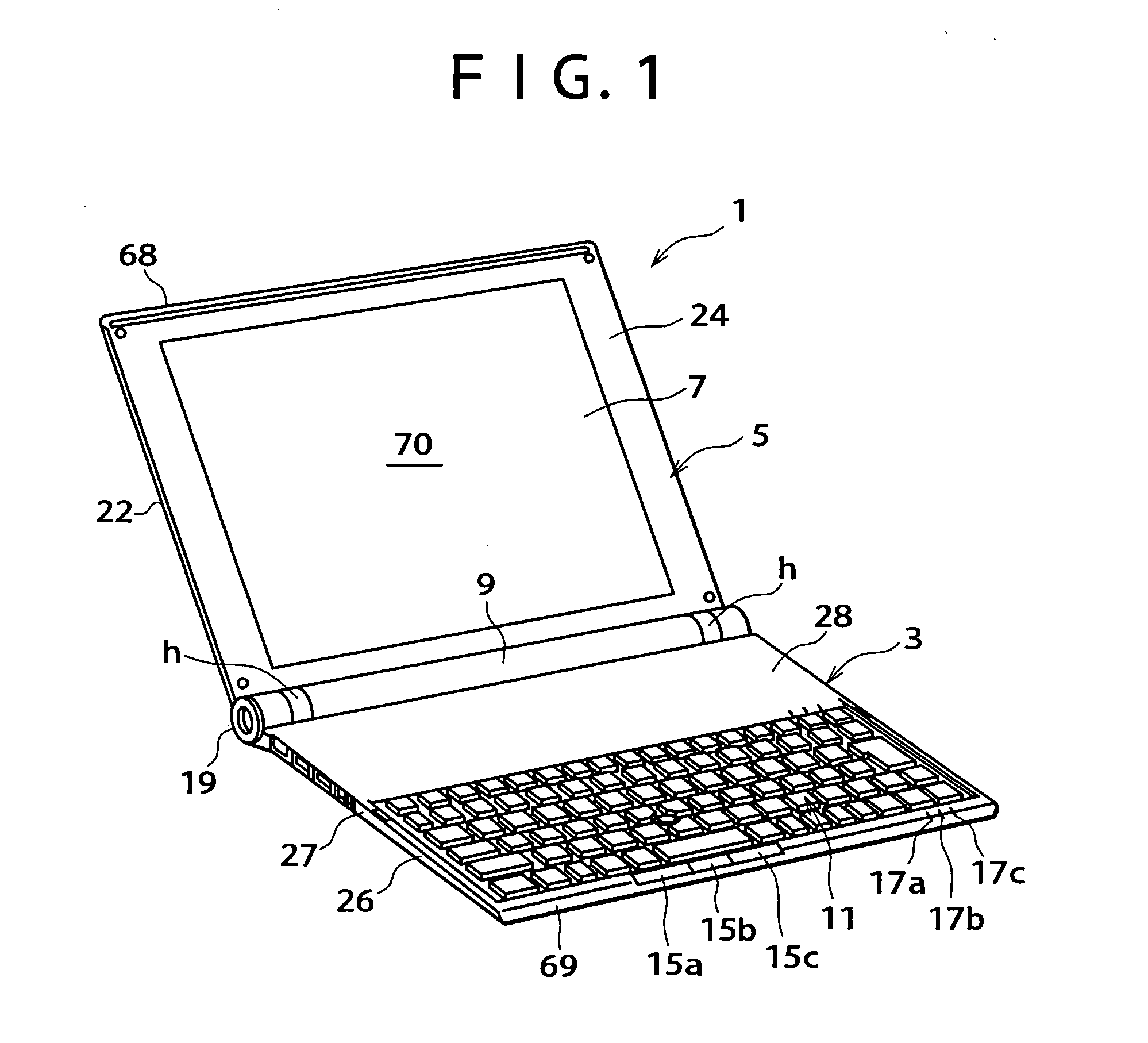

Manipulating apparatus and mobile terminal including the same

ActiveUS8263889B2Reduce exerciseFacilitate thinningEmergency actuatorsContact surface shape/structureElastomerEngineering

Disclosed herein is a manipulating apparatus (mobile terminal) including a chassis provided with a manipulating portion (directional manipulating portion) with which an input manipulation is carried out. The manipulating portion includes: a key top exposed to an outside of the chassis through an opening portion, which the chassis has, and a key main body having a base portion on which the key top is formed within the chassis; a circuit board in which a detecting portion (switches) is disposed in a position corresponding to the key top; and a flat plate-shaped elastic body (elastic body) interposed between the key main body and the detecting portion; in which the elastic body is provided integrally with the base portion. According to the manipulating apparatus, not only the soft click feeling can be obtained from the elastic body, but also the manipulating apparatus can be thinned as compared with the case where the existing elastic body (contact rubber) is adopted by adjusting the thickness size each of the elastic body.

Owner:SONY COMPUTER ENTERTAINMENT INC

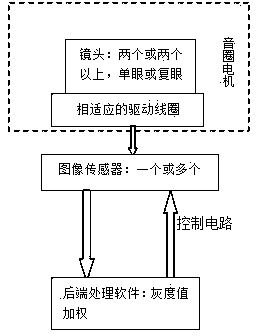

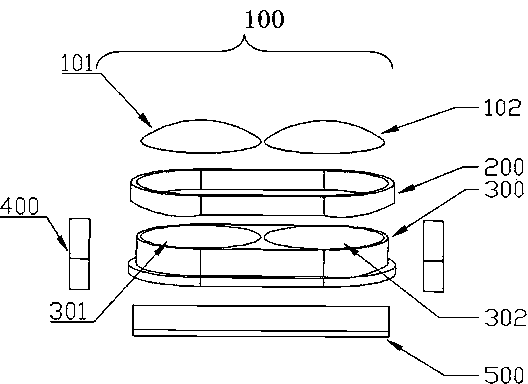

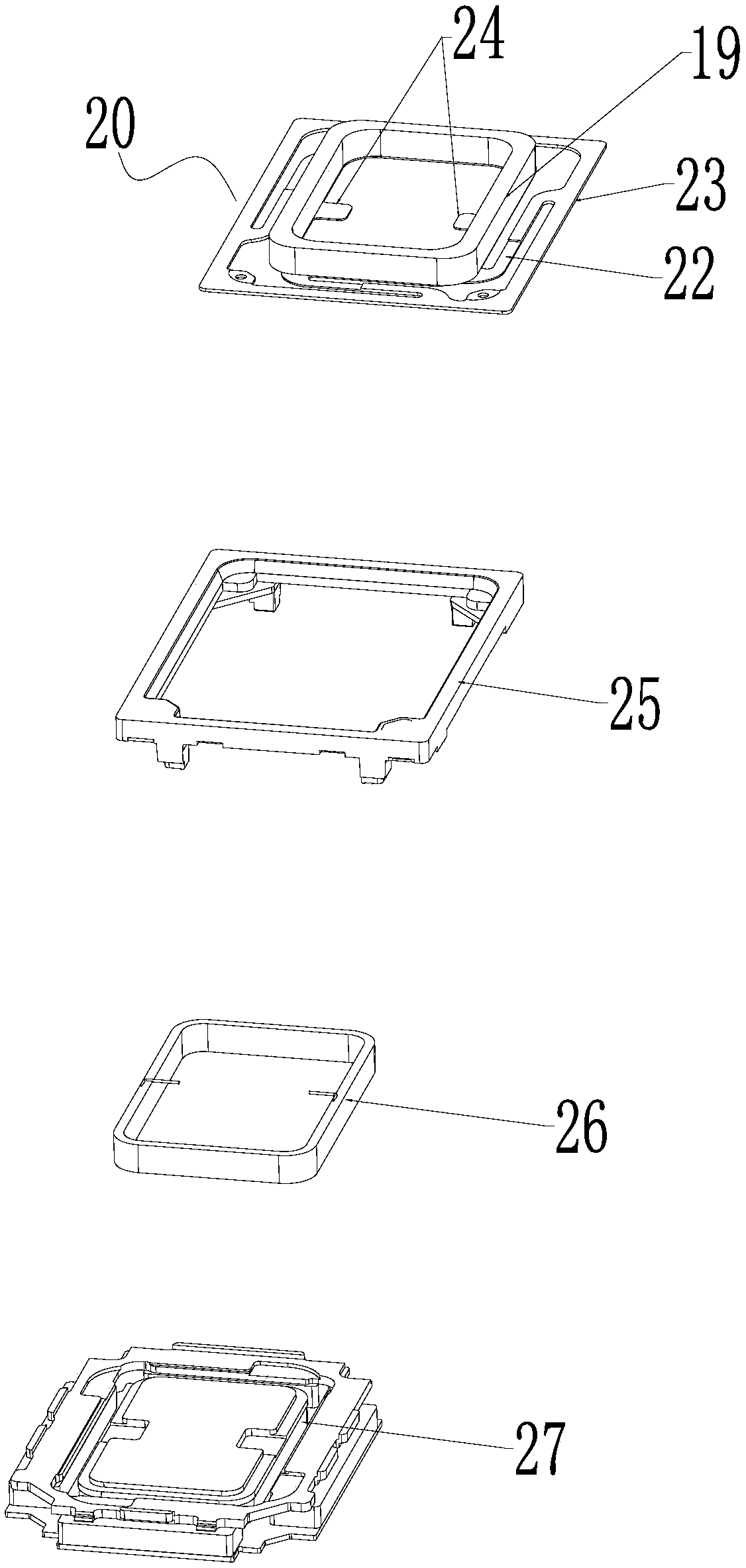

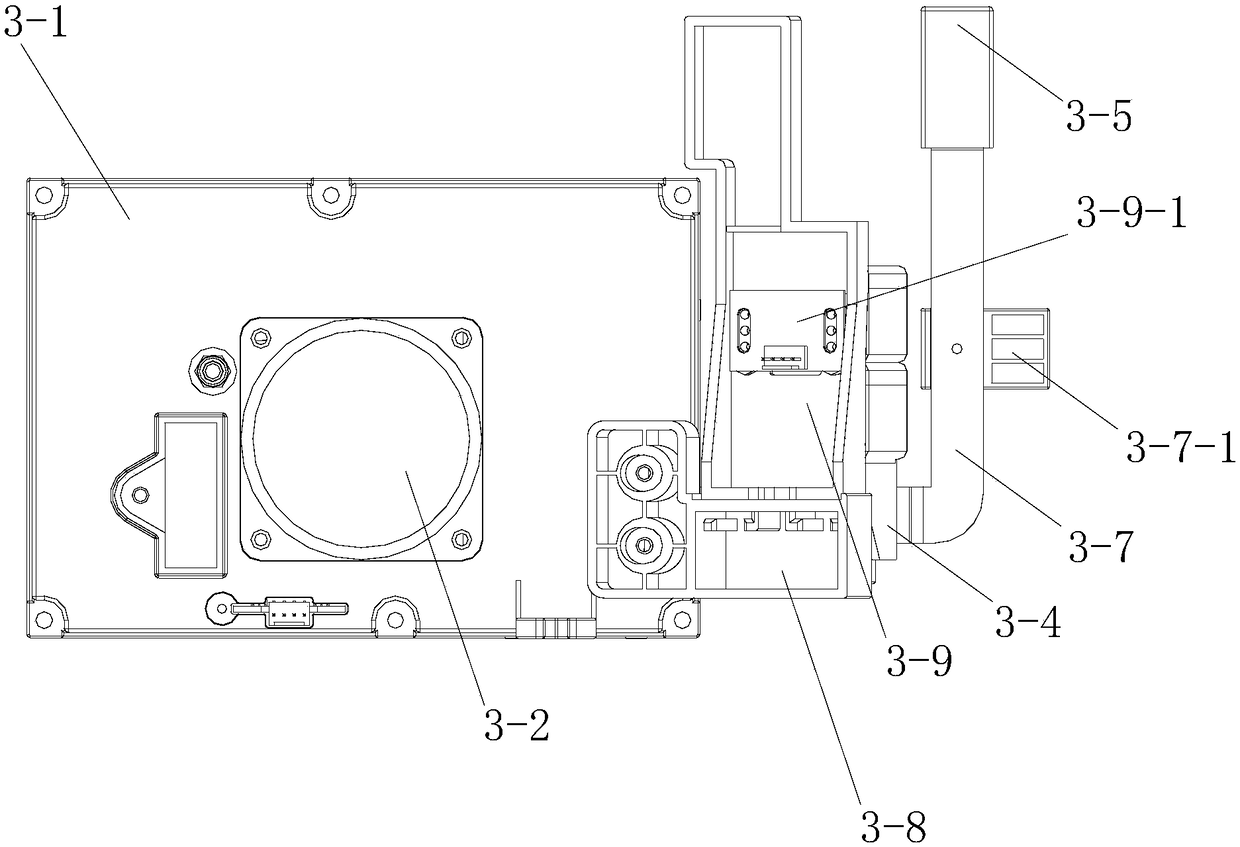

Novel three-dimensional image shooting module

InactiveCN103841404AAchieve shootingMiniaturizationTelevision system detailsColor television detailsCamera lensCamera module

The invention relates to a novel three-dimensional image shooting module which can achieve synchronous focusing control over portable electronic product dual lens or multiple lens and three-dimensional image shooting. The module comprises a plurality of camera modules fixed on a voice coil motor, the voice coil motor which can bear the camera modules at the same time, an image sensor which is used for collecting shot image information, a control circuit and back end processing software which can carry out grey level weighting and three-dimensional image synthesis. The camera modules have the same parameters and are borne on the same voice coil motor, synchronous focusing can be carried out, the number of the image sensor can be one or more, the back end processing software carries out weighting according to a preset factor through the grey levels of two images during a focusing process, and feedback fine focusing is carried out after a comprehensive grey level is obtained. The shooting module can be used on a micromation portable electronic product conveniently for three-dimensional image shooting, and quality and shooting effect can be improved.

Owner:江西省一元数码科技有限公司 +1

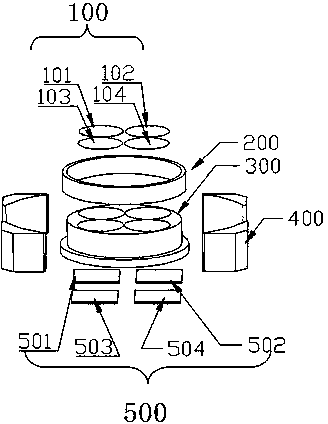

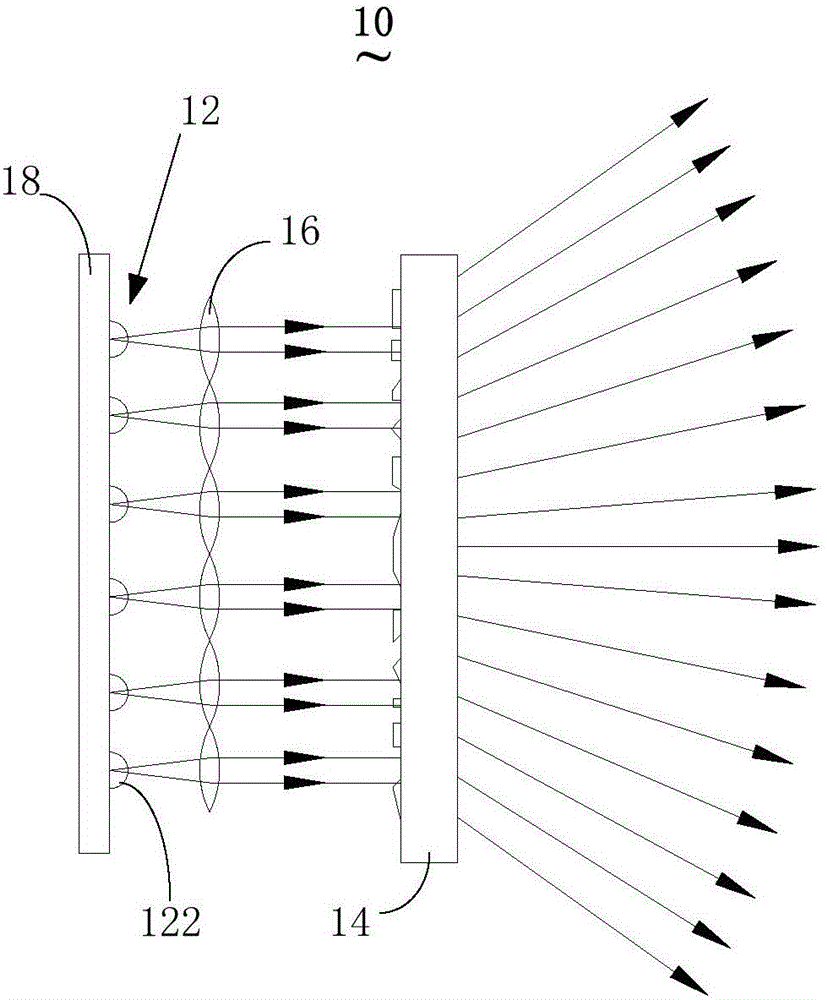

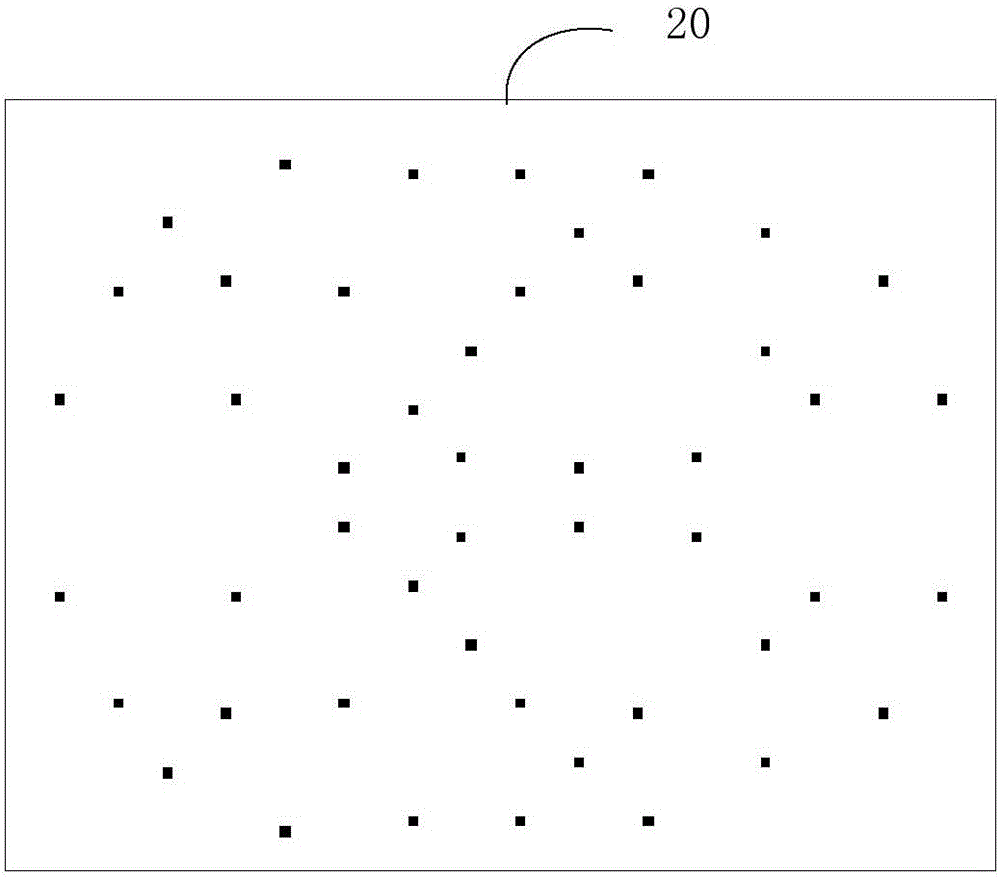

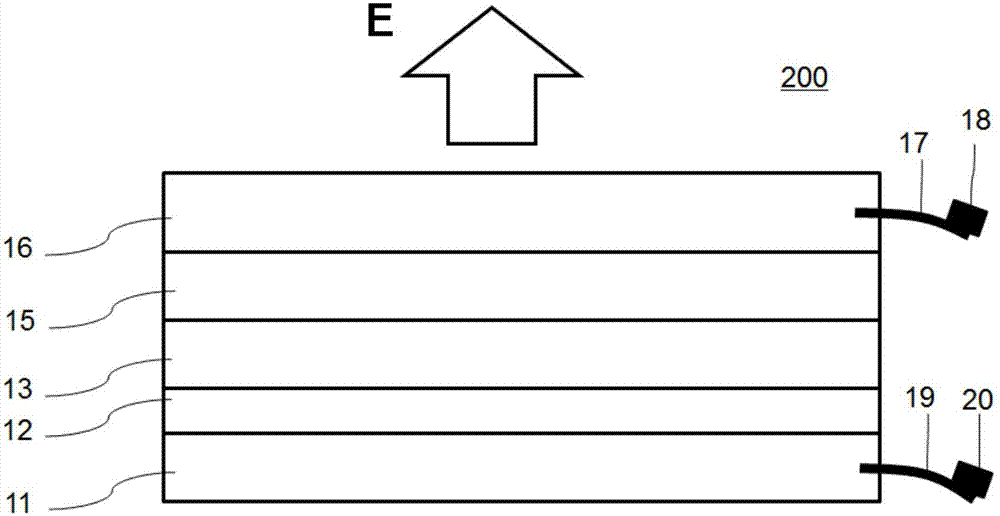

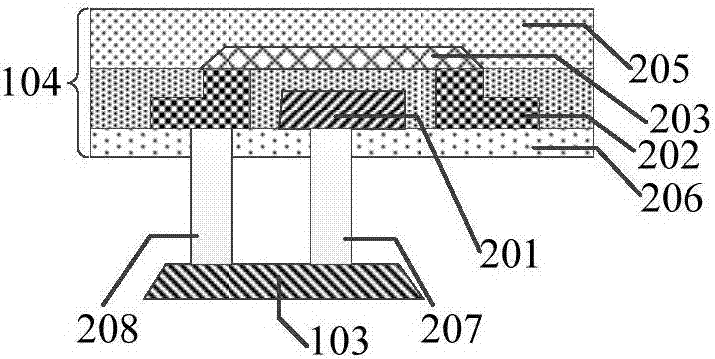

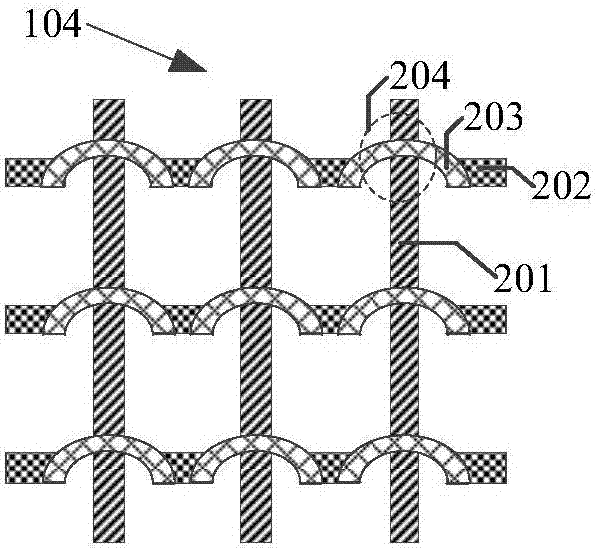

Planar array projection device and depth camera

ActiveCN106406002AGood optical projectionFacilitate thinningProjectorsCamera body detailsLight beamLaser patterning

The invention discloses a planer array projection device and a depth camera. The planer array projection device comprises a planer array light source and a diffractive optical element, wherein the planer array light source comprises multiple light emitting elements for emitting laser; the diffractive optical element is used for carrying out beam expanding on the laser emitted by the planer array light source and converting the laser to patterned laser; the multiple light emitting elements are arranged into a first optical pattern; a pattern formed after a single beam of light is expanded through the diffractive optical element is a second optical pattern; the first optical pattern and the second optical pattern are composite to form a composite optical pattern, and the composite optical pattern is the patterned laser pattern; the first optical pattern, the second optical pattern and the composite optical pattern comprise multiple light beams; and the light beam layout in the composite optical pattern has local irrelevance, and the uniformity index is smaller than a preset threshold. Through the above mode, better optical projection effects can be achieved with a smaller light source, integration in a small device is realized, and the light weight and the thinness of the device are improved.

Owner:SHENZHEN ORBBEC CO LTD

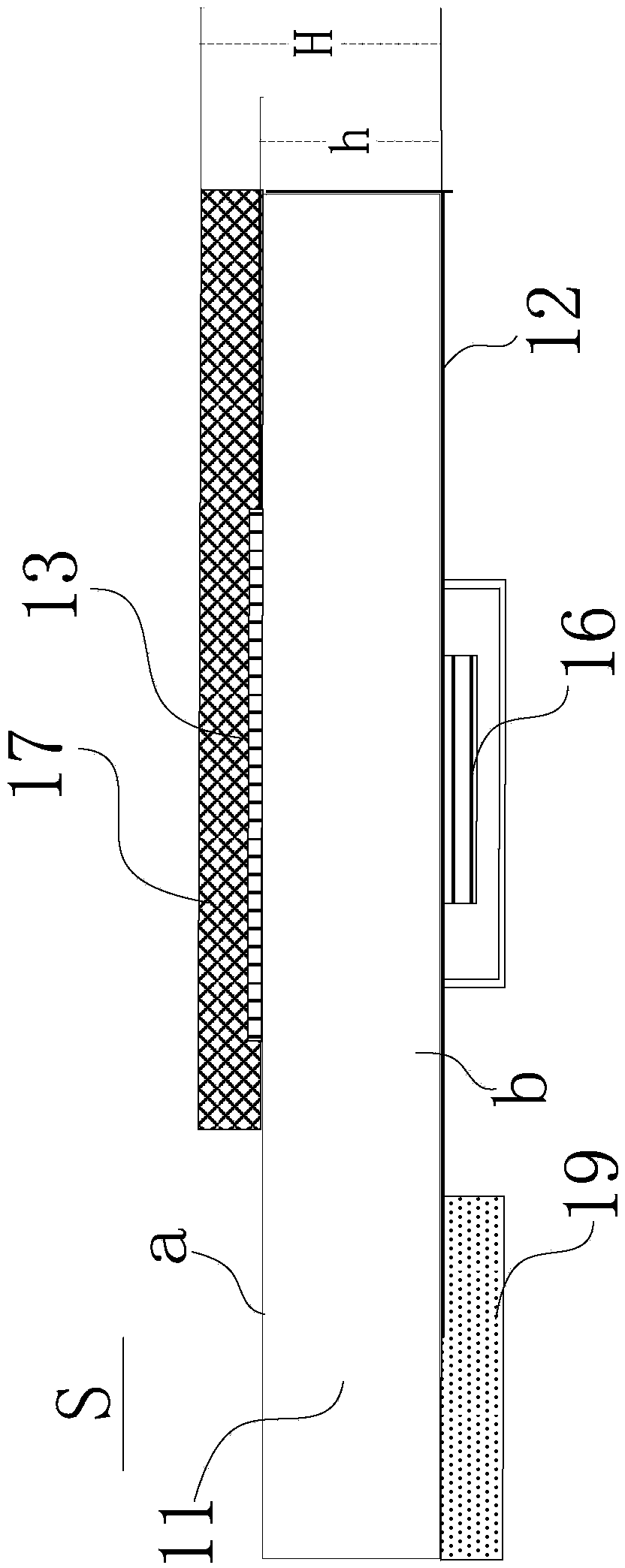

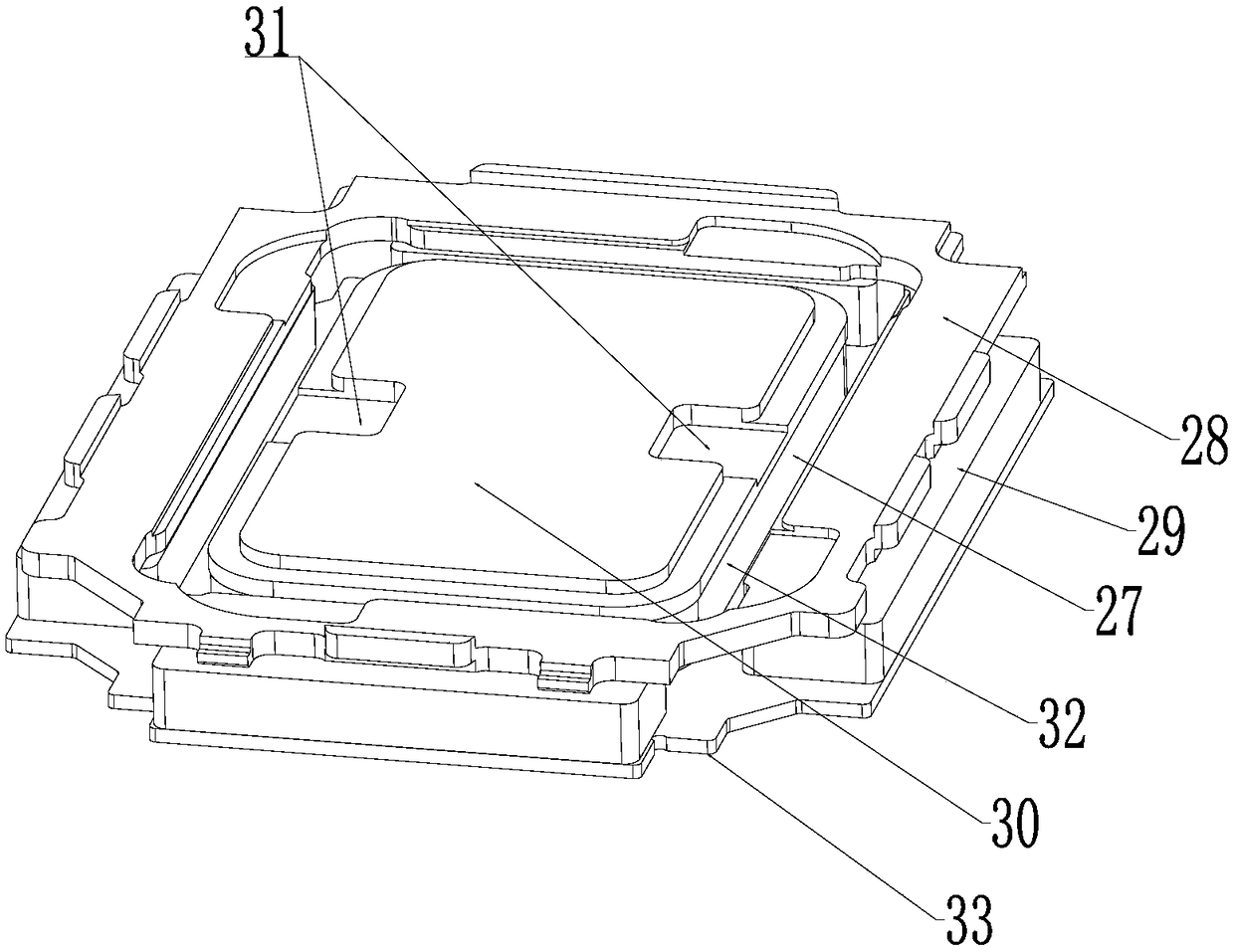

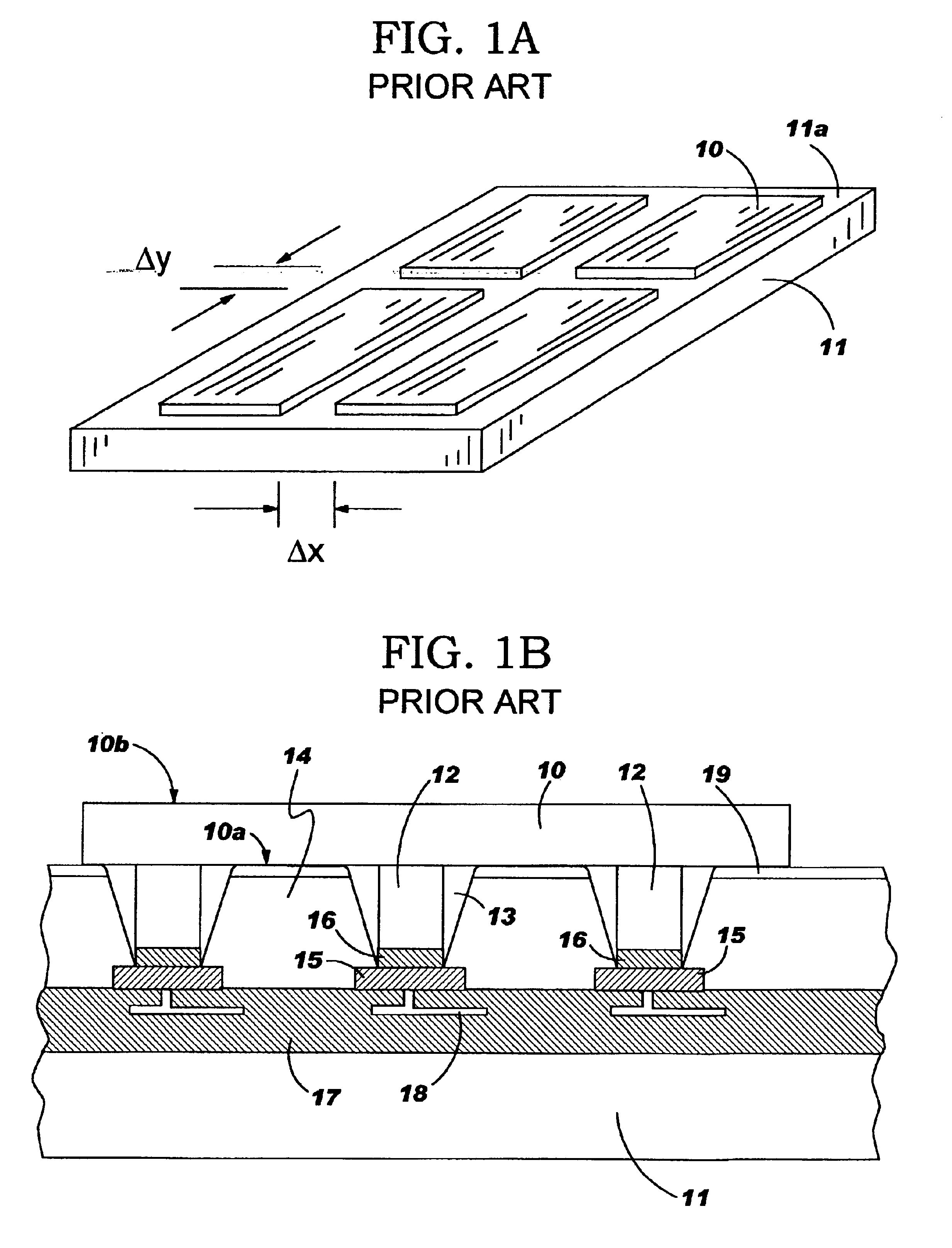

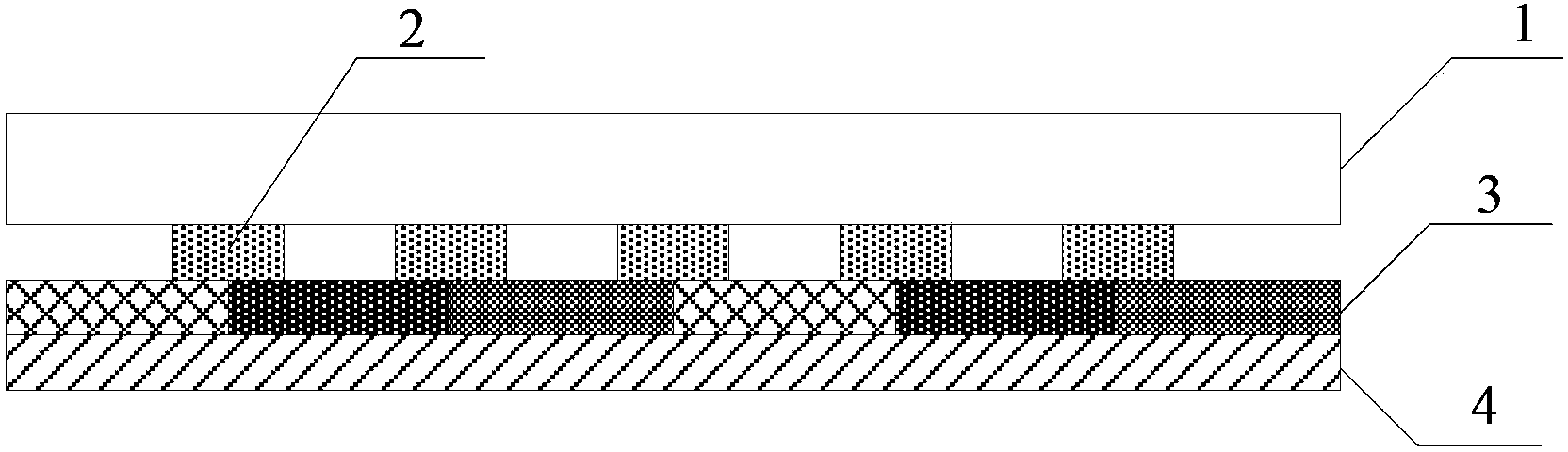

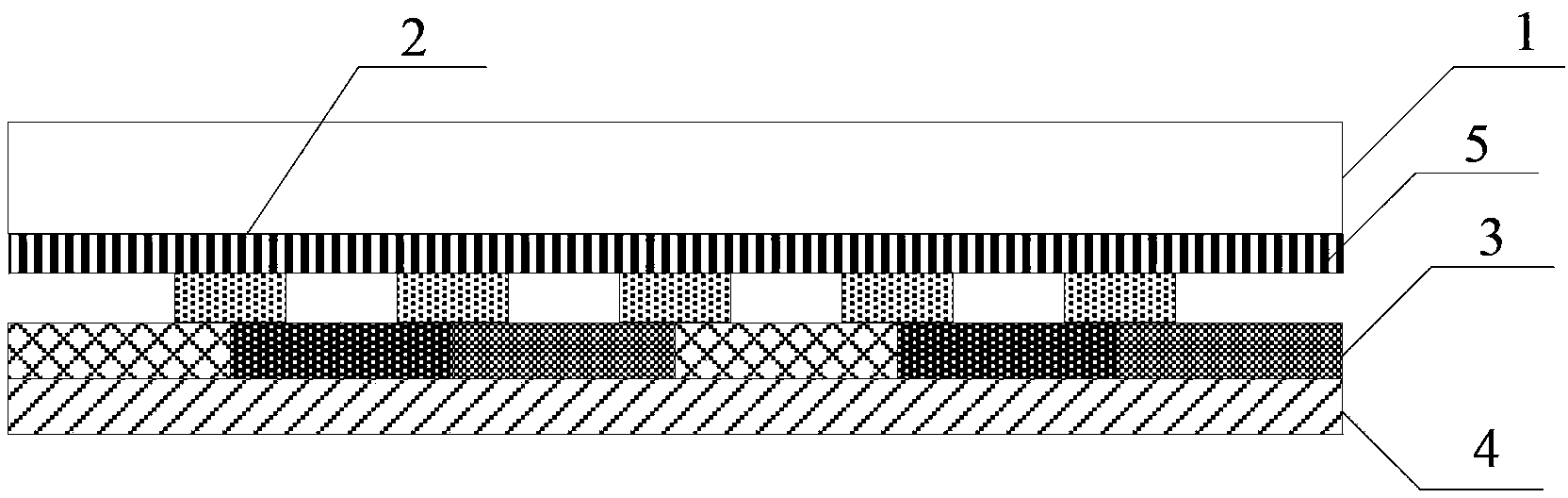

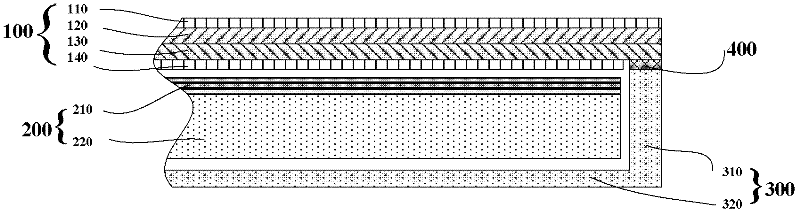

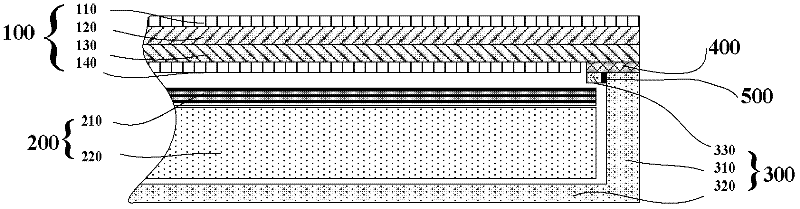

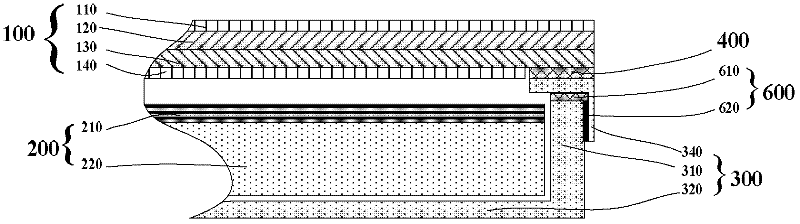

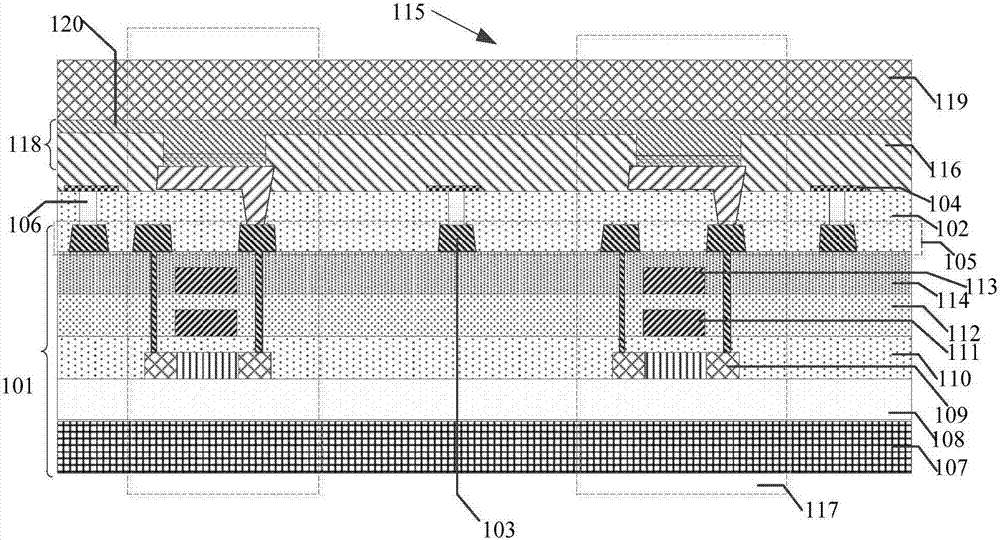

Fingerprint identification and detection assembly and electronic device of fingerprint identification and detection assembly

ActiveCN104134063AImprove the final imaging effectBroaden applicationCharacter and pattern recognitionEngineeringFingerprint detection

The invention discloses a fingerprint identification and detection assembly and an electronic device of the fingerprint identification and detection assembly. The fingerprint identification and detection assembly comprises a cover plate and a fingerprint sensing module, the cover plate is provided with a first face and a second face opposite to the first face, and a groove is formed in the second face of the cover plate; the fingerprint sensing module is located in the groove of the cover plate, and fingerprints which correspond to an induction area of the fingerprint sensing module and are operated on the first face of the cover plate are identified and detected through the fingerprint sensing module. The fingerprint sensing module comprises a fingerprint detection element and a fingerprint identification chip, the fingerprint detection element is located at the bottom of the groove of the cover plate, the fingerprint identification chip is electrically connected with the fingerprint detection element, and the fingerprint detection element is located between the bottom of the groove of the cover plate and the fingerprint identification chip. By means of the fingerprint identification and detection assembly and the electronic device, the groove is formed in the cover plate and used for containing the fingerprint sensing module, the overall thickness of the cover plate and the fingerprint sensing module is reduced, thinning of electronic devices such as portable terminals is facilitated, and the fingerprint identification and detection assembly and the electronic device are particularly suitable for mobile phones without solid HOME keys.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

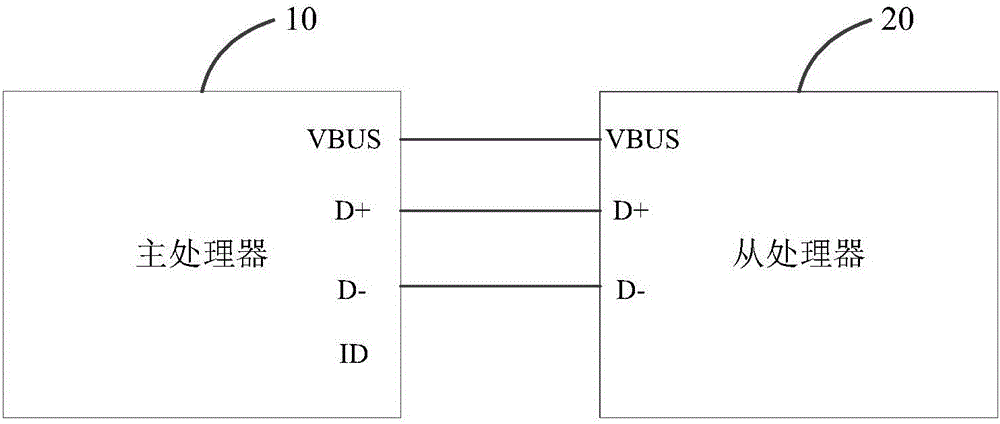

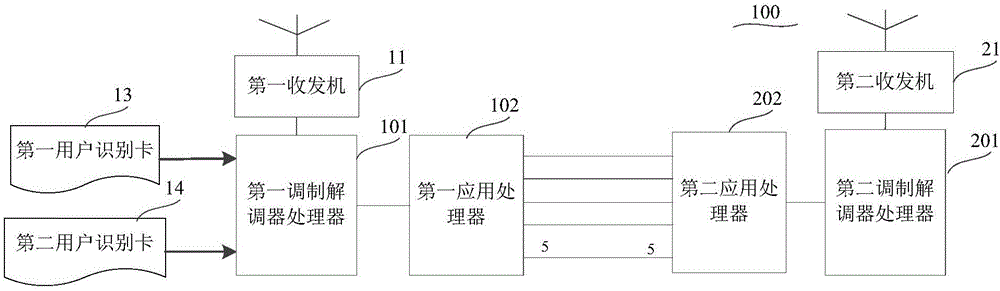

Dormancy awakening method and processor

The invention discloses a dormancy awakening method, a processor and user equipment, and belongs to the technical field of communications. The method suitable for a main processor in the user equipment with dual processor comprises the following steps: when a slave processor in the user equipment is in the dormancy state, detecting whether an awakening event has occurred in the main processor or not, if the awakening event has occurred, sending an awakening signal to the slave processor through a USB data line between the main processor and the slave processor. Through the adoption of the method disclosed by the invention, the USB data line between the main processor and the slave processor is directly used for awakening, the dormancy awakening method and connection between the main processor and the slave processor are simplified, and the method is in favor of the lighting and thinning of a mobile terminal.

Owner:NUBIA TECHNOLOGY CO LTD

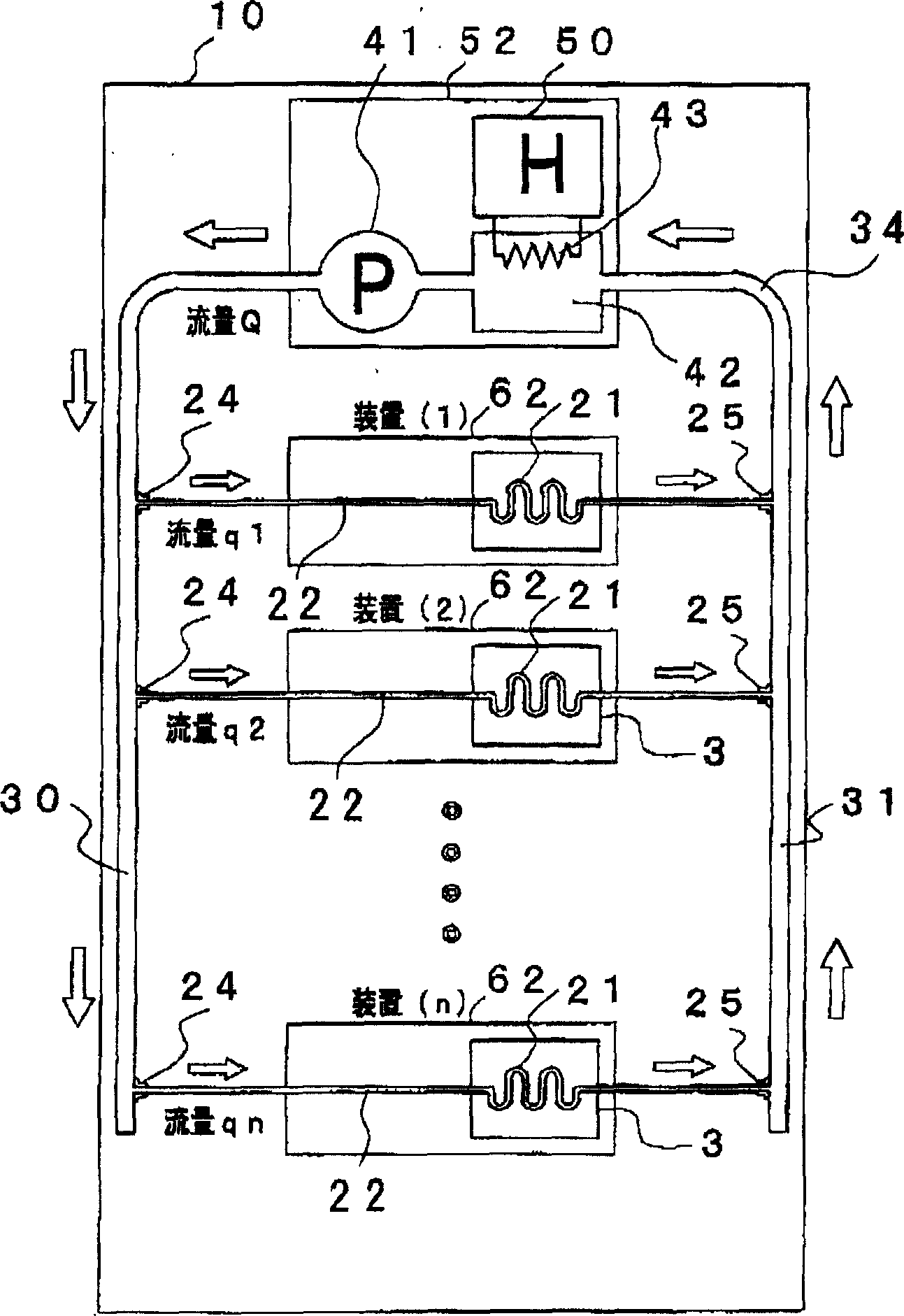

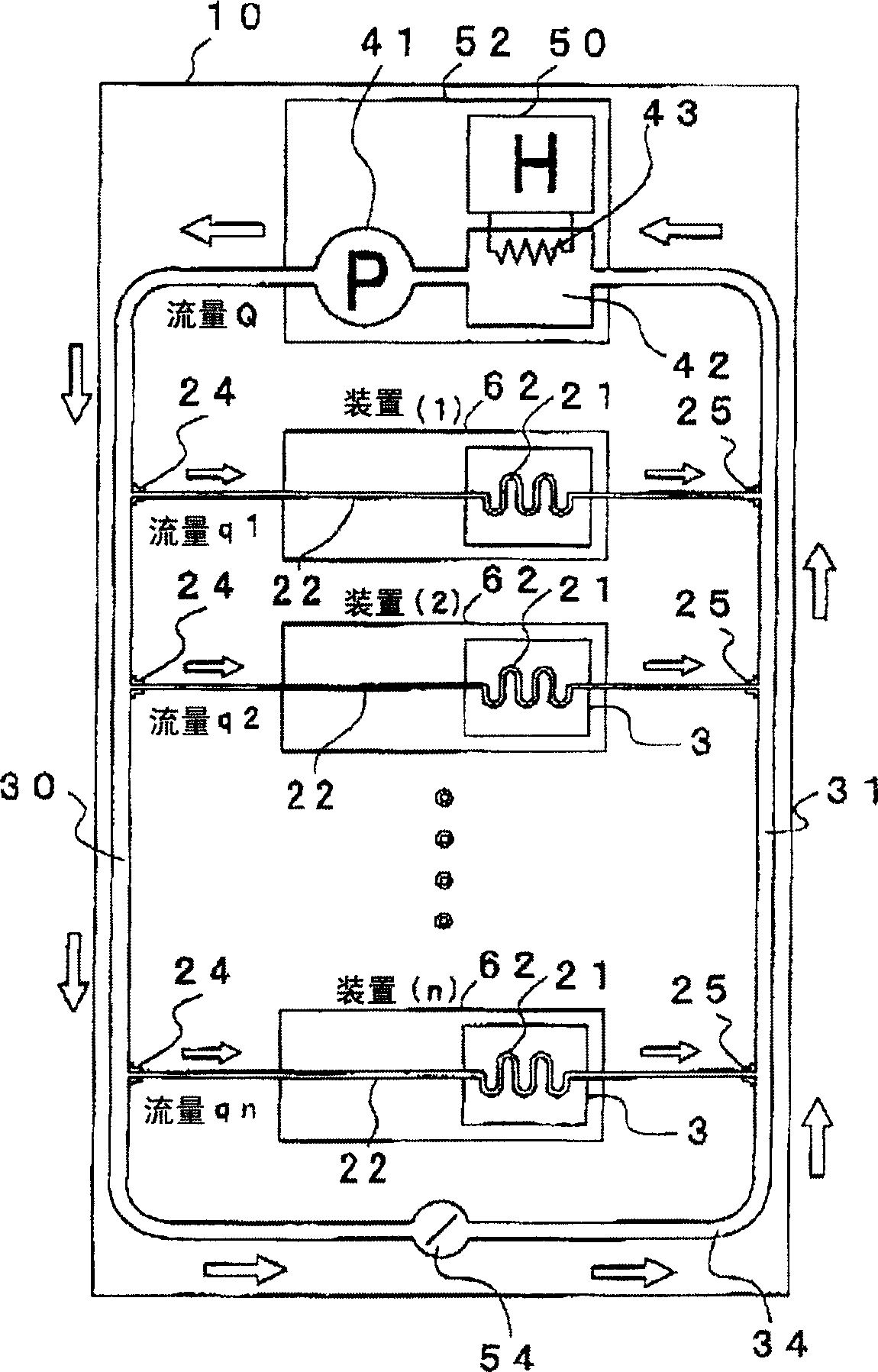

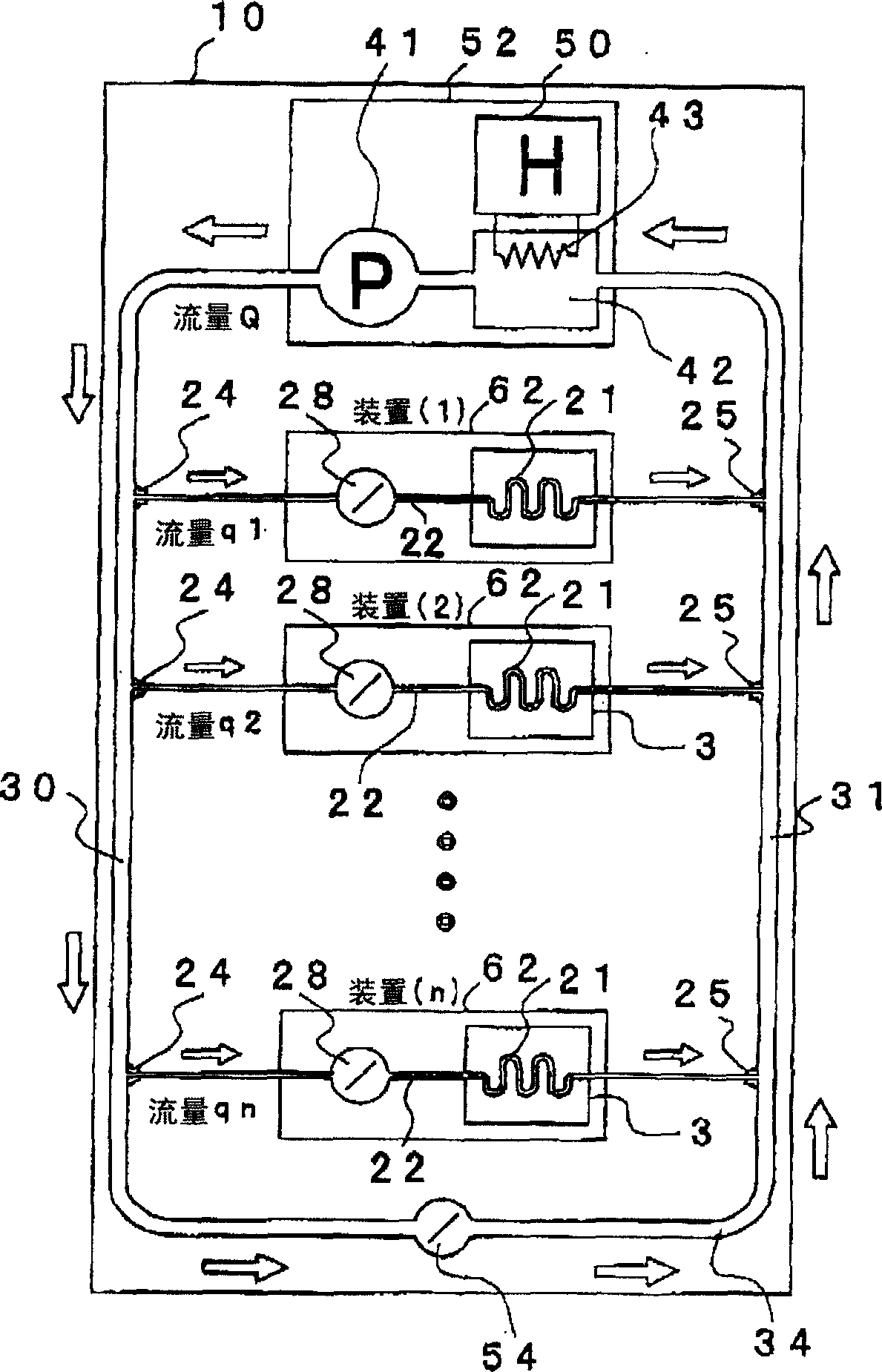

Rack-mount server system, its cooling system, rack cabinet and server assembly

ActiveCN1521591AImprove performanceFacilitate thinningDigital data processing detailsRack/frame constructionNuclear engineeringLiquid cooling system

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as CPU is cooled by a coolant, is composed of: a plurality of server modules with heat-generating components which are cooled by the circulating coolant; a coolant circulation path to which the server modules are connected in parallel and through which the coolant to cool the server modules is circulated; and a cooling unit connected in the middle of the coolant circulation path, the cooling unit circulating the coolant and cooling the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules. In this manner, the cooling enough to ensure the reliability of a plurality of server modules mounted in the rack cabinet can be achieved.

Owner:MAXELL HLDG LTD

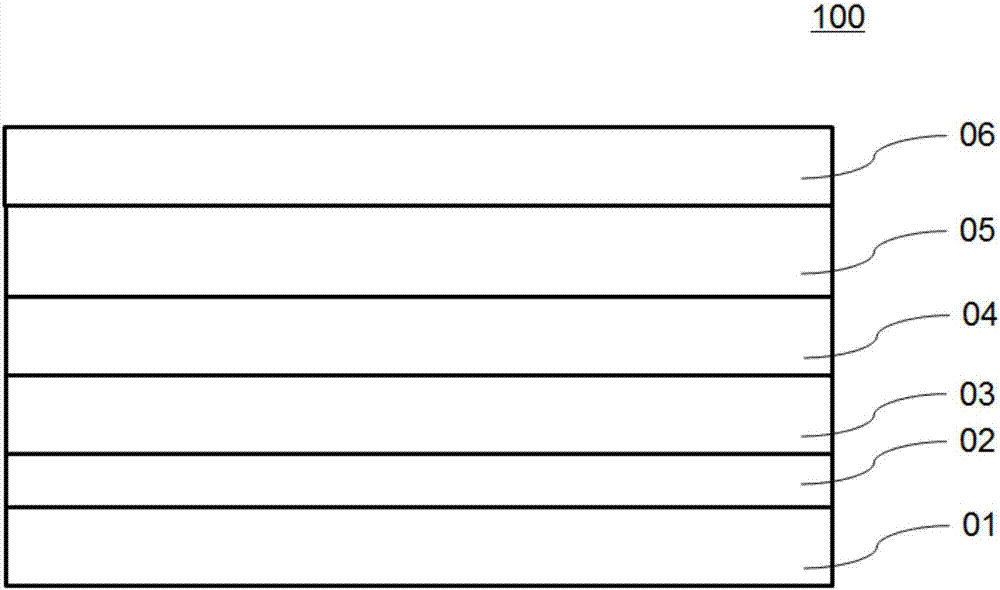

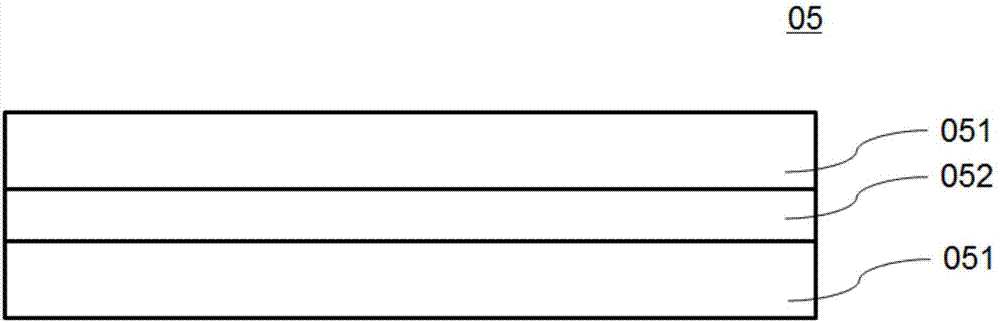

Display panel, display panel manufacturing method and electronic device

ActiveCN106952941AFew layersThin film thicknessFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention provides a display panel, an electronic device comprising the display panel, and a display panel manufacturing method. The display panel comprises: an array substrate, which includes a substrate and a driving unit arranged on the substrate; a light emitting function layer, which is arranged at one side, away from the substrate, of the driving unit and is electrically connected with the driving unit; a packaging film, which is arranged at one side, away from the array substrate, of the light emitting function layer; and a polarizing function layer, which is arranged at a light outgoing side of the display panel and contains a coated polarizing layer. The flexible display panel has much fewer layers and comprises the layers that are thinner, so the flexible display panel becomes thin conveniently and is greatly improved in bending performance. Moreover, display light leakage is avoided when the display panel is bent flexibly. In addition, the manufacturing process of the display panel is easy, the production cost is low, the production efficiency is high, and large-scale industrialized applications can be facilitated.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Direct drive type exciter and screen sounding device

ActiveCN108616797ASimple structureFew partsElectrical transducersLoudspeakersEngineeringSounds device

The invention discloses a direct drive type exciter and a screen sounding device. The exciter comprises a magnetic circuit system and a vibration system. The magnetic circuit system connected with thedevice is used for forming a magnetic gap. The vibration system consists of a coil, an elastic support member and a connecting member; the elastic support member includes an outer connecting portion,an inner connecting portion and an elastic portion arranged between the outer connecting portion and the inner connecting portion; a coil and a connecting element are fixed on the two surface of theinner connecting portion respectively; one end, far away from the inner connecting portion, of the coil is inserted into the magnetic gap; one end, far away from the inner connecting portion, of the connecting element is configured to connect a screen; and the outer connecting portion is fixed at a side magnetic circuit part.

Owner:GOERTEK INC

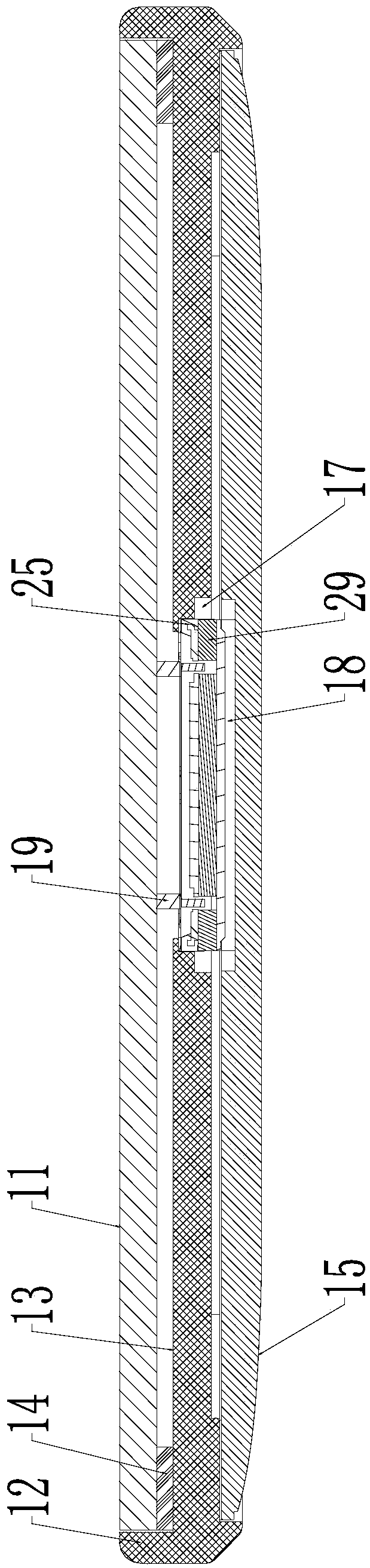

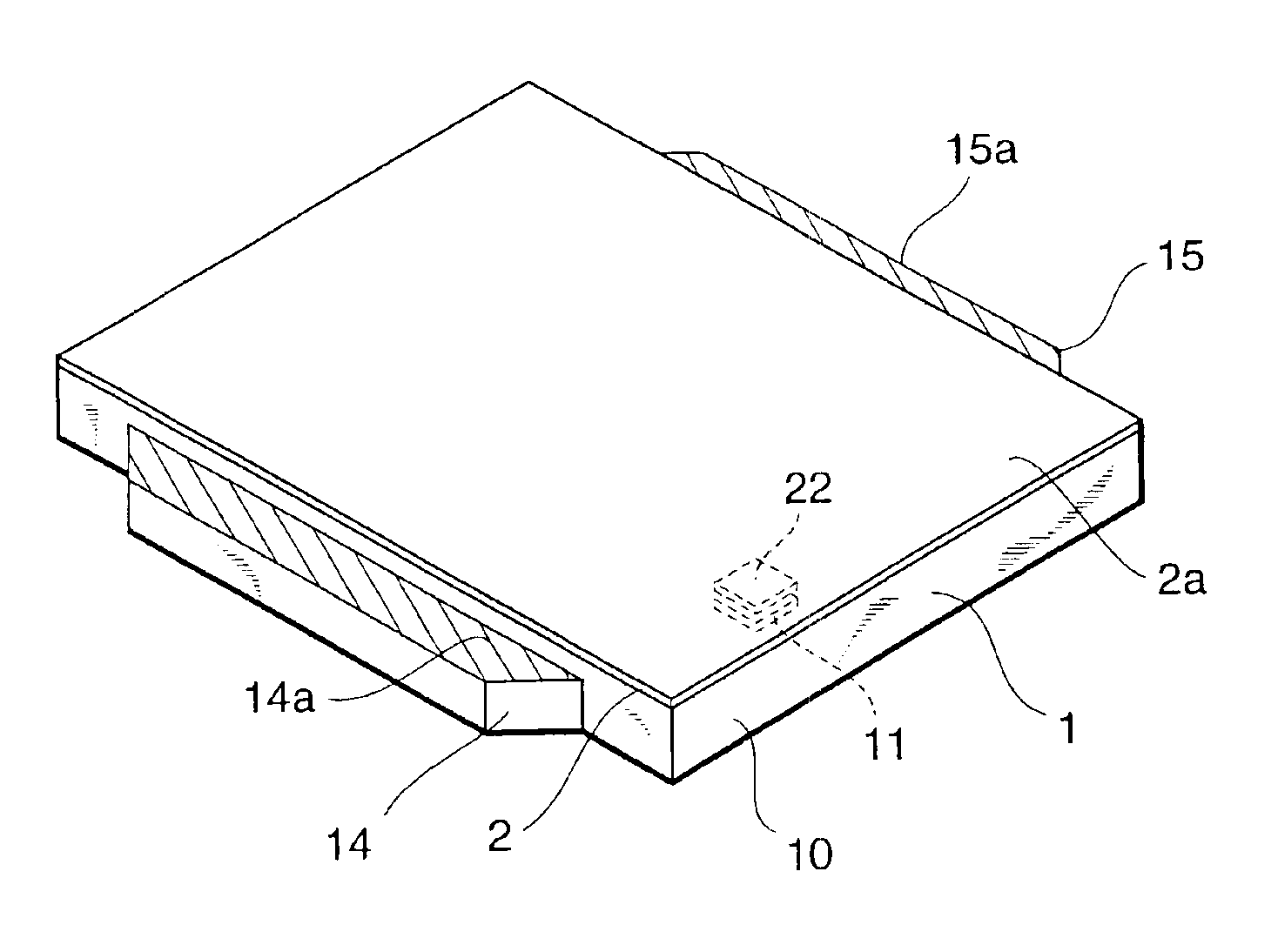

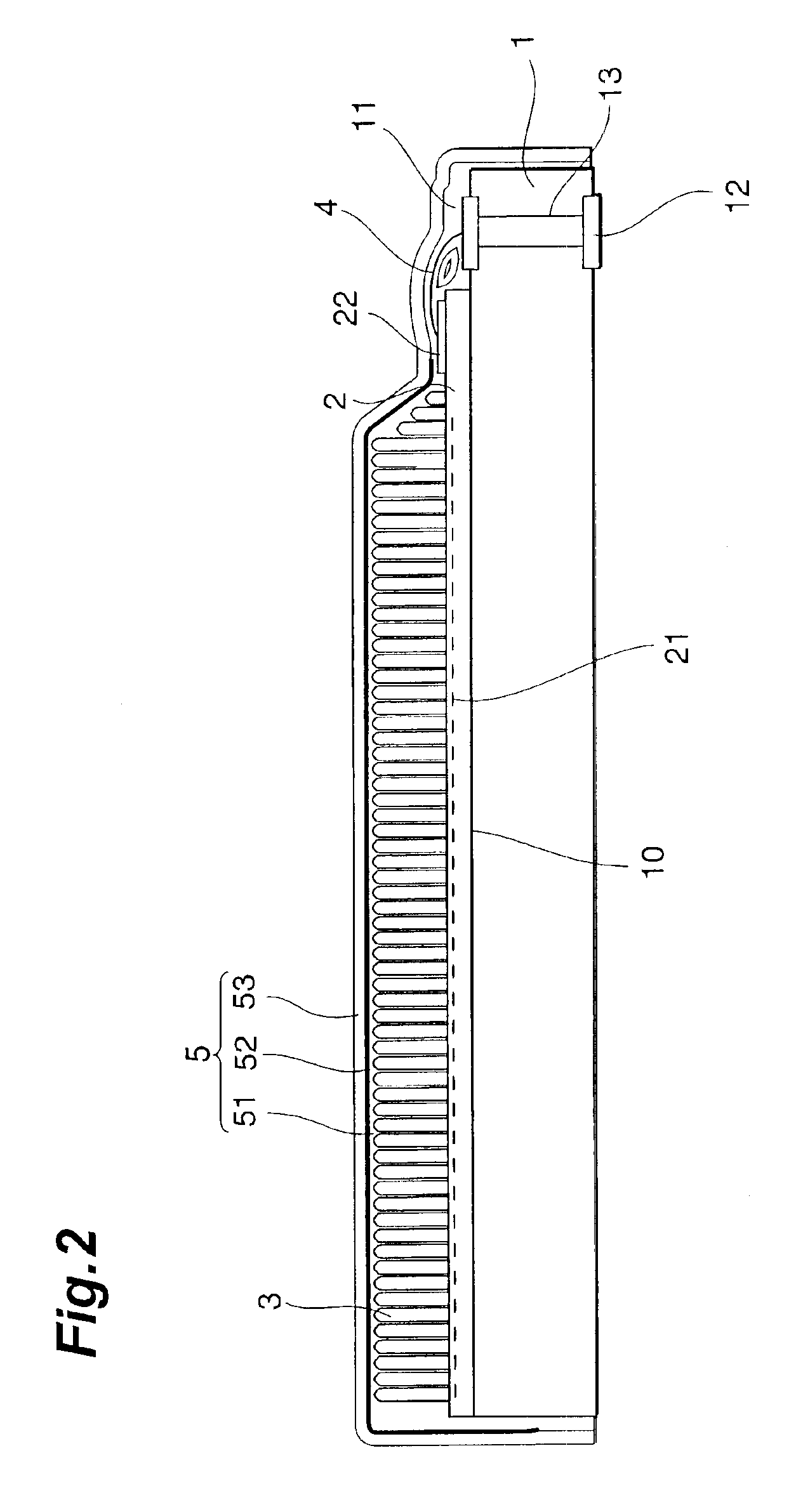

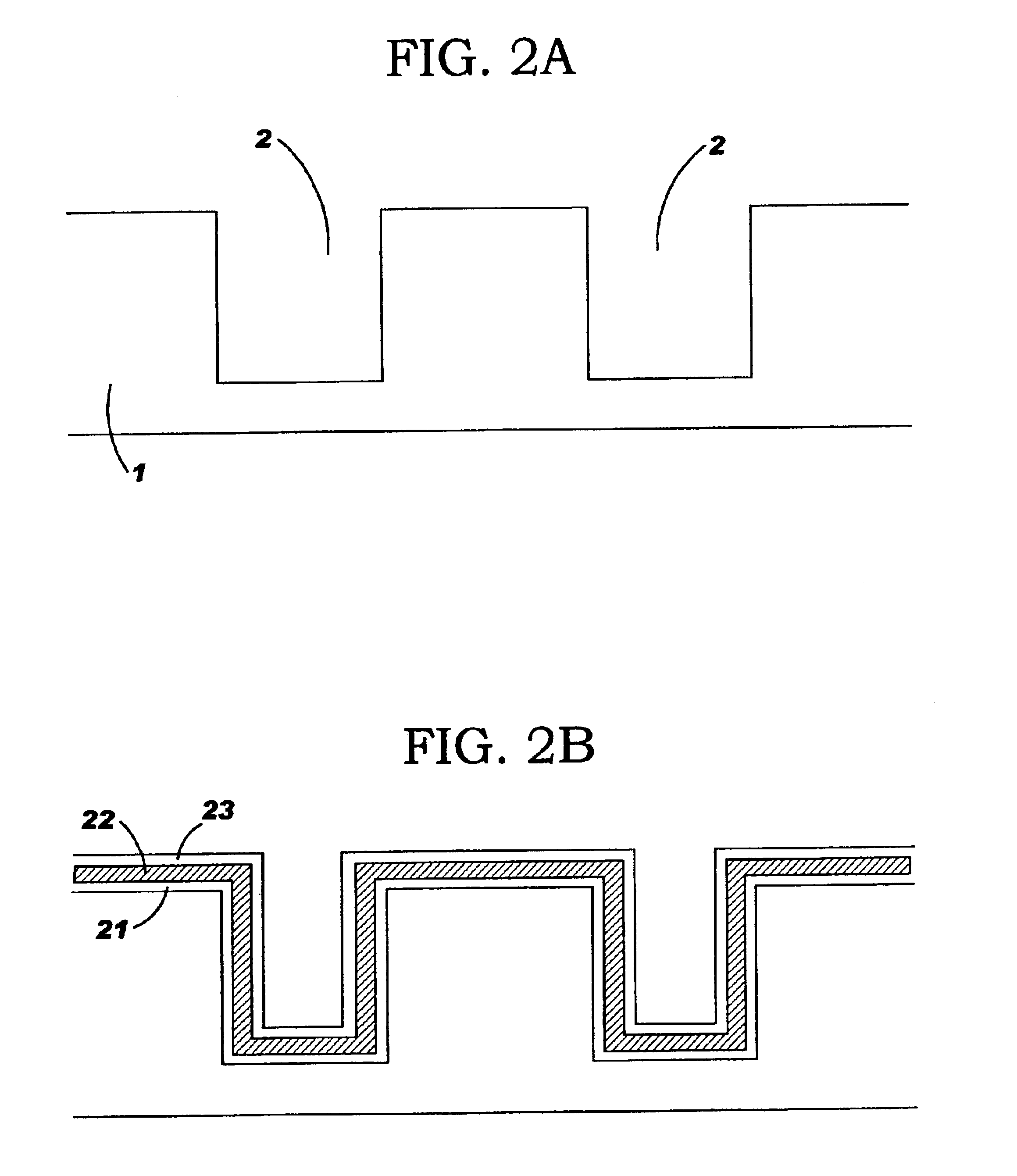

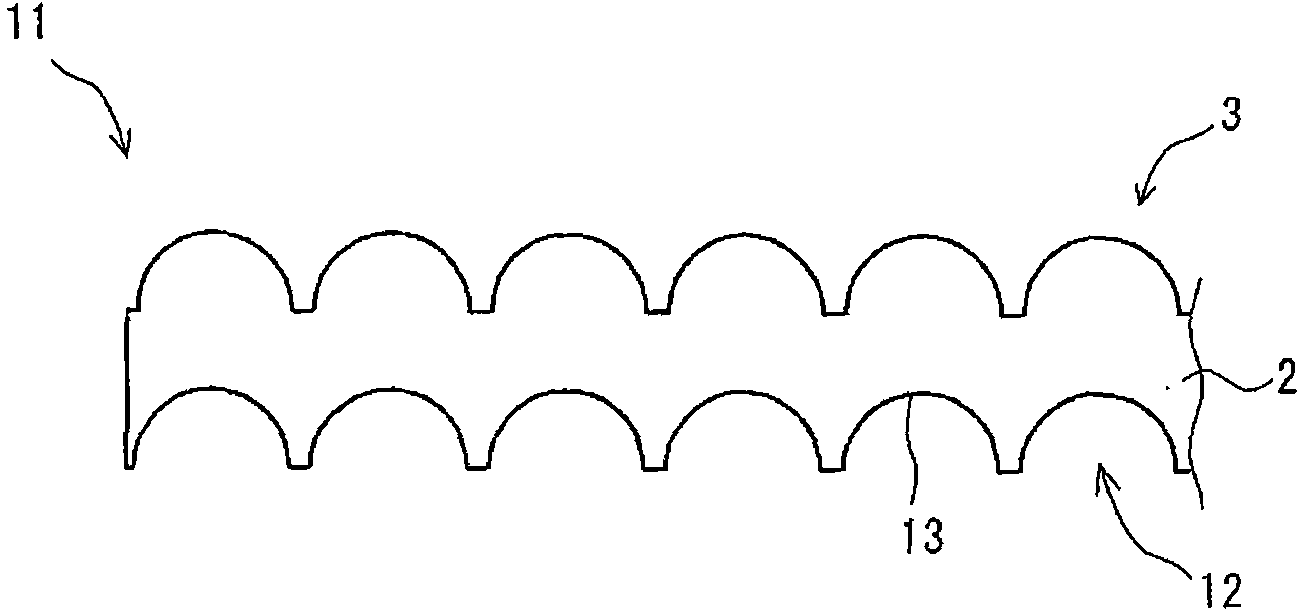

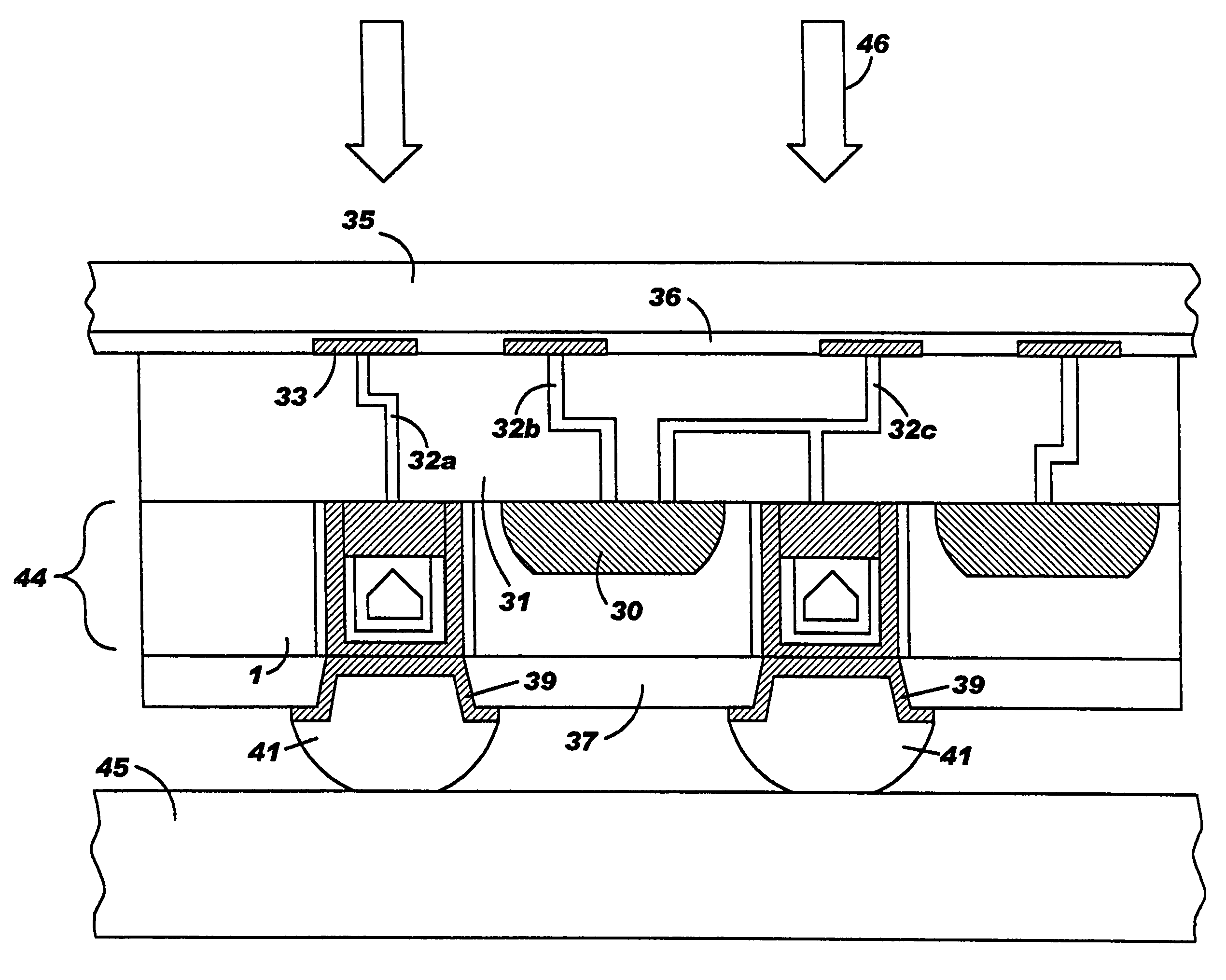

Radiation detector and method of manufacture thereof

InactiveUS6919569B2Thin and small structureLarge imaging areaTelevision system detailsPhotometryEngineeringPhotoelectric conversion

A solid-state imaging element 2 having a light-receiving portion where a plurality of photoelectric conversion elements 21 are arranged, and electrode pads 22 electrically connected to the photoelectric conversion elements 21 is mounted on a substrate 1. A scintillator 3 is formed on the surface of the light-receiving portion of the solid-state imaging element. Around a support surface 10 where the solid-state imaging element 2 of the substrate 1 is mounted, holding portions 14 and 15 are formed on opposing side walls to hold and project the surface of the light-receiving portion from a vapor deposition holder toward a vapor deposition chamber in forming the scintillator 3.

Owner:HAMAMATSU PHOTONICS KK

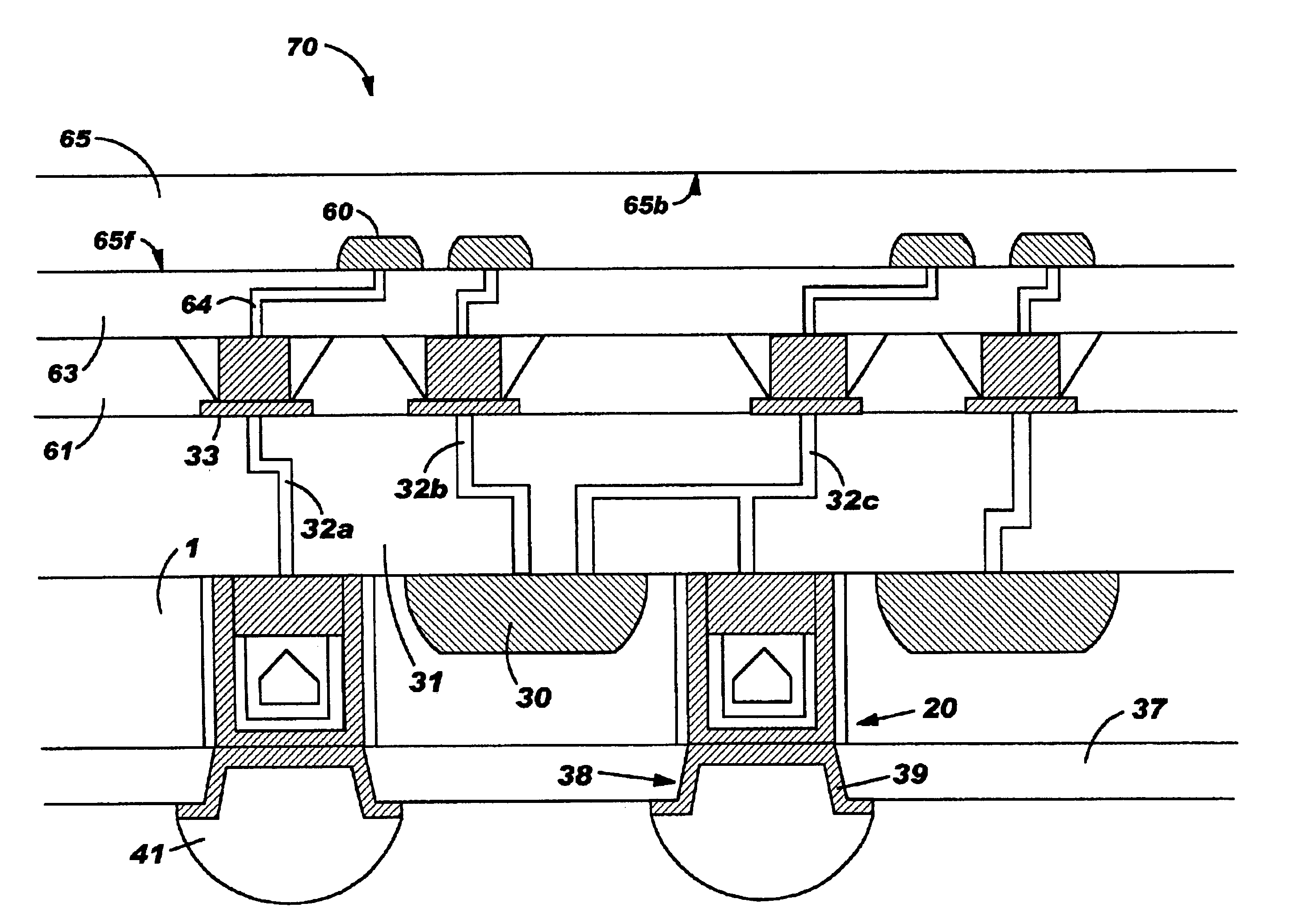

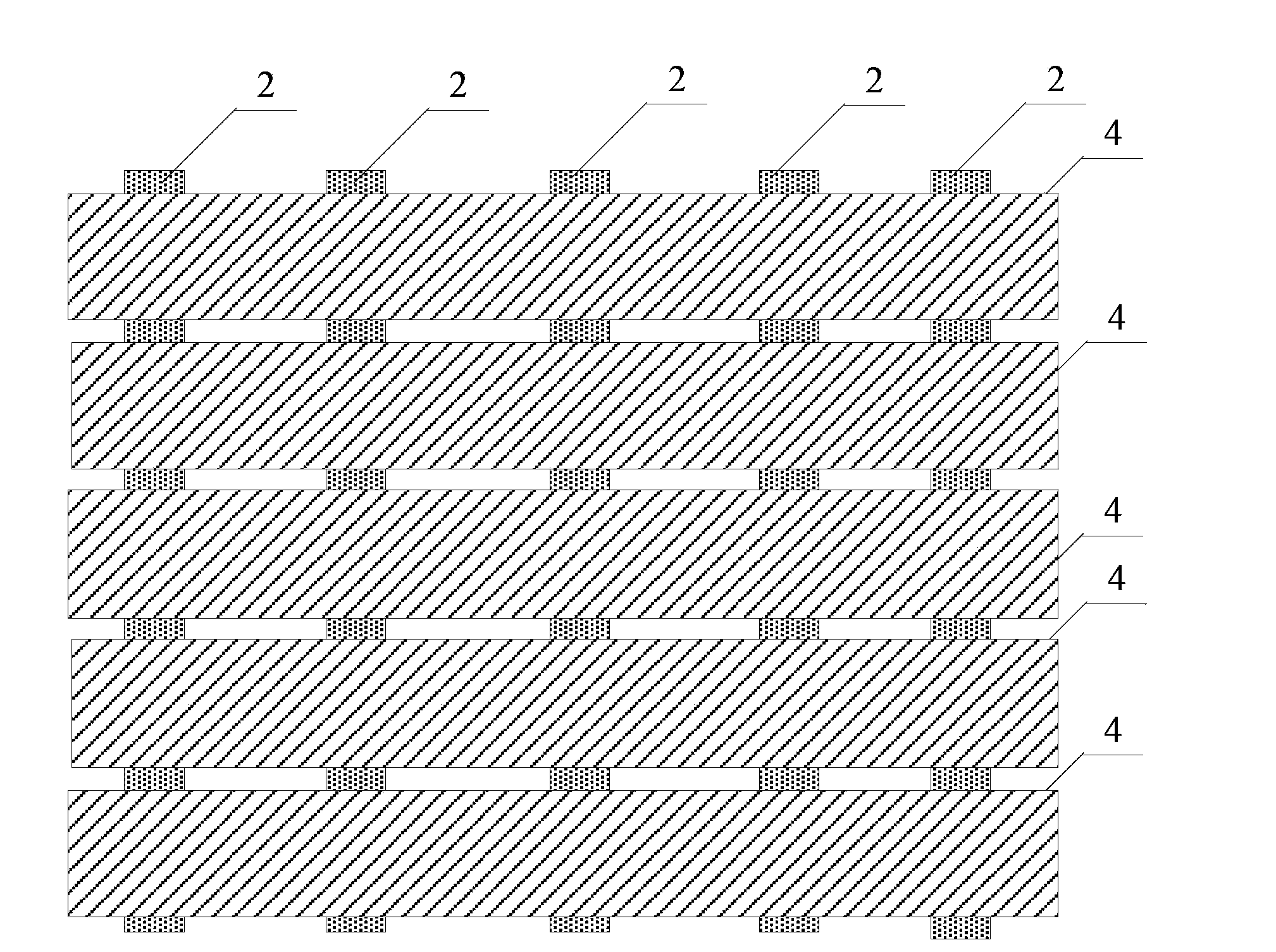

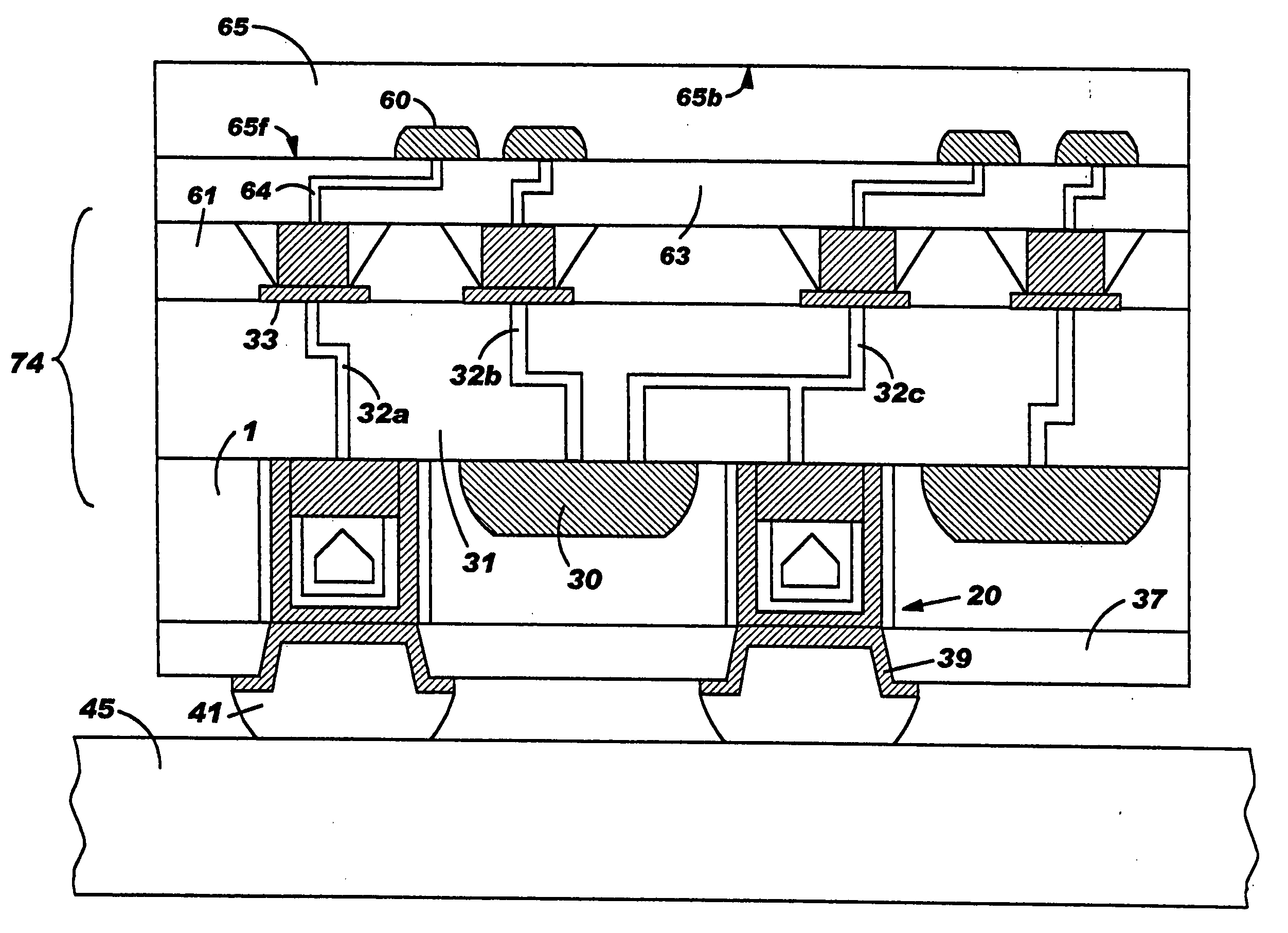

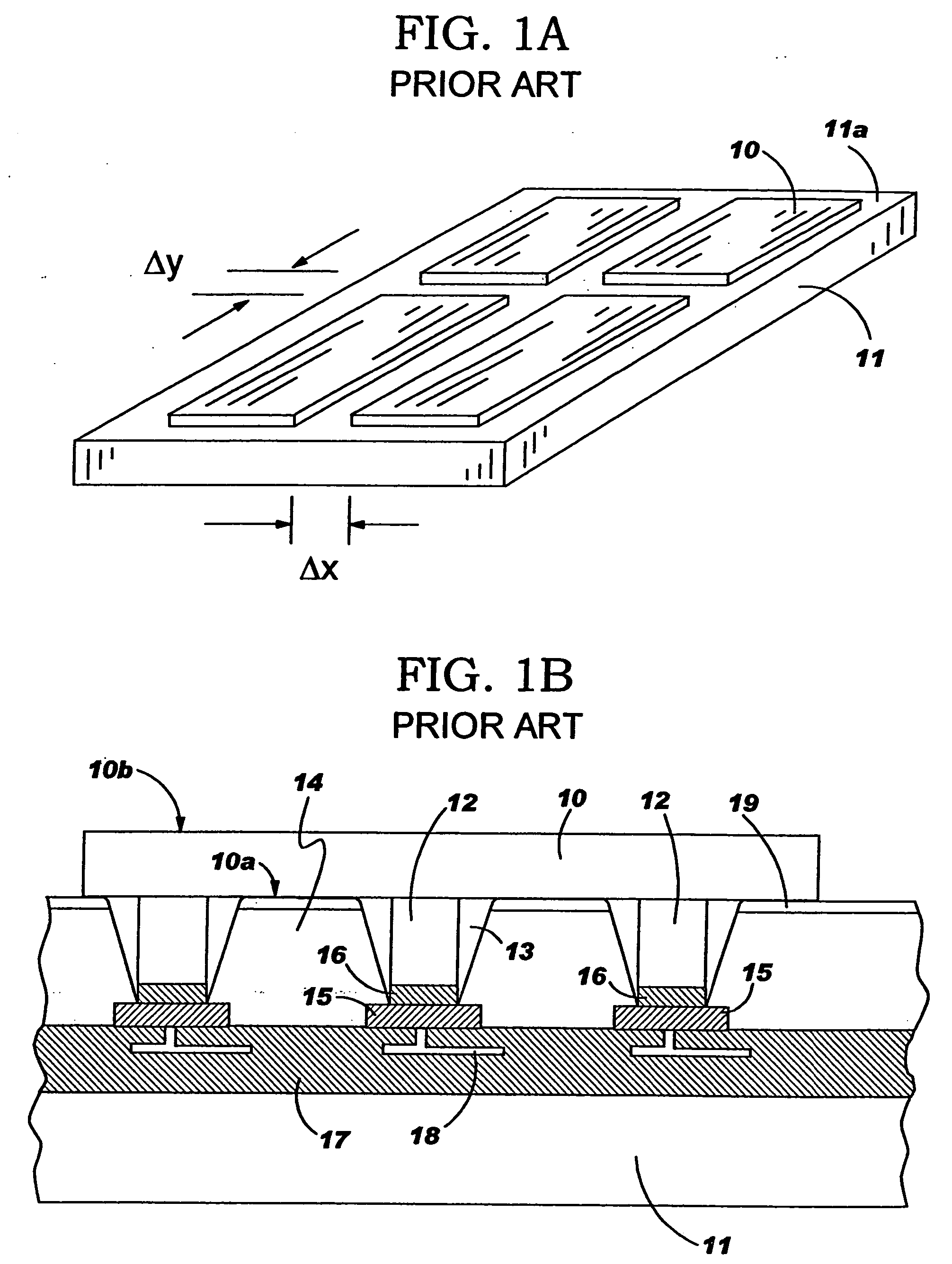

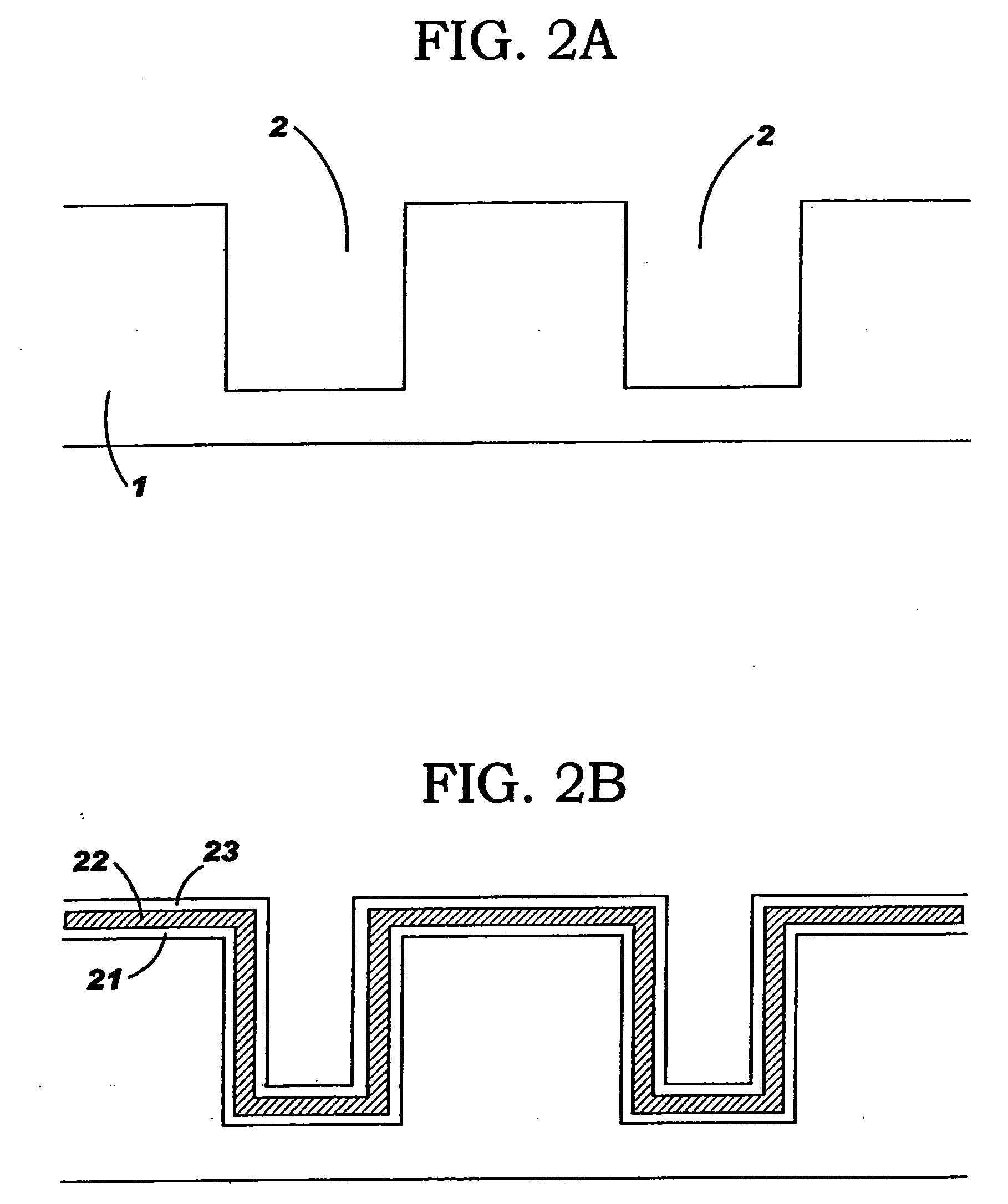

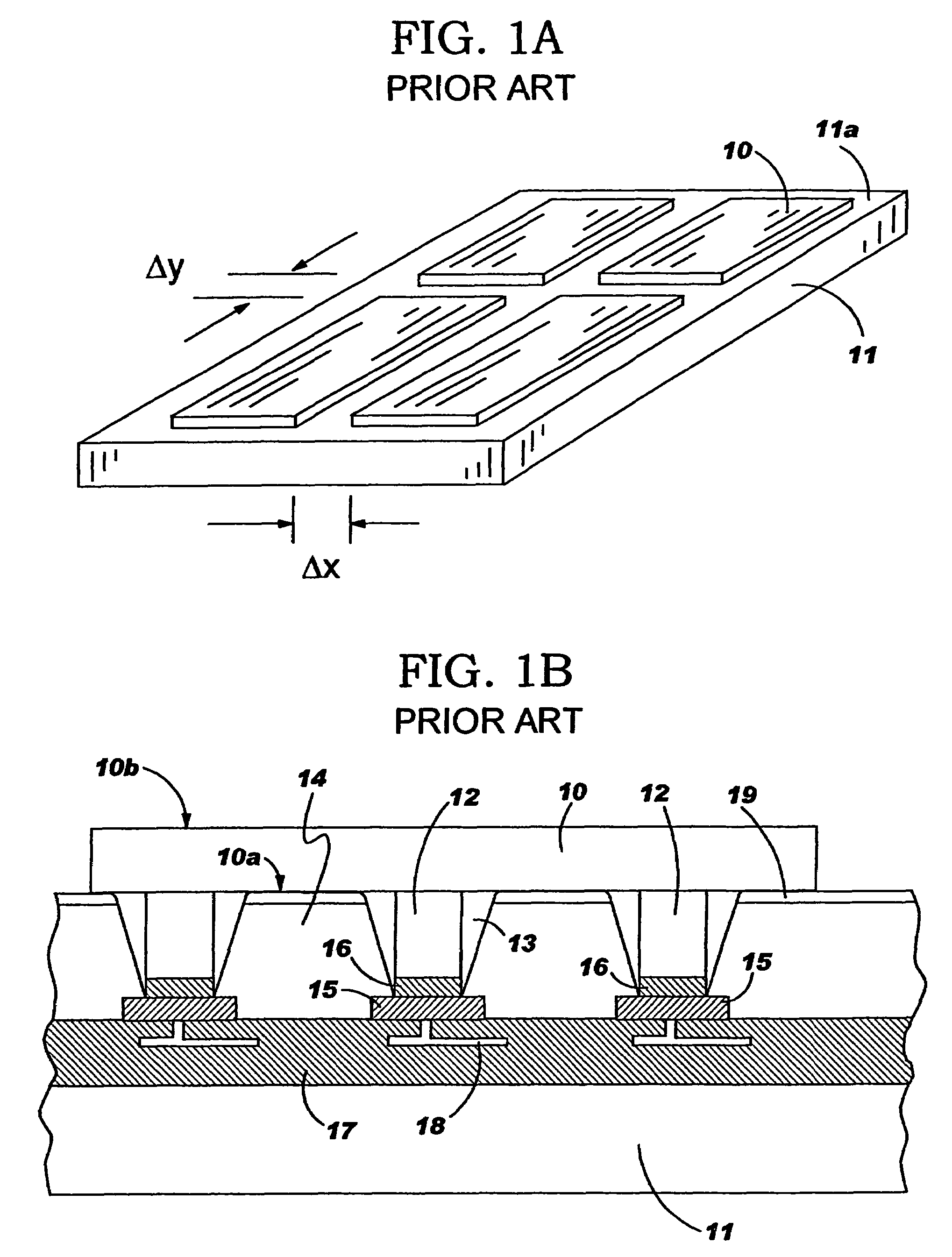

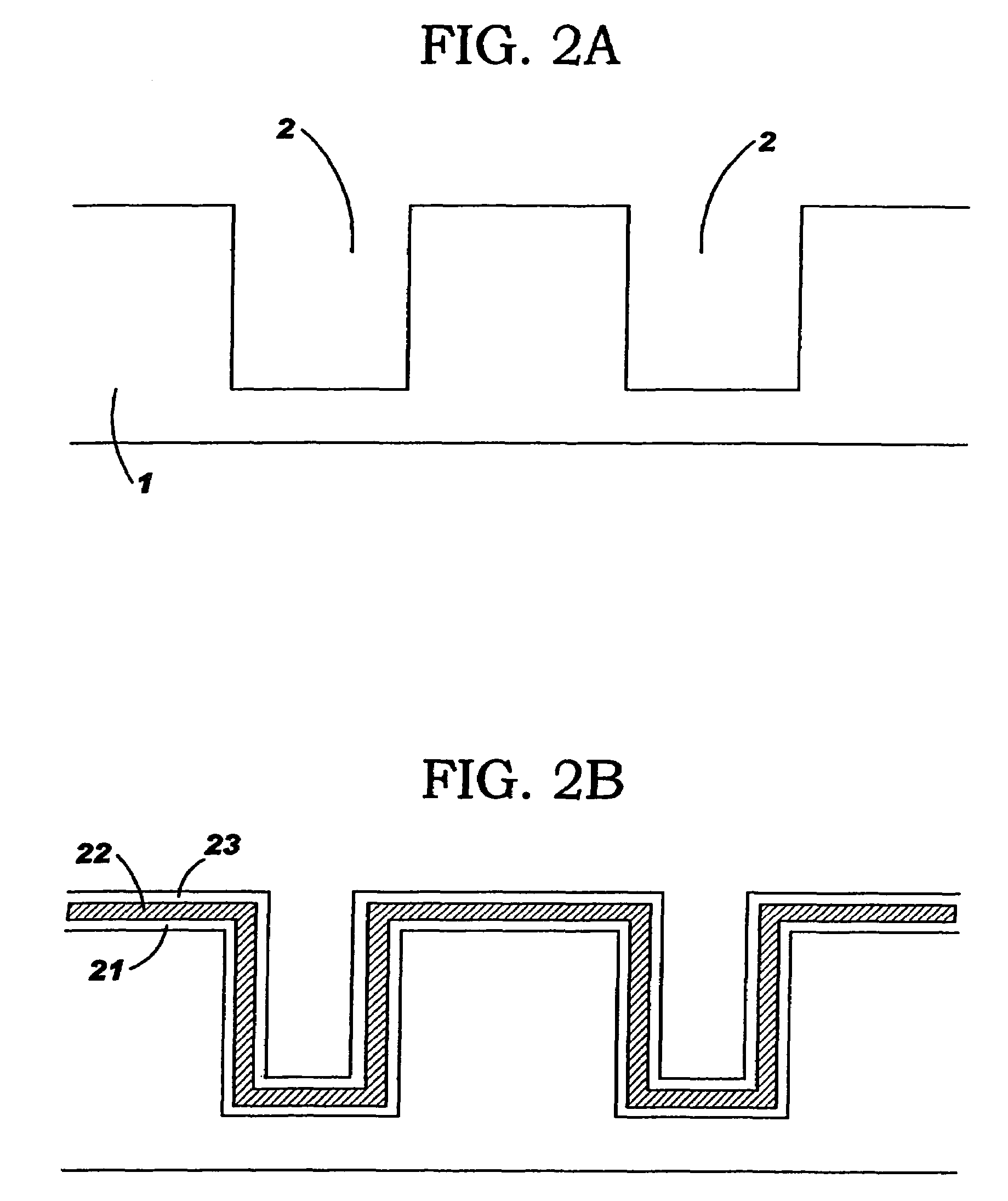

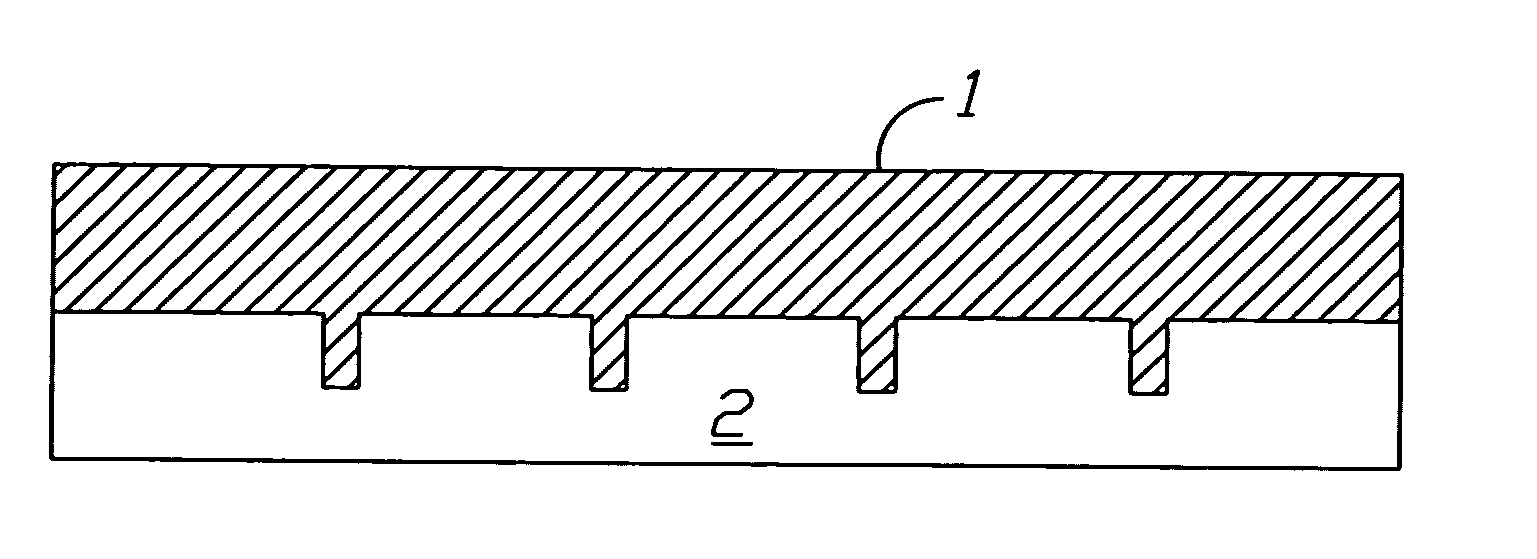

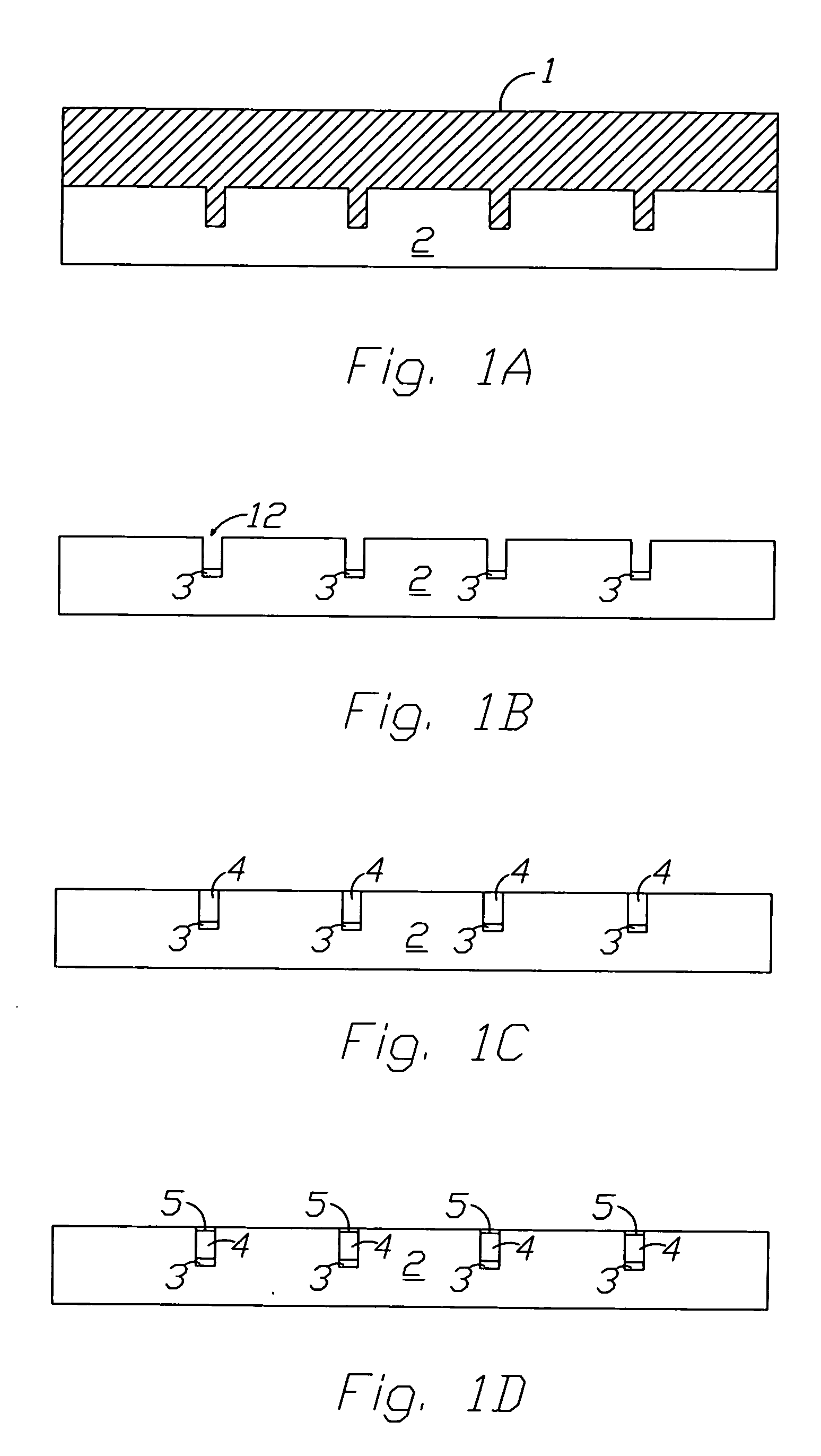

Chip and wafer integration process using vertical connections

InactiveUS6856025B2Improve fidelityHighly accurate chip placementSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A process is described for semiconductor device integration at chip level or wafer level, in which vertical connections are formed through a substrate. A metallized feature is formed in the top surface of a substrate, and a handling plate is attached to the substrate. The substrate is then thinned at the bottom surface thereof to expose the bottom of the feature, to form a conducting through-via. The substrate may comprise a chip having a device (e.g. DRAM) fabricated therein. The process therefore permits vertical integration with a second chip (e.g. a PE chip). The plate may be a wafer attached to the substrate using a vertical stud / via interconnection. The substrate and plate may each have devices fabricated therein, so that the process provides vertical wafer-level integration of the devices.

Owner:GLOBALFOUNDRIES US INC

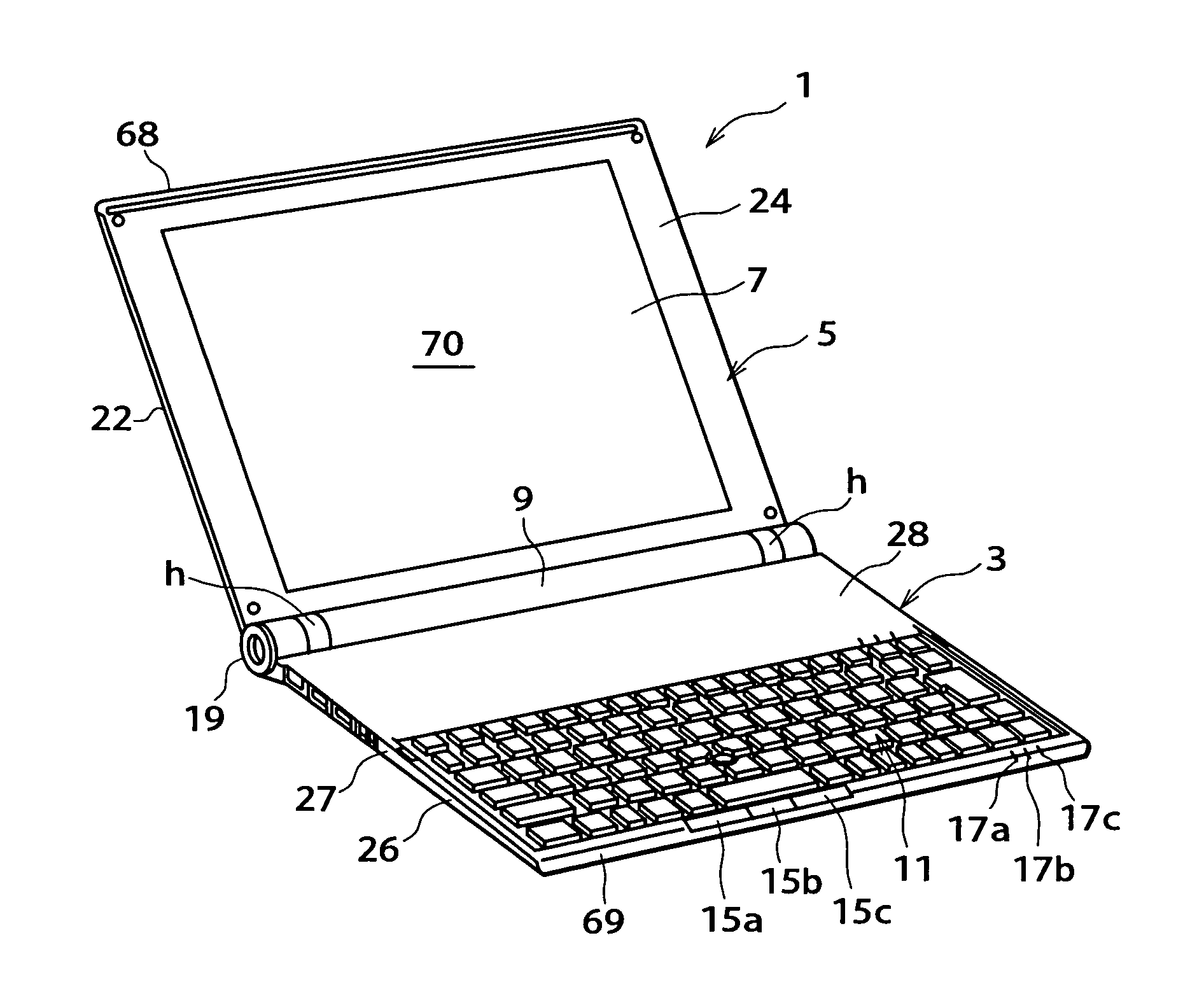

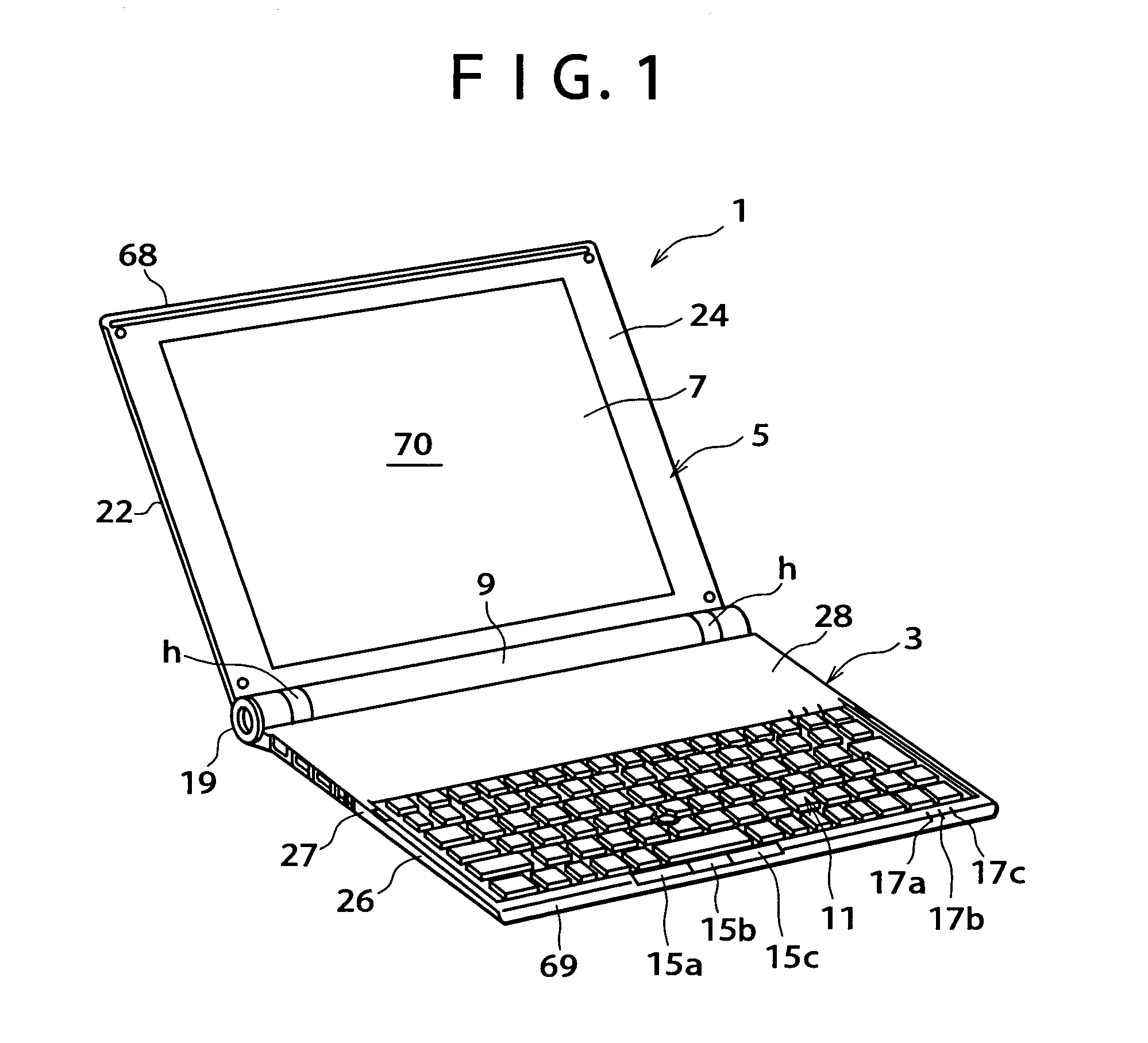

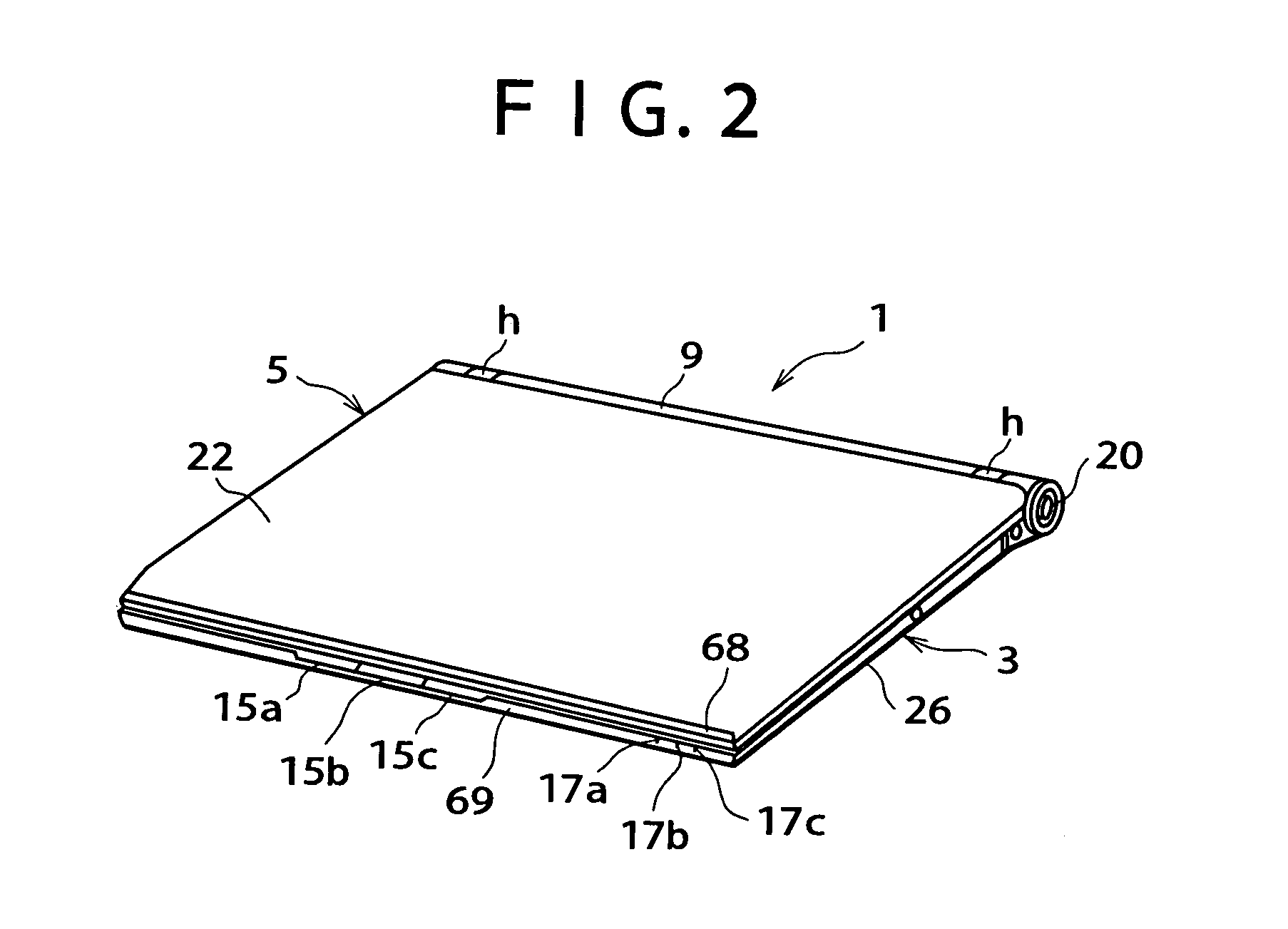

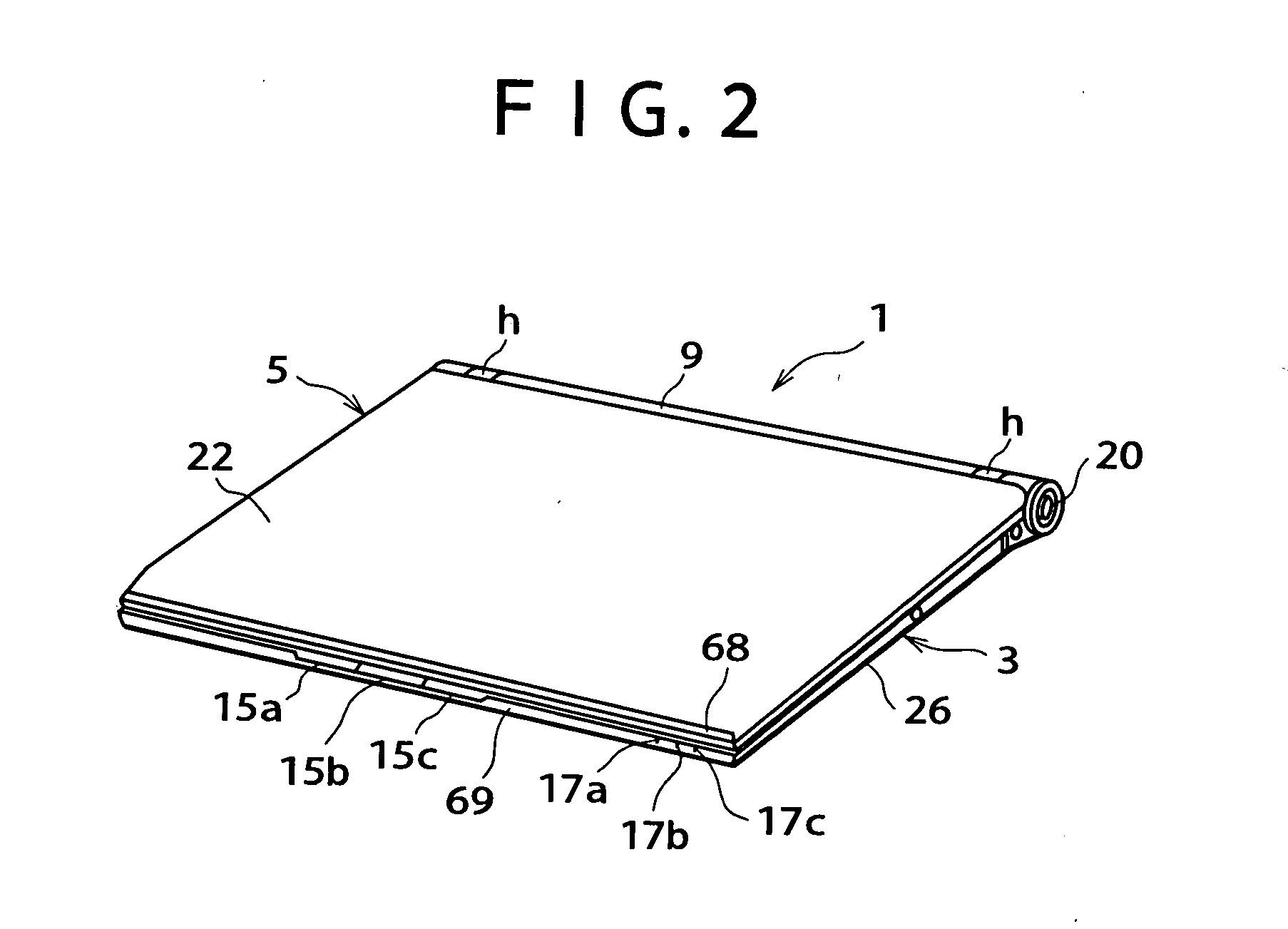

Electronic device

InactiveUS7489507B2Components in expandedImprove the display effectFurniture partsCabinetsDisplay deviceEngineering

Owner:SONY CORP

Touch panel and display device

InactiveCN104216578AWith shading functionAct as a touchDigital data processing detailsInput/output processes for data processingDisplay deviceTouchscreen

A touch panel and a display device. The touch panel comprises: a first substrate, wherein a colour film layer is arranged on the first substrate. The colour film layer comprises a plurality of colour pixel units arranged in the form of a matrix. The first substrate further comprises a plurality of touch-control inductive electrodes and a plurality of touch-control drive electrodes, wherein the touch-control inductive electrodes are arranged between adjacent lines or adjacent rows of colour pixel units and have a light-shading function; and the touch-control drive electrodes and the touch-control inductive electrodes are insulated from each other and are arranged crosswise, touch-control scanning signals are applied to the touch-control drive electrodes at a touch-control stage, while common electrode signals are applied to same at a display stage. The touch panel simplifies the structure and the manufacturing process of an embedded touchscreen.

Owner:BOE TECH GRP CO LTD

Chip and wafer integration process using vertical connections

InactiveUS20050121711A1Facilitate thinningConveniently removedTransistorSemiconductor/solid-state device detailsDevice materialEngineering

A process is described for semiconductor device integration at chip level or wafer level, in which vertical connections are formed through a substrate. A metallized feature is formed in the top surface of a substrate, and a handling plate is attached to the substrate. The substrate is then thinned at the bottom surface thereof to expose the bottom of the feature, to form a conducting through-via. The substrate may comprise a chip having a device (e.g. DRAM) fabricated therein. The process therefore permits vertical integration with a second chip (e.g. a PE chip). The plate may be a wafer attached to the substrate using a vertical stud / via interconnection. The substrate and plate may each have devices fabricated therein, so that the process provides vertical wafer-level integration of the devices.

Owner:GLOBALFOUNDRIES U S INC

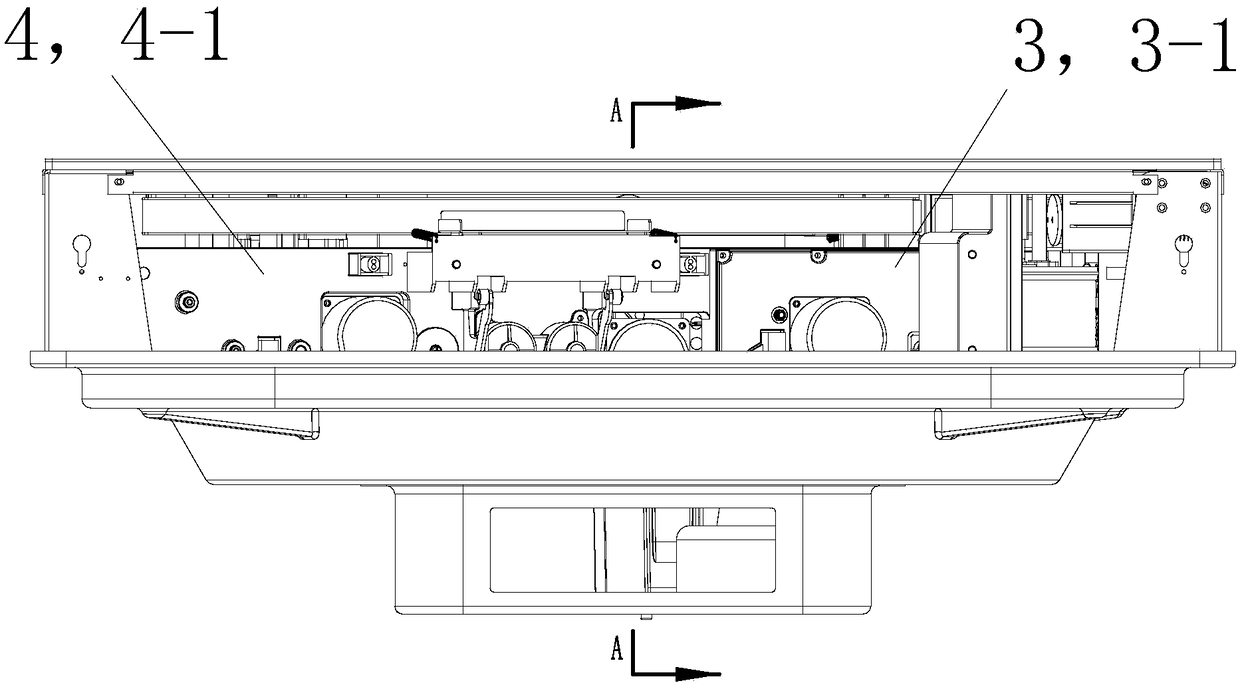

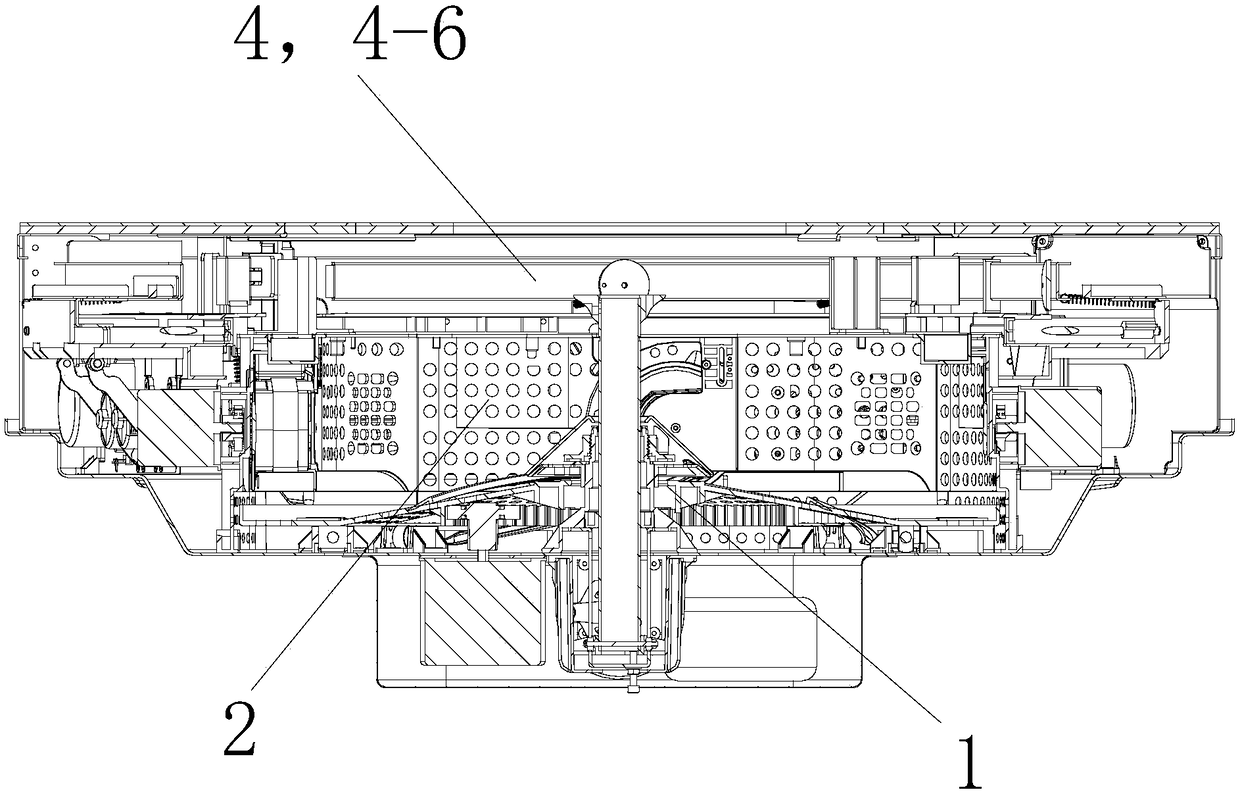

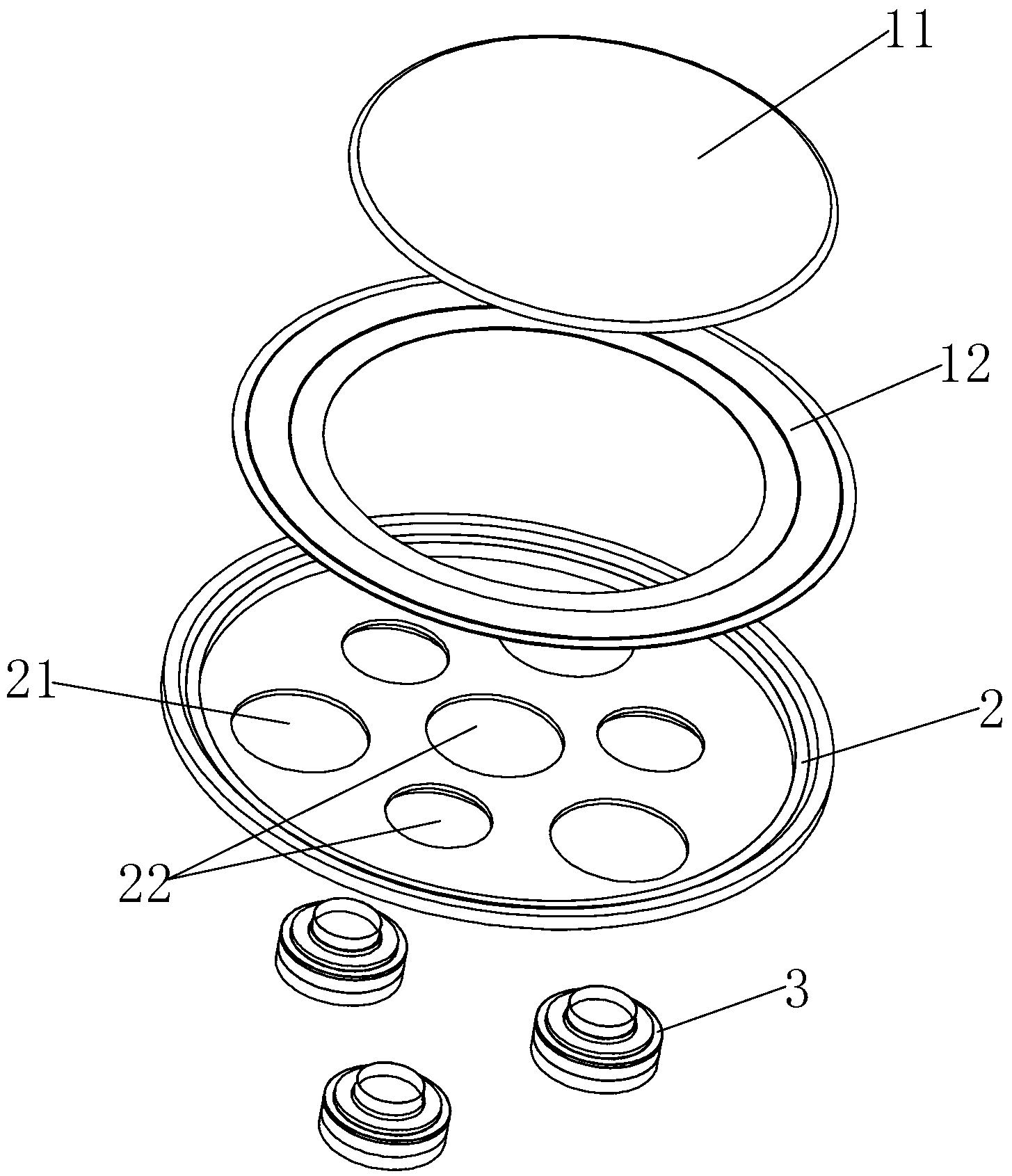

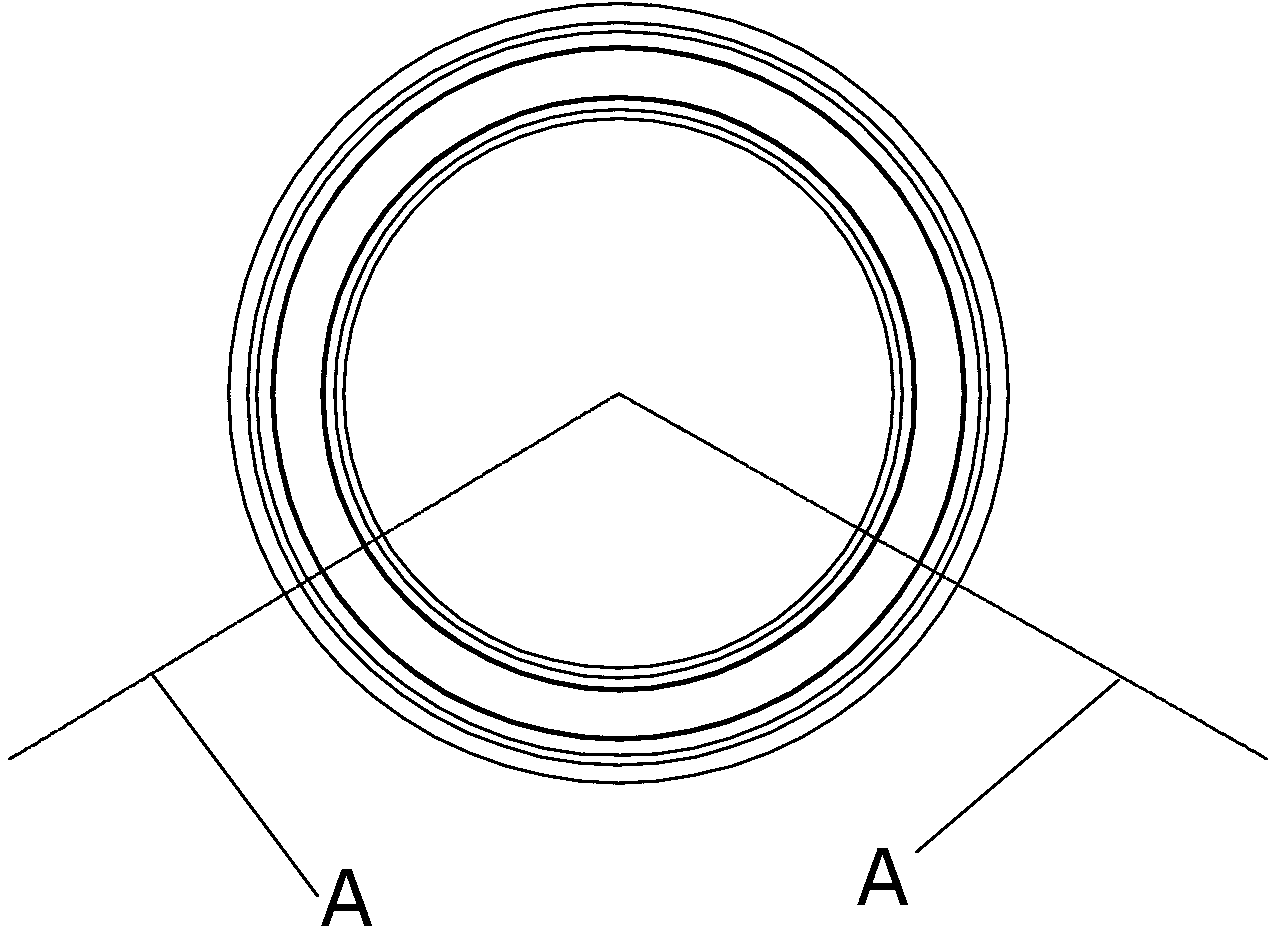

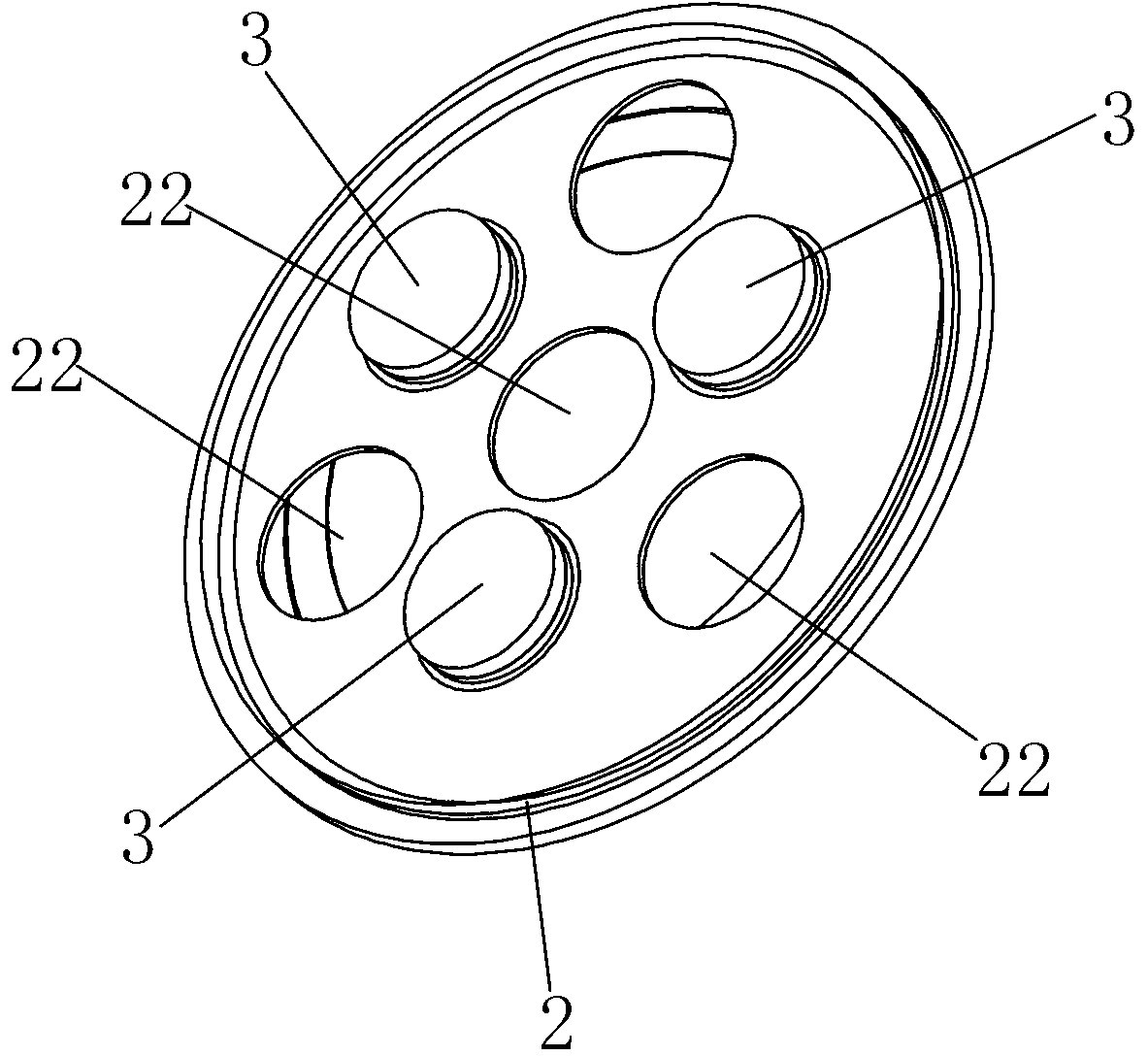

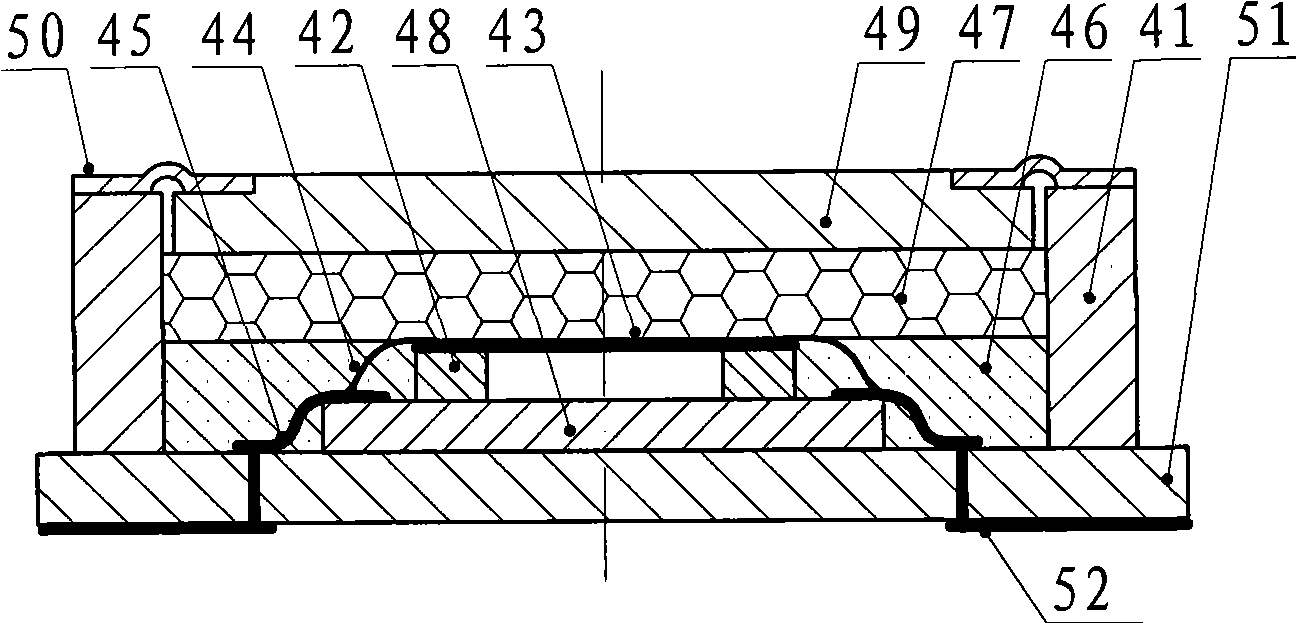

Mahjong machine

PendingCN109381855AIngenious structureSave entertainment timeIndoor gamesEngineeringMechanical engineering

The invention discloses a mahjong machine. Mahjong tiles of the mahjong machine are lifted to the table top of the mahjong machine at one time in a manner of inclining to the surrounding edges of thetable top of the mahjong machine and being close to the center of the table top of the mahjong machine. The machine is ingenious in structure, the surrounding mahjong tiles of the mahjong machine canbe raised to the position for drawing the tiles at one time so that the surrounding mahjong tiles can be directly drawn after being raised to the table top, the step that the mahjong tiles need to beartificially tilted or artificially arranged after being released is eliminated, and entertainment time is saved.

Owner:德兴市永达娱乐设备有限公司

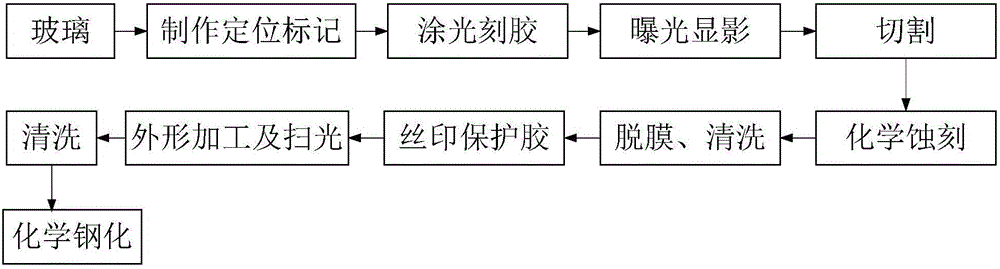

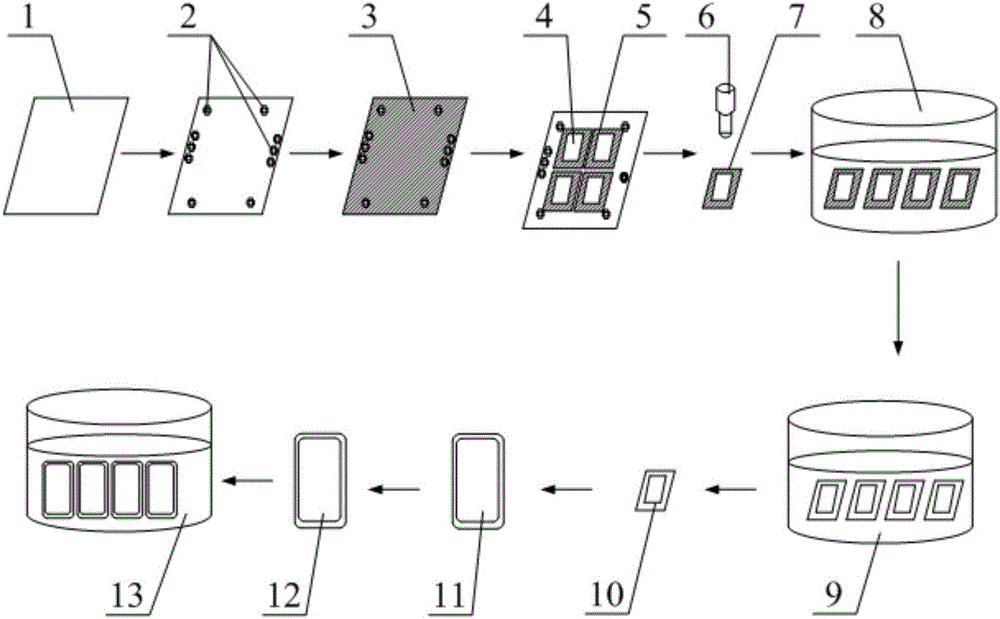

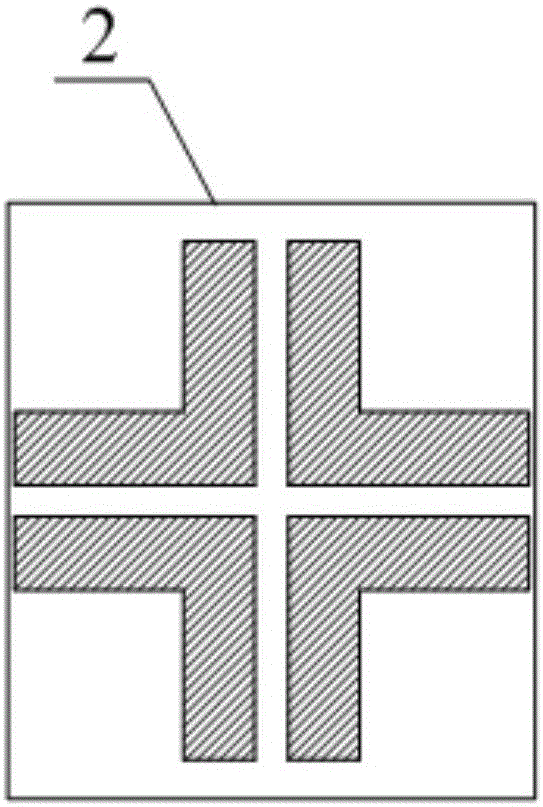

3D (three-dimensional) glass cover plate and method for manufacturing same

InactiveCN105948520AFacilitate thinningGuaranteed StrengthTelevision system detailsDigital data processing detailsNumerical controlGlass cover

The invention discloses a 3D (three-dimensional) glass cover plate and a method for manufacturing the same. The method includes main steps of coating photoresist on glass; developing target patterns by means of exposure; chemically etching display regions and forming grooves by means of machining; removing the photoresist on the surfaces of the glass by the aid of release agents; carrying out appearance processing and light sweeping, to be more specific, processing the glass by the aid of a numerical-control machine tool to obtain the outer contour of the cover plate and 2.5D (2.5-dimensional) edges of the upper surface of the cover plate and then carrying out light sweeping on the 2.5D edges and the grooves; chemically tempering the glass to obtain the 3D glass cover plate which is a finished product. The target patterns include protected regions and etched regions, the photoresist covers the protected regions and does not cover the etched regions, and the etched regions include the display regions, and touch display modules can be correspondingly laminated on the display regions. The 3D glass cover plate and the method have the advantages that the integral thicknesses of touch screens can be reduced, 2.5D and 3D effects can be realized by the appearance of the edges, and requirements on lightening and thinning the 3D glass cover plate can be met; chemical etching processing technologies are exquisite, and accordingly the strength, the precision, the production efficiency and the high degree of automation of the product can be guaranteed.

Owner:TRULY OPTO ELECTRONICS

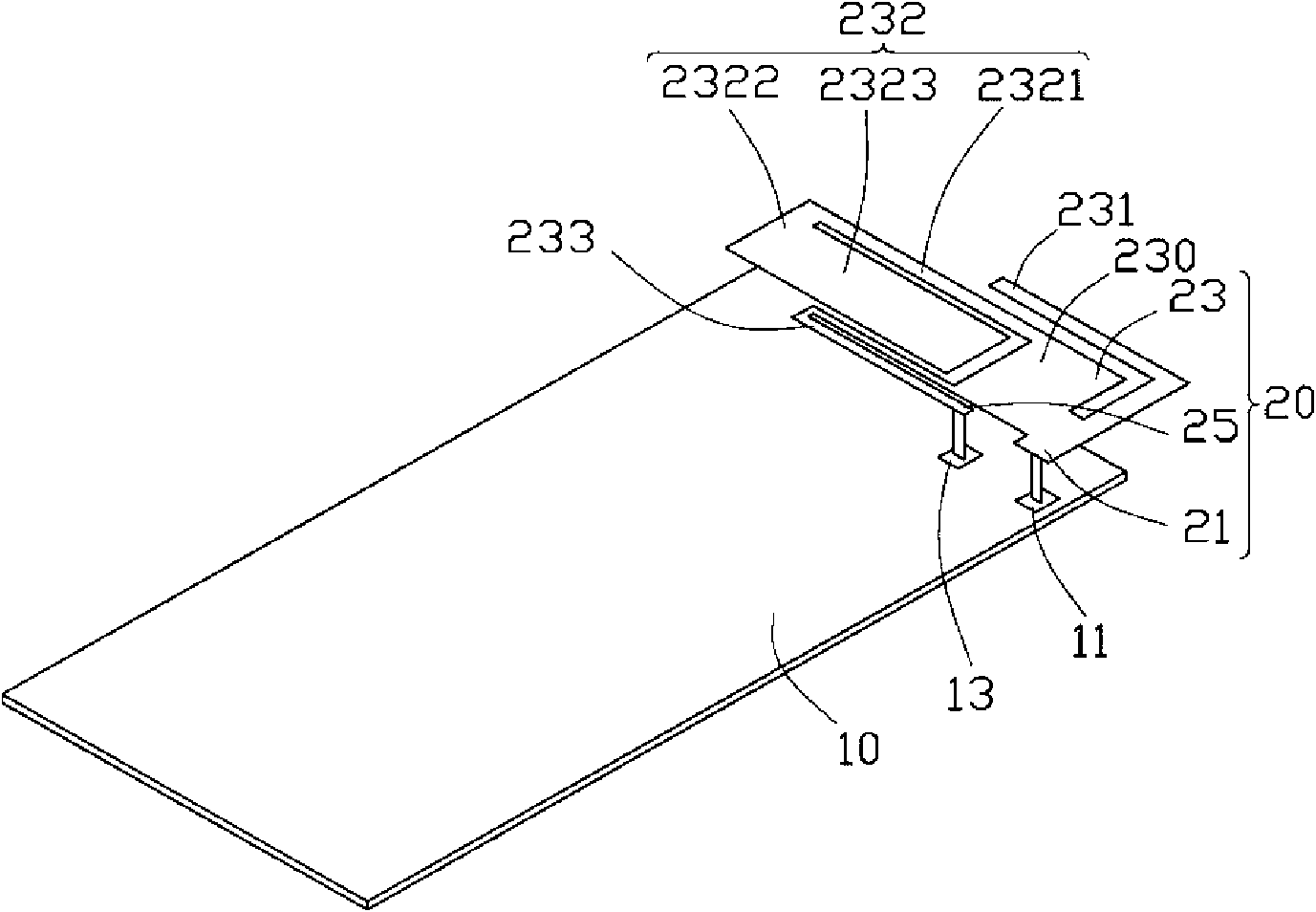

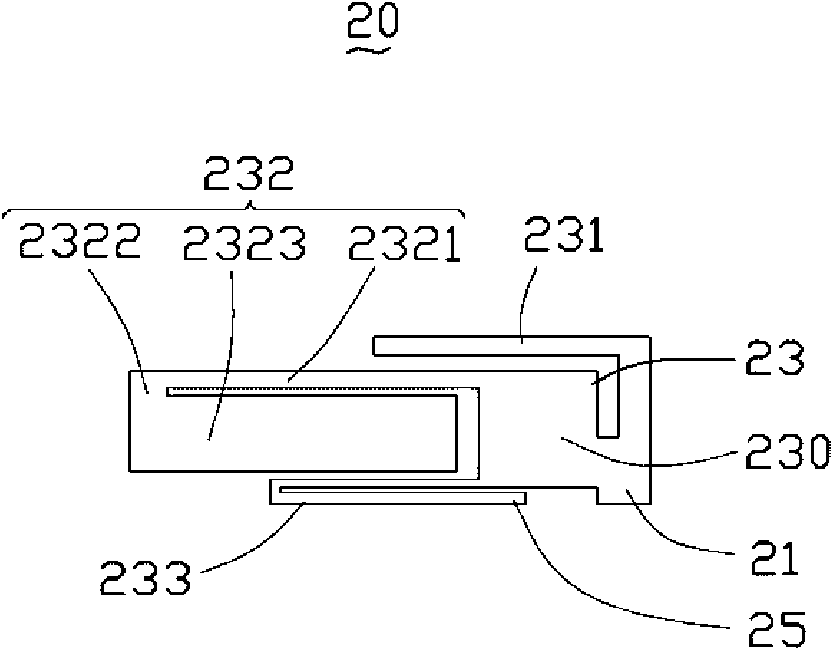

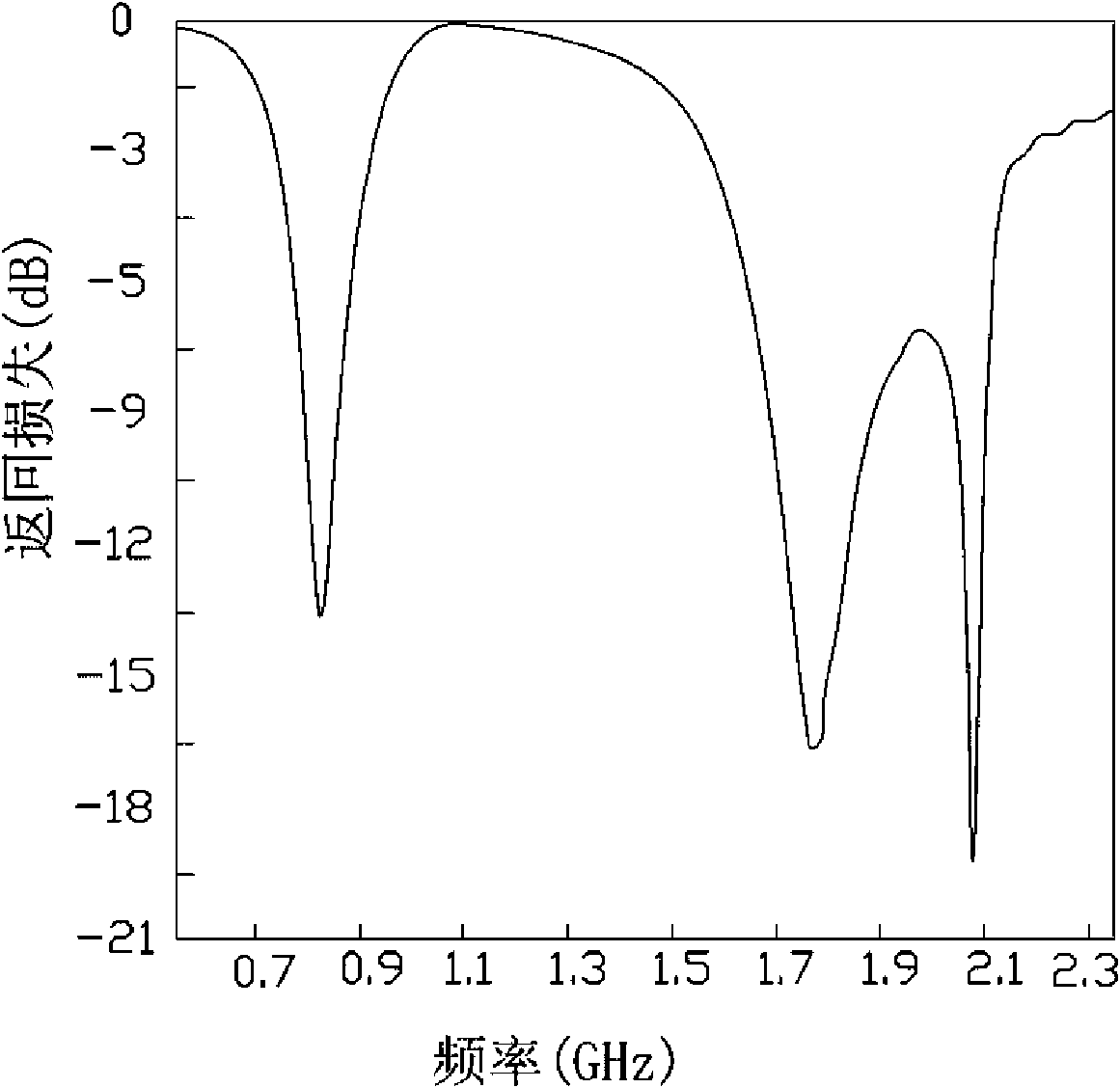

Multi-frequency antenna and radio communication system having same

InactiveCN101587983AHigh bandwidthImprove versatilitySimultaneous aerial operationsRadiating elements structural formsCommunications systemResonance

The invention discloses a multi-frequency antenna, which is a plate type antenna and comprises a feed-in end, a transmitter and a grounding end. The transmitter comprises a main body, a first transmitting arm, a second transmitting arm and a third transmitting arm, wherein the first transmitting arm, the second transmitting arm and the third transmitting arm are formed by extending and bending the main body and share the feed-in end. During the operation of the multi-frequency antenna, the first transmitting arm, the second transmitting arm and the third transmitting arm of the multi-frequency antenna generate three resonance frequencies according to a radio-frequency signal fed in by the feed-in end to generate different operation frequencies, so that the multi-frequency antenna has a property of multi-frequency operation. The invention also discloses a radio communication system having the multi-frequency antenna.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

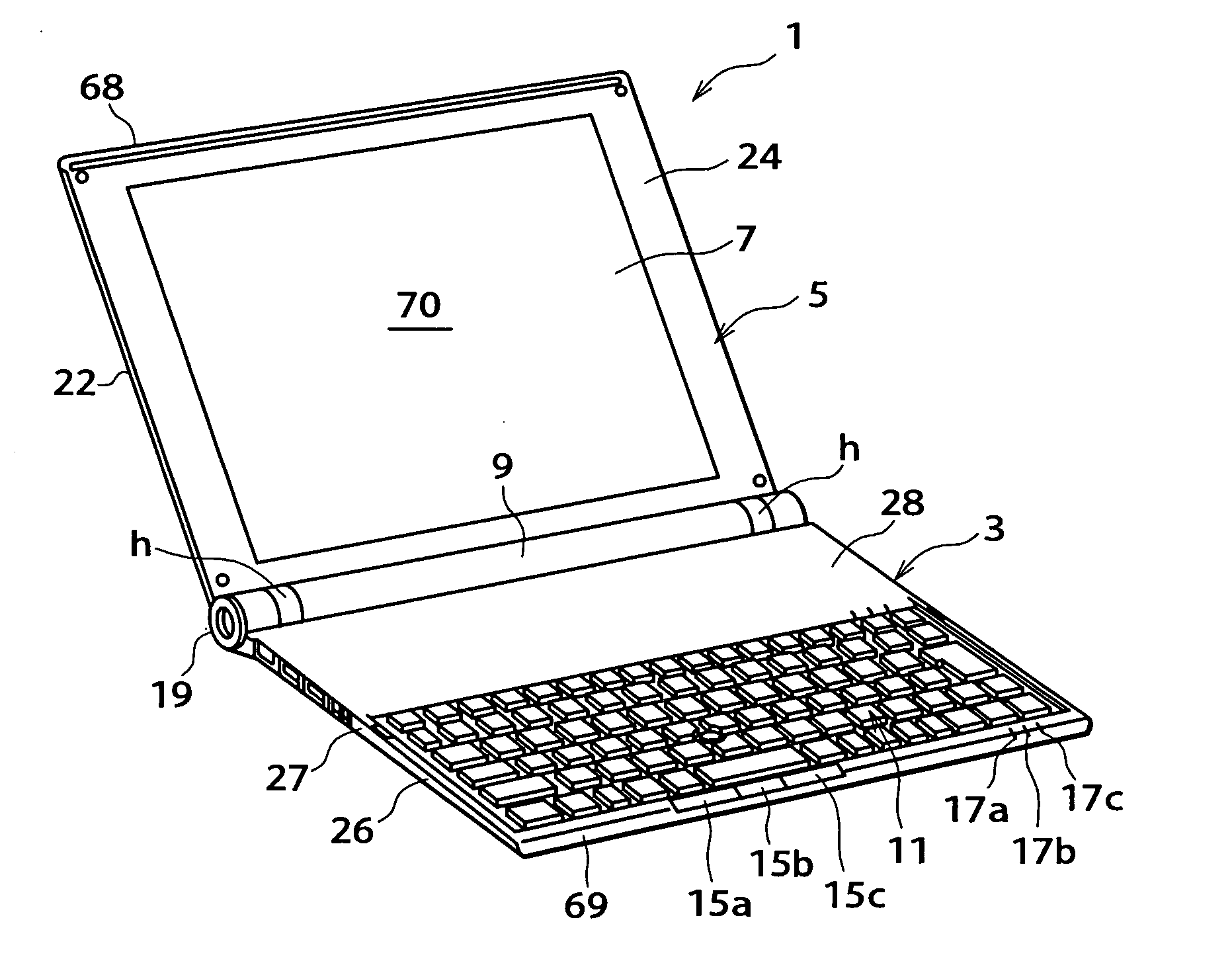

Electronic device

InactiveUS20050117286A1Manipulation is accurateReduce component countDetails for portable computersElectrical apparatus contructional detailsDisplay deviceEngineering

Owner:SONY CORP

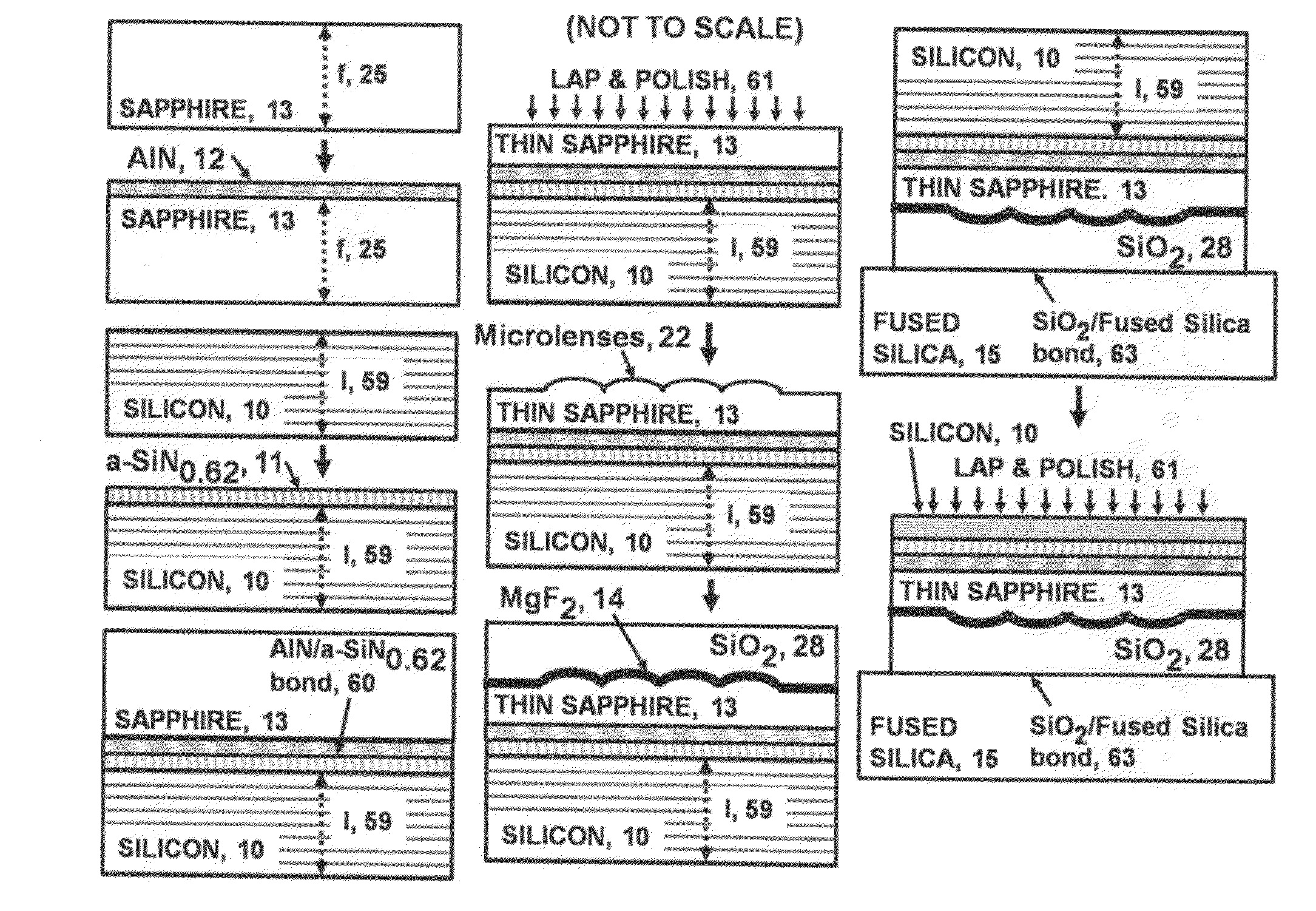

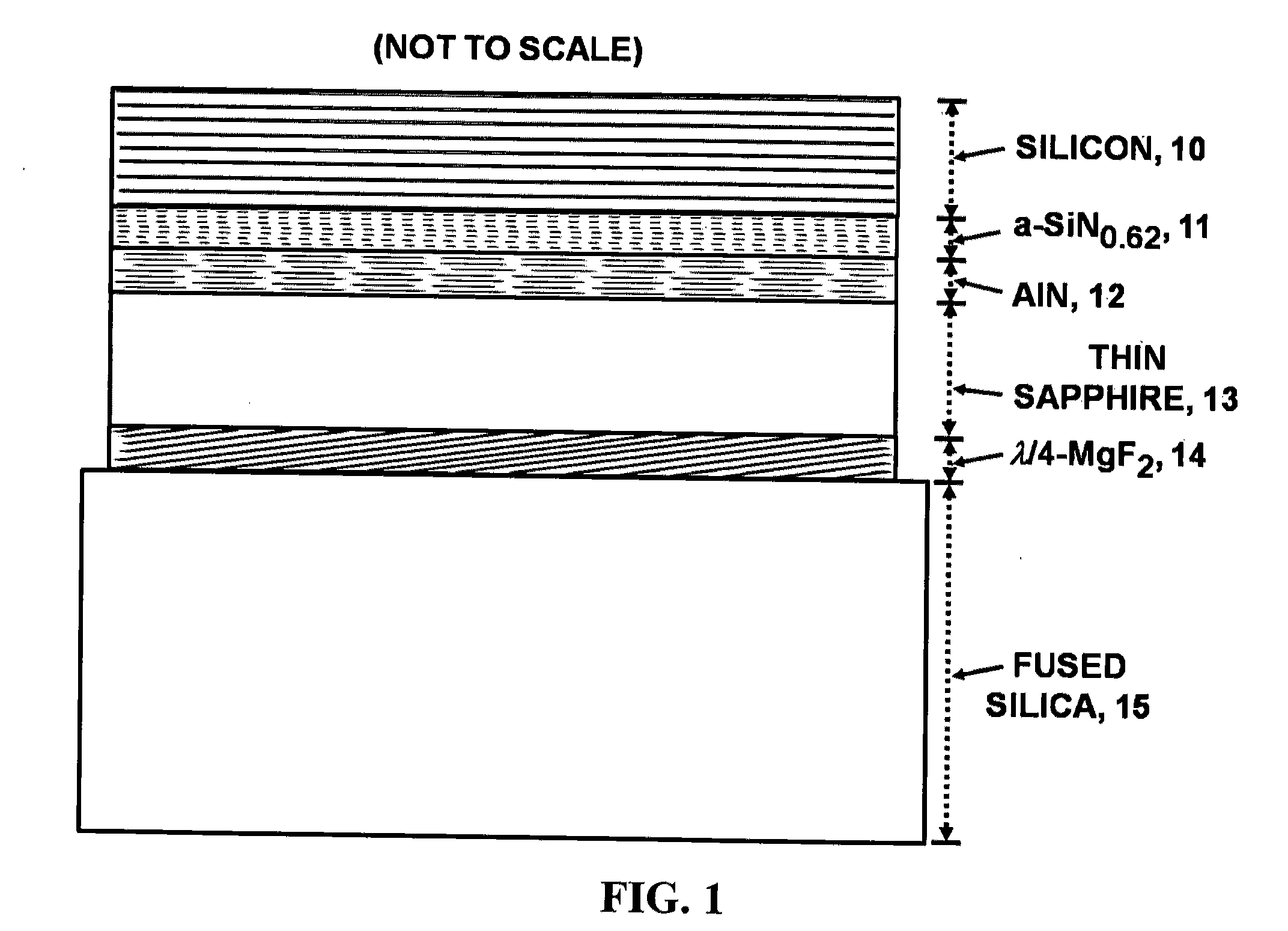

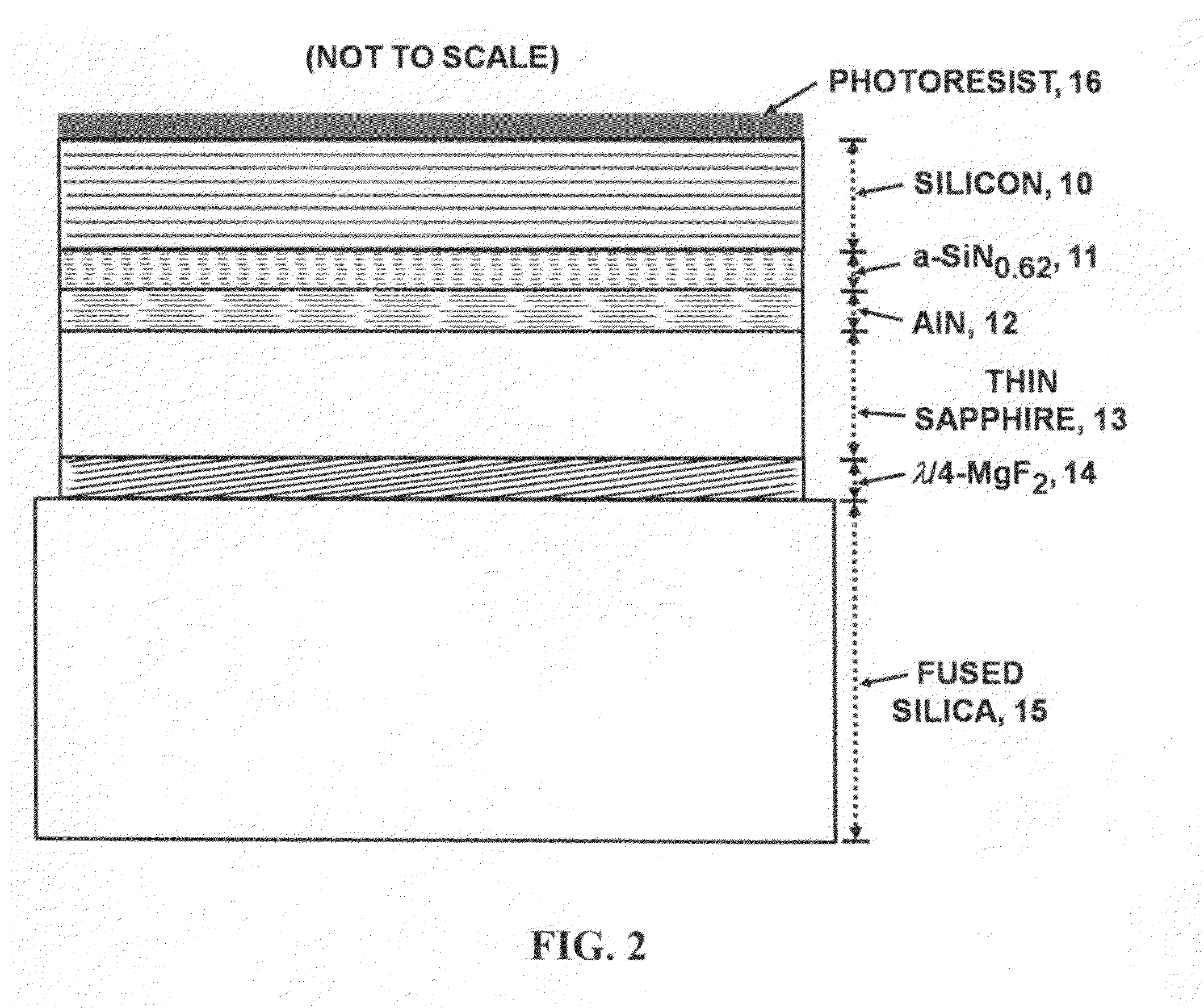

Thin, very high transmittance, back-illuminated, silicon-on-saphire semiconductor substrates bonded to fused silica

InactiveUS20120299143A1High light transmittanceSuppression problemSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalSilicon dioxide

A very high transmittance, back-illuminated, silicon-on-thin sapphire-on-fused silica wafer substrate design is presented for enabling high quantum efficiency and high resolution, silicon or silicon-germanium avalanche photodiode detector arrays with improved indirect optical crosstalk suppression. The wafer substrate incorporates a stacked antireflective bilayer between the sapphire and silicon, comprised of single crystal aluminum nitride (AlN) and non-stoichiometric, silicon rich, amorphous silicon nitride (a-SiNX<1.33), as well as a one quarter wavelength, magnesium fluoride (λ / 4-MgF2) back-side antireflective layer which is bonded to a fused silica wafer. The fused silica provides mechanical support, allowing the sapphire to be thinned to optimal thickness below 50 μm, for improved optical transmittance and in conjunction with monolithic sapphire microlenses, suppression of indirect optical crosstalk from multiple reflections of APD emitted light. After solid-state device fabrication, the silicon can be coated with photoresist and the fused silica dissolved in buffered hydrogen fluoride (HF) to recover the thin Si—(AlN / a-SiNX<1.33)-sapphire-(MgF2).

Owner:STERN ALVIN GABRIEL

Display device

InactiveCN102654660AReduce thicknessFacilitate thinningLayered productsElectrical equipmentDisplay deviceEngineering

The invention discloses a display device comprising a display panel used for displaying images and a supporting element used for supporting the display panel, wherein the display panel and the supporting element are mutually connected through a first connecting element therebetween. An upper shell especially used for covering the upper edge of the display device is not used in the display device and the supporting element is used for covering the lower end or side of the display device, thereby reducing the overall thickness of the display device and reducing the frame width of the display device; and the front part of the display device is seen as an integral structure from vision, so that the appearance is beautiful.

Owner:BOE TECH GRP CO LTD

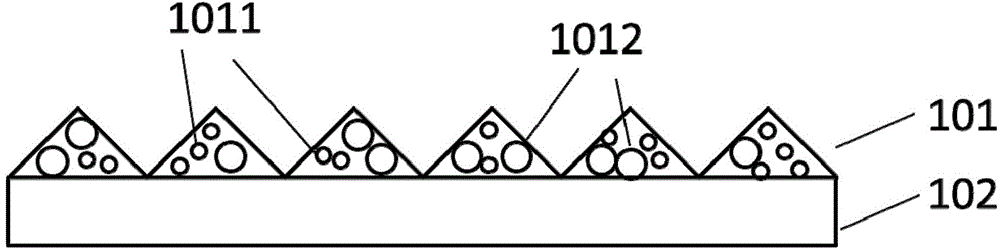

Prism film excited to emit light

ActiveCN106199789AFacilitate thinningSmall sizePrismsDiffusing elementsLiquid-crystal displayAdhesive

The invention relates to the technical field of thin film display, and particularly relates to a prism film excited to emit light. The technical problem that too many films are used in a backlight module in the prior art is solved. The thinning process of a liquid crystal display is effectively promoted. The prism film excited to emit light comprises a transparent substrate layer and an adhesive layer which is adhered to one surface of the transparent substrate layer. The adhesive layer comprises an adhesive and a material which is excited to emit light, wherein the material excited to emit light is dispersed in the adhesive. The surface of the adhesive layer has a regular microstructure. The prism film excited to emit light has the optical functions of excited light emission, light diffusion, brightness enhancement and the like; and the amount of films used in the display backlight module can be reduced.

Owner:NINGBO EXCITON TECH

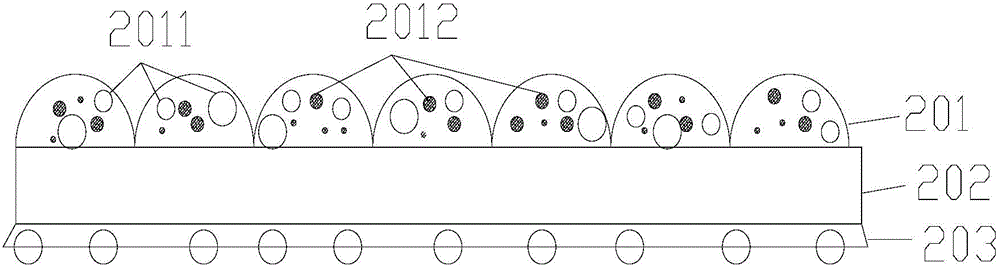

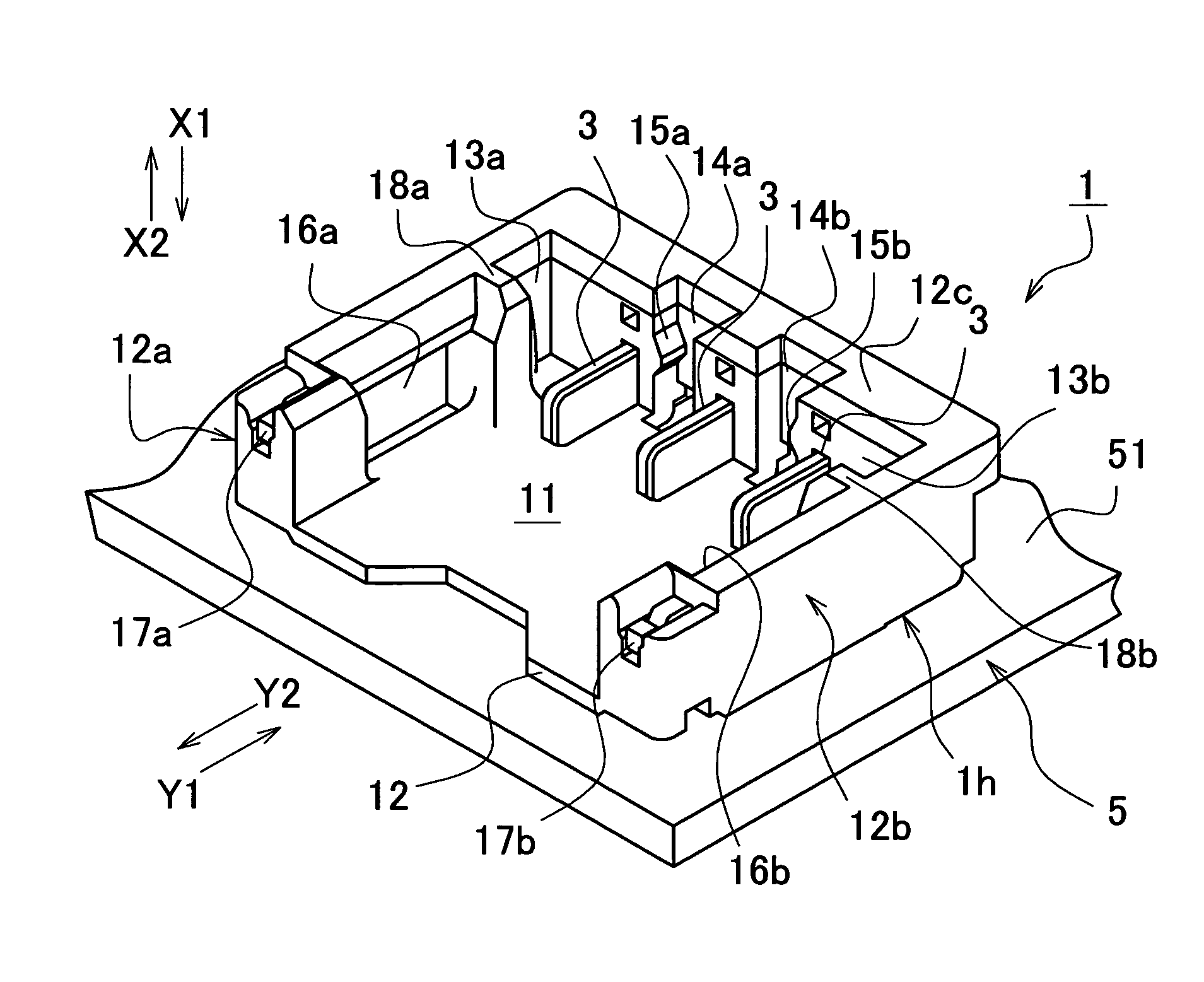

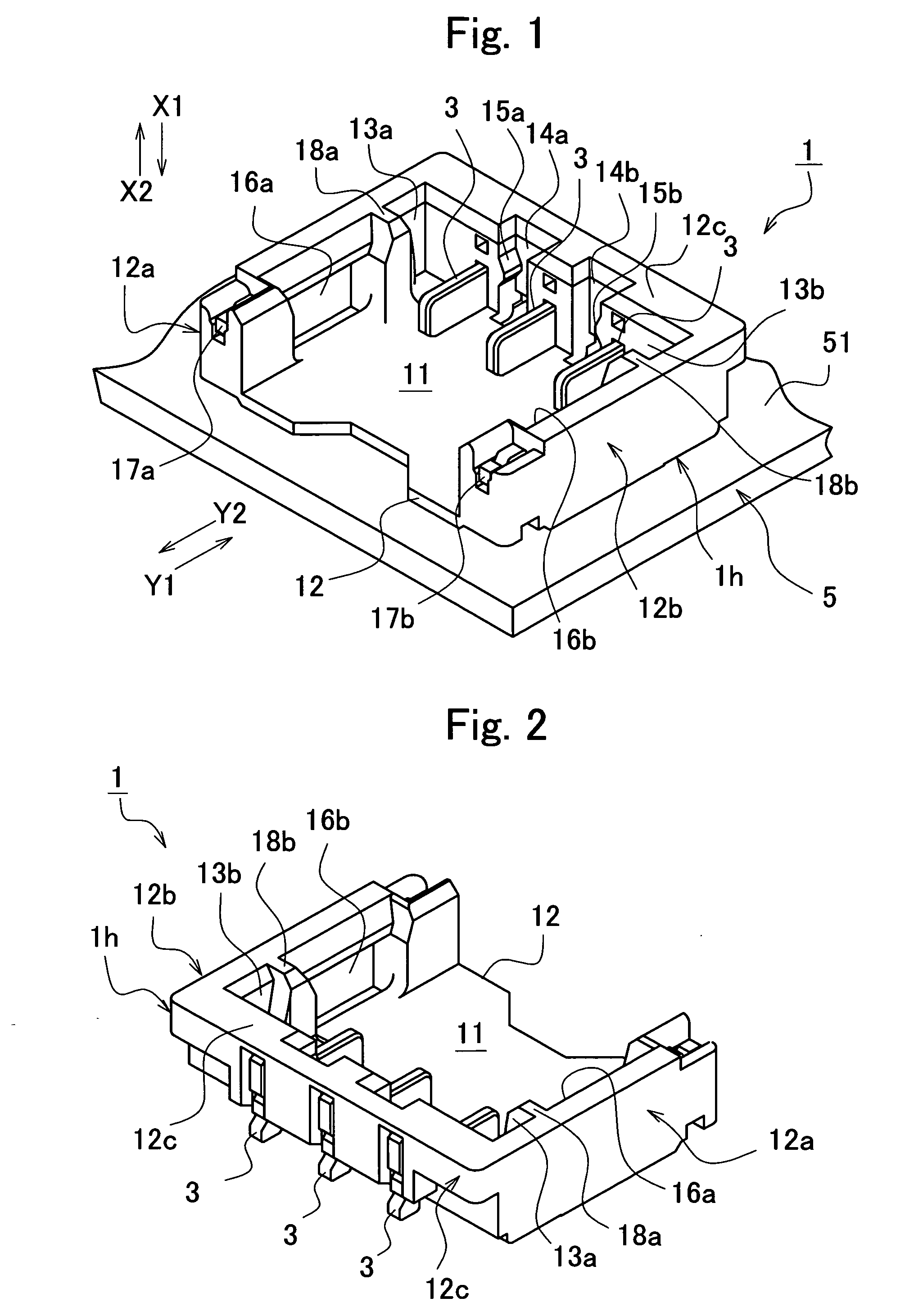

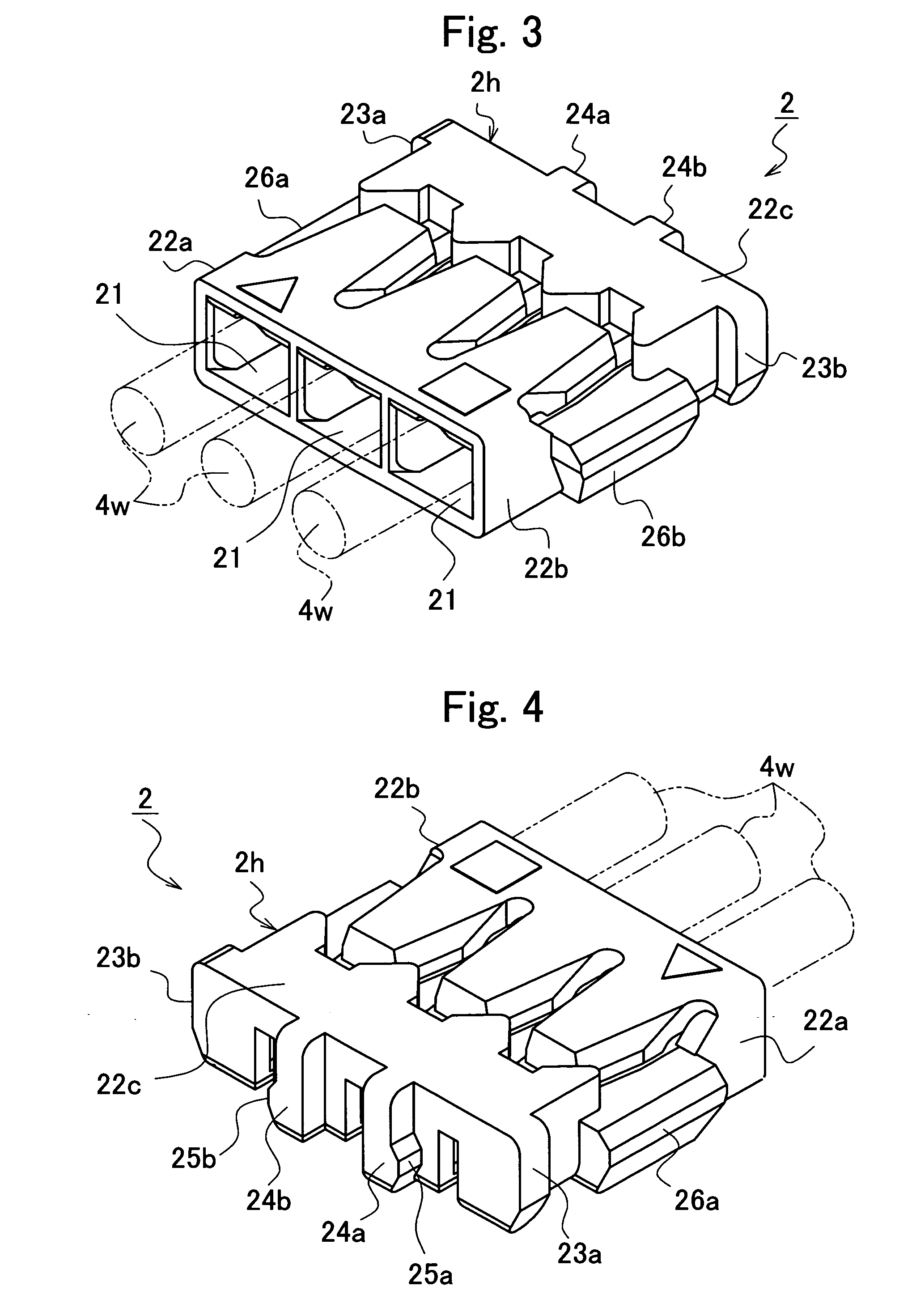

Electrical connector

ActiveUS7118424B2Increase freedomPrevent movementElectrically conductive connectionsElectric discharge tubesLocking mechanismEngineering

An electrical connector comprises: a base connector having a base housing and fixed to a print board, the base housing defining a recess having a plurality of plane opponent contacts; a socket connector having a socket housing that houses a plurality of socket contacts to be connected with the opponent contacts, the socket connector inserted into and removed from the recess; a plurality of lead wires extending in a direction substantially parallel to an attachment face of the print board; a pair of first locking mechanisms provided with the base housing and the socket housing, respectively, the first locking mechanisms engaging each other in a direction perpendicular to the direction of extension of the lead wires; and a pair of second locking mechanisms provided with the base housing and the socket housing, respectively, the second locking mechanisms engaging each other in a direction opposite the direction of extension of the lead wires.

Owner:JST MFG CO LTD

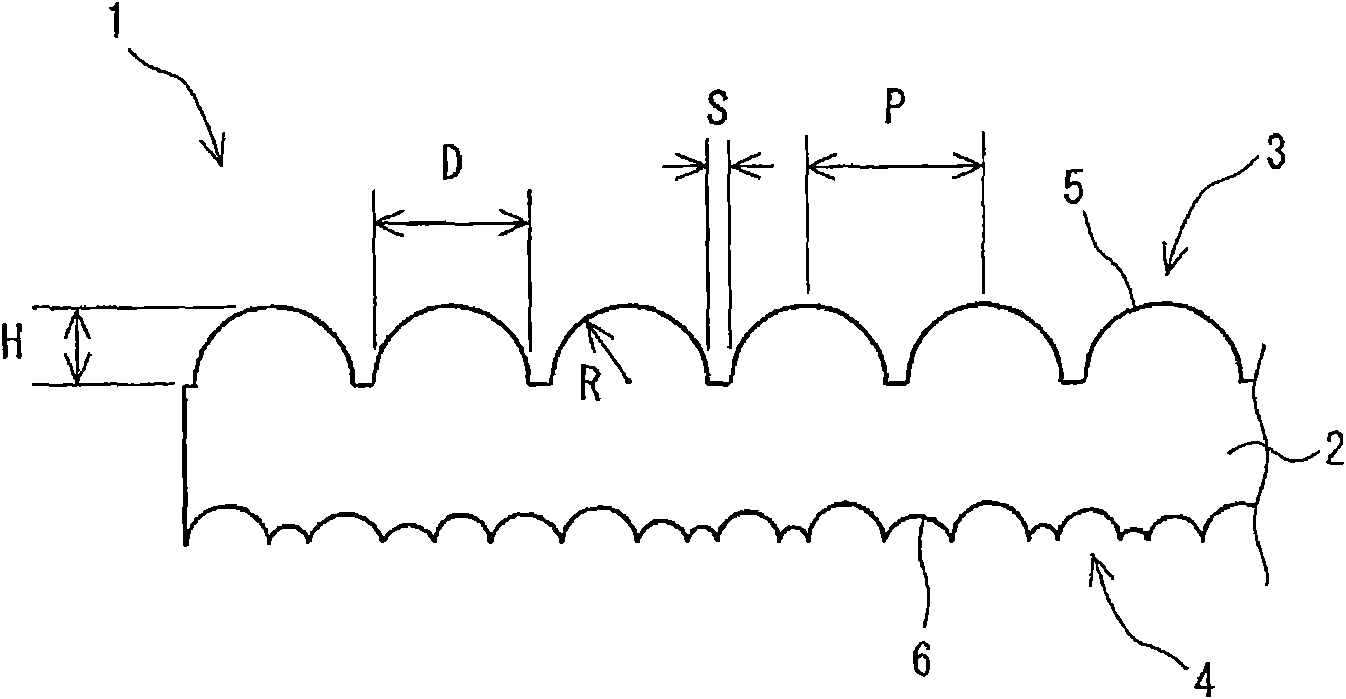

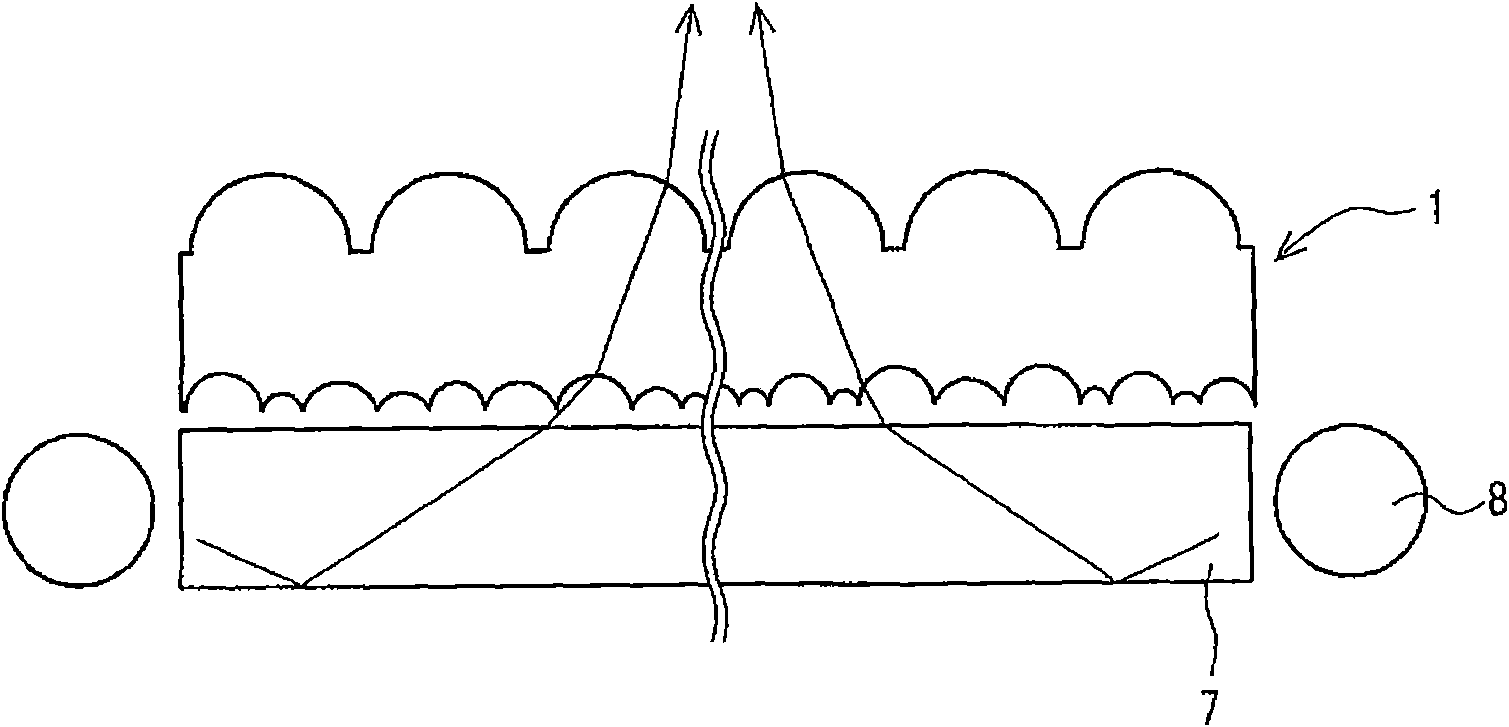

Optical sheet for liquid crystal display apparatus and backlight unit using the same

ActiveCN101793379AGood optical performanceExcellent light diffusion performanceNon-linear opticsLensVisual field lossLiquid-crystal display

The objective of the invention is to provide an optical sheet for liquid crystal display apparatus and a backlight unit suing the same. The optical sheet for liquid crystal display apparatus has excellent optical functions, specifically optical diffusion function; the backlight unit optimizes visual field angle, removes lamp source images, becomes thinner, and also hoists the like qualities. The invention is an optical sheet for liquid crystal display apparatus, which has a transparent substrate layer and a microlens array, wherein the microlens array is composed of a plurality of microlens formed by the substrate surface and back face, wherein the back microlens can be a concave lens, the back microlens array is preferably composed of a plurality of microlens with random diameter, the average radius of the surface microlens can be from 3[mu]m to 90[mu]m. In addition, the average radius of the back microlens is from 2[mu]m to 10[mu], and is about 1 / 12 to 1 of the average radius of thesurface microlens.

Owner:KEIWA INCORPORATED

Woofer and electronic device applying same

The invention discloses a woofer comprising a round flat-panel-shaped vibrating diaphragm, the vibrating diaphragm comprises a rigid ball top located at the center position and a ring folding part located at the edge position, and the ball top is of a flat-panel-shaped structure. The woofer further comprises an outer shell, the vibrating diaphragm is combined on the upper lateral face of the outer shell, wherein a plurality of voice coils arranged in a distributed mode are combined on the surface, close to the outer shell, of the vibrating diaphragm, the voice coils drive the vibrating diaphragm to vibrate in a balanced mode, each voice coil corresponds to an independent magnetic circuit system, and the magnetic circuit systems are contained and fixed in the outer shell. According to the structure, the thickness of the woofer is reduced, and therefore the woofer of the structure can be applied to thin-type electronic devices and is favorable for thinning of the electronic devices.

Owner:GOERTEK INC

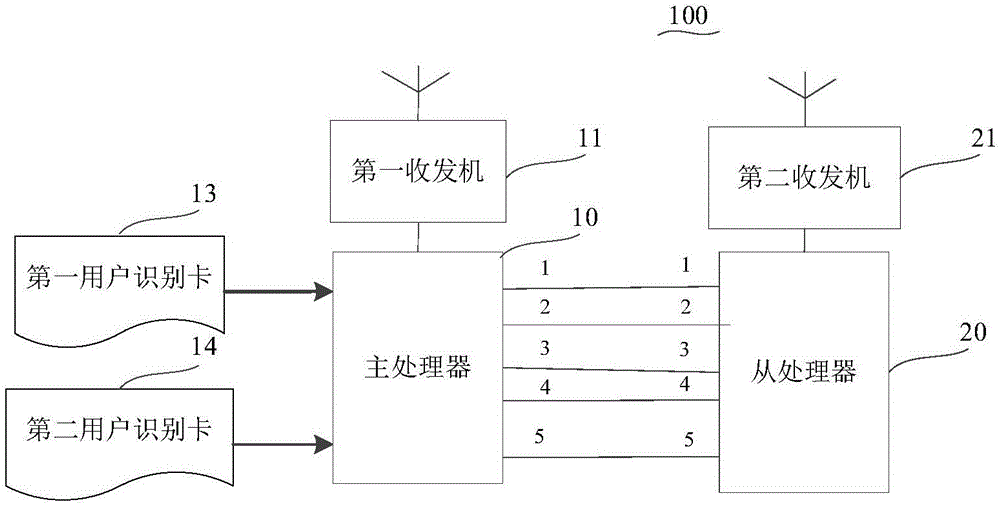

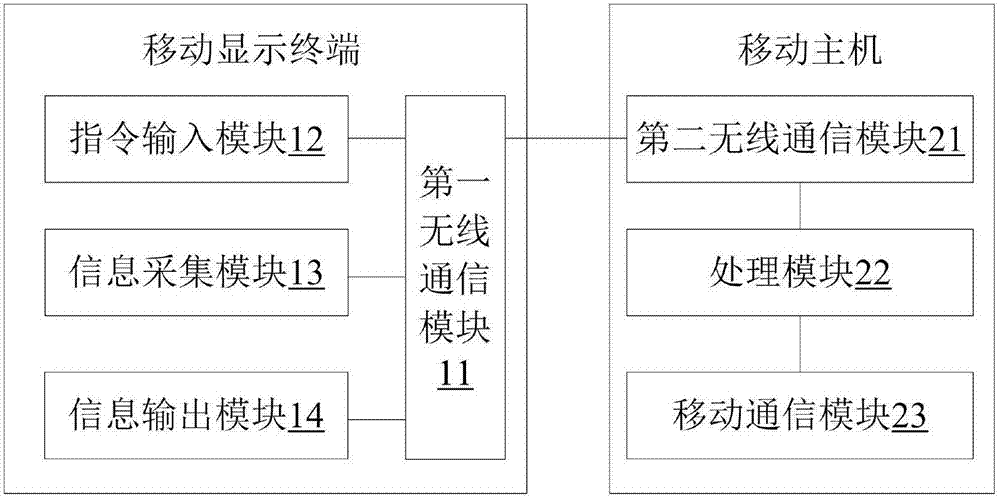

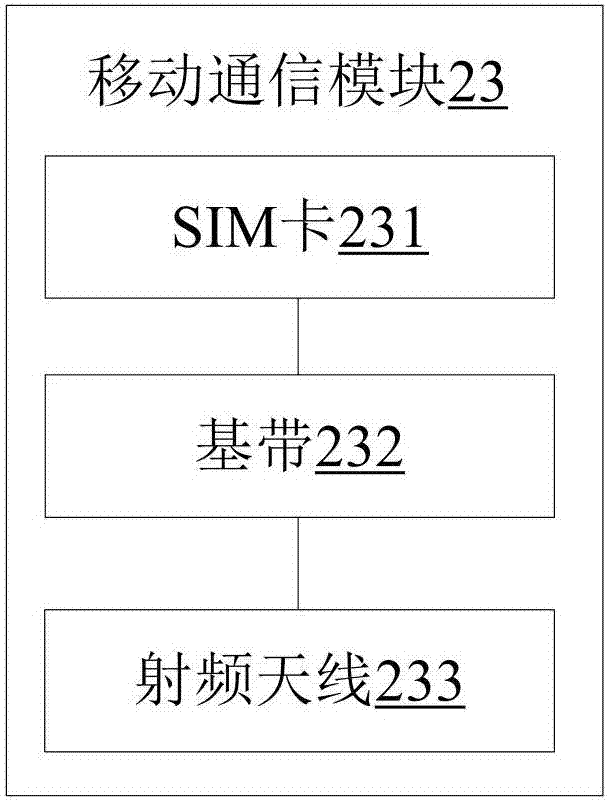

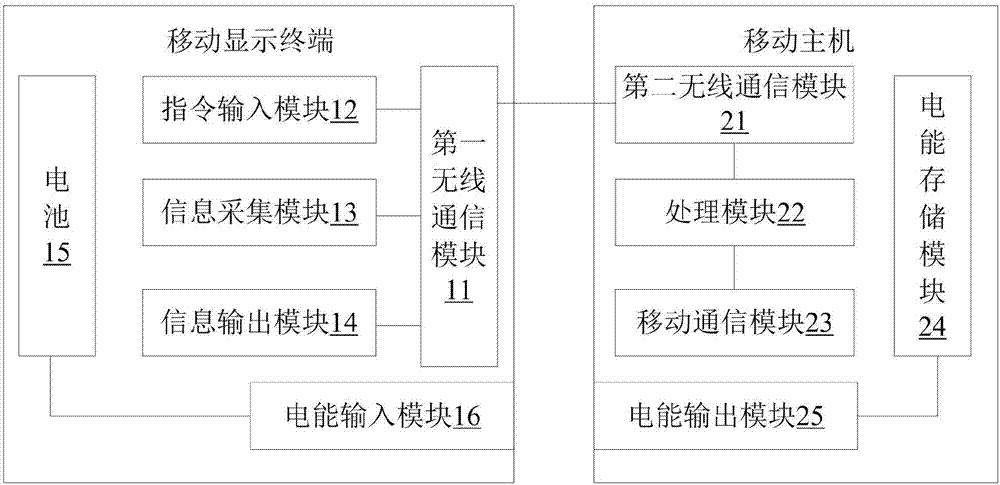

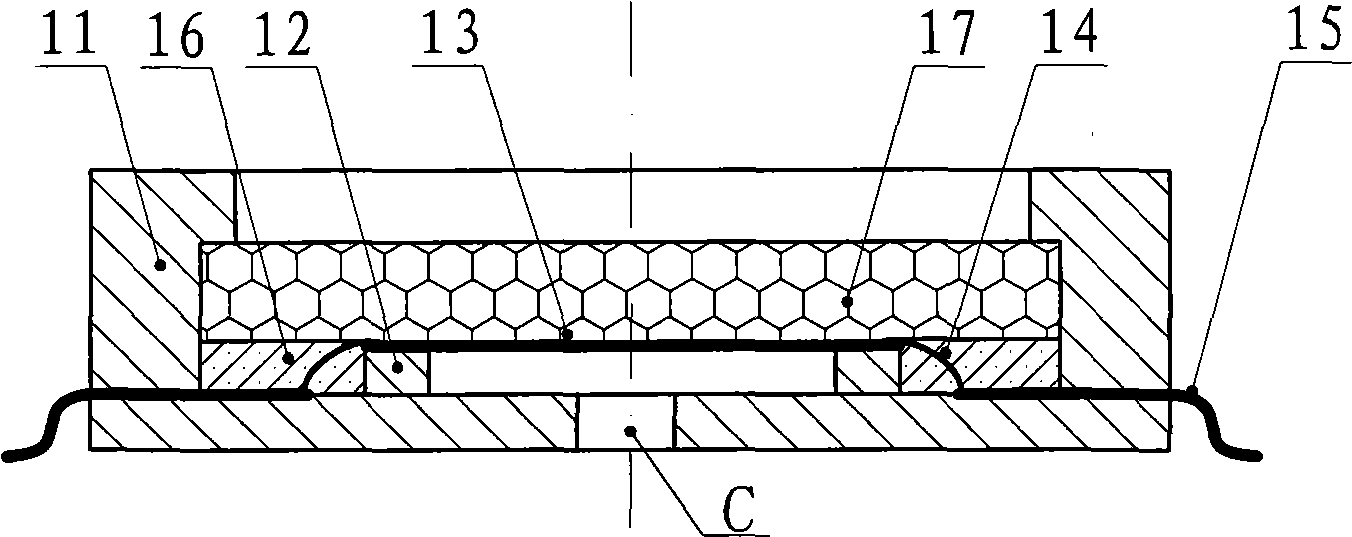

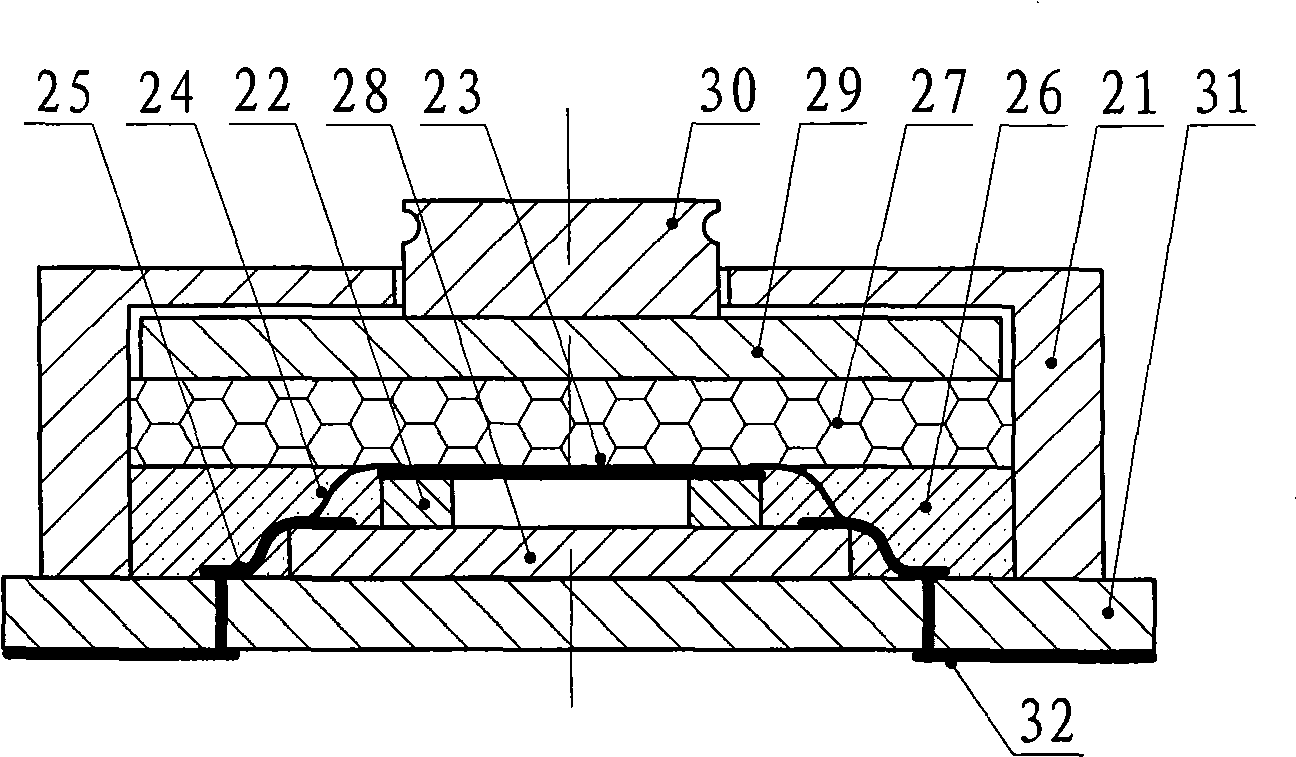

Separate communication device and mobile host

InactiveCN107070478AReduce power consumptionImprove battery lifeTransmissionTelephone set constructionsComputer moduleComputer terminal

The invention discloses a separate communication device and a mobile host. The device comprises a mobile display terminal and a mobile host, the mobile display terminal comprises a first wireless communication module, and an instruction input module, an information collection module and an information output module connected with the first wireless communication module, the mobile host comprises a second wireless communication module, a processing module and a mobile communication module, which are connected in sequence, and the first wireless communication module communicates with the second wireless communication module. The existing mobile terminal is set into the mobile display terminal and the mobile host, only necessary components of user interaction are arranged in the mobile display terminal handheld operated by a user, and an SIM card, a base band, a radio frequency antenna, a processing module, a memory and other power consumption components and parts of the mobile communication module are omitted, thereby greatly reducing the power consumption of the mobile display terminal and improving the cruising ability of the mobile display terminal and the lighting and thinning of a battery, and thus the lighting and thinning design of the mobile display terminal is facilitated.

Owner:SHENZHEN WATER WORLD CO LTD

Force sensor

InactiveCN101532889AMiniaturizationFacilitate thinningTelevision system detailsSemi-permeable membranesElectricityCapacitance

The invention relates to a force sensor, in particular to a microminiature force sensor, comprising a shell, a pressure-sensing element, a force coupling medium; wherein, the force coupling medium is made of flexible material and is not bonded with the pressure-sensing element and the inner wall of the shell; insulation material is cured around an electricity in-out bonding lead wire of the pressure-sensing element; a thin film is arranged between the force coupling medium and the pressure-sensing element; the pressure-sensing element is a piezoresistive pressure-sensing element or capacitance pressure-sensing element; the piezoresistive pressure-sensing element is a silicon piezoresistive pressure-sensing element.

Owner:许建平

Chip and wafer integration process using vertical connections

InactiveUS7388277B2Facilitate thinningConveniently removedTransistorSemiconductor/solid-state device detailsInterconnectionEngineering

A process is described for semiconductor device integration at chip level or wafer level, in which vertical connections are formed through a substrate. A metallized feature is formed in the top surface of a substrate, and a handling plate is attached to the substrate. The substrate is then thinned at the bottom surface thereof to expose the bottom of the feature, to form a conducting through-via. The substrate may comprise a chip having a device (e.g. DRAM) fabricated therein. The process therefore permits vertical integration with a second chip (e.g. a PE chip). The plate may be a wafer attached to the substrate using a vertical stud / via interconnection. The substrate and plate may each have devices fabricated therein, so that the process provides vertical wafer-level integration of the devices.

Owner:GLOBALFOUNDRIES U S INC

Embedded touch OLED display device and manufacture method thereof

InactiveCN107272958APromote thinningSimple production processInput/output processes for data processingDisplay deviceComputer science

The invention discloses an embedded touch OLED display device and a manufacture method thereof. The device comprises an array substrate, multiple leading wires, an organic flattening layer, and a touch electrode layer, wherein the array substrate is provided with a source drain layer, the multiple leading wires and the source drain layer are arranged on the same layer, the organic flattening layer is arranged on the source drain layer and multiple leading wires and is provided with multiple through holes, and the touch electrode layer is arranged at one side, far from the array substrate, of the organic flattening layer and is connected with multiple leading wires through multiple through holes. The structure makes the embedded touch OLED display device thinner, the production process is simplified, and the production cost is saved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

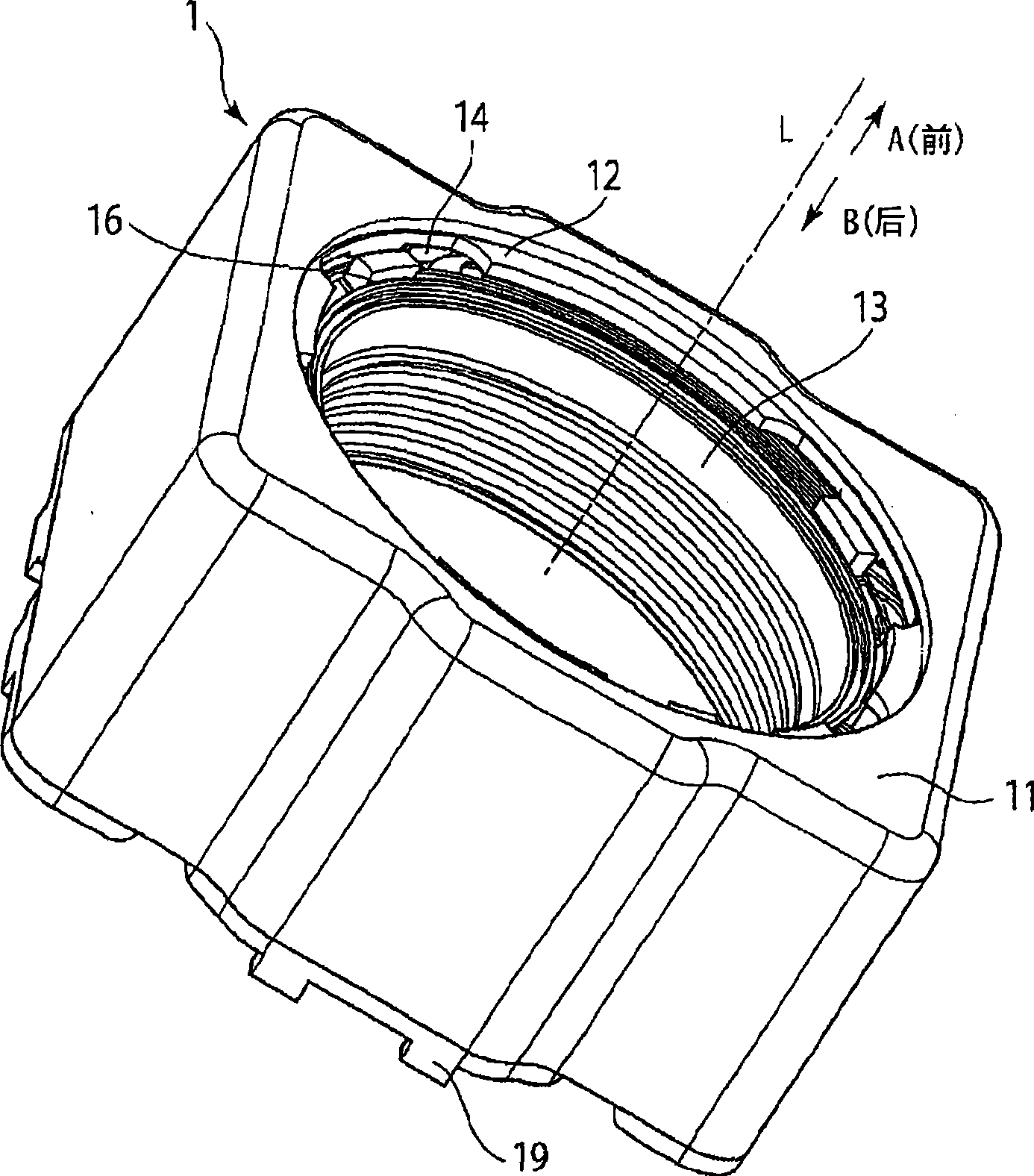

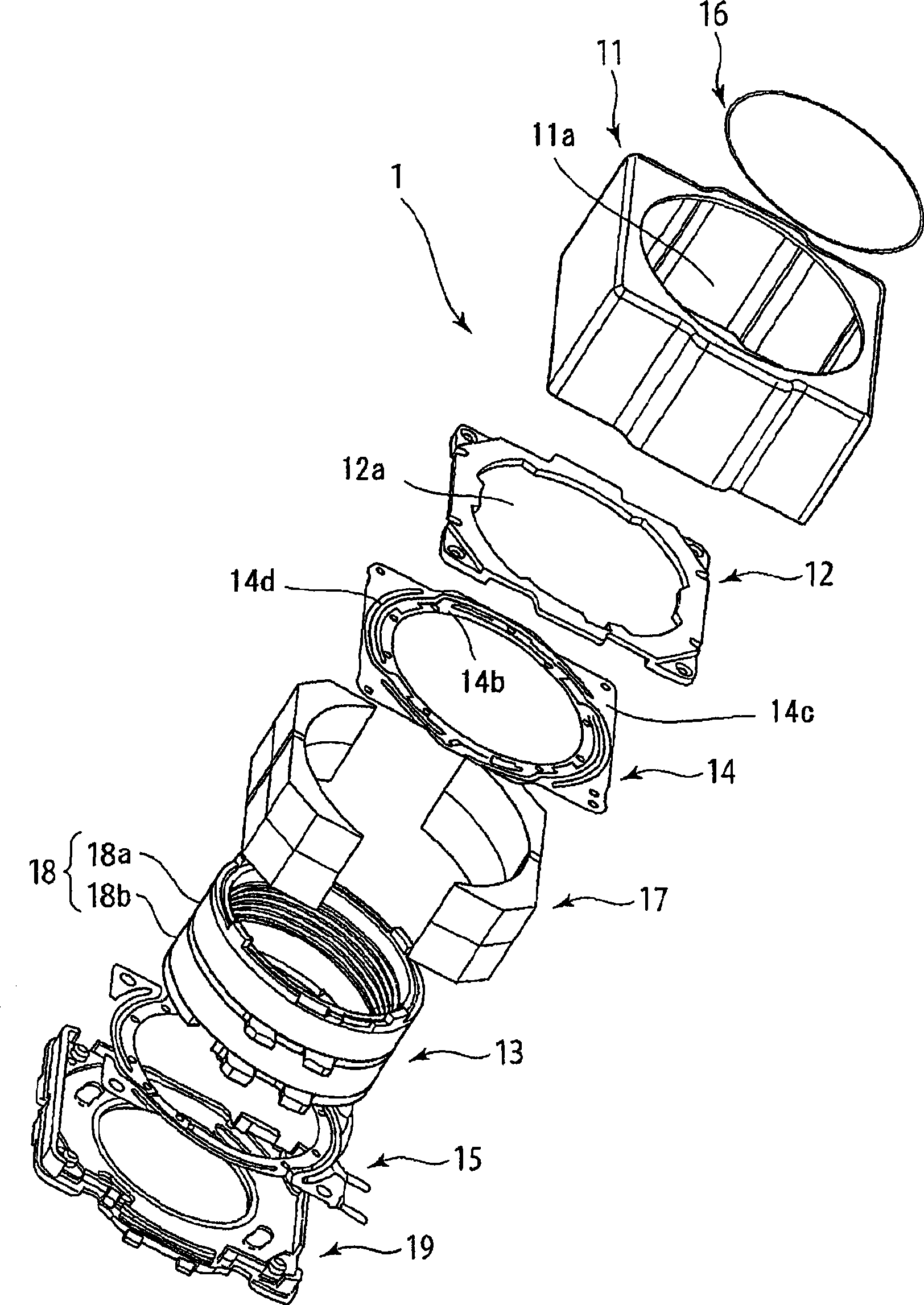

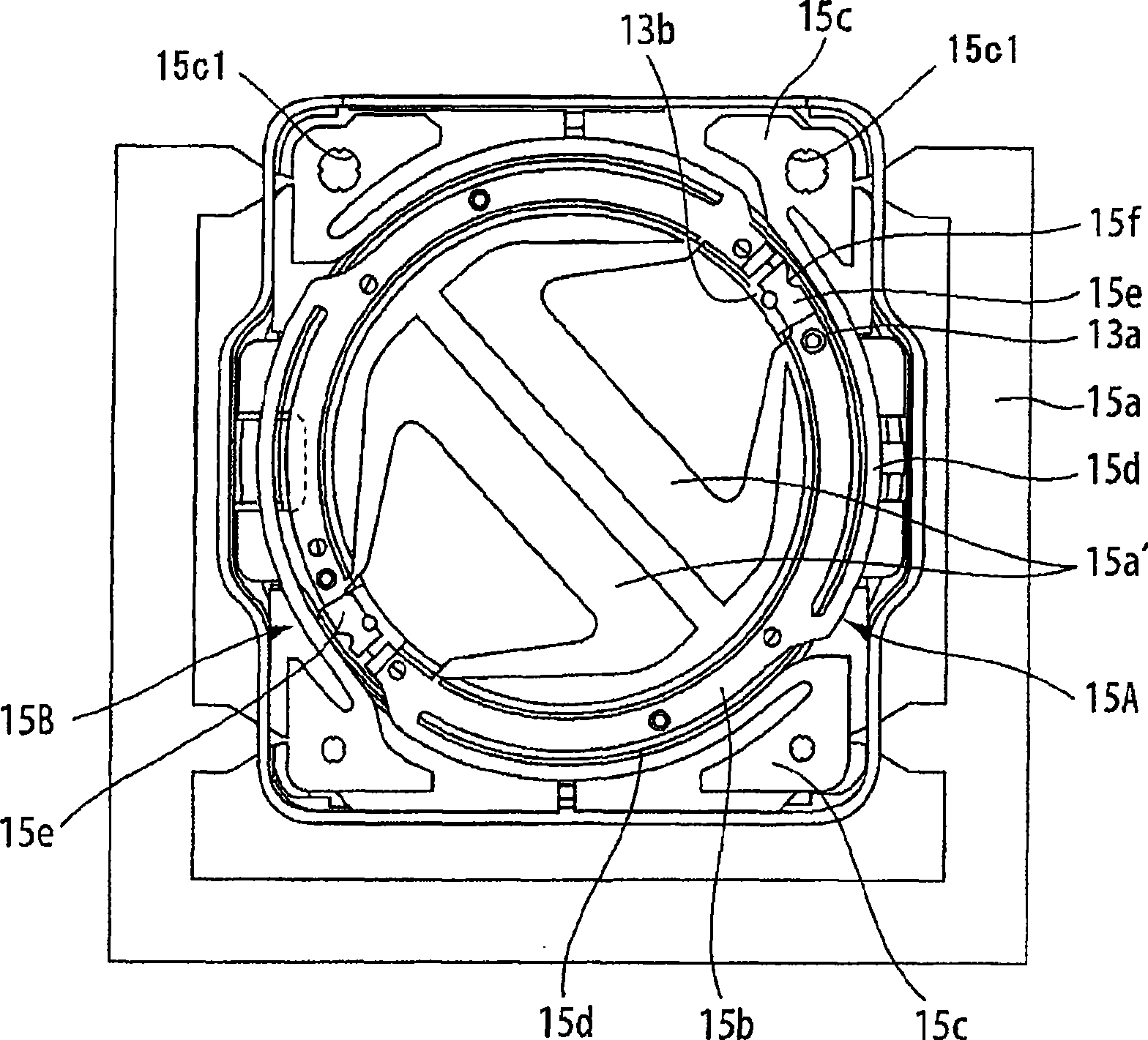

Lens drive device, spring member and manufacturing methods therefor

InactiveCN101435908AFacilitate thinningEnsure intervalDynamo-electric machinesMountingsElectricityEngineering

A lens drive device, spring member and manufacturing method thereof prevents narrow space of soldering tin of part wherein braze welding is implemented in a designed space to accelerate the device to be slim. The lens drive device (1) includes a movable body (sleeve 13) movable in an optical axis direction, a support body (maintaining element 19) supporting the movable body through a spring member and a magnetic drive mechanism having a coil (18) on the movable body and driving the movably body along the optical axis, the spring element (second plate spring) which may include spring pieces (15A, 15B) electrically separated from each other, formed with a coil connecting part (15e) to which one of a winding start part and a winding end part of the coil is electrically connected. The movablebody is provided with an accommodating part (13b) for accommodating the coil connecting part (15e) bended.

Owner:NIDEC SANKYO CORP

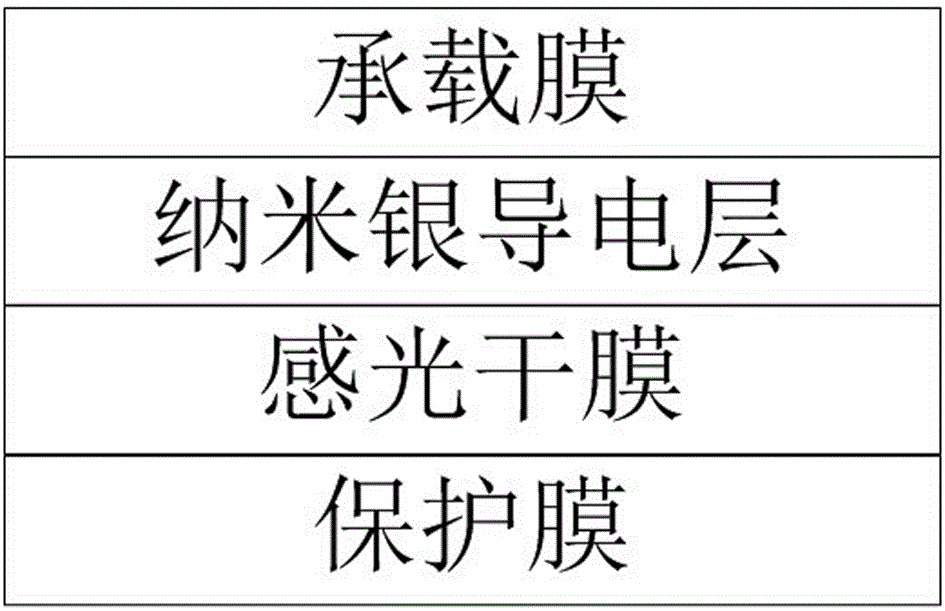

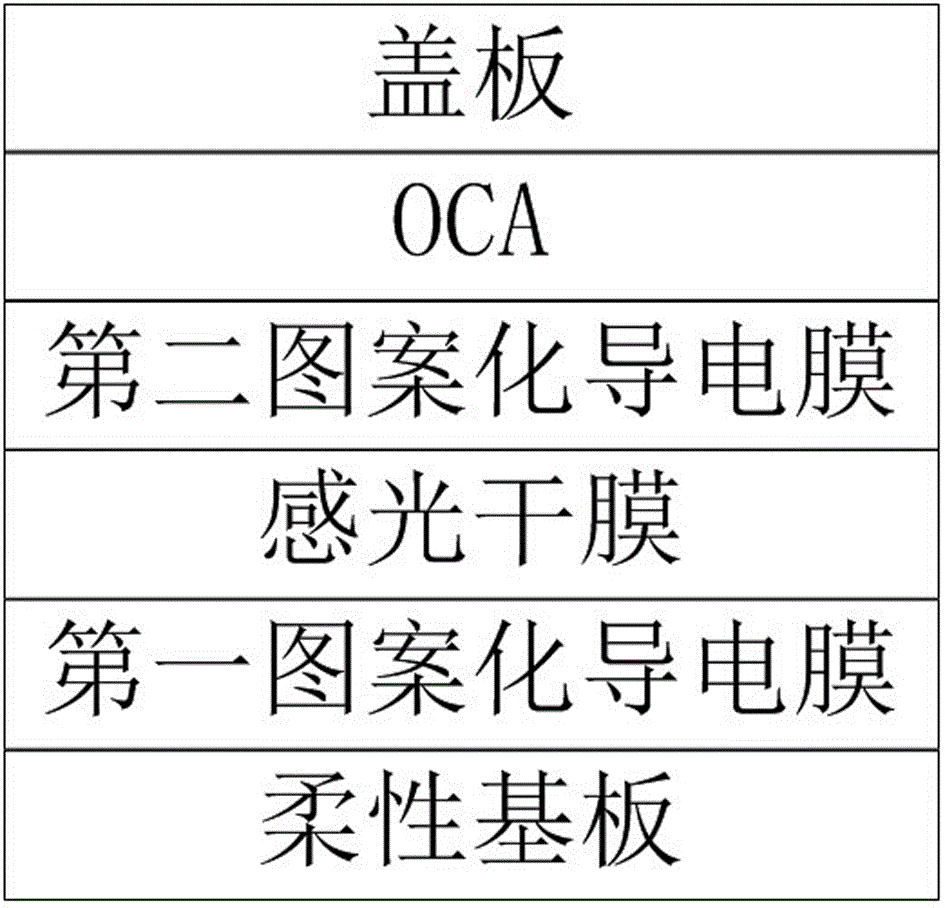

Touch screen and manufacturing method thereof

InactiveCN106020571AImprove adhesionFacilitate thinningInput/output processes for data processingBi layerEngineering

The invention discloses a touch screen and a manufacturing method thereof. The manufacturing method comprises the following steps: providing TCTF and a flexible substrate, wherein the TCTF integrates a dry film and a nano-silver conducting layer, the flexible substrate comprises a first patterned conducting film, and the conducting materials of the first patterned conducting film comprise nano-silver particles and / or nano-silver wires; relatively laminating a conducting surface of the flexible substrate with a non-conducting surface of the TCTF; carrying out exposure development on a conducting surface of the TCTF, so as to form a second patterned conducting film. According to the manufacturing method, an ultrathin touch screen structure formed by the nano-silver flexible substrate and the TCTF integrating the dry film and the nano-silver conducting layer is selected, the conducting surface of the flexible substrate is laminated with the non-conducting surface of the TCTF, a patterned conducting layer is formed after the exposure development of the conducting surface of the TCTF, and then the cambered or flexible touch screen is manufactured; a high-adhesion, thinned and bending-resistant double-layer nano-silver touch screen is manufactured, and great possibility is provided for the development of subsequent irregular, cambered or flexible products.

Owner:TRULY OPTO ELECTRONICS

Structure of an electromagnetic shield layer for a plasma display panel and method for manufacturing the same

InactiveUS20070128412A1Avoid influenceGood light transmissionElectric discharge tubesMagnetic/electric field screeningDisplay boardPlastic materials

A structure of an electromagnetic shield layer for a plasma display panel and a method for manufacturing the same. The manufacturing method of the electromagnetic shield layer uses integrated technologies of hot embossing, coating, and electroplating. The structure according to the present invention is a metal layer with an electromagnetic-wave shielding effect and is built in a plastic material. The aspect ratios of the geometric patterns on the metal layer are above 75%.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com