Prism film excited to emit light

A technology of stimulated light emission and prism film, which is applied in the direction of prisms and diffusion elements, can solve the problem of excessive film usage, achieve broad market prospects, promote the production of large-size displays, and achieve the effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

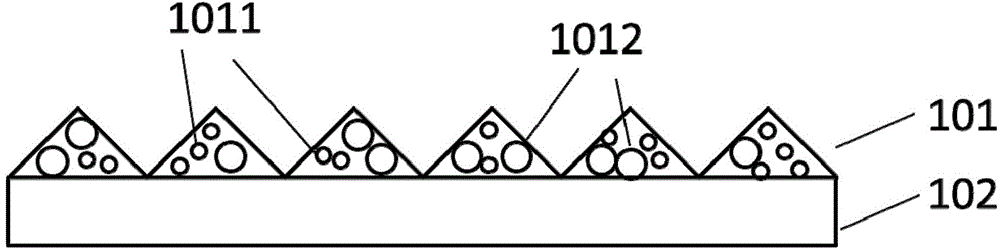

[0049] The invention provides a prism film for excited light, the prism film includes an adhesive layer with a microstructure and a transparent substrate layer, the adhesive layer includes 100 parts by weight of acrylic resin, 10 parts by weight of yellow fluorescent powder (ingredient: aluminate, particle size: 10-15 μm), 15 parts by weight of yellow light quantum dots (ingredient: CdSe, particle size: 4-6 nm) and 40 parts by weight of diffusion microbeads with a particle size of 10 μm (Ingredient: PMMA). The adhesive layer has a microstructure, the microstructure is a linear triangular prism strip, the height of the prism strip is 50 μm, and the apex angle is 90°. The transparent substrate is PET with a thickness of 250 μm. There is a protective coating on the lower surface of the prism film, the material of the protective coating is polyurethane resin, the thickness of the coating is 8 μm, and there are irregular protrusions of 3 μm on the coating.

Embodiment 2

[0051] The invention provides a prism film for excited light, the prism film includes an adhesive layer with a microstructure and a transparent substrate layer, the adhesive layer includes 100 parts by weight of acrylic resin, 30 parts by weight of yellow fluorescent powder (ingredient: aluminate, particle diameter: 8-12 μm) and 20 parts by weight of diffusion microbeads (ingredient: PMMA) with a particle diameter of 5-10 μm. The adhesive layer has a microstructure, the microstructure is a linear prism strip, the height of the prism strip is 45 μm, and the apex angle is 90°. The transparent substrate is PET with a thickness of 100 μm.

Embodiment 3

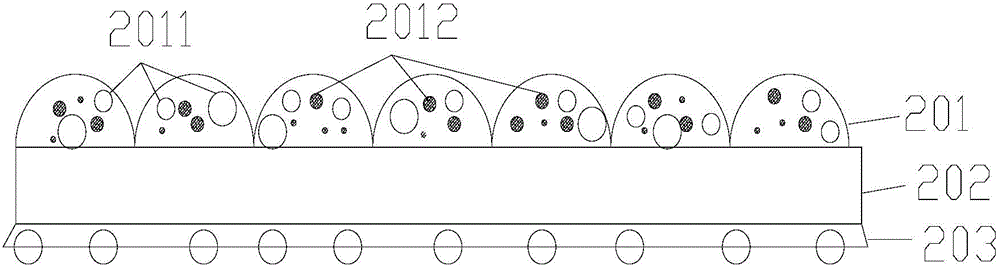

[0053] The invention provides a prism film for excited light, the prism film includes an adhesive layer with a microstructure and a transparent substrate layer, the adhesive layer includes 100 parts by weight of acrylic resin, 25 parts by weight of green fluorescent powder (ingredient: silicate, composition: 15-25 μm), 5 parts by weight of red fluorescent powder (ingredient: nitride, particle size: 10-15 μm) and 5 parts by weight of diffusion microparticles with a particle size of 3 μm Beads (Ingredient: Silicon Dioxide). The adhesive layer has a microstructure, the microstructure is a linear prism strip, the cross section of the prism strip is semicircular, the height of the prism strip is 25 μm, and the width of the prism strip is 50 μm. The transparent substrate is PET with a thickness of 150 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com