Touch screen and manufacturing method thereof

A manufacturing method and touch screen technology, applied in the direction of instruments, electrical digital data processing, input/output process of data processing, etc., to achieve the effect of improving high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for manufacturing a touch screen, which includes the following steps:

[0034] Step 1. Provide a TCTF integrating a dry film and a nano-silver conductive layer and a flexible substrate with a first patterned conductive film.

[0035] The conductive material of the first patterned conductive film is nano-silver particles and / or nano-silver wires, which are formed on the flexible substrate after etching. The flexible substrate can be an ultra-thin glass or plastic substrate. In this embodiment, it is preferably a polymer plastic substrate, and the thickness is preferably about 2-50 μm. The etching method may be yellow photoetching or laser etching.

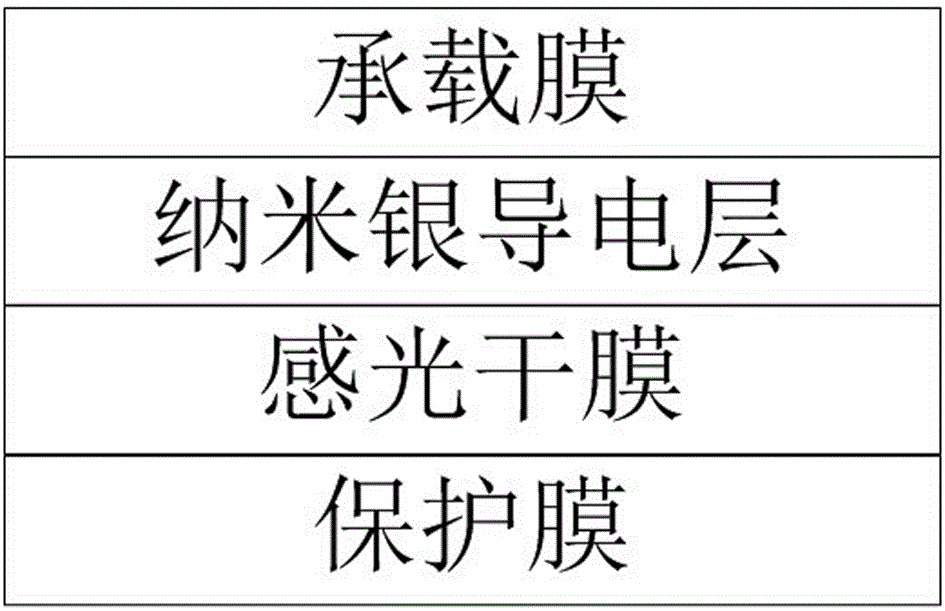

[0036] like figure 1 As shown, the TCTF includes a photosensitive dry film, a nano-silver conductive layer coated on the photosensitive dry film and cured, a carrier film positioned on the nano-silver conductive layer, and a film for protecting the photosensitive dry film. protective film...

Embodiment 2

[0046] The only difference between this embodiment and Embodiment 1 is that the manufacturing method of the flexible substrate includes the following steps:

[0047] Step A1, curing and forming a conductive film on the rigid substrate, the material for forming the conductive film is nano-silver wire and / or nano-silver particle.

[0048]After curing, the resistance of the conductive layer of the conductive film is preferably 50-80Ω / □, and the transmittance is >90%. The curing temperature of the conductive film is 120-160° C., and the curing time is 10-60 minutes. Preferably, the curing temperature is 150° C., and the curing time is 30 minutes.

[0049] The rigid substrate is a tempered or non-tempered substrate, preferably a glass substrate in the present invention.

[0050] Step A2, printing conductive silver paste on the frame of the conductive film.

[0051] Step A3, performing laser etching on the conductive film and the conductive silver paste at the same time to obtain ...

Embodiment 3

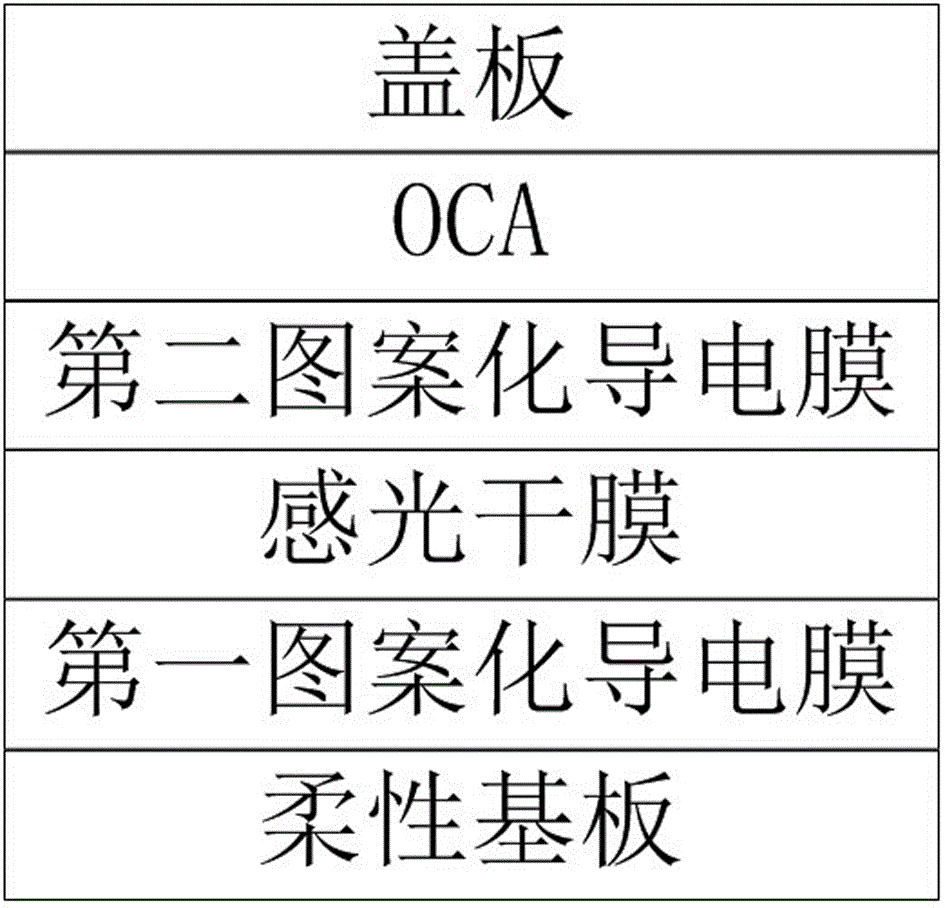

[0060] like figure 2 As shown, the present embodiment provides a touch screen, comprising: a flexible substrate having a first patterned conductive film, a TCTF integrating a dry film and a nano-silver conductive layer, the conductive surface of the flexible substrate faces the TCTF The non-conductive surface is relatively attached and bonded to the circuit board, and a second patterned conductive film is formed on the TCTF by exposure and development.

[0061] Further, the conductive material of the first patterned conductive film is nano-silver particles and / or nano-silver wires.

[0062] Further, the patterns of the first patterned conductive film and the second patterned conductive film are the same or different.

[0063] Further, the flexible substrate may be an ultra-thin glass or plastic substrate, and in this embodiment, it is preferably a polymer plastic substrate, and the thickness is preferably about 2-50 μm.

[0064] like figure 1 As shown, the TCTF includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com