Woofer and electronic device applying same

A loudspeaker and bass technology, applied in the fields of woofers and electronic devices, can solve problems such as waste, large magnet size, and excess magnet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

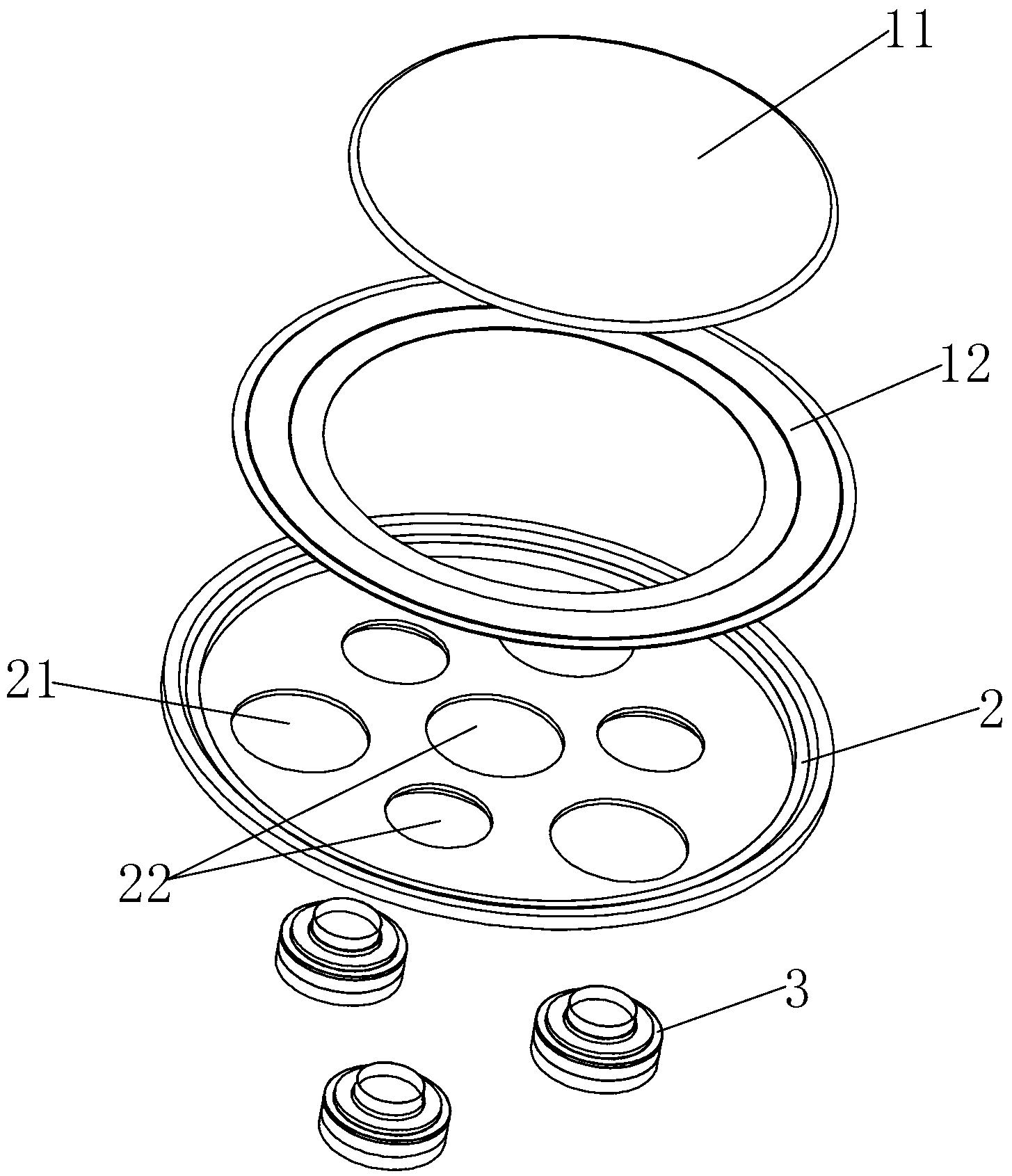

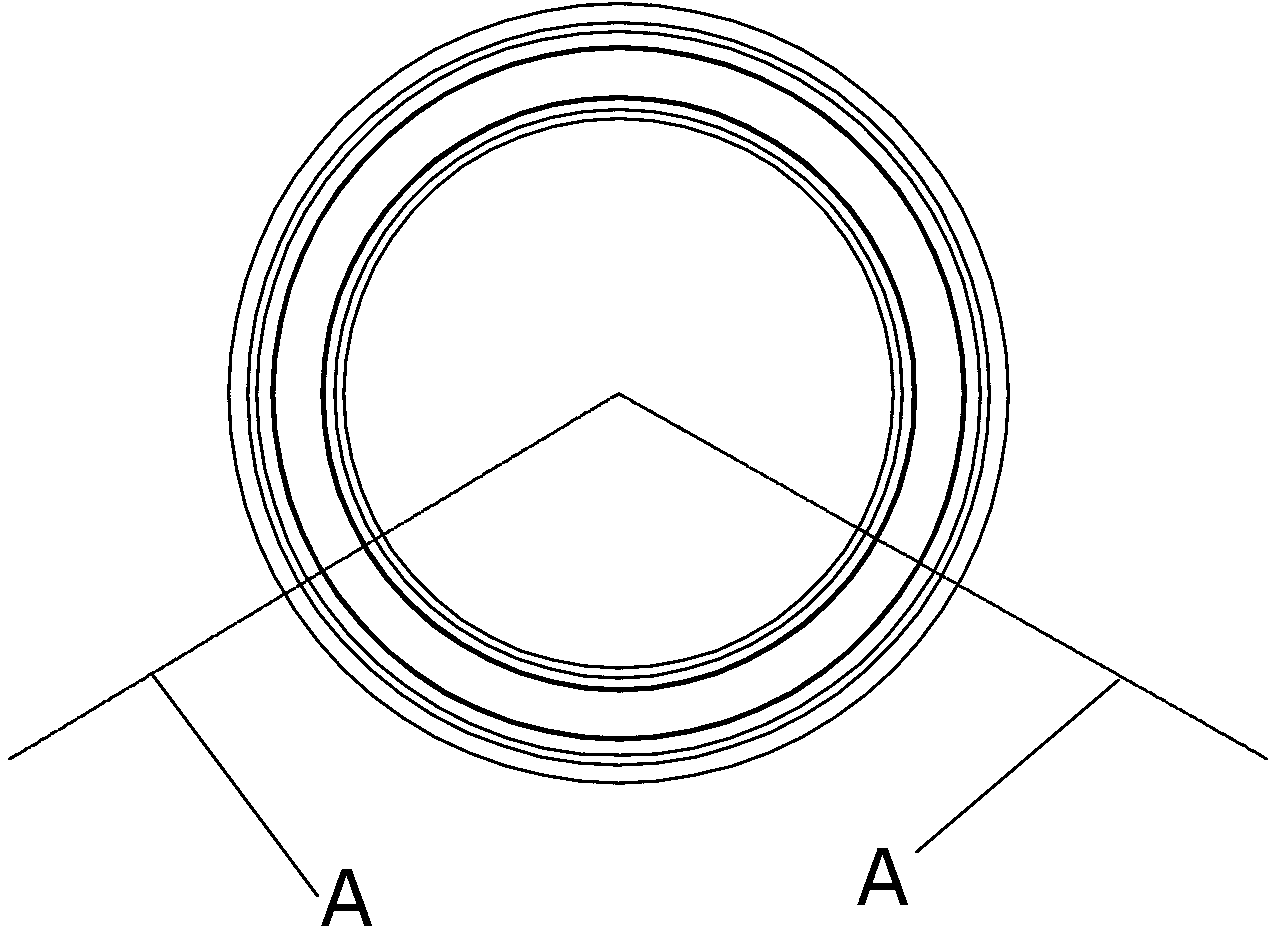

[0031] Such as Figure 1 to Figure 4 As shown, the woofer of the present invention includes a diaphragm and a drive unit combined on one side of the diaphragm, wherein the diaphragm is a circular plate-shaped structure, including a rigid ball top 11 at the center and a flexible dome at the edge. The ring part 12, the ball top 11 and the ring part 12 are fixedly combined by bonding or the like. The loudspeaker of the present invention is a subwoofer, therefore, the area of the diaphragm is relatively large to ensure the low-frequency sound effect of the product. Wherein, the diaphragm includes a plurality of drive units 3 dispersedly arranged, and each drive unit 3 includes a voice coil 31 and a magnetic circuit system for accommodating the voice coil 31 , wherein the voice coil 31 is fixedly combined with the diaphragm. It also includes a housing 2. The housing 2 includes a mounting surface for installing the magnetic circuit system and a side wall located around the mounti...

Embodiment 2

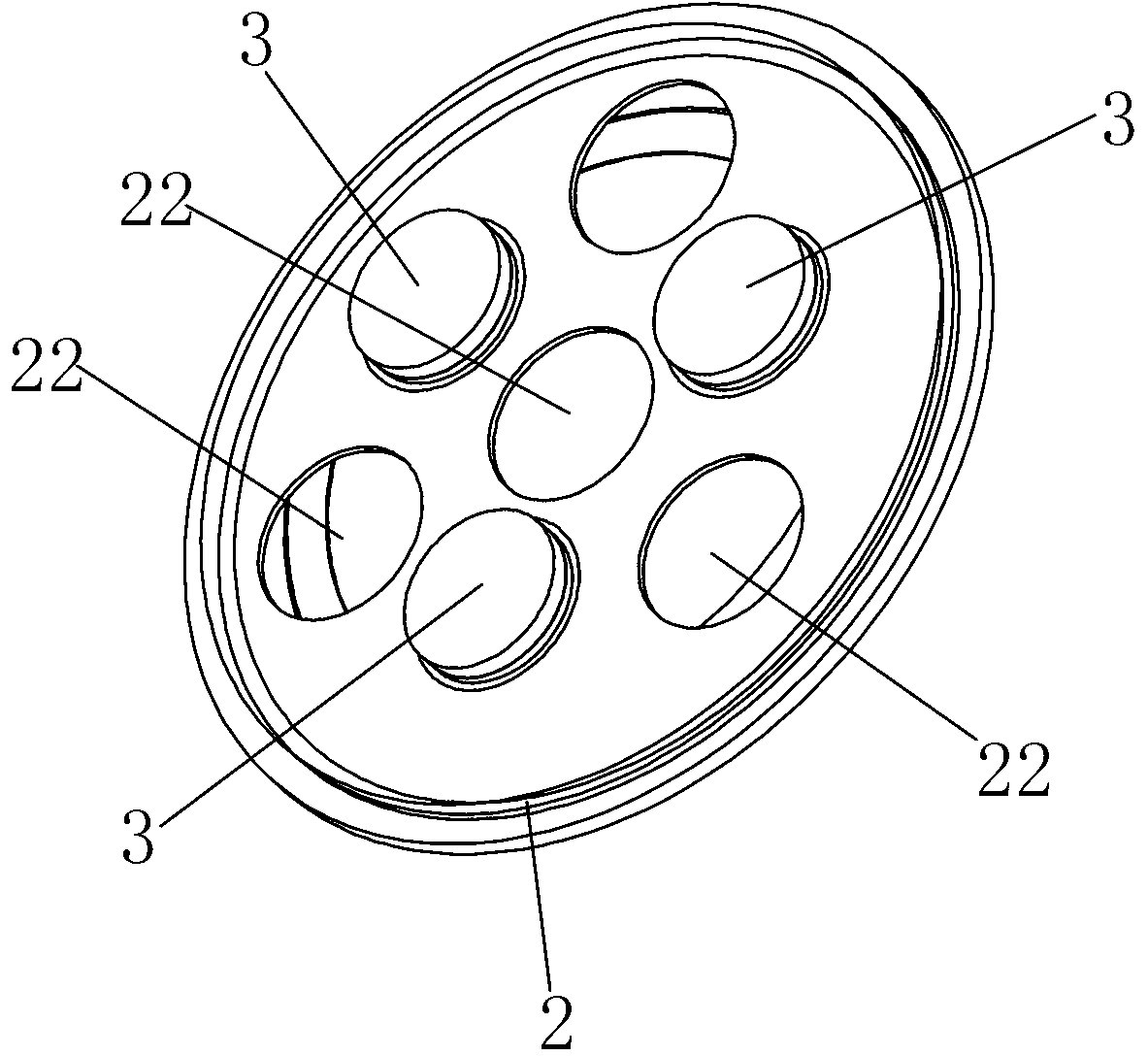

[0038] Such as Figure 6 and Figure 7 As shown, the woofer includes a diaphragm and four drive units 3 combined on the lower side of the diaphragm. Same as the previous embodiment, the diaphragm includes a rigid ball top 11 at the center and a ring portion 12 at the edge. The shell 2' is set corresponding to the drive unit 3, and has four mounting holes 21 for installing the drive unit 3. Similarly, the shell 2' is also provided with sound holes 22 communicating with the outside, and the sound holes 22 are respectively located on the shell 2' and directly opposite The position of the center of the diaphragm and between two adjacent drive units 3 . In this embodiment, the four drive units 3 are located on the same circumference and have the same distance from the center of the diaphragm circle, and the distances between two adjacent drive units 3 are equal, that is, the distance between two adjacent drive units 3 and the center of the circle is equal. The included angle is 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com