Optical sheet for liquid crystal display apparatus and backlight unit using the same

A liquid crystal display device and optical sheet technology, applied in the field of optical sheets, can solve the problems of lowering the brightness of the liquid crystal display device, hindering the thinning of the backlight unit, and the light source image erasing effect is small, and achieves enhancement optimization and excellent light diffusion function. , simple and well-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

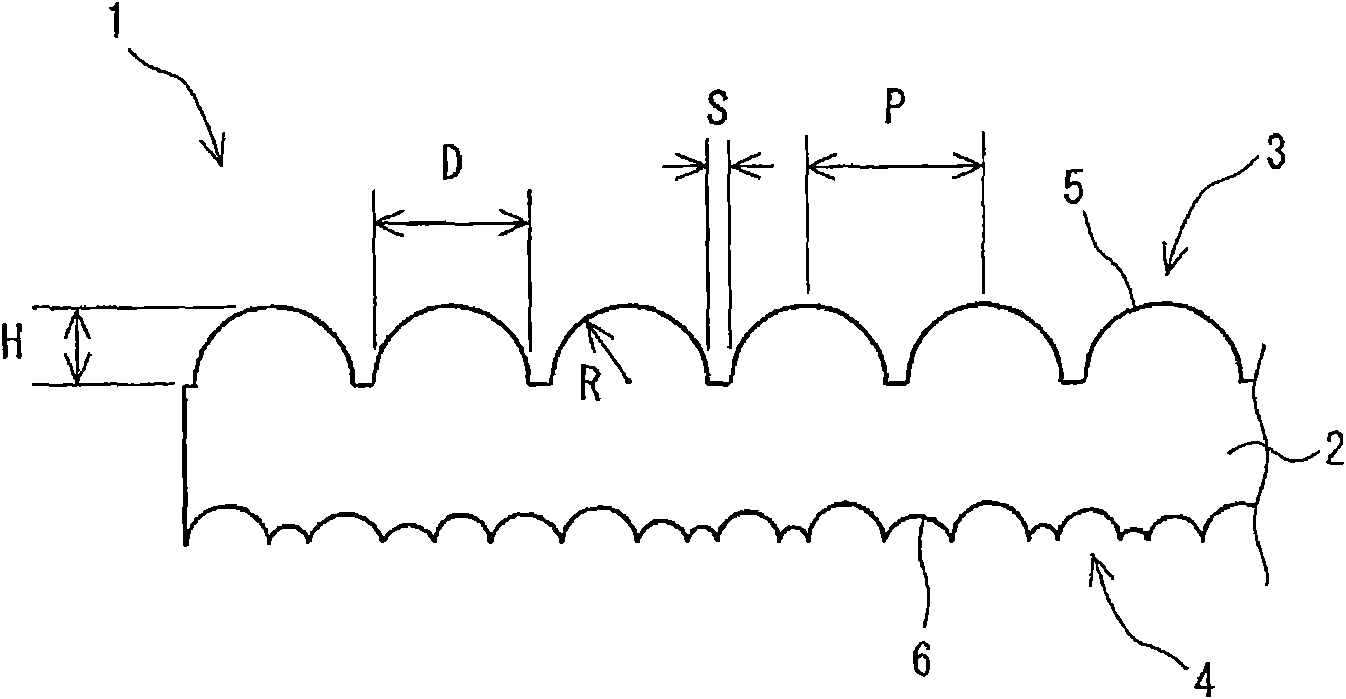

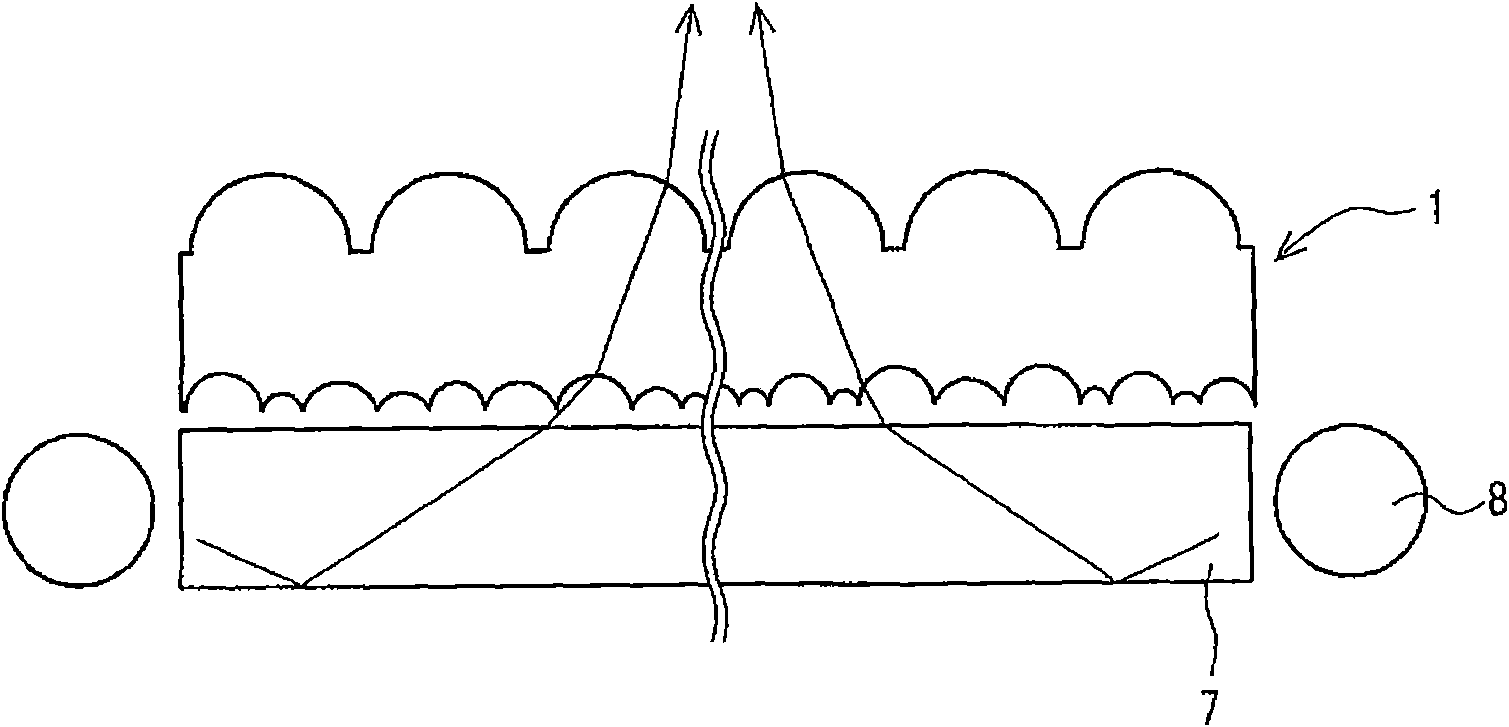

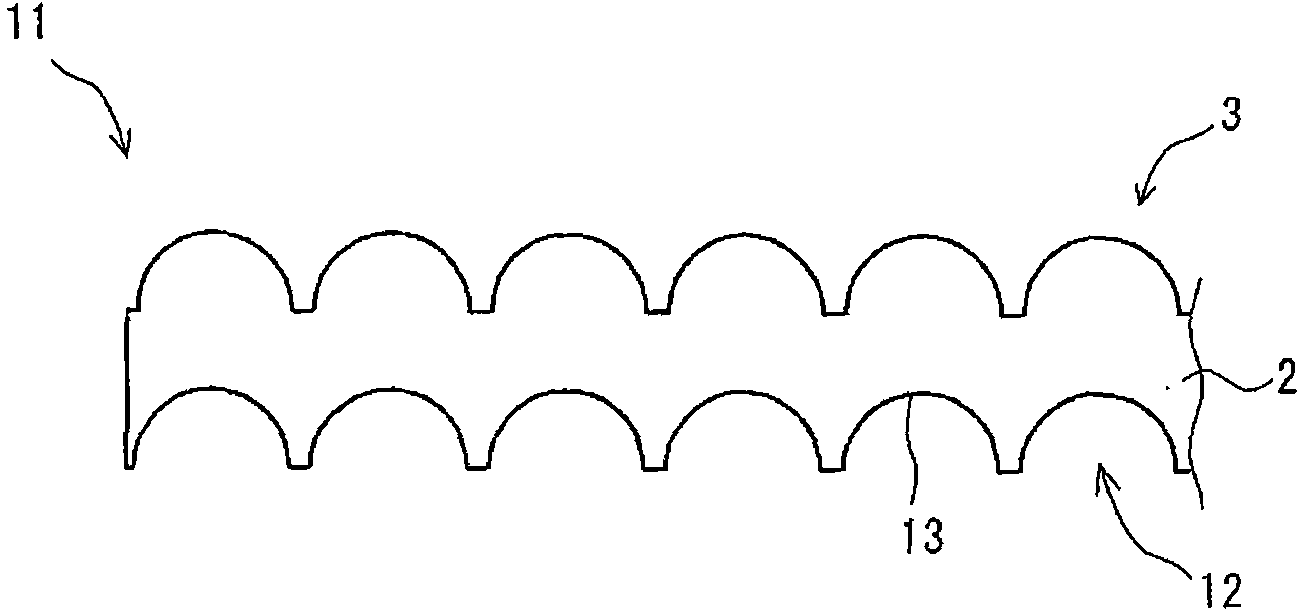

[0097] On the surface of a transparent polyethylene terephthalate film with a thickness of 100 μm, a microlens array composed of convex lens microlenses was provided, and a microlens array having the following shapes was provided on the back surface. The optical sheet for liquid crystal display devices of Example 1 was obtained by providing a microlens array composed of microlenses having concave lenses having random diameters on the back surface. The optical sheet for liquid crystal display devices of Example 2 was obtained by providing the microlens array which consists of the microlens of the concave lens which has substantially the same diameter on the back surface. The optical sheet for liquid crystal display devices of Example 3 was obtained by providing a microlens array composed of microlenses having convex lenses having random diameters on the back surface. The optical sheet for liquid crystal display devices of Example 4 was obtained by providing the microlens array ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com