Display device and backlight module thereof

By using a diffusion material layer with a transmittance of 65% to 85% in the display device and arranging multiple light sources in the reflective sheet, the problem of deformation and bending of the optical control film is solved, and the backlight module is made thinner and the optical quality is improved. , while improving the edge brightness of the display area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The invention provides a display device and a backlight module thereof with a thin design to reduce the possibility of deformation of an optical control film. Hereinafter, the details of the display device and its backlight module of the embodiment of the present invention will be described in detail with reference to the drawings.

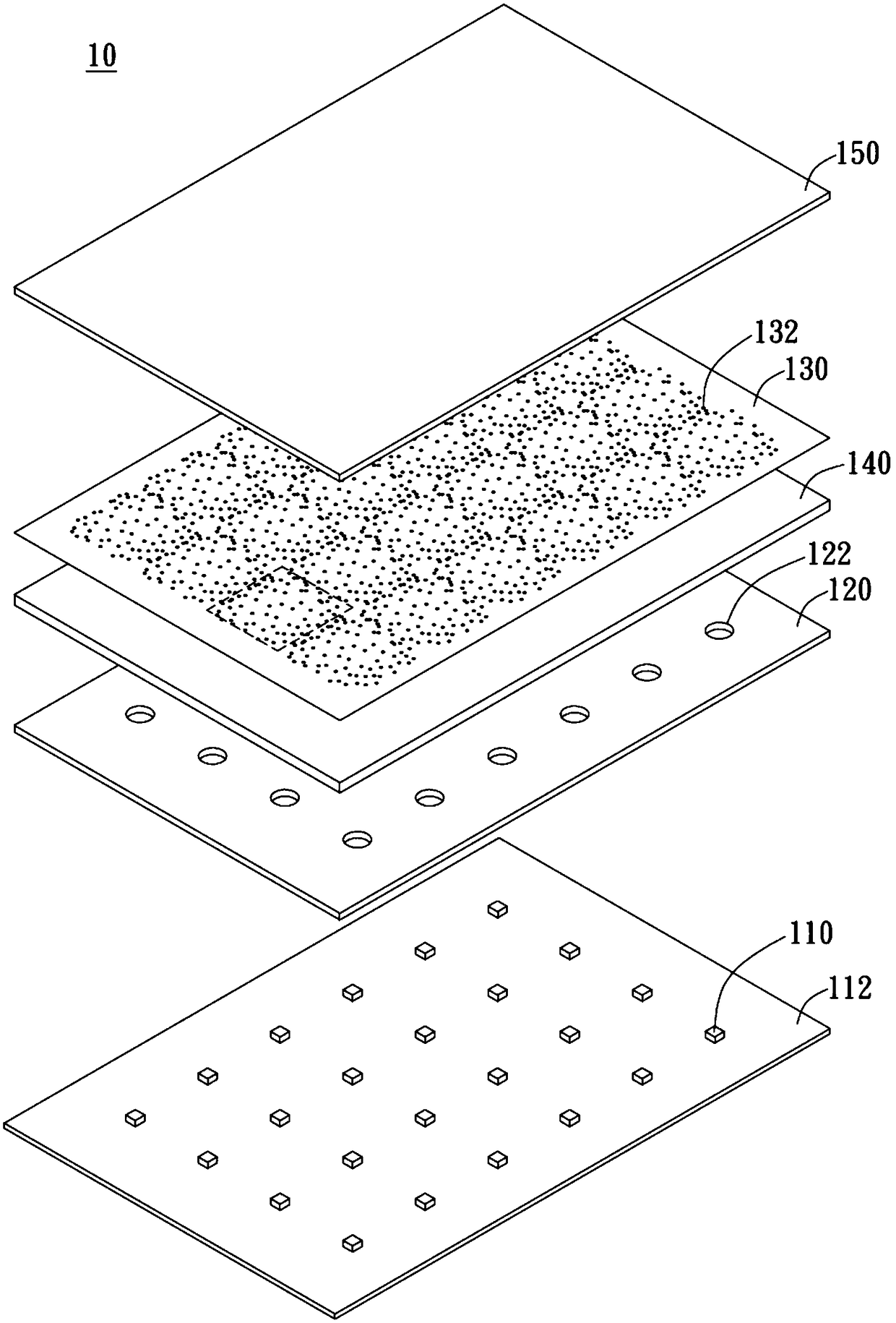

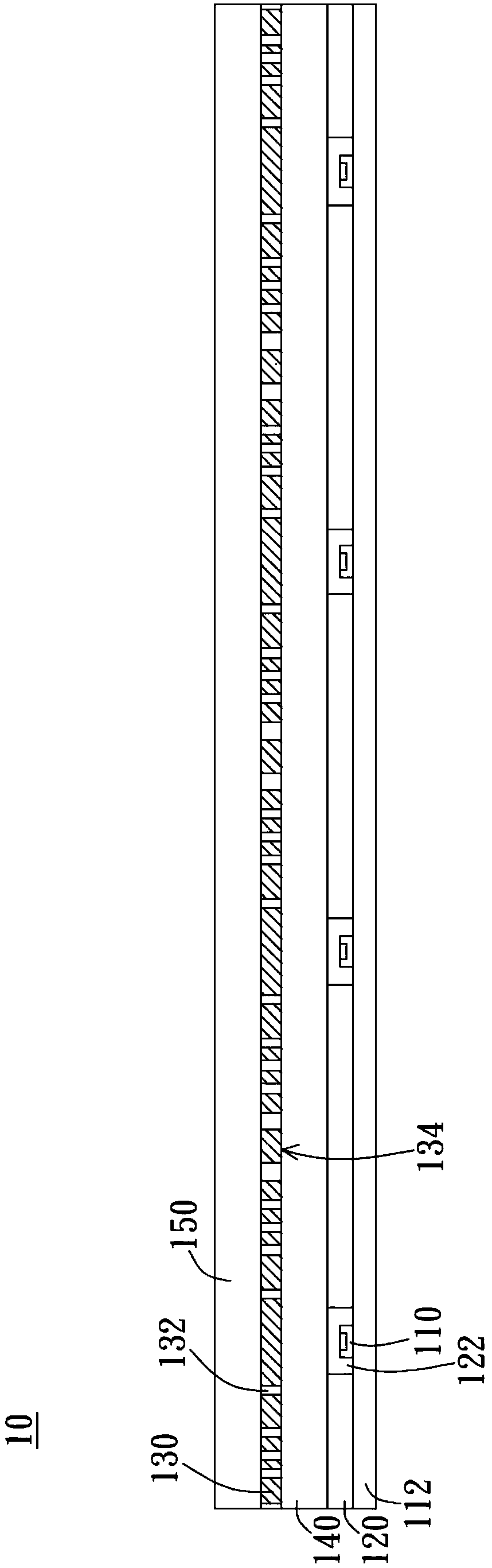

[0061] Such as Figure 1A and Figure 1B As shown, in one embodiment, the backlight module 10 includes a plurality of light sources 110, a reflective sheet 120, an optical control film 130, a diffusion material layer 140, and a diffusion plate 150. The reflective sheet 120 is arranged corresponding to the multiple light sources 110. The optical control film 130 is disposed above the plurality of light sources 110 and the reflective sheet 120, and the optical control film 130 has a plurality of light-emitting structures 132. The diffusion material layer 140 is sandwiched between the reflective sheet 120 and the optical control film 130, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com