Patents

Literature

53results about How to "Increased risk of failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

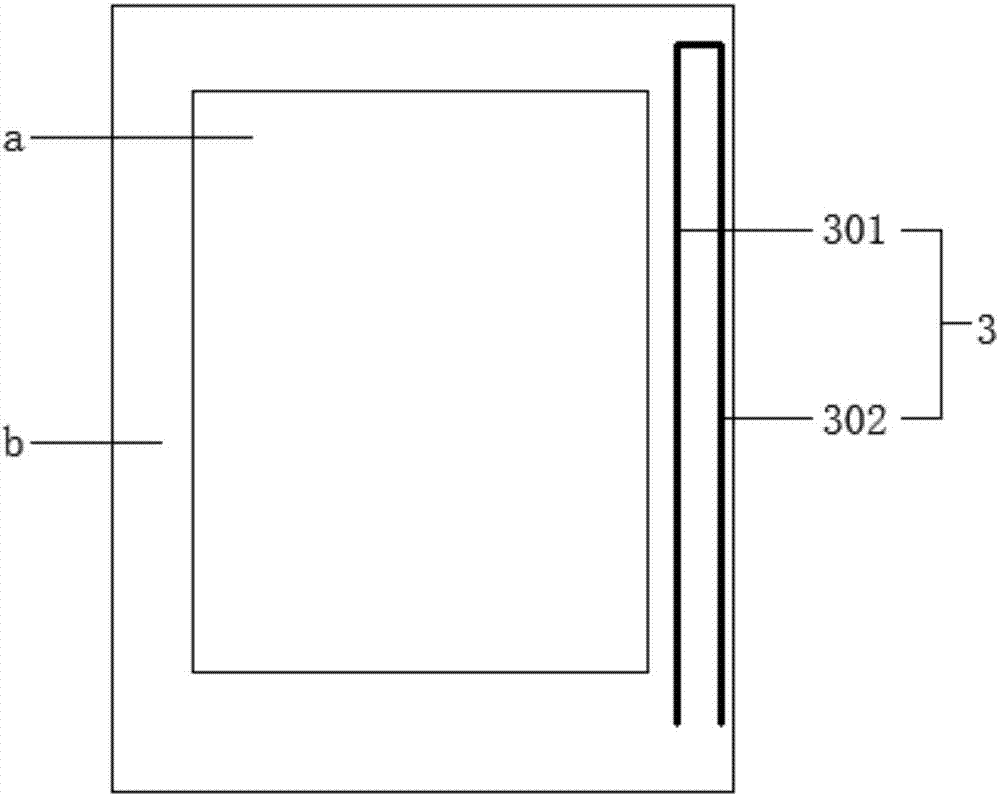

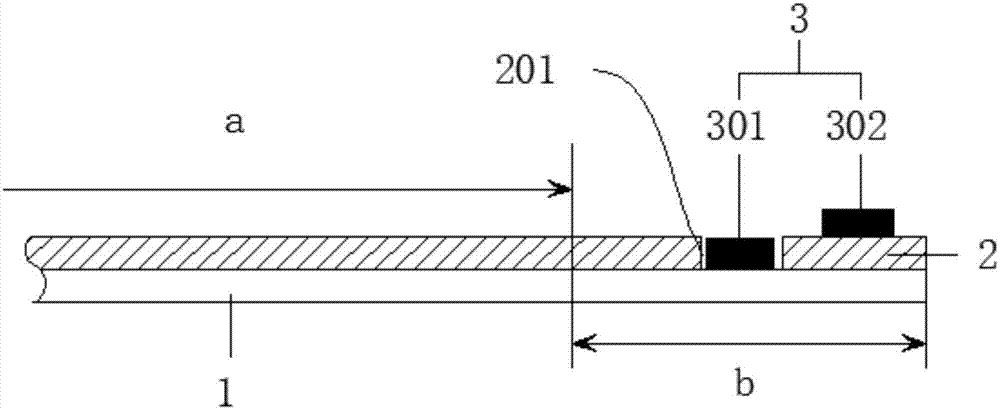

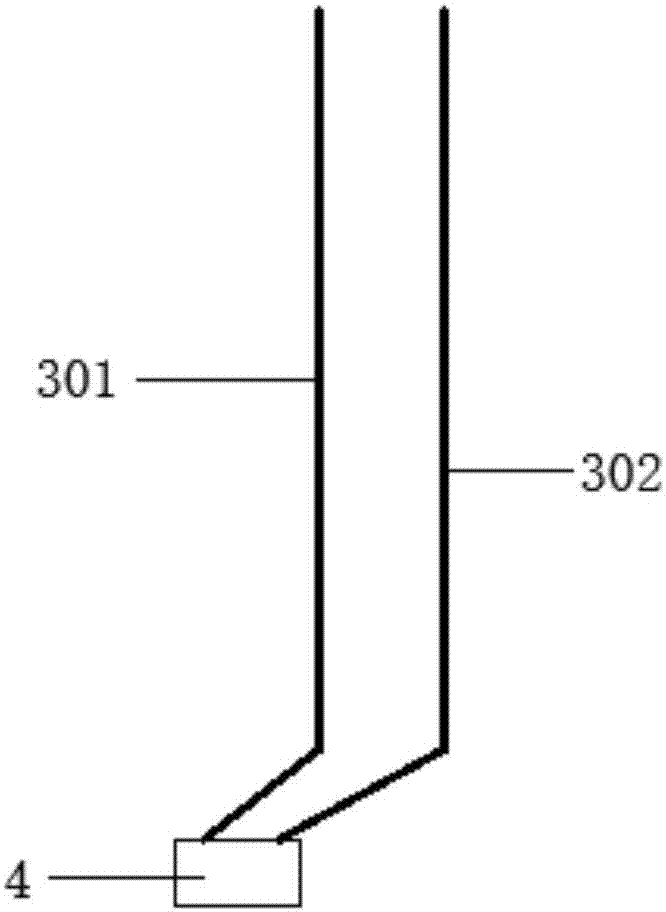

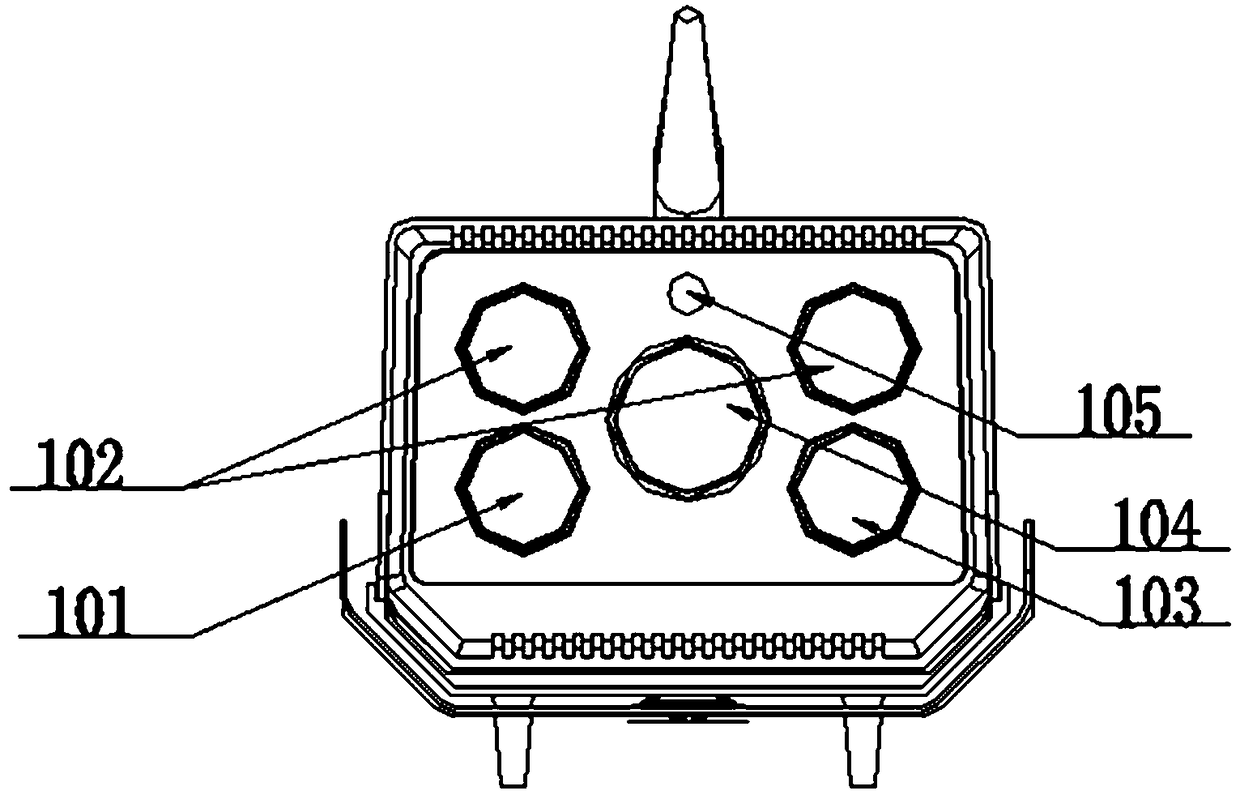

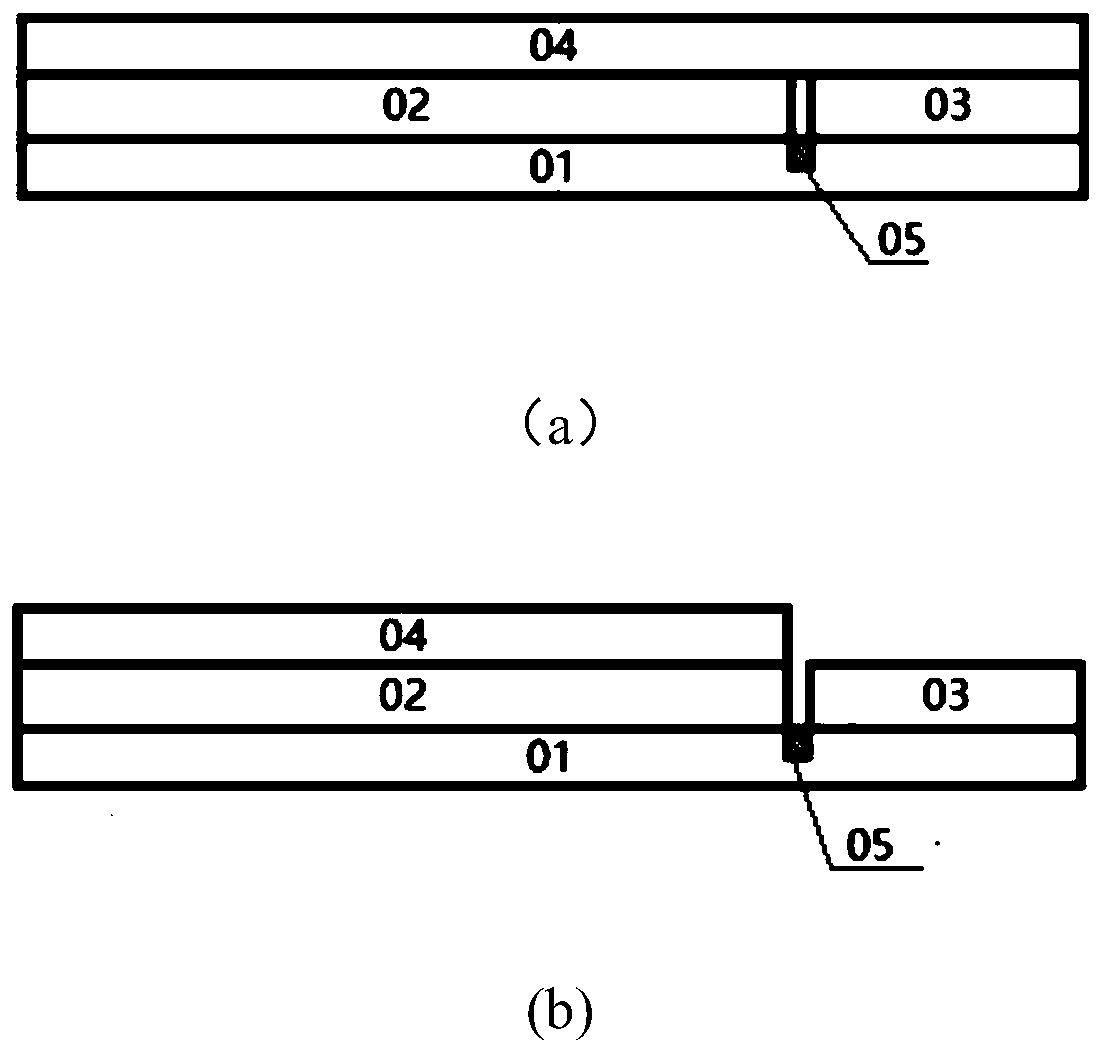

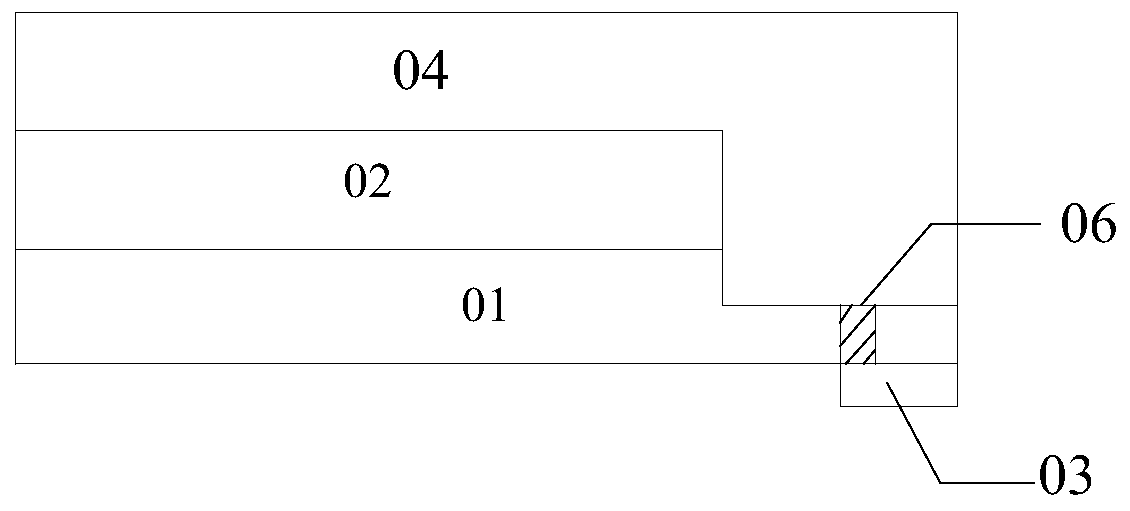

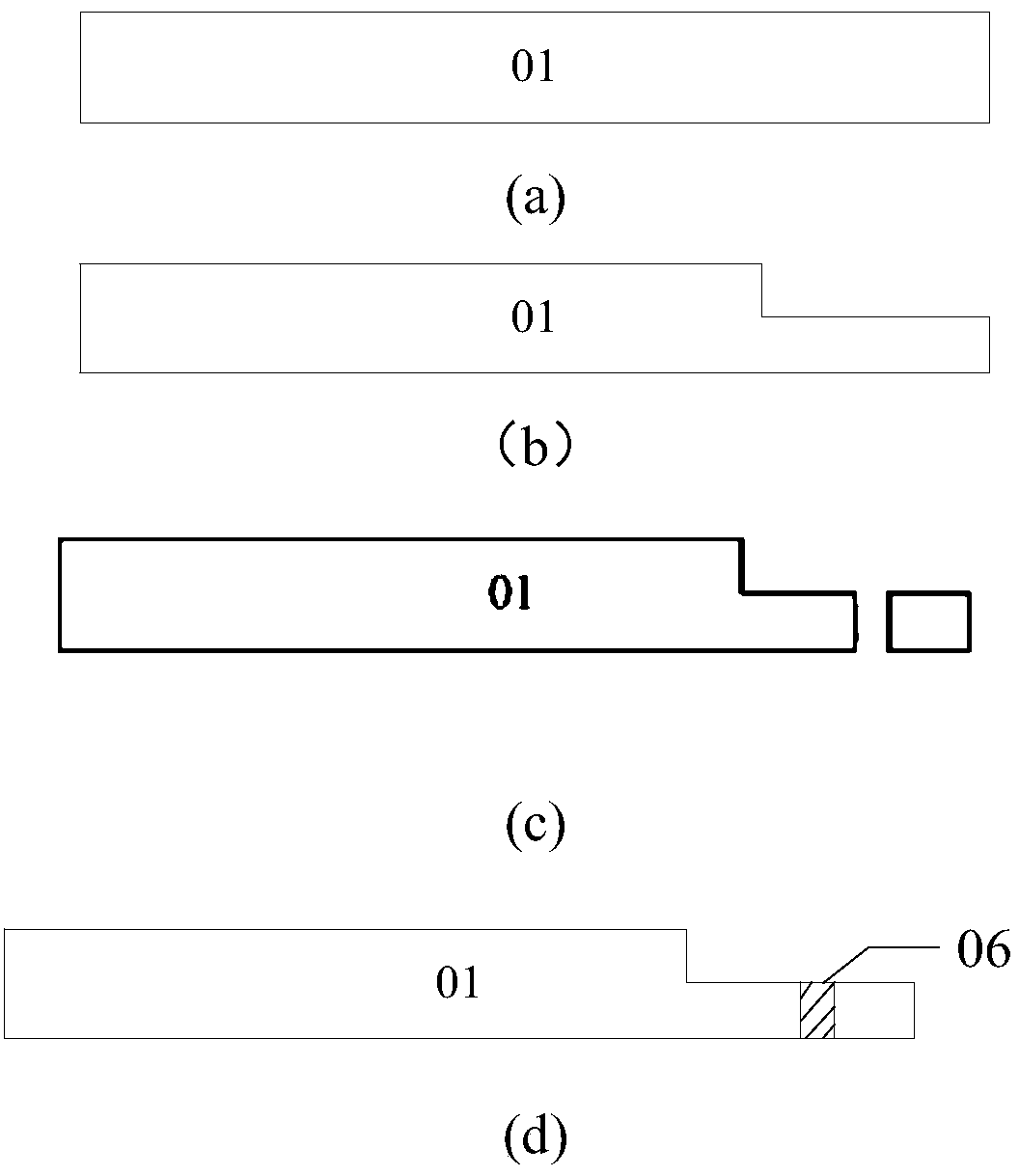

Flexible display device

ActiveCN107464512AImprove the detection rateSave production materialsStatic indicating devicesInput/output processes for data processingEngineeringFlexible display

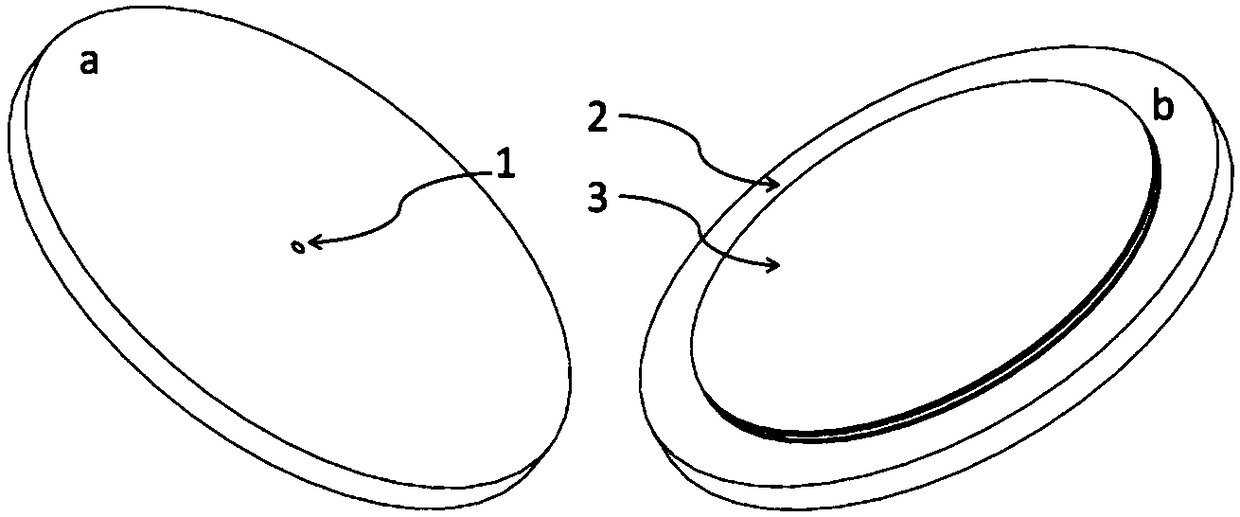

The invention discloses a flexible display device which comprises a display area and a non-display area encircling the display area, a first flexible substrate, an inorganic layer arranged on the first flexible substrate, and grounding wires arranged on the inorganic layer, wherein the grounding wires are arranged in the non-display area and form a detection circuit; at least two grounding wires are arranged in the non-display area on the same side of the display area at least; the at least two grounding wires comprise at least one first grounding wire and at least one second grounding wire; the inorganic layer is provided with a groove; the first grounding wire is arranged in the groove; the second grounding wire is arranged on the surface of the inorganic layer. According to the flexible display device disclosed by the invention, crack positions can be judged by the detection circuit, whether the cracks exist on the inorganic layer and on the first flexible substrate can be judged, and the detection rate of risk products is improved; meanwhile, since the first grounding wire is positioned in the groove, and the second grounding wire is positioned on the surface of the inorganic layer, the horizontal distance among the various grounding wires can be reduced, and the narrow bezel design of the flexible display device is promoted.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

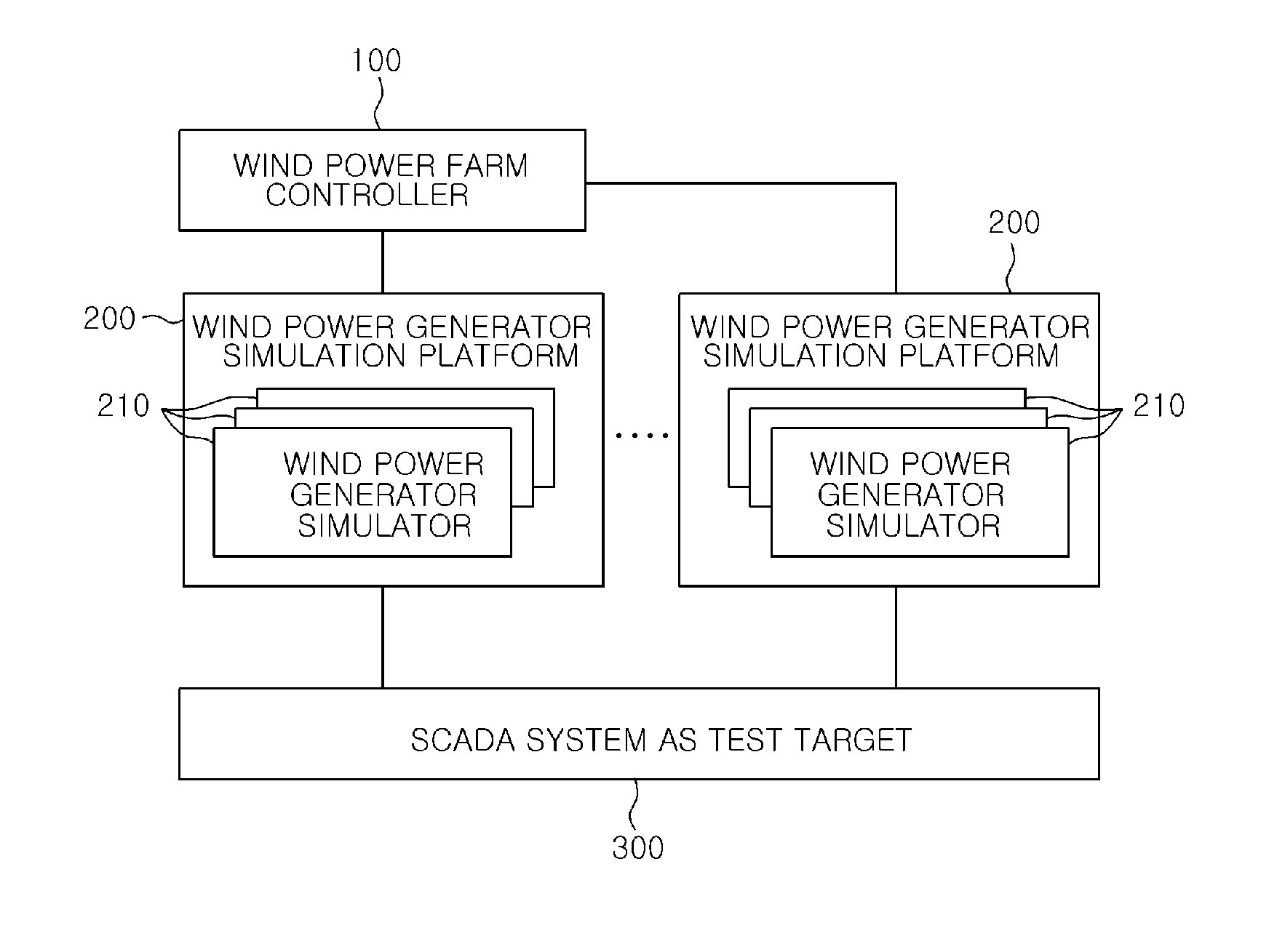

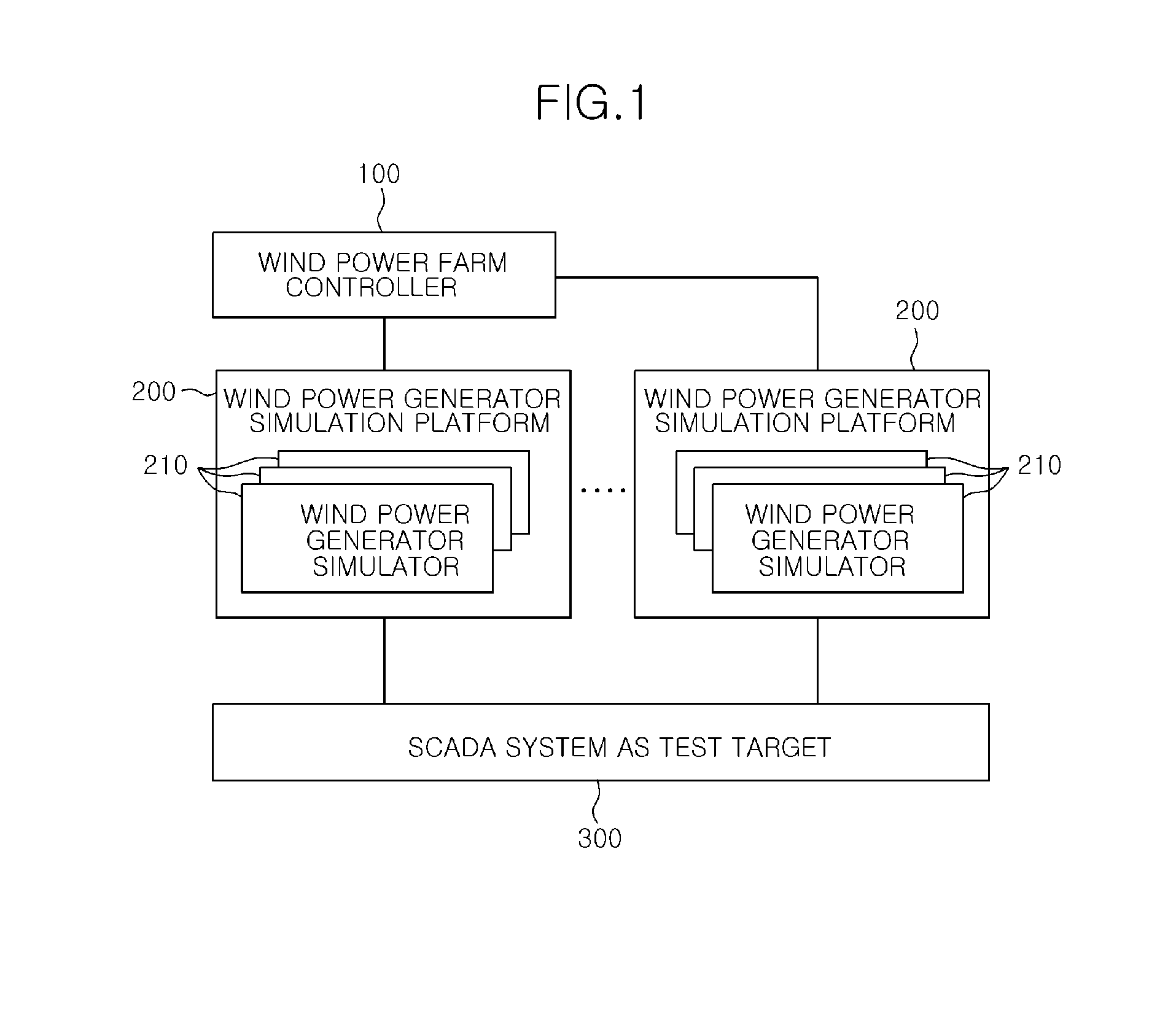

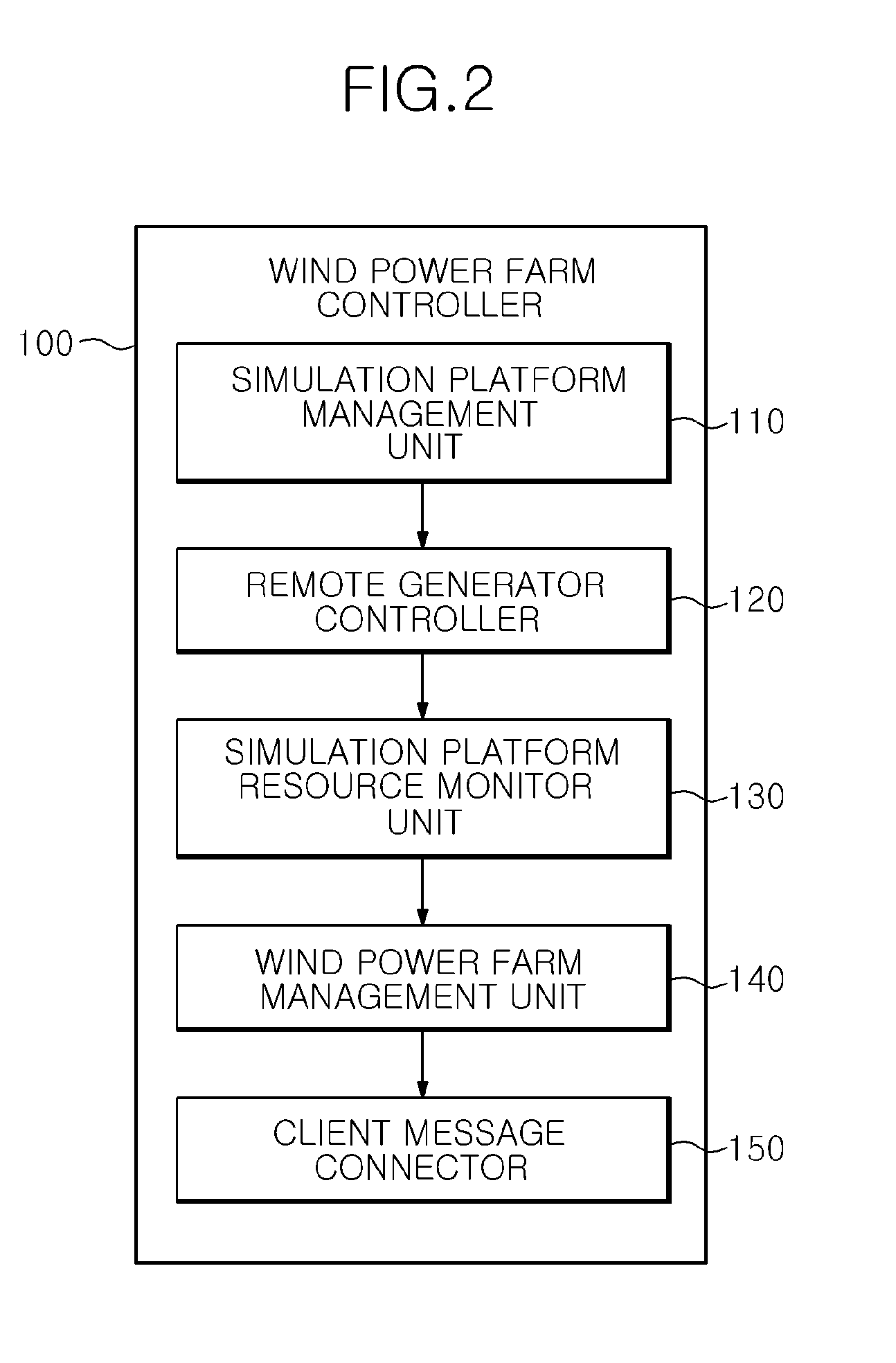

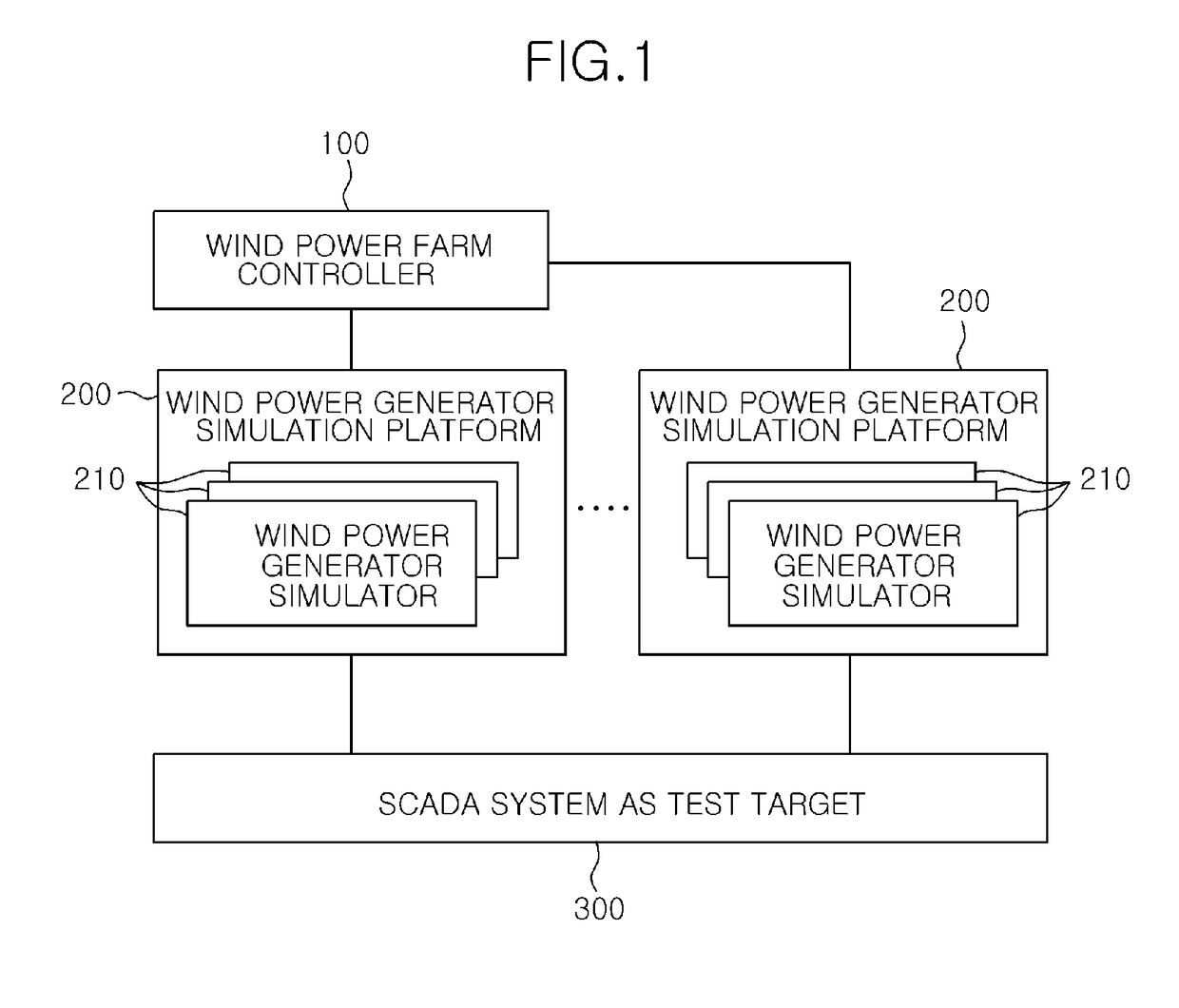

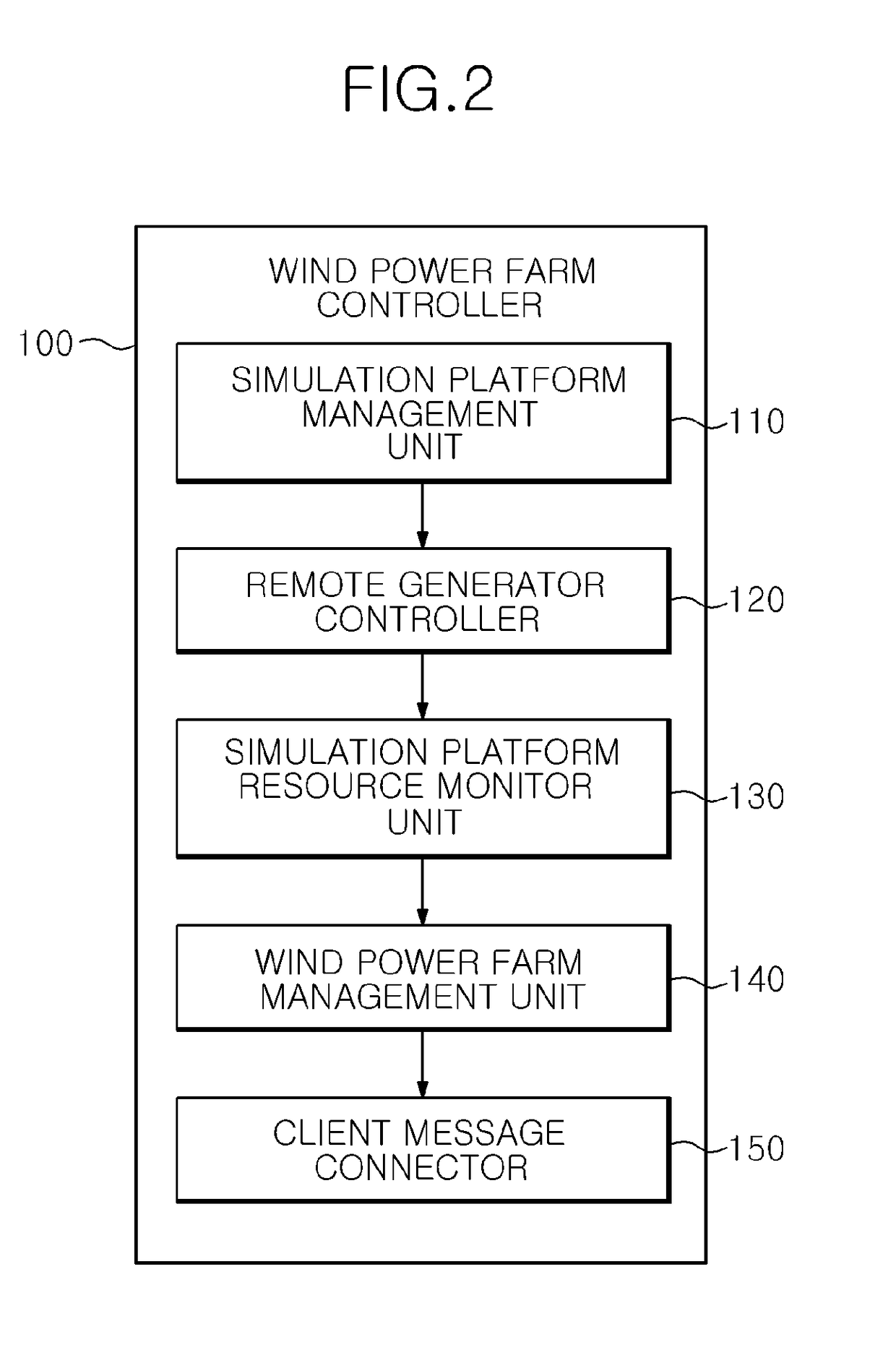

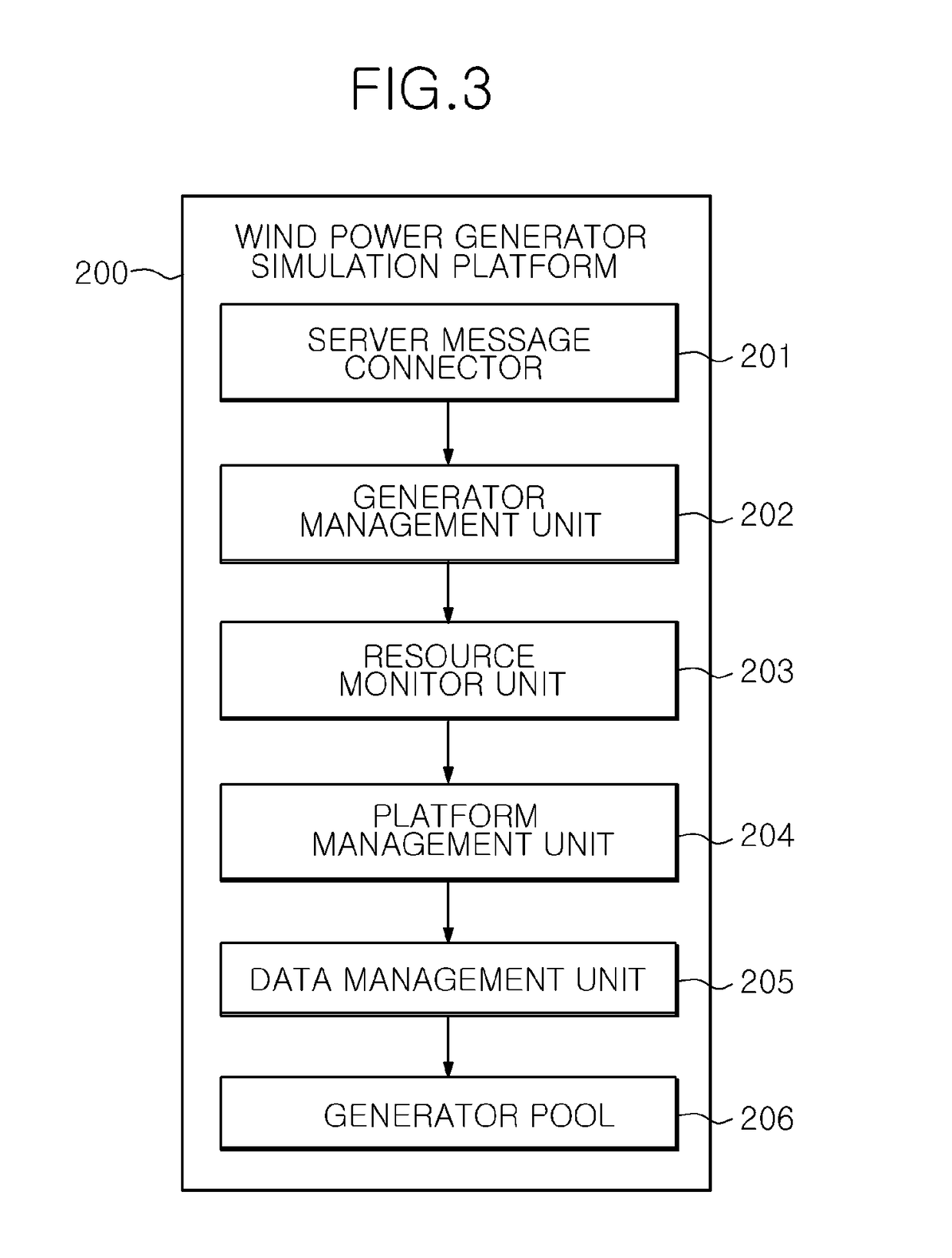

Apparatus for simulating wind power farm

InactiveUS20150095004A1Efficiently and stably mangeEasy to operateWind motor controlEngine fuctionsSCADAData acquisition

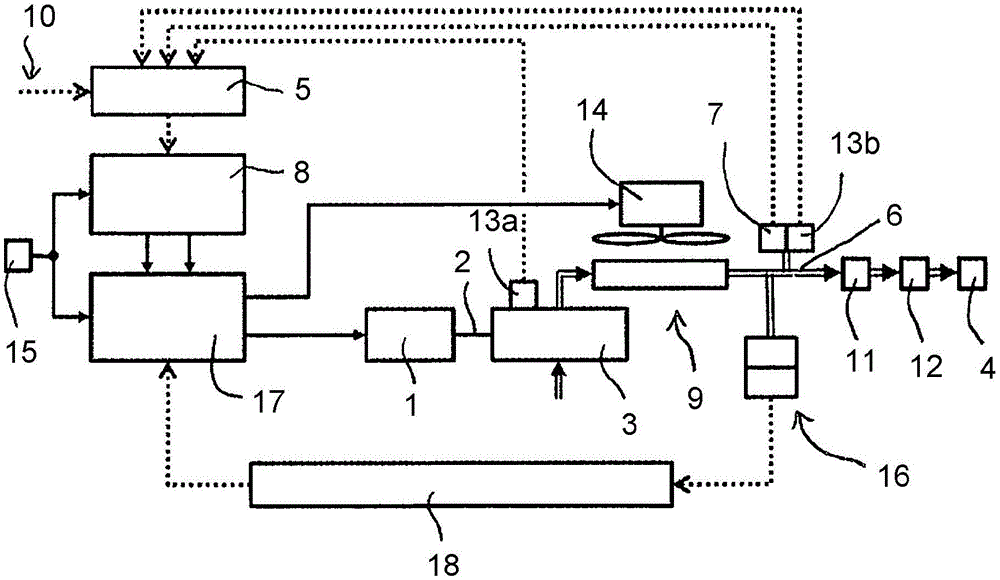

An apparatus for simulating a wind power farm includes a wind power generator simulator configured to act as a virtual wind power generator to dynamically generate an attribute value and provide the attribute value to a supervisory control and data acquisition (SCADA) system to be tested; a wind power generator simulation platform configured to generate and manage a plurality of wind power generator simulators within one system, monitor the system, monitor operation states of the plurality of wind power generator simulators, and transmit a result of monitoring the operation states; and a wind power farm controller configured to generate a wind power farm by grouping a plurality of wind power generator simulation platforms into a single cluster, and manage a simulation environment of the wind power farm.

Owner:KOREA ELECTRIC POWER CORP

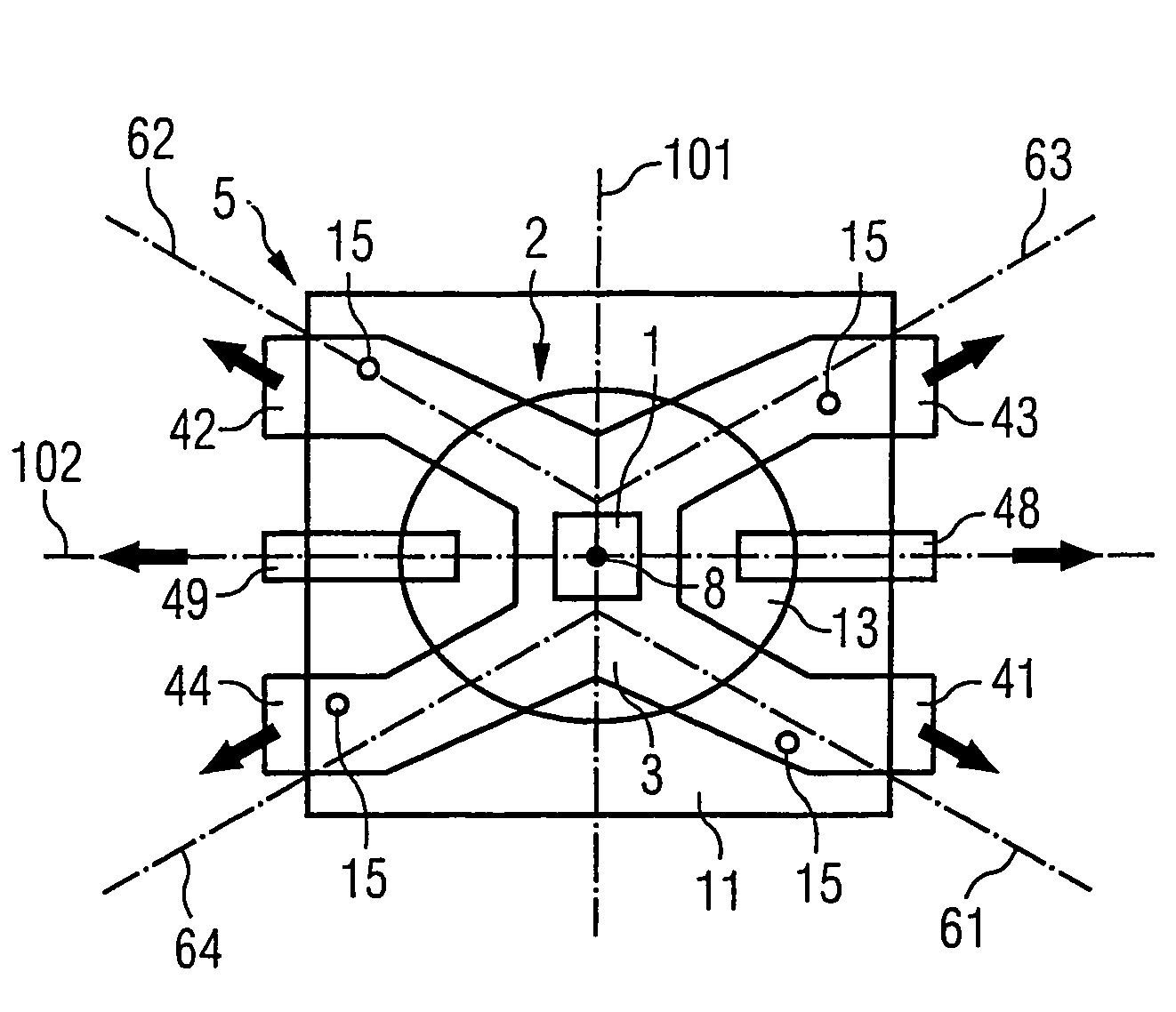

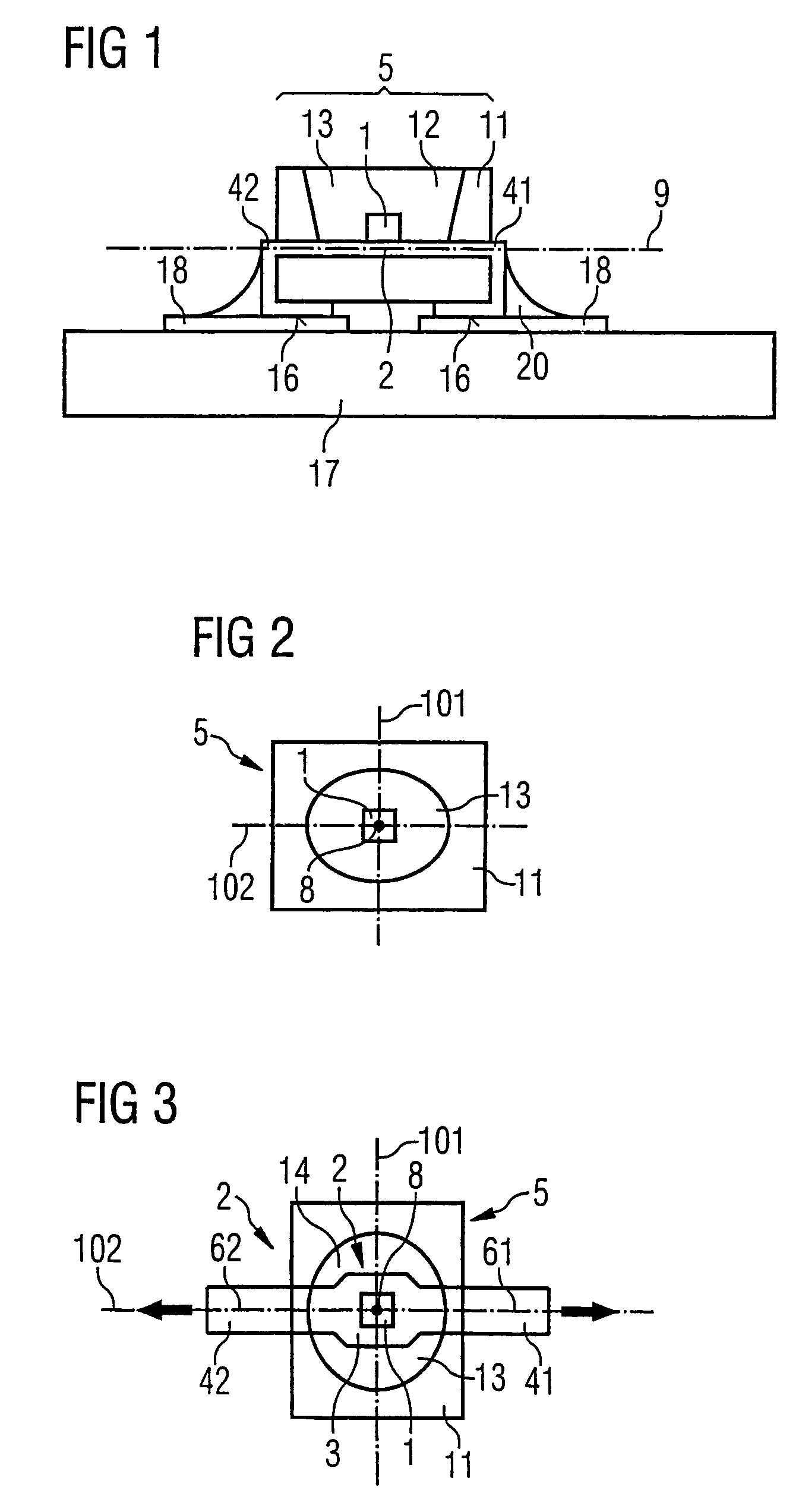

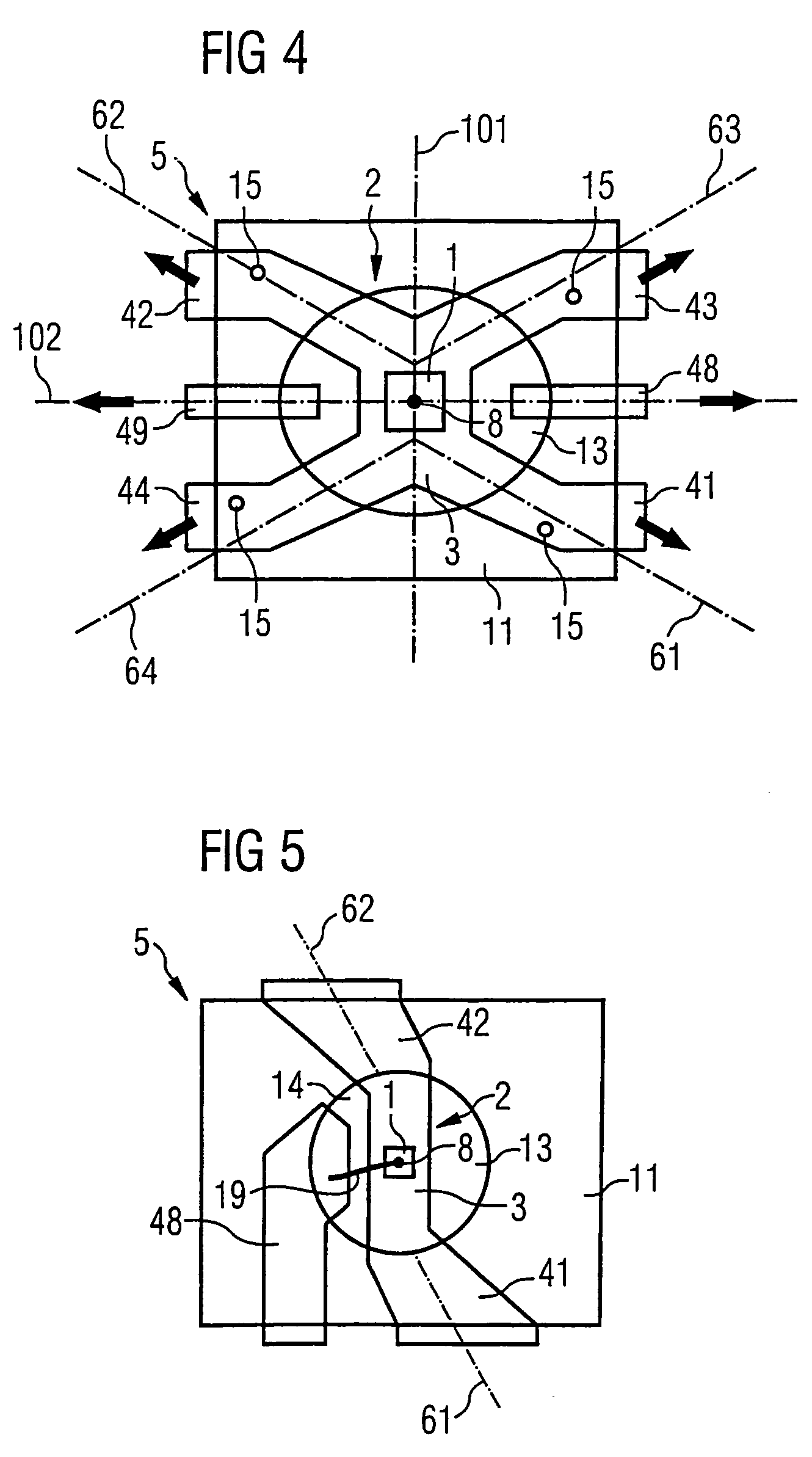

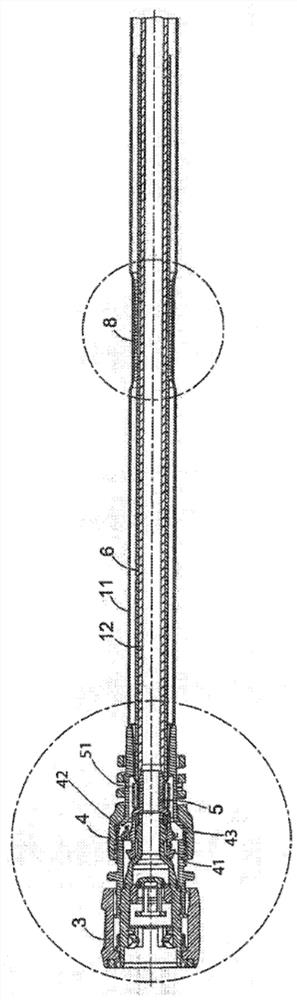

Optoelectronic component

ActiveUS7271425B2Increased risk of failureImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesOpto electronicChip carrier

The invention relates to an optoelectronic component containing an optoelectronic chip (1) and containing a chip carrier (2) that has a central region (3) on which the chip is fixed and that comprises terminals (41, 42, 43, 44) extending outwardly from the central region of the chip carrier (2) to the outside, wherein the chip and portions of the chip carrier are enveloped by a body (5) and wherein the projection of the body and that of each of the longitudinal axes of the terminals onto the contact plane between the chip and the chip carrier are substantially point-symmetrical with respect to the central point of the chip. The invention further relates to an arrangement comprising said component. The advantage of the symmetrical configuration of the component is that the risk of thermomechanically induced failures of the component is reduced.

Owner:OSRAM OLED

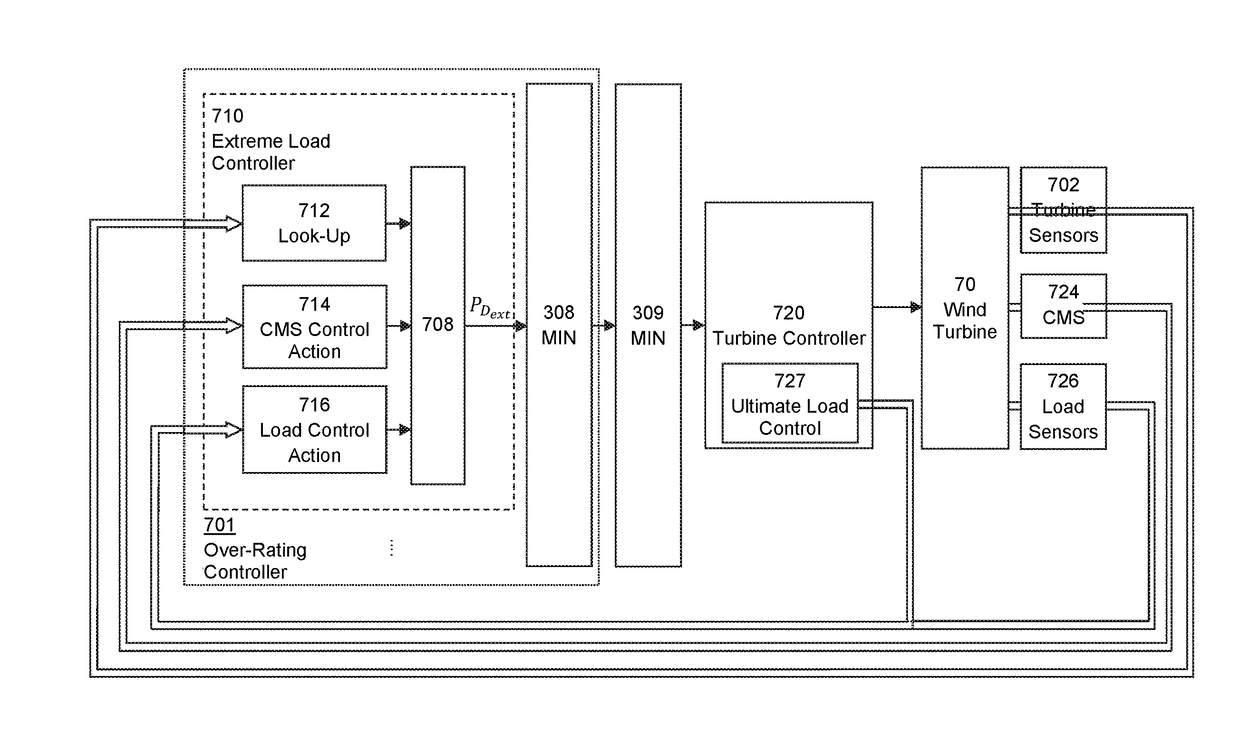

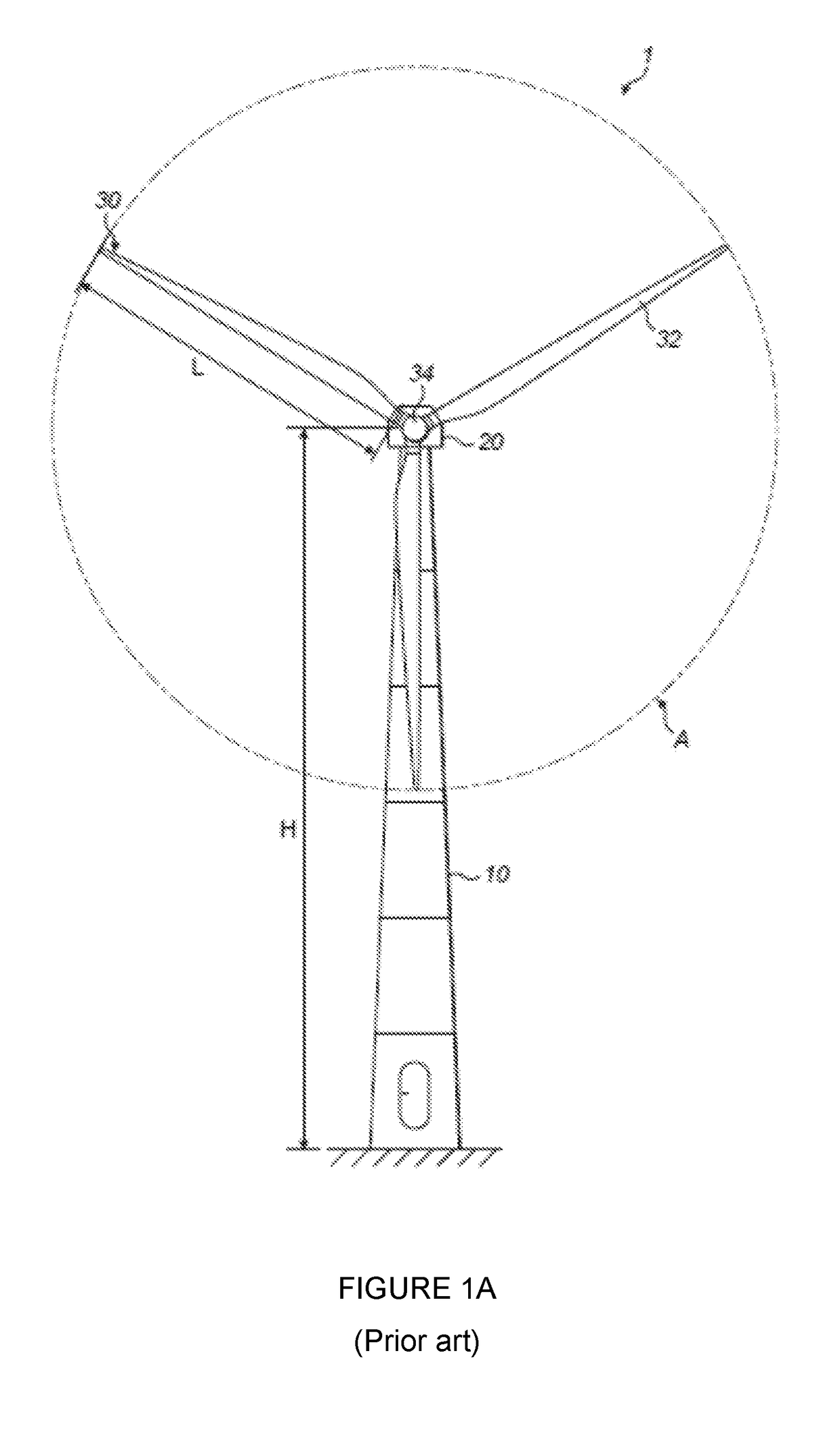

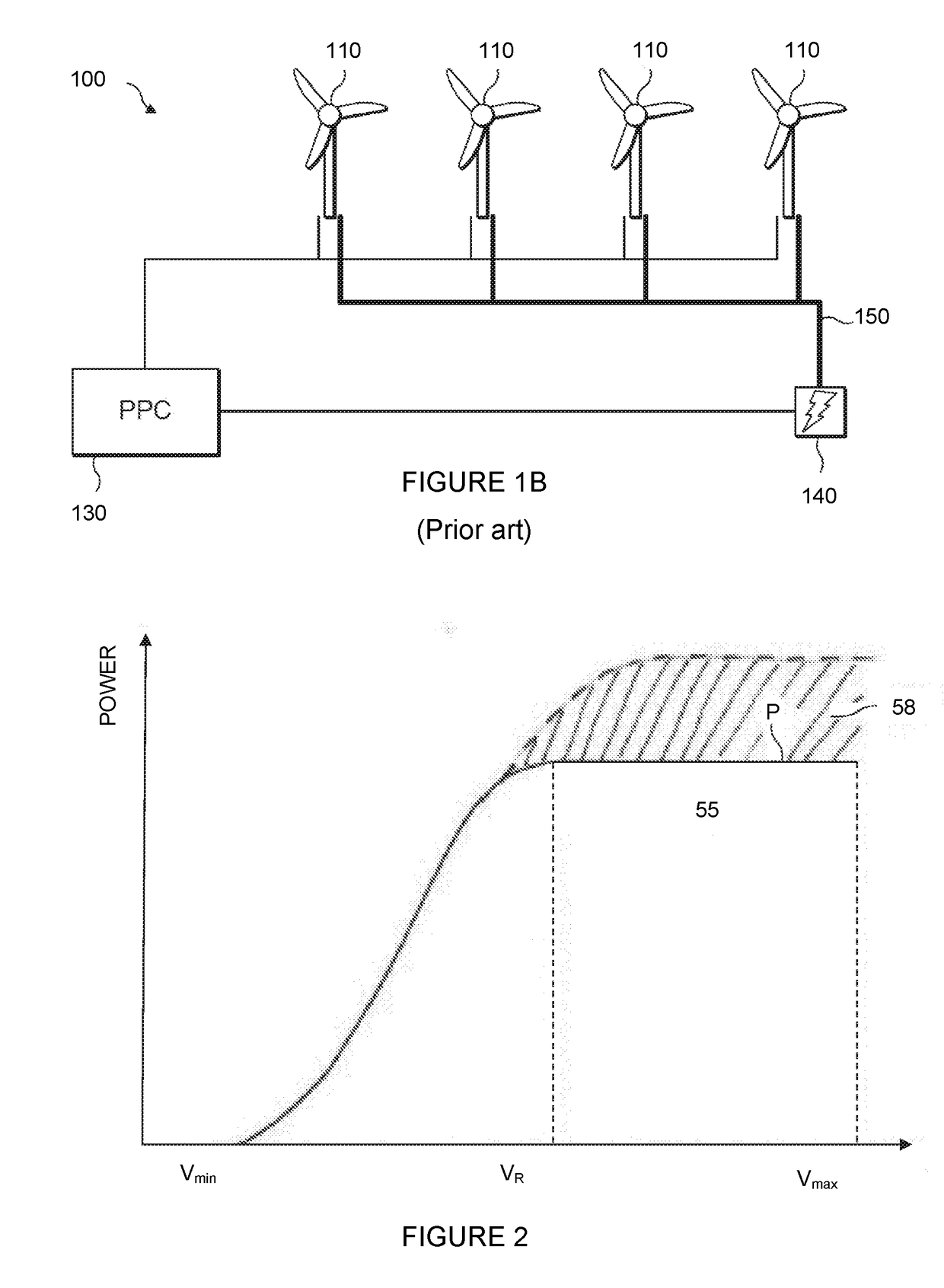

Extreme load control

ActiveUS20180171978A1Reduce riskProduced in advanceSafety arrangmentsComparison table algorithmsPeaking power plantPower station

Methods for calculating a maximum safe over-rated power demand for a wind turbine operating in non-standard conditions include the steps of determining a value indicative of a risk of exceeding an ultimate design load during operation in a standard operating condition, and establishing a maximum over-rated power demand corresponding to a maximum power that the turbine may produce under the non-standard operating condition without incurring an increased risk of exceeding the ultimate design load, with respect to operation in the standard condition. A method of over-rating a wind turbine, a wind turbine controller, a wind turbine and a wind power plant are also claimed.

Owner:VESTAS WIND SYST AS

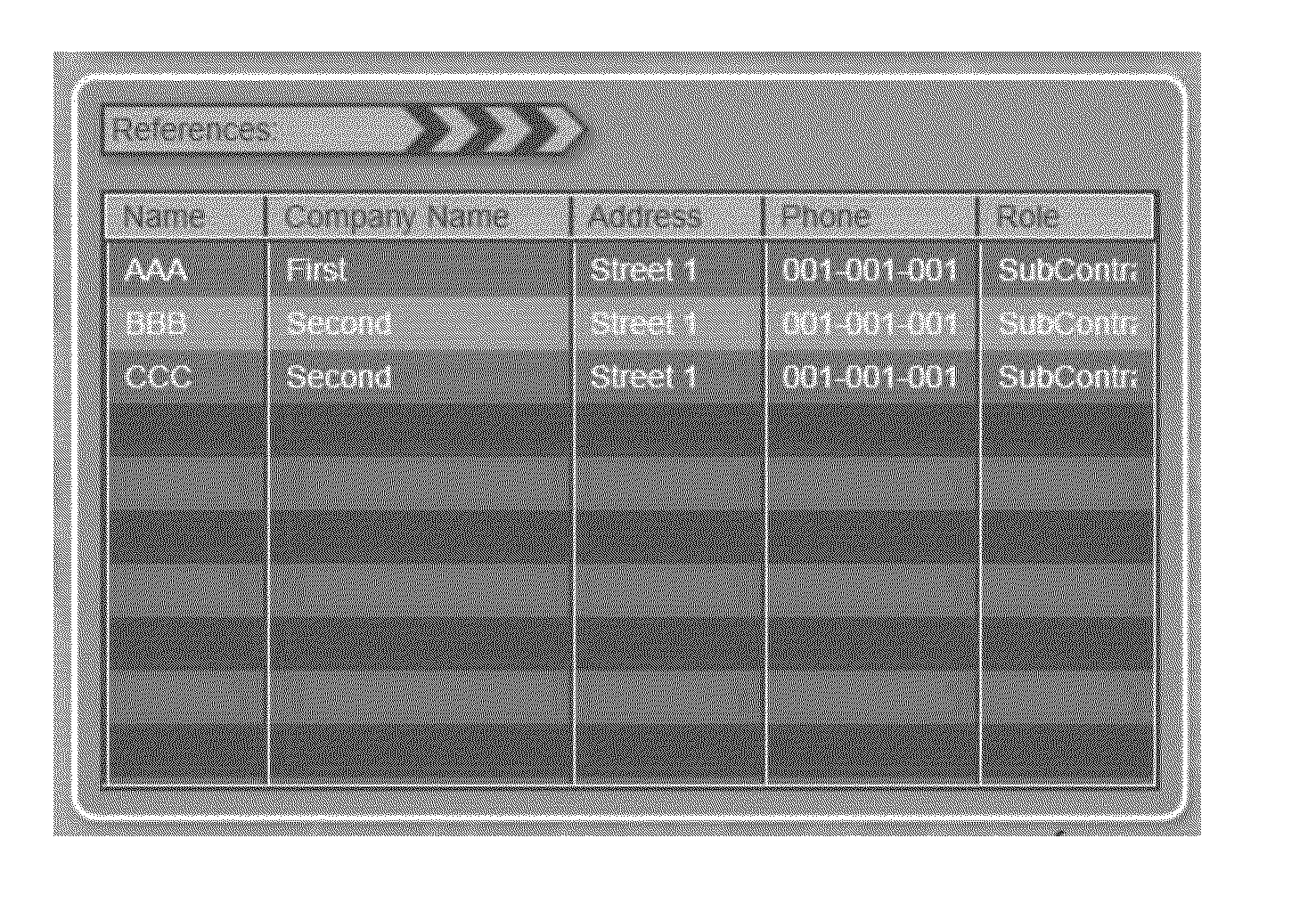

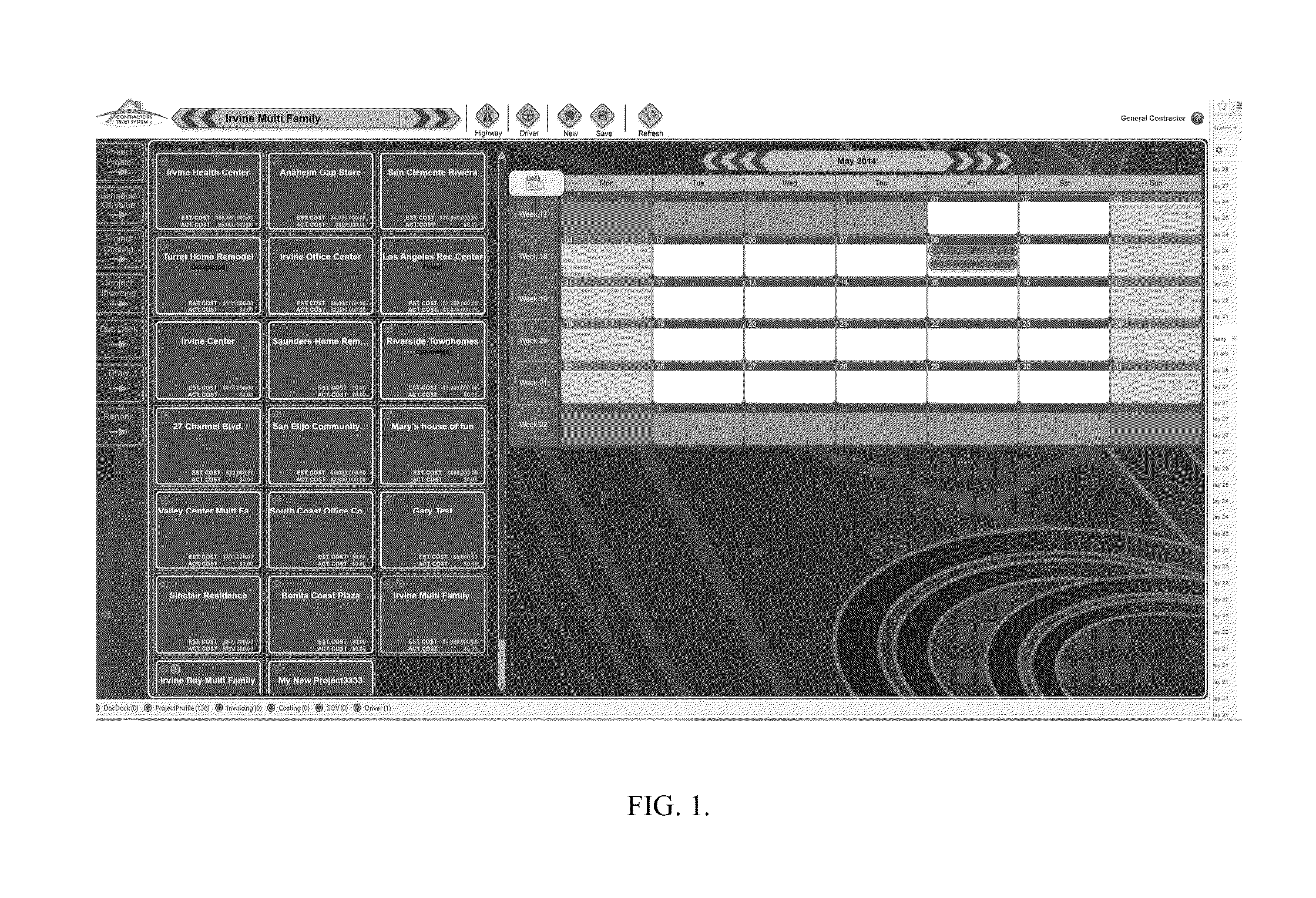

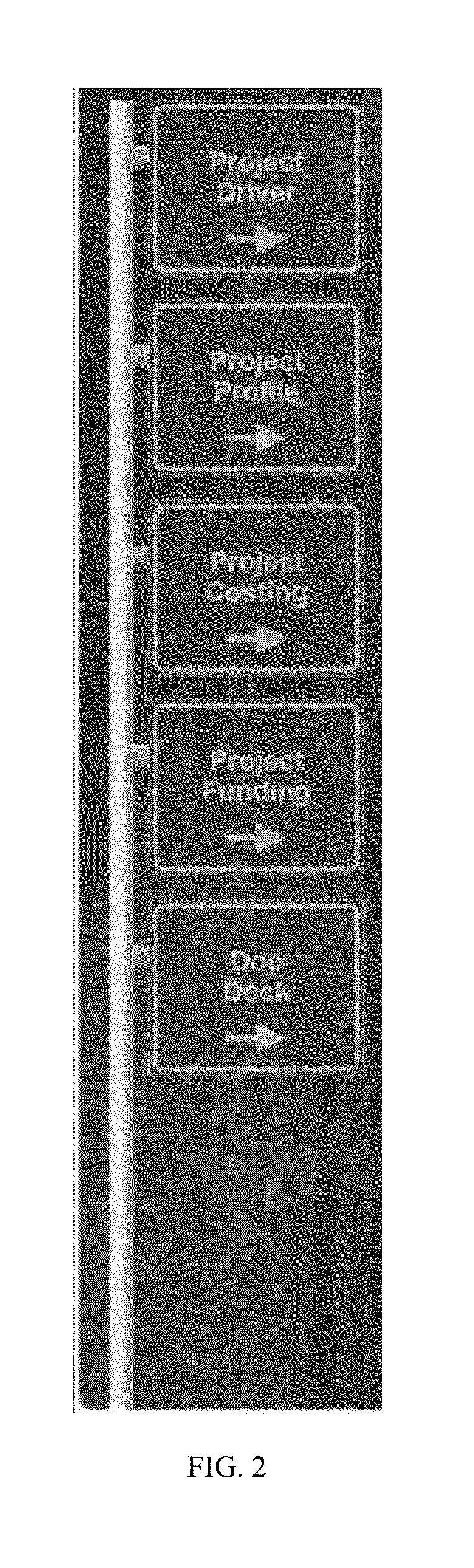

Hierarchical Workflow Management System

InactiveUS20140278705A1Increase investmentIncreased risk of failureResourcesThree levelWorkflow process

Hierarchical workflow management systems and methods are provided that enable users in the building trades to coordinating workflows for projects having at least three levels.

Owner:MEYADI

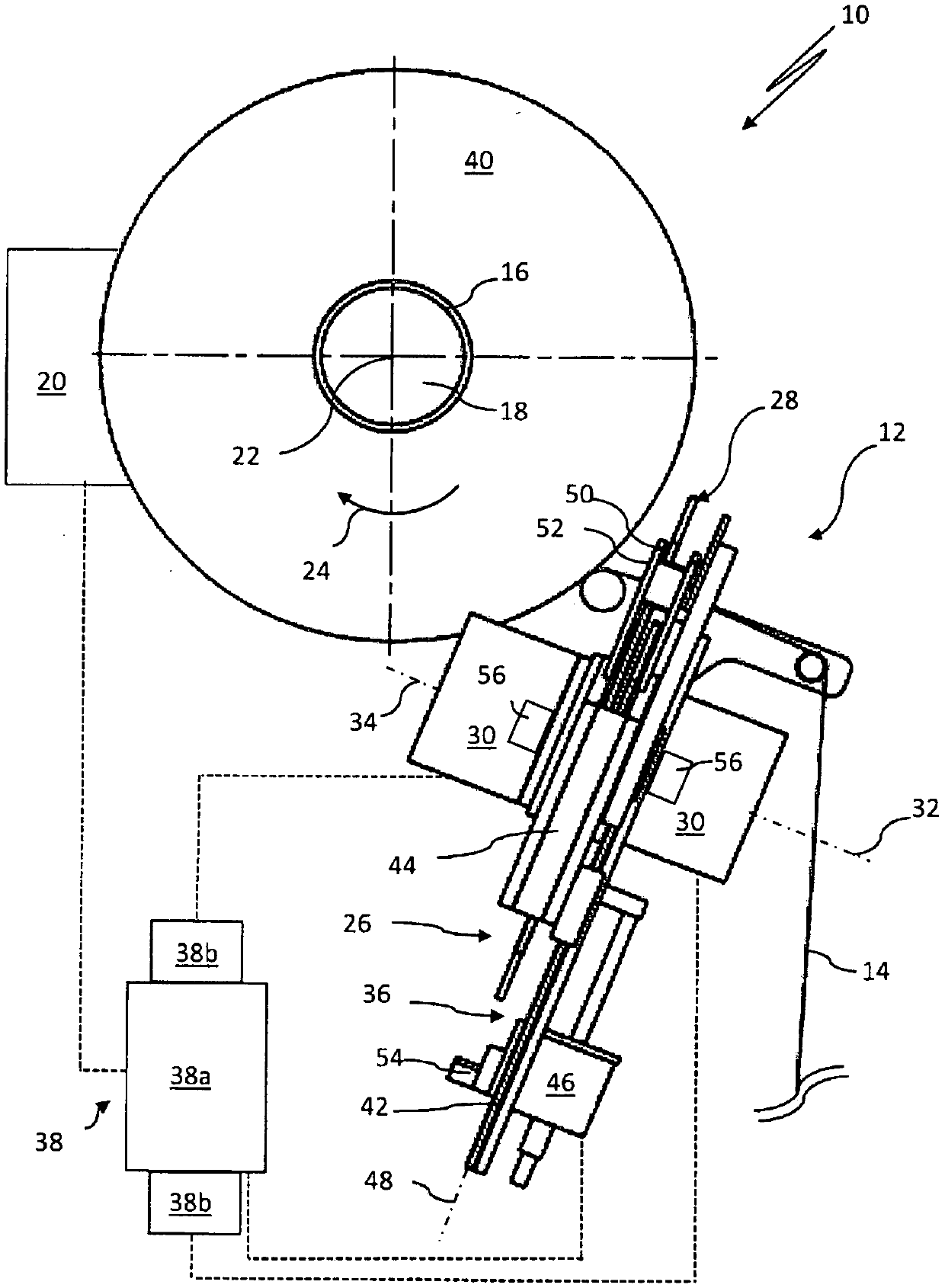

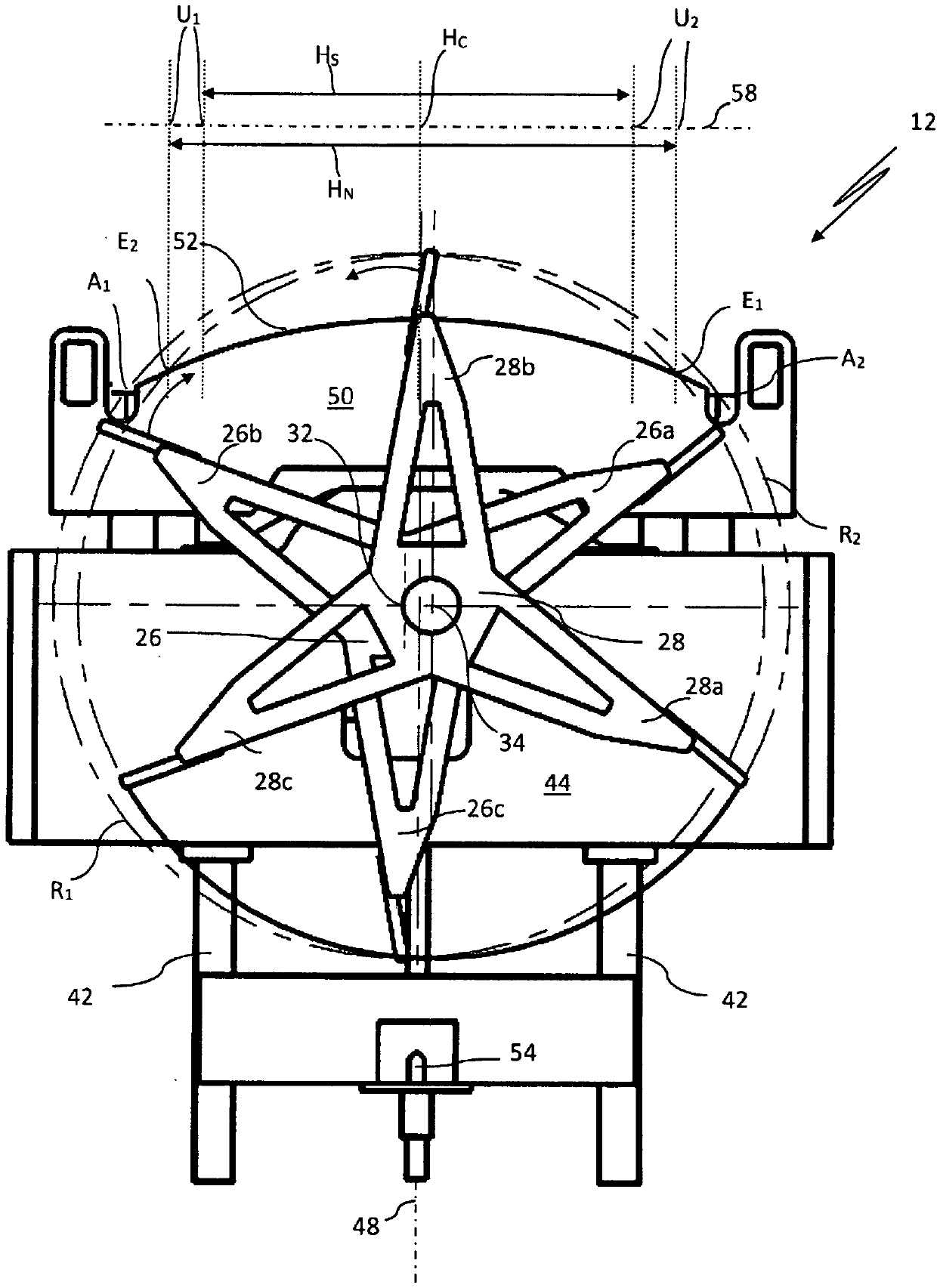

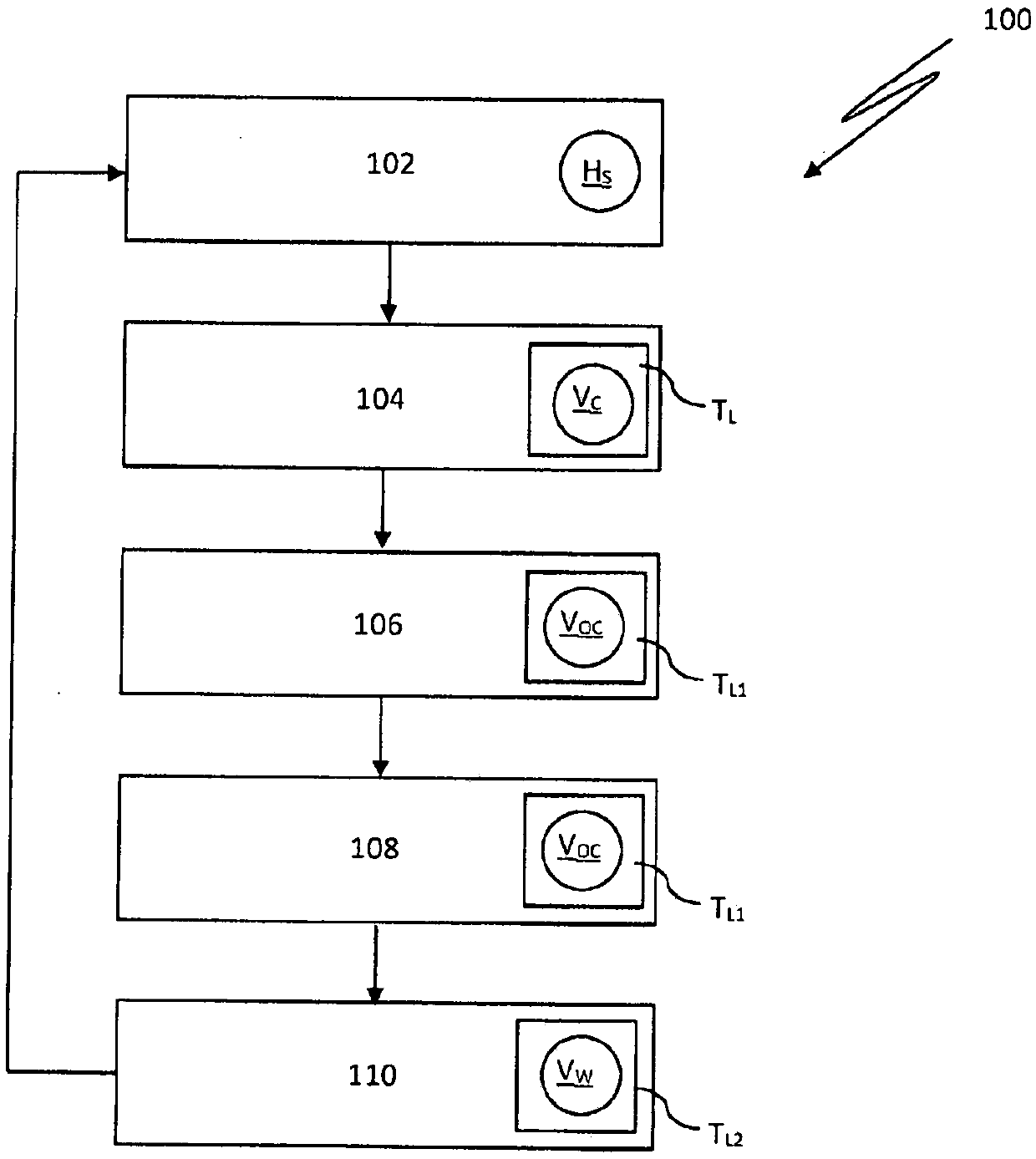

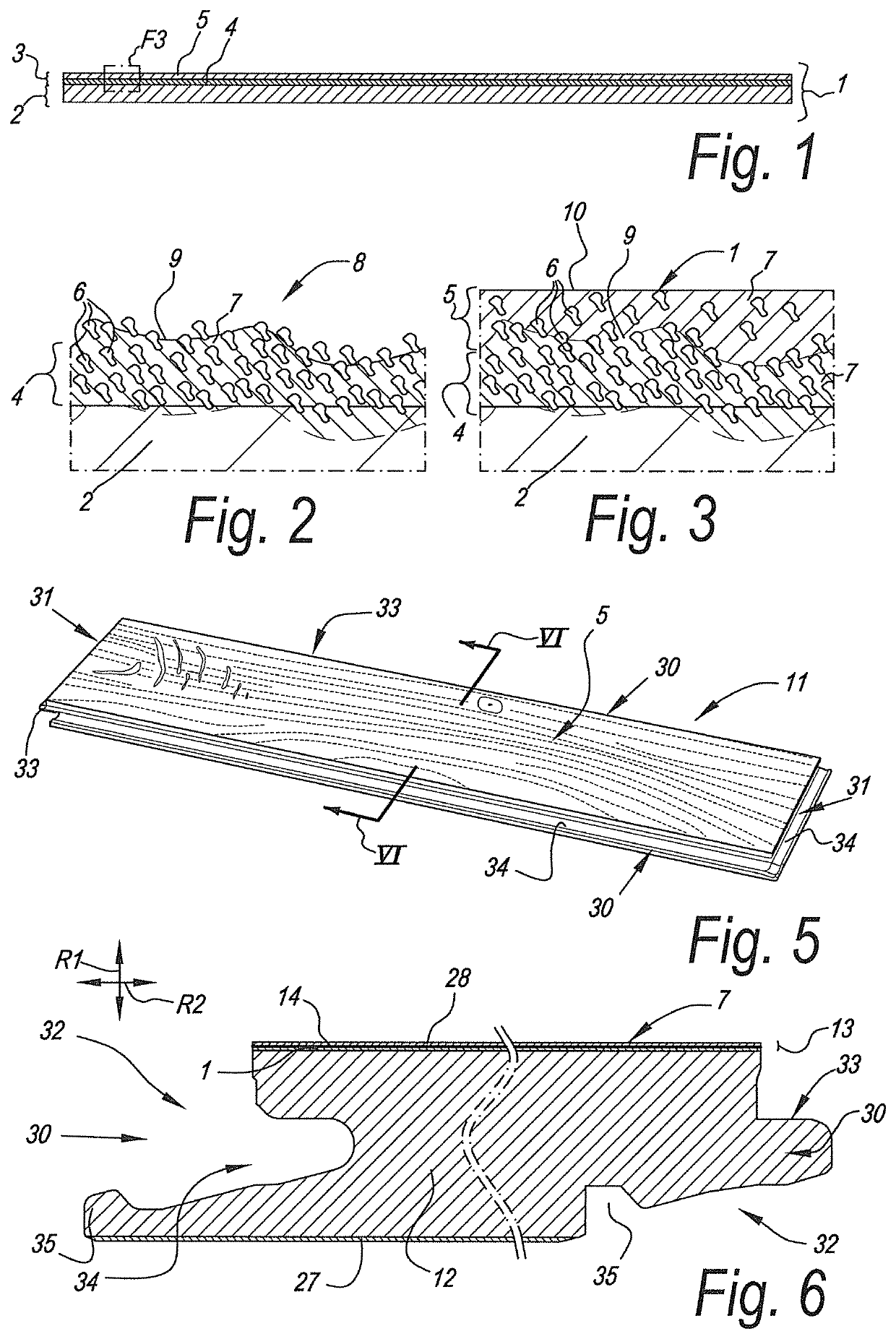

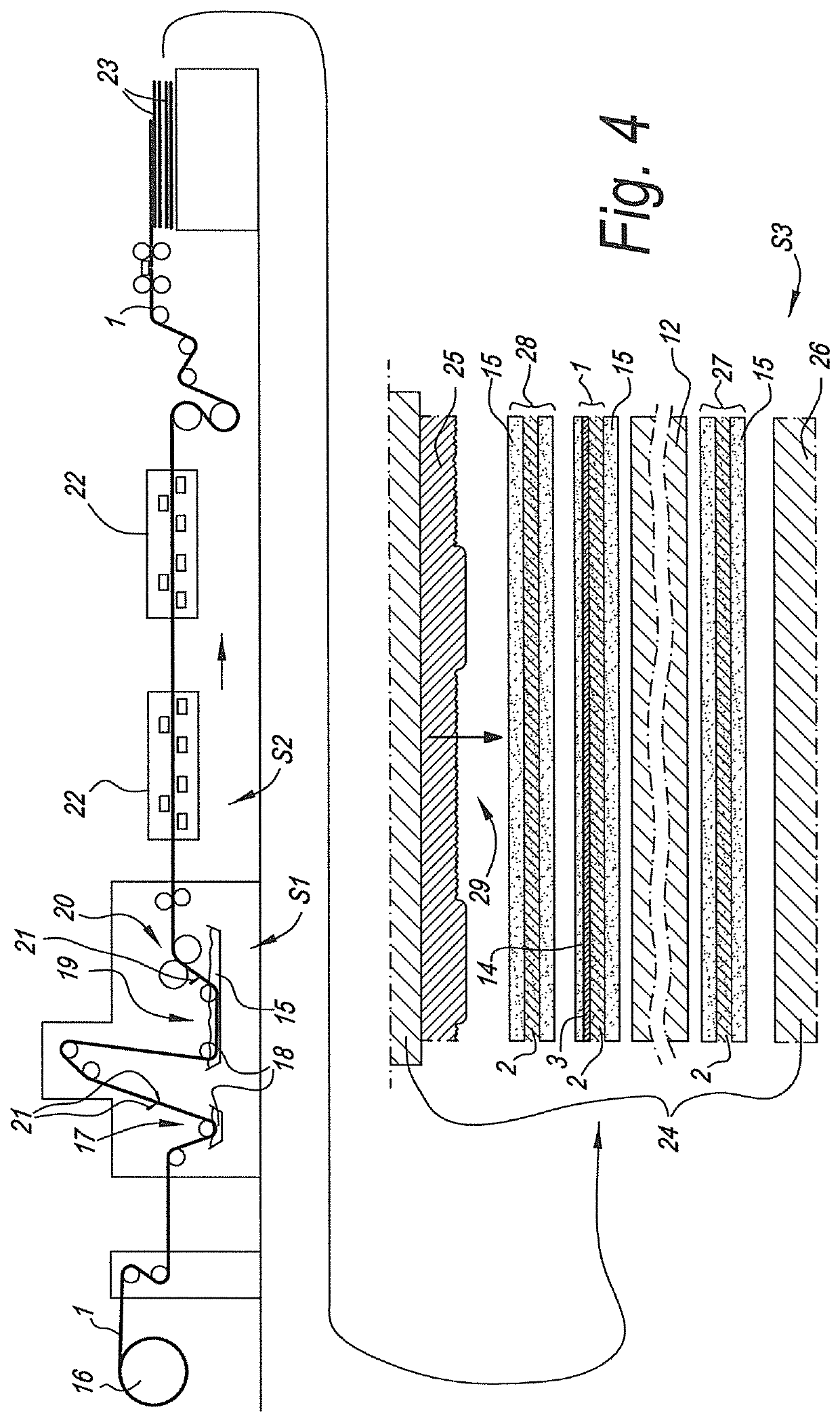

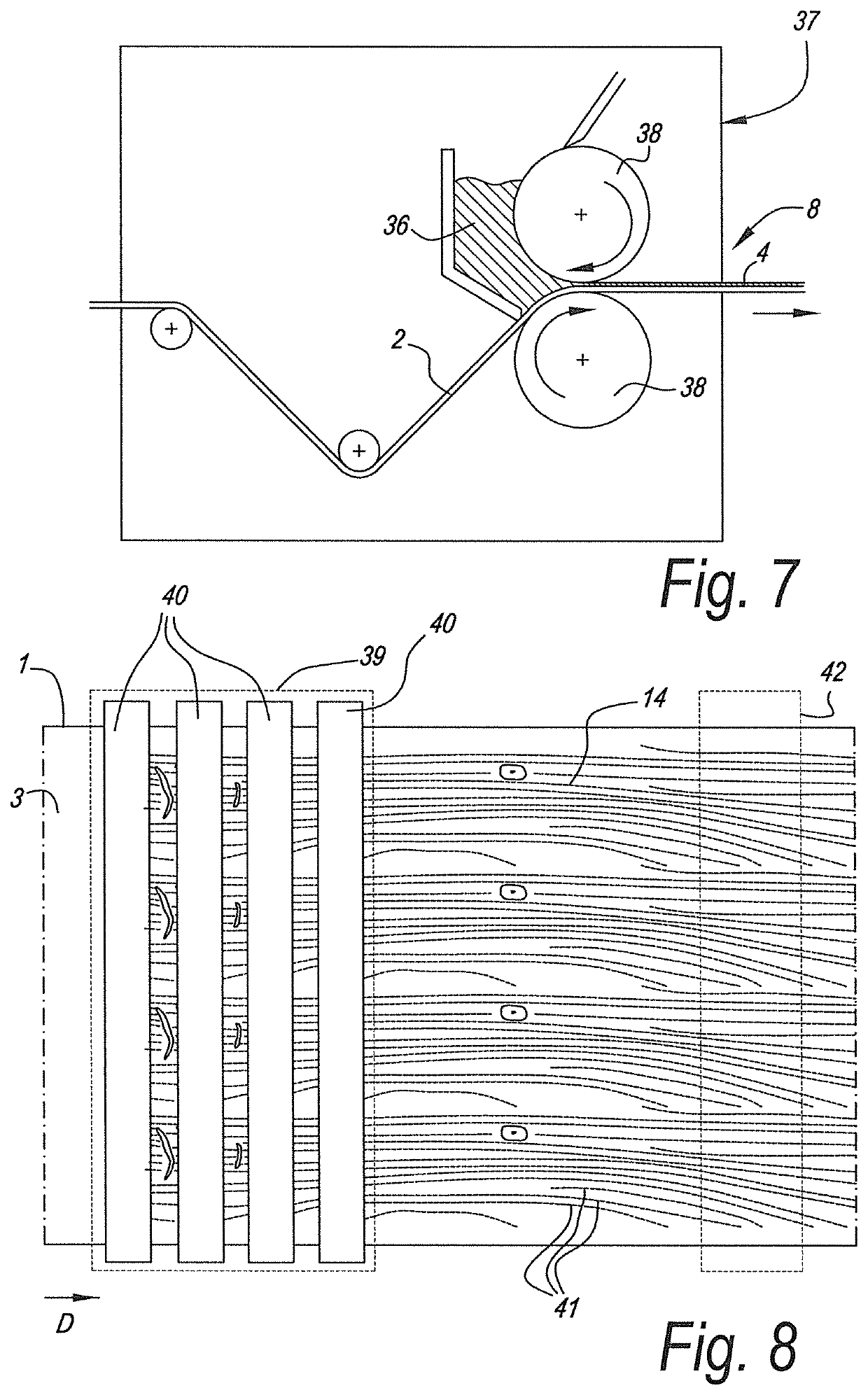

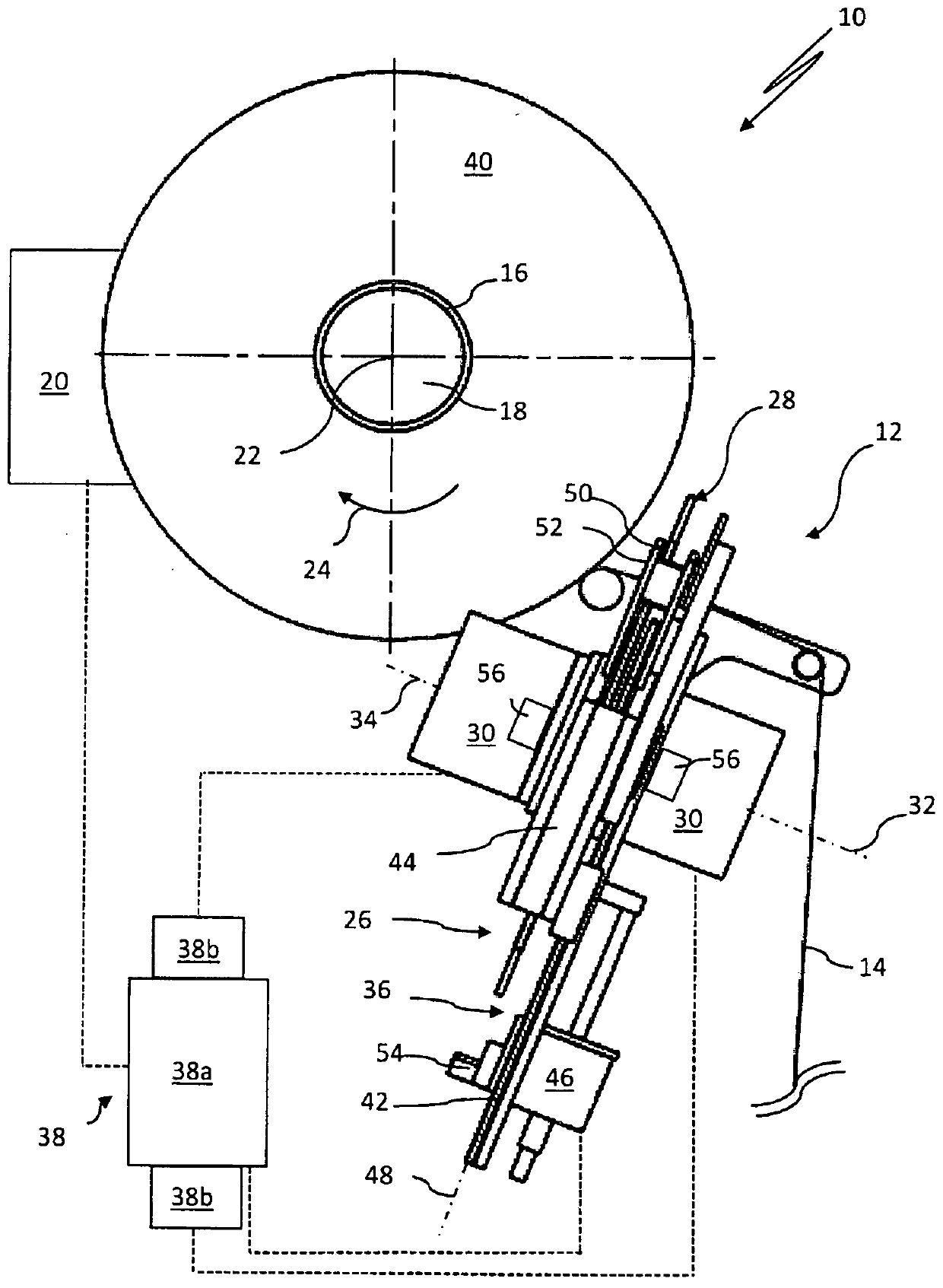

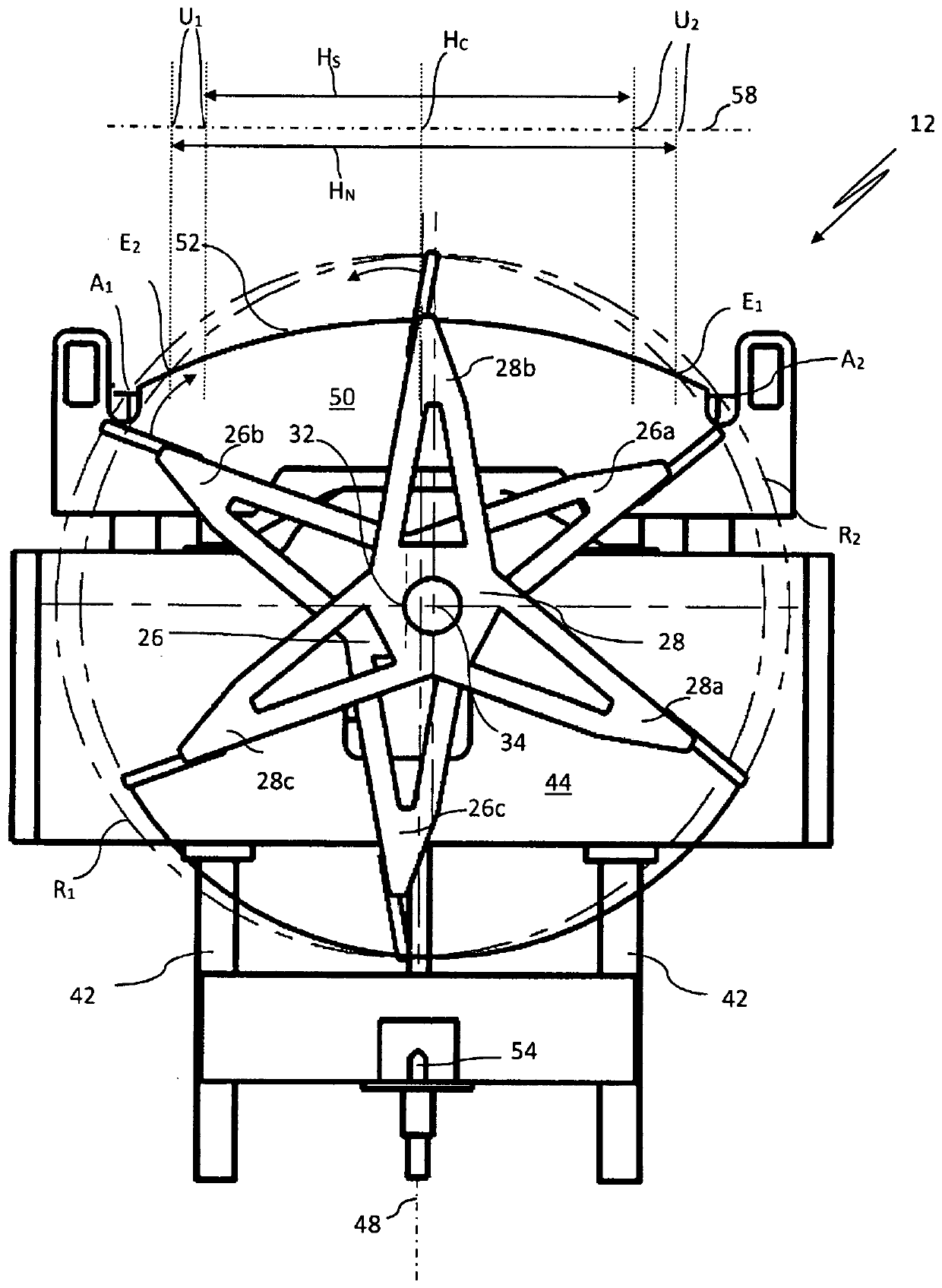

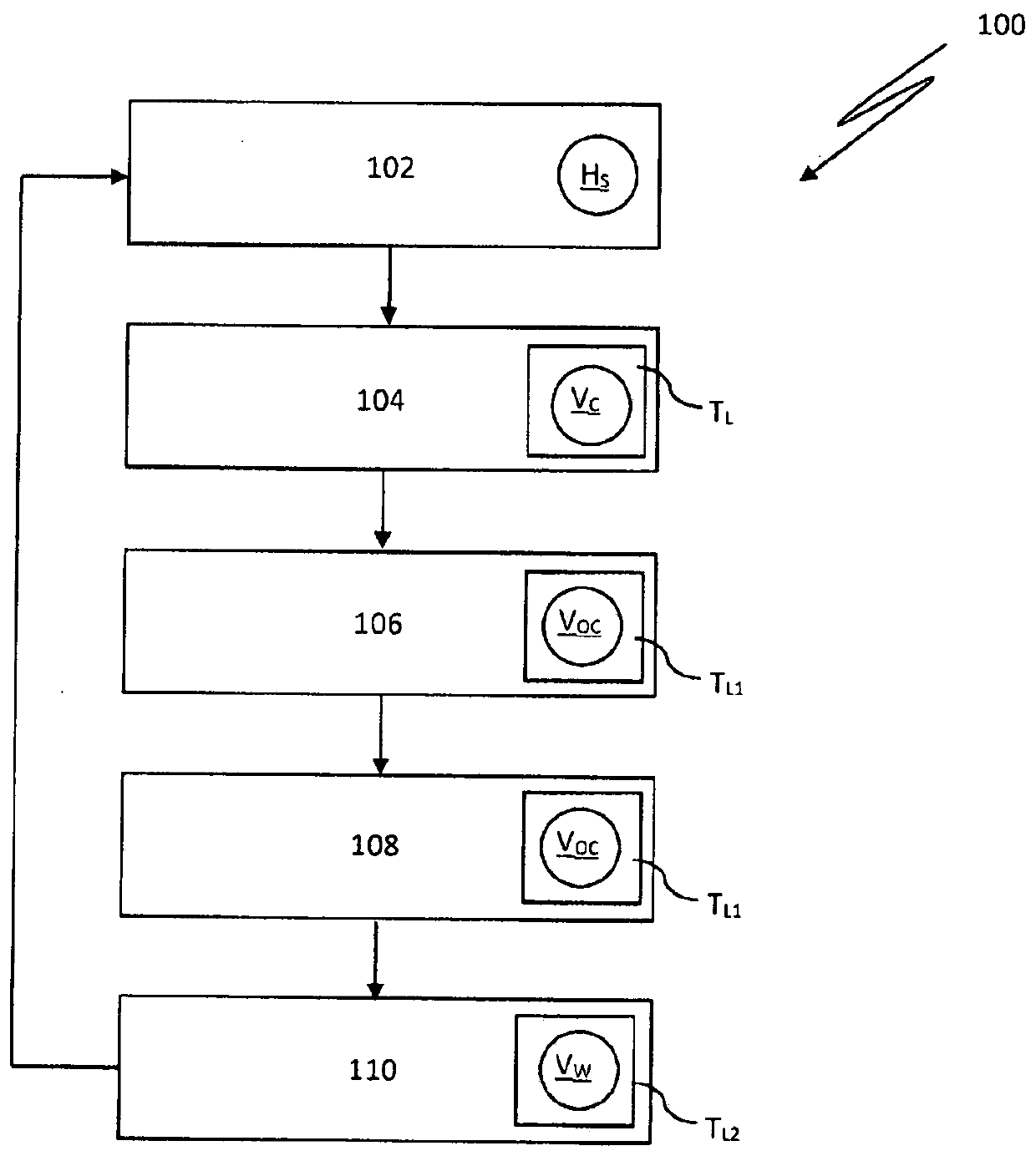

Method for controlling an impeller-type thread laying device, impeller-type thread laying device, and winding machine

The invention relates to a method (100) for controlling a thread laying device comprising two impellers (26, 28) which can be driven in opposite directions in order to move a thread to be wound on a rotating spool back and forth between two turning points (U1, U2) along the spool longitudinal axis by means of a traversing movement with a target traversing stroke width (Hs) of the thread laying device, said target traversing stroke width differing from a base traversing stroke width (HN). According to the invention, each impeller (26, 28) being moved in the idle traversing stroke, i.e. each idle traversing stroke impeller (26, 28), is first accelerated or braked to an overcompensation angular speed (Voc) in the idle traversing stroke interval (TL) of the impeller, said overcompensation angular speed being determined on the basis of a theoretical constant compensation angular speed (Vc) required to transfer the thread in the next turning point (U1, U2) of the traversing movement of the thread. The impeller is then moved at its specified operating angular speed (Vw) in order to receive the thread from the other impeller (26, 28) guiding the thread at the operating angular speed (Vw) in the next turning point (U1, U2) of the traversing movement of the thread. The invention further relates to a thread laying device and to a winding machine comprising such a thread laying device.

Owner:SSM萨罗瑞士麦特雷有限公司

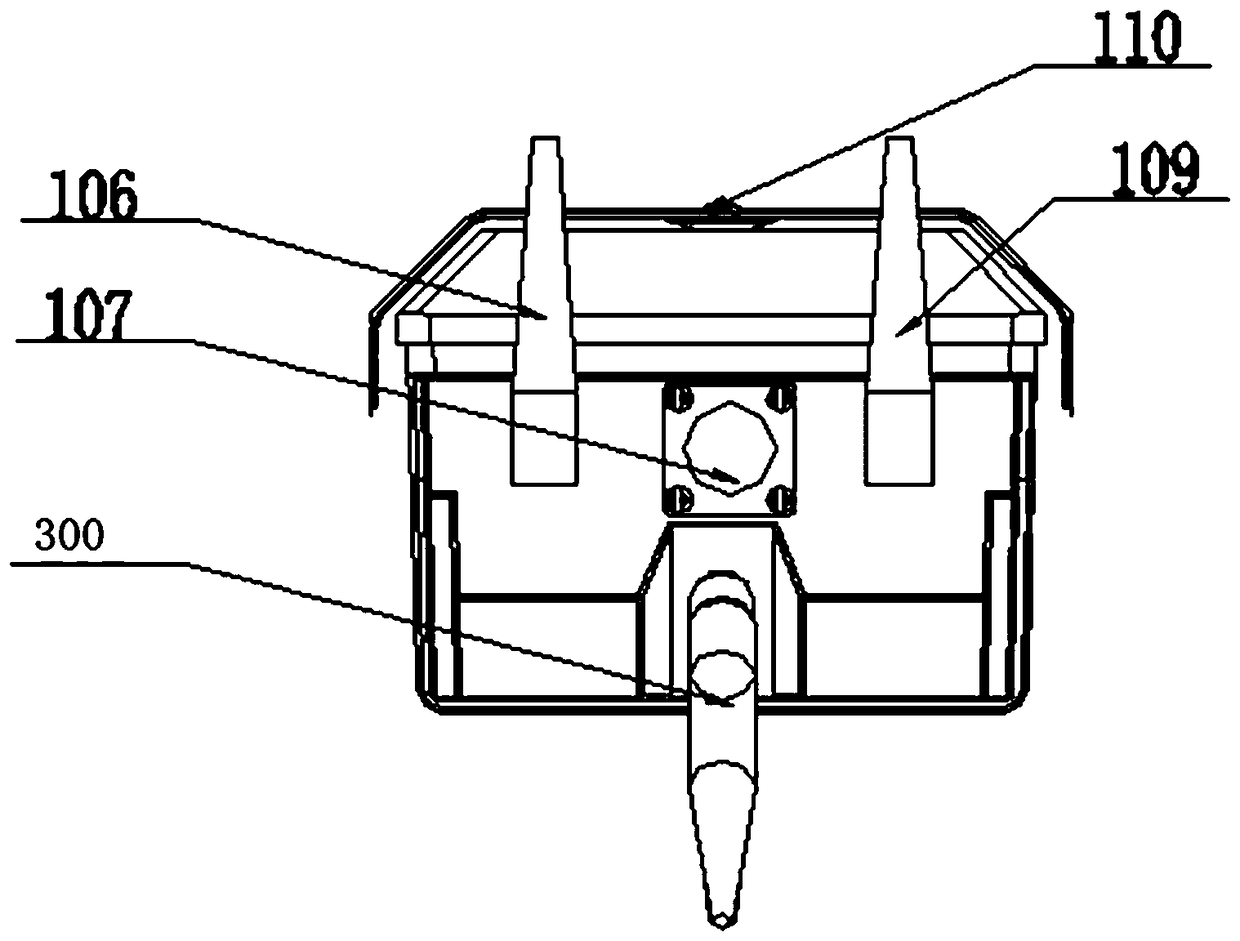

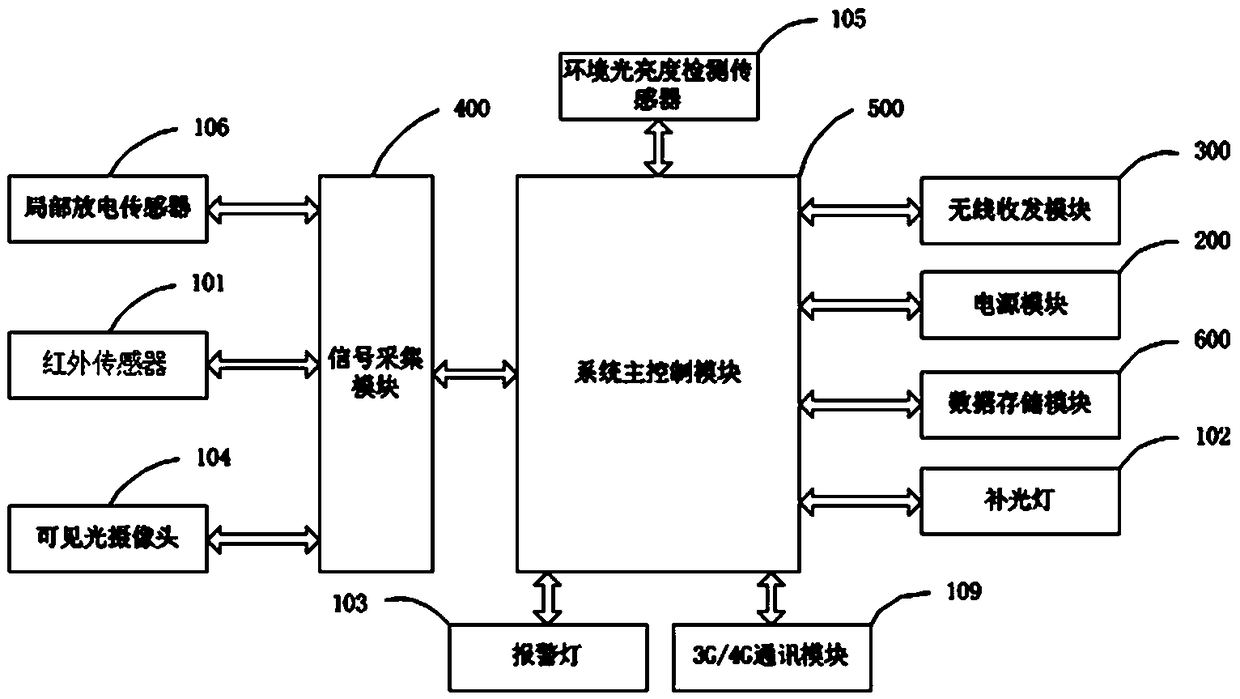

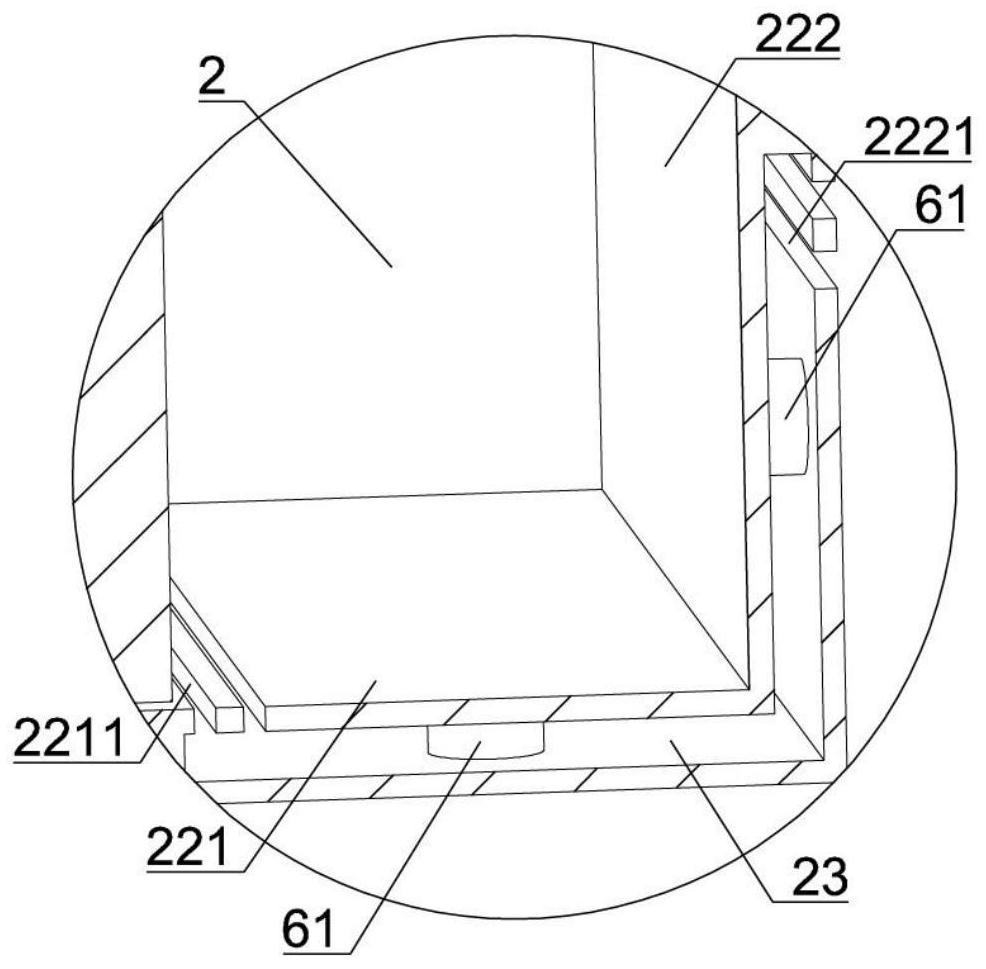

Integrated non-contact online monitoring device for combined electric equipment in substation

InactiveCN109470959AIncreased risk of failureReduce complexityElectrical testingElectric equipmentUltrahigh frequency

The invention discloses an integrated non-contact online monitoring device for combined electric equipment in a substation. The device comprises a signal acquisition front end part for monitoring thecombined electric equipment and outputting corresponding data, a system main control module for acquiring the monitored data and outputting result information of comprehensive analysis of the data, asignal acquisition module for receiving the data monitored by the signal acquisition front end part and uploading signals obtained after analog-to-digital conversion and modulation of the data to thesystem main control module, and a wireless receiving and transmitting module for receiving the result information and transmitting the result information to a background server; the signal acquisitionfront end part is provided with an infrared sensor for shooting infrared images of the combined electric equipment regularly to monitor temperature and outputting infrared signals, a visible light camera for recording videos or shooting images of the combined electric equipment in the substation regularly and outputting video and image signals, and a partial discharge sensor for acquiring and detecting ultrahigh frequency signals radiated by the combined electric equipment in real time and outputting partial discharge signals.

Owner:上海迈内能源科技有限公司

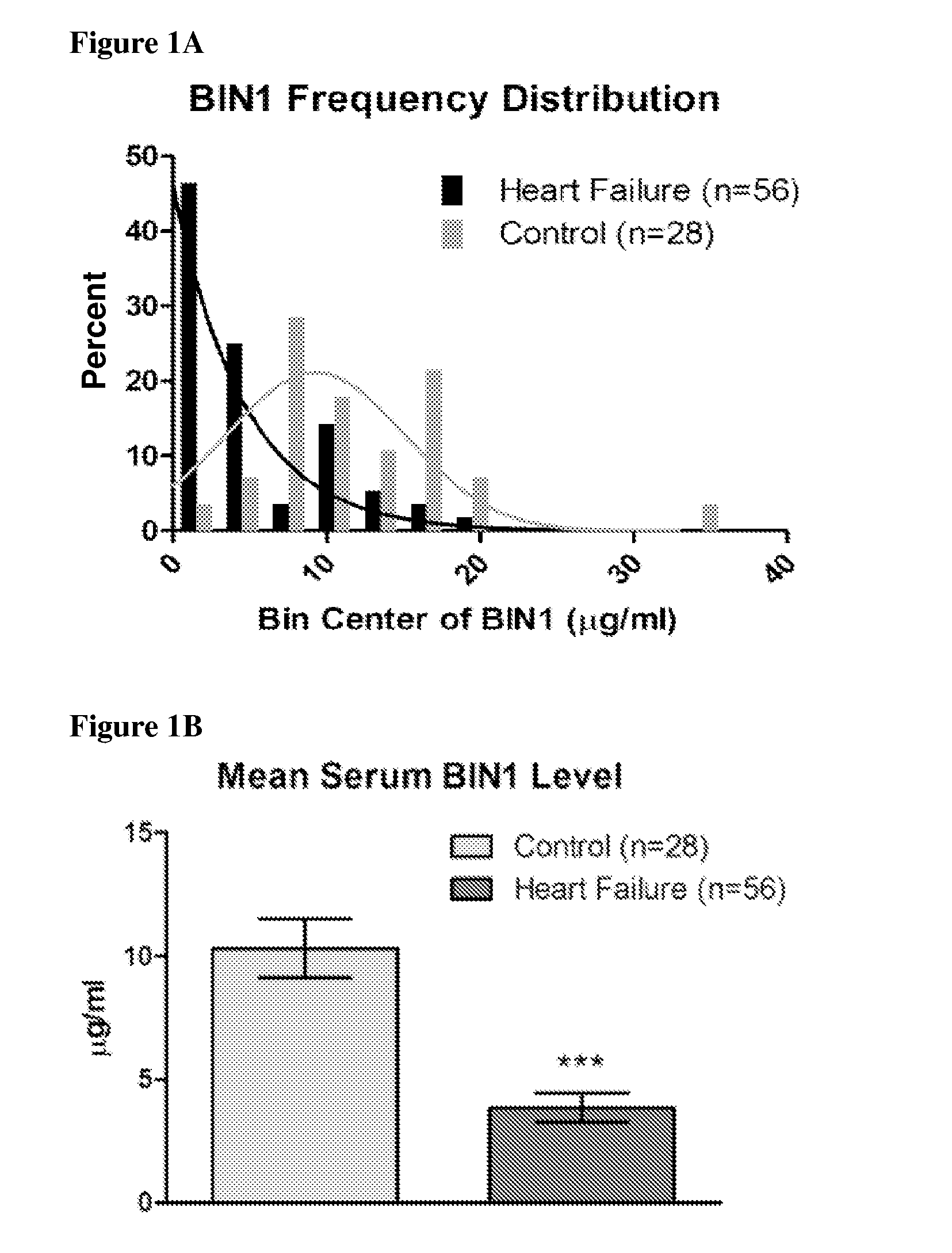

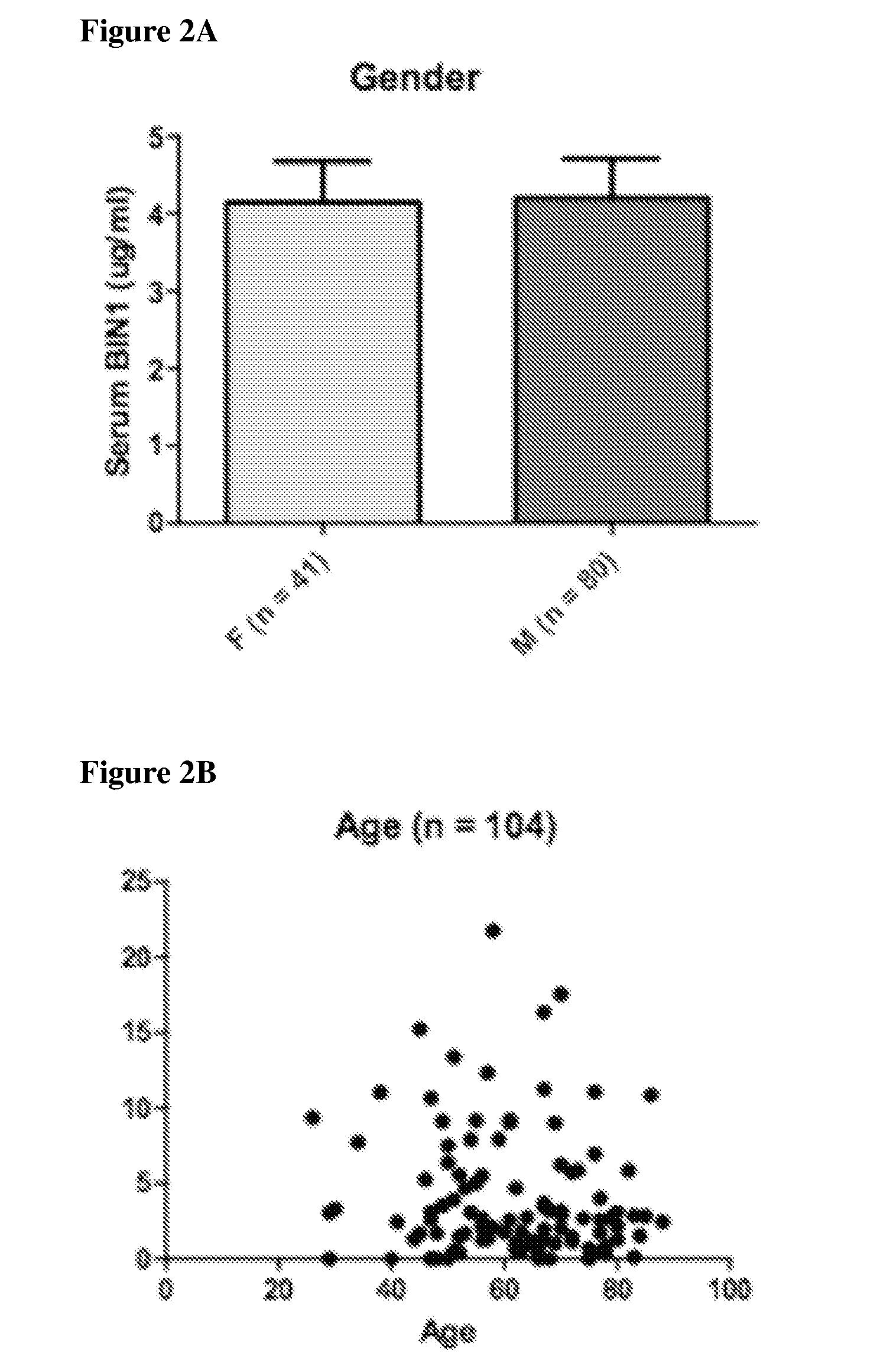

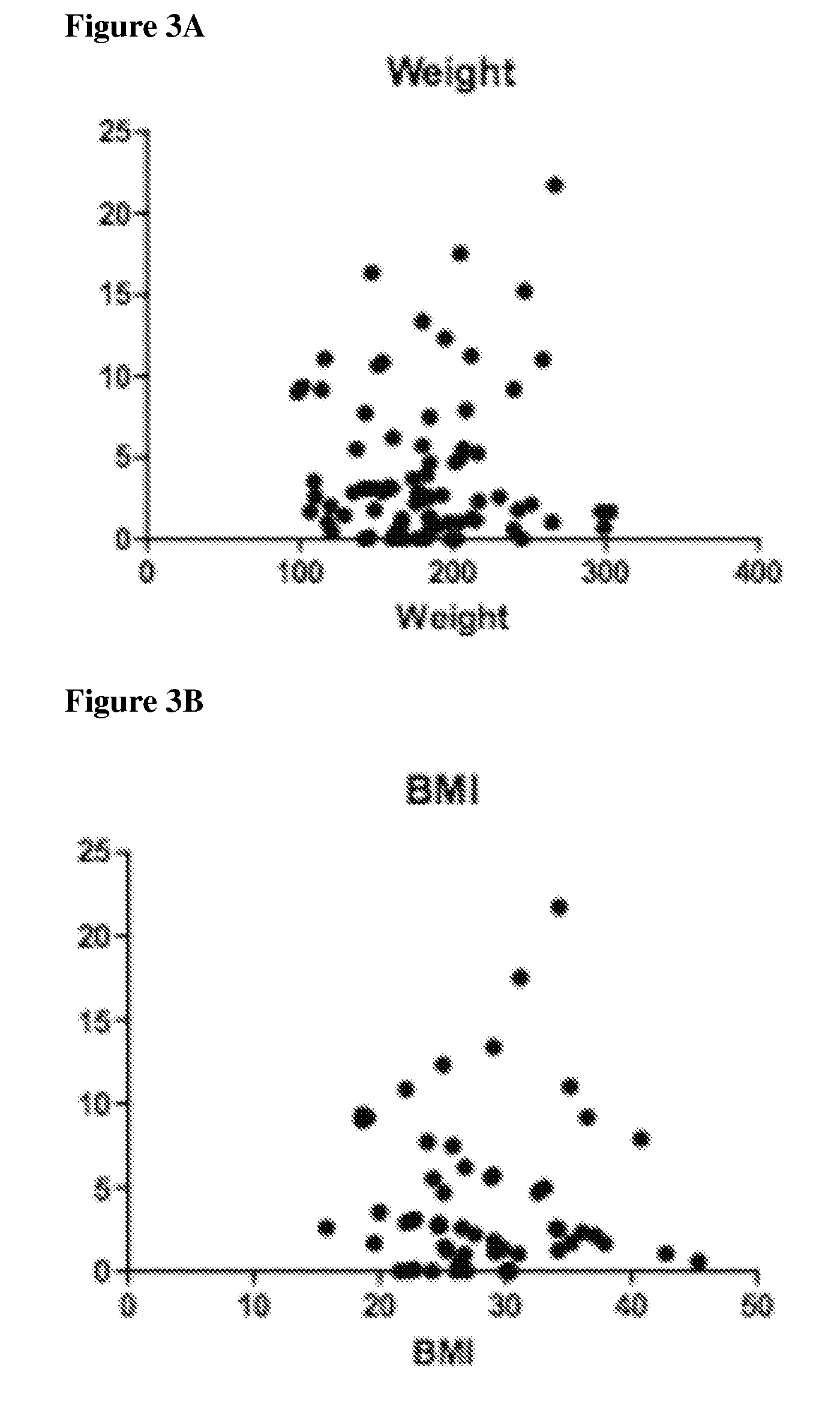

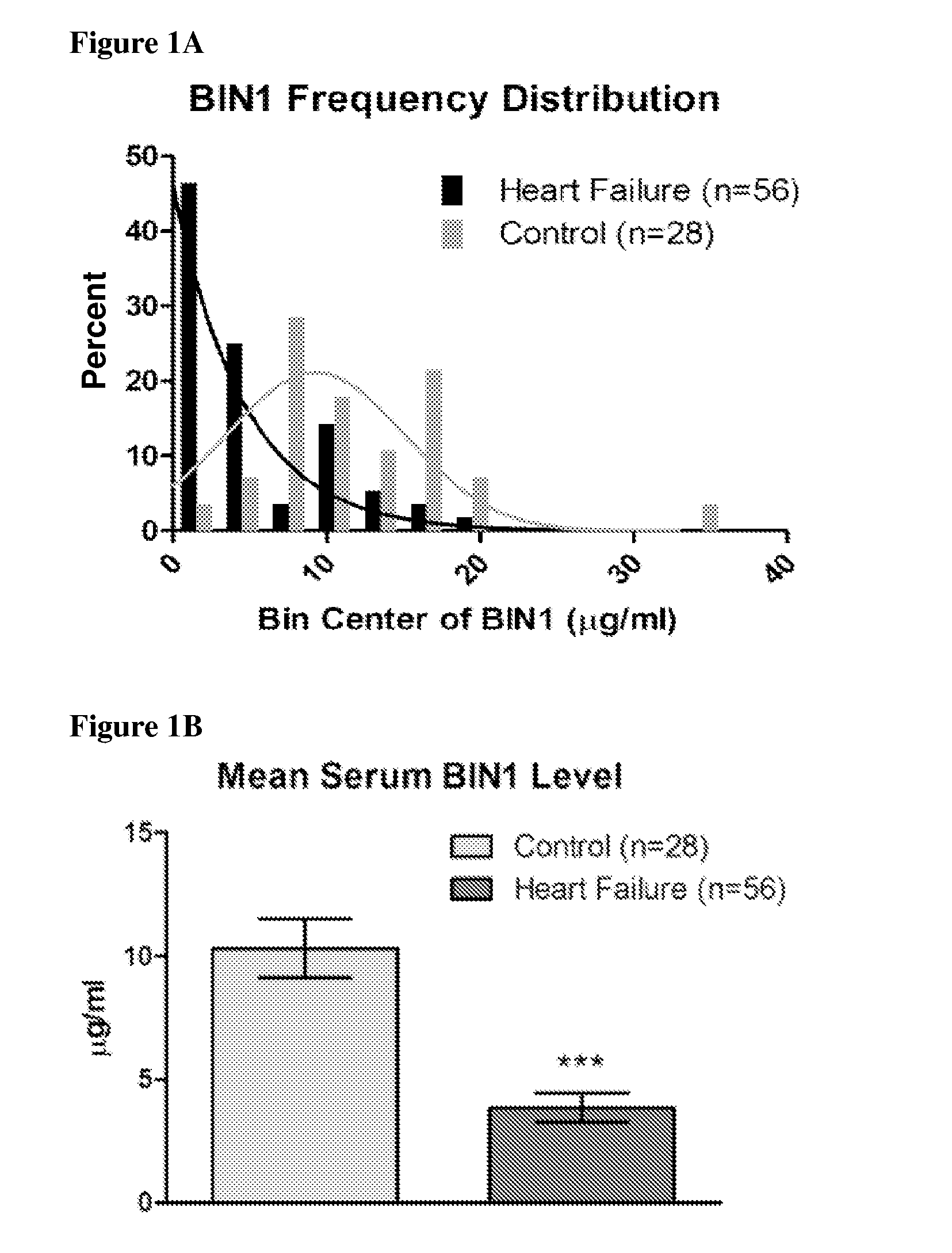

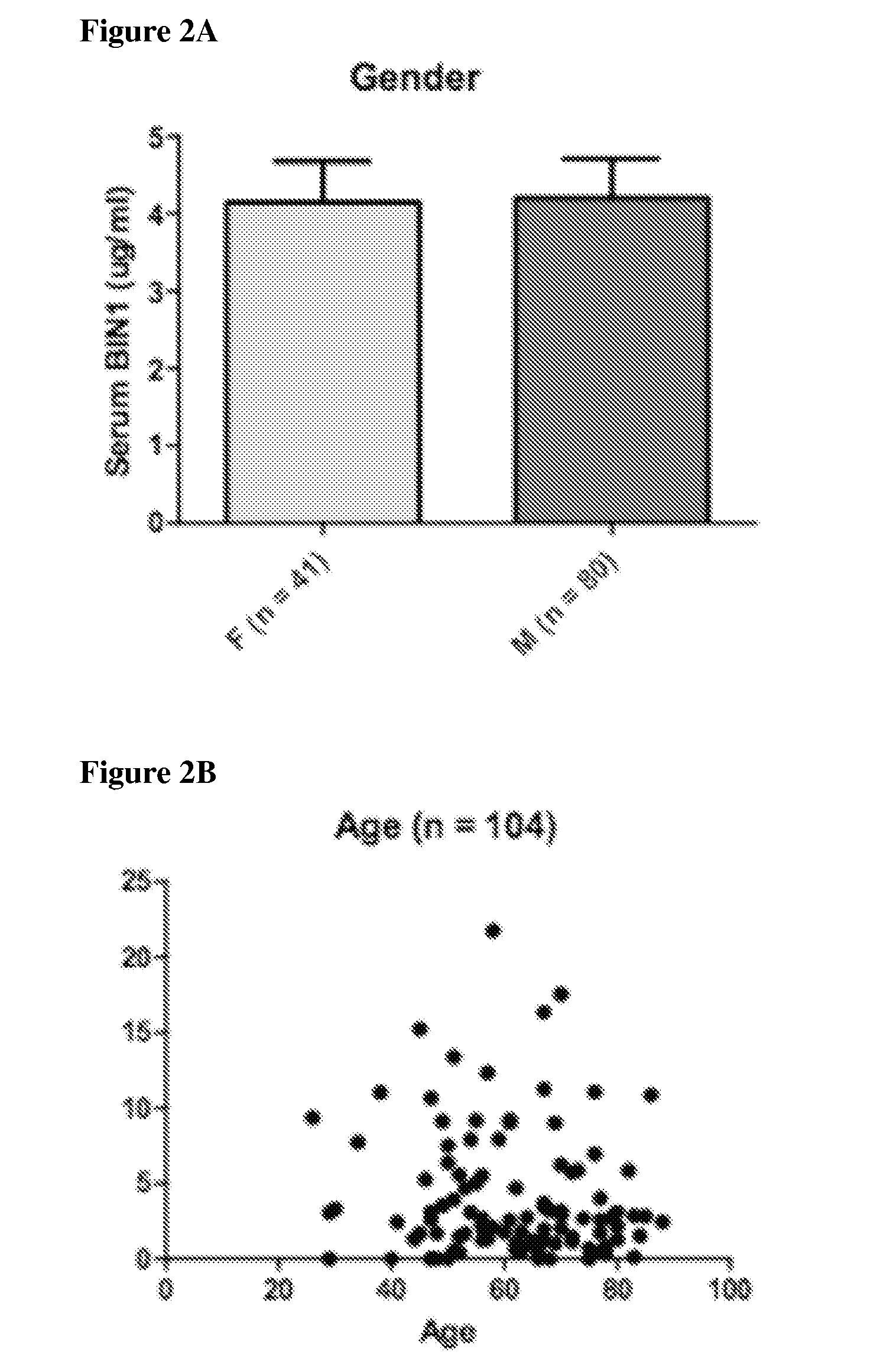

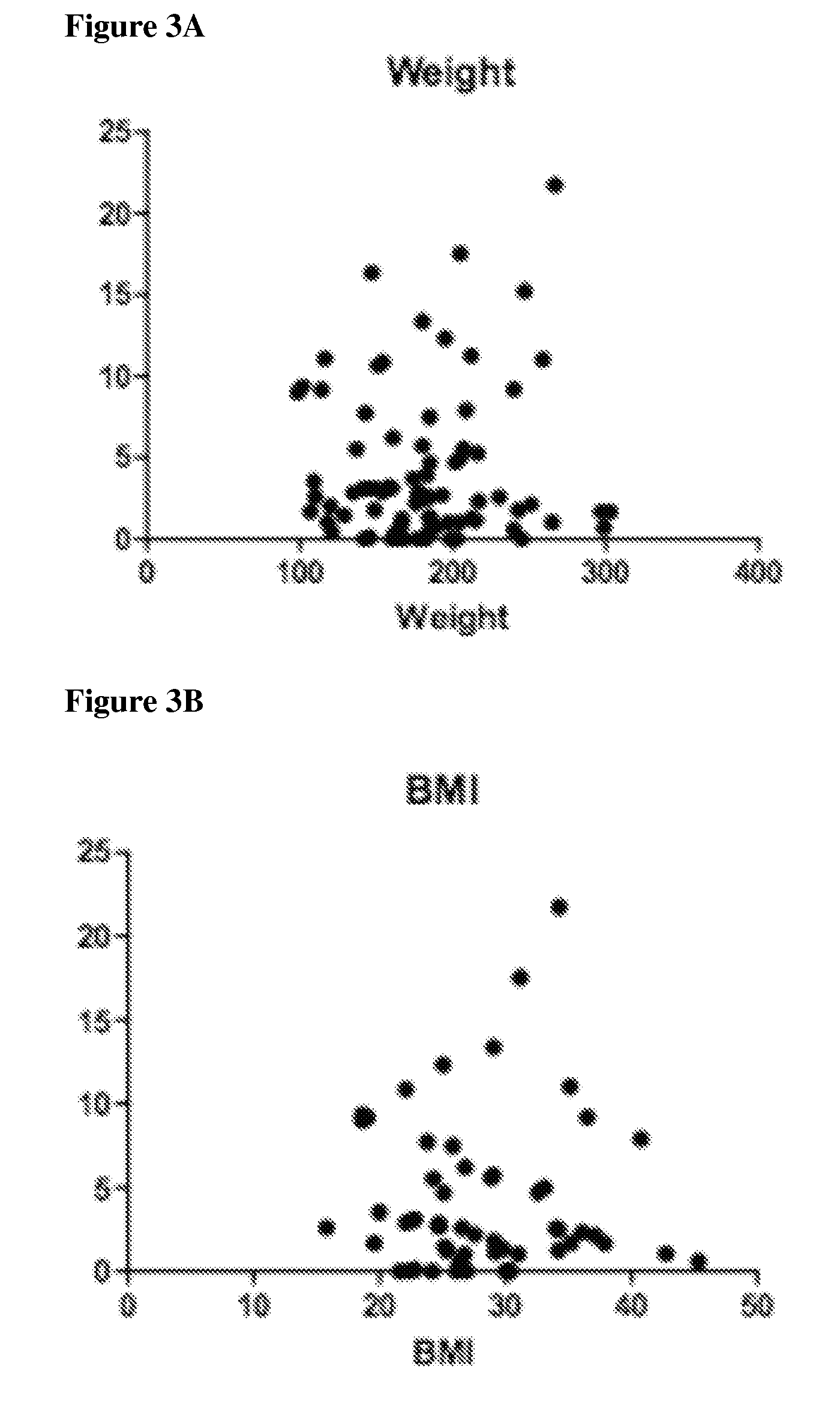

Body Fluid BIN1 as a Marker of Cardiac Health

ActiveUS20130266975A1Increase riskIncreased riskDisease diagnosisBiological testingBiological fluidTreatment effect

The present disclosure provides methods involving use of BIN1 protein levels in biological fluid of a subject in evaluating cardiac health of the subject. The method provided herein may be used to predict a risk of a poor outcome in a subject. The methods also find use in evaluating subjects for assessing patients diagnosed with heart failure. These methods are also useful in assessing therapy options and efficacy of treatment in heart failure patients.

Owner:RGT UNIV OF CALIFORNIA

Apparatus for simulating wind power farm

InactiveUS10180997B2Efficiently and stably mangeEasy to operateWind motor controlEngine fuctionsSCADAData acquisition

An apparatus for simulating a wind power farm includes a wind power generator simulator configured to act as a virtual wind power generator to dynamically generate an attribute value and provide the attribute value to a supervisory control and data acquisition (SCADA) system to be tested; a wind power generator simulation platform configured to generate and manage a plurality of wind power generator simulators within one system, monitor the system, monitor operation states of the plurality of wind power generator simulators, and transmit a result of monitoring the operation states; and a wind power farm controller configured to generate a wind power farm by grouping a plurality of wind power generator simulation platforms into a single cluster, and manage a simulation environment of the wind power farm.

Owner:KOREA ELECTRIC POWER CORP

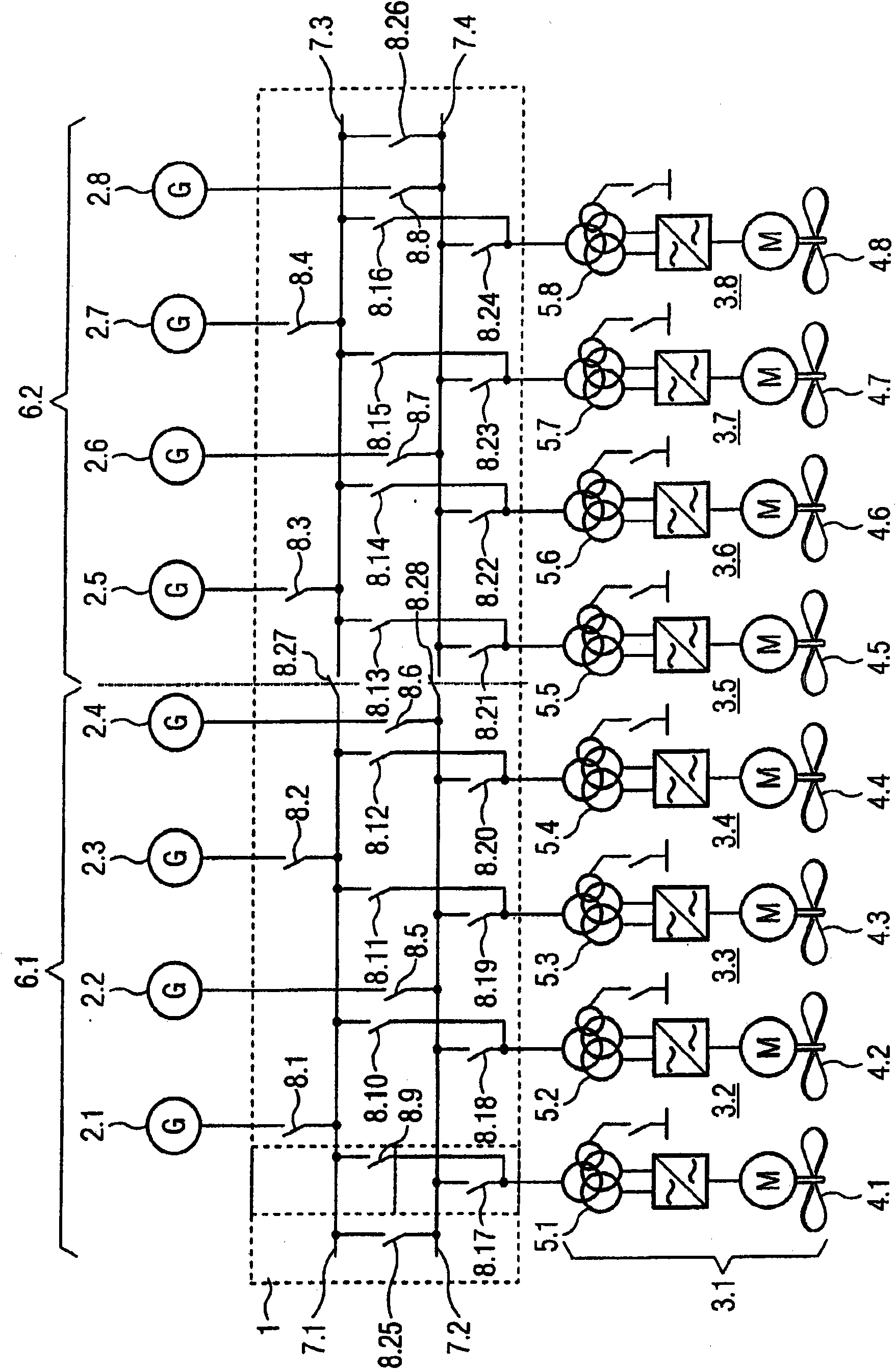

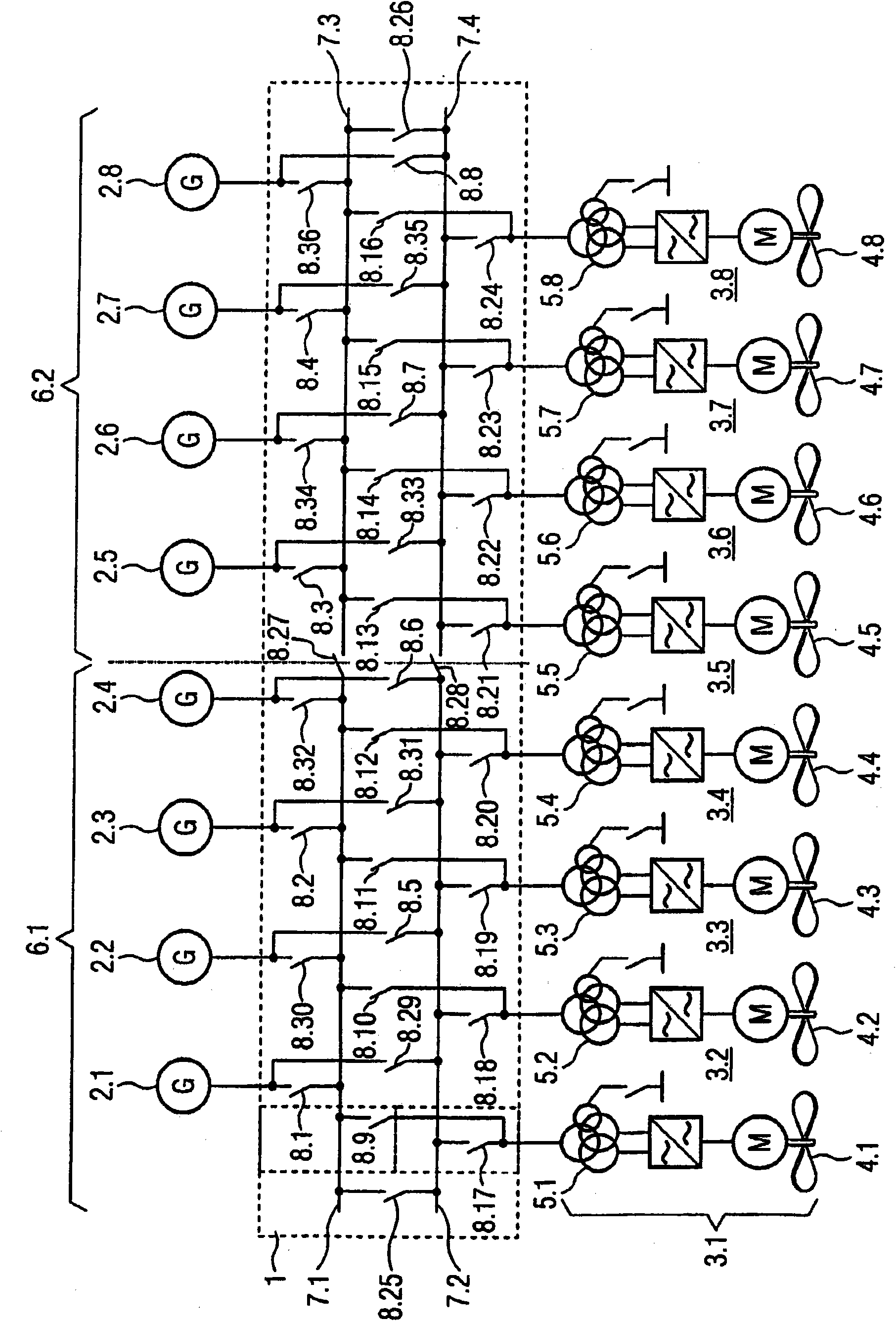

Electrical switchgear, particularly for connecting generators and thrusters in dynamically positioned vessels

InactiveCN101836342AAvoid high current loadsIncreased risk of failureInformation technology support systemAc network circuit arrangementsElectric energyElectric generator

The invention refers to an electrical switchgear (1) for feeding at least two electrical consumers (3.1 to 3.n) with electrical energy from at least two energy sources (2.1 to 2.n), comprising at least one section (6.1 to 6.n) with two 0 busbars (7.1 to 7.n) and a number of switches (8.1 to 8.n), wherein each busbar (7.1 to 7. n) is connec table to at least one of the energy sources (2.1 to 2.n) via one of the switches (8.1 to 8.n) for each energy source (2.1 to 2.n), respectively and wherein each busbar (7.1 to 7.n) is 5 connectable to each one of the electrical consumers (3.1 to 3.n) via one of the switches (8.1 to 8.n) for each electrical consumer (3.1 to 3.n), respectively.

Owner:SIEMENS AG

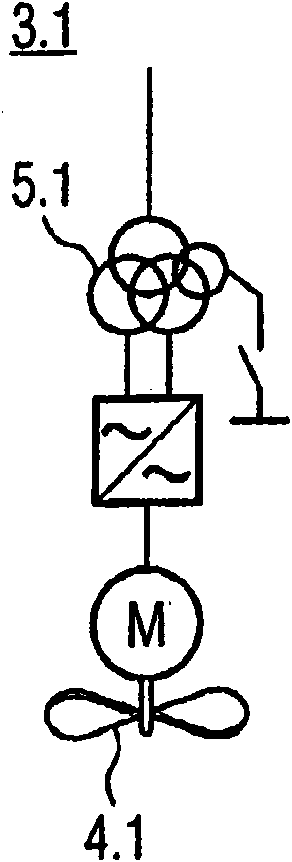

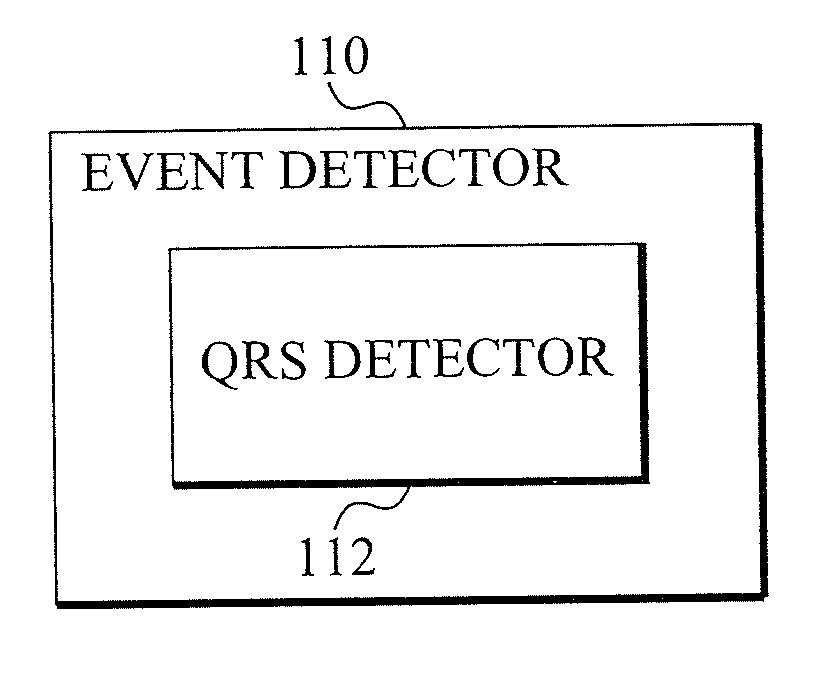

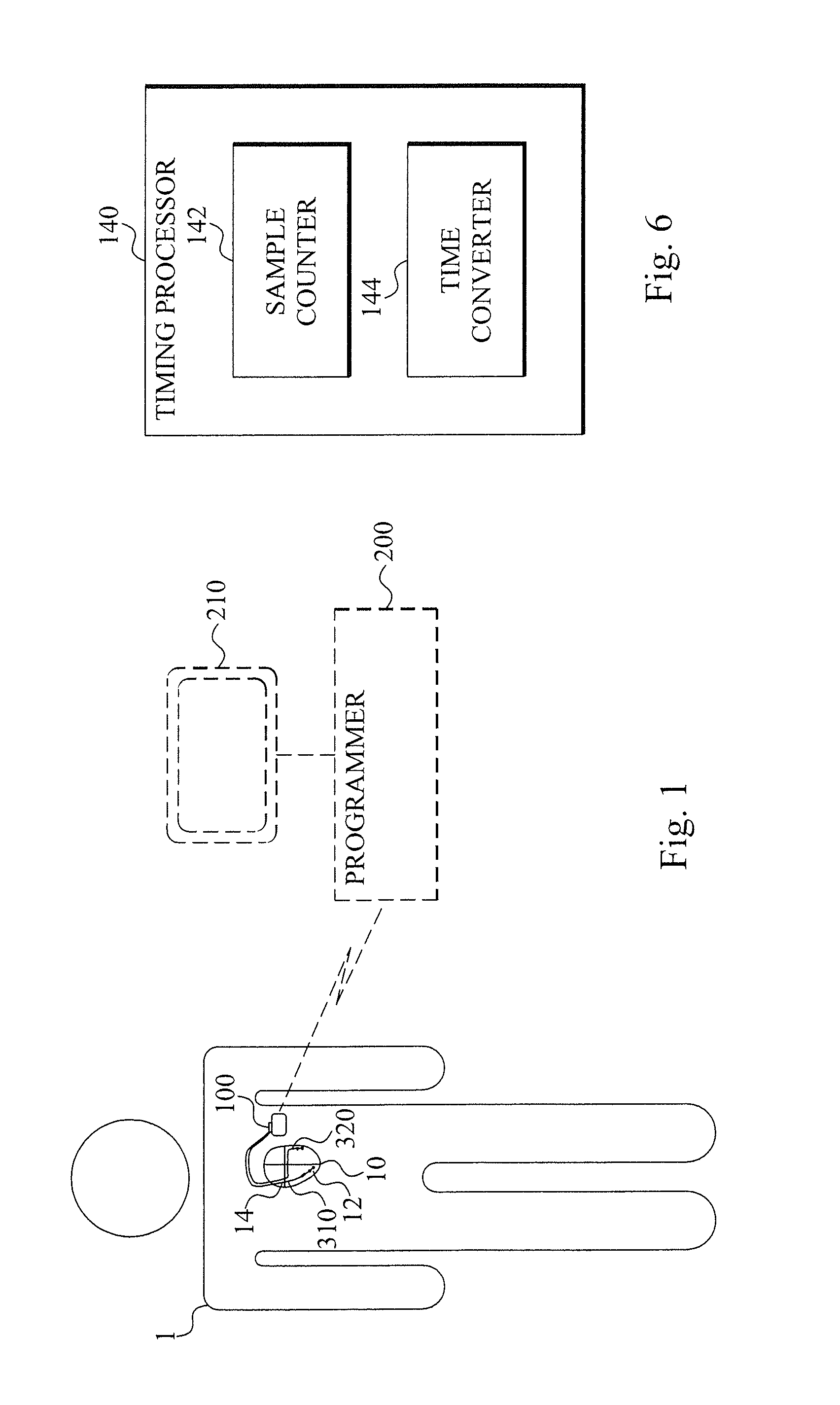

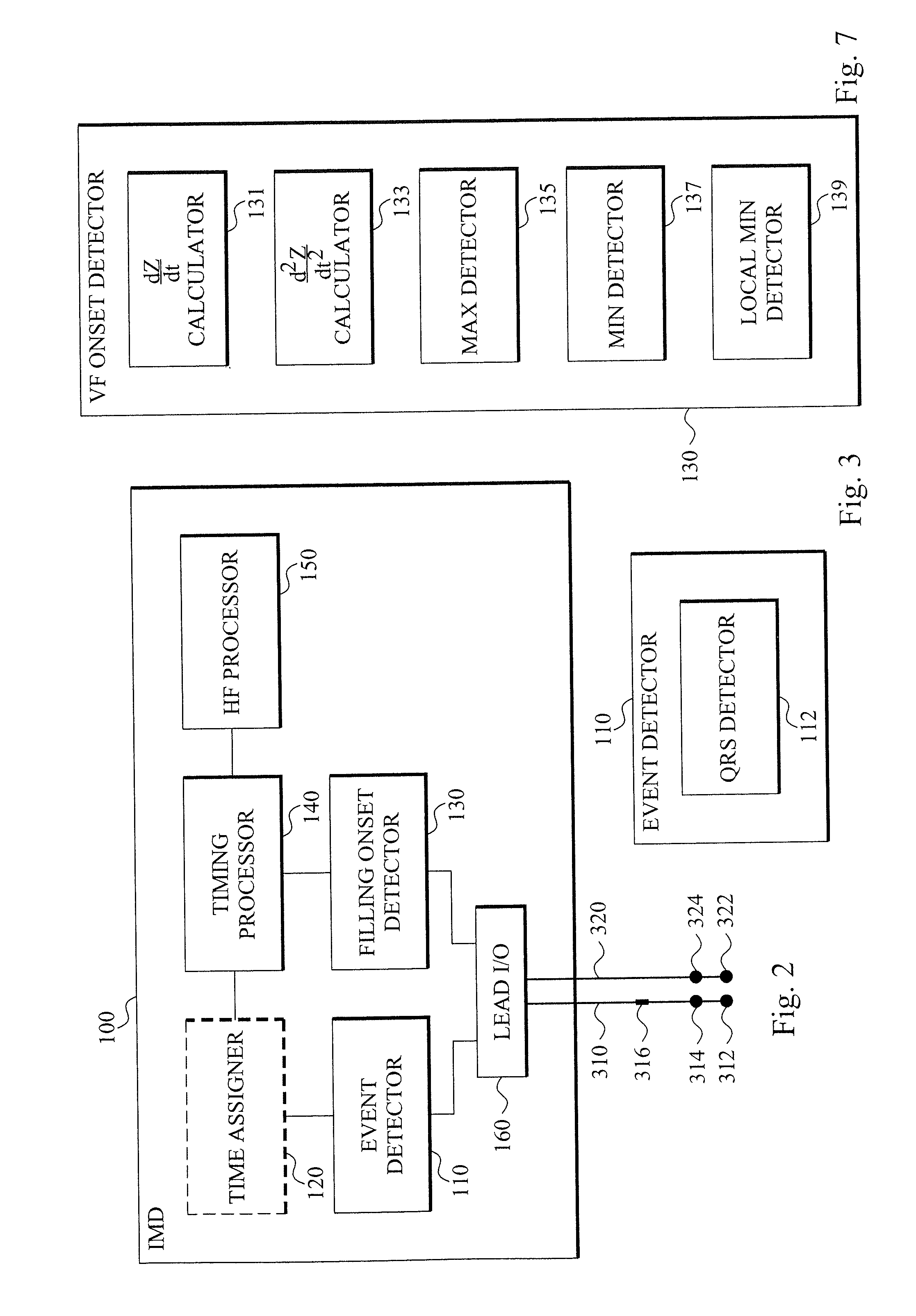

Heart failure detecting medical device

InactiveUS20110028855A1Increase opportunitiesIncreased risk of failureMechanical/radiation/invasive therapiesElectrocardiographyVentricular fillingIncreased risk

An implantable medical device has an event detector that detects a predetermined cardiac event during a heart cycle of a subject. A reference time is assigned to this detected cardiac event. An onset detector detects the onset of ventricular filling of the heart during the heart cycle. The relative time of the detected filling onset is determined based on the assigned time reference. An increased risk of heart failure of the subject is automatically determined based on the determined relative time for the filling onset. Generally, a reduction in the relative time, as determined at different points in time, indicates an increased heart failure risk or the presence of a heart failure condition.

Owner:UNI CHARM CORP +1

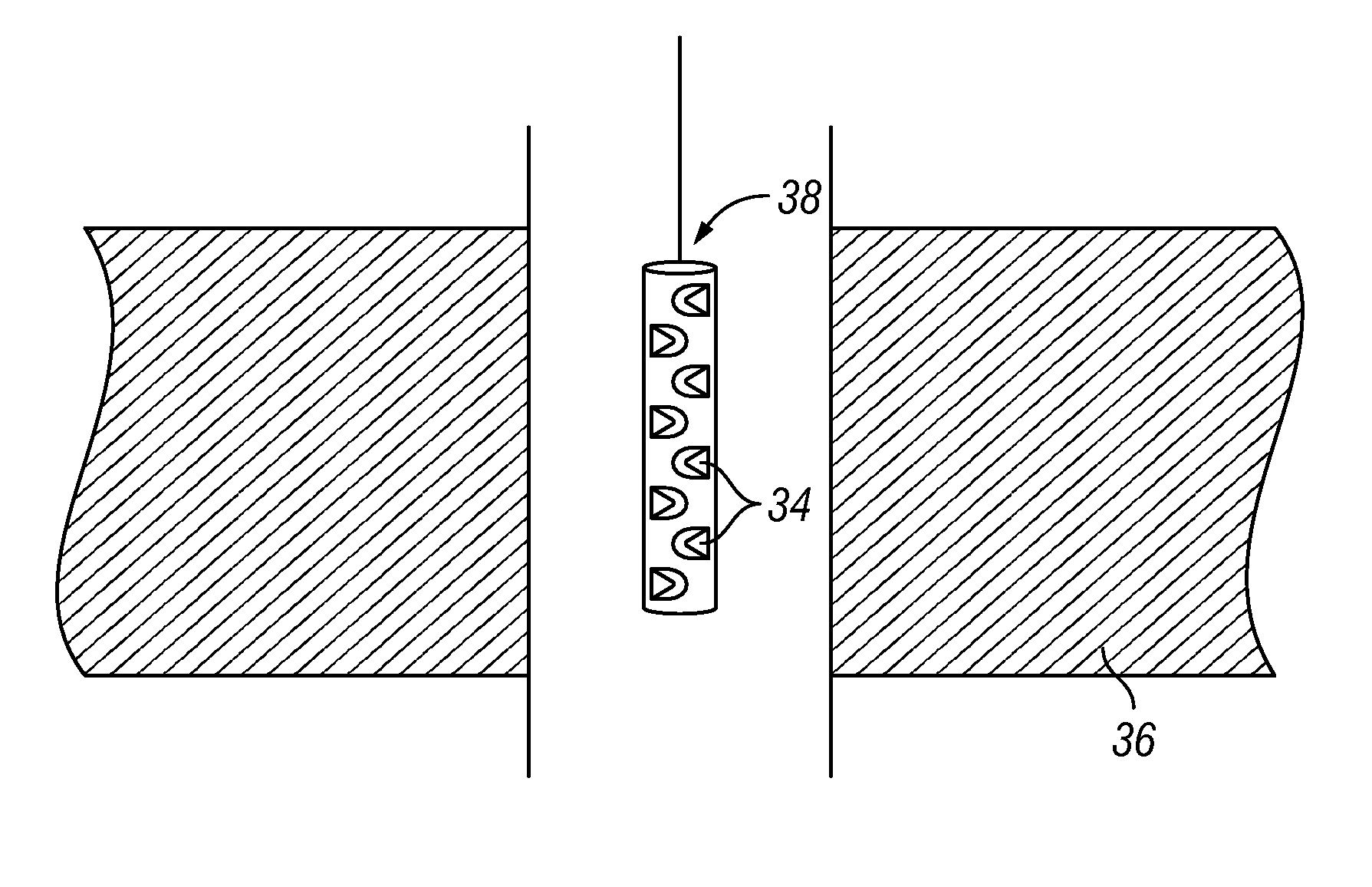

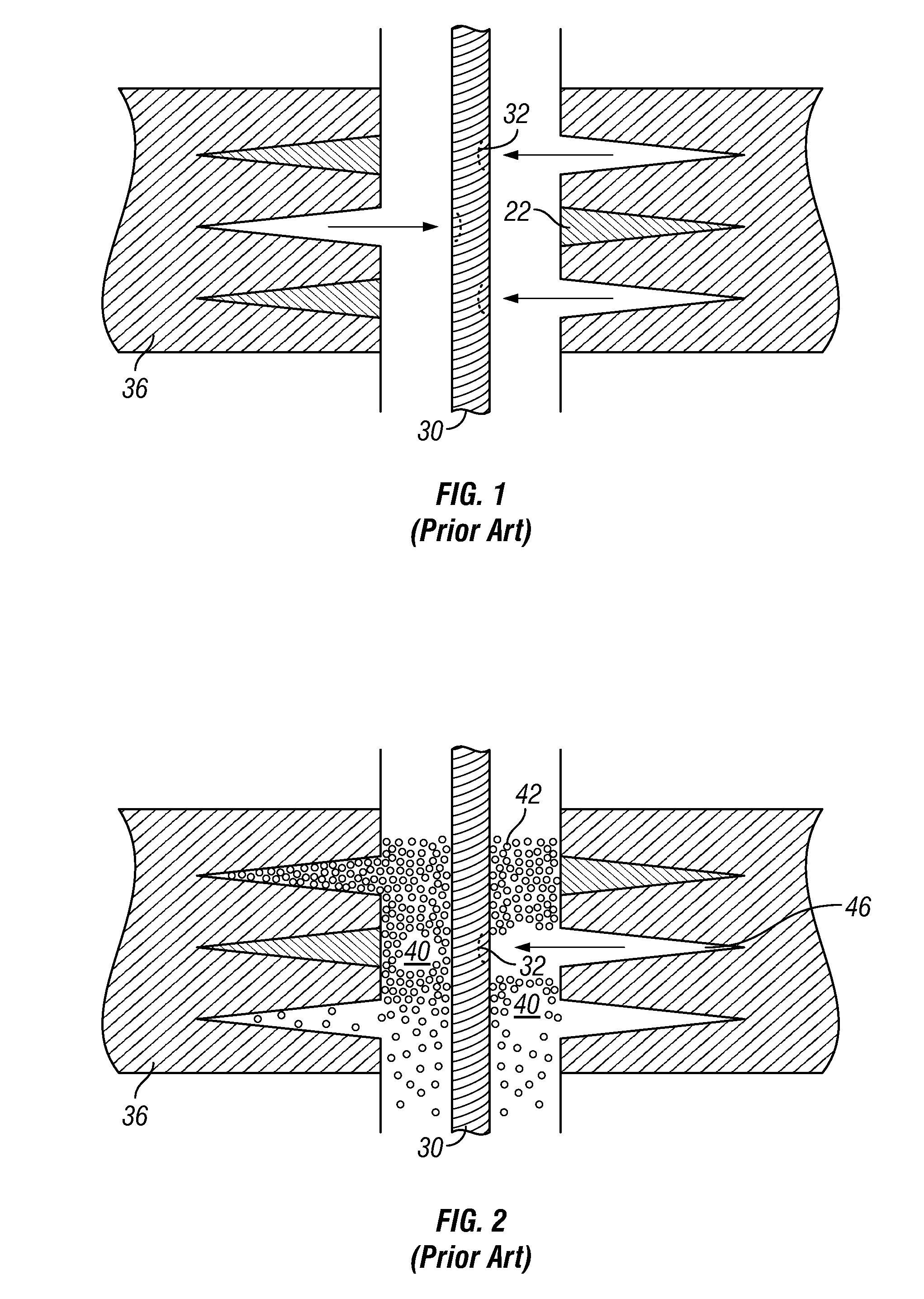

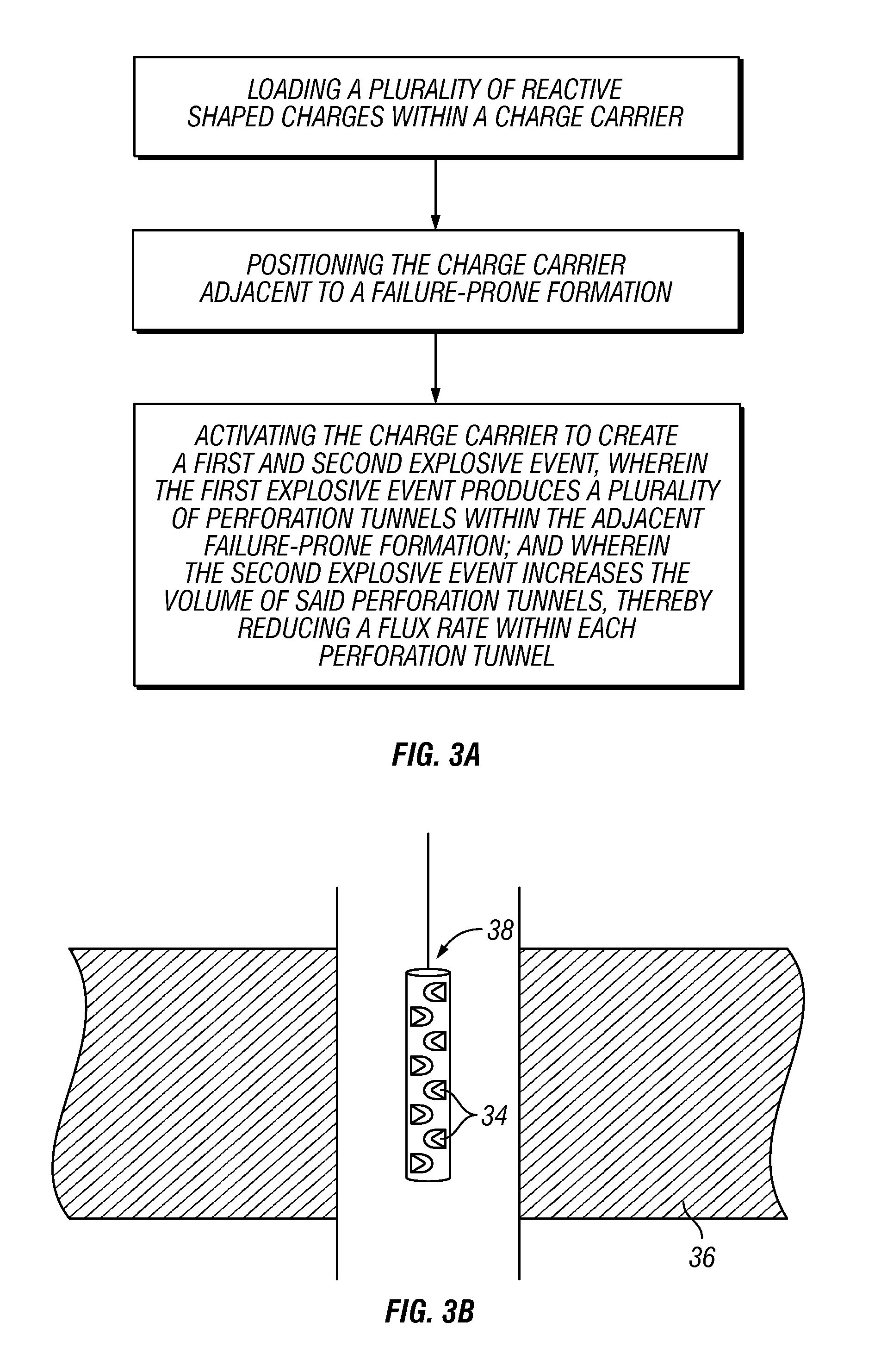

Method for perforating failure-prone formations

ActiveUS8245770B2Reduction tendencyImprove productivityAmmunition projectilesFluid removalProduction rateShaped charge

By using reactive shaped charges to perforate failure prone formations, the present invention is able to keep formation sand in place and increase productivity. An efficient flow distribution is surprisingly produced without requiring surge flow or post-perforation stimulation. Further, using the secondary reactive effects of reactive shaped charges allows for the reduction of the risk of erosion and minimization of sand production. In a preferred embodiment, a liner capable of producing a strongly exothermic intermetallic reaction between liner components within and around the tunnel is used to achieve a high percentage of substantially clean and enlarged perforation tunnels conducive to flow or gravel packing.

Owner:WELLS FARGO BANK NAT ASSOC +1

Body fluid BIN1 as a marker of cardiac health

ActiveUS8999659B2Increased riskIncreased risk of failureDisease diagnosisBiological testingMedicineTherapeutic effect

The present disclosure provides methods involving use of BIN1 protein levels in biological fluid of a subject in evaluating cardiac health of the subject. The method provided herein may be used to predict a risk of a poor outcome in a subject. The methods also find use in evaluating subjects for assessing patients diagnosed with heart failure. These methods are also useful in assessing therapy options and efficacy of treatment in heart failure patients.

Owner:RGT UNIV OF CALIFORNIA

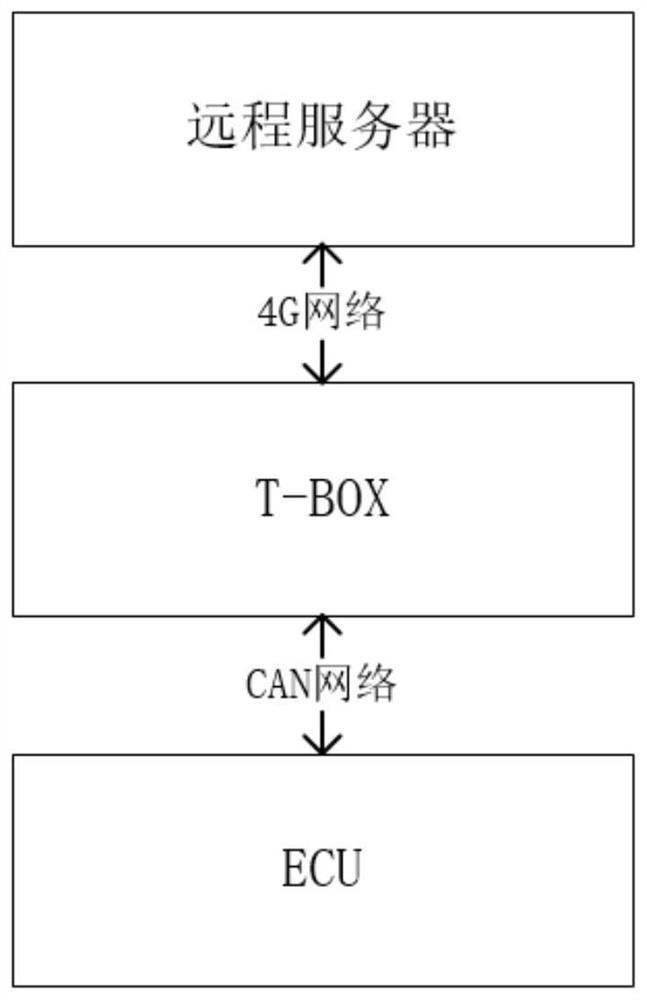

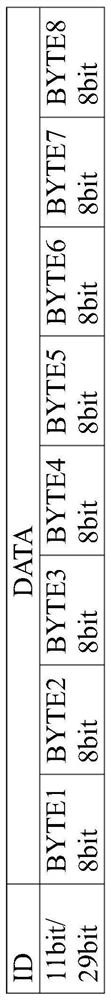

Method of supporting remote semaphore configuration

The invention discloses a method for supporting remote semaphore configuration. The method comprises the steps that S1, a remote server selects a correspondingly configured BIN file according to requirements and issues the BIN file to a TBOX; S2, the TBOX analyzes the correspondingly configured BIN file and issues the BIN file to the ECU through the CAN network; S3, the ECU executes a corresponding CAN communication process; S4, the TBOX communicates with the ECU through a CAN network and obtains related semaphore; and S5, the TBOX uploads the obtained related semaphore to a remote server, andthe remote server analyzes the related semaphore into actual semaphore data according to the configuration file. According to the method for supporting remote semaphore configuration, the semaphore can be changed without upgrading software, inconvenience in use and fault risks due to frequent software upgrading are avoided, and the method has the advantage of flexible configuration.

Owner:嘉兴行适安车联网信息科技有限公司

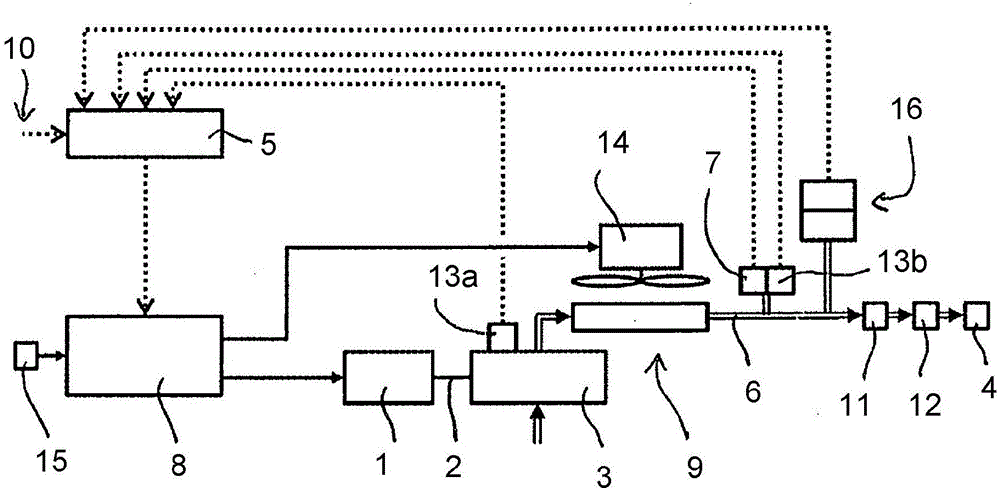

Integration Process and Product for Digital Systems

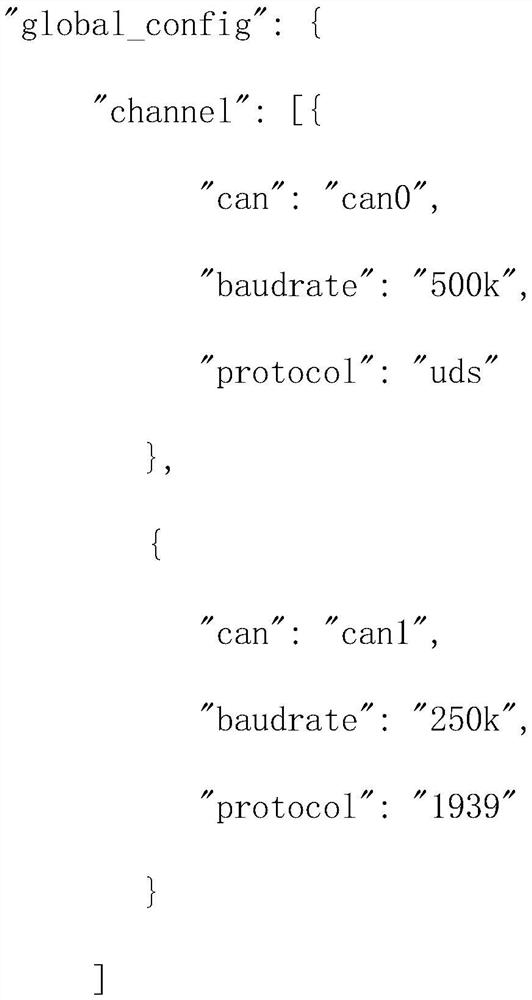

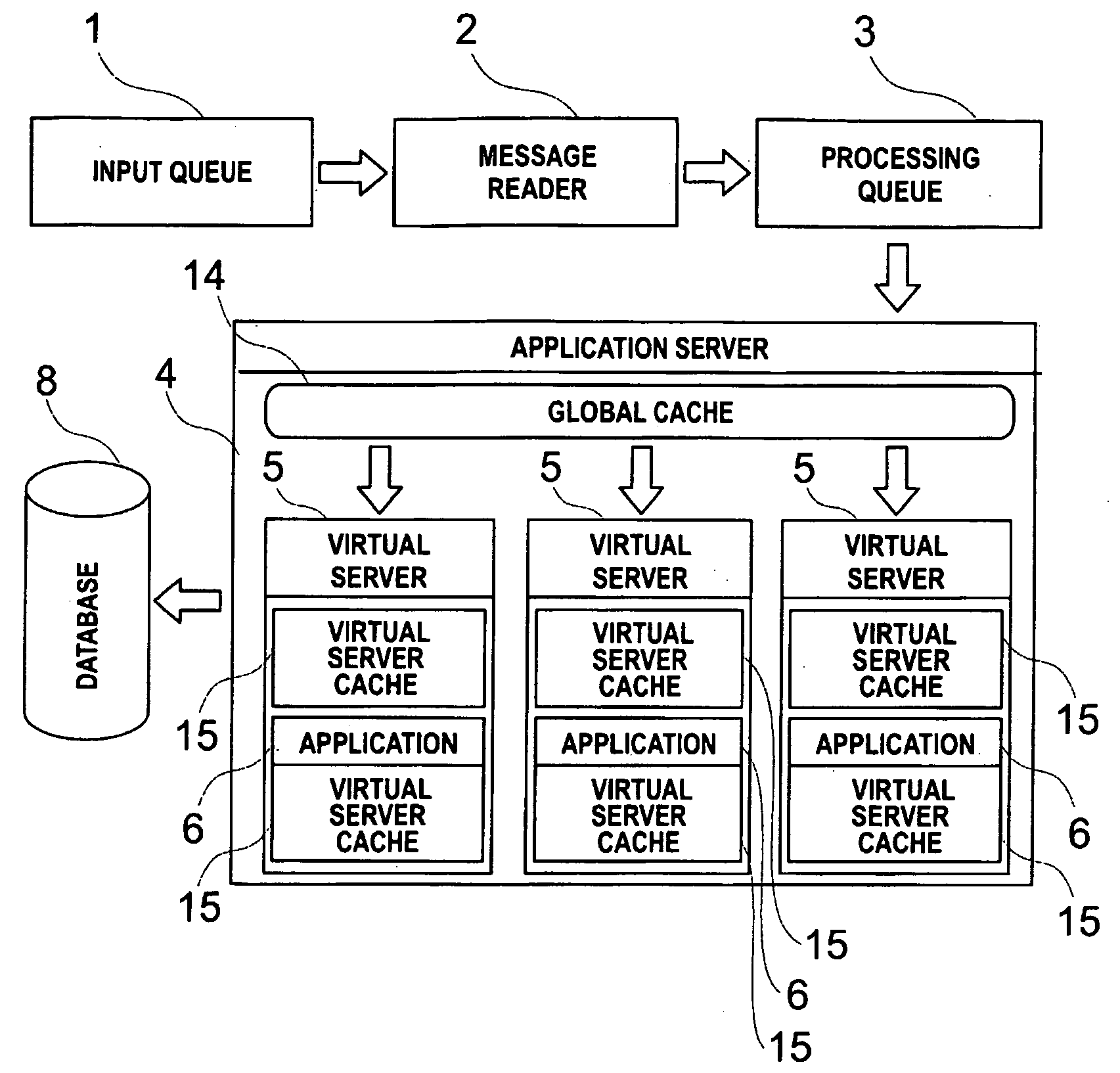

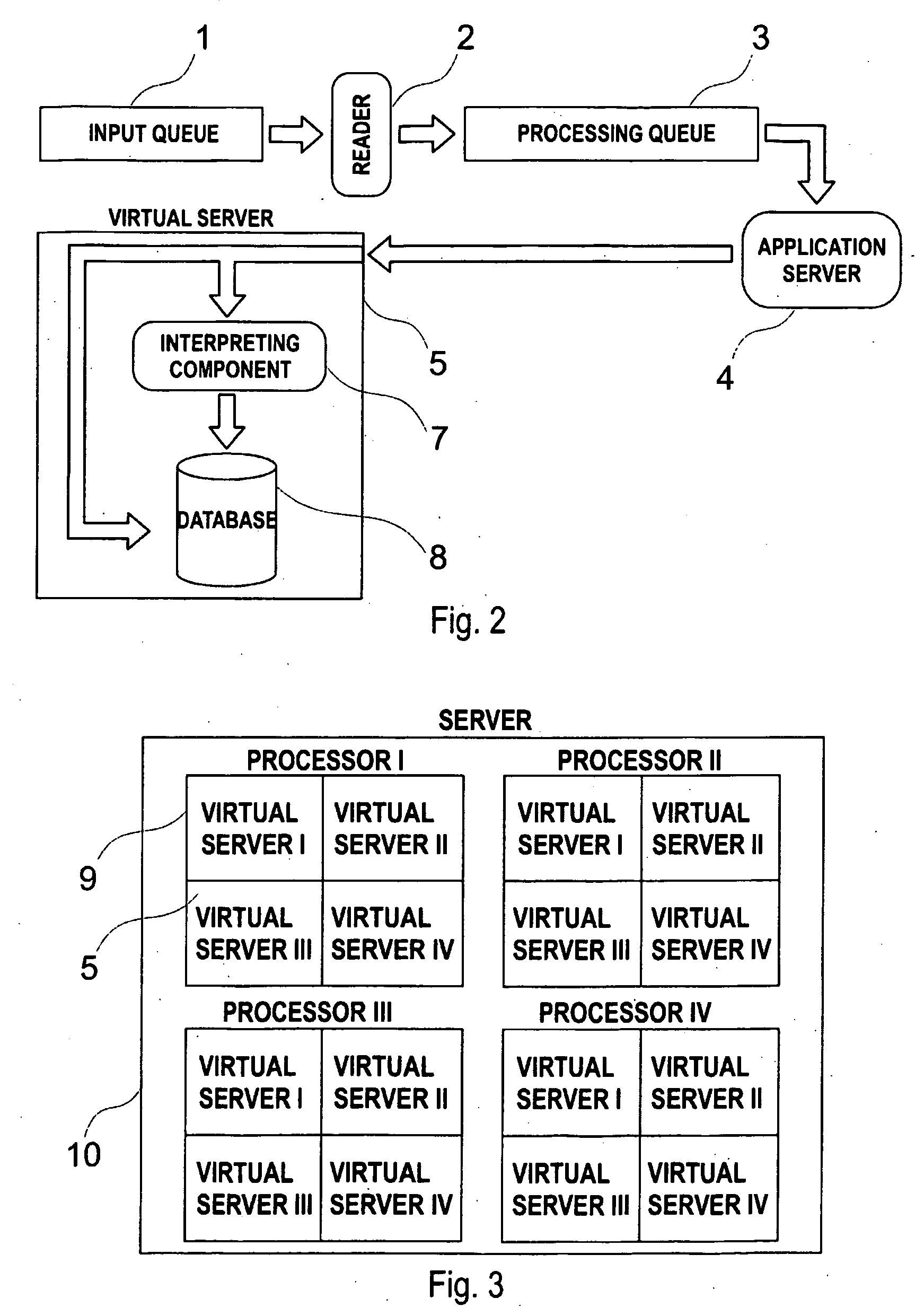

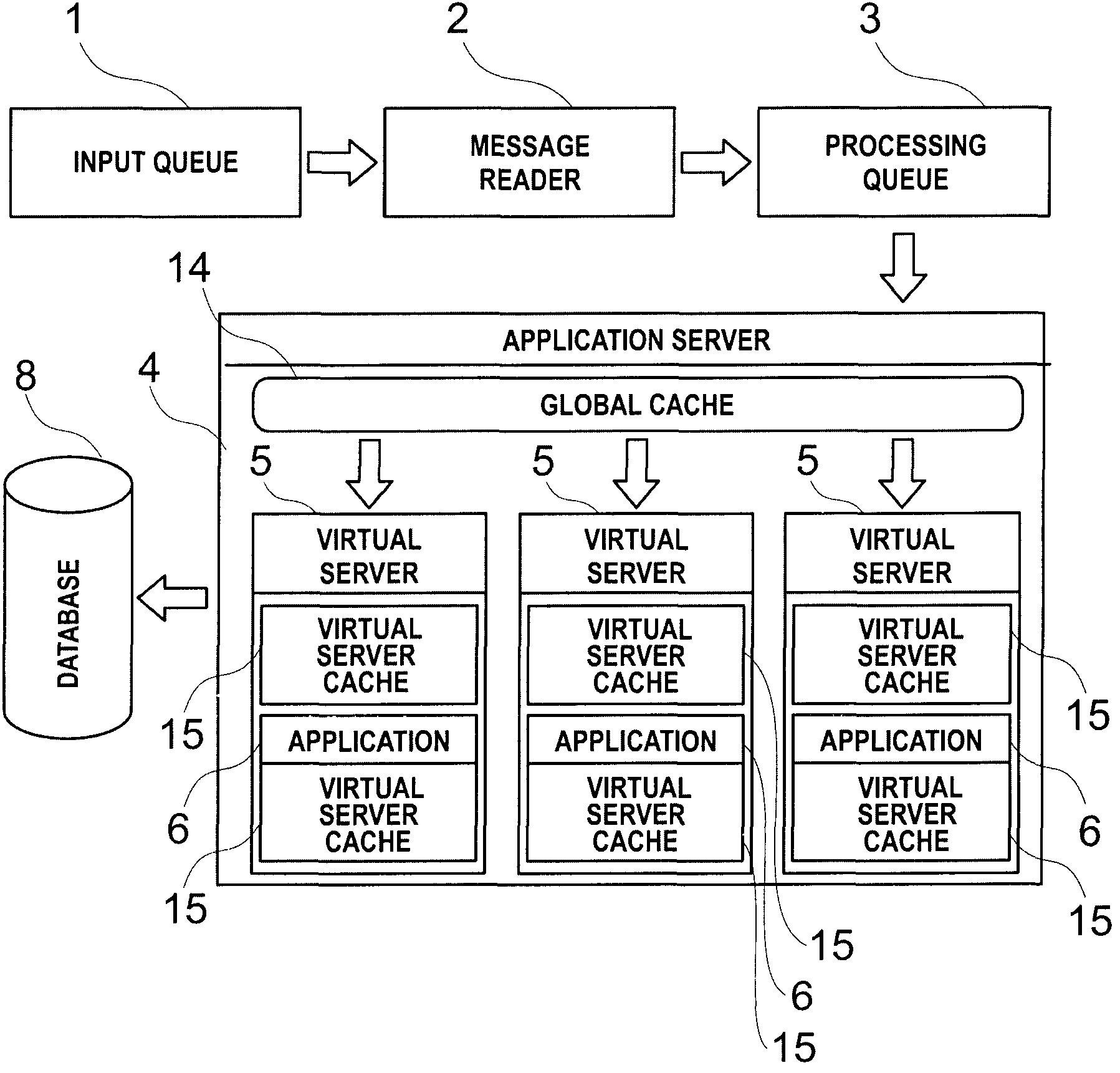

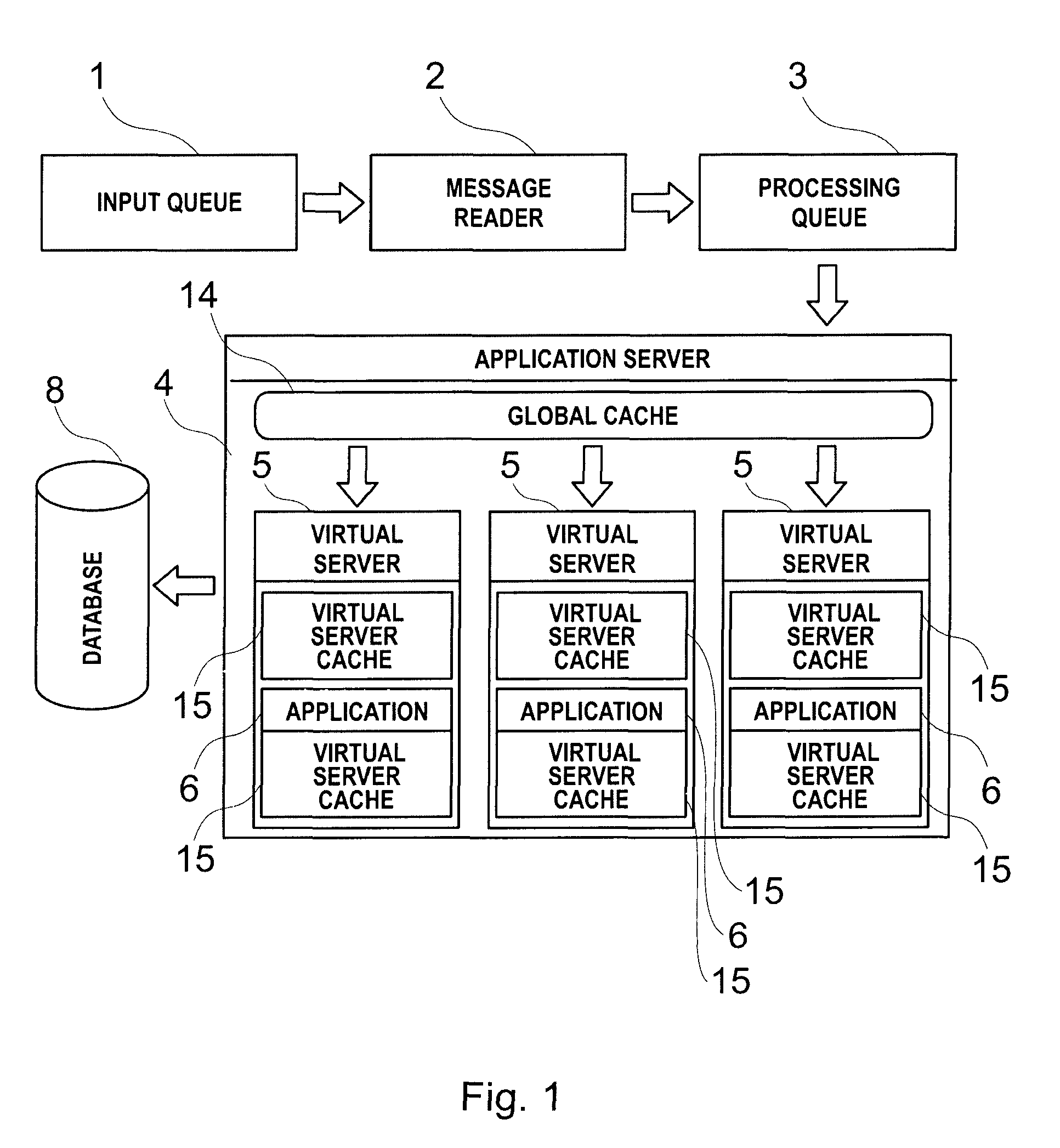

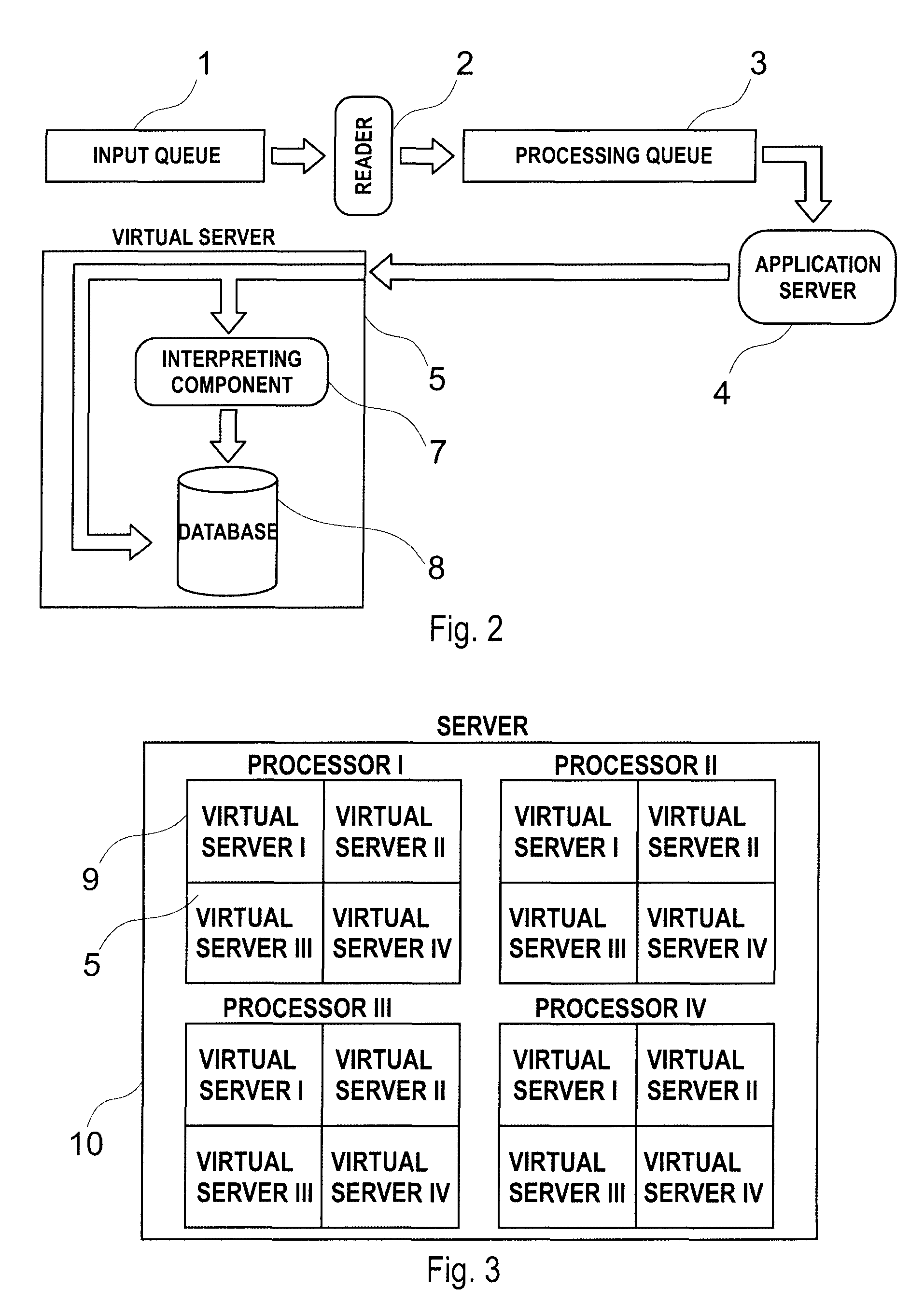

InactiveUS20080222231A1Great productivity and securityHigh performance and integrityResource allocationMultiple digital computer combinationsMessage passingApplication server

The present invention relates to a digital system integration process through a virtual server (5), which comprises a process that distributes instances of message management and processing application according to the number of processors (9) present in each server (10). A message reader component (2) removes the message from one of the input queues (1) and verifies if it is a valid message. Then the messages are stored in the internal processing queue (3) according to the environment configurations and the application server (4) marks the message with the respective virtual server (5). The application server (4) removes the message from the processing queue (3) and delivers the message to the client application (6). Finally, the message is validated and, after it is processed, excluded from the database (8).

Owner:RIBEIRO LEONARDO LARSEN

Integration process and product for digital systems

InactiveUS7769800B2Great productivity and securityImprove integrityResource allocationMultiple digital computer combinationsSystem integrationApplication server

The present invention relates to a digital system integration process through a virtual server (5), which comprises a process that distributes instances of message management and processing application according to the number of processors (9) present in each server (10). A message reader component (2) removes the message from one of the input queues (1) and verifies if it is a valid message. Then the messages are stored in the internal processing queue (3) according to the environment configurations and the application server (4) marks the message with the respective virtual server (5). The application server (4) removes the message from the processing queue (3) and delivers the message to the client application (6). Finally, the message is validated and, after it is processed, excluded from the database (8).

Owner:RIBEIRO LEONARDO LARSEN

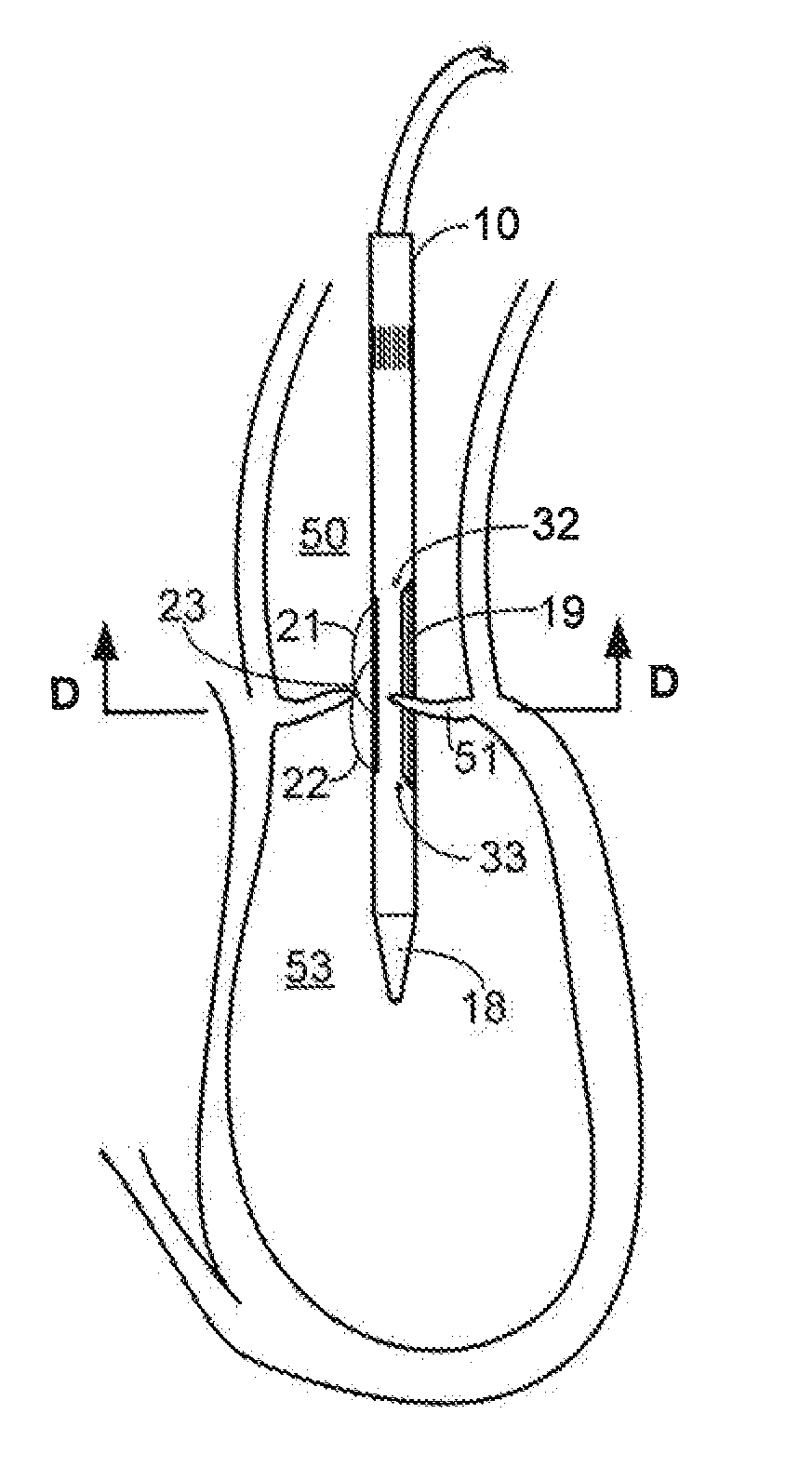

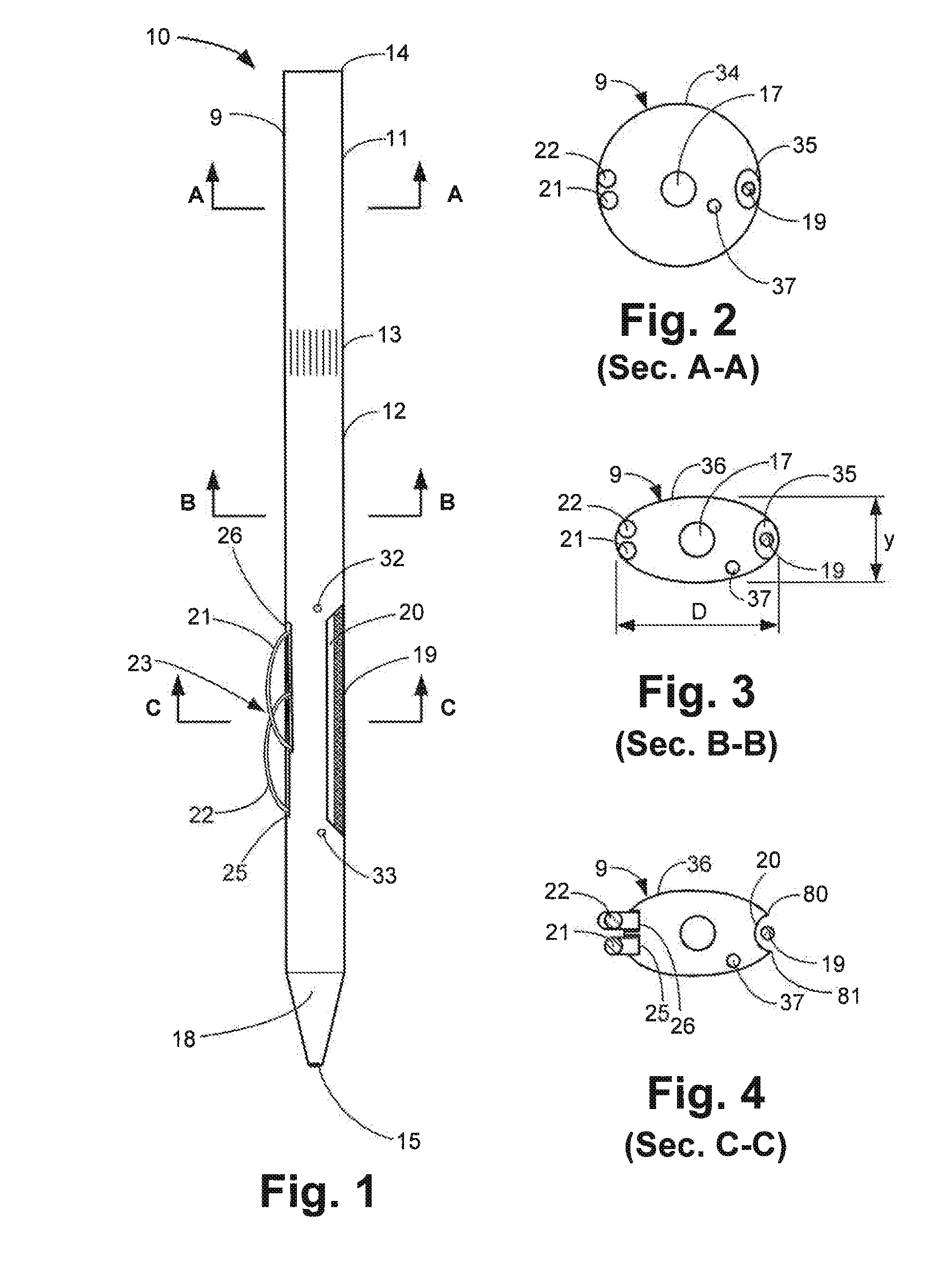

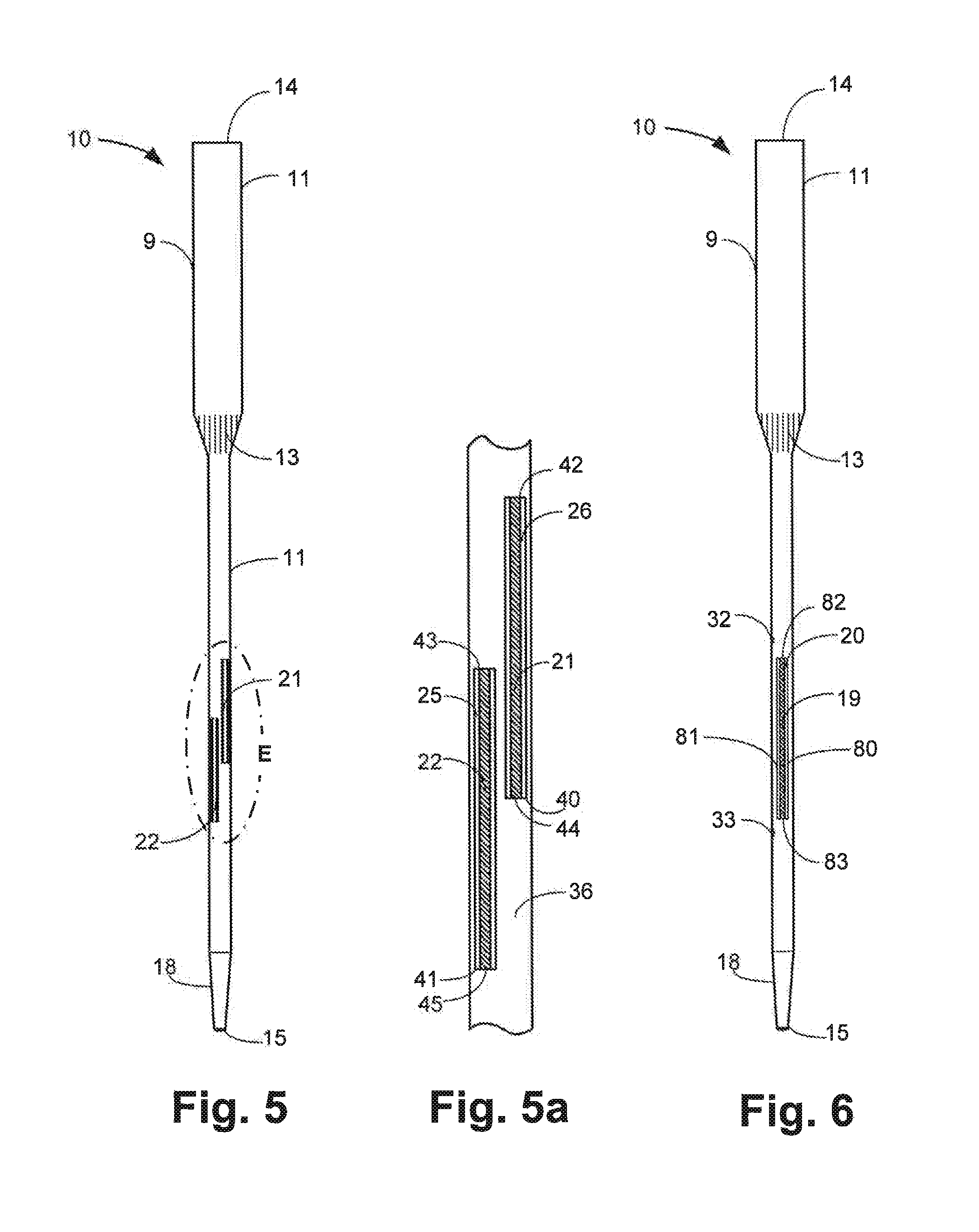

Valve Cutter

A cardiac valve cutter of the present disclosure has a flexible housing with a central lumen for receiving a guide wire. A high-speed cutting blade is disposed within the housing near an edge of the housing. A trough cut into a side of the housing exposes a portion of the cutting blade so that the cutting blade can cut valve tissue. Two pusher wires are disposed on an opposite side of the housing from the cutting blade. Troughs cut into the side of the housing form openings from which the pusher wires can extend. The pusher wires are staggered with respect to one another in the longitudinal direction. When the pusher wires are advanced, they extend outwardly from the troughs and can be used to stabilize the cutter at the cardiac valve and push the cutting blade against the valve on the opposite side.

Owner:MCDONALD MICHAEL B

A compressor system for a rail vehicle and method for operating the compressor system with safe emergency operation

InactiveCN105940221AImprove securityIncrease speedFluid parameterRailway heating/coolingDrive shaftPressure sensor

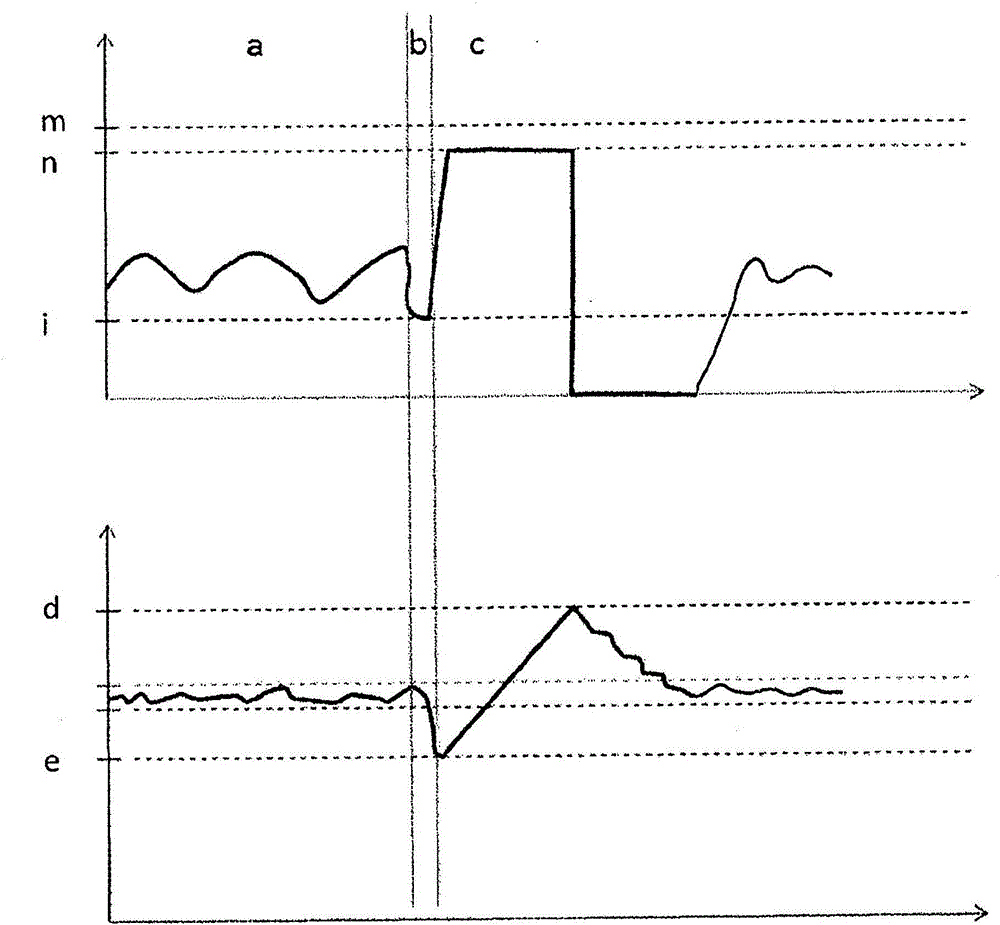

The invention relates to a compressor system for a rail vehicle, comprising a compressor (3), driven by an electrical machine (1) via a drive shaft (2), for producing compressed air for at least one compressed air tank (4), wherein the electrical machine (1) can be activated at least indirectly via a control device (5) for operating the electrical machine (1) at at least one nominal speed (n) between a maximum speed (m) and a minimum speed (i), wherein furthermore at least one pressure sensor (7) for determining the pressure for the control device (5) is disposed in a compressed-air-carrying line (6) downstream of the compressor (3). According to the invention, a final control element (8) for continuously influencing the speed of the electrical machine (1) is disposed between an electrical supply (15) and the electrical machine (1), wherein the final control element (8) can be activated via the control device (5), and wherein a pressure switch (16) for monitoring the pressure in the at least one compressed air tank (4) and for influencing at least the speed of the electrical machine (1) is disposed in the compressed-air-carrying line (6) downstream of the compressor (3). Furthermore, the invention also relates to a method for controlling the compressor system according to the invention, wherein the compressor (3) is operated at a variable speed, assuming any intermediate value between the maximum speed (m) and the minimum speed (i), and wherein the pressure switch (16) monitors the pressure in the at least one compressed air tank (4) and has an indirect influence at least on the speed of the electrical machine (1).

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Ceramic chip antenna and preparation method thereof

PendingCN109400178AGuaranteed performanceImprove bindingRadiating elements structural formsPlatinumCopper

The invention discloses a ceramic chip antenna. Metal circuits are attached to the outer surface of a ceramic base and a via hole formed in the ceramic base, the metal circuit positioned on the outersurface serves as a ceramic antenna body, the metal circuit positioned at the via hole serves as a circuit functioning in conduction, the metal circuits comprise a first metal circuit, a second metalcircuit, a third metal circuit, a fourth metal circuit and a fifth metal circuit, the first metal circuit is selected from high-temperature-resistant tungsten, molybdenum and platinum, the third metalcircuit is selected from copper, silver, chromium, iron and cobalt with high conductivity, the second metal circuit is arranged between the first metal circuit and the third metal circuit and used for transition, and the fourth metal circuit and the fifth metal circuit are arranged on an outer layer and used for protection and welding. As a plurality of metal circuits are designed, the ceramic base and the metal circuits can be subjected to a co-firing process to form the ceramic chip antenna, cost is controlled, metal materials with excellent conductivity can be adopted, and antenna performances are ensured.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

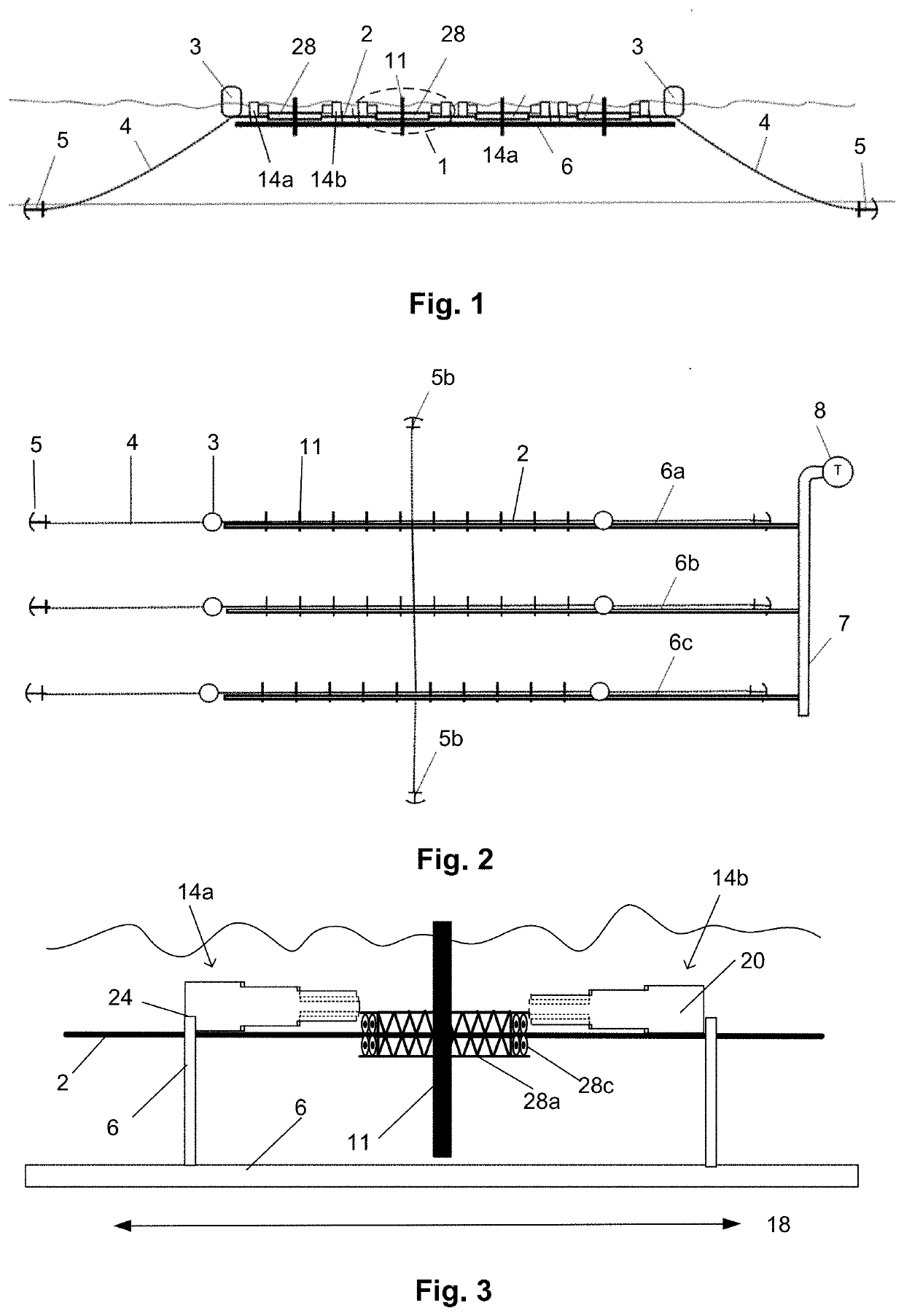

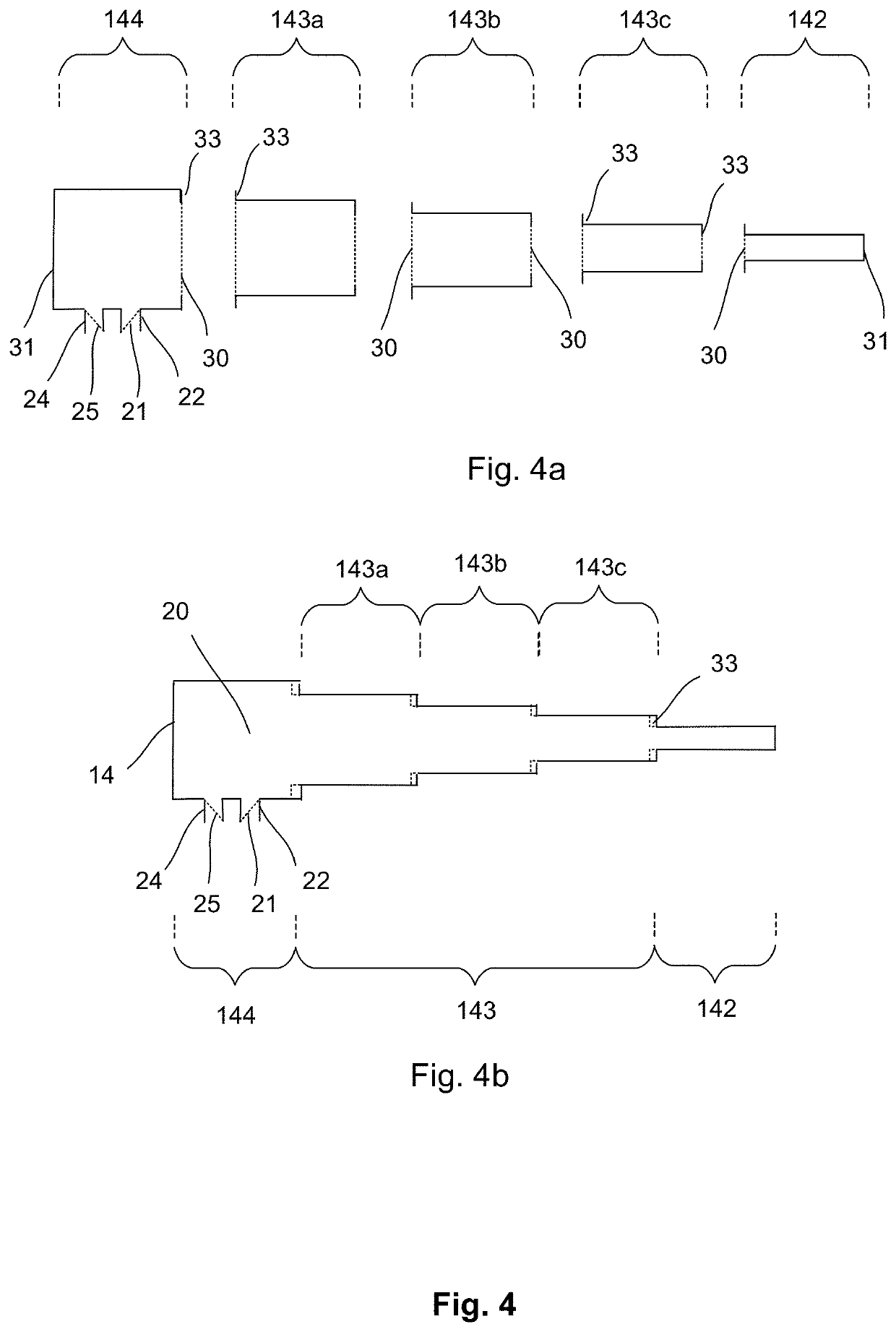

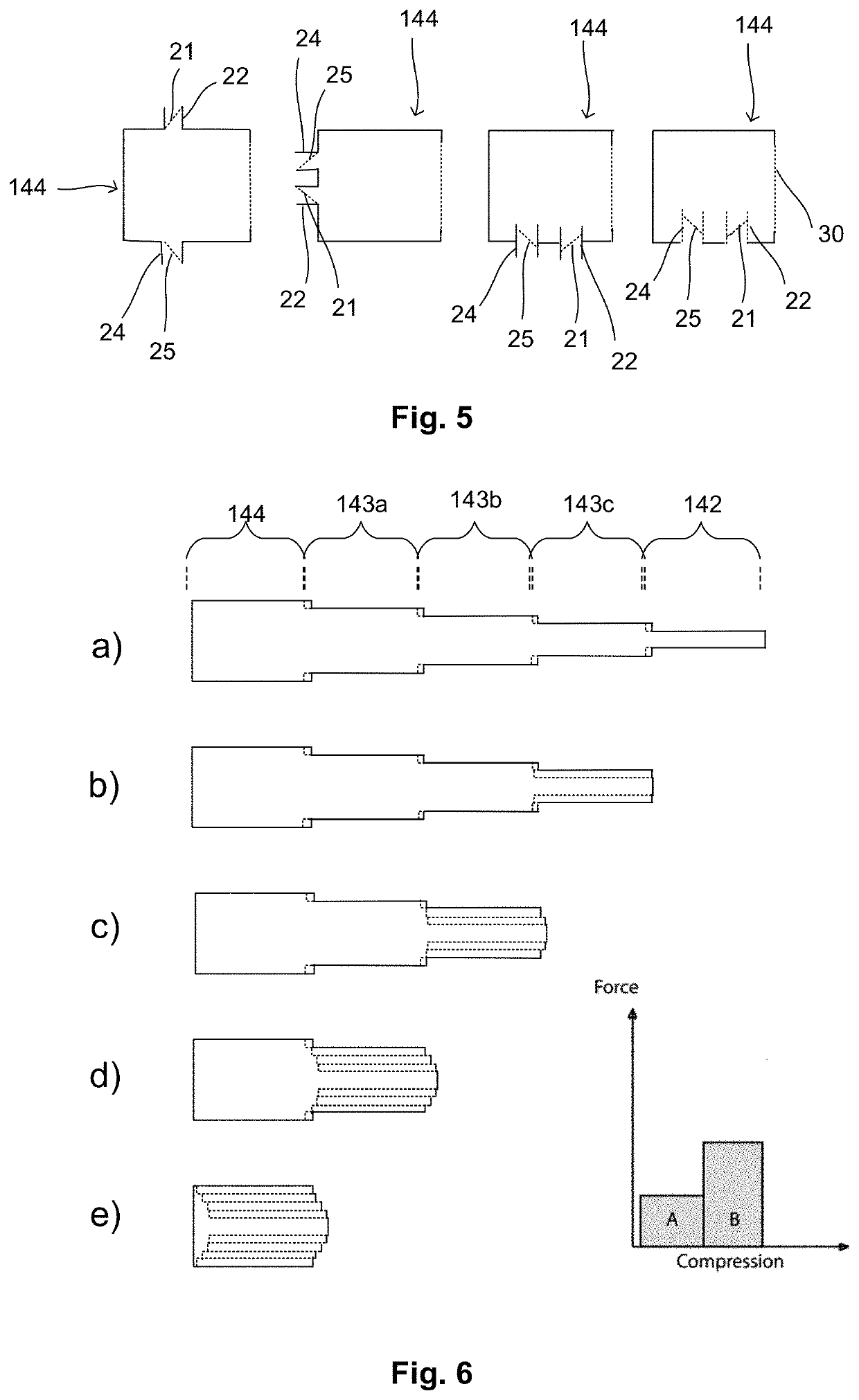

Wave power device

ActiveUS20200088155A1High margin against damageReduce probabilityEngine fuctionsMachines/enginesWave power generationClassical mechanics

The present invention relates to a wave power device for extracting energy from water waves. The waver power device comprise a reference structure and effectors moving relative to the reference structure. The effectors are connected 5 to two hydraulic rams, symmetrically positioned around each effector. The hydraulic rams have an effective hydraulic area which is stepwise increased as the length of the hydraulic rams are compressed and stepwise increased as the length of the hydraulic rams are increased.

Owner:WAVEPISTON

Micro OLED displayer structure and preparation method thereof

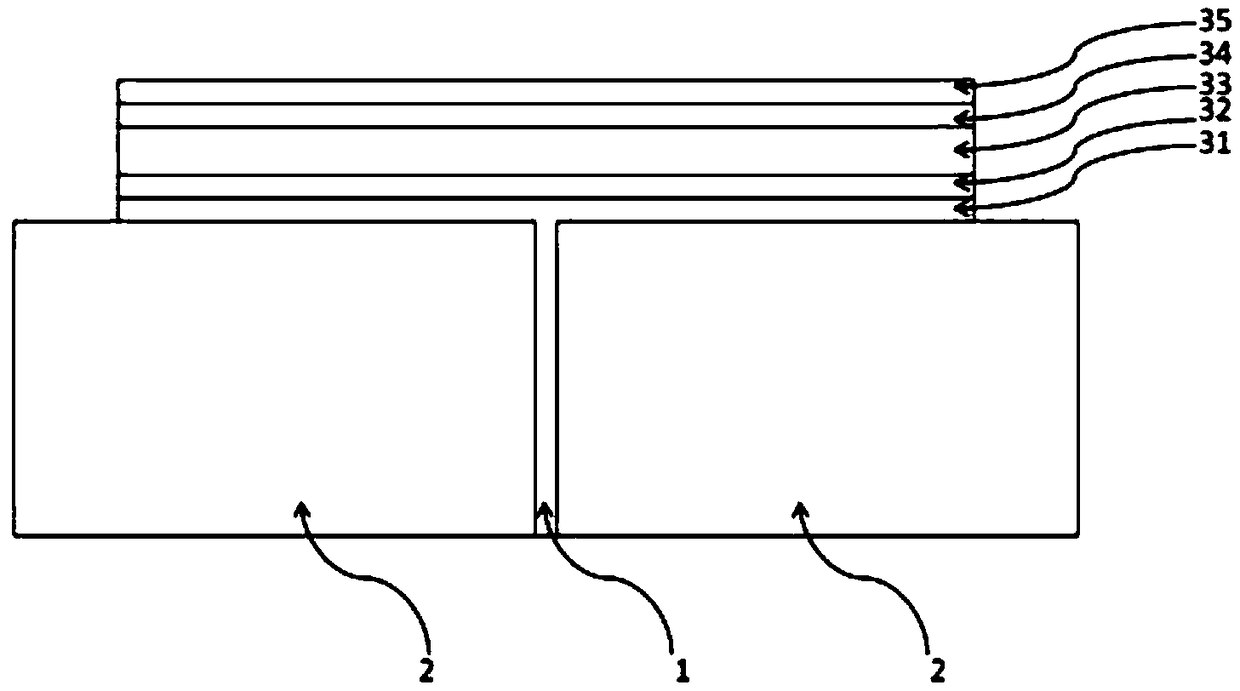

PendingCN110739341AReduce process complexityReduce process costSemiconductor/solid-state device detailsSolid-state devicesPhysicsMetal metal

The invention discloses a Micro OLED displayer structure and a preparation method thereof. The structure comprises a substrate which comprises a PAD connection region and a non-PAD connection region.The substrate thickness of the PAD connection region is thinner than the substrate thickness of the non-PAD connection region. A CMOS driving circuit is arranged on the non-PAD connection region. ThePAD connection region is provided with a plurality of TSV vias, and metal columns adaptted to the size of the TSV vias are formed in the TSV vias. A metal PAD is arranged on the lower surface of the substrate. The upper surface of the metal PAD covers the bottom surface of the whole metal columns. An OLED light emitting region is arranged on the upper surface of the substrate. Continuous packagingfilms are arranged on the upper surface of the OLED light emitting region, the upper surface of the substrate not covering the OLED light emitting region and the top surface of the metal columns. Themetal PAD is connected with the CMOS circuit through the conductive medium through the technical means of the silicon deep hole, the metal PAD is arranged on the opposite side of the OLED light emitting region, the TFE patterning process is not required, the process complexity is reduced, the process cost is saved and the yield rate of the overall process is improved.

Owner:ANHUI SEMICON INTEGRATED DISPLAY TECH CO LTD

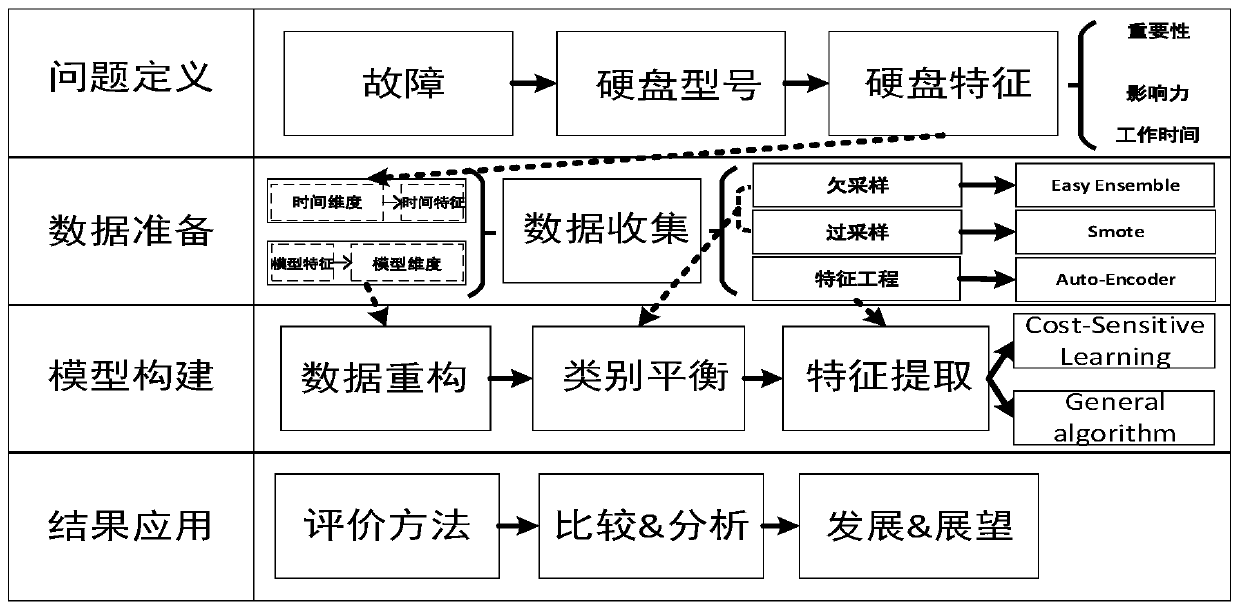

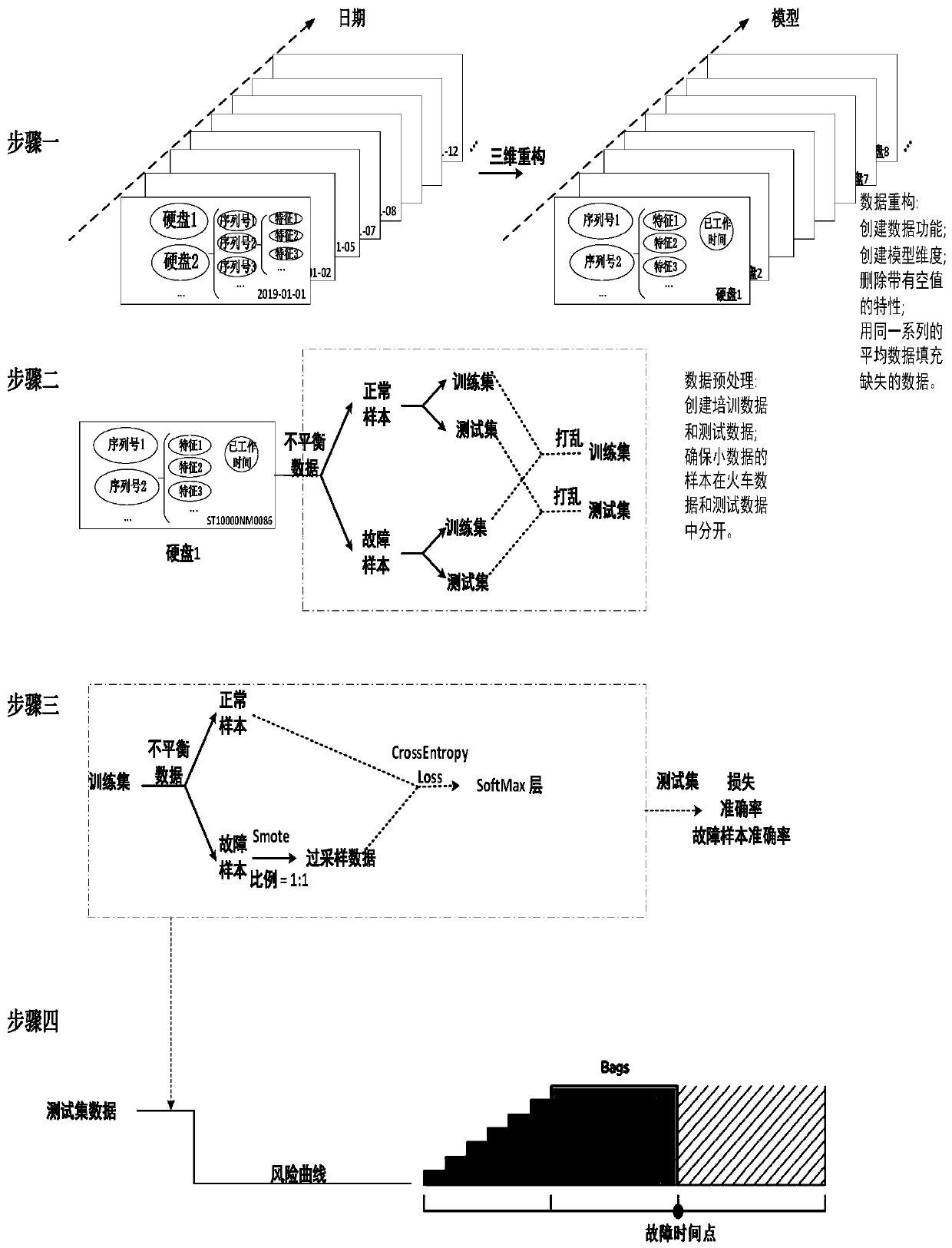

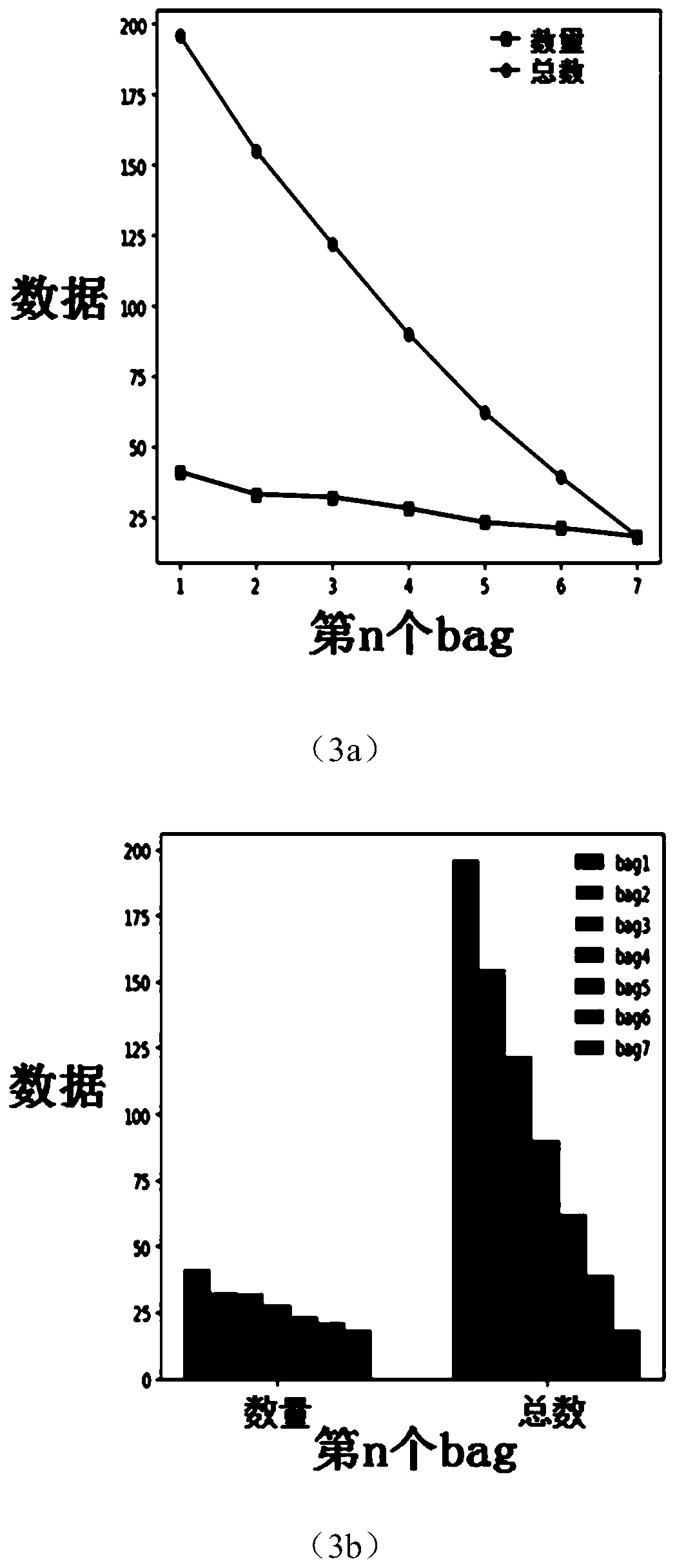

Unbalanced hard disk data fault diagnosis method based on deep learning

ActiveCN111414286AImprove accuracyHigh application generalizationDetecting faulty hardware using neural networksFaulty hardware testing methodsData classEngineering

The invention relates to an unbalanced hard disk data fault diagnosis method based on deep learning. The method comprises the following steps: 1) carrying out preprocessing and three-dimensional reconstruction on original hard disk data; 2) performing data category balance processing on the hard disk data after three-dimensional reconstruction, and performing division to obtain a training set anda test set of a deep learning network; and 3) constructing a deep learning network and performing training through the training set, and finally performing fault prediction by adopting the trained deep learning network to judge whether the hard disk data is faulty or not. Compared with the prior art, the method has the advantages of high accuracy, high application generalization, low environmentalrequirements, risk prediction and the like.

Owner:TONGJI UNIV

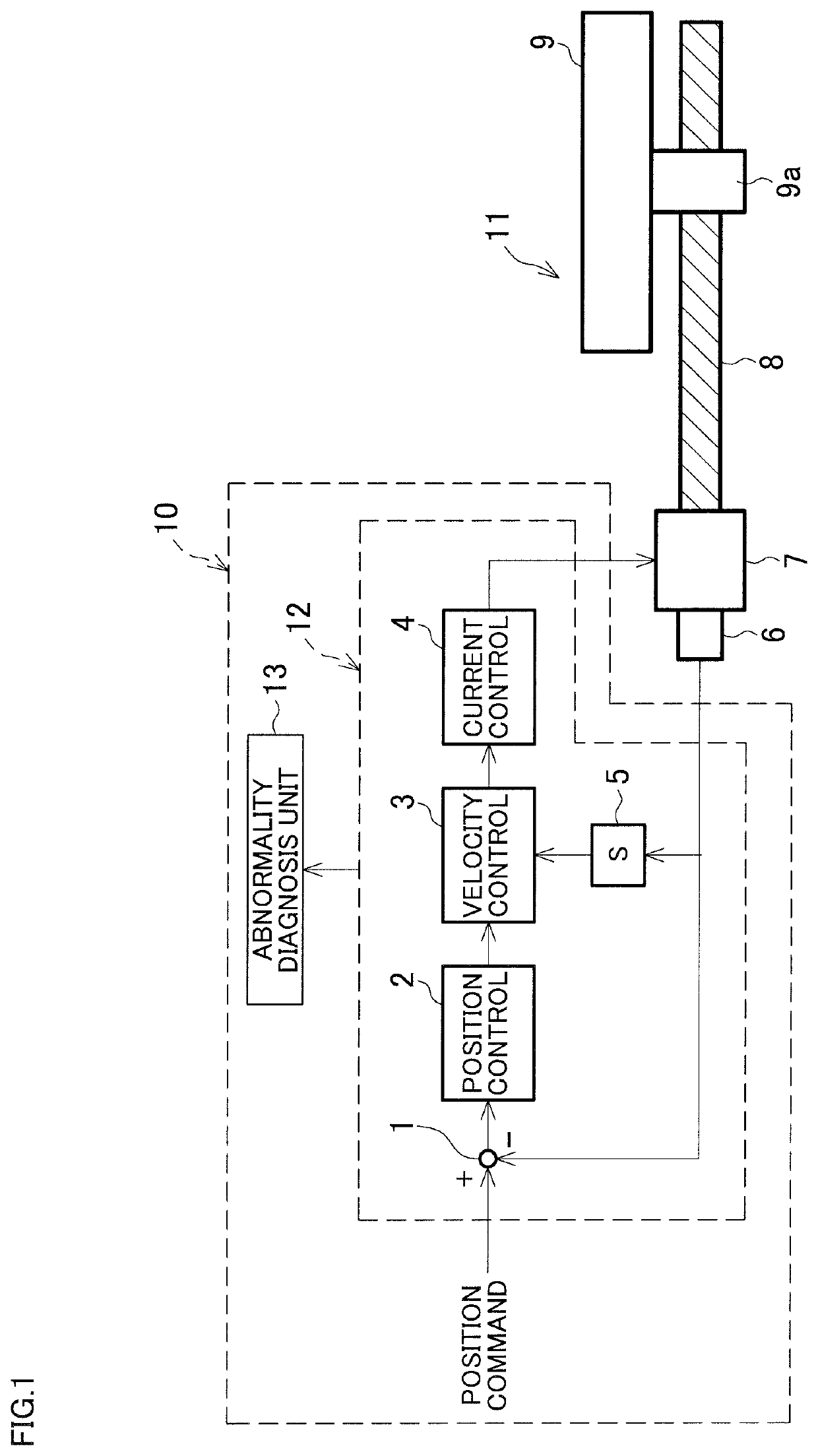

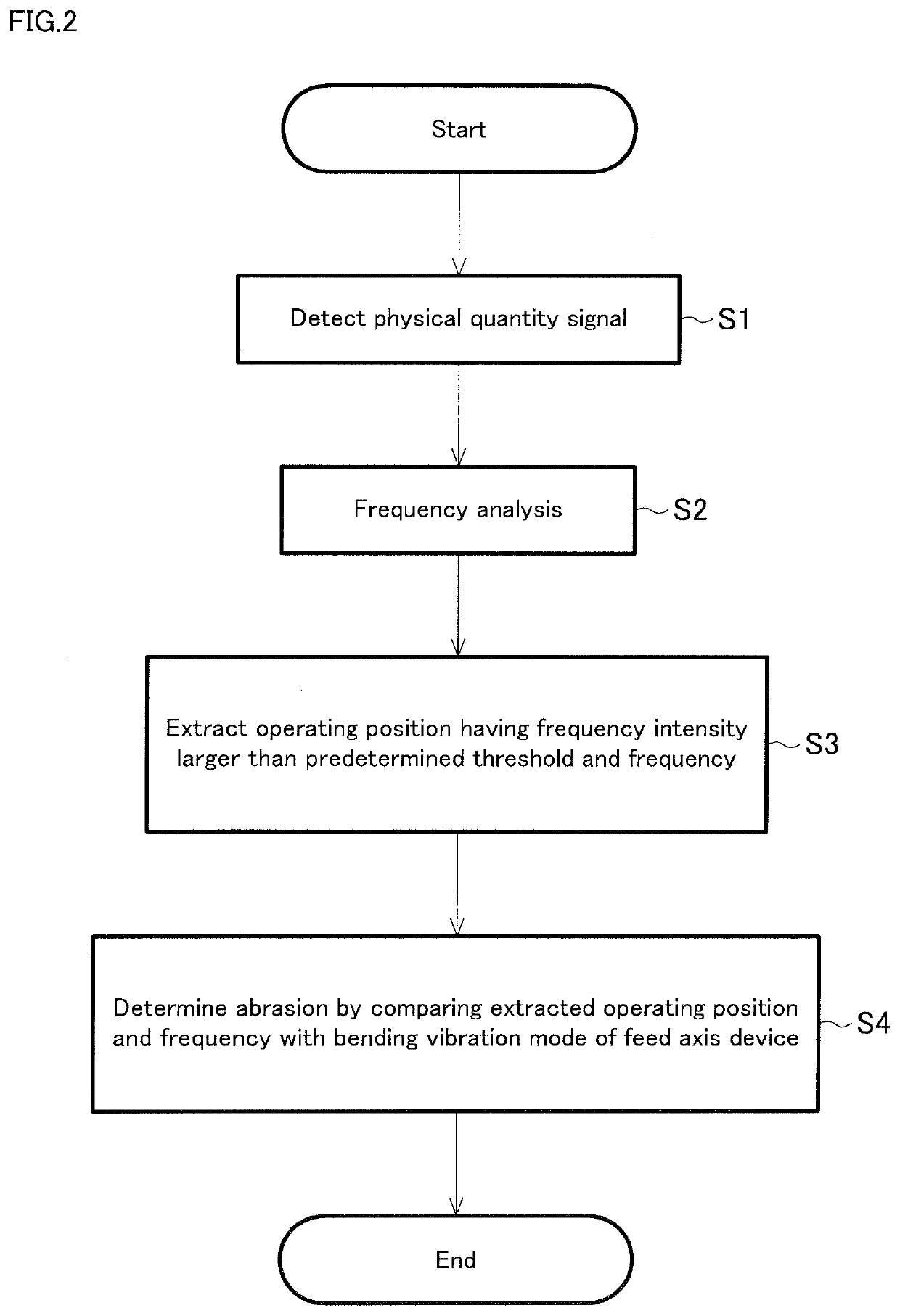

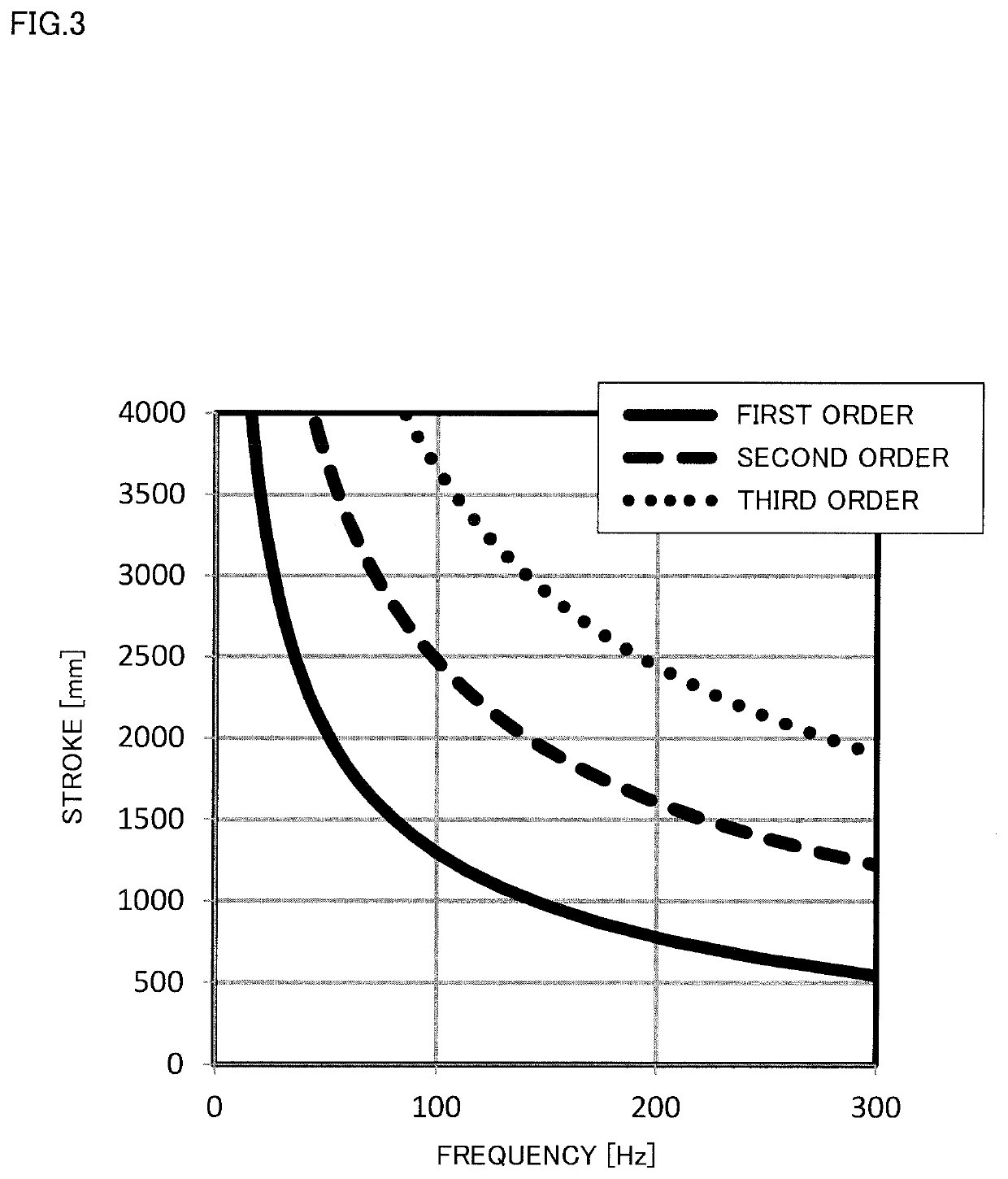

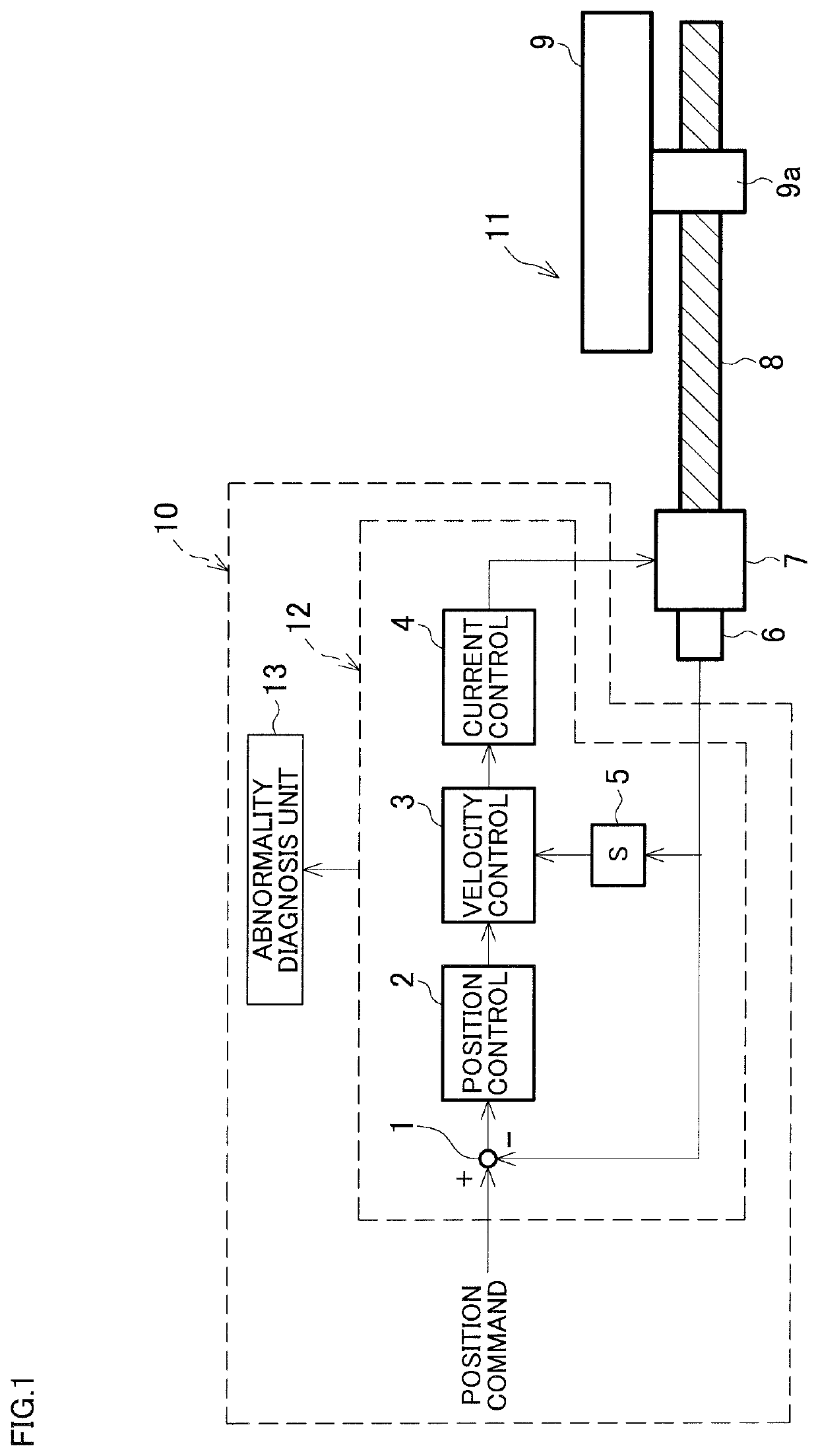

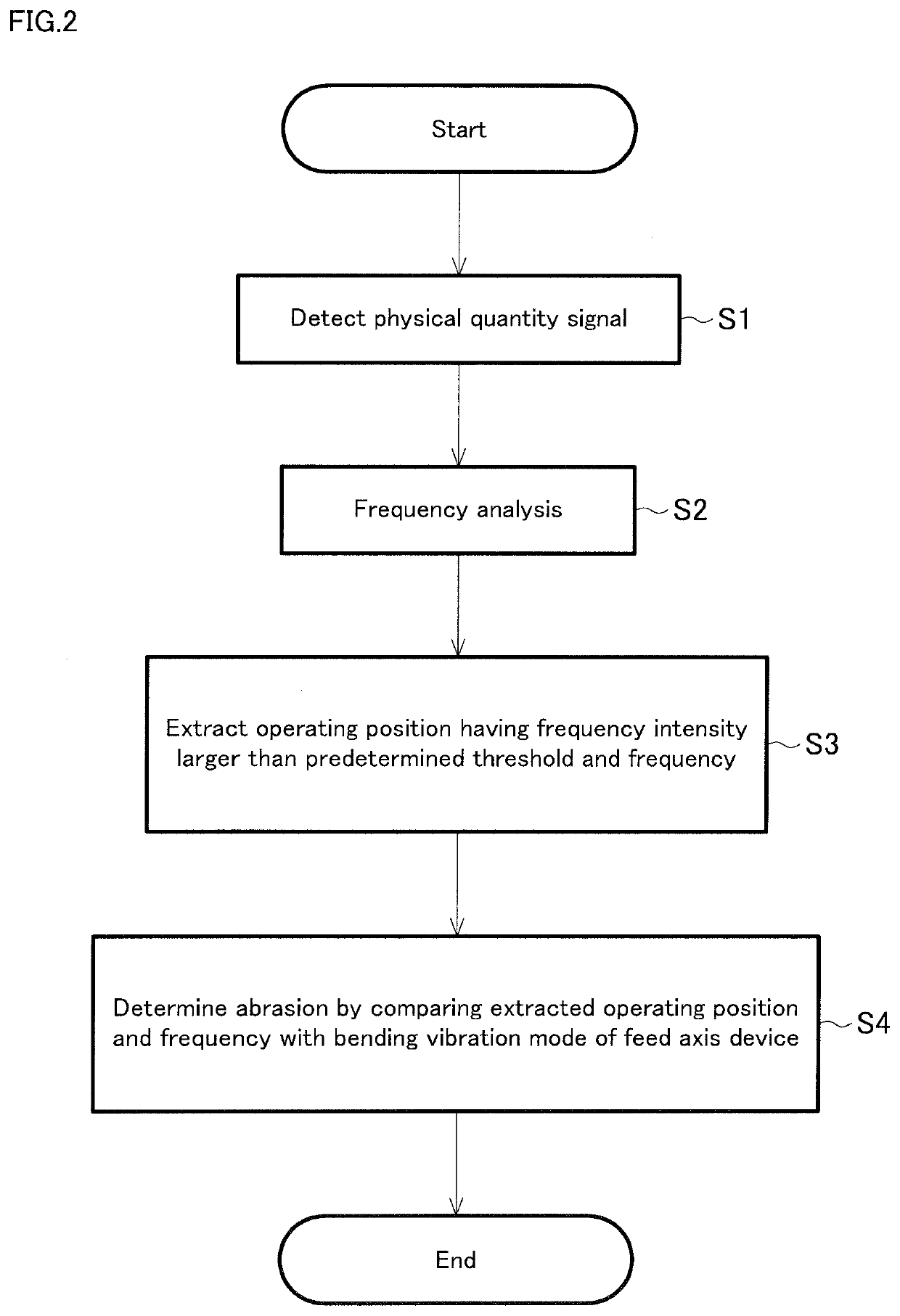

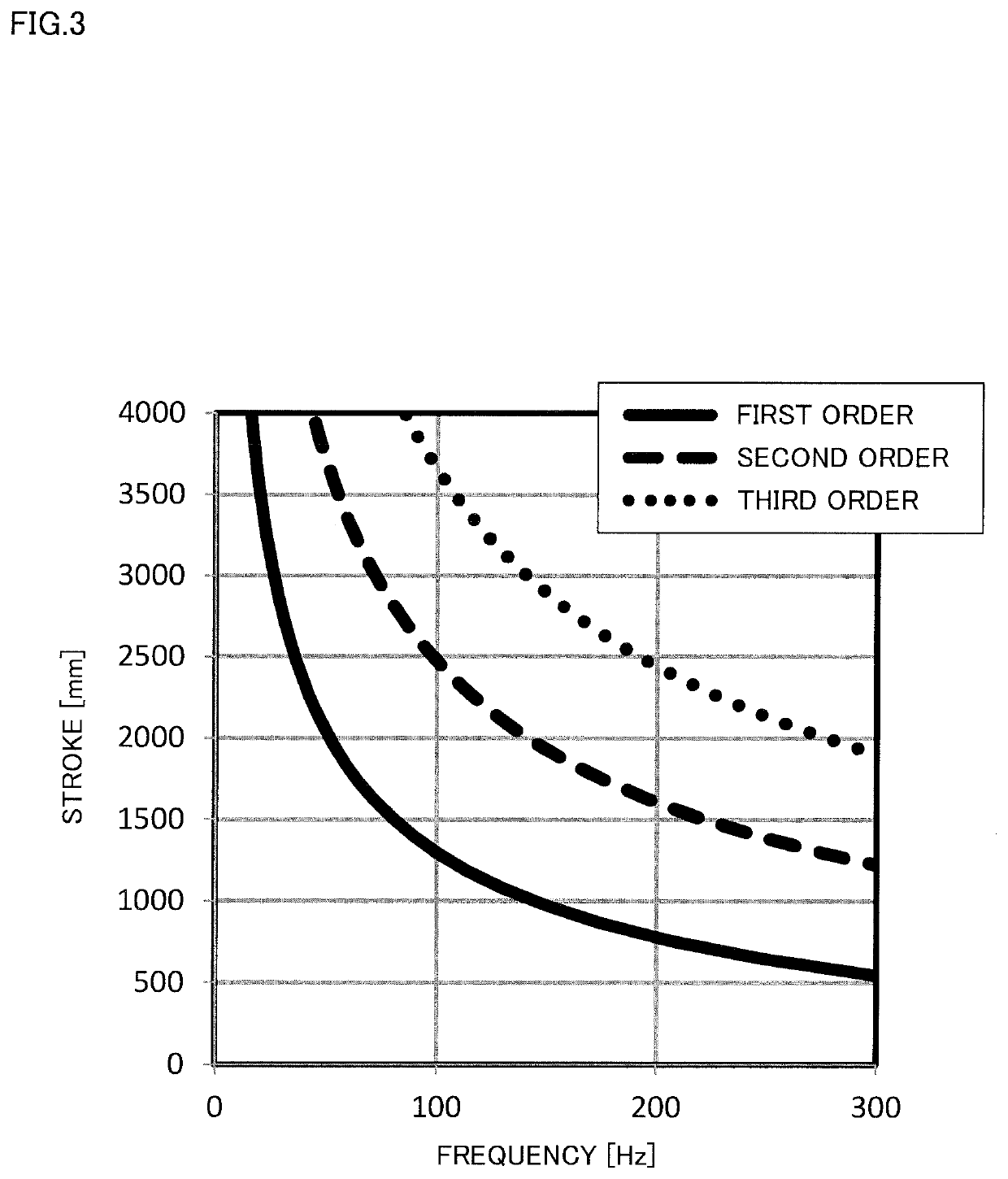

Abnormality diagnostic method and abnormality diagnostic device for feed axis device

ActiveUS20210140853A1Increase risk of failureLow costMachine part testingMeasurement/indication equipmentsAbnormalityBiomedical engineering

An abnormality diagnostic method for a feed axis device that diagnoses an abnormality of the feed axis device including a screw shaft and a nut, the feed axis device being incorporated in mechanical equipment, the abnormality diagnostic method includes controlling an operation of the feed axis device such that the screw shaft operates in a predetermined operating pattern, detecting a physical quantity signal generated from the feed axis device, and performing an abnormality diagnosis for the feed axis device based on the physical quantity signal detected by the detecting in accordance with a predetermined abnormality diagnosis algorithm. The performing includes performing a frequency analysis on the physical quantity signal to extract respective frequencies corresponding to a plurality of operating positions in the operating pattern and performing the abnormality diagnosis based on change of the frequencies corresponding to the respective operating positions.

Owner:OKUMA CORP

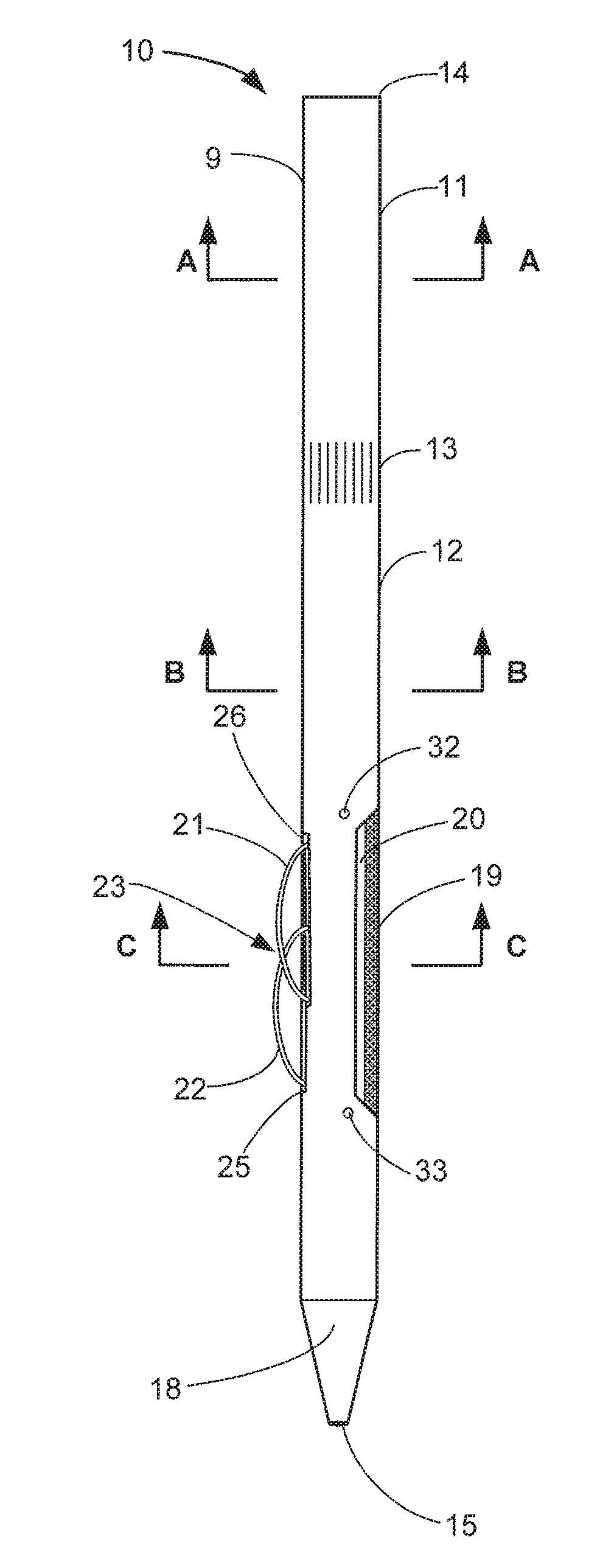

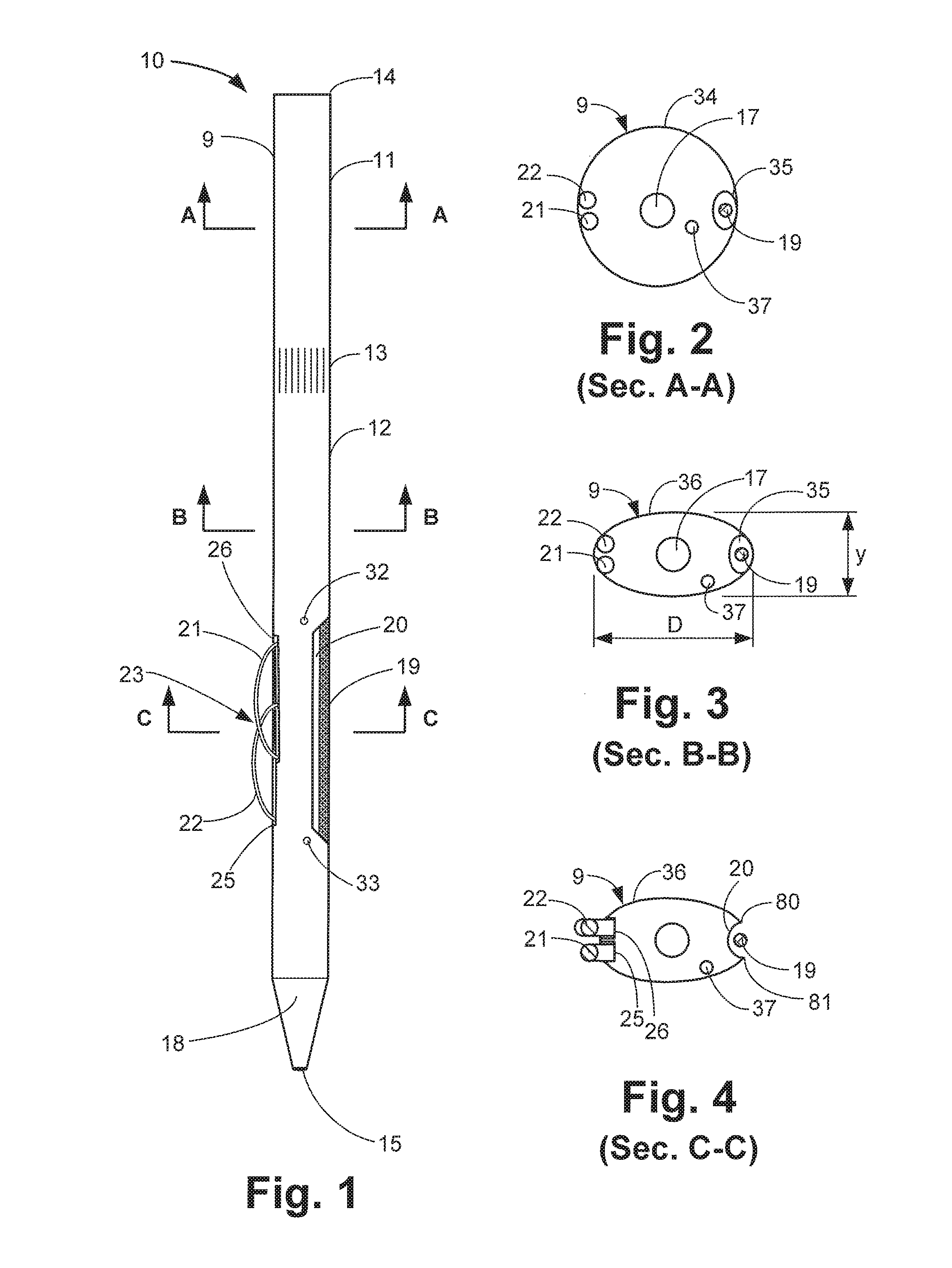

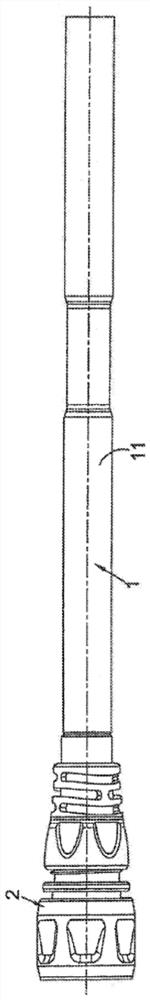

Aortic Valve Cutter

ActiveUS20140155924A1Increase in sizeControl flowDiagnosticsExcision instrumentsAortic valve areaTransducer

An aortic valve cutter of the present disclosure comprises a flexible housing with a central lumen for receiving a guide wire. A high-speed rotating wire is disposed within the housing near an edge of the housing. A trough cut into a side of the housing exposes a portion of the rotating wire such that the rotating wire can be used as a cutter. Two pusher wires are disposed on an opposite side of the housing from the rotating wire, also housed within the housing. Troughs cut into the side of the housing form openings from which the pusher wires can extend if they are advanced. The pusher wires are staggered with respect to one another in the longitudinal direction. When the pusher wires are advanced, they extend outwardly from the troughs and can be used to stabilize the cutter at the aortic valve and push the cutting wire against the valve on the opposite side. Two wire pressure transducers are disposed on the housing, one above the rotating wire and another below the rotating wire. The pressure transducers allow for monitoring of the pressure gradient across the valve as the cutting proceeds. By monitoring the transvalve gradient while the cuts are made to the aortic valve, the aortic valve area can be estimated during the procedure.

Owner:MCDONALD MICHAEL B

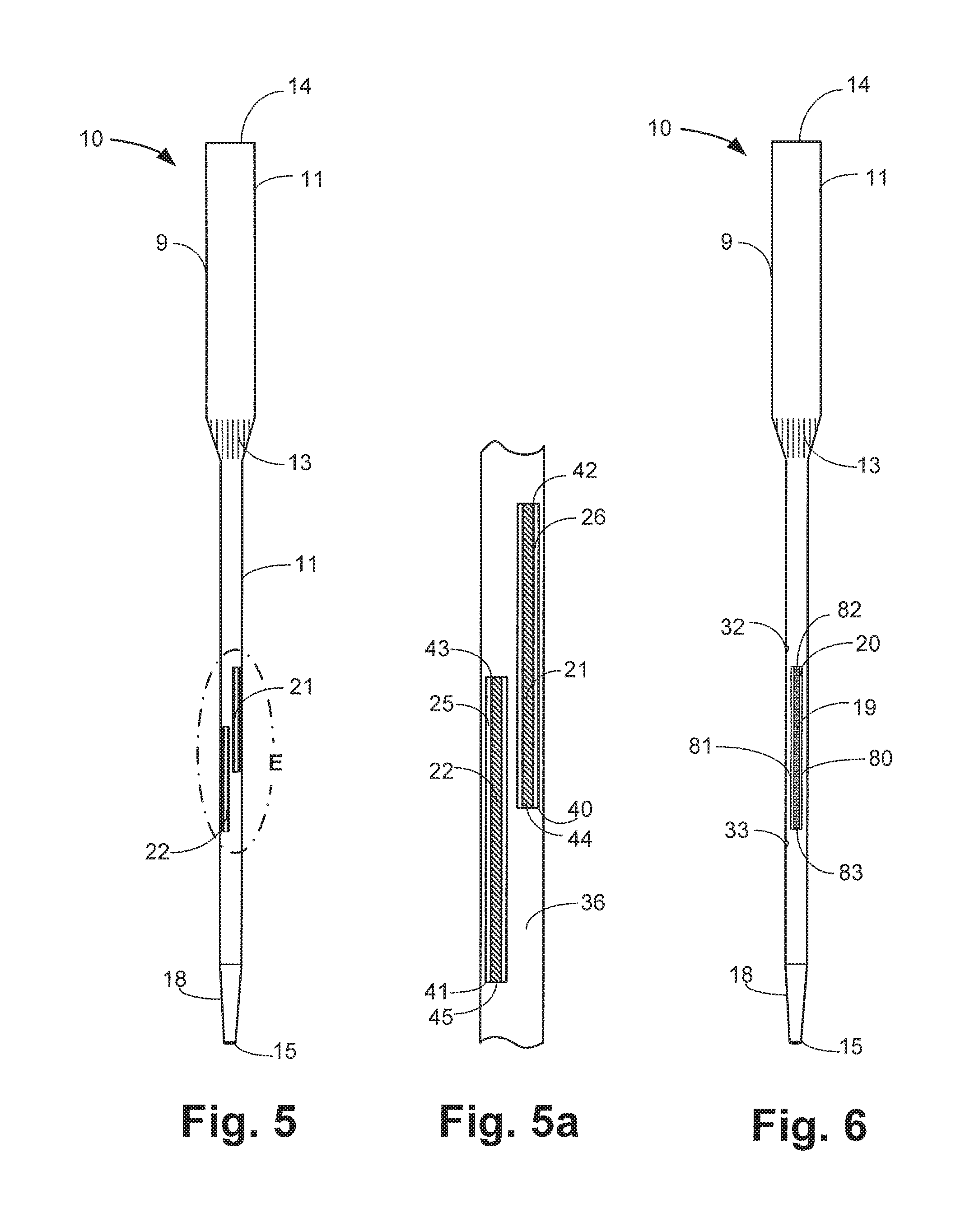

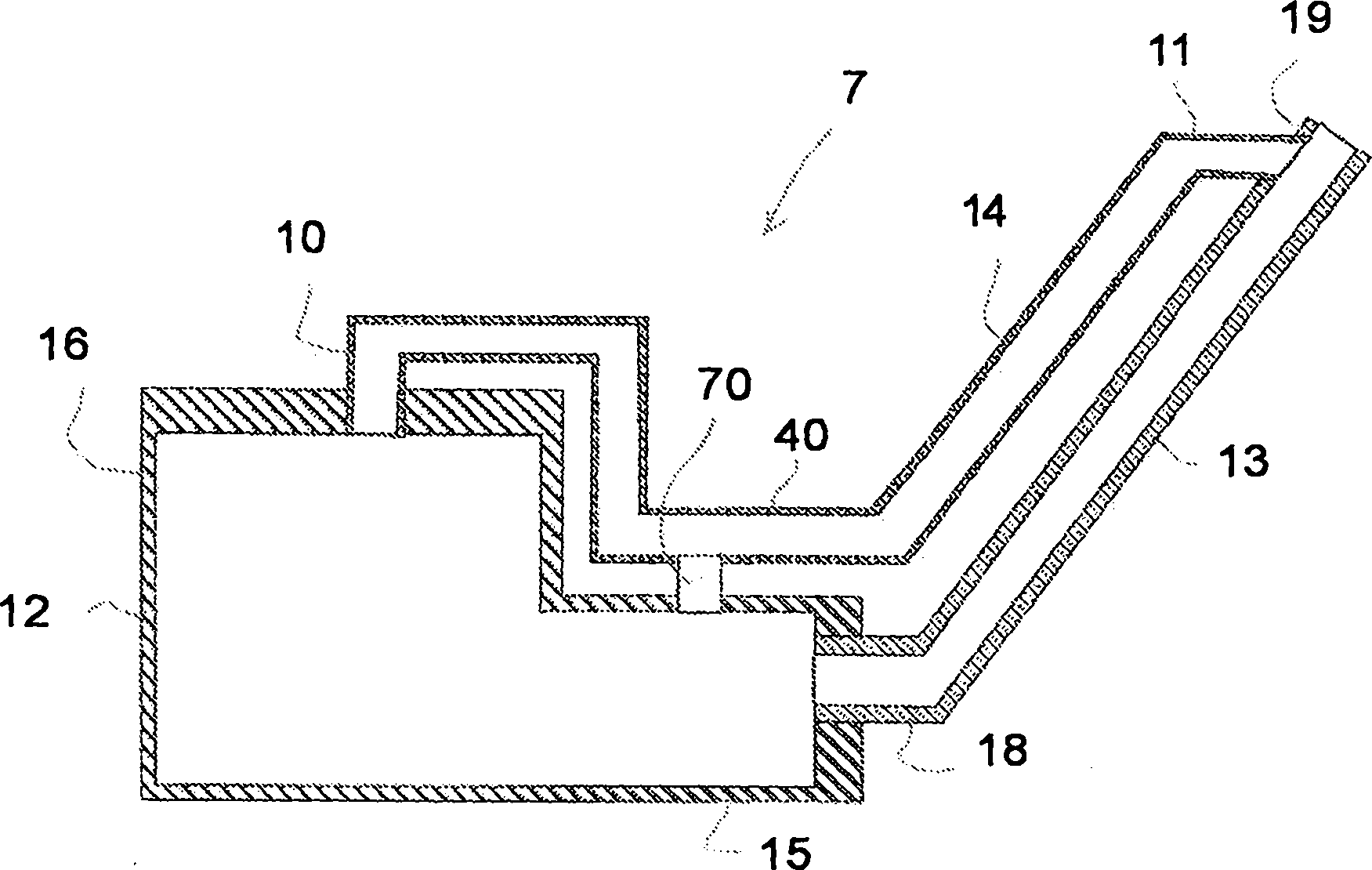

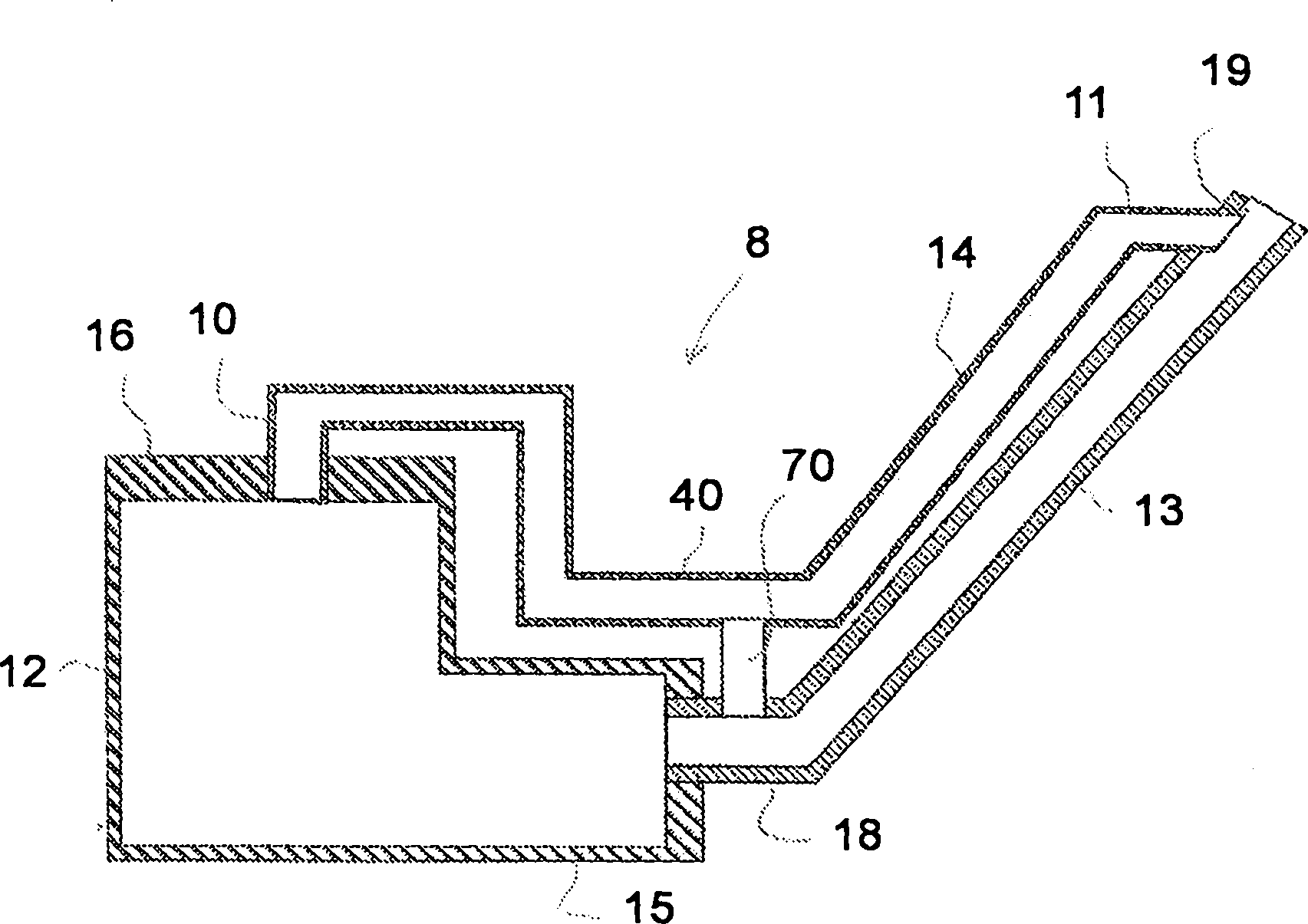

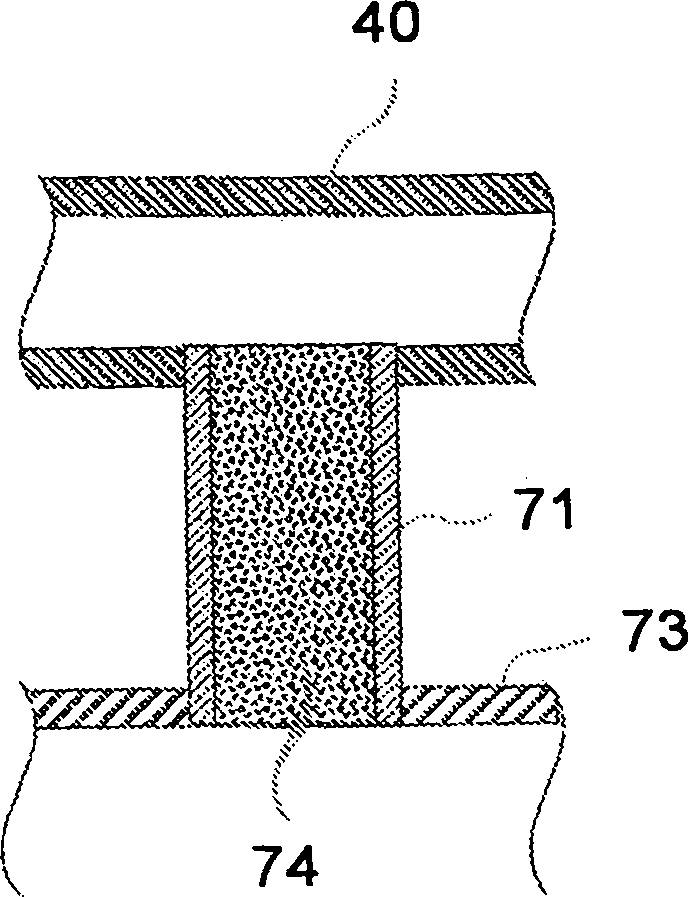

Device for filling tank of motor vehicle

InactiveCN103562510AIncreased risk of failureInternal combustion piston enginesExhaust apparatusVentilation ductEngineering

In order to fill a tank (12) of a motor vehicle with a liquid, particularly for a selective catalytic reduction system, a device (7) of the invention includes a filling tube (13) that comprises a bottom end (18) penetrating into the tank (12) and a top end (19) for receiving the liquid so as to fill the tank (12). A ventilation duct (14) comprises an inlet end (10) penetrating into a top portion (16) of the tank (12), an outlet end (11) penetrating into the tube (13) near the top end (19), and a lower section (40) located at a first structural level below the inlet and outlet ends (10, 11). A stationary head-loss generating element (70, 71, 72) places the lower section (40) in communication with a cavity (15) located at a second structural level below the first structural level.

Owner:RENAULT SA

Method for manufacturing inkjet printable paper or foil for use as a decor paper or foil

ActiveUS11148451B2Good dispersionPrevent coagulationDuplicating/marking methodsSpecial ornamental structuresPolymer sciencePolymer chemistry

A method is provided for manufacturing a paper or a thermoplastic foil or a vitrimeric foil printable with an inkjet printer for use as a decor paper, respectively a decor foil in a laminate or laminated panel. The method may involve providing a paper layer, respectively a foil. At least one side of the paper layer, respectively of the foil, may be coated with an inkjet receiver coating that includes at least pigment and binder. The inkjet receiver coating may include an ink reactive compound. The papers and foils may be provided with a printed pattern and used as a decor in the panels.

Owner:FLOORING IND LTD

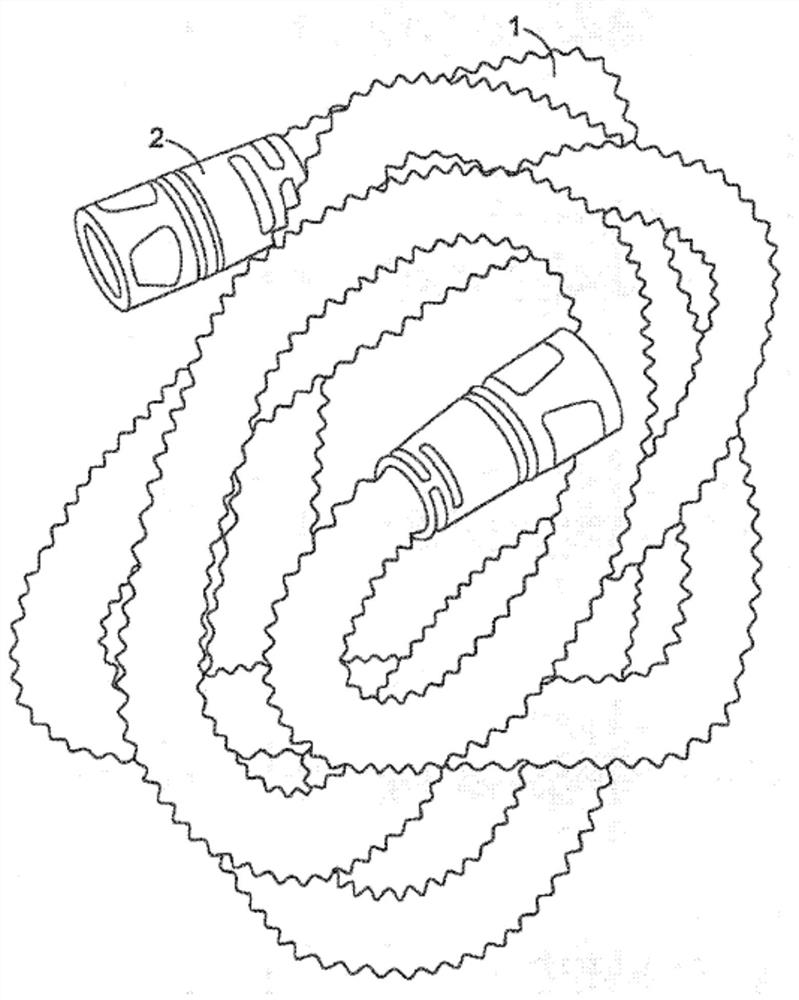

Hose arrangements

A hose arrangement comprising an outer tube (11) of flexible material and an inner tube (12) of an elastic material for carrying fluid through the hose arrangement, wherein due to the action of the elastic inner tube, the hose arrangement has a shorter length in a contracted state in the absence of fluid pressure in the interior of the inner elastic tube and a longer length in an expanded state when fluid pressure is applied to the interior of the elastic inner tube, and the outer tube has an undulating state when the hose arrangement is in the contracted state and serves to control and contain expansion of the inner tube when the hose arrangement is in the expanded state. The flexible material of the outer tube comprises a woven fabric which is woven from two types of yarn, a first type of yarn (9a) being of a first material and a second type of yarn (9b) being of a second material, which is different from the first material.

Owner:EXCEL IND INC

Abnormality diagnostic method and abnormality diagnostic device for feed axis device

ActiveUS11268884B2Increased risk of failureLow costMachine part testingMeasurement/indication equipmentsRadiologyEngineering

Owner:OKUMA CORP

Method for controlling impeller type yarn laying device, impeller type yarn laying device and winder

ActiveCN107848726BAvoid malfunctionReliable and responsive handlingFilament handlingWinding machineYarn

The invention relates to a method (100) for controlling a thread laying device comprising two impellers (26, 28) which can be driven in opposite directions in order to move a thread to be wound on a rotating spool back and forth between two turning points (U1, U2) along the spool longitudinal axis by means of a traversing movement with a target traversing stroke width (Hs) of the thread laying device, said target traversing stroke width differing from a base traversing stroke width (HN). According to the invention, each impeller (26, 28) being moved in the idle traversing stroke, i.e. each idle traversing stroke impeller (26, 28), is first accelerated or braked to an overcompensation angular speed (Voc) in the idle traversing stroke interval (TL) of the impeller, said overcompensation angular speed being determined on the basis of a theoretical constant compensation angular speed (Vc) required to transfer the thread in the next turning point (U1, U2) of the traversing movement of the thread. The impeller is then moved at its specified operating angular speed (Vw) in order to receive the thread from the other impeller (26, 28) guiding the thread at the operating angular speed (Vw) in the next turning point (U1, U2) of the traversing movement of the thread. The invention further relates to a thread laying device and to a winding machine comprising such a thread laying device.

Owner:SSM萨罗瑞士麦特雷有限公司

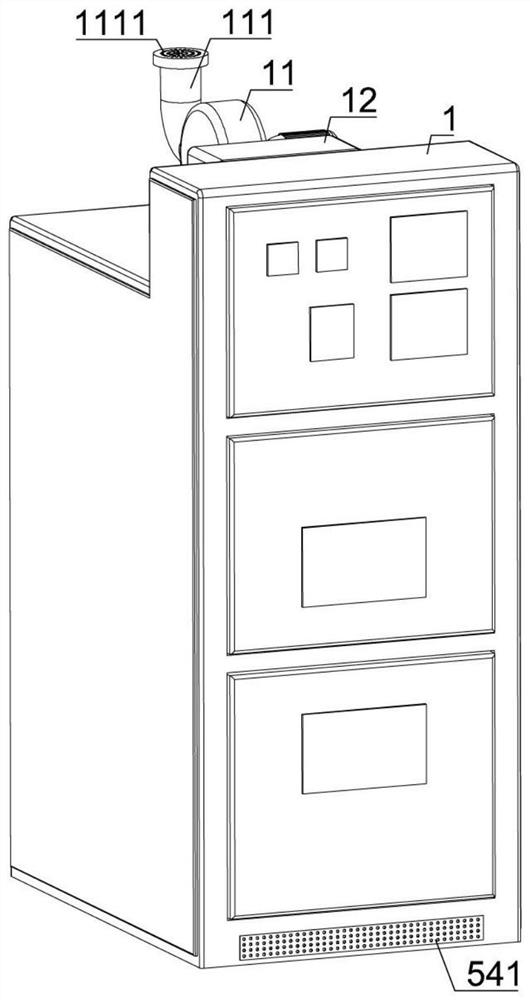

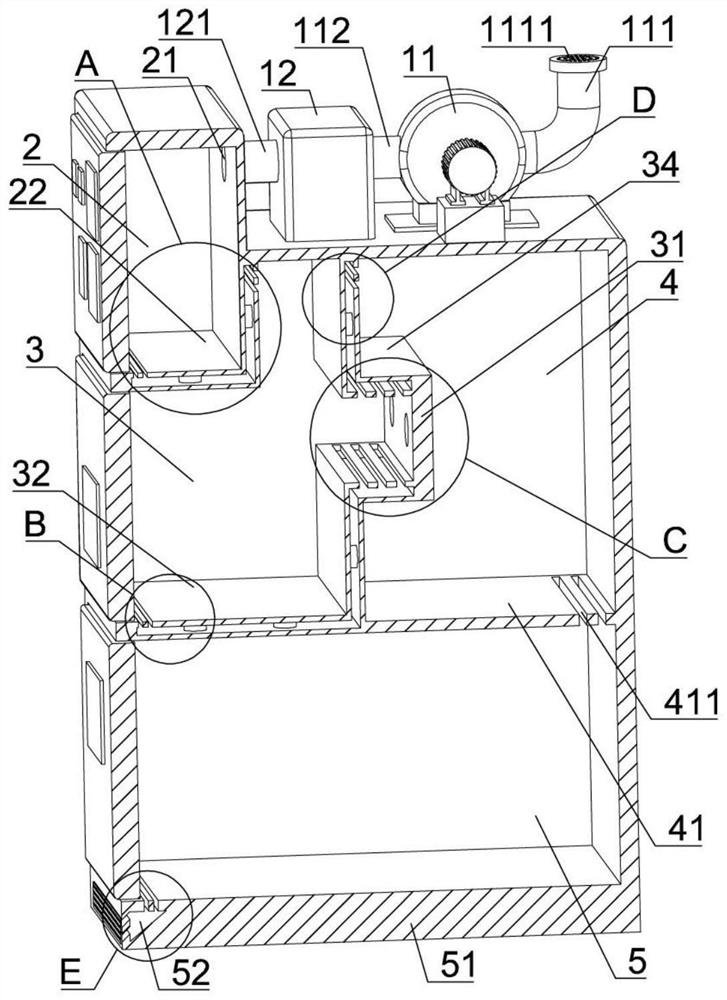

A central cabinet with good cooling and heat dissipation effect

ActiveCN111181057BEffective coolingExtended service lifeSwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationBusbarCooling effect

The invention belongs to the technical field of central cabinets, and specifically relates to a central cabinet with good cooling and heat dissipation effects, including a cabinet body, which includes a relay instrument room, a circuit breaker handcart room, a bus room and a cable room, and a circuit breaker handcart room. The vehicle compartment is equipped with a contact box, and the relay instrument room is equipped with a first partition. The first partition includes a first horizontal plate and a first vertical plate. The first horizontal plate and the first vertical plate are hollow inside and communicate with each other to form a second One air duct, the circuit breaker handcart room is provided with a second partition, the second partition includes a second horizontal plate, a third horizontal plate and a second vertical plate, the second horizontal plate, the third horizontal plate and the second vertical plate The boards are hollow inside and communicate with each other to form the second air duct. The handcart room of the circuit breaker is provided with a third partition. The third partition includes a fourth horizontal board and a third vertical board. The inside of the fourth horizontal board and the third vertical board Hollow and interconnected to form a third air channel, the busbar room is provided with a fourth partition, the cable room is provided with a base, the base is provided with a cavity, and the front side of the cavity is provided with an exhaust groove.

Owner:LIAOYUAN POWER SUPPLY COMPANY STATE GRID JILIN ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com