Prestress support cable mesh tent

A technology of prestressing and supporting cables, applied in the field of tents, can solve problems such as complex structure, wind resistance, rain resistance, high heat preservation requirements, and many components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

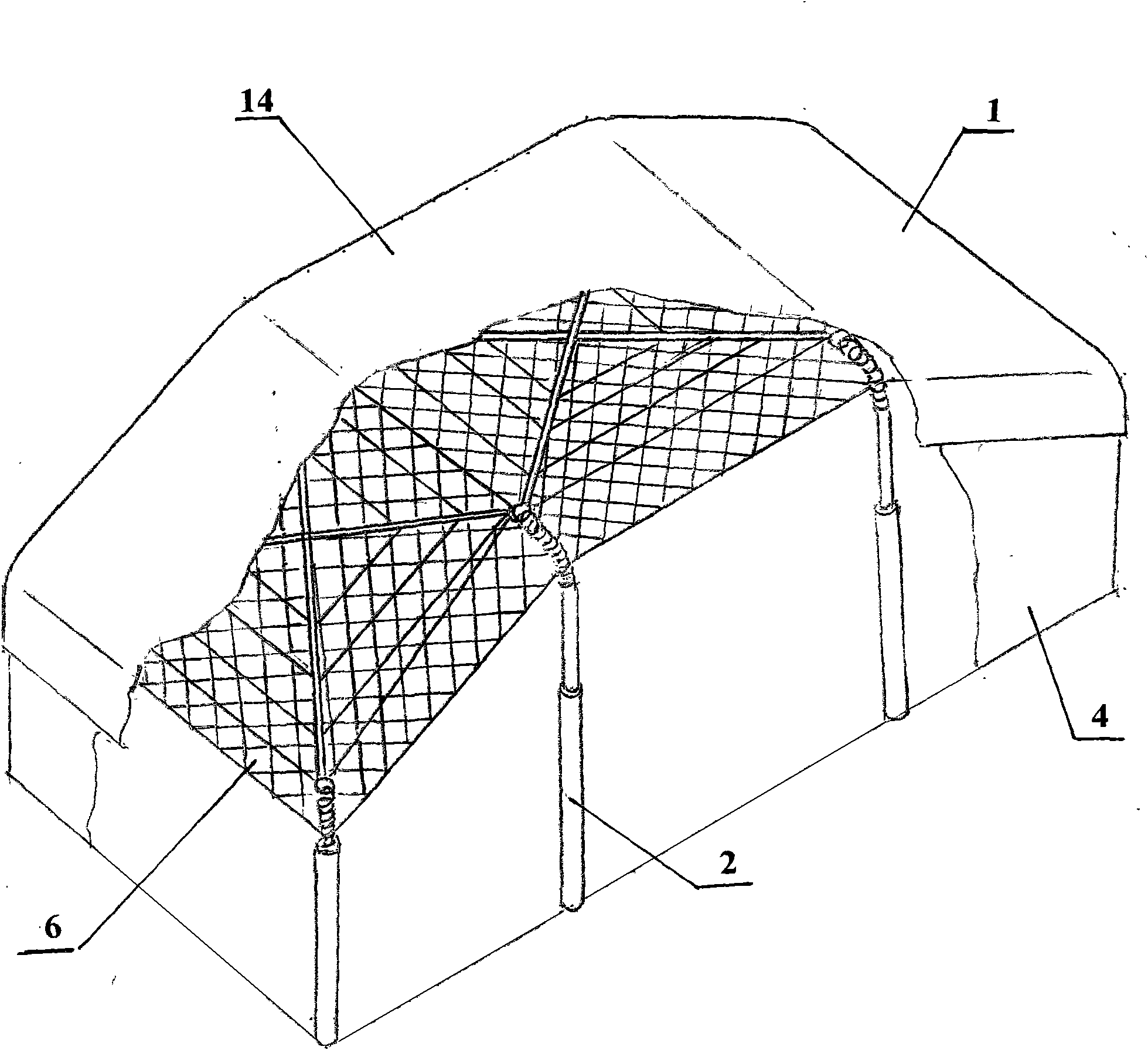

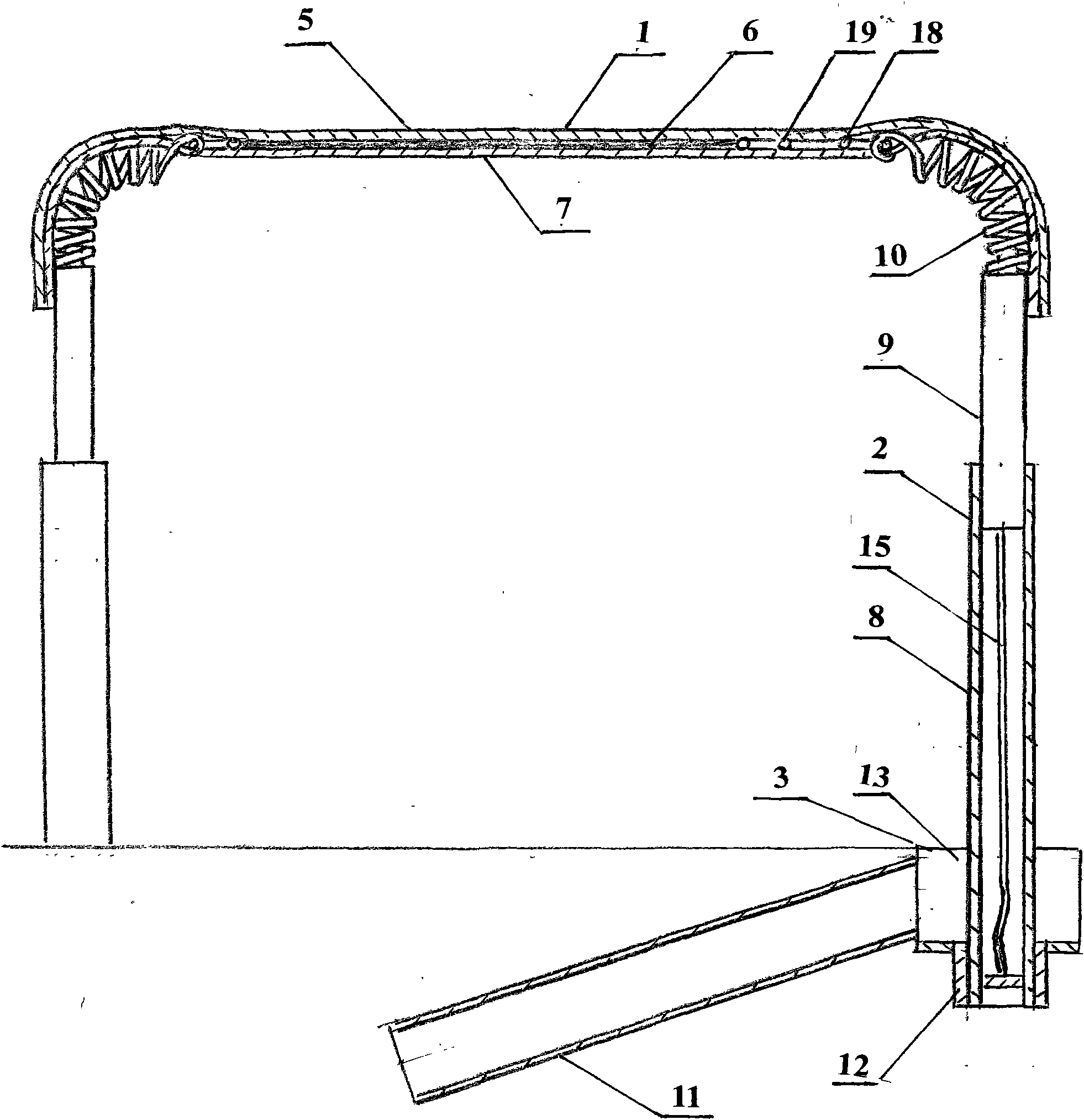

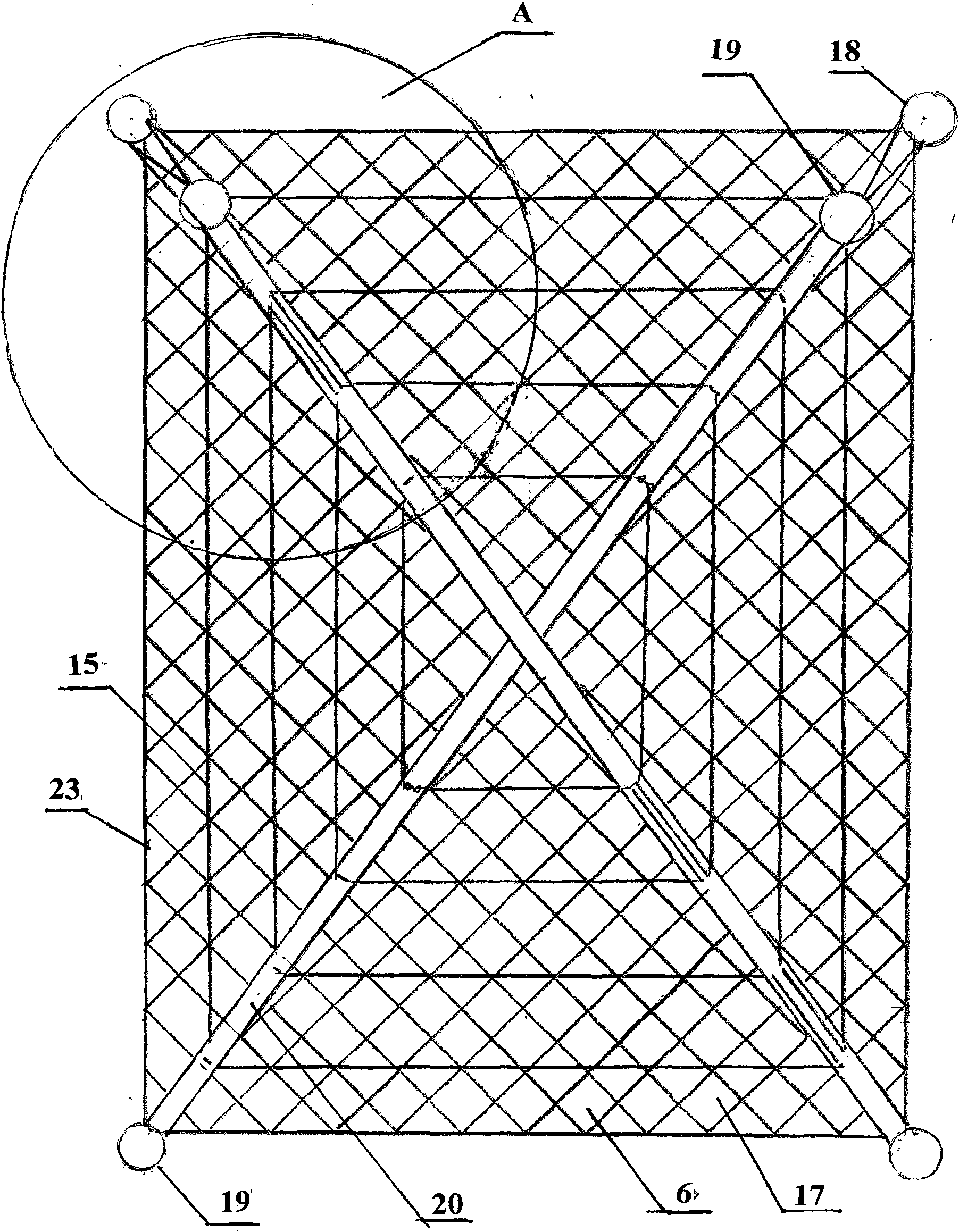

[0015] refer to figure 1 and figure 2 , a kind of car tent 14 is a specific embodiment of the present invention, and it is a kind of prestressed support cable net tent, is made of canopy 1, spring expansion rod 2, ground rod device 3 and awning 4; Consists of a tarpaulin 5, a prestressed support cable net 6 and an inner lining cloth 7, the tarpaulin 5 is placed on the prestressed support cable net 6, and the inner lining cloth 7 is placed under the prestressed support cable net 6 connected thereto, The canopy 1 is connected with the spring telescopic rod 2 through the prestressed support cable net.

[0016] The spring telescopic rod 2 is composed of a sleeve rod 8 at the lower end, a telescopic rod 9 and a spring 10. The spring 10 is fixedly connected to the upper end of the telescopic rod 9. The spring 10 and the telescopic rod 9 can be placed on the sleeve rod 8 or retracted in the sleeve rod 8. Reduce the length of the spring telescopic rod 2, or extend the spring telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com