Novel ultrathin battery and preparation method thereof

A kind of battery, ultra-thin technology, applied in the direction of primary battery, secondary battery manufacturing, primary battery components, etc., can solve the problems of complex production process, many consumables, high cost, to solve the complex production process, increase capacity, reduce The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

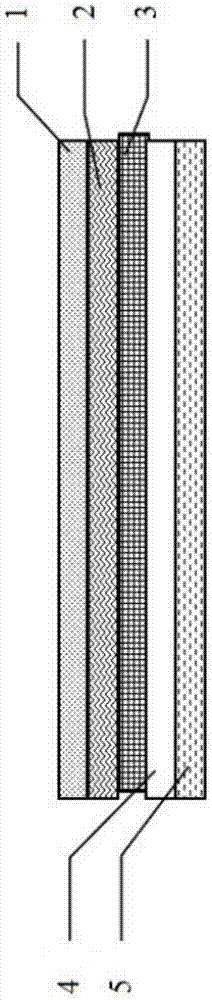

[0036] The positive electrode particle material is LiCoO2, the negative electrode particle material is graphite, the battery positive electrode base material 1 and the battery negative electrode base material 5 are both made of polyethylene terephthalate (PET), the diaphragm is made of polypropylene PP film, and the positive electrode metal mesh 2 is made of aluminum mesh , the negative electrode metal mesh 4 is made of copper mesh, and the adhesive is made of rubber.

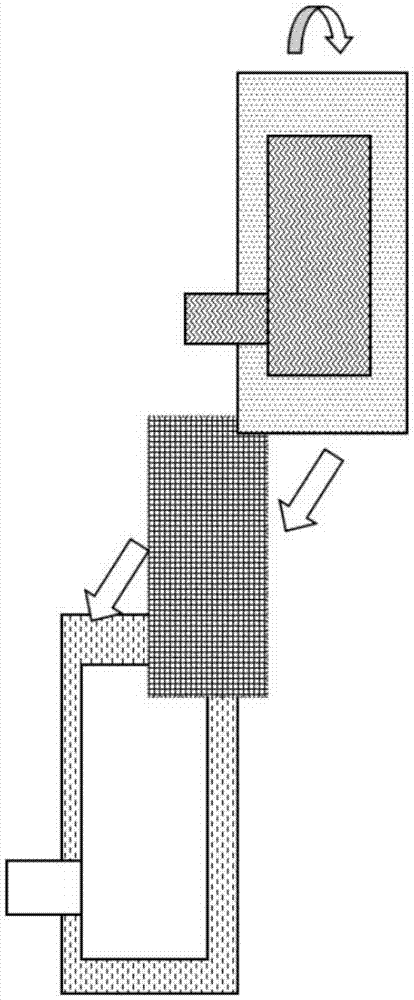

[0037] On the 10 μm battery positive electrode substrate 1 (PET), evenly coat 2 μm of viscous rubber, and cut the 12 μm aluminum mesh into figure 2 The metal mesh shape of the positive electrode is covered on the positive electrode substrate 1 of the battery. After LiCoO2 is ground and sieved into particles below 20 μm, LiCoO2 particles are evenly sprayed on the surface and gap of the aluminum mesh by spraying to obtain the positive electrode sheet. The final positive electrode sheet The total thickness is bet...

Embodiment 2

[0041]The positive electrode particle material and the negative electrode particle material are all made of graphene, the battery positive electrode base material 1 and the battery negative electrode base material 5 are both made of polypropylene plastic (PP), the separator is made of polyethylene PE film, the positive electrode metal mesh 2 is made of nickel mesh, and the negative electrode metal mesh 4 Nickel mesh is used, and acrylic glue is used as the adhesive.

[0042] Evenly coat 2 μm of viscous acrylic glue on two pieces of 8 μm insulating substrate PP, and cut the 10 μm nickel mesh into figure 2 The shape of the metal mesh is covered on the insulating substrate. After the graphene is ground and sieved into particles below 15 μm, the graphene particles are evenly sprayed on the surface and the gap of the nickel mesh by spraying to obtain the pole piece. The final total of the pole piece is The thickness is between 42μm-46μm;

[0043] Cover the two pole pieces with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com