Method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method

A biological enzyme method and silkworm chrysalis powder technology, applied in the field of bioengineering, can solve the problems of high price of silkworm chrysalis defatted powder, difficult emulsion breaking, difficult research and development, etc., and achieve good industrial production practical application value and low residual fat content , Remove grease with high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 pepsin and alkaline protease double enzymolysis silkworm chrysalis powder:

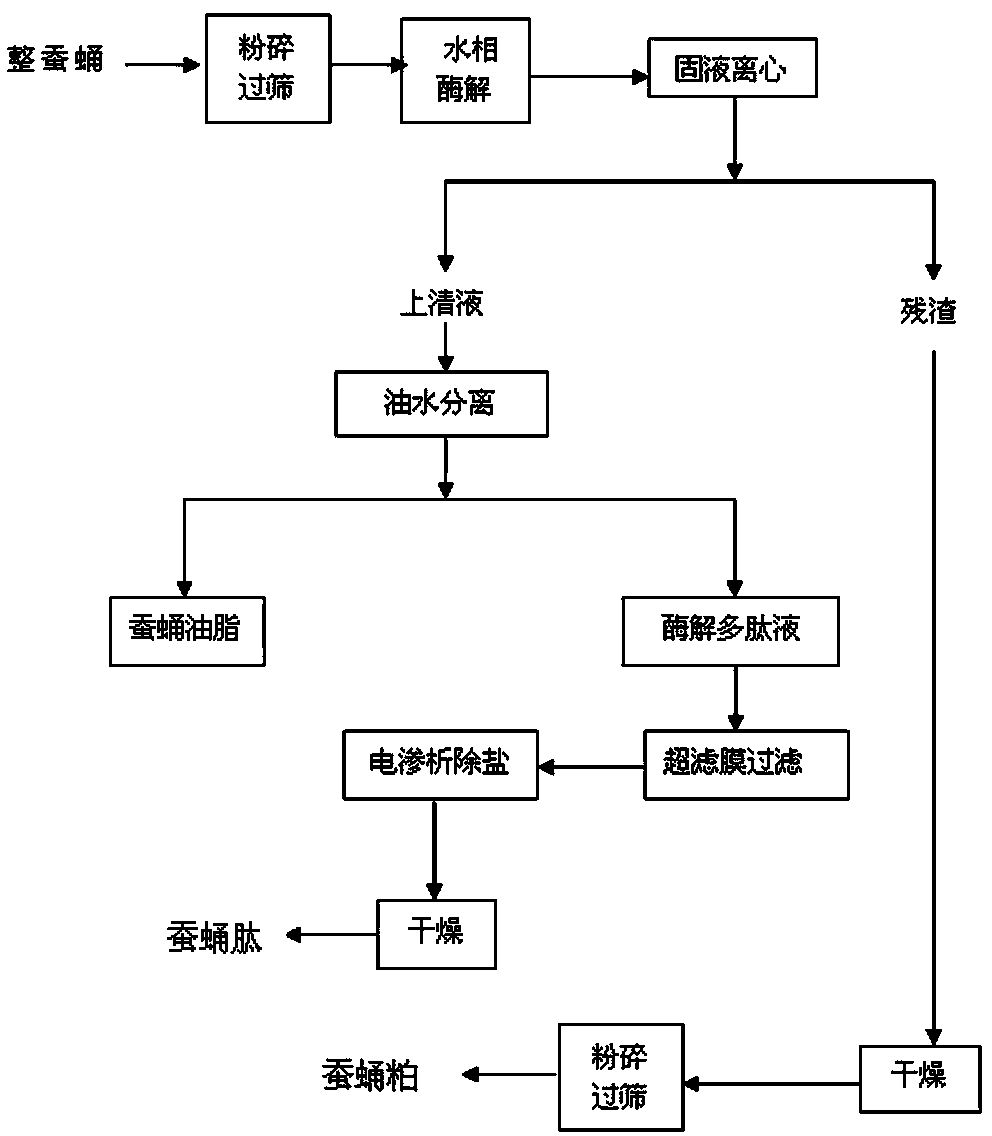

[0032] A method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method, such as figure 1 As shown, the specific method includes the following steps:

[0033] (1) Drying and crushing: Dry the silkworm chrysalis after reeling by blast at 100°C to a moisture content of 12%, and then crush them through a 24-mesh sieve to obtain silkworm chrysalis powder for later use;

[0034] (2) Water-phase enzymatic hydrolysis: Mix silkworm chrysalis powder and water in the reaction tank according to the mass ratio of material and water 1:3, and then carry out enzymatic hydrolysis in two steps: first, add pepsin according to the ratio of 2.0% of the mass of silkworm chrysalis powder, Enzymolyze at 30°C for 2 hours, control the pH value to 2.0 during the whole process of enzymolysis, then add alkaline protease according to the proportion of ...

Embodiment 2

[0044] Embodiment 2 pepsin and alkaline protease double enzymolysis silkworm chrysalis powder:

[0045] A method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method, the specific method comprises the following steps:

[0046] (1) Drying and crushing: Dry the silkworm chrysalis after reeling by blast at 100°C to a moisture content of 12%, and then crush them through a 24-mesh sieve to obtain silkworm chrysalis powder for later use;

[0047] (2) Water-phase enzymatic hydrolysis: Mix silkworm chrysalis powder and water in the reaction tank according to the mass ratio of material and water 1:6, and then carry out enzymatic hydrolysis in two steps: first, add pepsin at a ratio of 1.0% of the mass of silkworm chrysalis powder, Enzymolyze at 40°C for 1 hour, control the pH value to 1.5~2.0 during the whole process of enzymolysis, then add alkaline protease according to the proportion of 1.0% of the mass of silkworm chrysal...

Embodiment 3

[0057] Embodiment 3 Flavor protease and papain double enzymolysis silkworm chrysalis powder:

[0058] A method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method, the specific method comprises the following steps:

[0059] (1) Drying and crushing: Dry the silkworm chrysalis after reeling by blast at 95°C until the water content is 10%, and then crush them through a 20-mesh sieve to obtain silkworm chrysalis powder for later use;

[0060] (2) Water-phase enzymatic hydrolysis: Mix silkworm chrysalis powder and water in the reaction tank according to the mass ratio of material and water 1:6, and then carry out enzymatic hydrolysis in two steps: first, add flavor protease according to the ratio of 1.0% of the mass of silkworm chrysalis powder, Enzymolyze at 53°C for 2 hours, and control the pH value to 6.5~7.0 during the enzymolysis process; then add papain according to the proportion of 1.0% of the mass of silkworm ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com