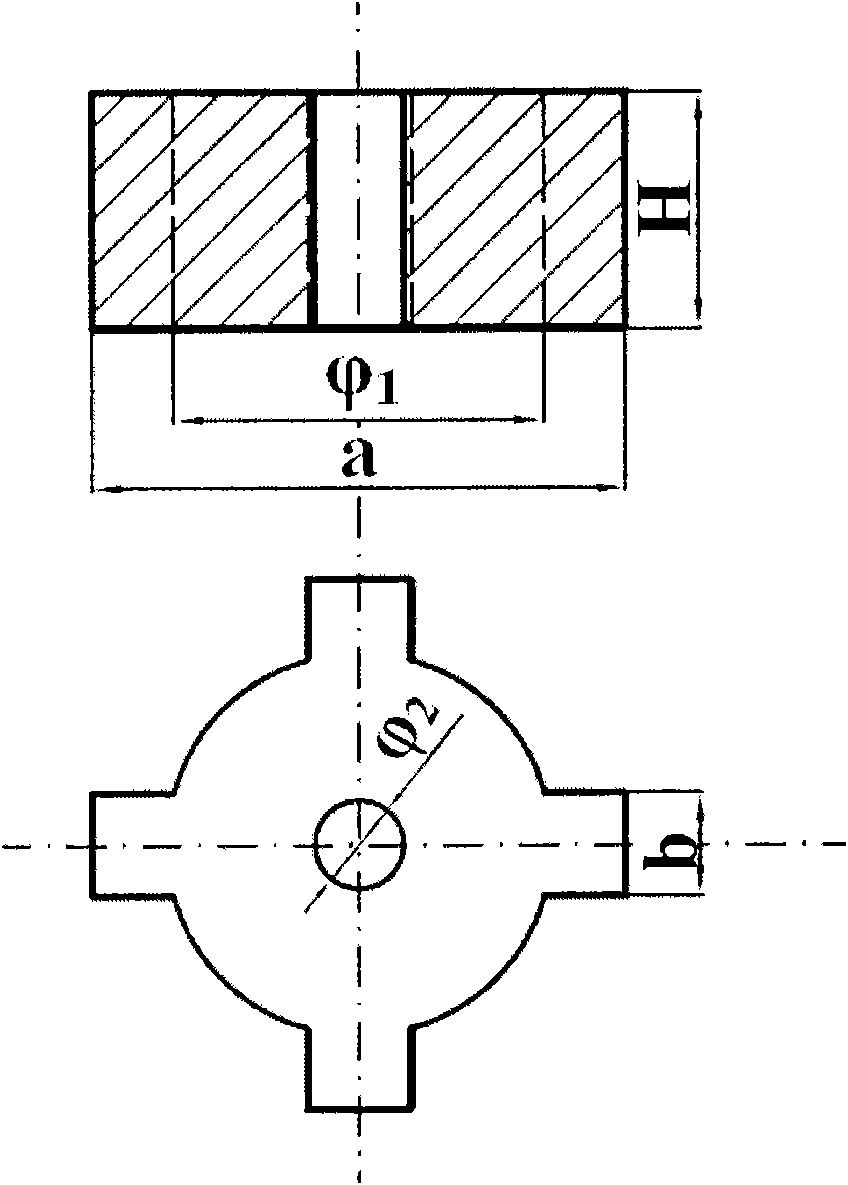

Method for manufacturing dentate special-shaped ceramic components by injection molding

An injection molding and ceramic technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty, cracking and deformation, and long time of multi-tooth-shaped special-shaped ceramic products, and achieves a small amount of machining, no deformation and cracking. Defects, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

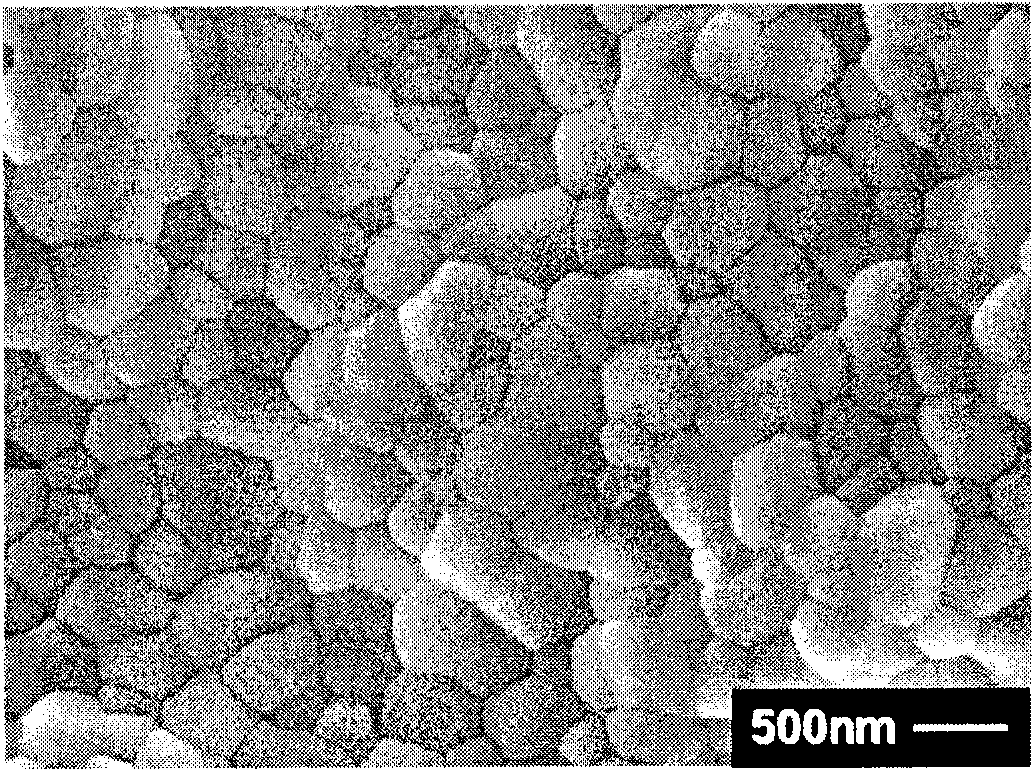

[0033] In this embodiment, the ceramic powder is made of zirconia ceramic powder, and the average particle size of the zirconia powder is d 50 =0.15μm, the specific surface area is 8.5m 2 / g, the organic binder is composed of a water-insoluble binder, a water-soluble binder, a surfactant, a low melting point organic matter and a plasticizer, and the water-insoluble binder is polyethylene terephthalate Combination with polymethyl methacrylate, polyethylene glycol as water-soluble binder, stearic acid as surfactant, dibutyl terephthalate as plasticizer, microcrystalline paraffin as low Melting point organics.

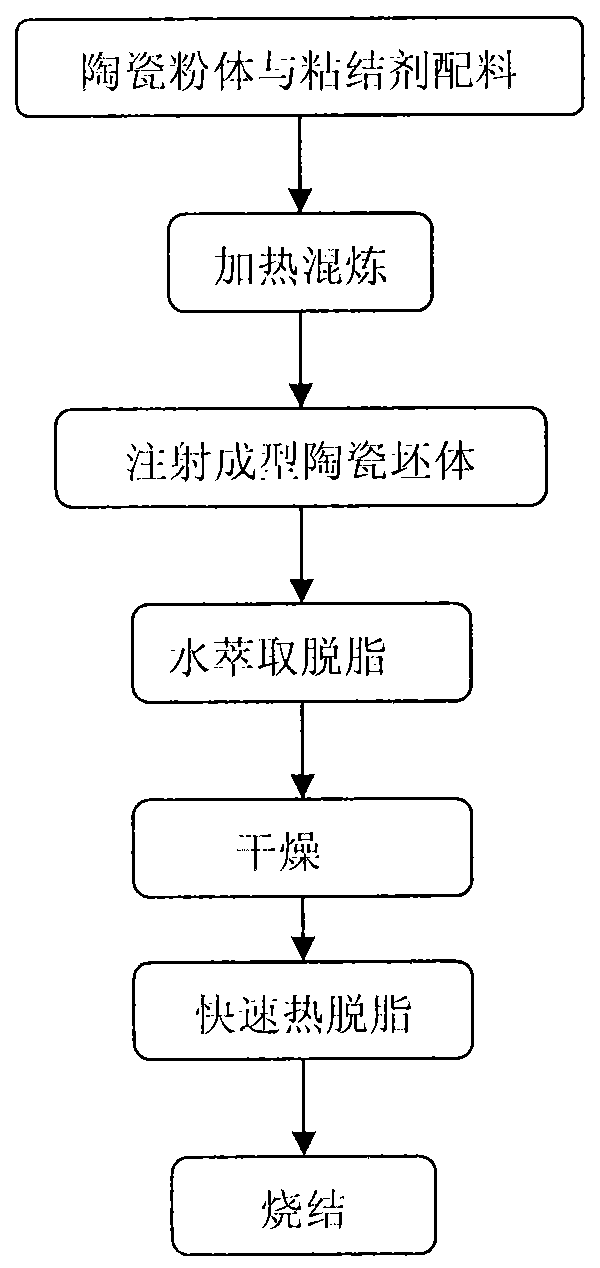

[0034] The steps of the method for manufacturing tooth-shaped special-shaped ceramic parts by injection molding are as follows, and the process flow is shown in figure 2 :

[0035] (1) Mix ceramic powder and organic binder: add 1000g zirconia ceramic powder, 12.4g polyethylene terephthalate, and 22.9g polymethyl methacrylate to a double-roll mill, at 190 Mix at 10°C ...

Embodiment 2

[0044] In this embodiment, alumina ceramic powder is selected as ceramic powder, and the average particle diameter of alumina powder is d 50 =0.08μm, the specific surface area is 13.5m 2 / g, the organic binder is composed of a water-insoluble binder, a water-soluble binder, a surfactant, a low melting point organic matter and a plasticizer, and the water-insoluble binder is polyethylene terephthalate Combination with polyvinyl butyral, polyethylene glycol as water-soluble binder, stearic acid as surfactant, dibutyl terephthalate as plasticizer, microcrystalline paraffin as low Melting point organics.

[0045] The steps of the method for manufacturing tooth-shaped special-shaped ceramic parts by injection molding are as follows:

[0046] (1) Mix ceramic powder and organic binder: add 1000g alumina ceramic powder, 11.0g polyethylene terephthalate, and 33.0g polyvinyl butyral to a double-roll mill, Mixing at ℃ for 10 minutes; the temperature dropped to 170℃, added 8.8g of stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com