Extrusion forming agent and preparation and use thereof

An extrusion forming and modifier technology, applied in the field of powder metallurgy forming, can solve the problem of low degreasing rate and achieve the effects of high degreasing efficiency, good degreasing and shape retention, and increasing loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

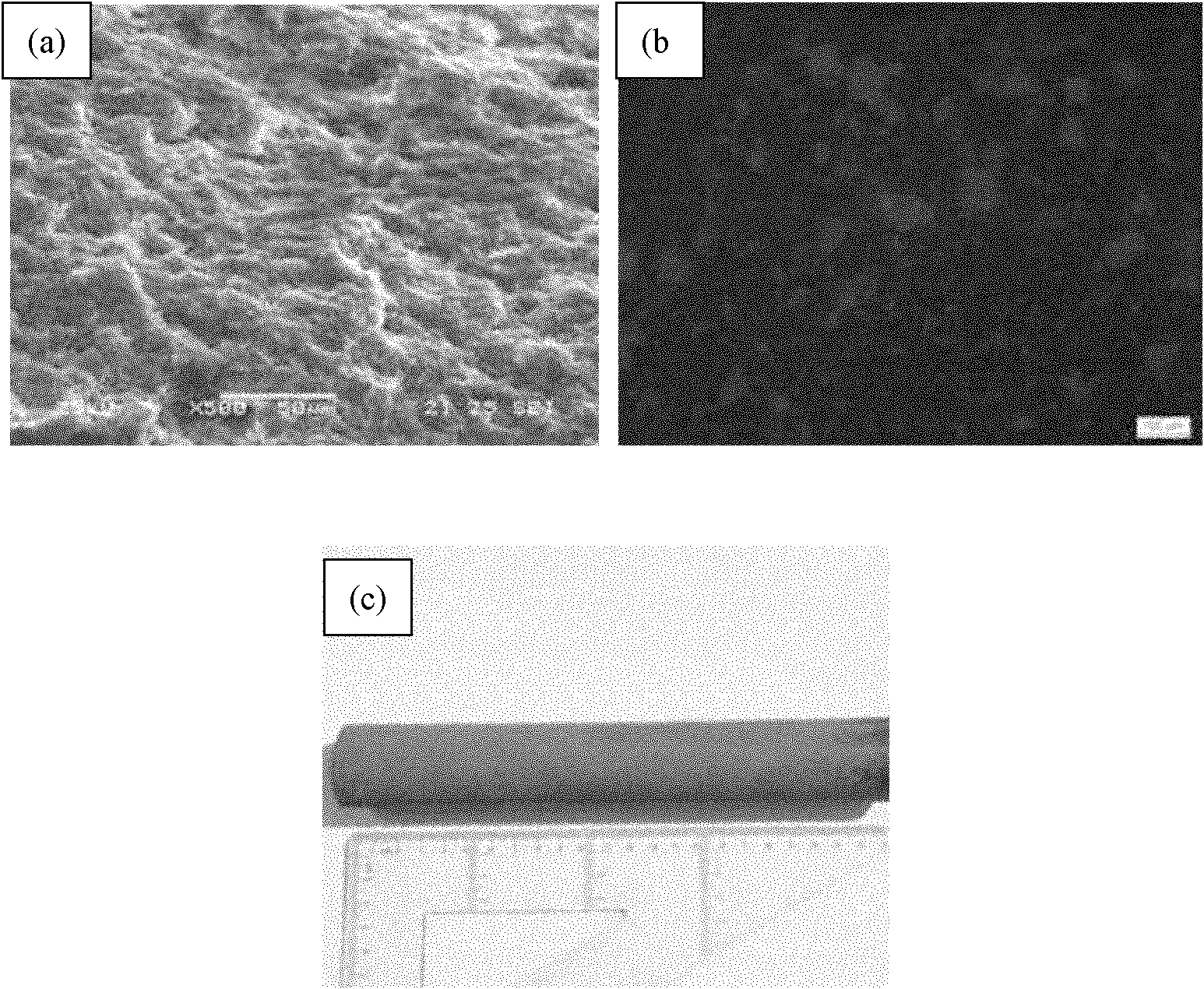

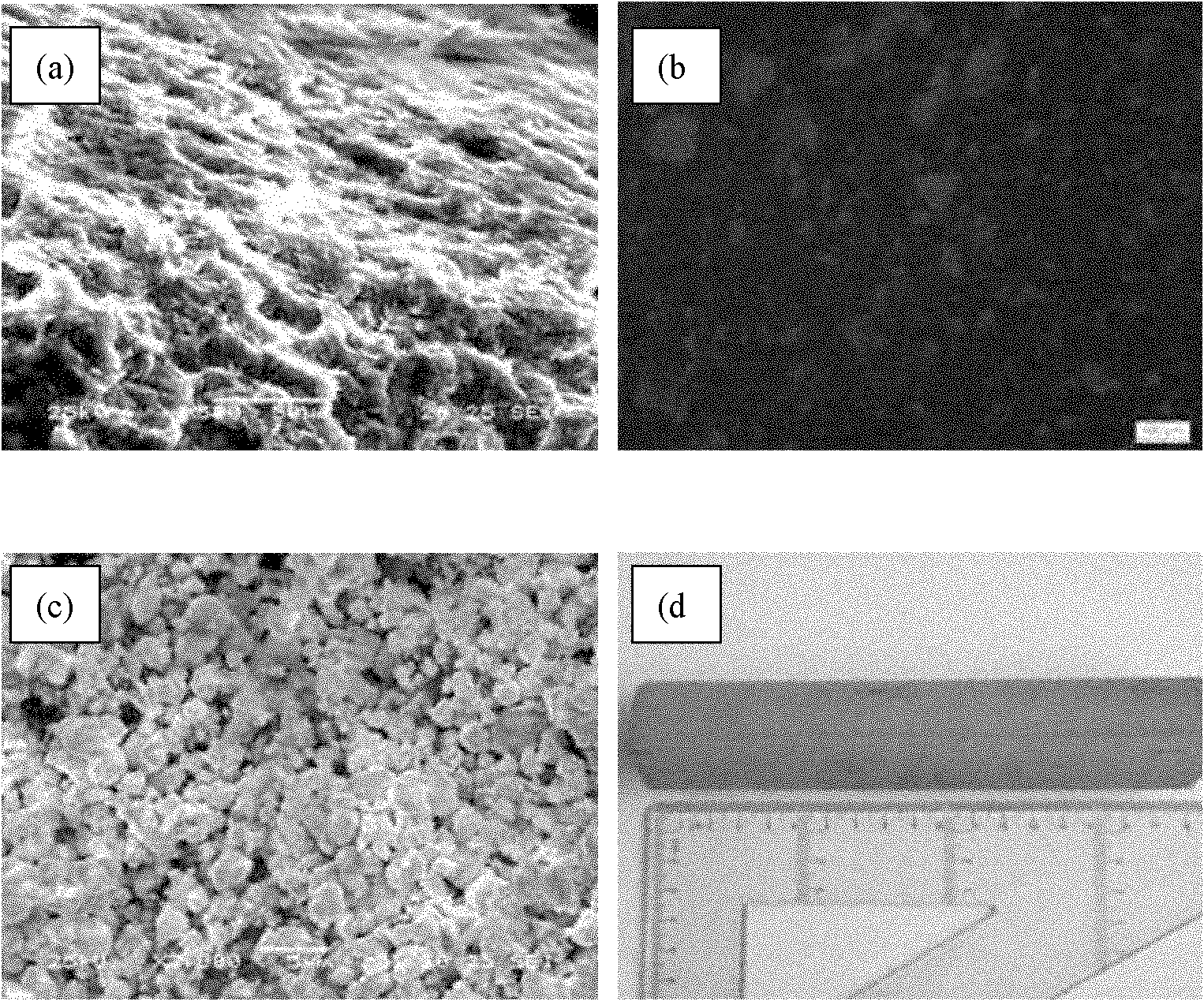

Image

Examples

Embodiment 1

[0026] (1) Take by weight 60% solid paraffin, 10% liquid paraffin, 8% high-density polyethylene, 8% ethylene-vinyl acetate copolymer, 4% plasticizer (dioctyl phthalate) , 1% stearic acid, 6% carnauba wax, 3% modifier (polyethylene wax).

[0027] (2) The temperature of the kneading device was raised to 160° C. and kept warm.

[0028] (3) Put the weighed 8% high-density polyethylene into the mixing device to heat and melt. After it is completely melted, slowly add 8% ethylene-vinyl acetate copolymer, and keep stirring until the two form a uniform molten mixture. .

[0029] (4) Lower the melt kneading temperature to 100° C., add 3% modifier (polyethylene wax) to the above melt blend, and keep stirring to make it blend together.

[0030] (5) Add the prepared solid paraffin, liquid paraffin and carnauba wax into the above-mentioned melt blend together in sequence, stir continuously, and the mixing time is 30 minutes.

[0031] (6) Add the prepared plasticizer and stearic acid int...

Embodiment 2

[0034] (1) Take by weight 55% solid paraffin, 15% liquid paraffin, 10% high-density polyethylene, 10% ethylene-vinyl acetate copolymer, 5% plasticizer (dioctyl phthalate) , 1% stearic acid, 3% carnauba wax, 1% modifier (polyethylene wax).

[0035] (2) Raise the temperature of the kneading device to 170° C. and keep it warm.

[0036] (3) Put the weighed 10% high-density polyethylene into the mixing device to heat and melt. After it is completely melted, slowly add 10% ethylene-vinyl acetate copolymer, and keep stirring until the two form a uniform molten mixture. .

[0037](4) Lower the melt kneading temperature to 110° C., add 1% modifier (polyethylene wax) to the above melt blend, and keep stirring to make it blend into one.

[0038] (5) Add the prepared solid paraffin, liquid paraffin and carnauba wax into the above-mentioned melt blend together in sequence, stir continuously, and the mixing time is 60 minutes.

[0039] (6) Add the prepared plasticizer and stearic acid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com