Method for manufacturing microarray through powder microinjection molding

A microarray and microinjection technology, which is applied in the field of powder microinjection molding based on water-soluble binder system and microarray preparation, can solve the problems of high production cost, difficult to process micro parts, and restrict mass production, etc., and achieve low cost , dense surface finish, and the effect of improving degreasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the powder is selected from 316L stainless steel powder, and the average particle diameter of 316L stainless steel powder is d 50 =0.6μm, the organic binder is composed of a water-insoluble binder, a water-soluble binder and a surfactant, and the water-insoluble binder is polyethylene and polymethyl methacrylate, with polyethylene glycol as Water-soluble binder, with stearic acid as surfactant.

[0025] The method steps of manufacturing microarray by powder microinjection molding are as follows,

[0026] (1) Mixing powder and binder system: Add 2000g 316L stainless steel powder and 67g polymethyl methacrylate, 78g polyethylene glycol, 67g polyethylene and 11g stearic acid into a twin-roller mixer and mix at 160°C for 1 hour, then cooling and crushing to obtain the mixture;

[0027] (2) Injection molding

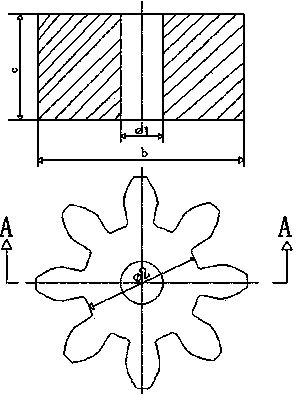

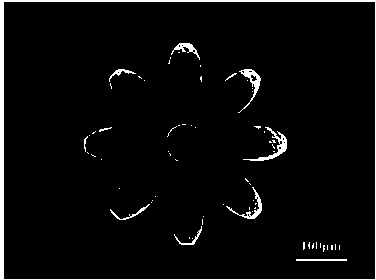

[0028] The obtained mixture is injected into a prefabricated body on an injection molding machine, and the shape of the green body is as follows...

Embodiment 2

[0035] In this embodiment, the powder is made of zirconia ceramic powder, and the average particle size of zirconia powder is d 50 =80nm, the organic binder is composed of a water-insoluble binder, a water-soluble binder and a surfactant, and the water-insoluble binder is ethylene-vinyl acetate and polymethyl methacrylate, polyethylene Alcohol is a water-soluble binder, stearic acid is used as a surfactant,

[0036] The method steps of manufacturing microarray by powder microinjection molding are as follows,

[0037] (1) Mixing powder and binder system: 2000g zirconia ceramic powder and 89g polymethyl methacrylate, 89g polyethylene glycol, 104g ethylene-vinyl acetate and 15g stearic acid were added to the double-roller mixer Mixed at 160°C for 1 hour, then cooled and crushed to obtain a mixture;

[0038] (2) Injection molding

[0039] The obtained mixture is injected into a prefabricated body on an injection molding machine, and the shape of the green body is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com