Method for extracting and purifying beta-glucan from highland barley grains

A glucan and grain technology, applied in the field of extracting and purifying beta-glucan, can solve problems such as differences in the ratio of glycosidic bonds, and achieve the effects of reducing material resource consumption, good effect, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

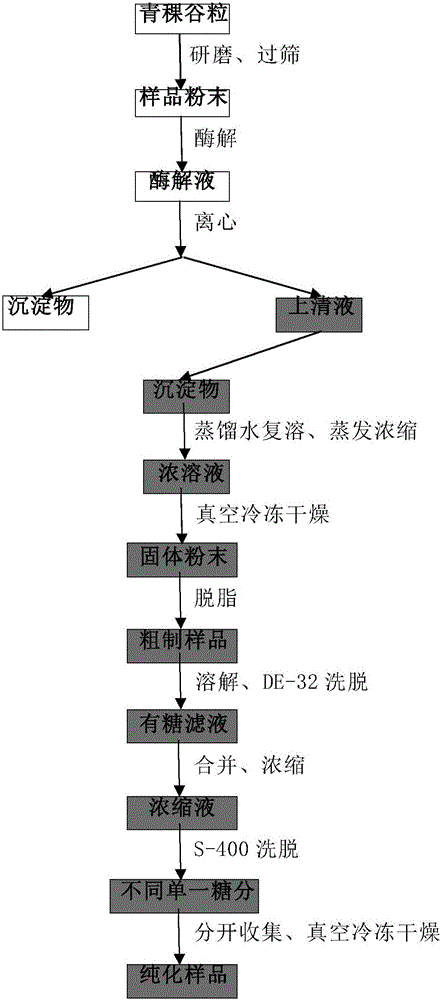

[0032] This example provides a method for extracting and purifying β-glucan from highland barley grains, the process is as follows figure 1 As shown, the specific steps are as follows:

[0033] Sorting several normal highland barley grains without lesions, grinding and passing through a 0.4mm sieve; weigh 10g of powdered samples and add 90mL of distilled water to dissolve them, add 50μL of high-temperature-resistant α-amylase, and bathe in 80°C water for 1 hour; adjust the temperature of the water bath to 60°C , add 15mg of papain, water bath for 1h; inactivate enzyme in 100℃ water bath for 10min, add 400μL glucoamylase after cooling, 60℃ water bath for 1h; inactivate enzyme in 100℃ water bath for 10min, after cooling in 86℃ water bath for 4h; The precipitate was saved and the supernatant was used for later use.

[0034] Slowly add 3 times the volume of absolute ethanol dropwise to the supernatant under the condition of magnetic stirring, and let it stand overnight; centrifug...

Embodiment 2

[0039] This example provides a method for extracting and purifying β-glucan from highland barley grains, which is basically the same as the method in Example 1, the only difference is that the elution flow rates of DE-32 and S-400 are different, that is, the implementation The elution flow rates of DE-32 and S-400 in Example 2 are both 0.5mL / min.

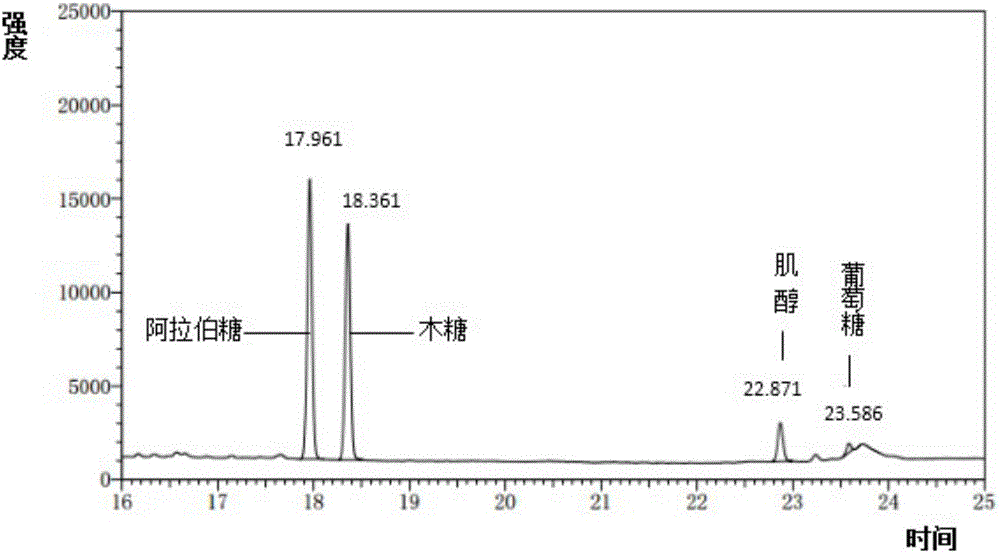

[0040] The β-glucan filtrate collected in this example contains a large amount of glucose according to the sugar composition measured by gas chromatography. Further, glucose was identified by using a β-1,3 glucan detection kit, and the result showed that the glucose in the filtrate was β-glucan. According to the detection results of liquid chromatography, it can be seen that the purity of the β-glucan prepared in this example is 97.63%, and the extraction rate of the β-glucan obtained after elution of the crude sample obtained after enzymolysis is 11.6%. Compared with Example 1, the purity of this example is equivalent to that of Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com