Ultrasonic-assisted corn protein extraction method

A corn gluten and corn technology, applied in the field of corn gluten extraction technology, can solve the problems of high protein yield and purity, low extraction rate and purity, low solvent consumption, etc., so as to shorten the extraction time, improve the extraction rate and purity, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

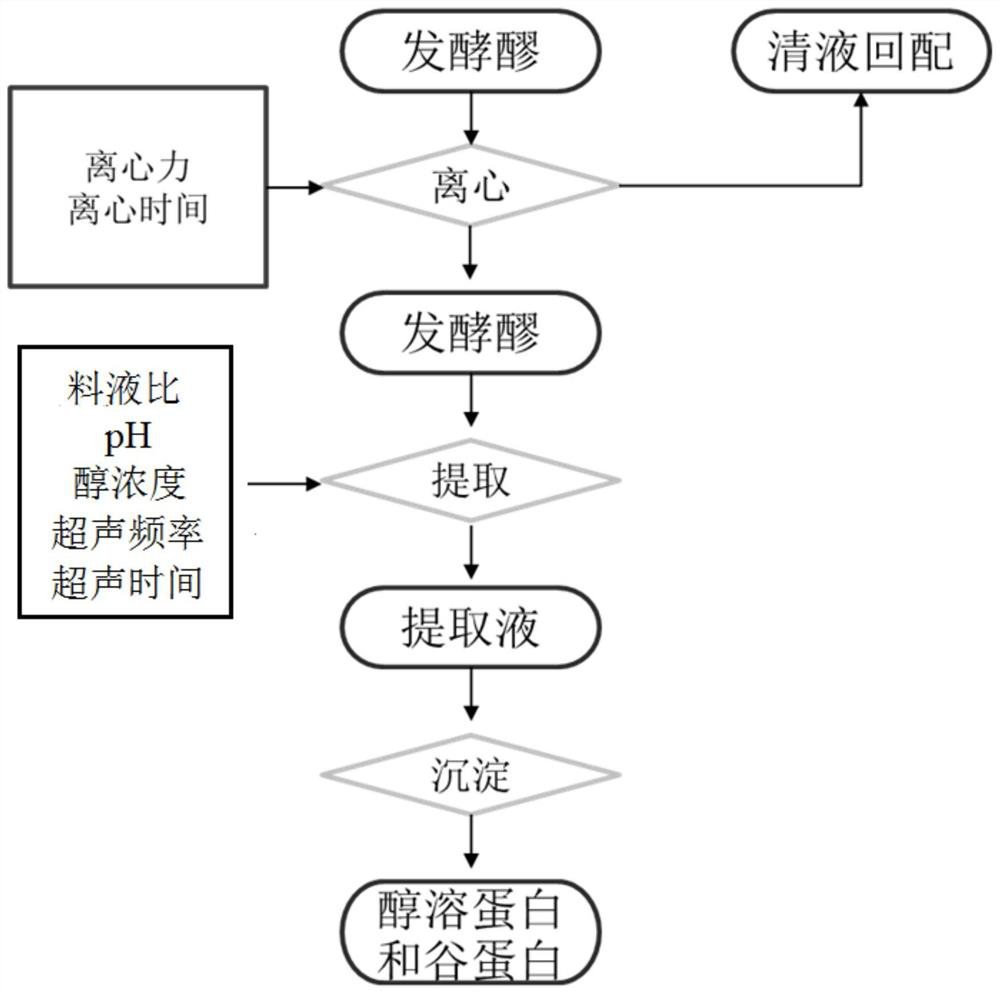

Method used

Image

Examples

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the corn fermented mash contains 3-4% by weight of crude protein.

[0026] According to the present invention, in step 1, the first solid-liquid separation method can be various conventional methods for separating the solid phase and the liquid phase in the mixed liquid, for example, it can be filtration, centrifugation and the like. According to a preferred embodiment of the present invention, the first solid-liquid separation is centrifugation. Wherein, the condition of the centrifugation can be selected in a wide range, preferably, the centrifugation condition is: the rotating speed is 3000-10000rpm, for example, it can be 3000rpm, 3500rpm, 4000rpm, 4500rpm, 5000rpm, 6000rpm, 7000rpm, 8000rpm, 9000rpm, 10000rpm, preferably 3000-8000rpm, more preferably 3500-4500rpm; time is 5-30min, for example, 5min, 10min, 15min, 20min, 25min, 30min, preferably 15-25min.

[0027] According to the present invention, in s...

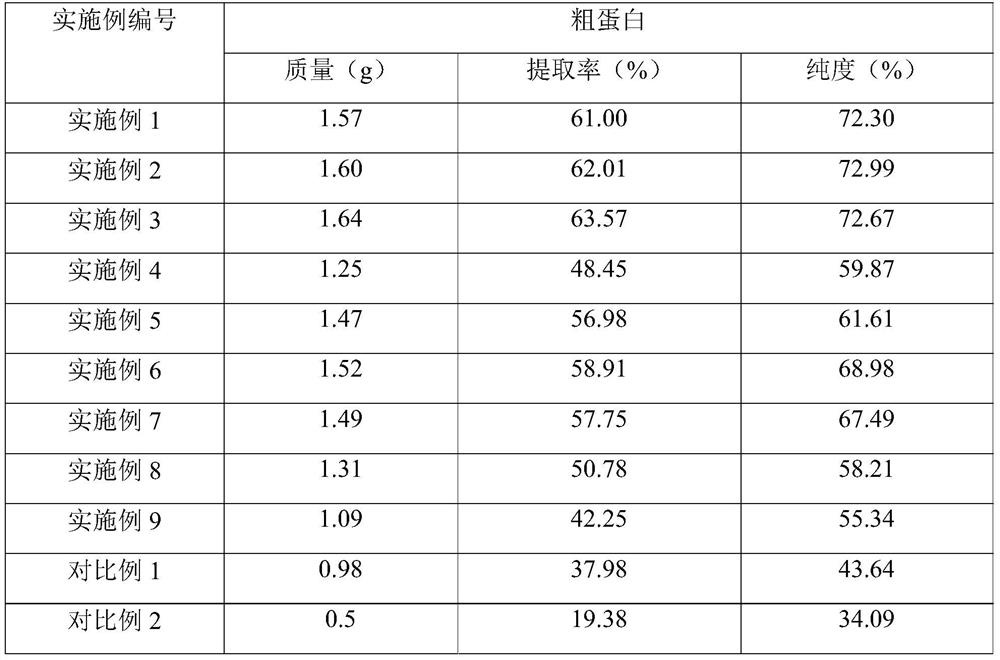

Embodiment 1

[0059] This embodiment is used to illustrate the method for extracting corn protein from corn fermented mash provided by the present invention

[0060] (1) Centrifuge the fermented mash, 4000rpm, 20min, collect 10g of distiller's grain solids, use ethanol as the extract, prepare the extract so that the ethanol content is 30% by volume, adjust the pH to 9 with sodium hydroxide, and obtain the feed liquid in the system The ratio is 1:10, add 0.2% (g / ml) sodium sulfite to the system, stir and mix well.

[0061] (2) Ultrasonic the above suspension, modulated at 60kHz, and ultrasonicated at 50°C for 120min;

[0062] (3) Separating the solid-liquid of the above-mentioned ultrasonically treated suspension, collecting the extract, and distilling under reduced pressure to remove part of the organic solvent, but no protein was precipitated.

[0063] (4) Adjust the pH of the above-mentioned distilled extract to 4.7, centrifuge to collect the precipitated zein, adjust the pH to 6.4 again...

Embodiment 2

[0066] This embodiment is used to illustrate the method for extracting corn protein from corn fermented mash provided by the present invention

[0067] (1) Centrifuge the fermented mash, 4000rpm, 20min, collect 10g of distiller's grain solids, use ethanol as the extract, prepare the extract so that the ethanol content is 50% by volume, adjust the pH to 9.5 with sodium hydroxide, and obtain the feed liquid in the system The ratio is 1:15, add 0.1% (g / ml) sodium sulfite to the system, stir and mix well.

[0068] (2) Sonicate the above suspension at 65kHz, and sonicate at 60°C for 130min.

[0069] (3) Separating the solid-liquid of the above-mentioned ultrasonically treated suspension, collecting the extract, and distilling under reduced pressure to remove part of the organic solvent, but no protein was precipitated.

[0070] (4) Adjust the pH of the above-mentioned distilled extract to 4.7, centrifuge to collect the precipitated zein, adjust the pH to 6.4 again, centrifuge to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com