Device and method for preparing rice protein through magnetic field-assisted electrostatic separation

A rice protein, electrostatic separation technology, applied in the field of rice protein, to avoid volatile organic solvents and toxic substances, high yield and purity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1 A method for preparing rice protein by magnetic field-assisted electrostatic separation, comprising the following steps:

[0069] S1: The rice dregs were ground in a factory-scale air impact mill with the rotor frequency set to 40Hz, and then the ground material was air-classified into fine powder in the air classifier, the classifier wheel frequency, feed The volume and the frequency of the induced draft fan are set to 50Hz, 6.0kg / h and 50Hz respectively.

[0070] S2: The electric blower pump equipment of the feeding system provides a stable air flow, the gas flow rate is 7L / min, and the fine powder particles are stored in the intermittent fluidized bed equipment of the feeding system and the fine powder particles are fully contacted with the air flow mix. Enter the spiral friction booster tube to charge the material. The spiral friction booster tube is made of polytetrafluoroethylene (PTFE) tube, the inner diameter of the tube is 6mm, and the length of th...

Embodiment 2

[0073] Example 2 A method for preparing rice protein by magnetic field-assisted electrostatic separation

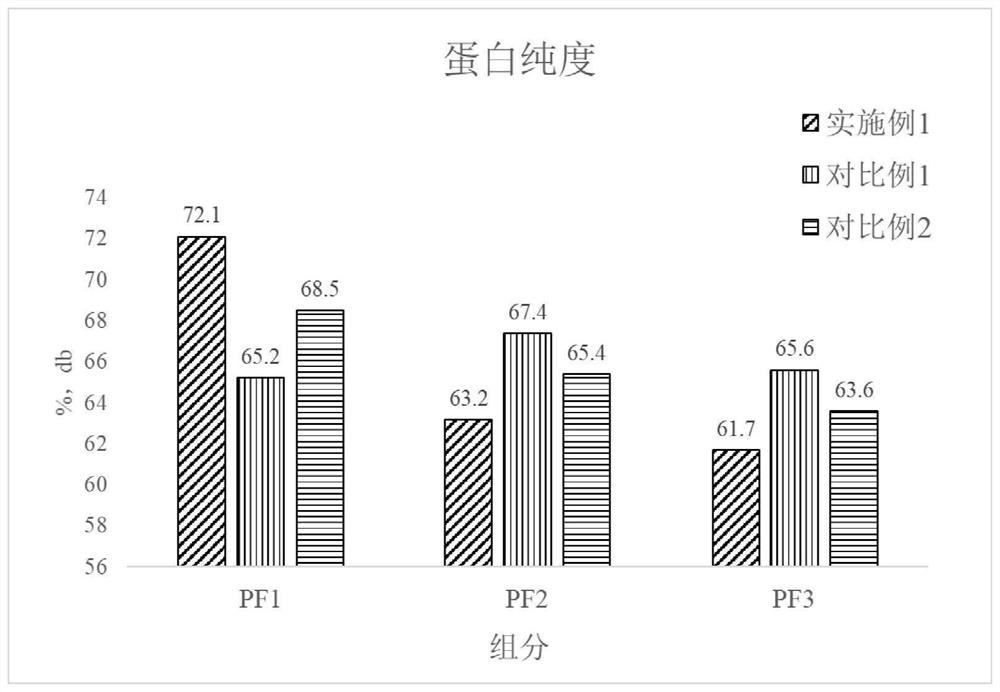

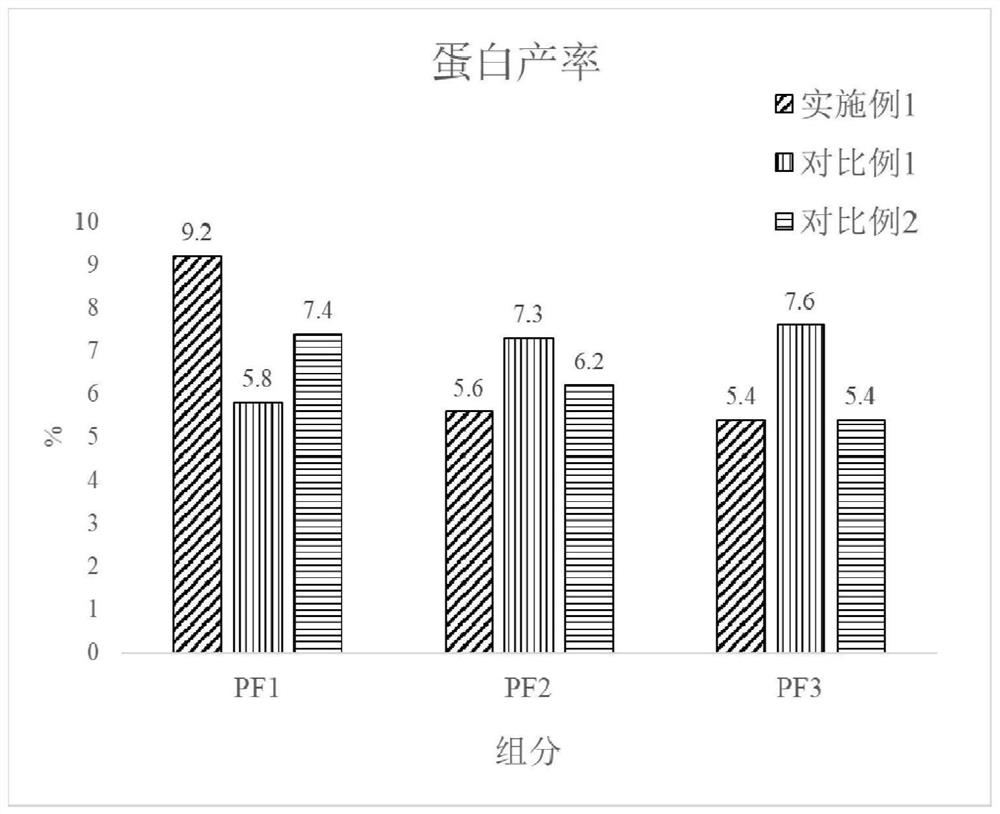

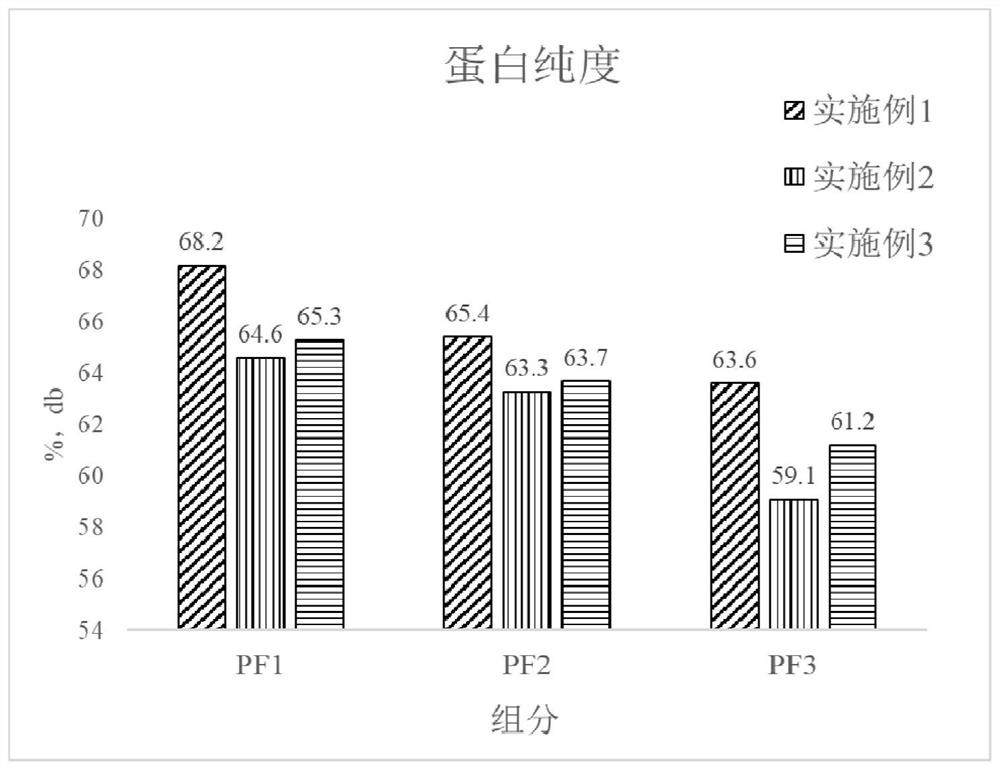

[0074]Same as Example 1, except that in S3, the electrode spacing is 10 cm, the voltage is 10 kv, and the electric field strength is 1 kv / cm. The purity results of rice protein in the negative electrode collection area are shown in image 3 , the yield results of rice protein in the negative electrode collection area are shown in Figure 4 .

Embodiment 3

[0075] Example 3 A method for preparing rice protein by magnetic field-assisted electrostatic separation

[0076] Same as Example 1, except that in S3, the electrode spacing is 20cm, the voltage is 20v, and the electric field strength is 1kv / cm. The purity results of rice protein in the negative electrode collection area are shown in image 3 , the yield results of rice protein in the negative electrode collection area are shown in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com