Automatic coating forming device and coating forming method for concentric-square-shaped supporting structural component

An automatic technology for structural parts, applied in the field of automatic coating and forming devices for return-shaped support structural parts, can solve the problems of high cost, large demand for human resources, low coating efficiency, etc., achieve smooth surface of structural parts, solve labor shortage, Coating and forming for efficient and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

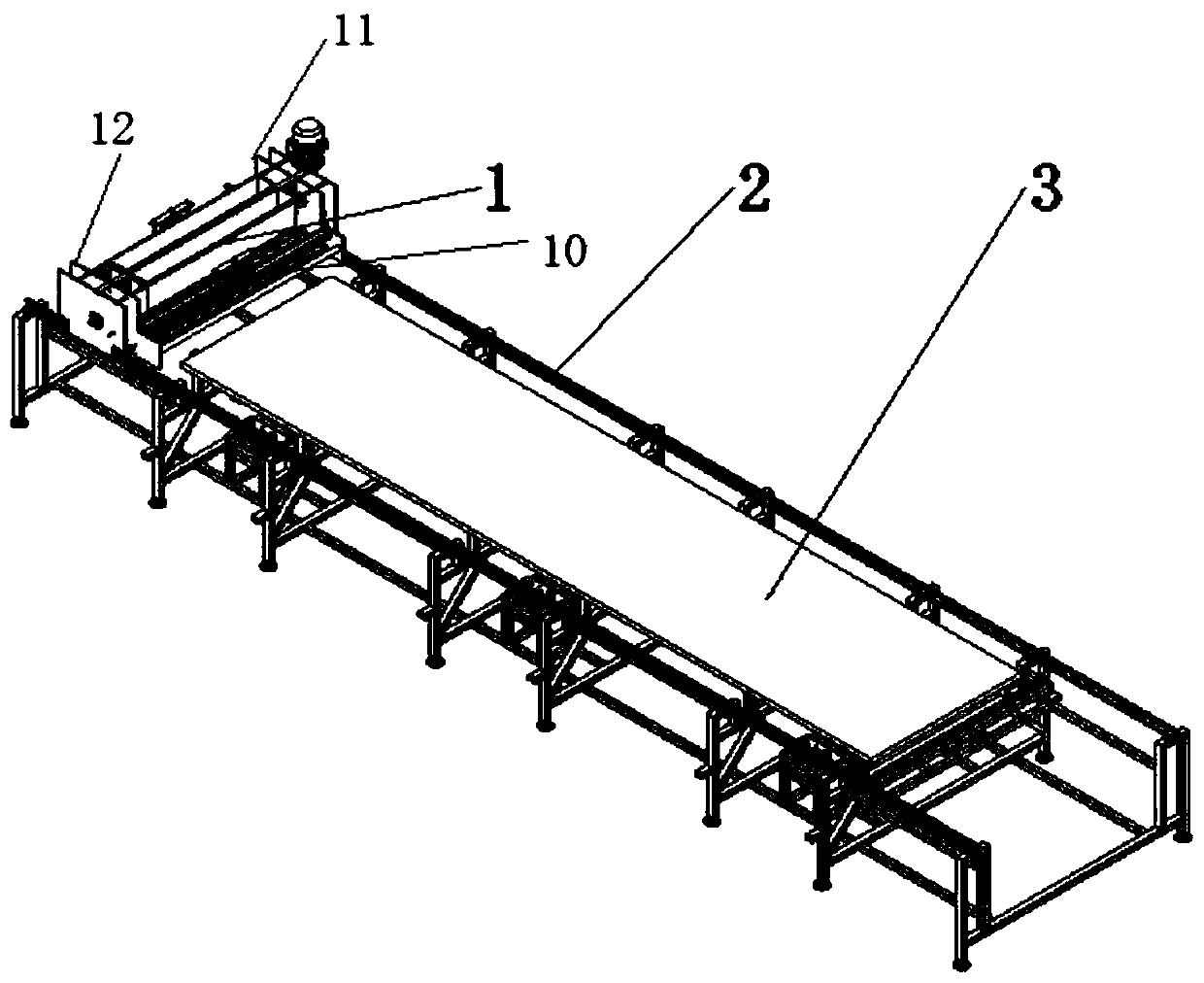

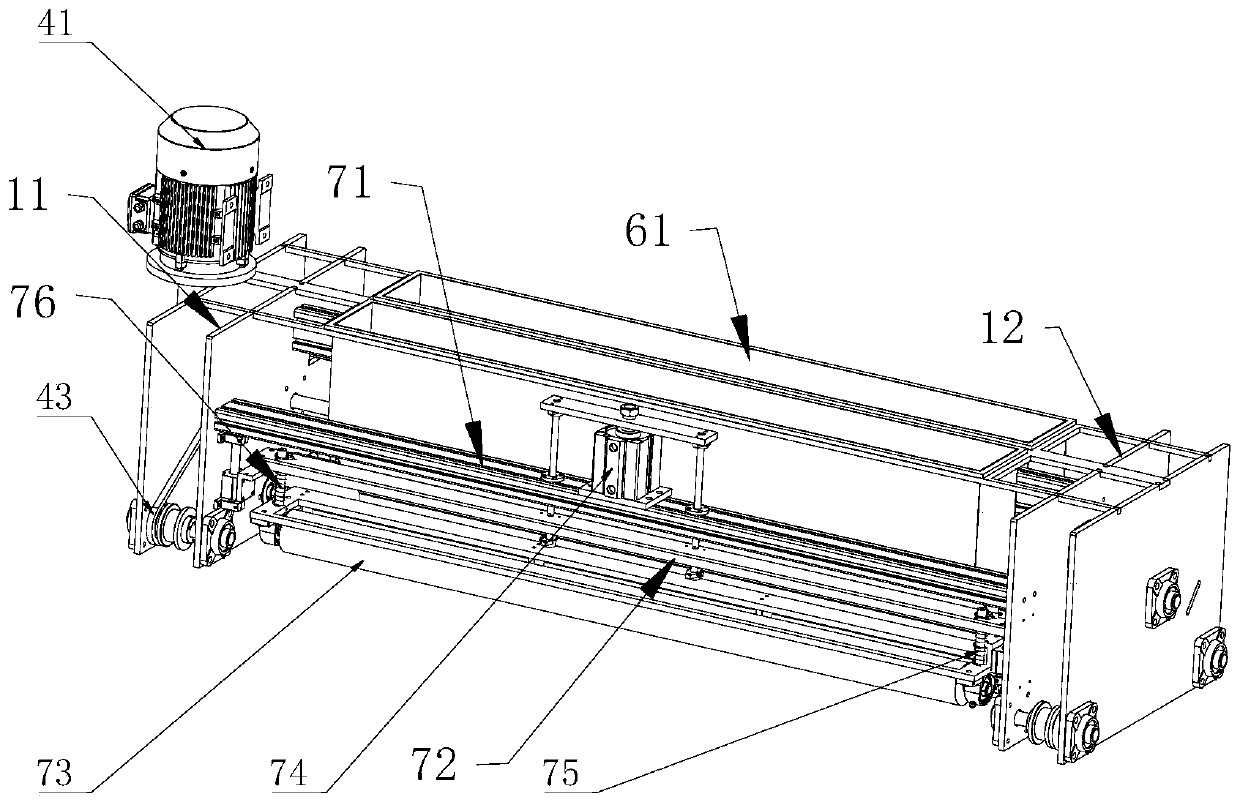

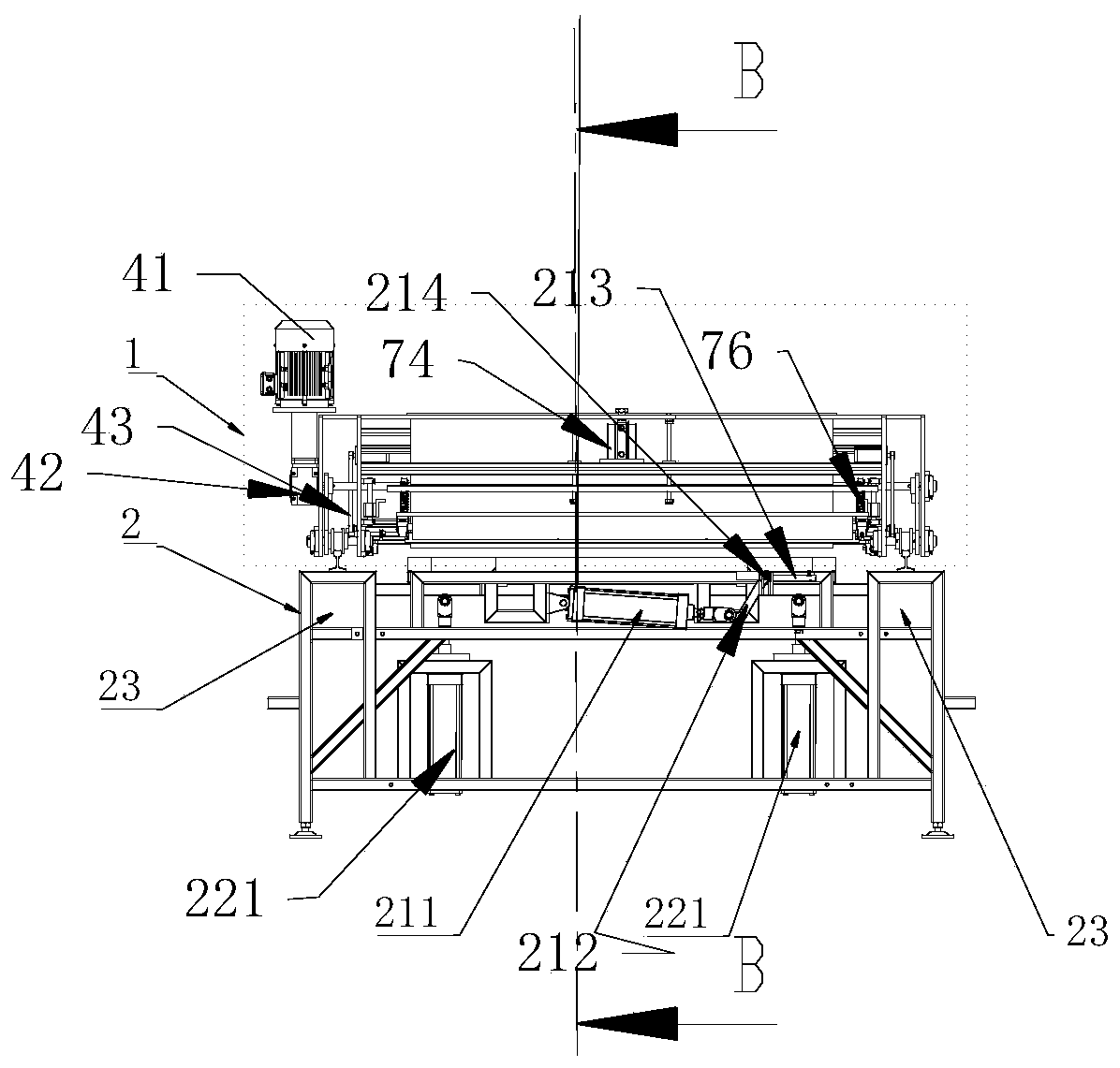

[0037] refer to Figure 1-Figure 12 As shown, a kind of automatic coating and forming device for back-shaped support structure of the present invention includes forming auxiliary frame 2 and mobile support 1, the main body of forming auxiliary frame is a frame composed of square steel, and its feet are movable feet, which are convenient for installation When adjusting the height of the device, the forming auxiliary frame main body includes a platform for placing the wooden formwork 3, a primary bending device 21, a secondary bending device 22 and the guide rail of the mobile support. In a specific embodiment of the present invention, the mobile support 1 can be a walking The material cart, the wooden mold 3 is placed on the platform of the forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com