Forming robot and forming method for reinforcing back ridge of corrosion-resistant aluminum formwork

A technology of aluminum templates and robots, which is applied in the field of corrugation, can solve the problems of easy corrosion and aging of corrugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

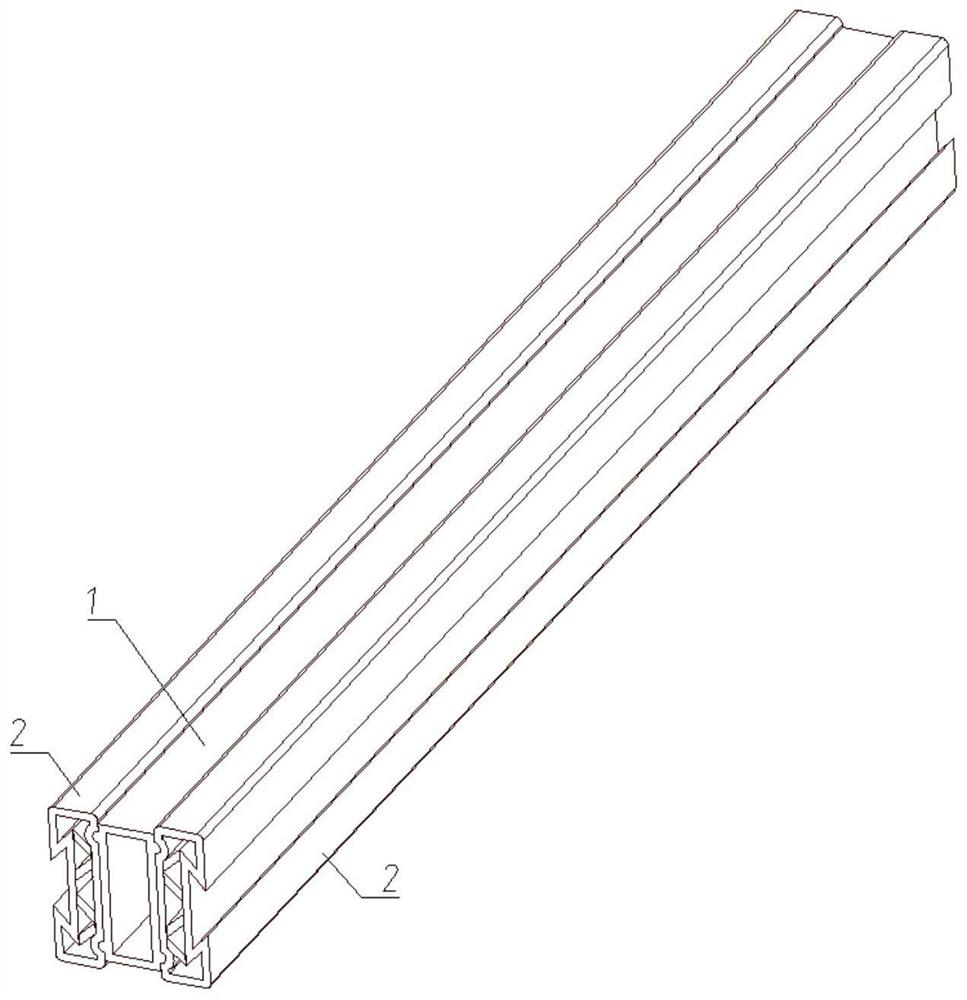

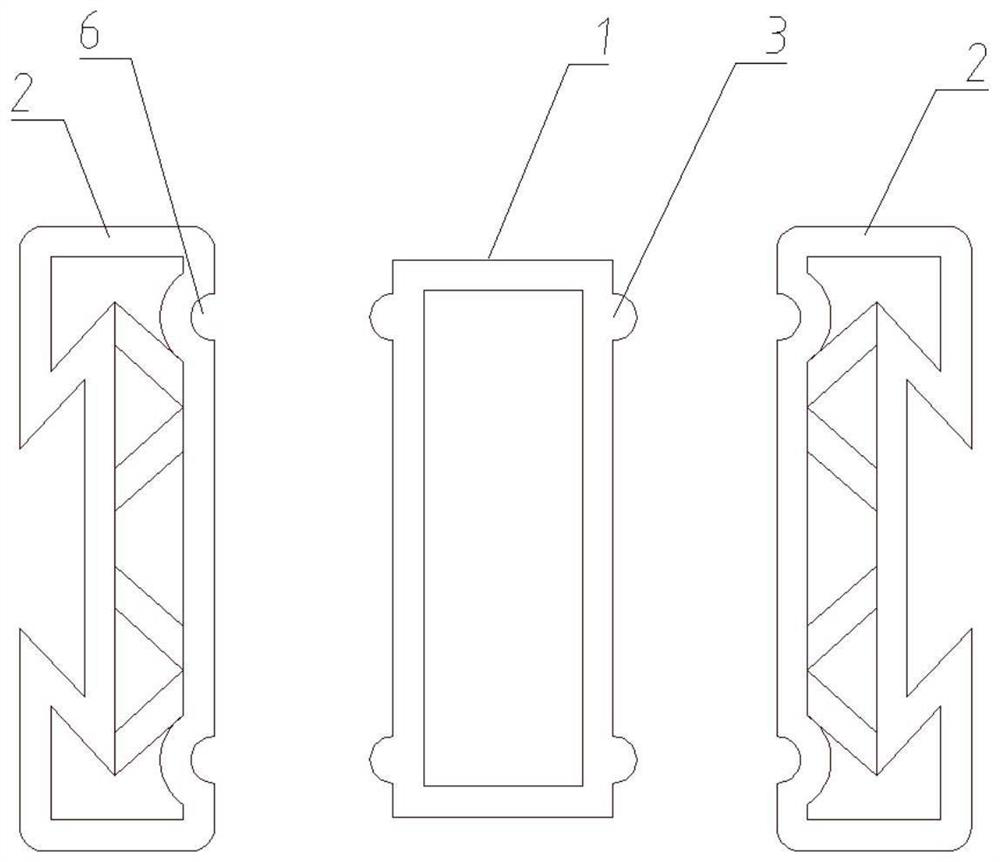

[0060] A reinforced back flute of a corrosion-resistant aluminum formwork, comprising an intermediate pipe 1 and side pipes 2 arranged on both sides of the intermediate pipe 1, the intermediate pipe 1 is a hollow structure with a rectangular cross section, and the edge of the intermediate pipe 1 is rectangular The first surfaces on both sides of the width direction are flat, and the two first surfaces are respectively provided with raised strips 3 extending along the length direction of the middle pipe 1, and the two side pipes 2 are aluminum profiles and are set On both sides of the middle pipe 1 along the width direction of the rectangle, the second surface of each side pipe 2 facing the side of the middle pipe 1 is a plane, and the second surface is attached to the first surface of the corresponding side. The two surfaces are provided with strip-shaped grooves 6 that cooperate with the protruding strips 3 . The two sides along the length direction of the rectangle are fixed...

Embodiment 2

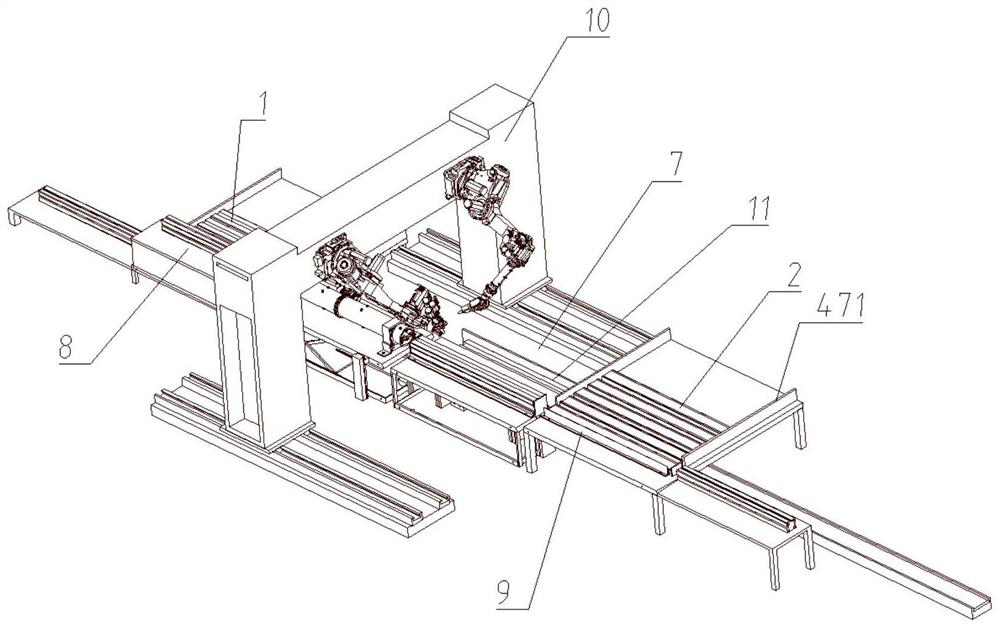

[0062] This embodiment provides a forming robot for the reinforced back flute of the corrosion-resistant aluminum formwork, which is used for assembling and welding the reinforced back flute in the first embodiment.

[0063] The forming robot includes a workbench 7 for supporting the back flute to be welded, a side pipe feeding mechanism 8 for moving the side pipe 2 to be welded to the workbench 7, and a side pipe feeding mechanism 8 for moving the side pipe 2 to be welded. The pipe 1 moves to the middle pipe feeding mechanism 9 on the workbench 7 and the welding mechanism 10 for welding the side pipe 2 and the middle pipe 1 that have been loaded. The side pipe feeding mechanism 8 and the middle pipe feeding mechanism 9 place the side pipe 2 on the upper and lower sides and the middle pipe 1 between the two side pipes 2 to feed the side pipe 2 and the middle pipe 1. After the feeding is completed , the welded structure 10 welds the edge of the gap between the middle 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com