Patents

Literature

78results about How to "Prevent shape change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

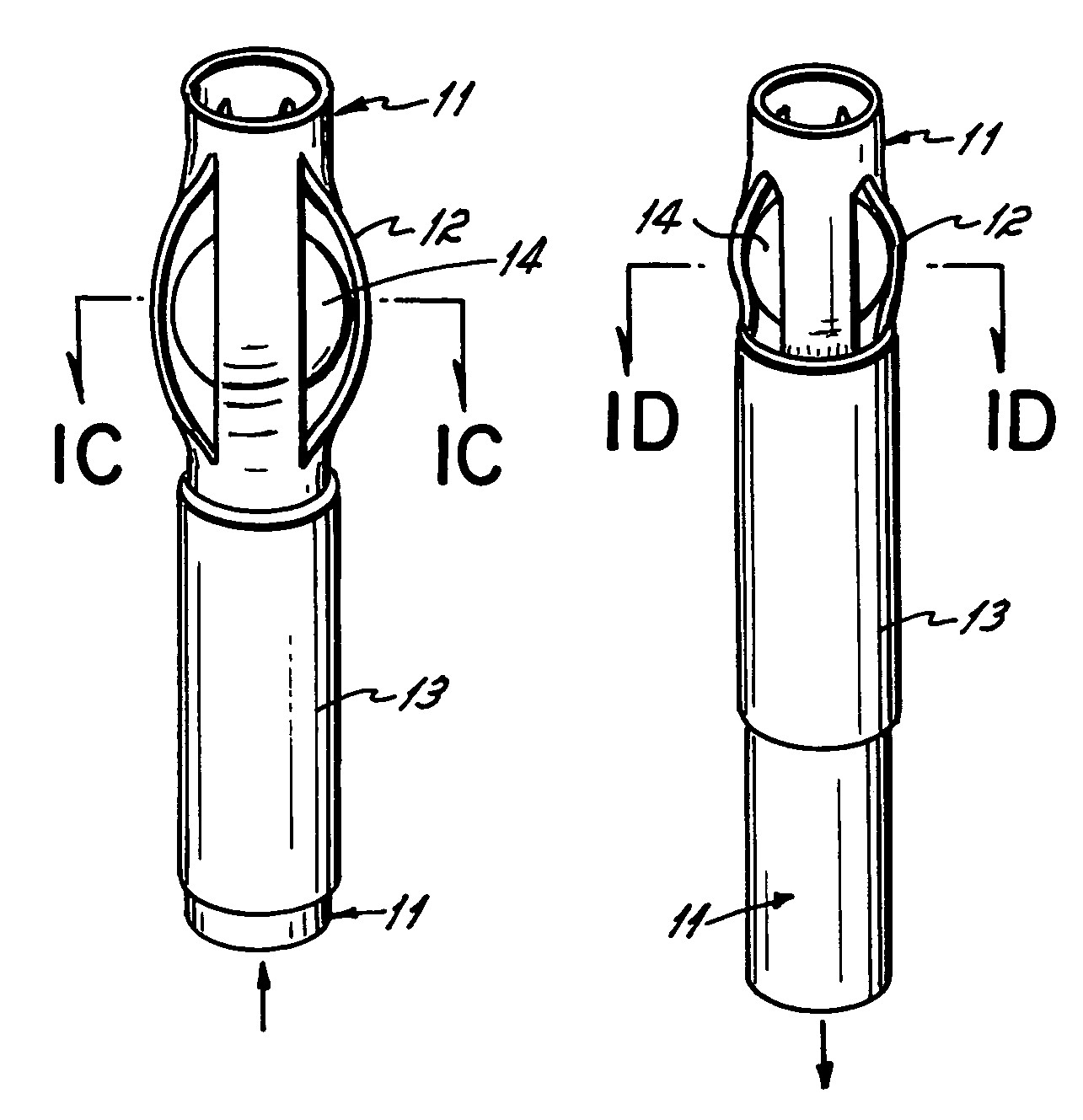

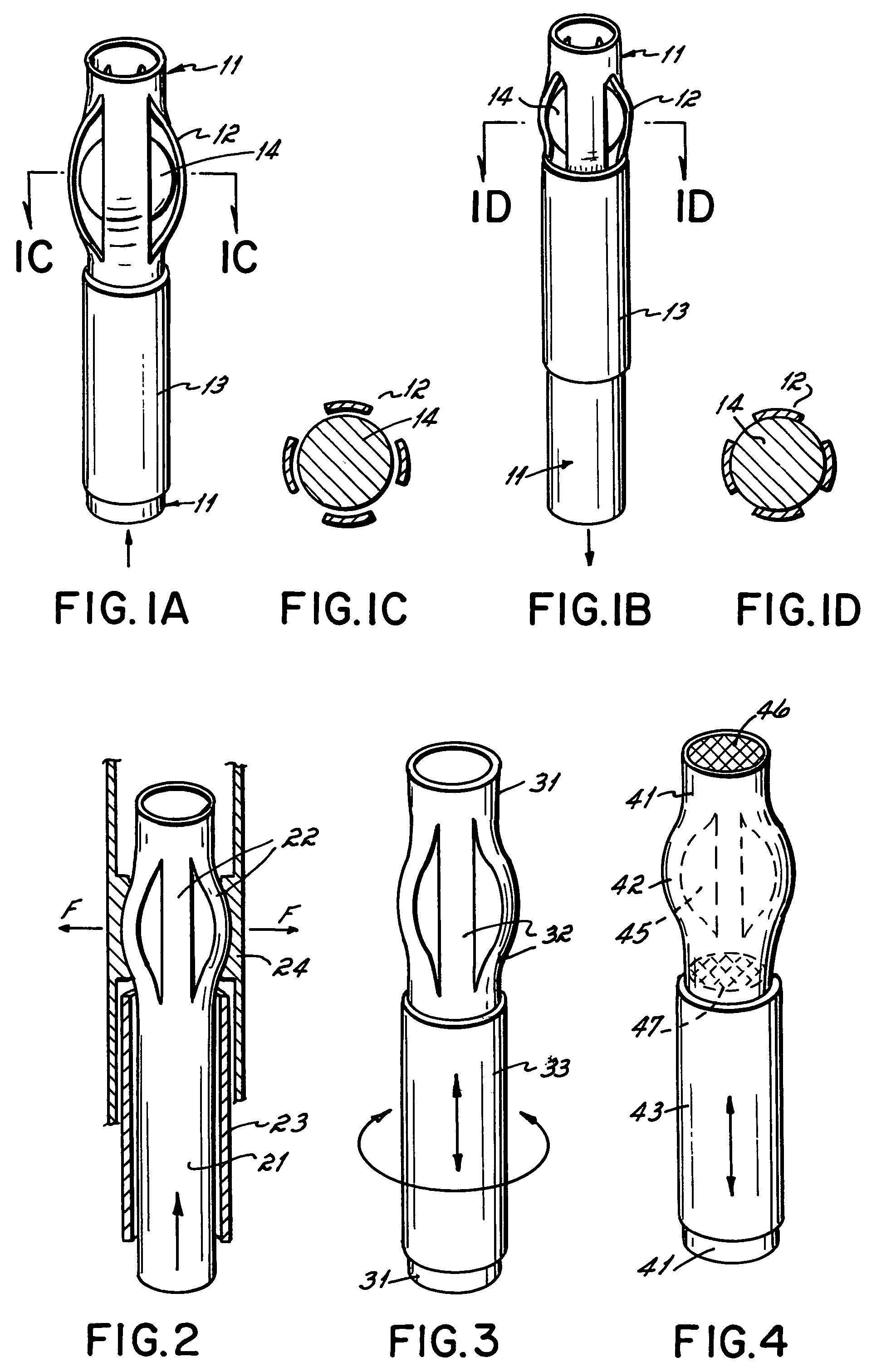

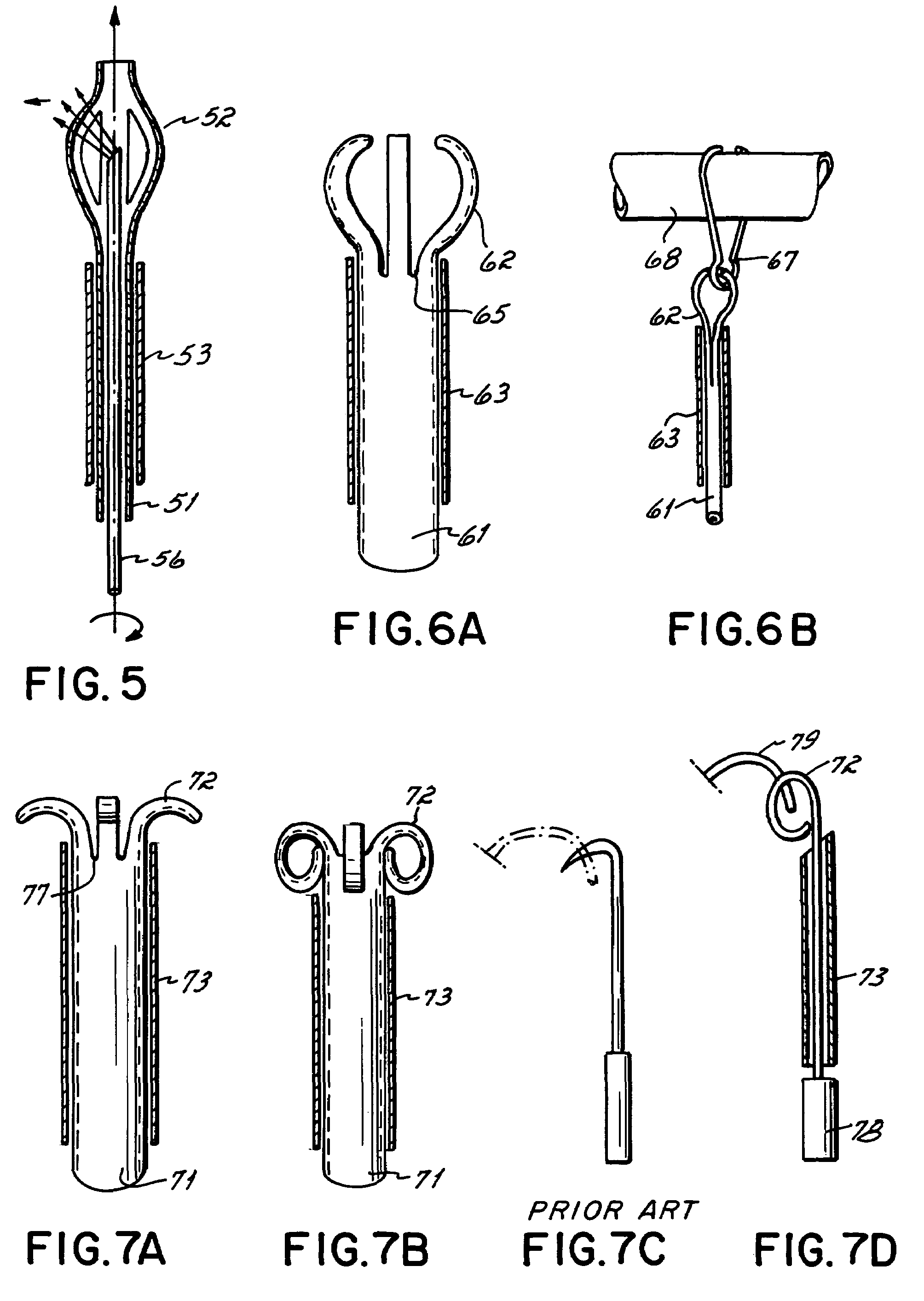

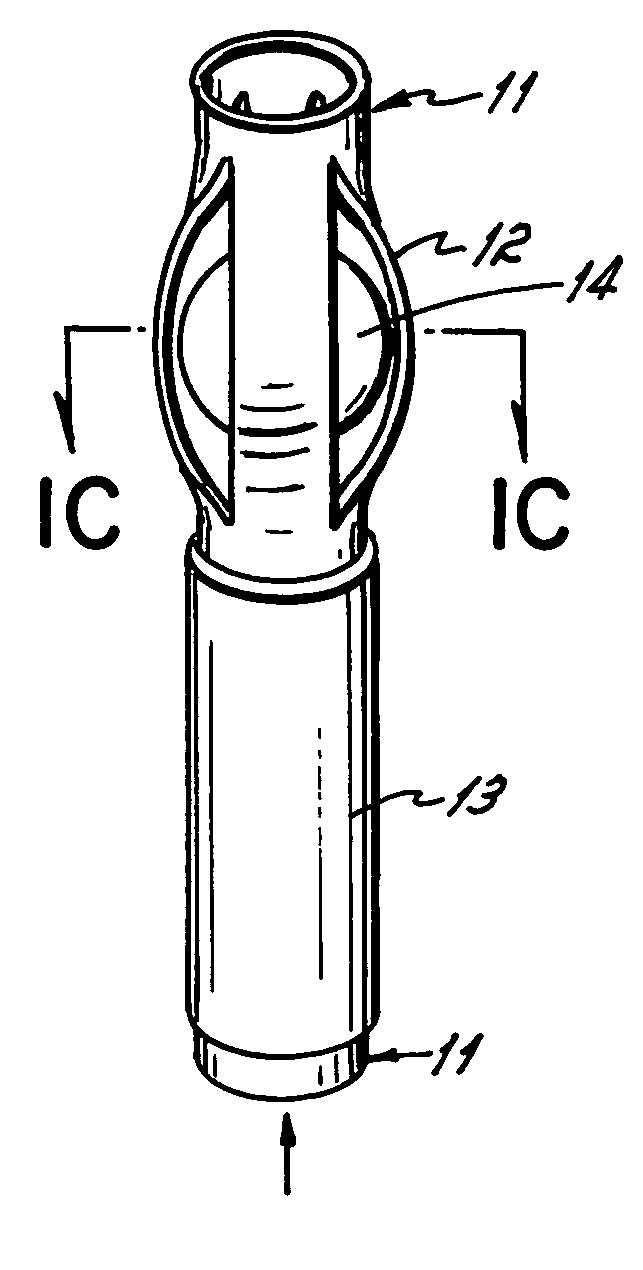

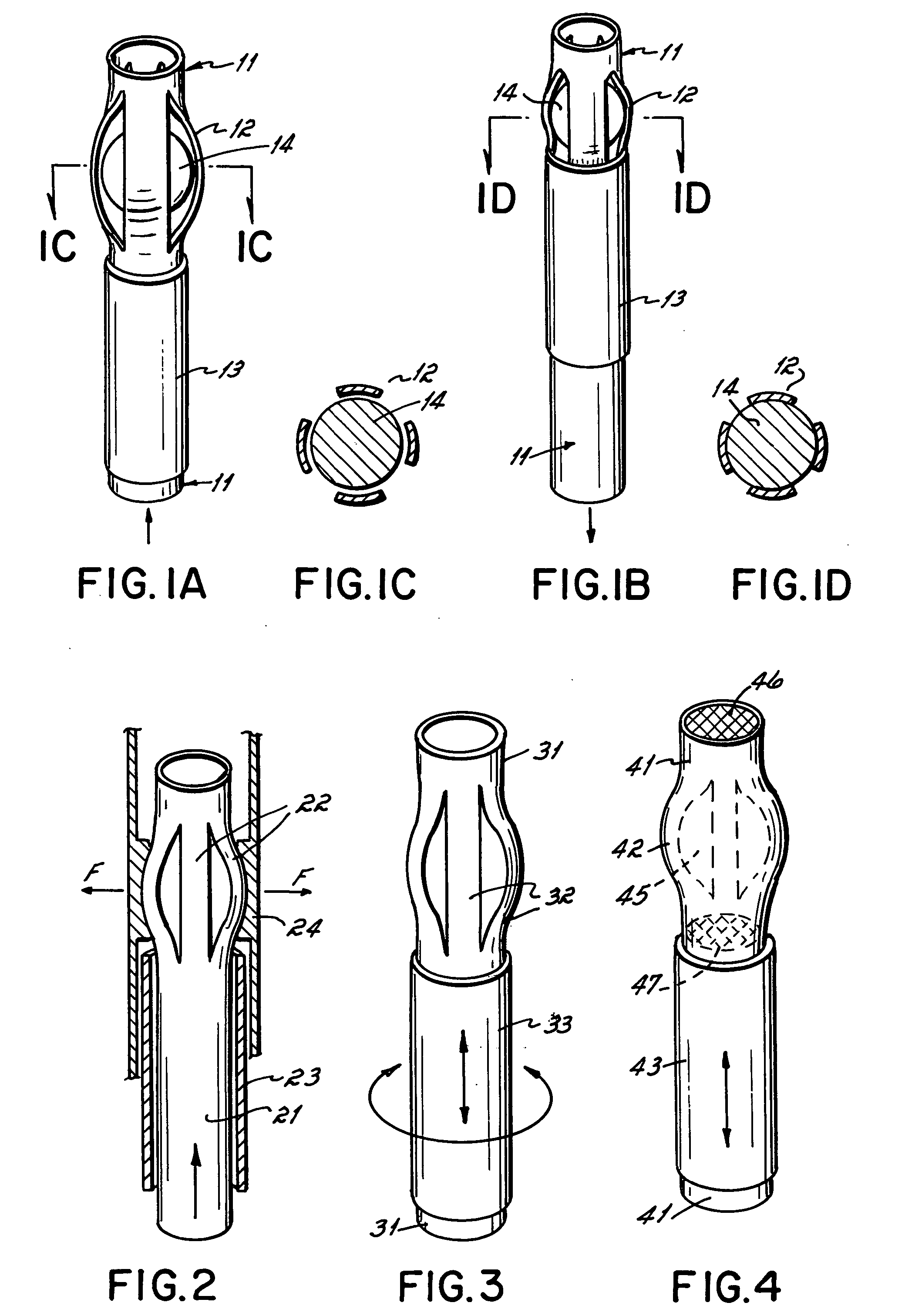

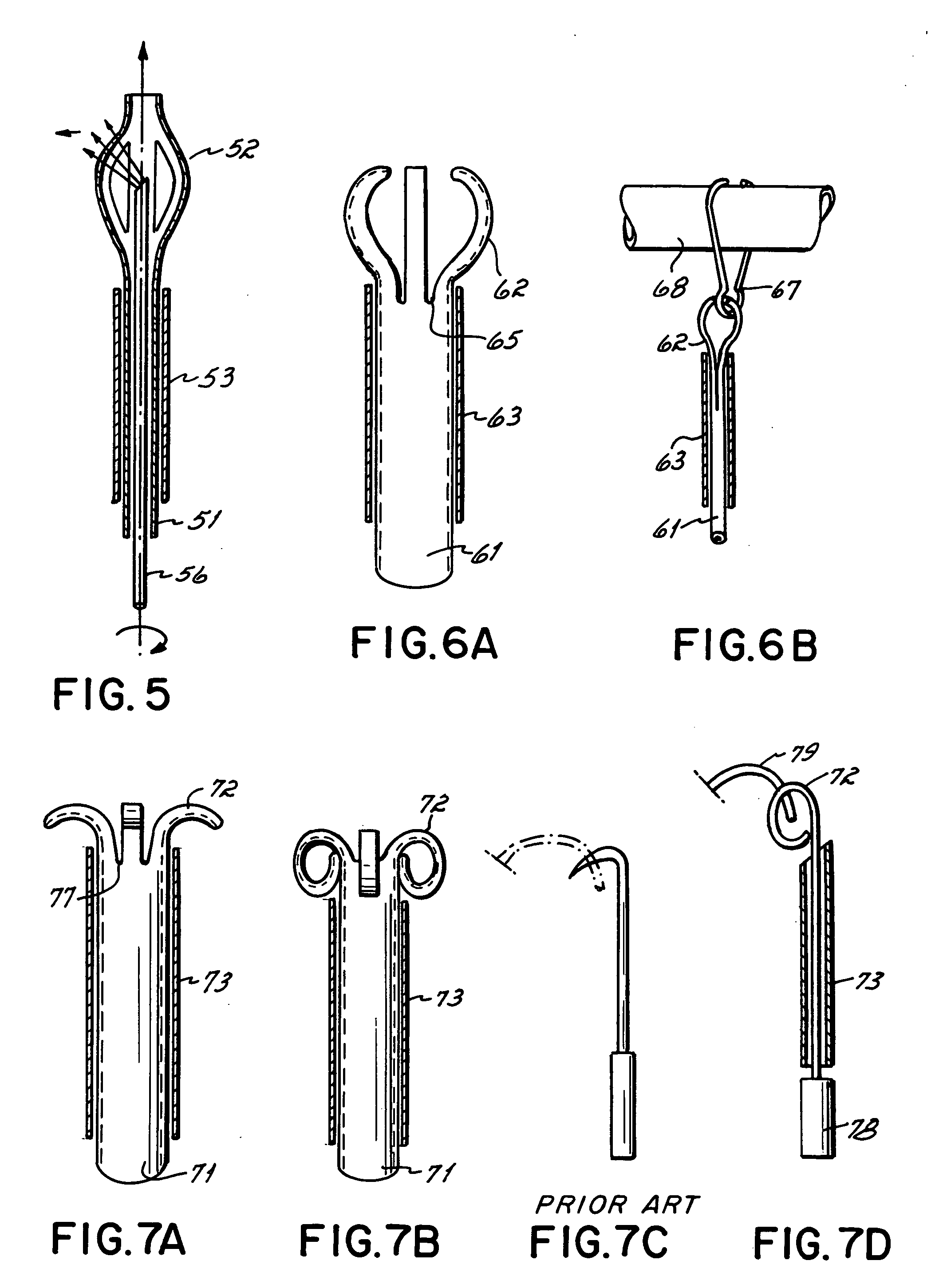

Medical device with slotted memory metal tube

A series of medical instruments can be made with the use of shape memory tube with a transformation temperature that is above or below the ambient temperature. In the first case, the material behaves with the shape memory effect and in the second case the behavior is superelastic. The wall of the tube has been provided with a plurality of slots in specific places, often near or at the distal end of the instrument, and in specific arrangements which allow local variations in diameter, shape, and / or length. These variations can either be caused by the memory effect during temperature change or by superelastic behavior during change of the mechanical influences on the memory metal by the surrounding material.

Owner:EVM SYST

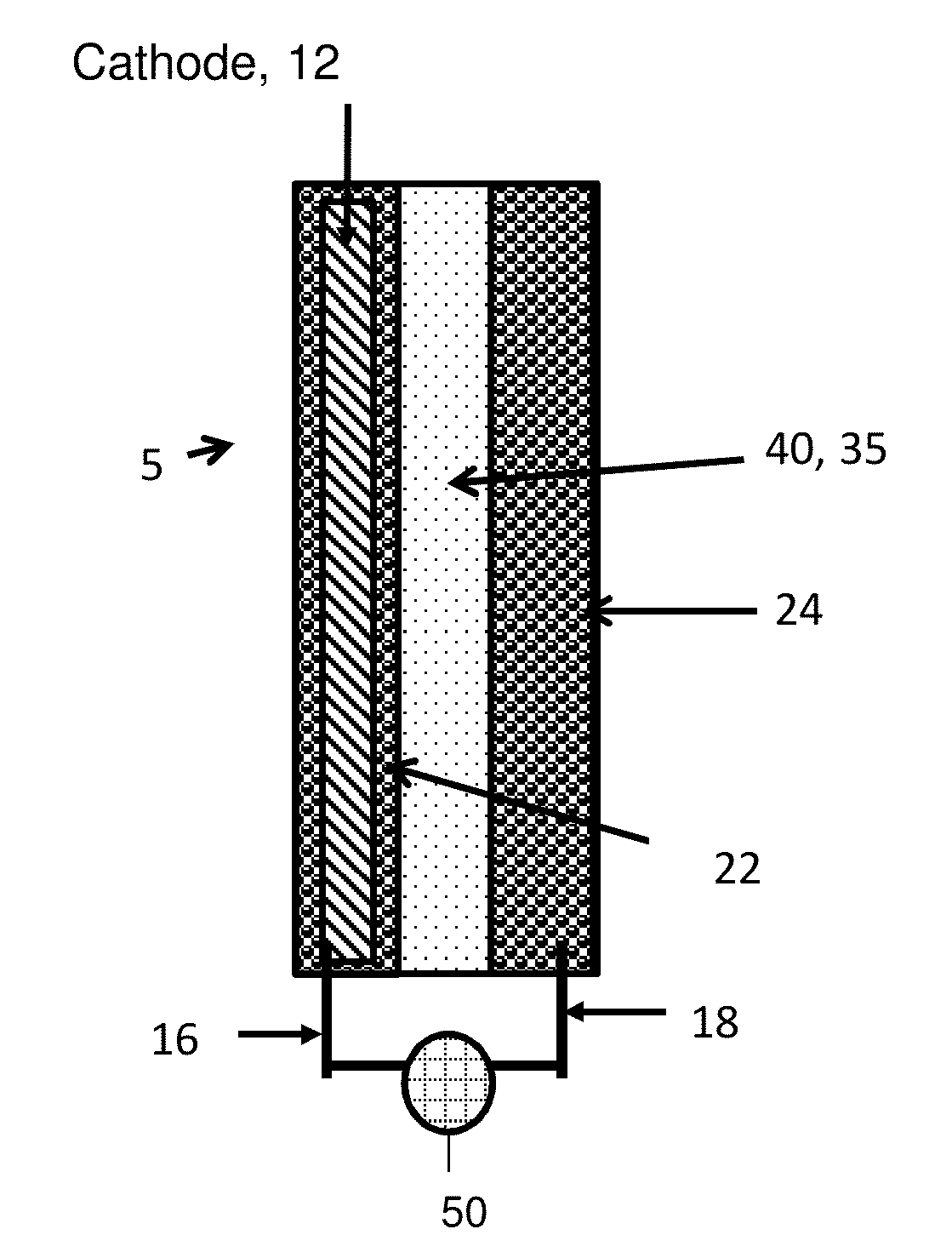

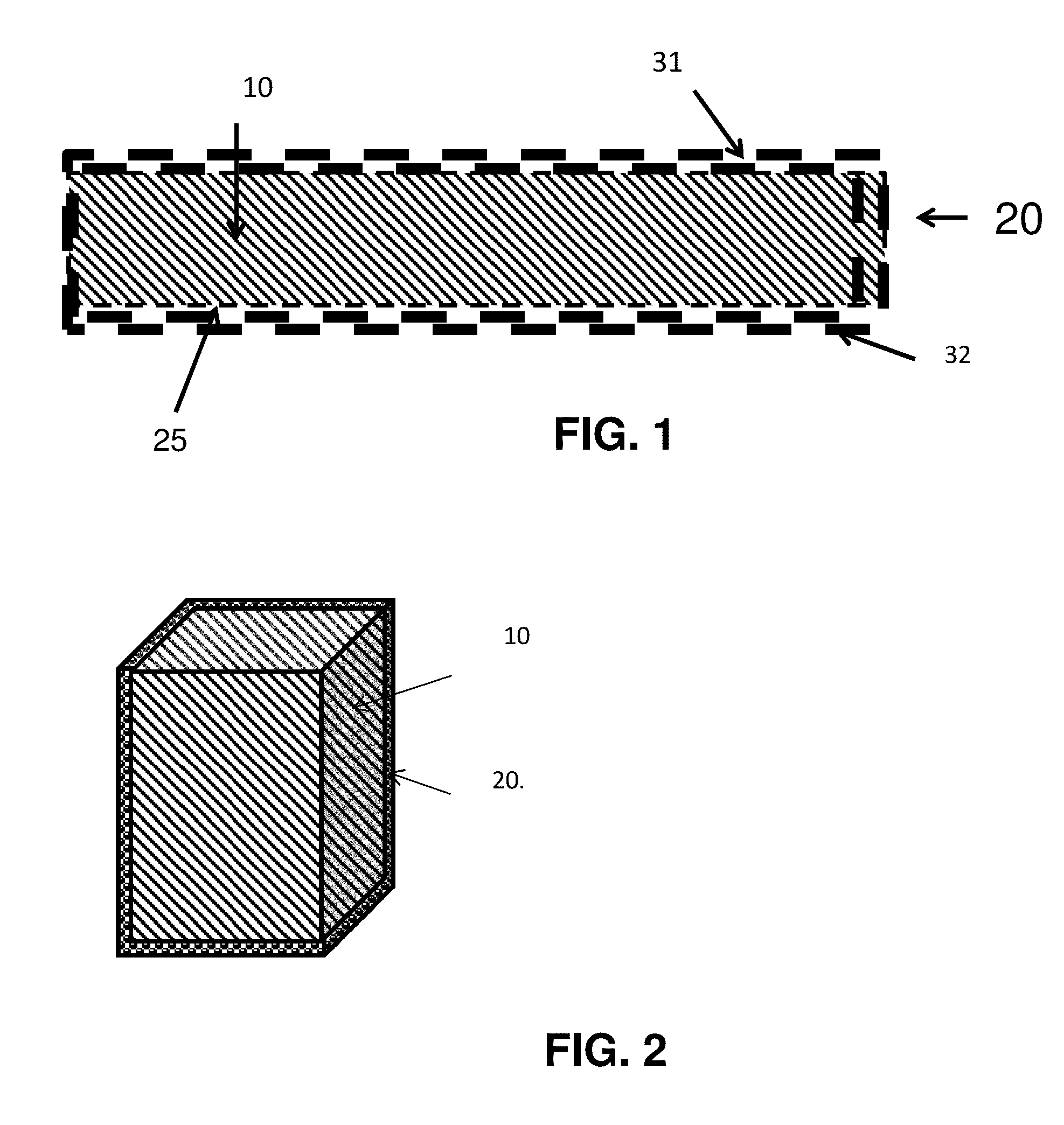

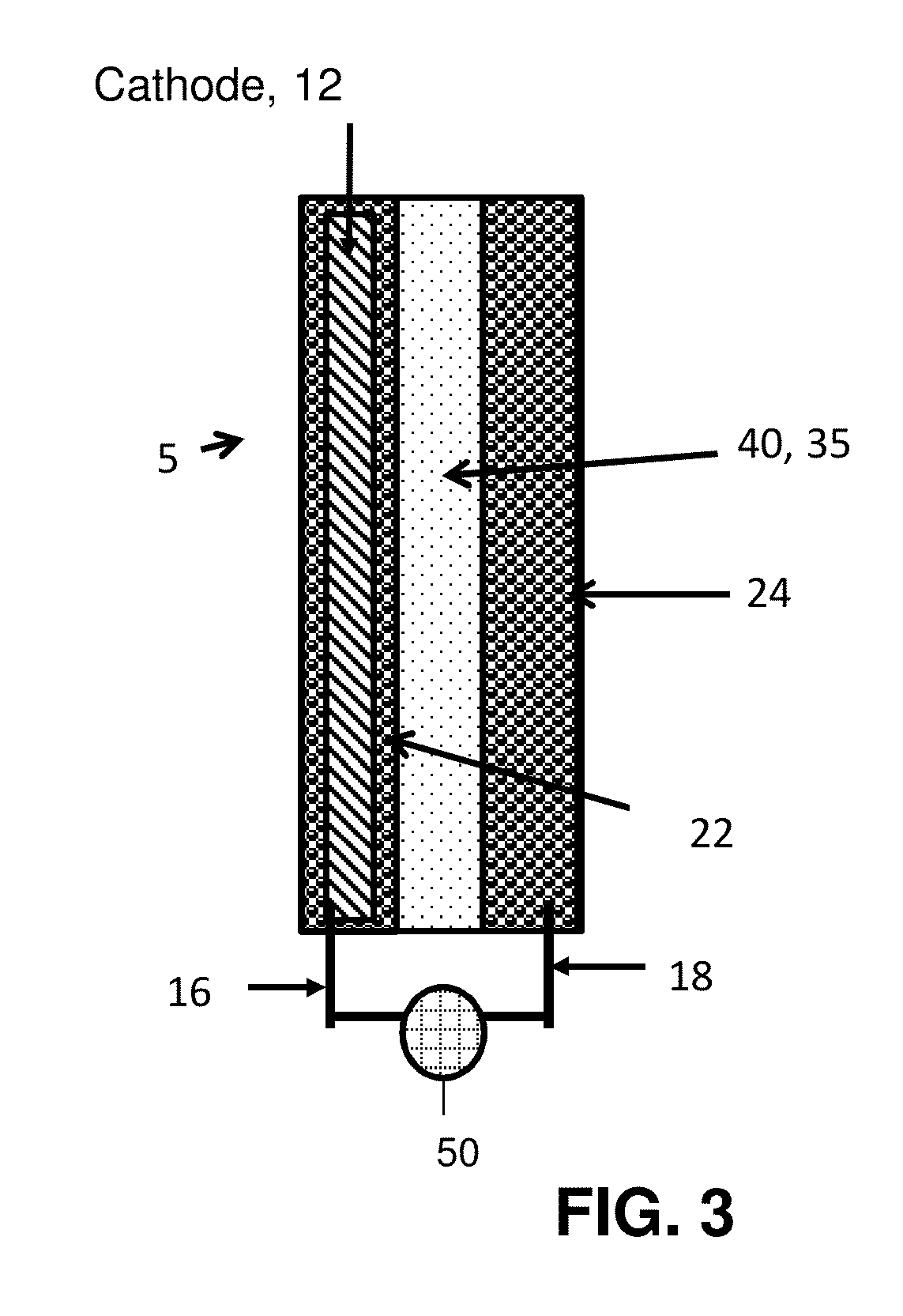

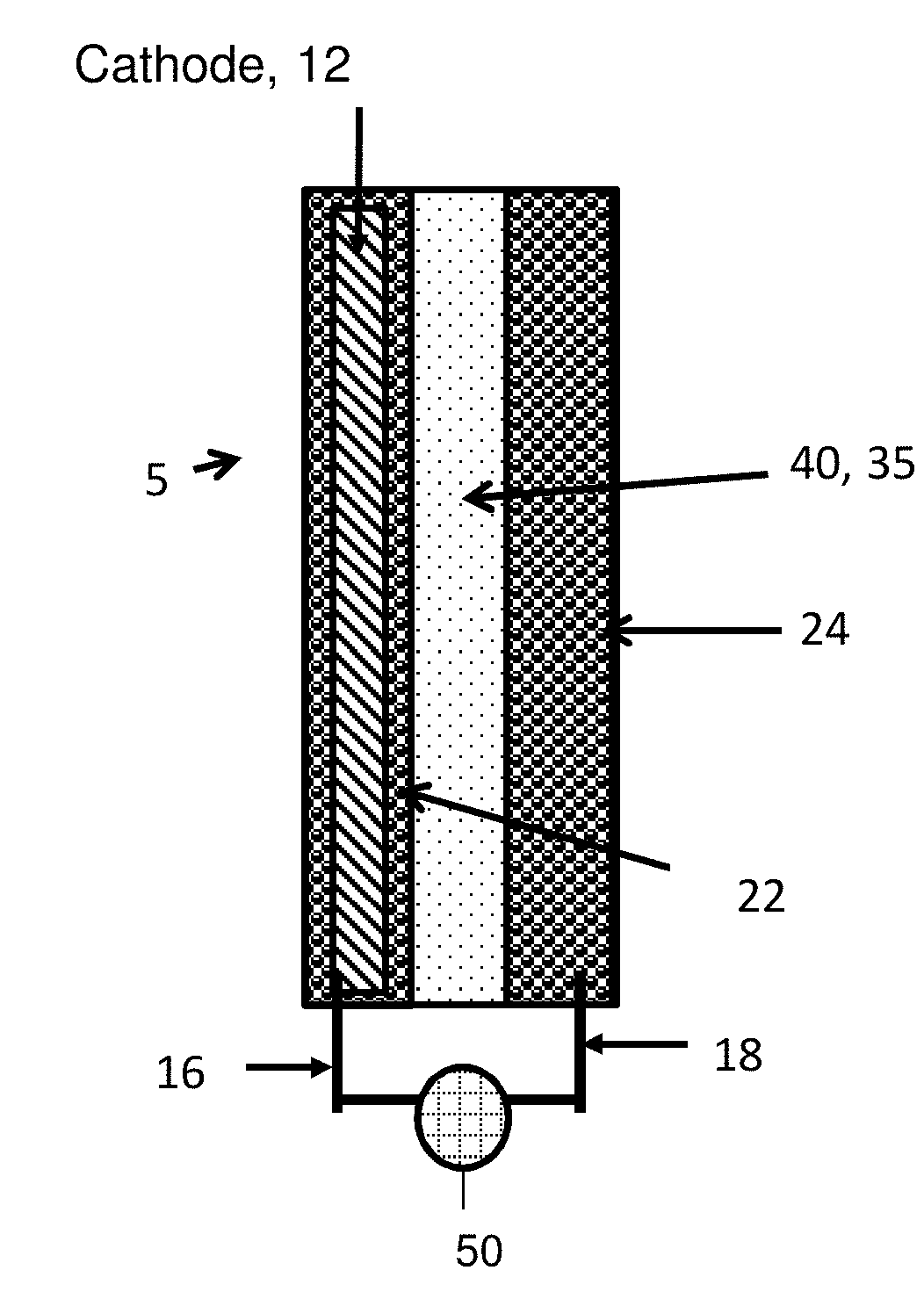

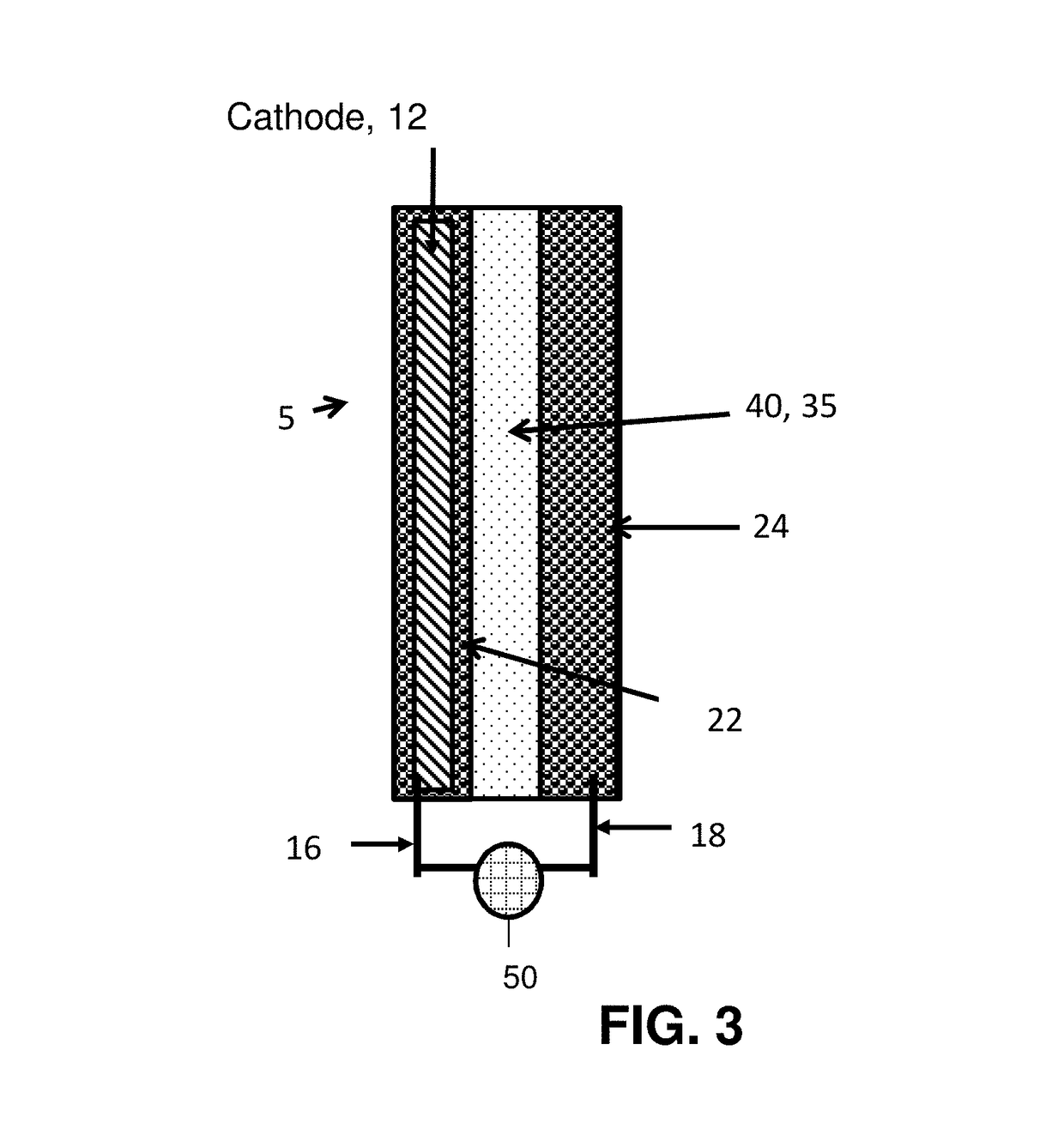

Separator enclosures for electrodes and electrochemical cells

ActiveUS20150180000A1Improve battery performanceAvoid material lossBatteries circuit arrangementsElectrical testingElectrical batteryEngineering

Owner:CALIFORNIA INST OF TECH

Medical instrument with slotted memory metal tube

A series of medical instruments can be made with the use of shape memory tube with a transformation temperature that is above or below the ambient temperature. In the first case, the material behaves with the shape memory effect and in the second case the behavior is superelastic. The wall of the tube has been provided with a plurality of slots in specific places, often near or at the distal end of the instrument, and in specific arrangements which allow local variations in diameter, shape, and / or length. These variations can either be caused by the memory effect during temperature change or by superelastic behavior during change of the mechanical influences on the memory metal by the surrounding material.

Owner:EVM SYST

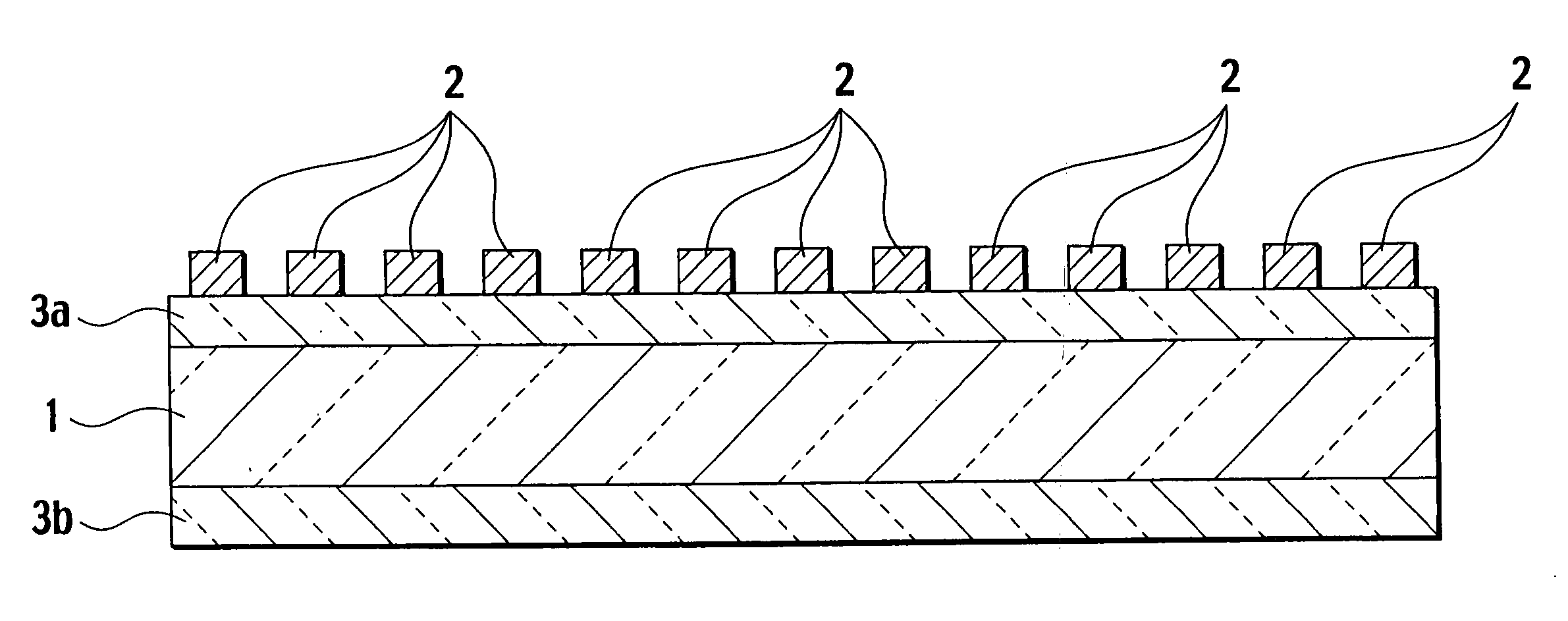

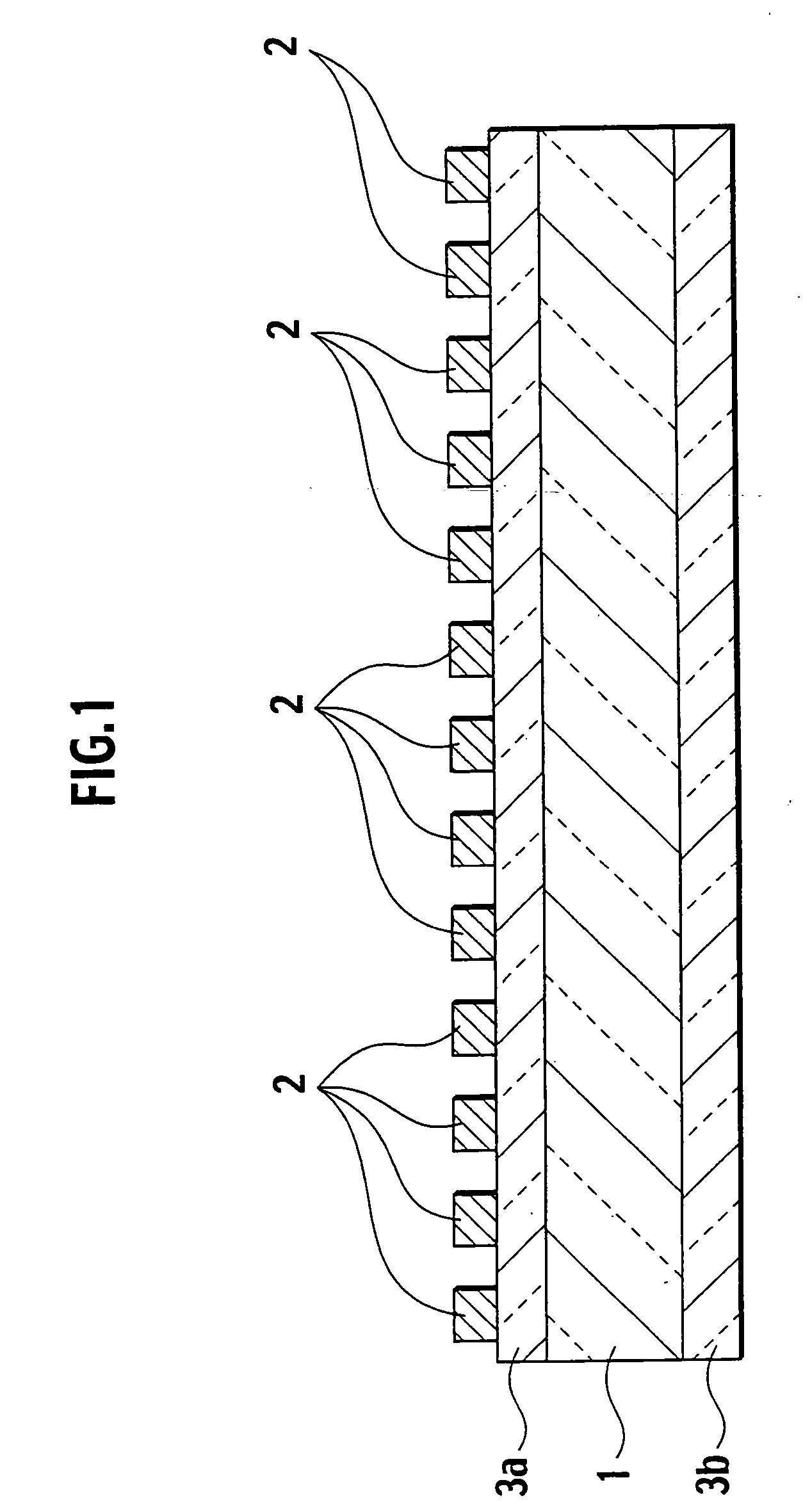

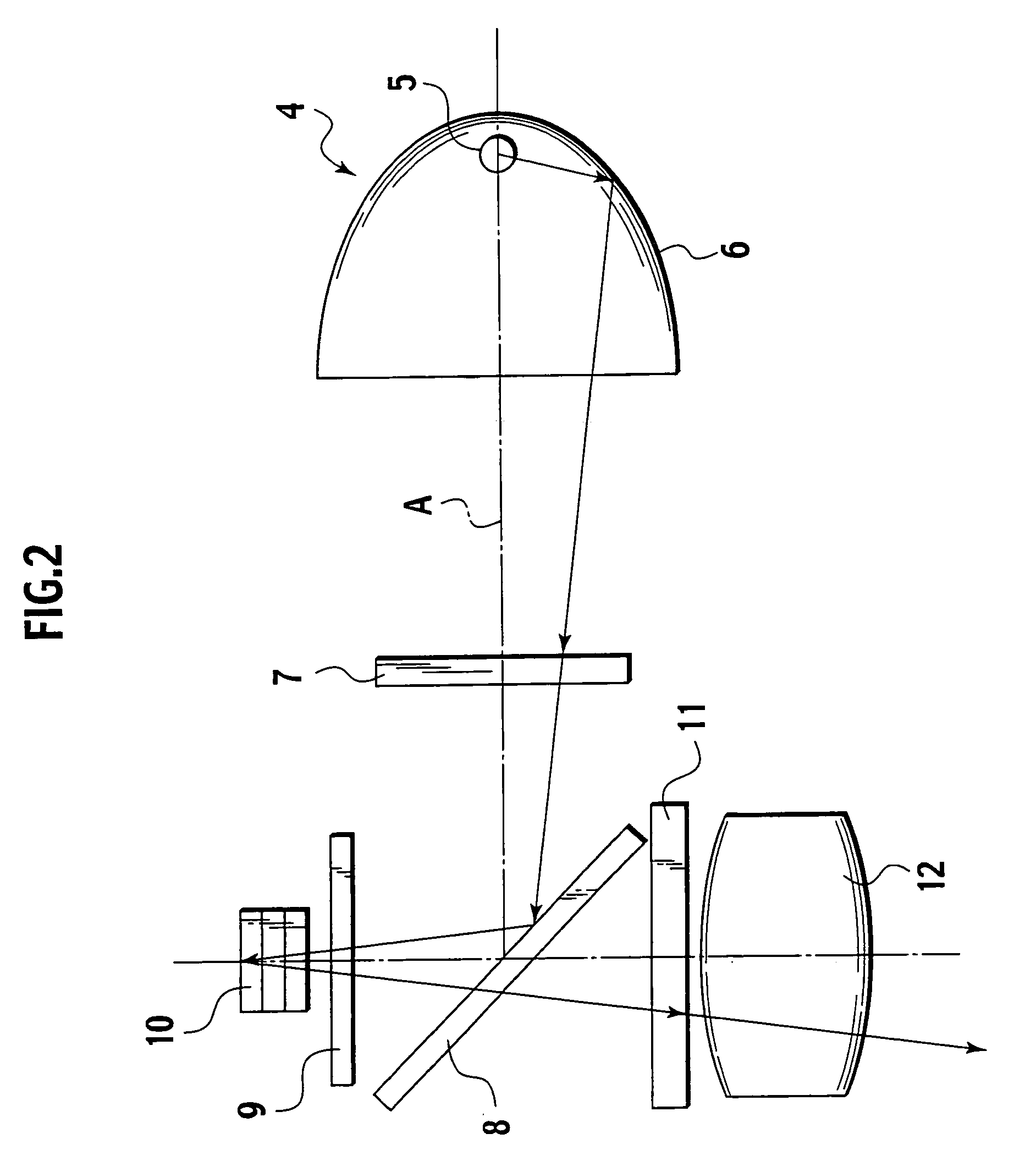

Wire grid polarizer

InactiveUS20050190445A1Reduce power consumptionEasy to usePolarising elementsNon-linear opticsWire gridDisplay device

To provide a wire grid polarizer used in an image display apparatus, in which even when the image display apparatus is of a small compact structure and provides high output of power from the light source, shape transformation of the glass substrate occurring due to generation of heat caused by light absorption in the wire grid is prevented and in which by efficient usage of light rays from the light source, high-quality images can be displayed by the image display device and power consumption is low. A wire grid 2 formed of metal in a fine comb shape is formed on a glass substrate 1 and antireflection coatings 3a and 3b are disposed respectively on the front surface part and the rear surface part of the wire grid 2 of the glass substrate 1.

Owner:VICTOR CO OF JAPAN LTD

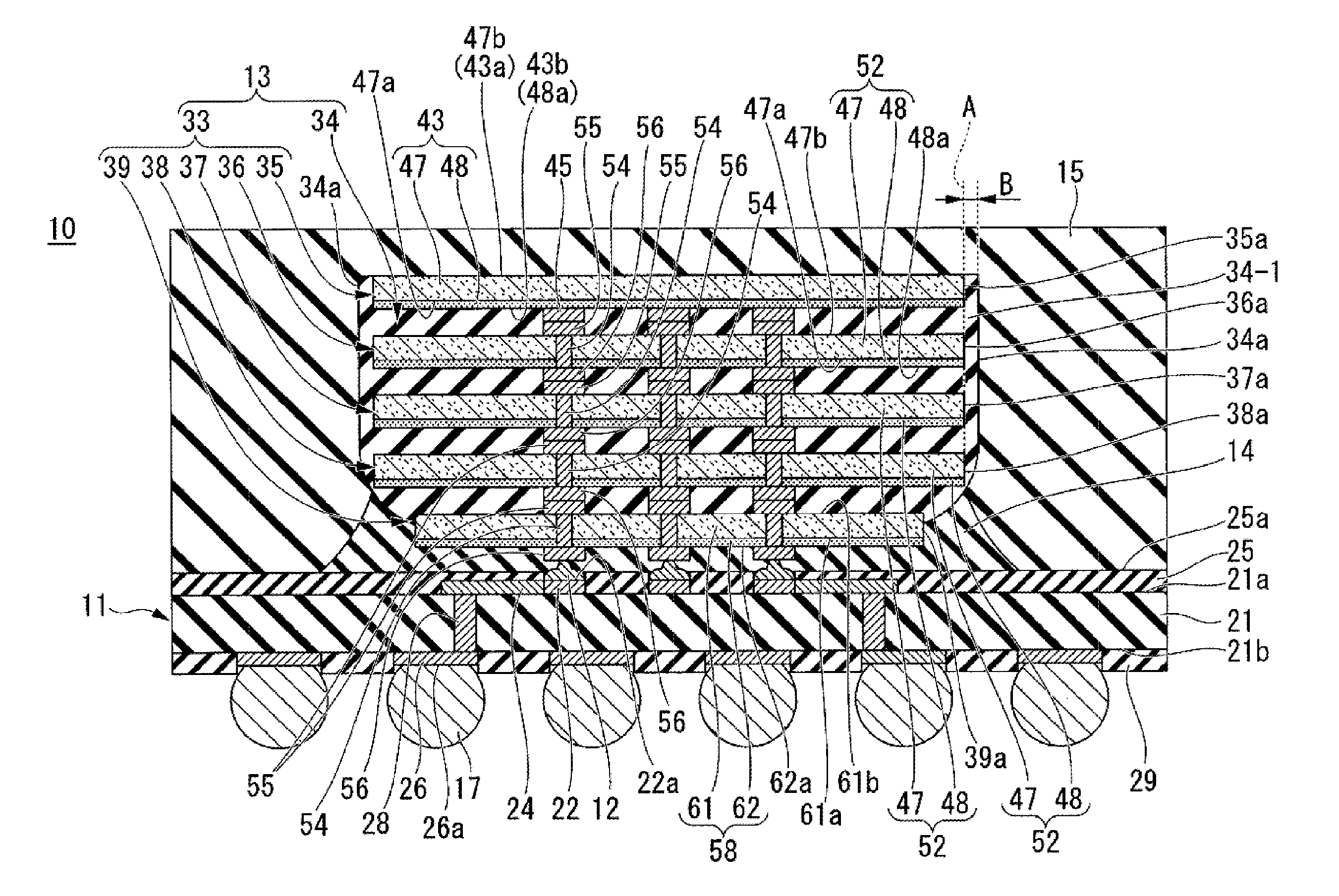

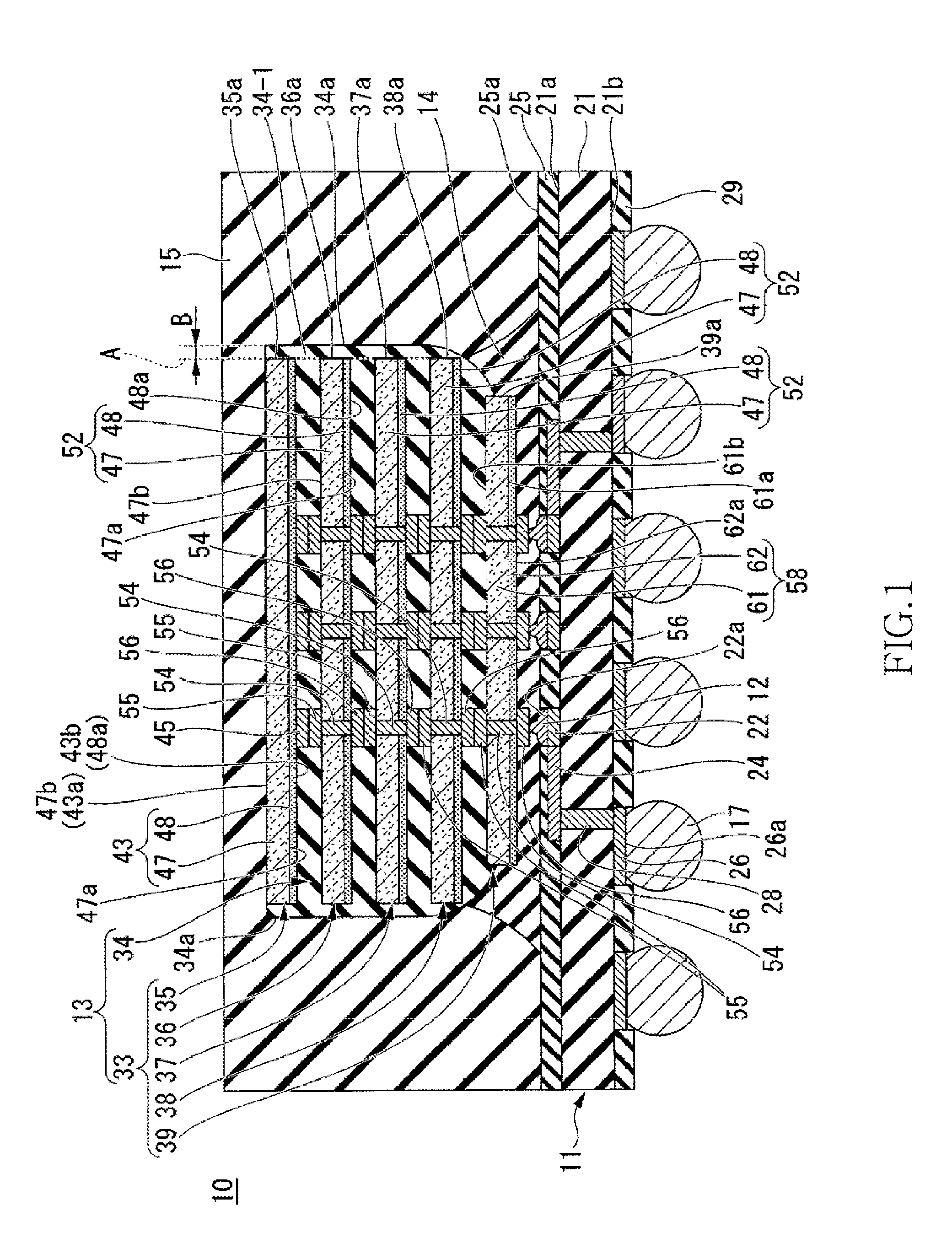

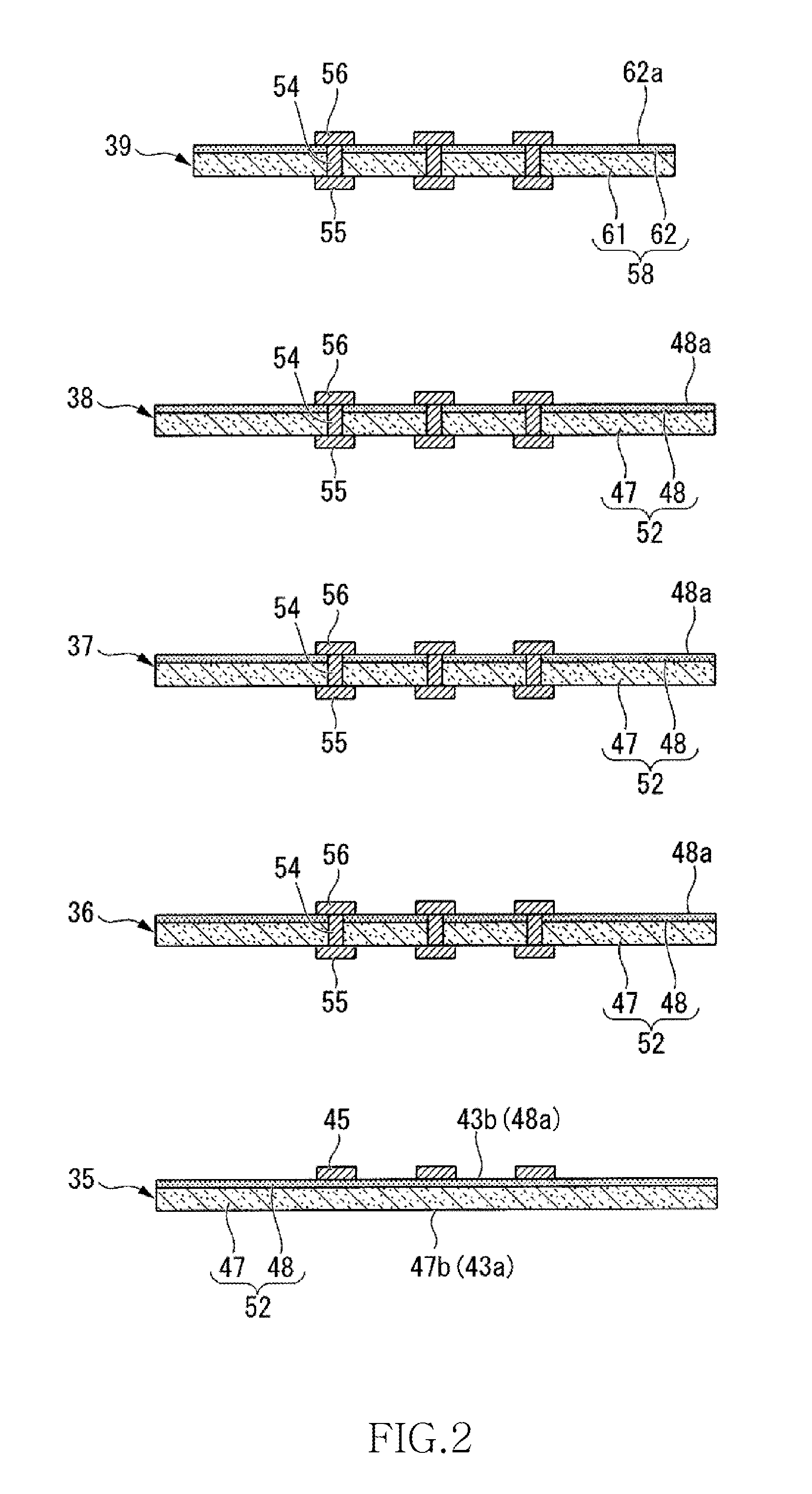

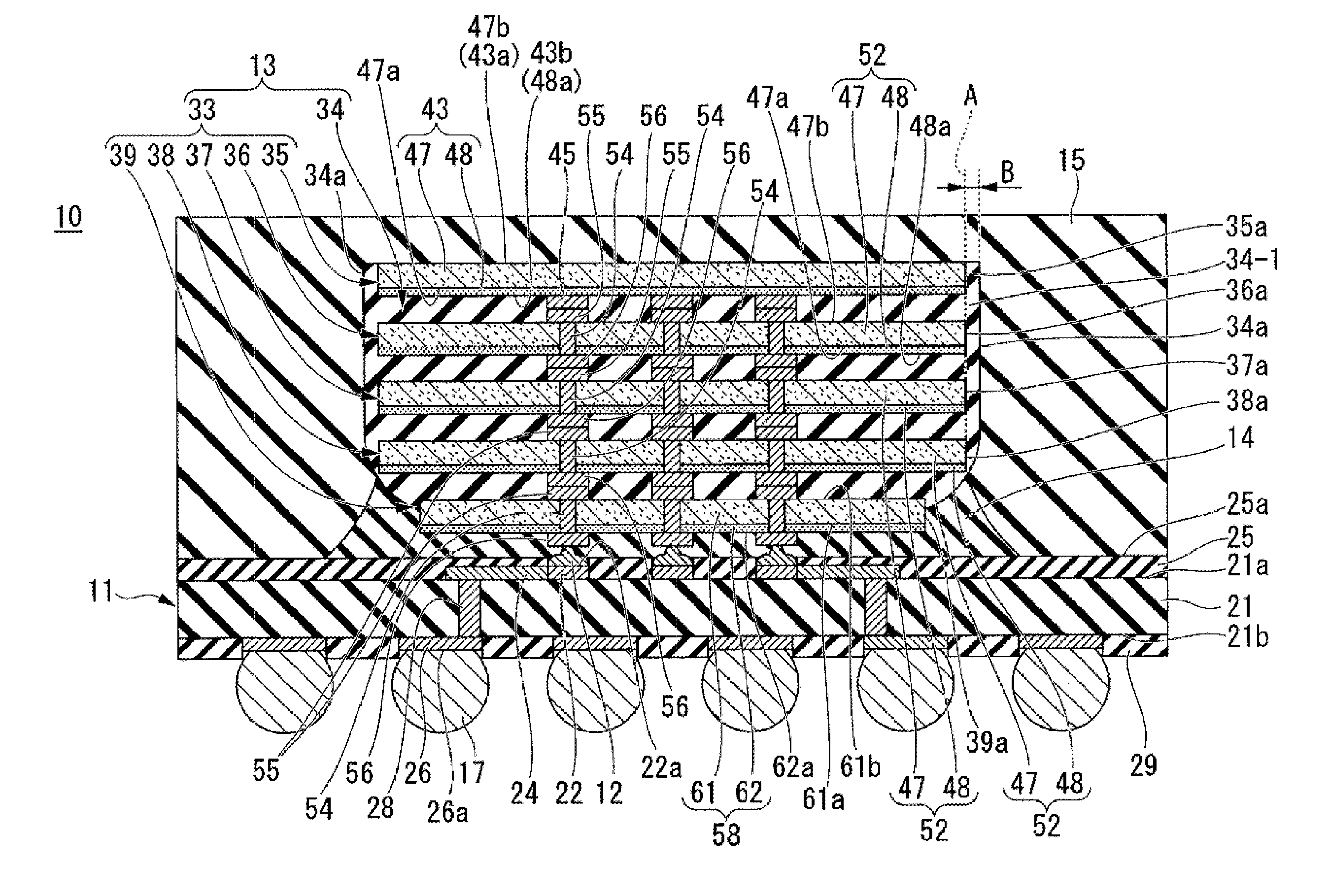

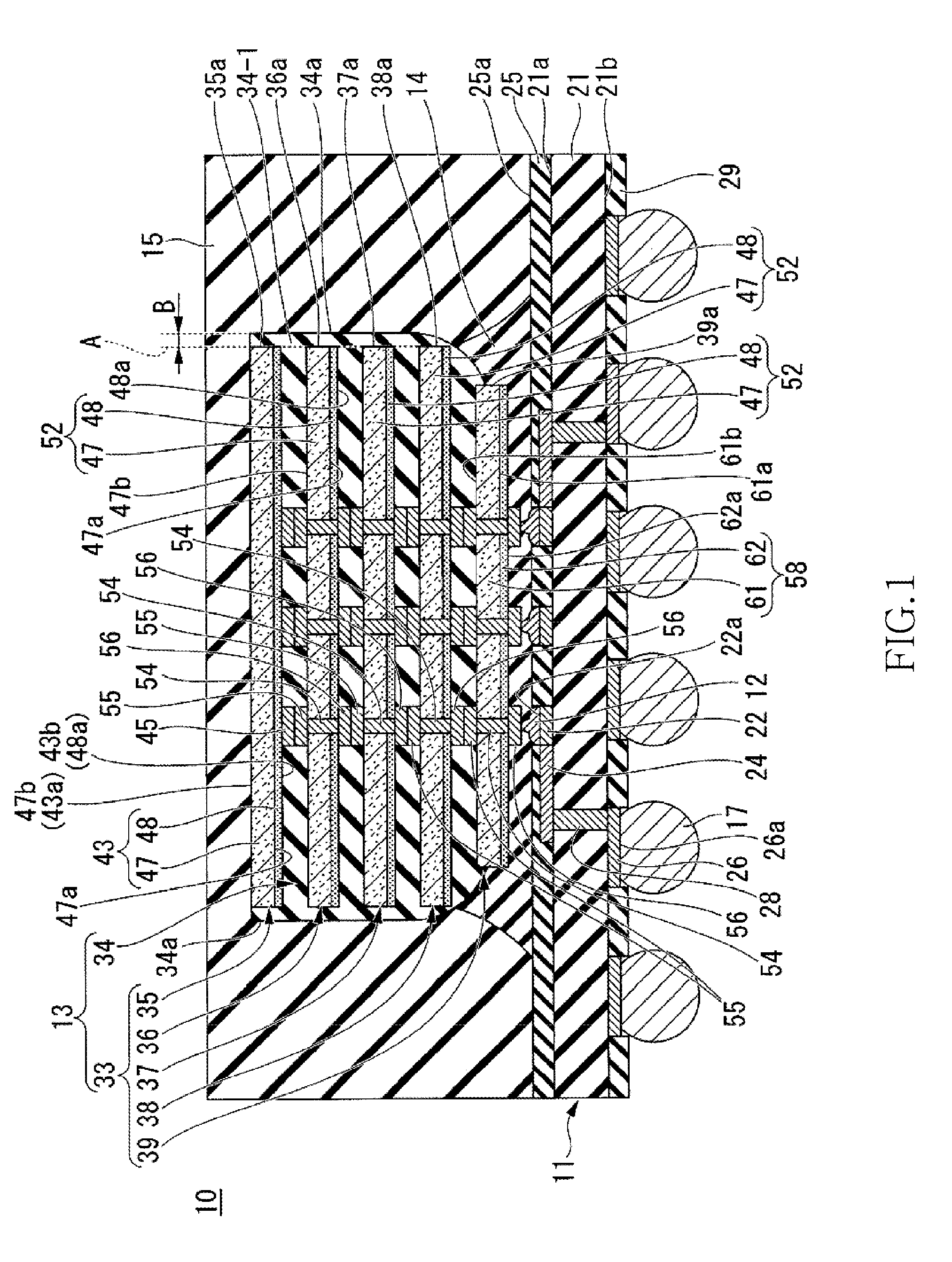

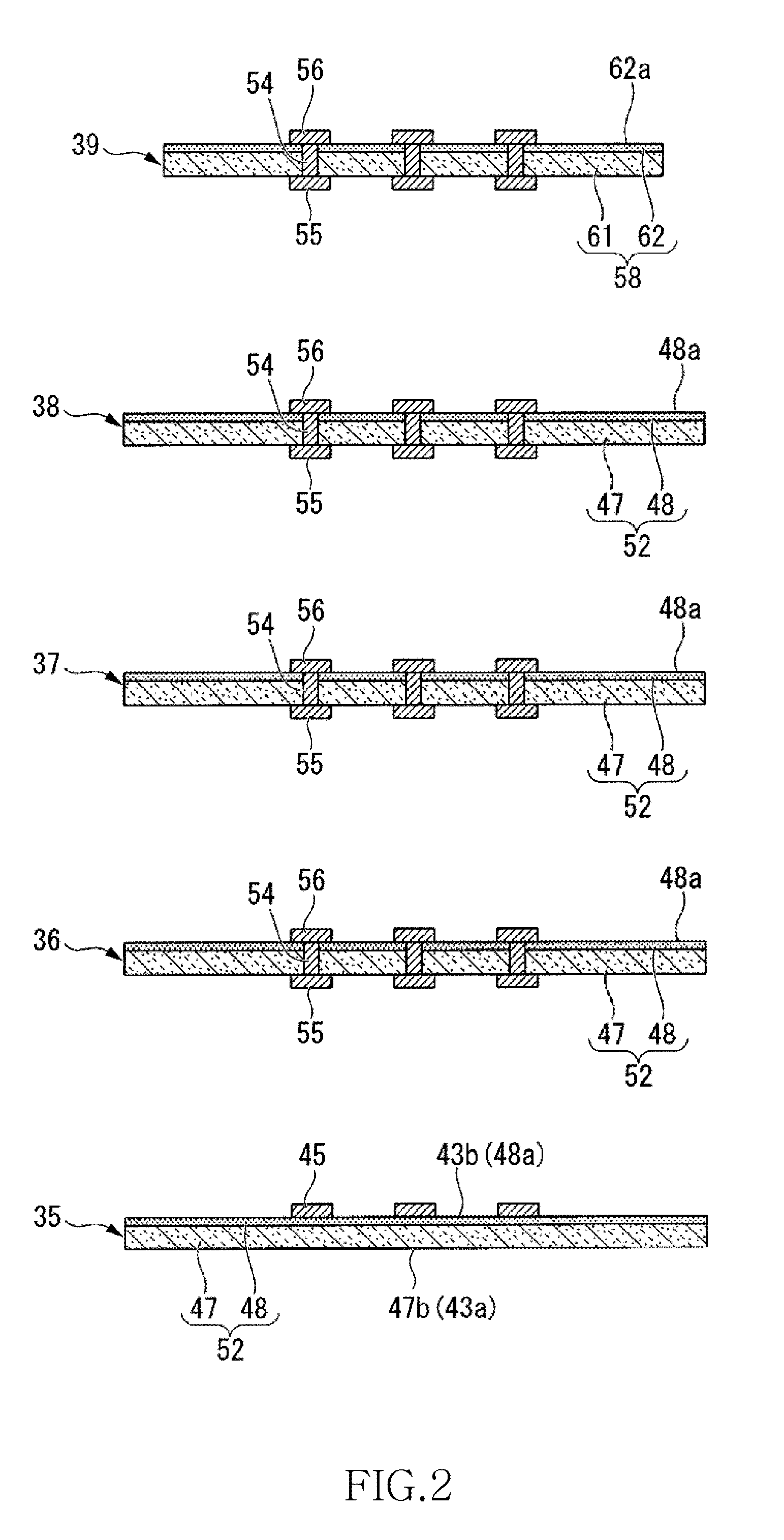

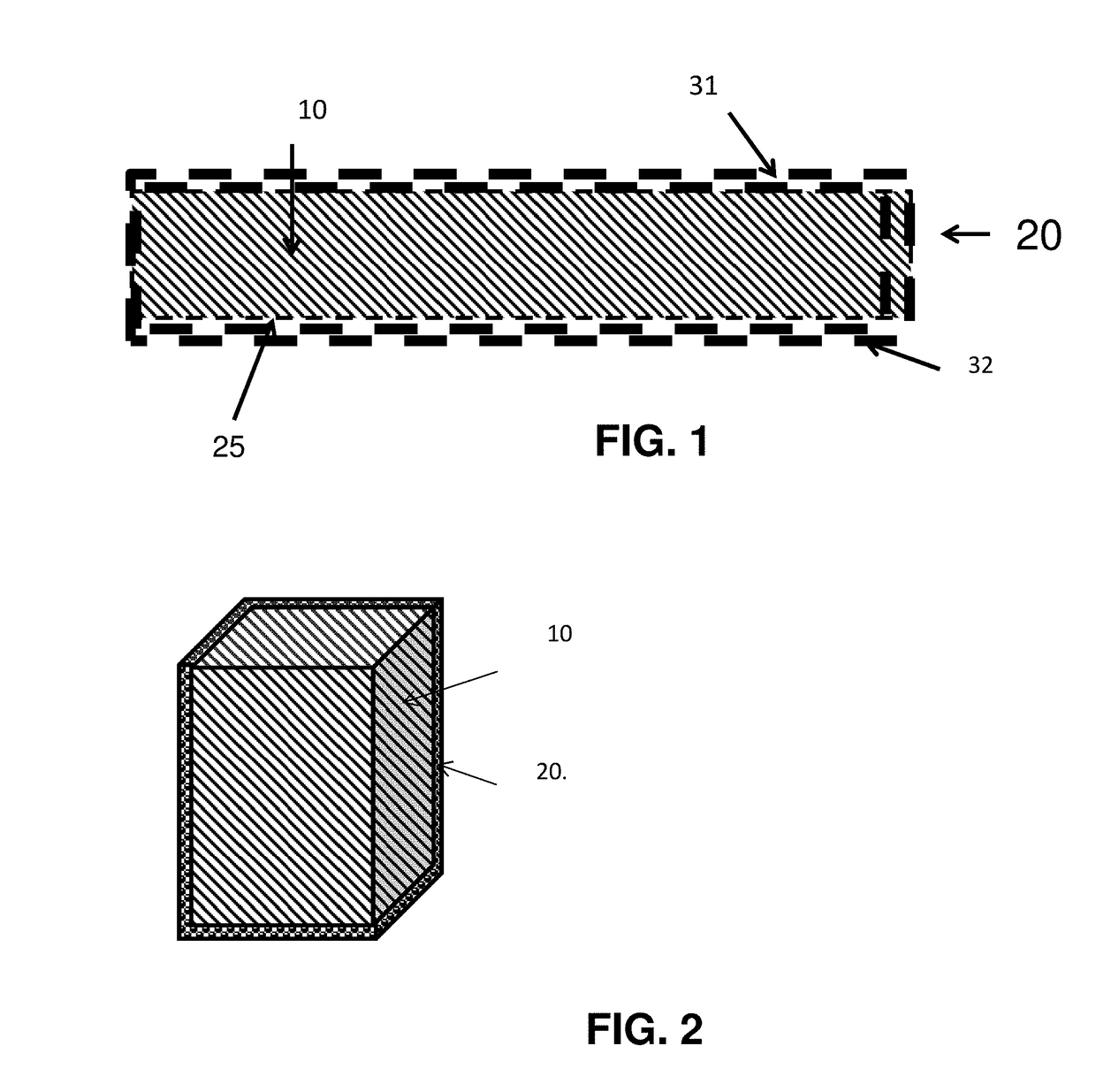

Method of manufacturing semiconductor device having plural semiconductor chips stacked one another

InactiveUS20130137216A1Prevent shape changeIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceFilling materials

Disclosed herein is a method of manufacturing a semiconductor device that includes stacking a plurality of semiconductor chips to form a first chip laminated body, providing an underfill material to fill gaps between the semiconductor chips so that a fillet portion is formed around the first chip laminated body, and trimming the fillet portion to form a second chip laminated body.

Owner:PS4 LUXCO SARL

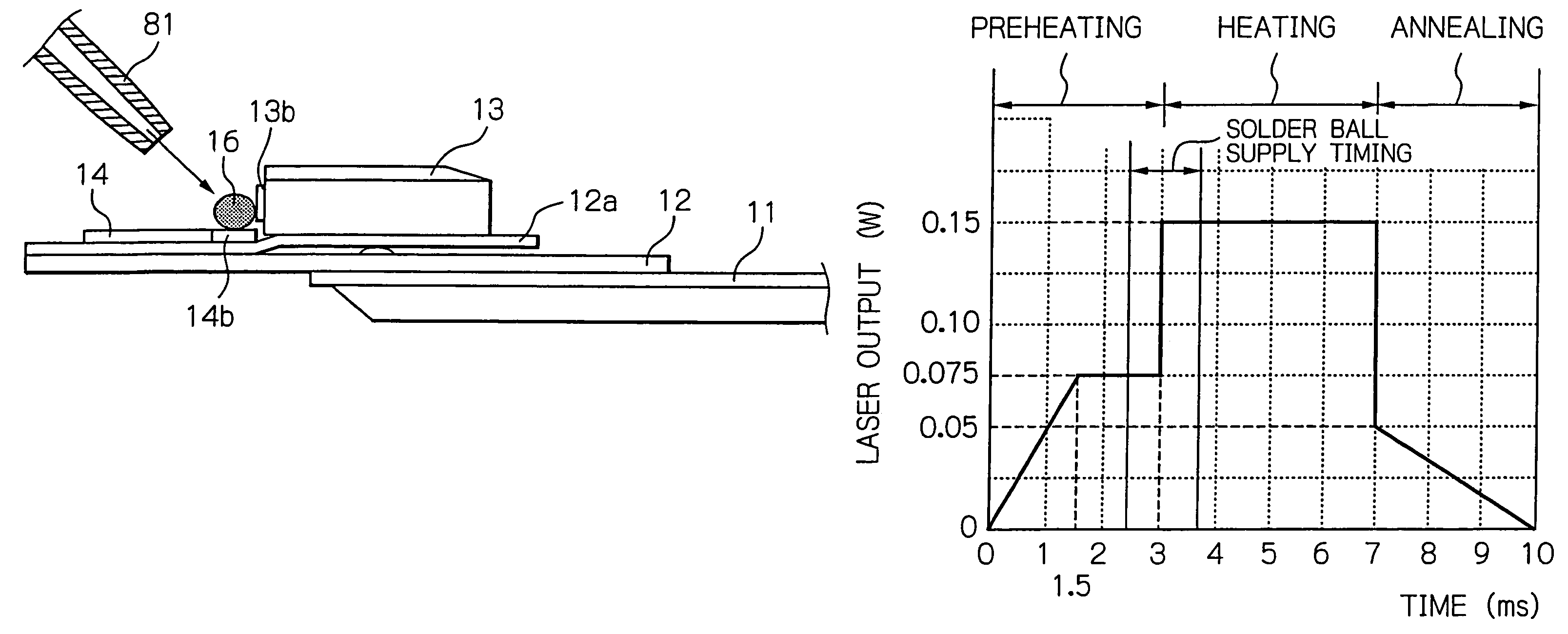

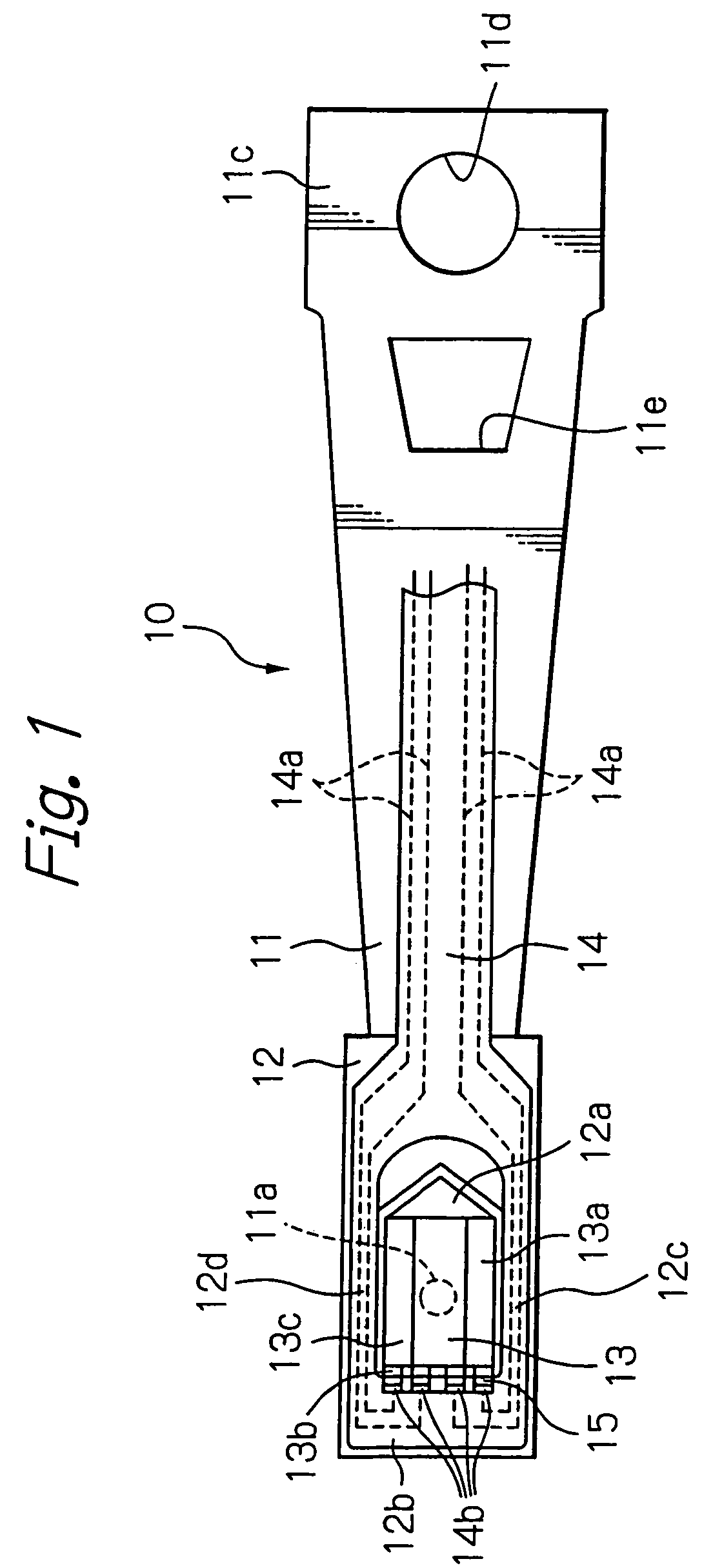

Method of manufacturing a magnetic head device

InactiveUS7287312B2Firmly connectedImprove reliabilityElectrical connection between head and armFinal product manufactureLaser beamsLead Conductor

A manufacturing method of a magnetic head device includes a preheating step of irradiating a laser beam to terminal pads of a magnetic head slider and to connection pads of a lead conductor member that is to be electrically connected to the magnetic head slider, a supply step of supplying conductive metal material for connecting the terminal pads and the connection pads during or after the preheating step, and a heating step of performing molten-metal connections between the terminal pads and the connection pads by irradiating a laser beam to the conductive metal material.

Owner:SAE MAGNETICS (HK) LTD

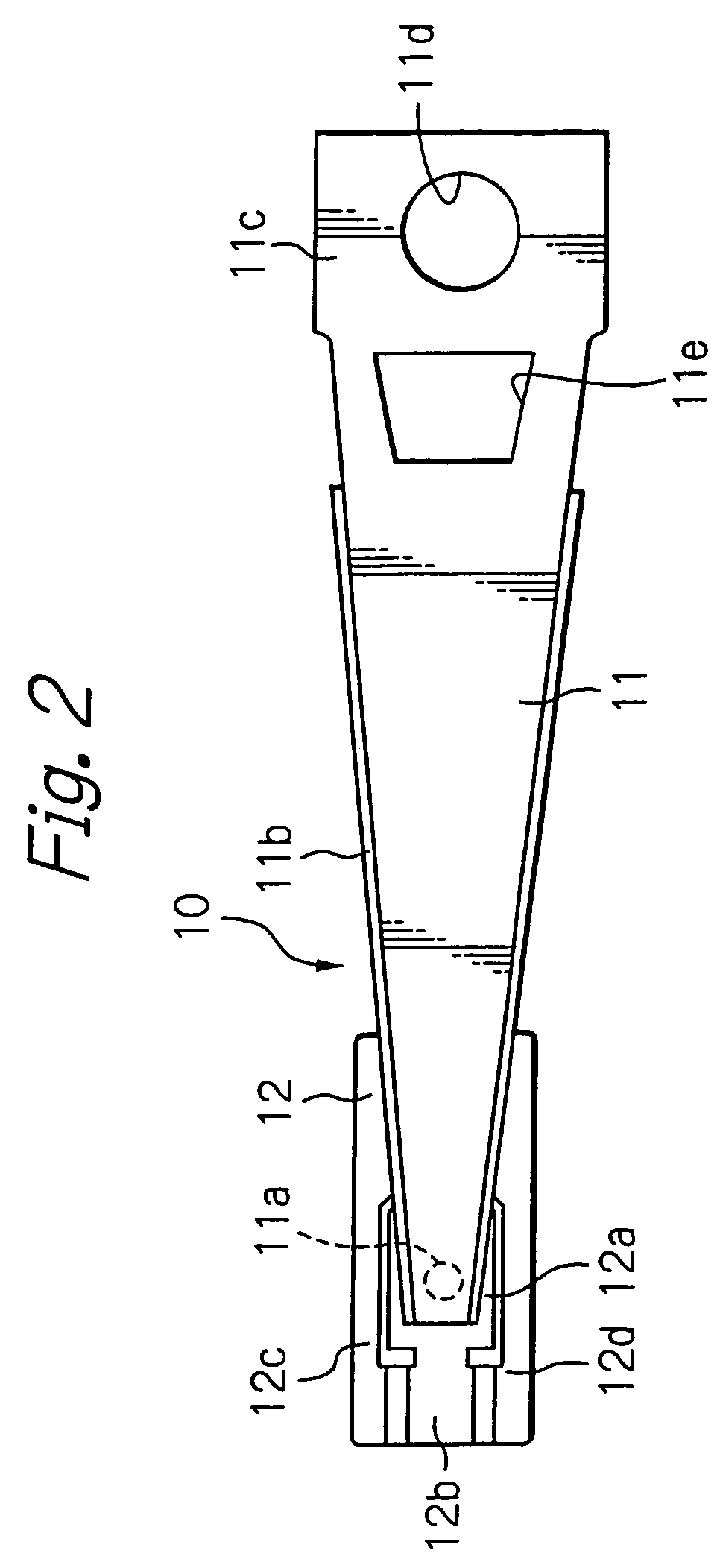

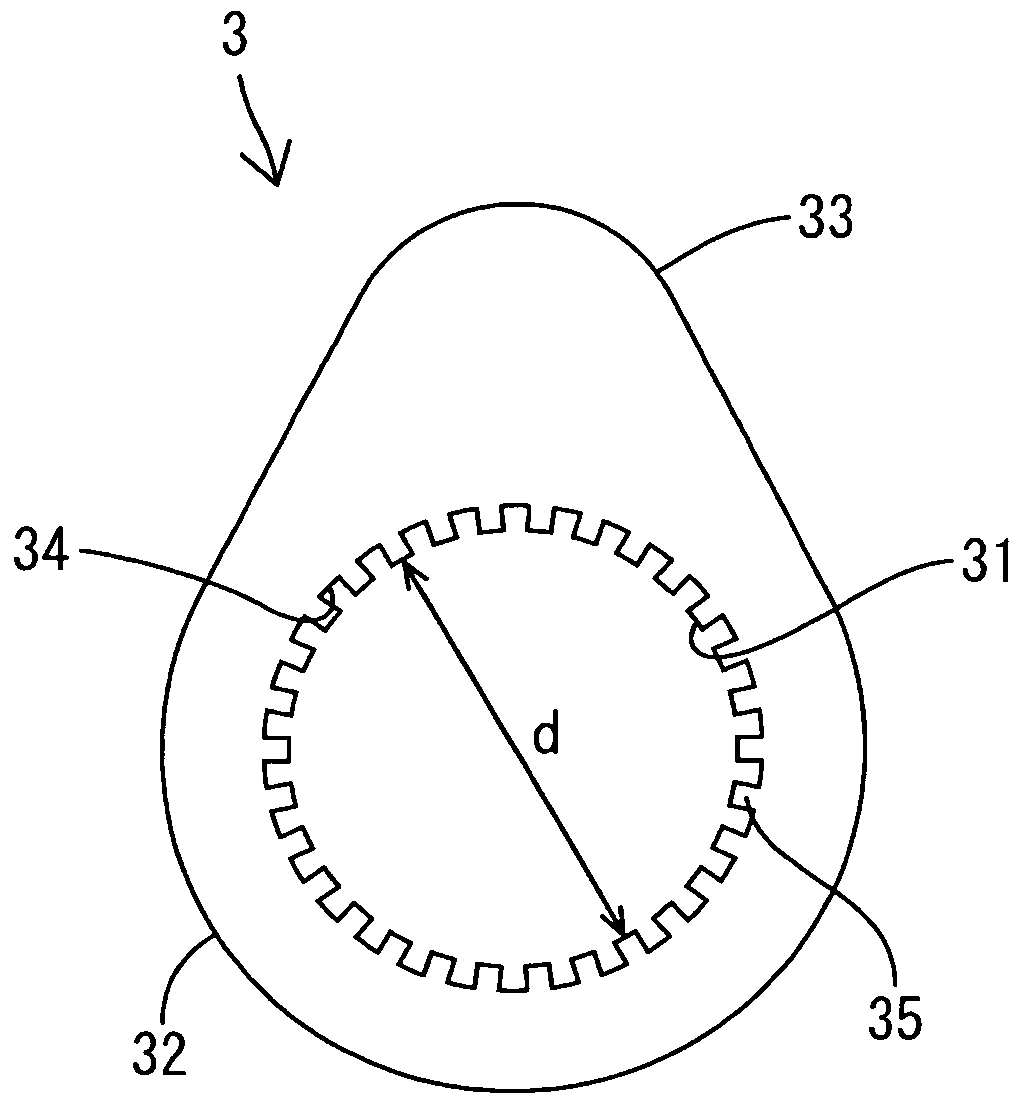

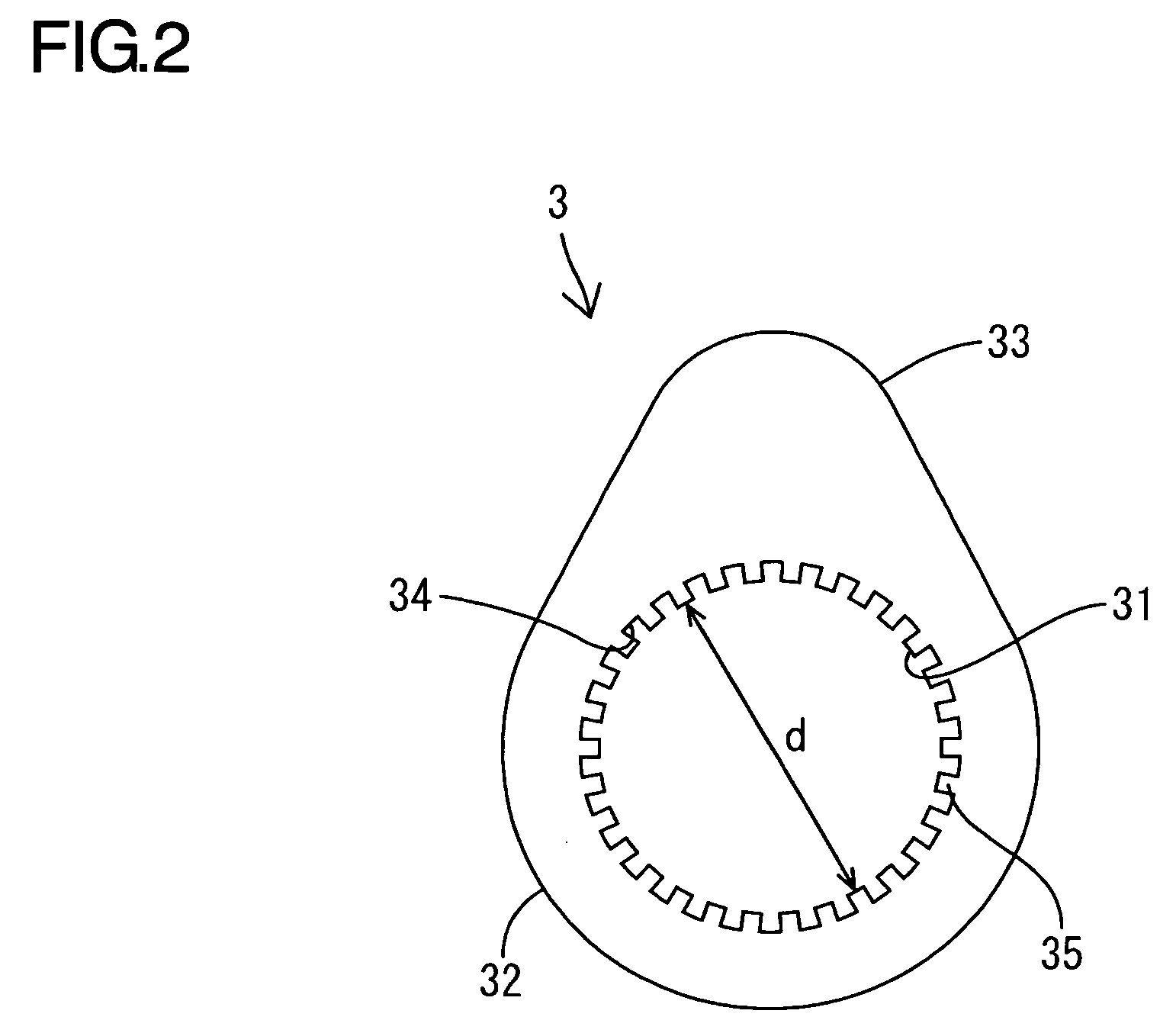

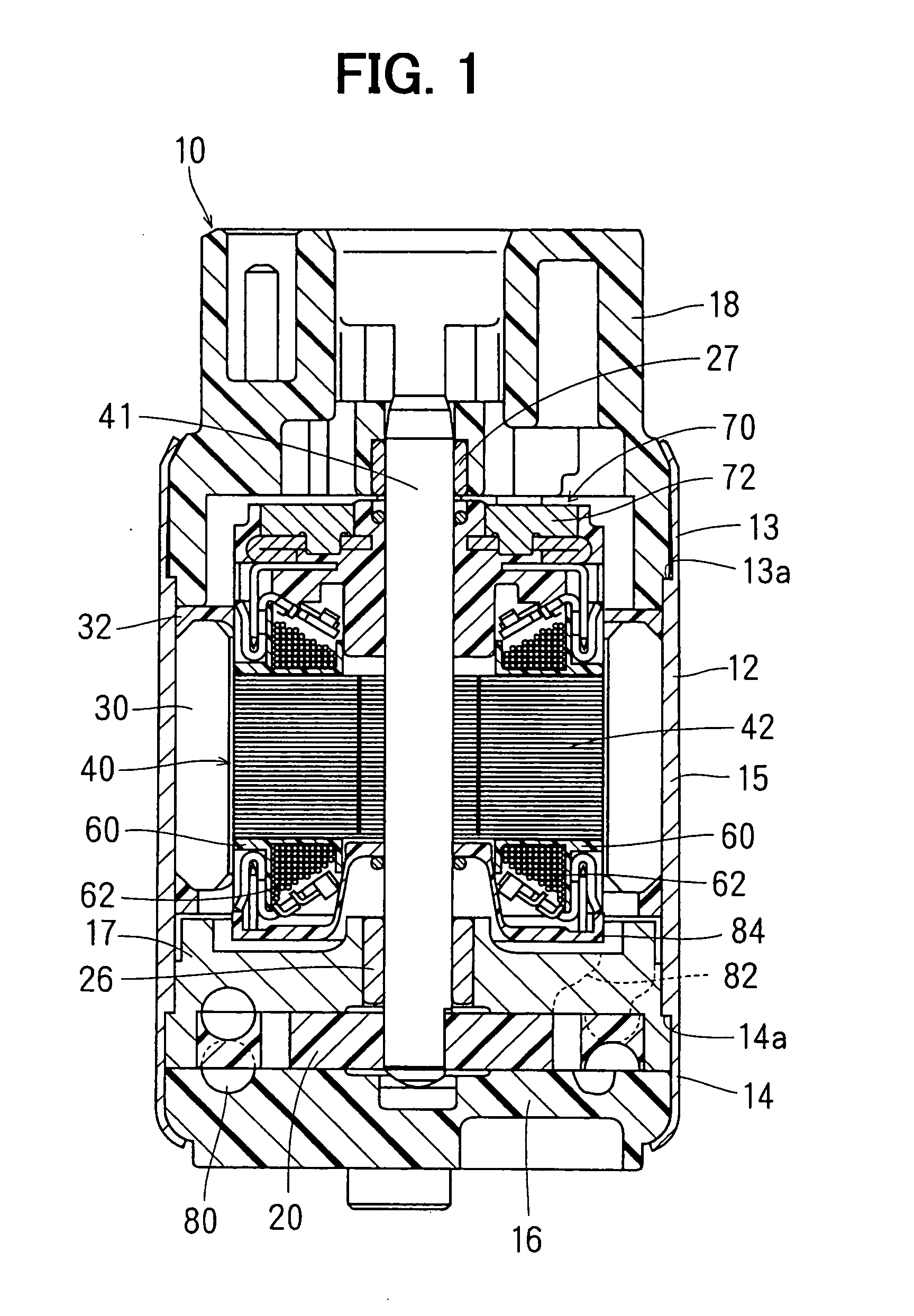

Rotating Assembly and Its Manufacturing Method

InactiveUS20080250895A1Resistance insertionImprove workabilityCamsMetal working apparatusDrive shaftEngineering

An inner hole 31 to which a driving shaft 2 is inserted is formed in a campiece 3 of a camshaft 1, and a plurality of grooves 34 extending in the insertion direction of the driving shaft 2 are formed in the inner hole 31. The driving shaft 2 is inserted into the inner hole 31 with the cam piece 3 heated to expand the diameter of the inner hole 31. By reducing again the diameter of the inner hole 31 by cooling it in this state, an outer circumferential surface of the driving shaft 2 is pressed and raised by the inner hole 31 and enters the groove 34, by which the cam piece 3 is firmly fixed onto the driving shaft 2.

Owner:OTICS CORP +1

Preparation method of honeysuckle flower tea

The invention discloses a preparation method of a honeysuckle flower tea, and belongs to the technical field of tea processing. The preparation method comprises the following steps: picking fresh honeysuckle flowers; soaking the picked fresh honeysuckle flowers by clear water for 40-60 minutes, wherein the temperature of the clear water is 20-30 DEG C; filtering the soaked honeysuckle flowers until no water is dripping; carrying out withering, namely withering the filtered honeysuckle flowers by hot air of which the temperature is raised in gradients, wherein the honeysuckle flowers are orderly heated by a first gradient temperature of 35-45 DEG C for 40-50 minutes, a second gradient temperature of 75-85 DEG C for 20-30 minutes, and a third gradient temperature of 70-90 DEG C for 10-15 minutes; carrying out rolling; continuously stir-frying the rolled honeysuckle flowers in a hot pan at 120-150 DEG C for 6-8 minutes, dishing the stir-fried honeysuckle flowers off, and air-cooling the honeysuckle flowers until the temperature of the honeysuckle flowers is 10-20 DEG C; and fermenting and drying the cooled honey suckles. The preparation method of the honeysuckle flower tea overcomes factors of concern of prior art, and sets rational technological conditions, so that the prepared honeysuckle flower final-products are reduced in bitter and astringent tastes after being brewed in water when compared with the honeysuckle flowers processed by existing technologies under the same conditions.

Owner:绥阳县吉帮昌盛金银花农业科技有限公司

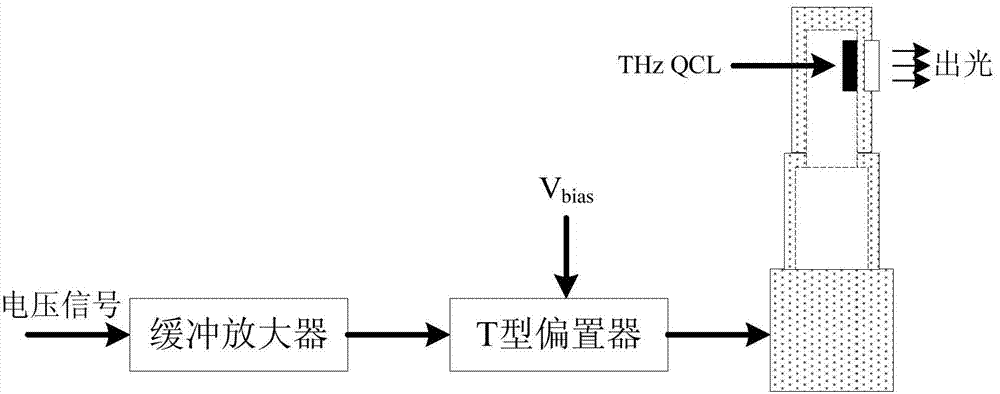

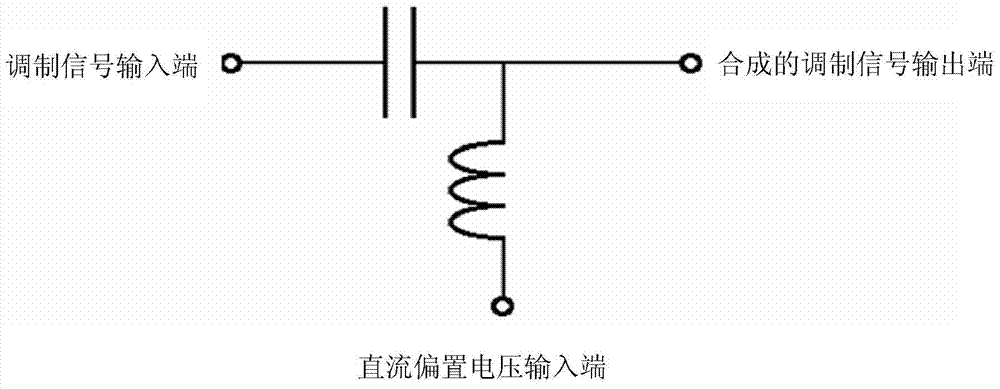

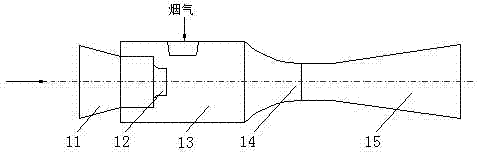

High-speed modulation method and device for terahertz quantum cascade laser

ActiveCN103928841ALow output impedanceLoad without distortionSemiconductor laser arrangementsLaser arrangementsDriving currentAudio power amplifier

The invention provides a high-speed modulation method and device for a terahertz quantum cascade laser. The device comprises a buffer amplifier, a T-shaped bias device connected with the output end of the buffer amplifier, and the terahertz quantum cascade laser connected with the output end of the T-shaped bias device. The high-speed modulation method for the terahertz quantum cascade laser can carry out high-speed modulation on the terahertz quantum cascade laser large in load, high in threshold voltage and large in drive current, ensure that modulation signals are loaded to the terahertz quantum cascade laser in a distortionless mode, and avoid distortion of impulse waveforms. The device is simple in structure, easy to operate and integrate and suitable for being applied to future THz communication.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

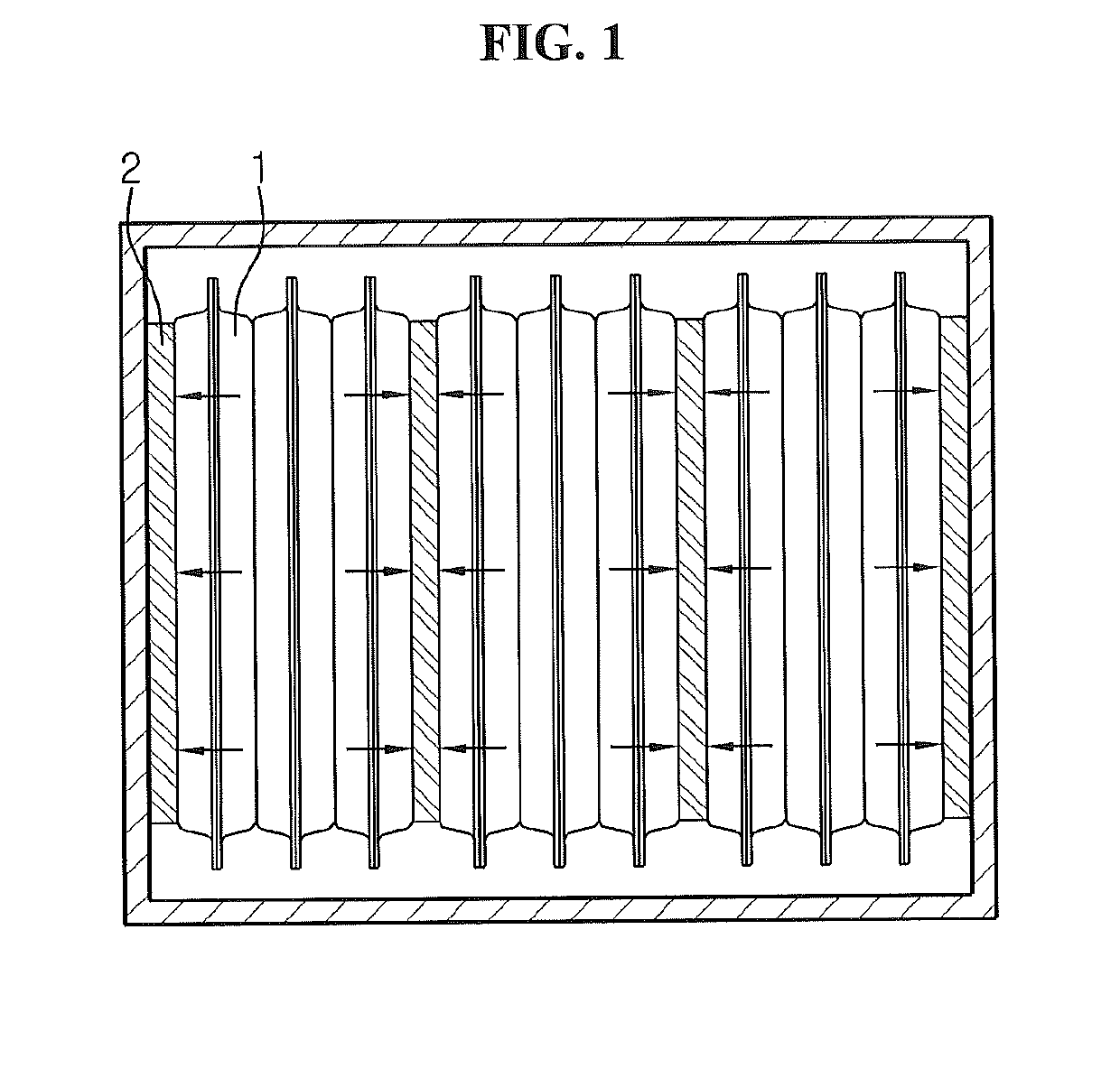

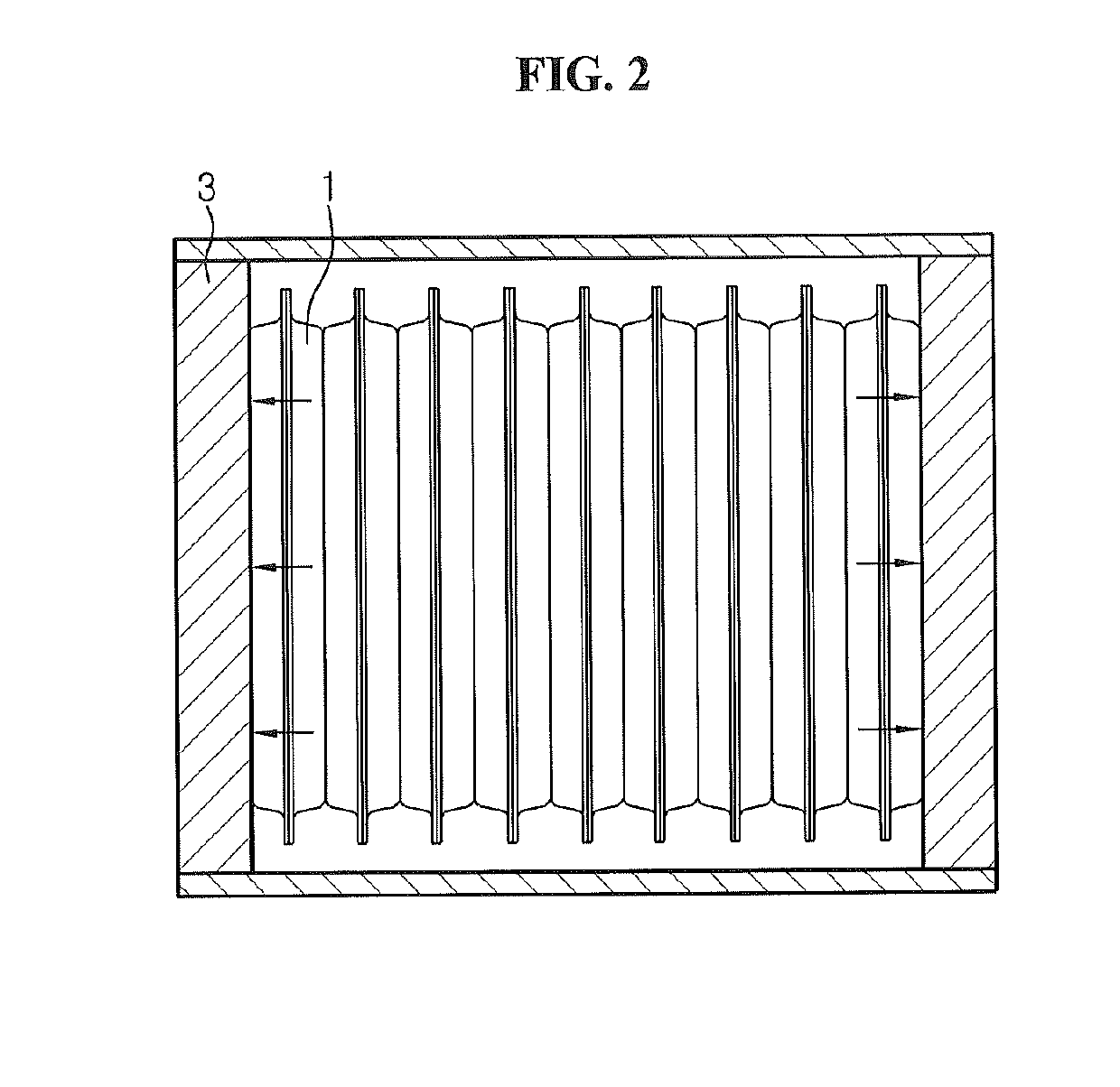

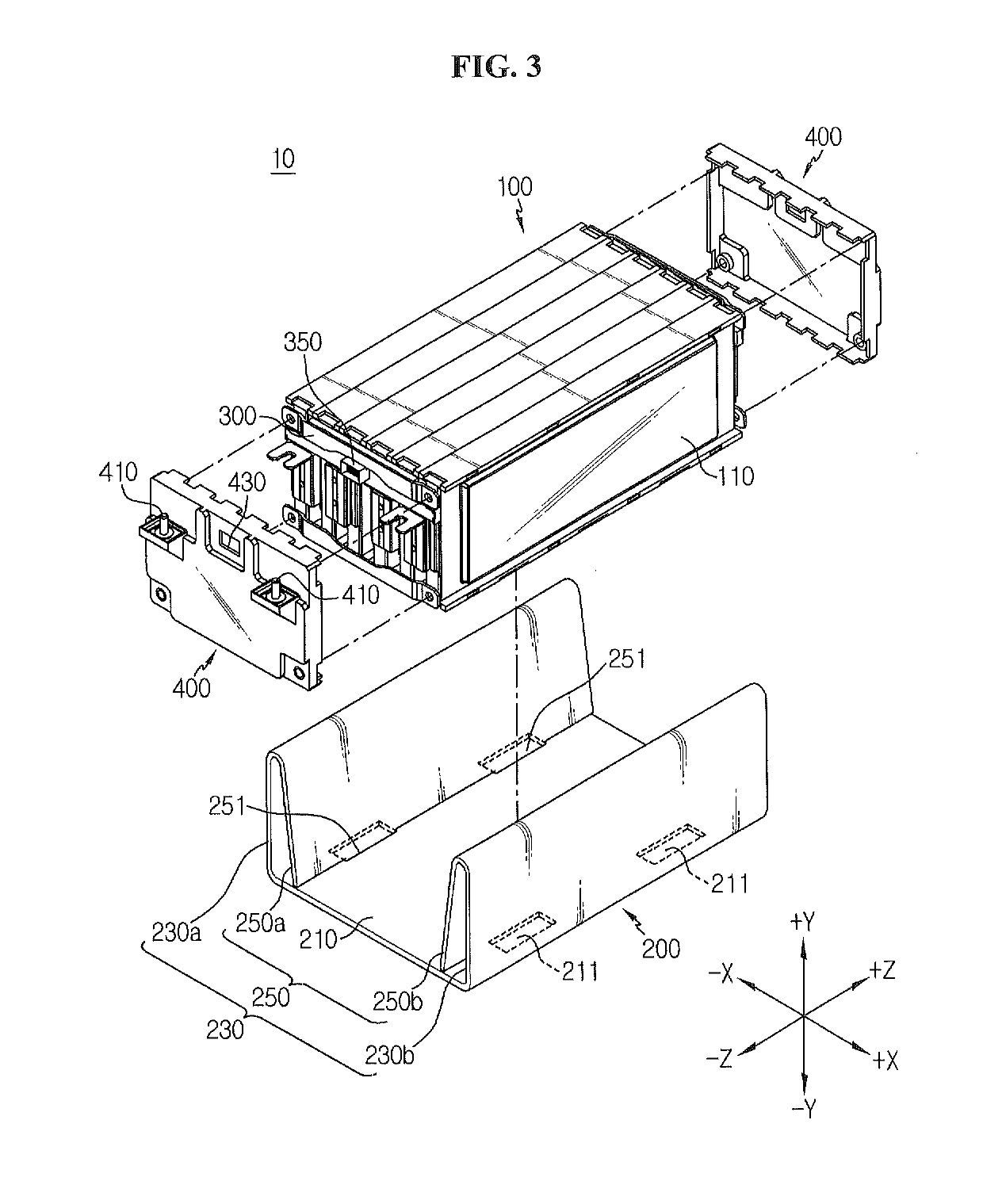

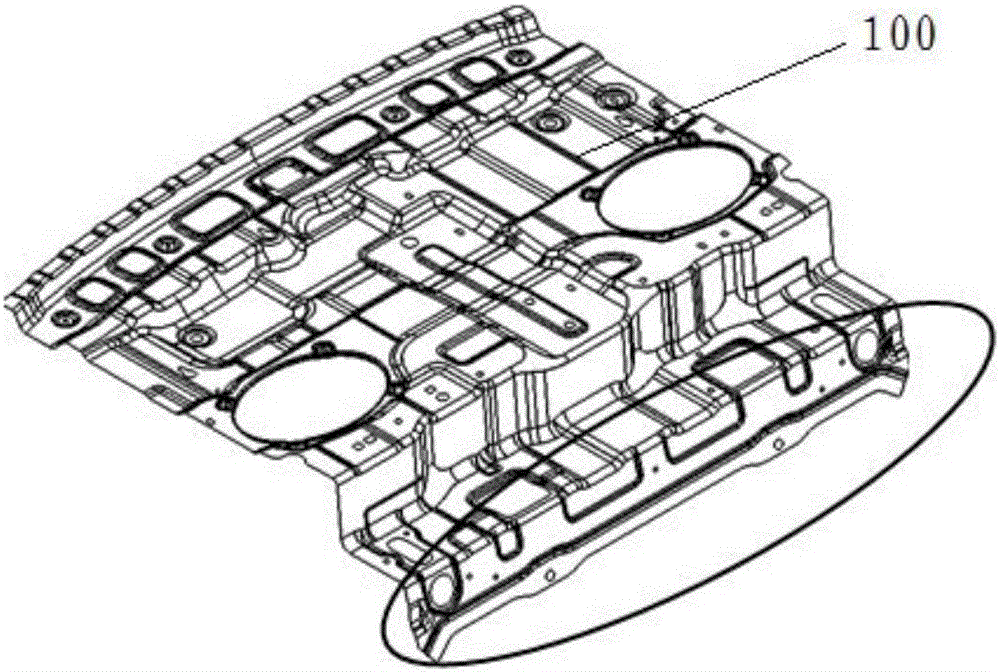

End Plate, Battery Module, Battery Pack Comprising the Battery Module and Vehicle Comprising the Battery Pack

ActiveUS20190267591A1Prevent shape changeReduce overall weight and volumeBattery isolationGas pressure propulsion mountingCell assemblyBattery cell

A battery module according to an embodiment of the present disclosure includes a cell assembly including a plurality of battery cells stacked side by side in a horizontal direction, each battery cell defining a respective plane extending in a vertical direction perpendicular to the horizontal direction, and an end plate having a support part configured to support a bottom of the cell assembly, an outer side part extending in the vertical direction from an end of the support part, and an inner side part extending downward and inward from a top of the outer side part.

Owner:LG ENERGY SOLUTION LTD

Method of manufacturing semiconductor device having plural semiconductor chips stacked one another

InactiveUS20140295620A1Prevent shape changeIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesFilling materialsSemiconductor chip

Owner:PS4 LUXCO SARL

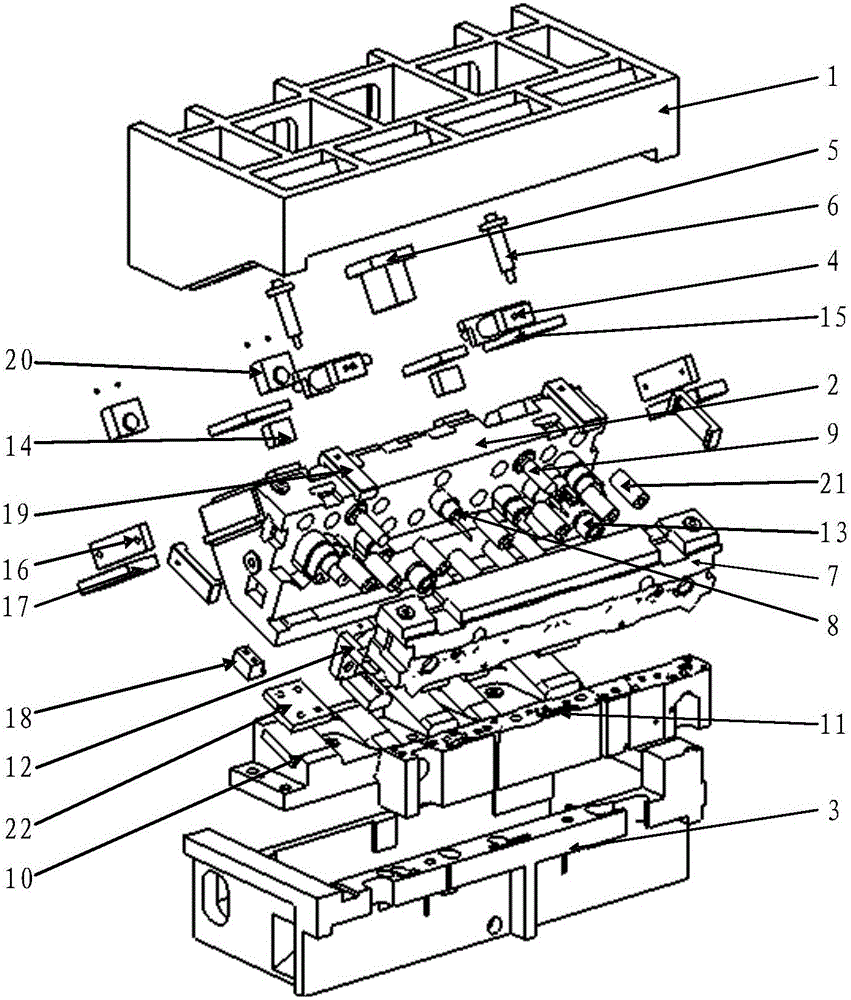

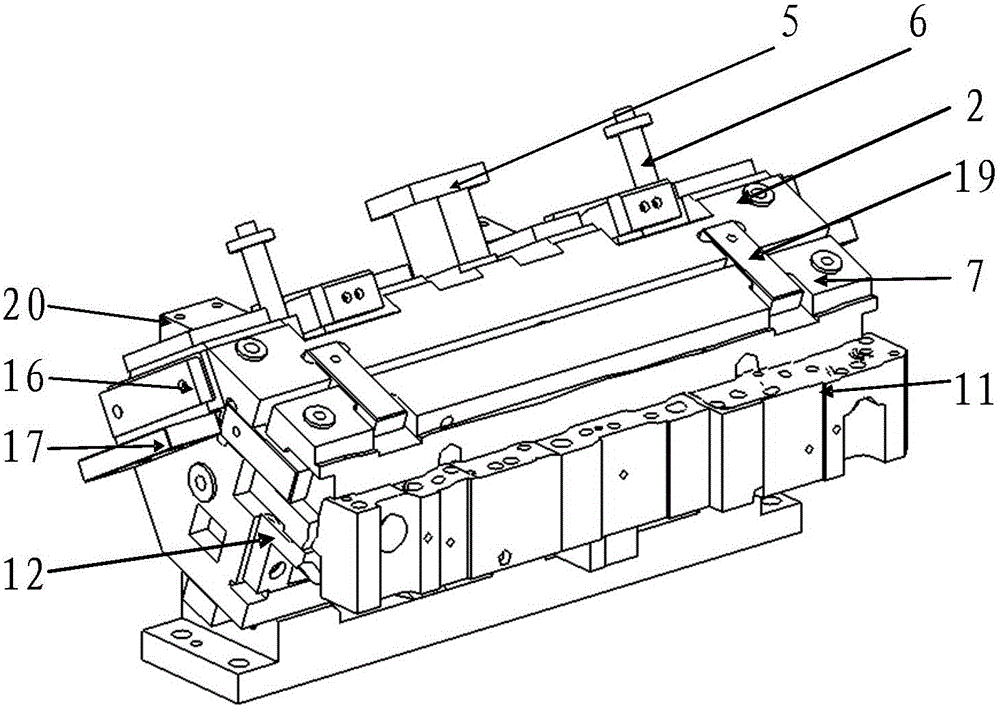

Inclined wedge mechanism with lateral material pressing function

InactiveCN105880372AImprove trimming and punching qualityEnsure lap qualityShaping toolsPerforating toolsPunchingWelding

The invention discloses an inclined wedge mechanism with a lateral material pressing function. The inclined wedge mechanism with the lateral material pressing function comprises an upper die seat, an inclined wedge body and a lower die seat, wherein the bottom of the upper die seat is provided with a nitrogen spring; a safety hook and a safety bolt penetrate through a through hole in the upper die seat, and then are fixedly connected with inclined wedge body; the inclined wedge body is provided with a material pressing core, a punching head upper die and a trimming knife; the material pressing core cooperates, in a sliding manner, with a guide post mounted on the inclined wedge body; the top of the lower die seat is provided with a driving block and a lower die; the driving block cooperates with the inclined wedge body in the sliding manner; and the lower die cooperates with the punching head upper die and the trimming knife. By using the inclined wedge mechanism with the lateral material pressing function, a material pressing problem that a position cannot be corrected and punched forwards can be solved; and a sheet metal component is prevented from generating profile change due to trimming and hole punching, so as to improve the welding and assembly precision of a whole car.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

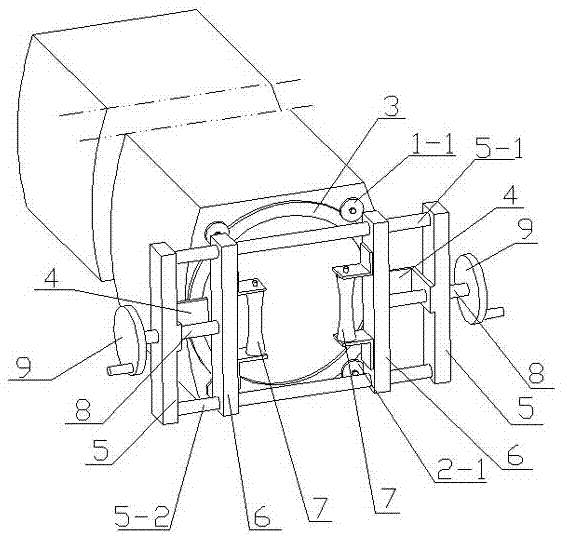

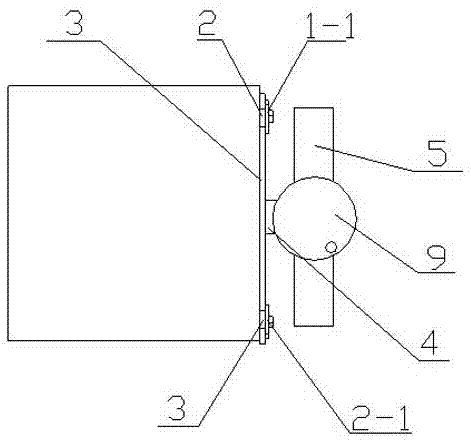

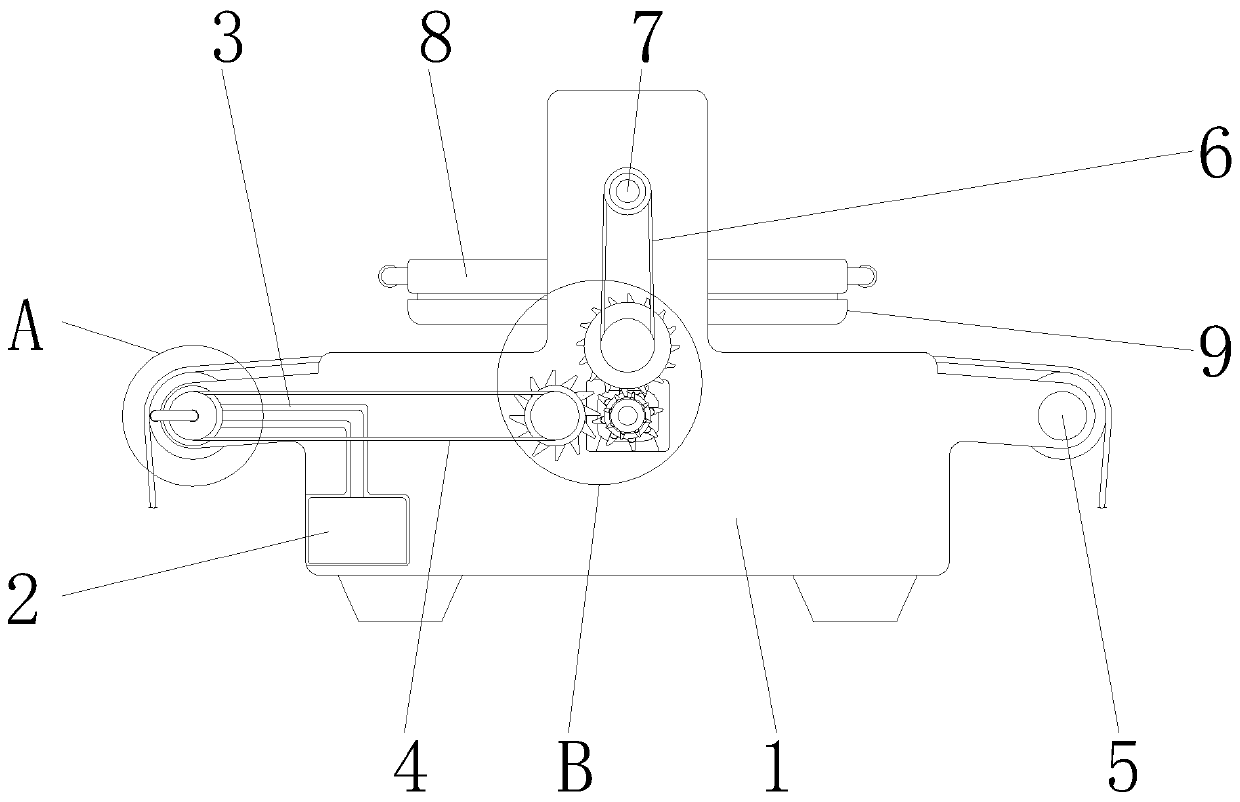

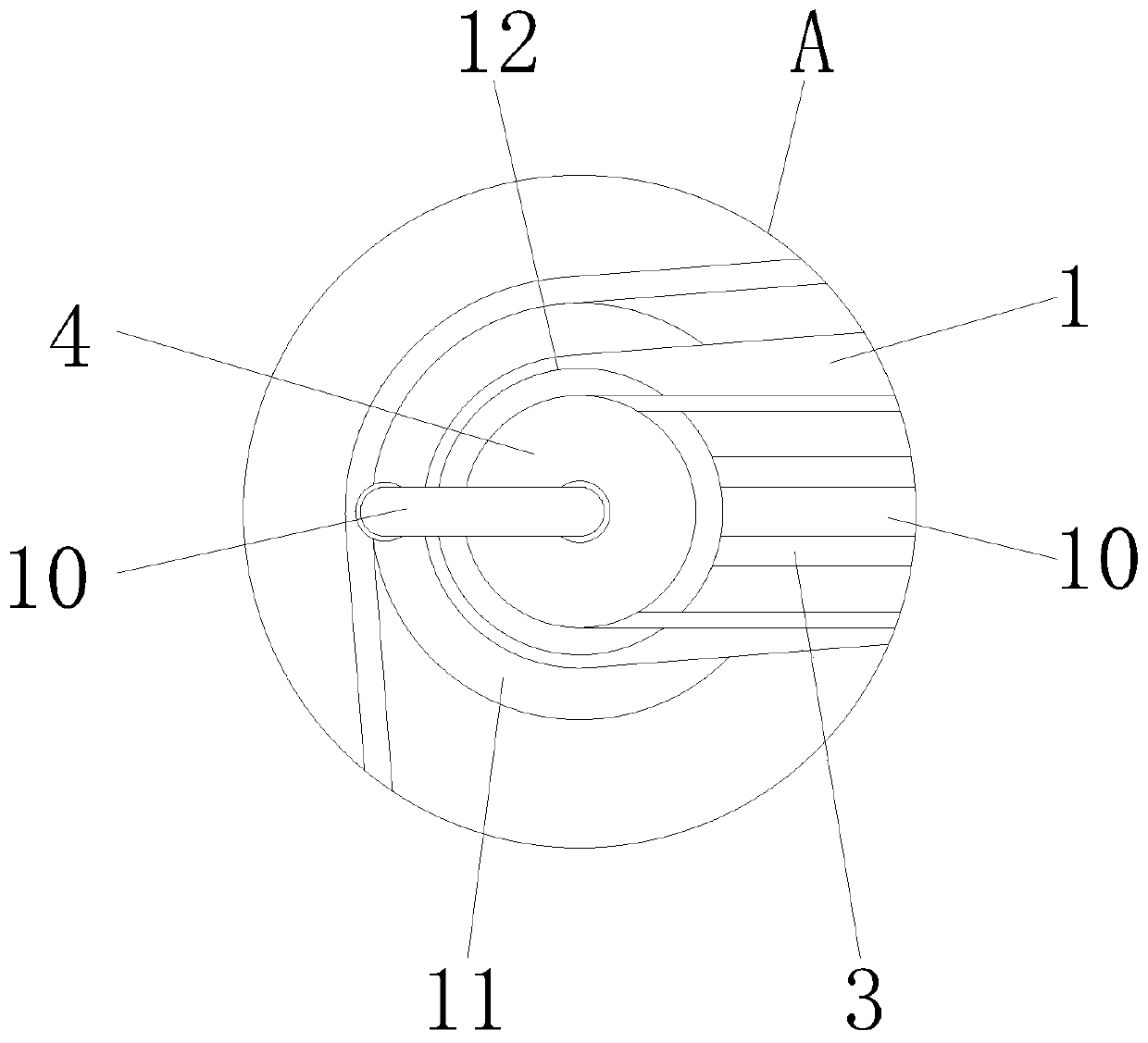

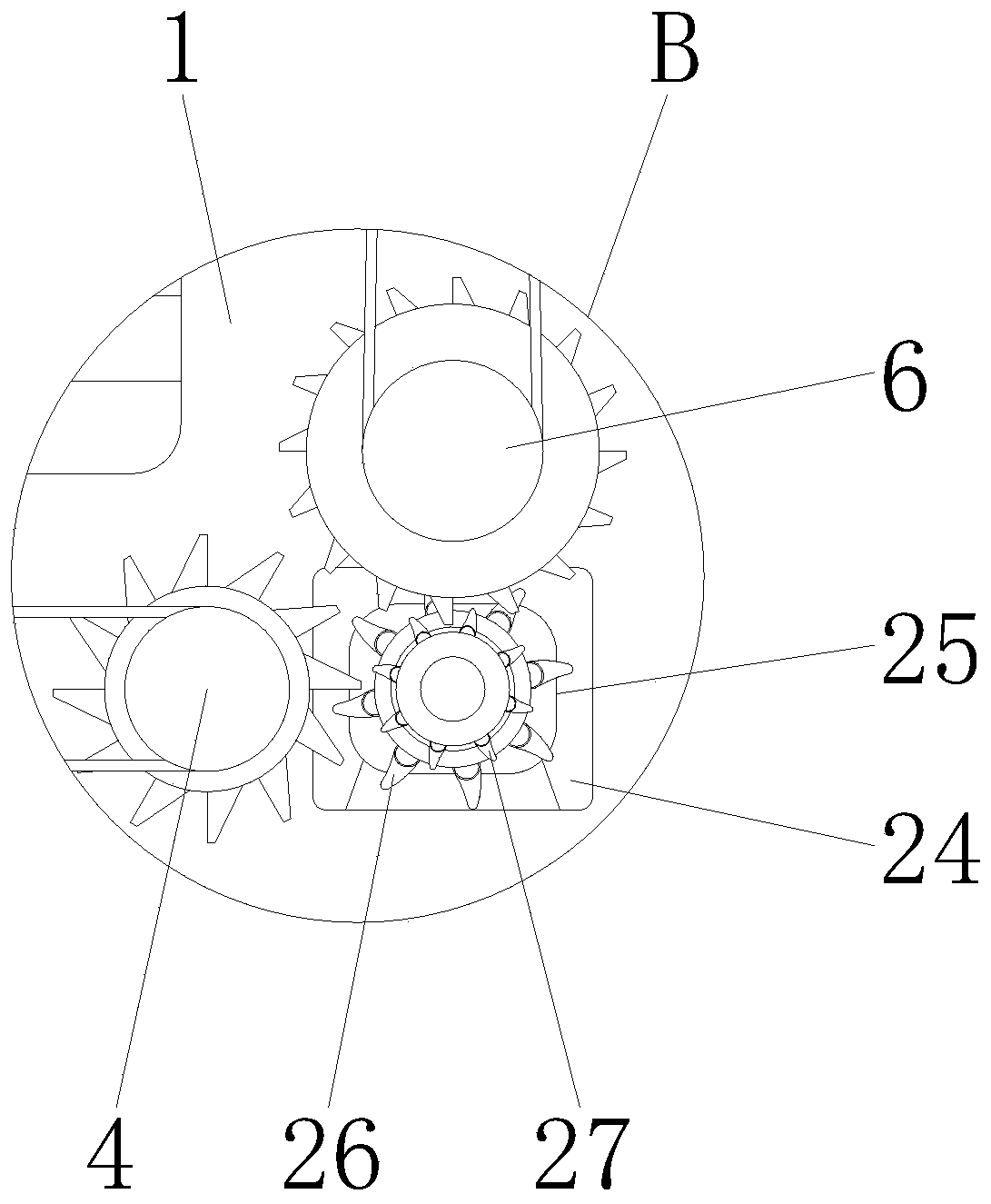

Plastic pipe shape correcting device for plastic pipe production line

InactiveCN106863767APrevent shape changeGuarantee product qualityTubular articlesProduction lineRotating disc

The invention discloses a plastic pipe shape correcting device for a plastic pipe production line. The plastic pipe shape correcting device is composed of a pair of upper positioning rollers (1), a pair of lower positioning rollers (2), a rotating disc (3), a pair of upper limiting blocks (1-1), a pair of lower limiting blocks (2-1), a pair of supports (4), a pair of fixed plates (5), an upper connection rod (5-1), a lower connection rod (5-2), a pair of clamping blocks (6), a pair of correcting rollers (7), a pair of screw rods (8) and a pair of hand wheels (9). The plastic pipe shape correcting device has the advantages that the shape of transferred plastic pipes is corrected through the device and prevented from being changed, and the final product quality is ensured.

Owner:付安丽

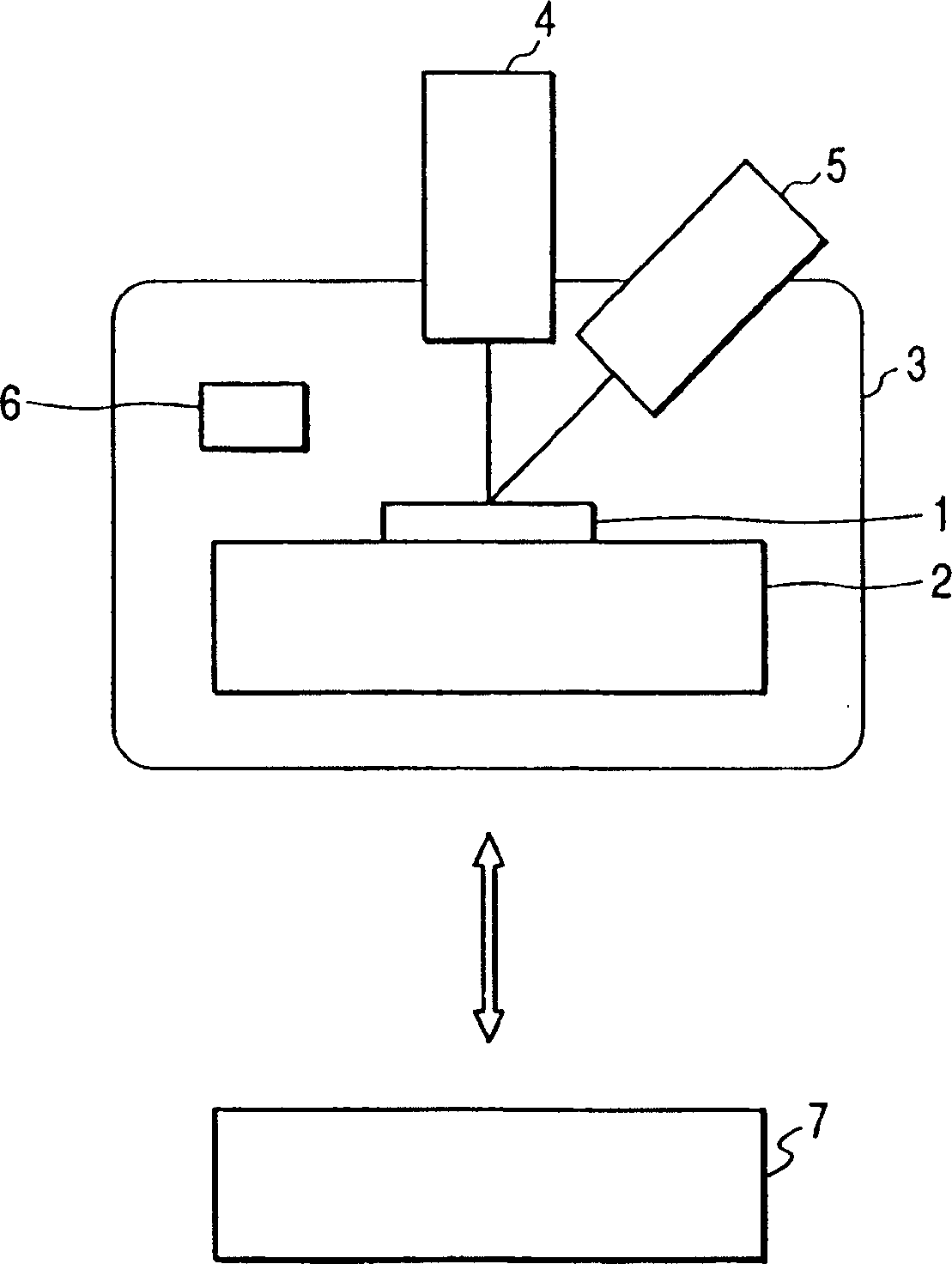

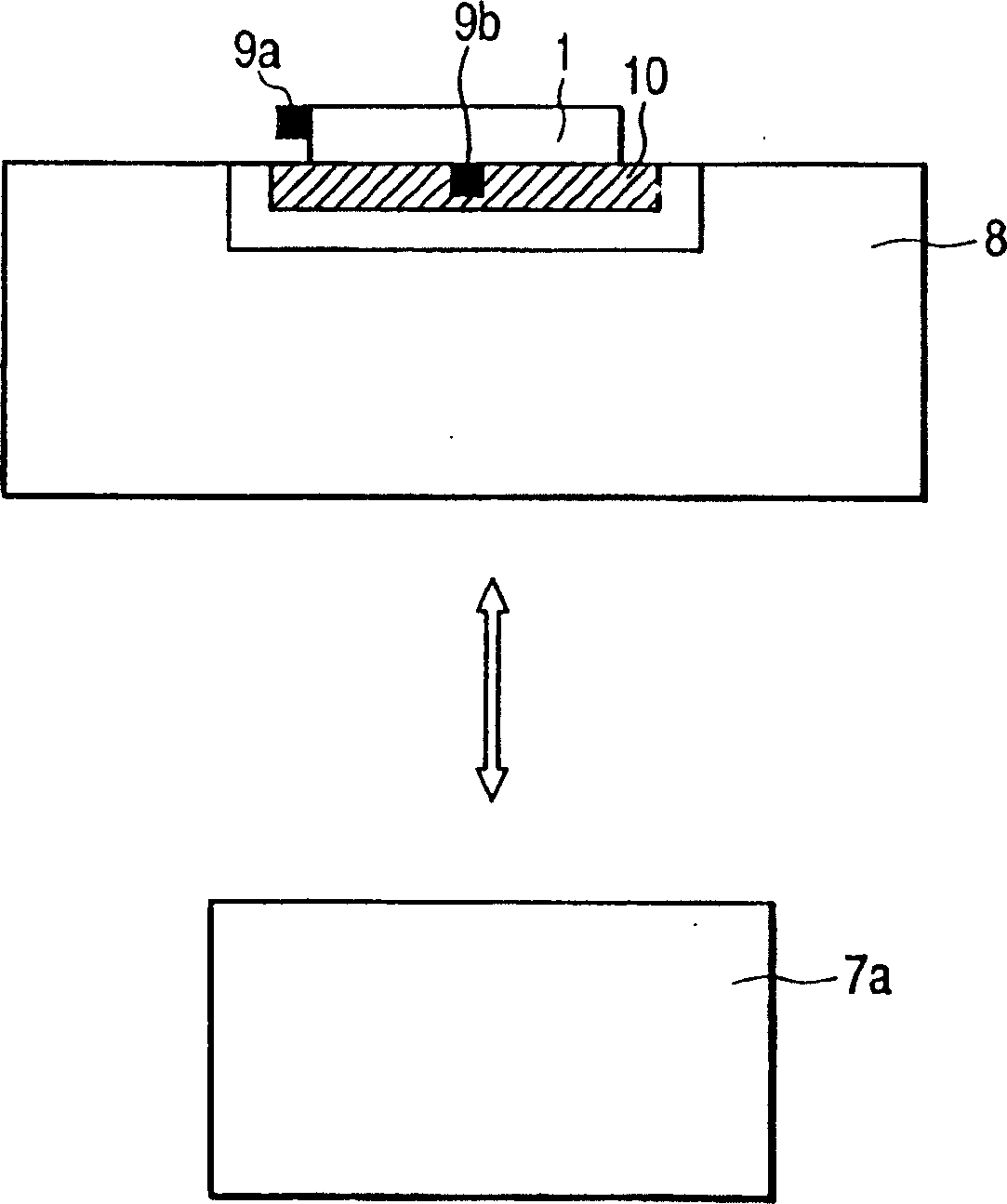

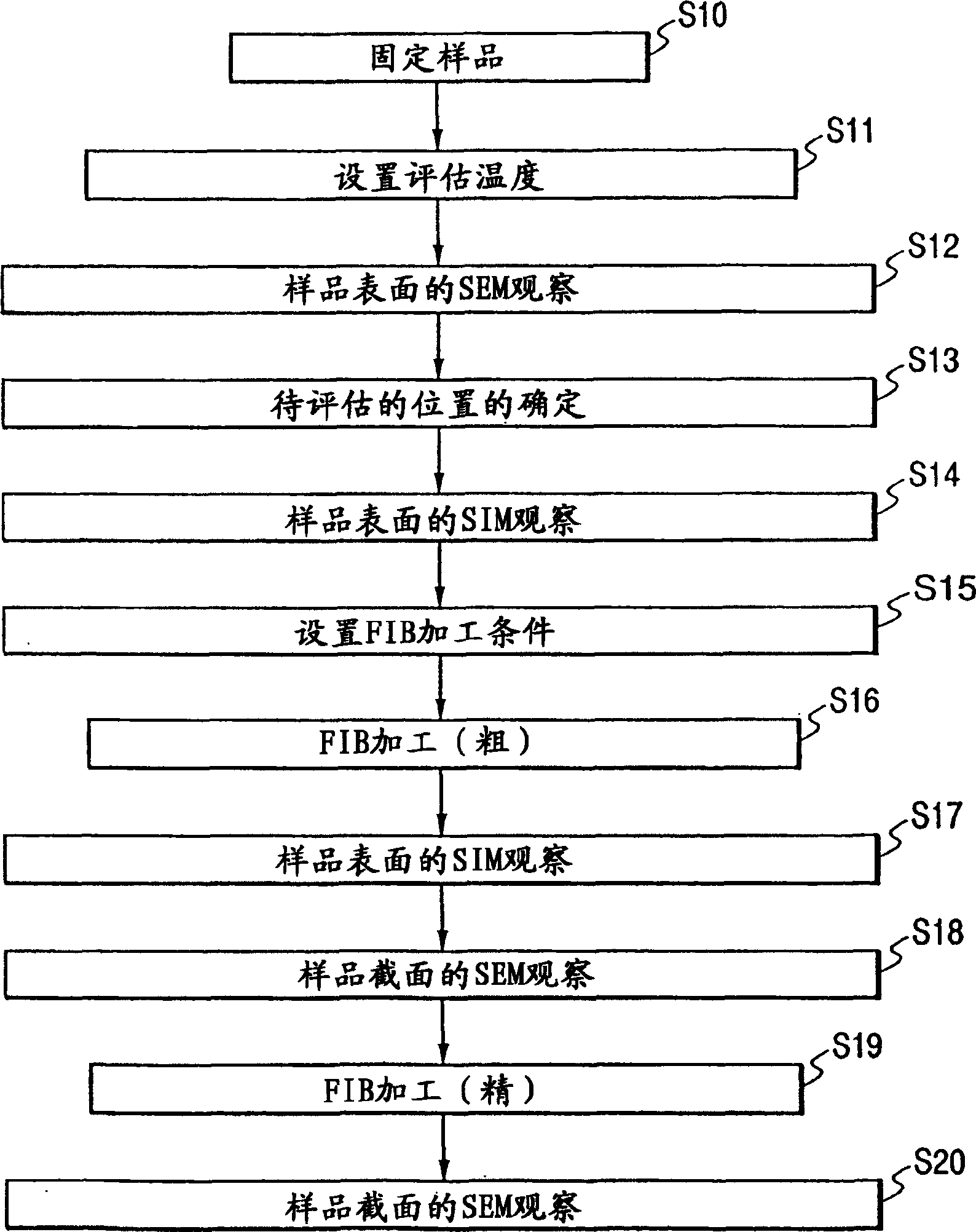

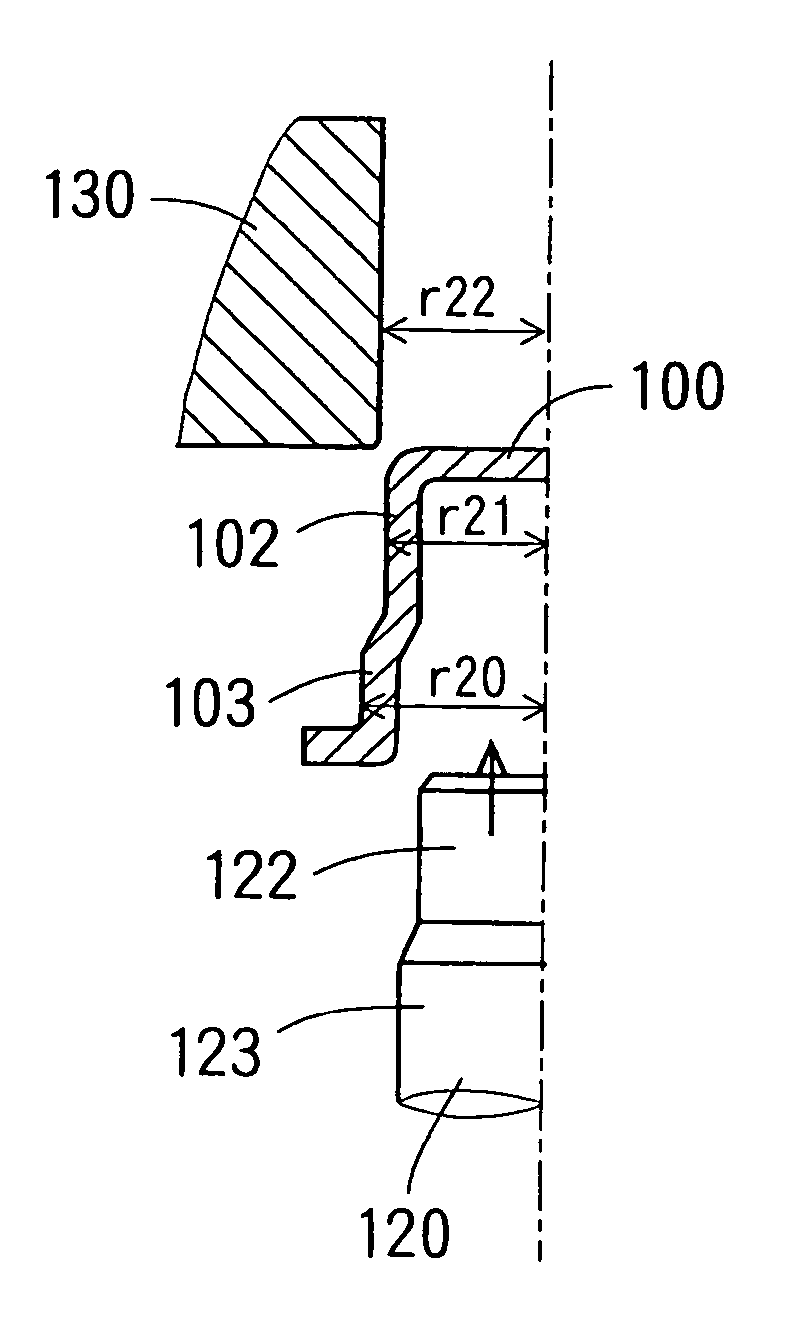

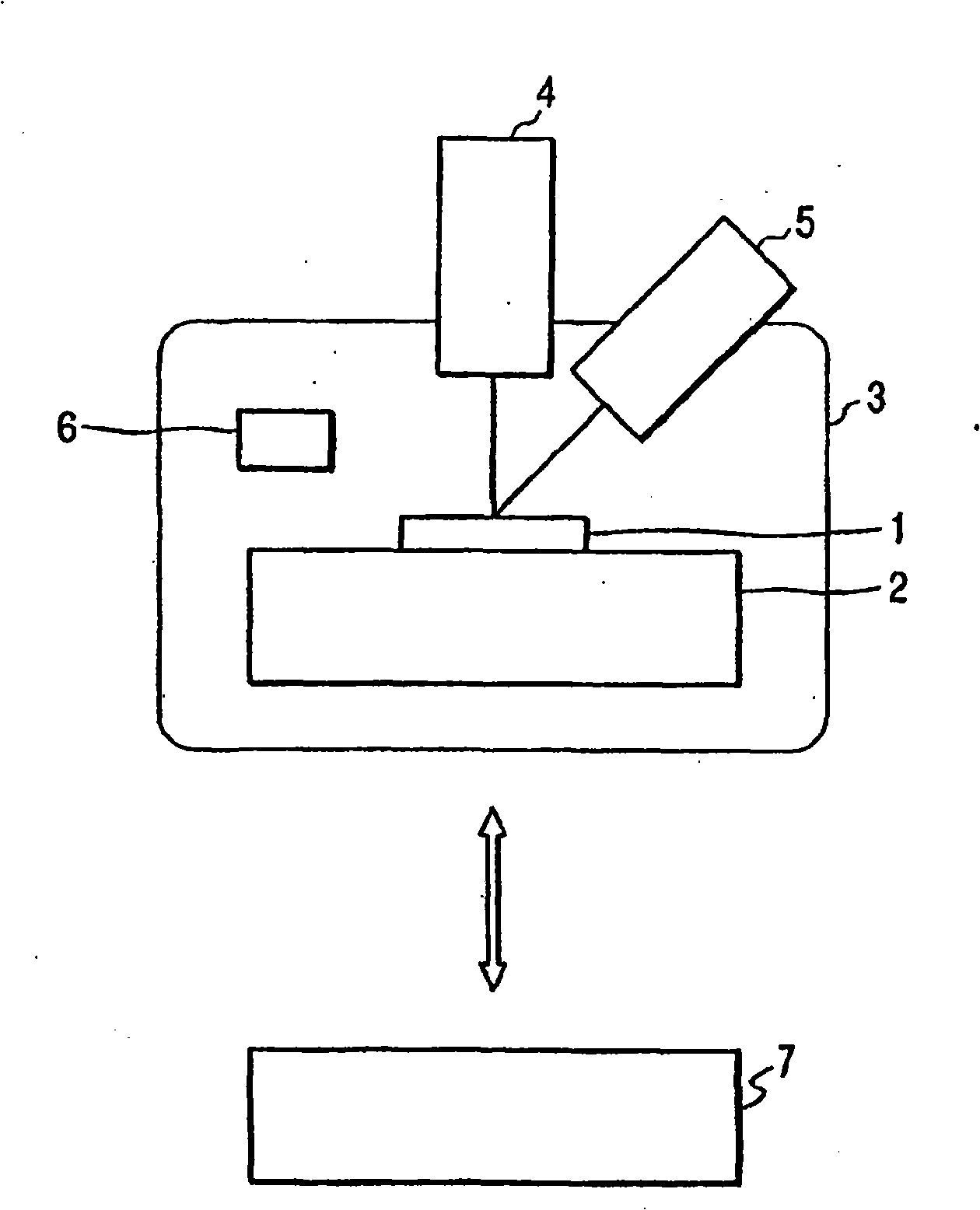

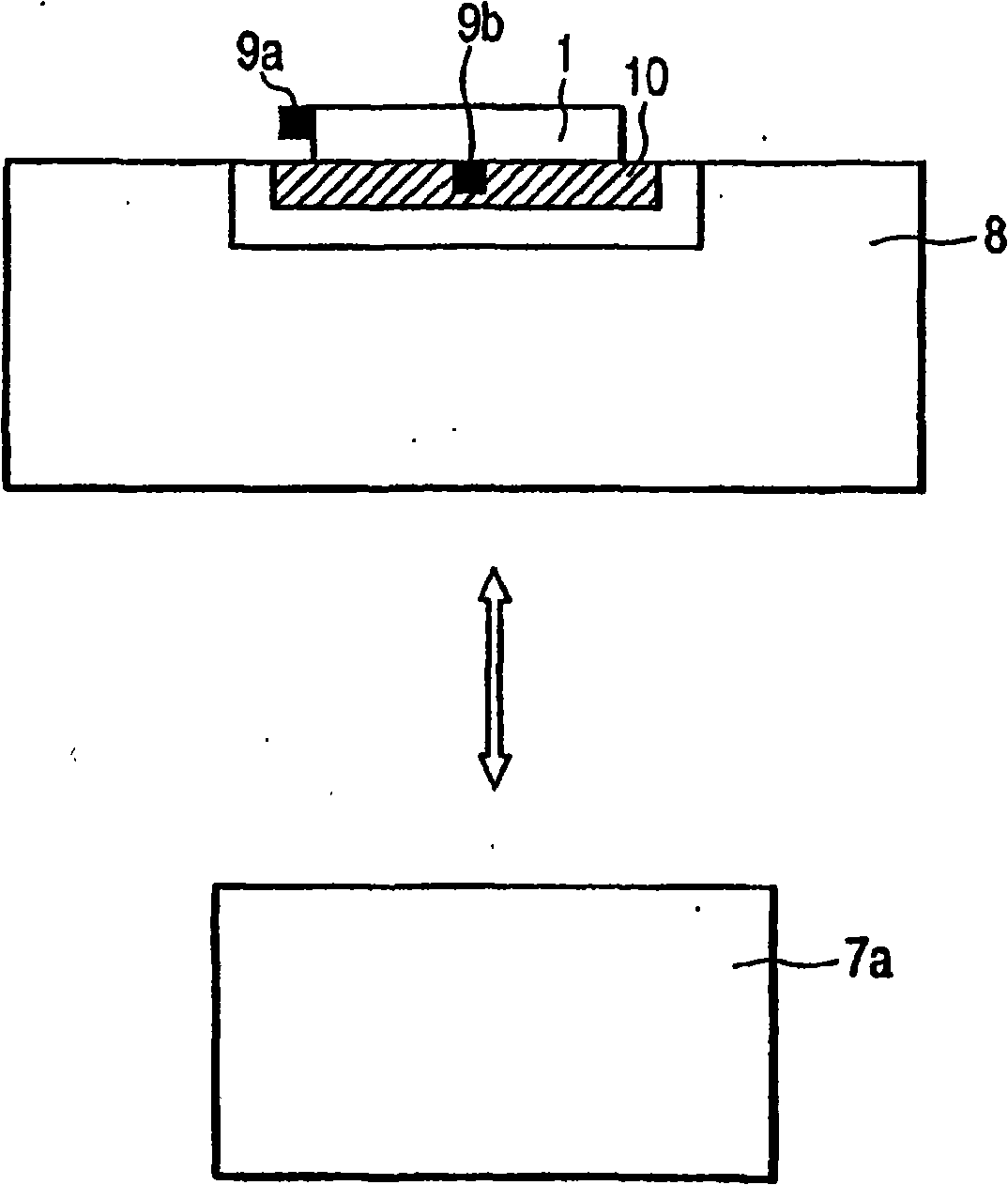

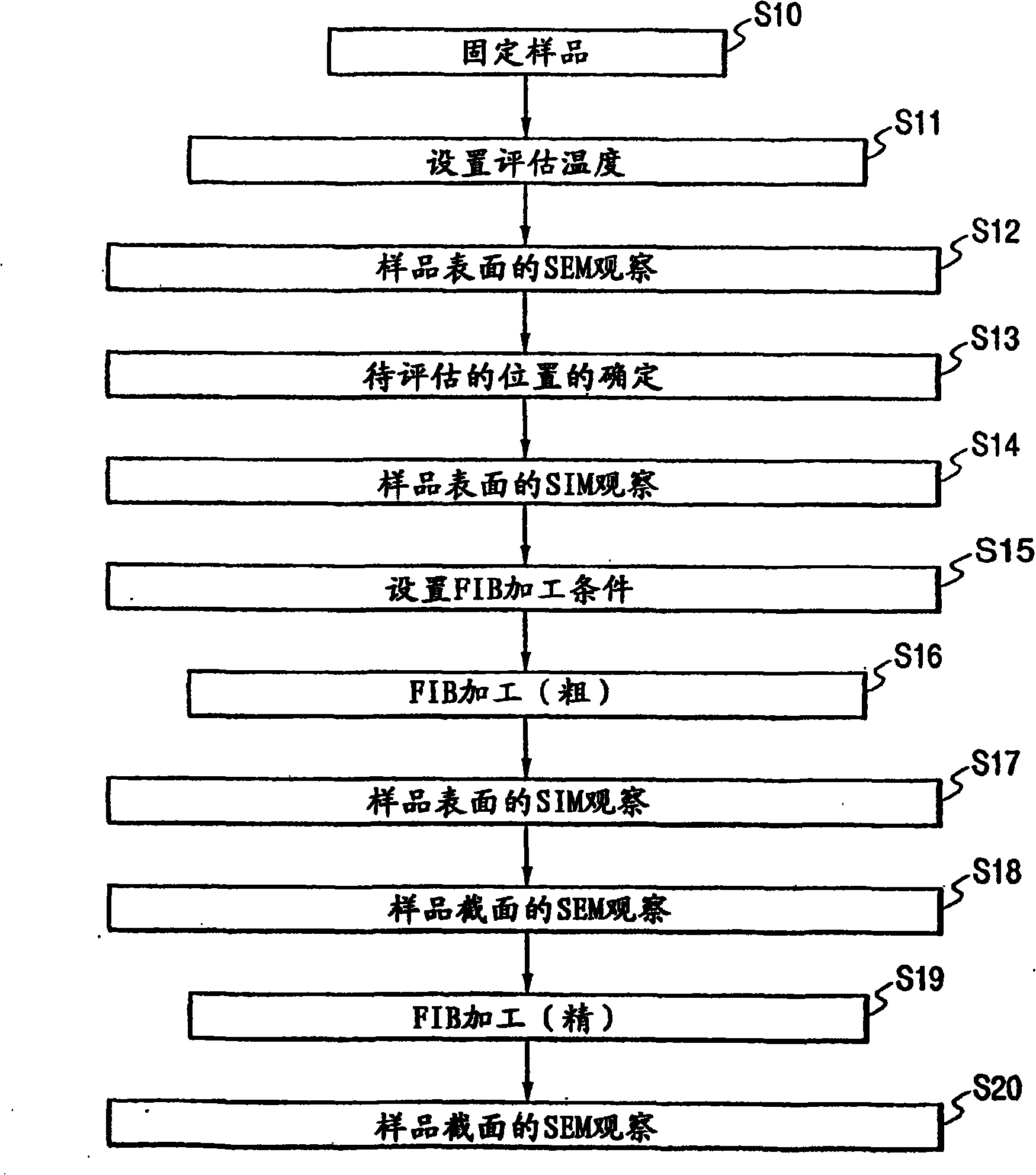

Information acquisition apparatus, cross section evaluating apparatus, cross section evaluating method

InactiveCN1565042APrevent statePrevent shape changeElectric discharge tubesAssessment methodsBiomedical engineering

The invention provides a cross section evaluating apparatus capable of analyzing the cross sectional structure in a state where the temperature of the specimen is regulated. There is disclosed an information acquisition apparatus comprising a stage for placing the specimen, temperature regulation means for regulating the temperature of the specimen, exposure means for exposing a surface, of which information is desired, of the specimen, and information acquisition means for acquiring information relating to the surface exposed by the exposure means.

Owner:CANON KK

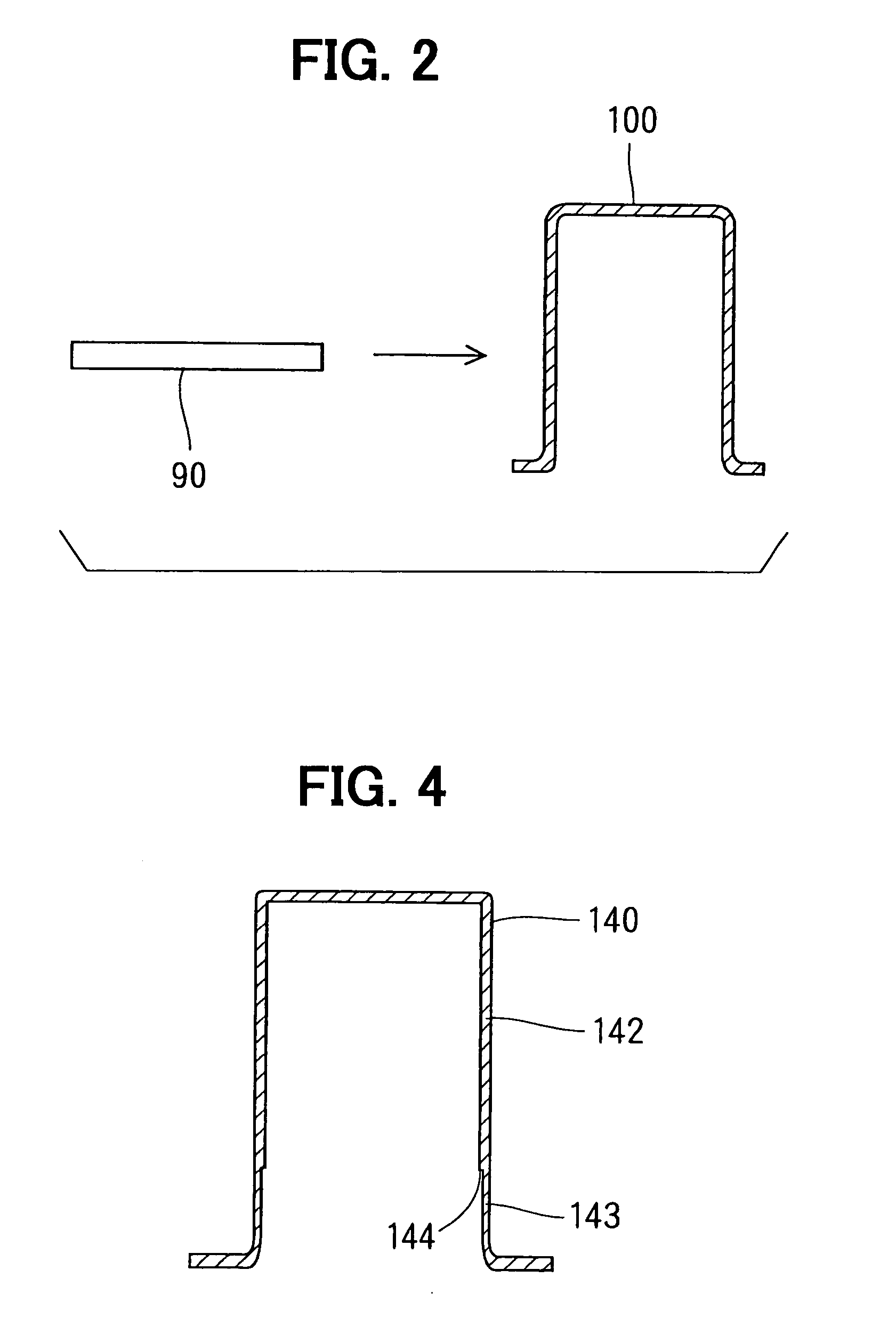

Manufacturing method for cylindrical part

ActiveUS20050115050A1Easy to separateAvoid stickingIntravenous devicesMetal working apparatusEngineeringThin walled

It is an object of the present invention to provide a method of manufacturing a cylindrical part with a thin-walled portion at a lower cost, and according to the manufacturing method of the present invention, a base metal formed with thin-walled portion adjacent to its closed end can be easily detached from working jigs. According to the method, a thin-walled portion is at first formed by the ironing process on a cylindrical wall adjacent to the closed end, so that an outer-side step portion is formed on an outer peripheral surface of the cylindrical wall. Then the closed end is punched out and the thin-walled portion is enlarged in a radial and outward direction to form an inner-side step portion on an inner peripheral surface of the cylindrical part.

Owner:NIHON PAKKIN +1

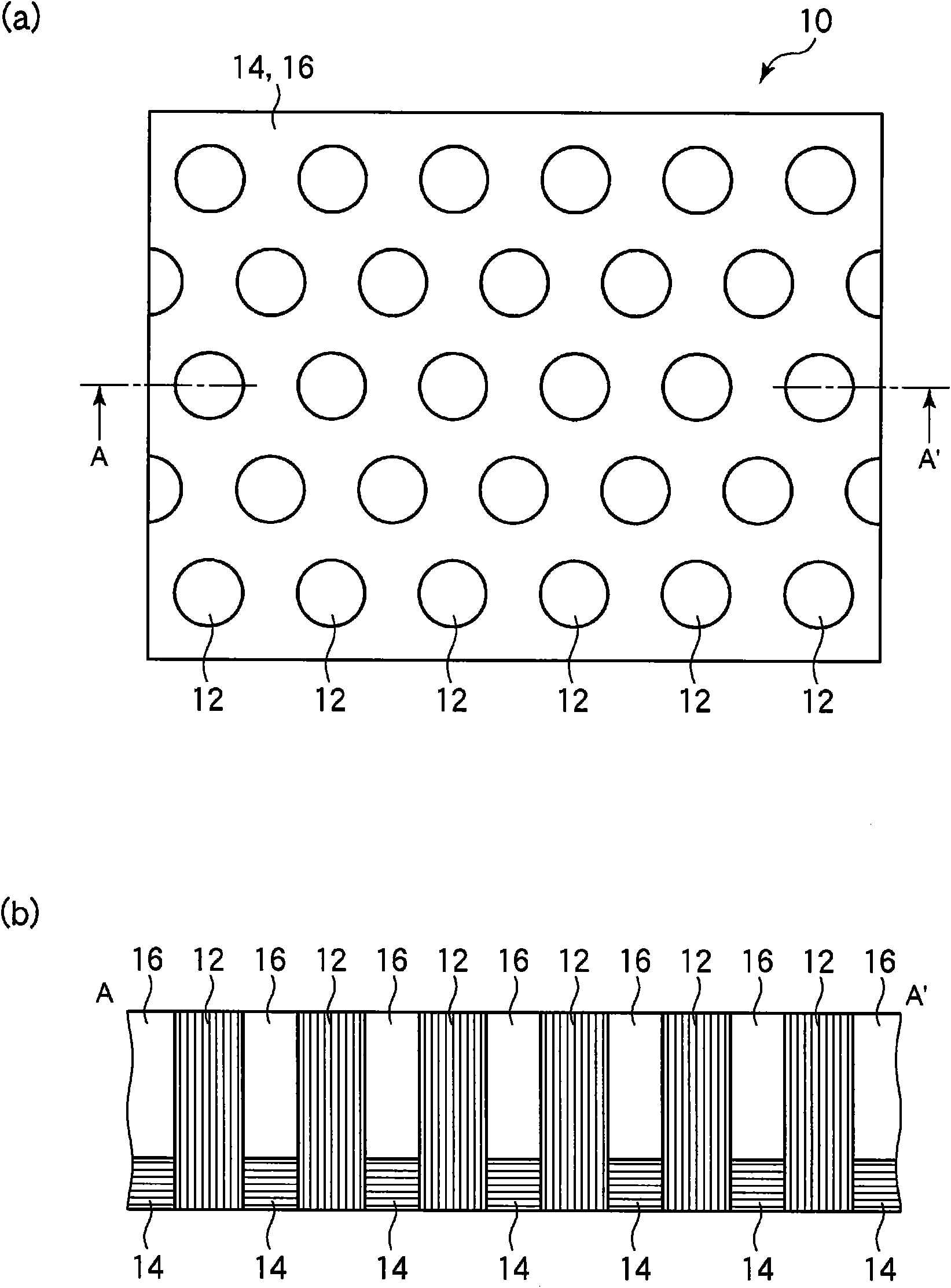

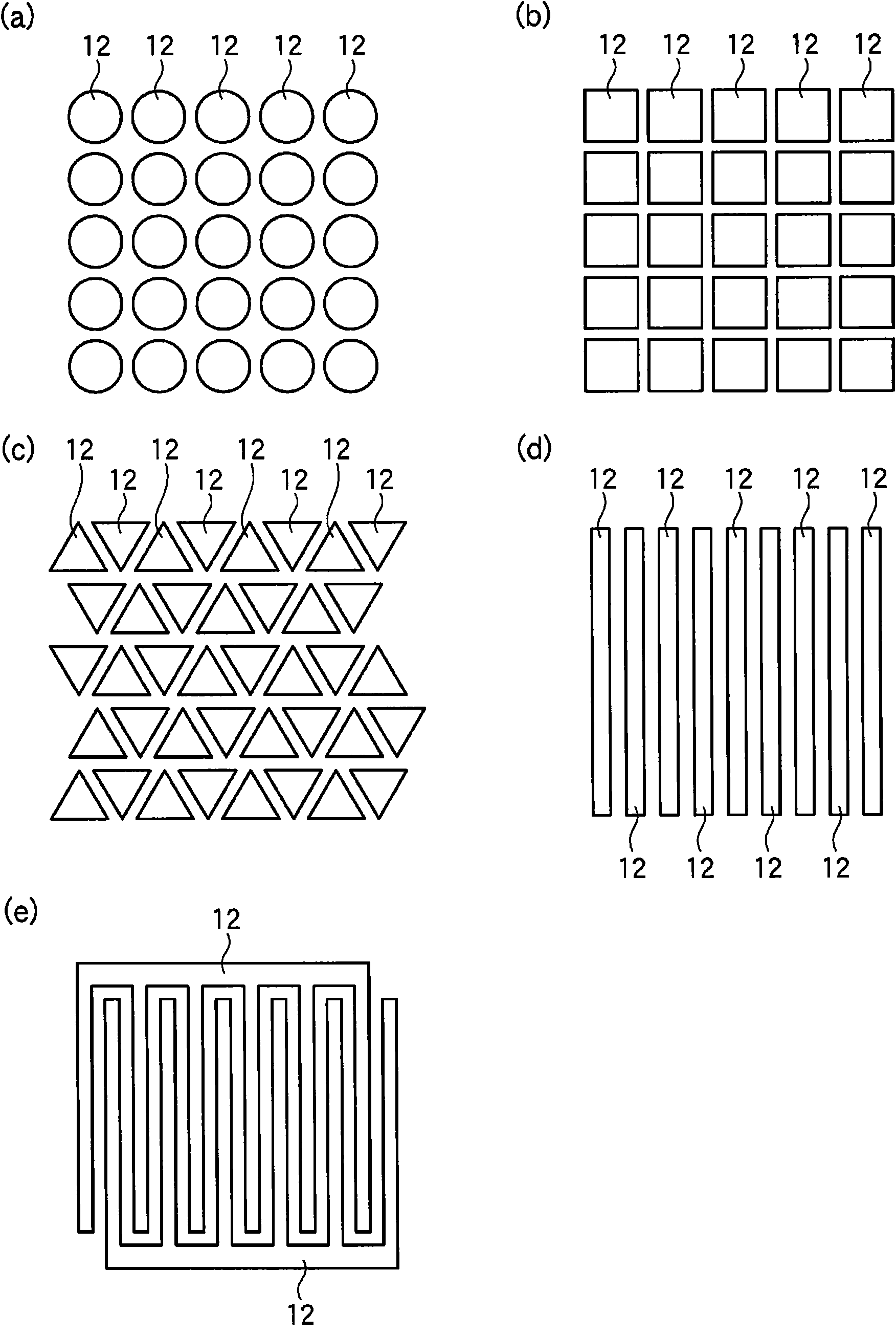

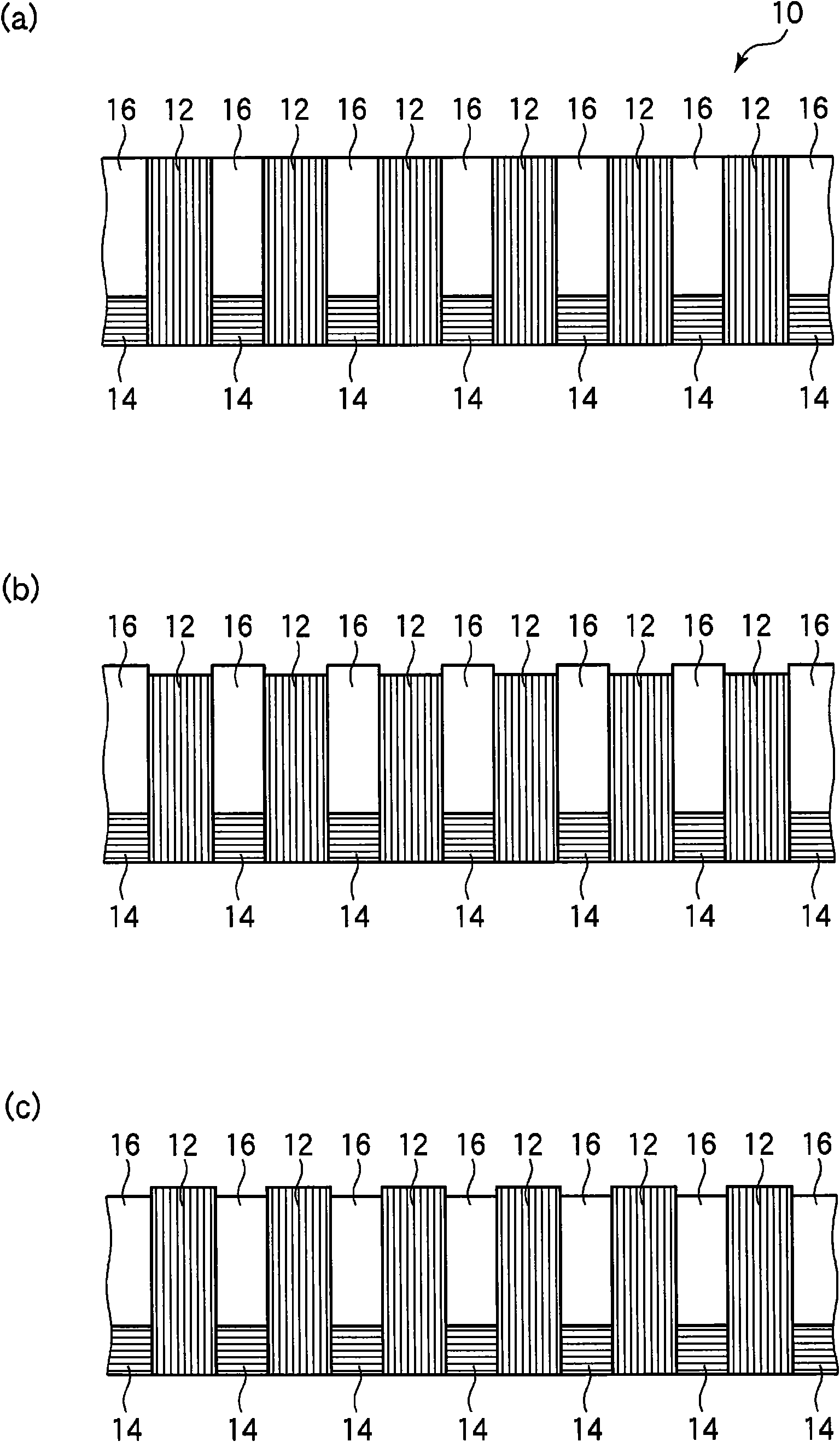

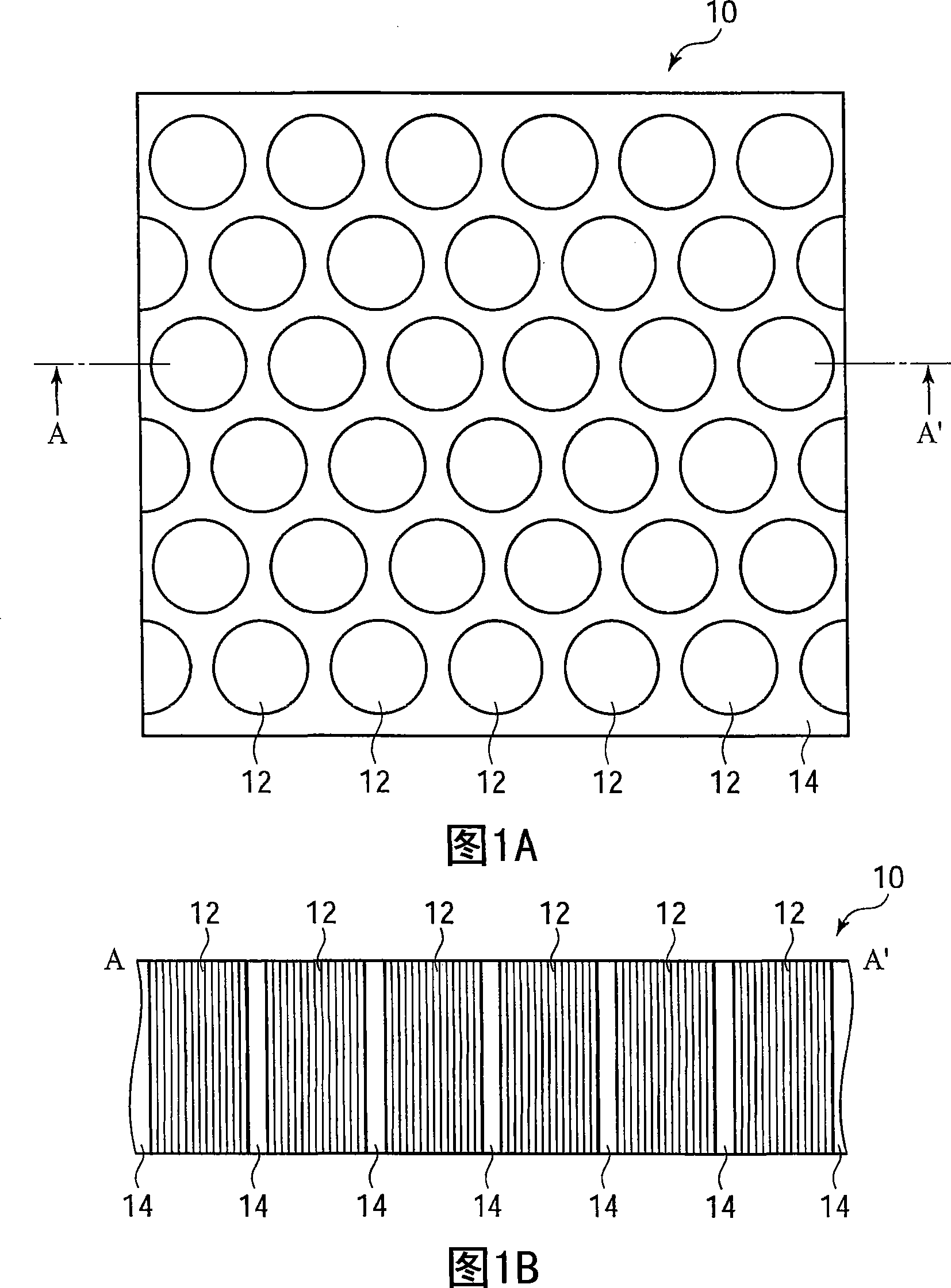

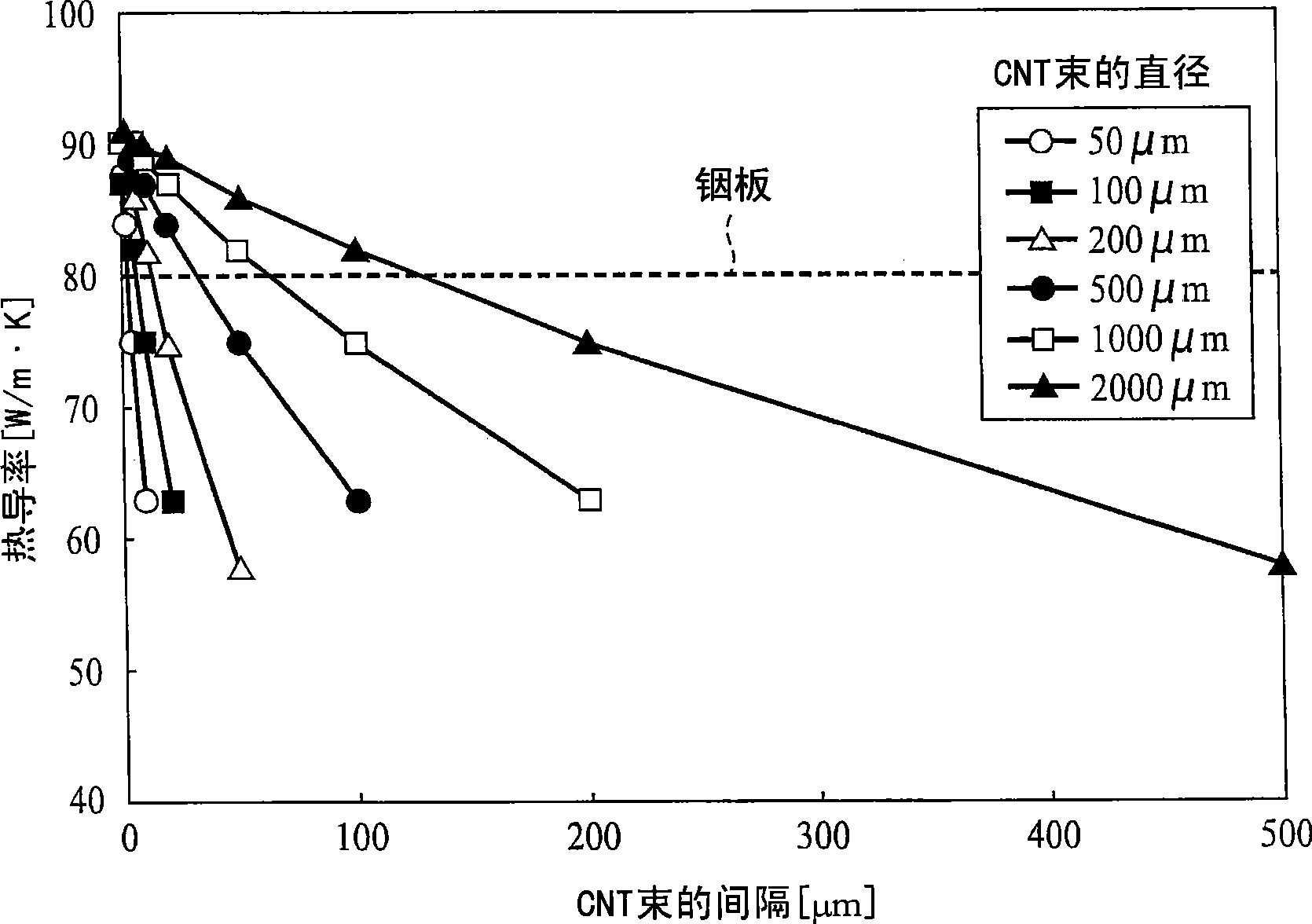

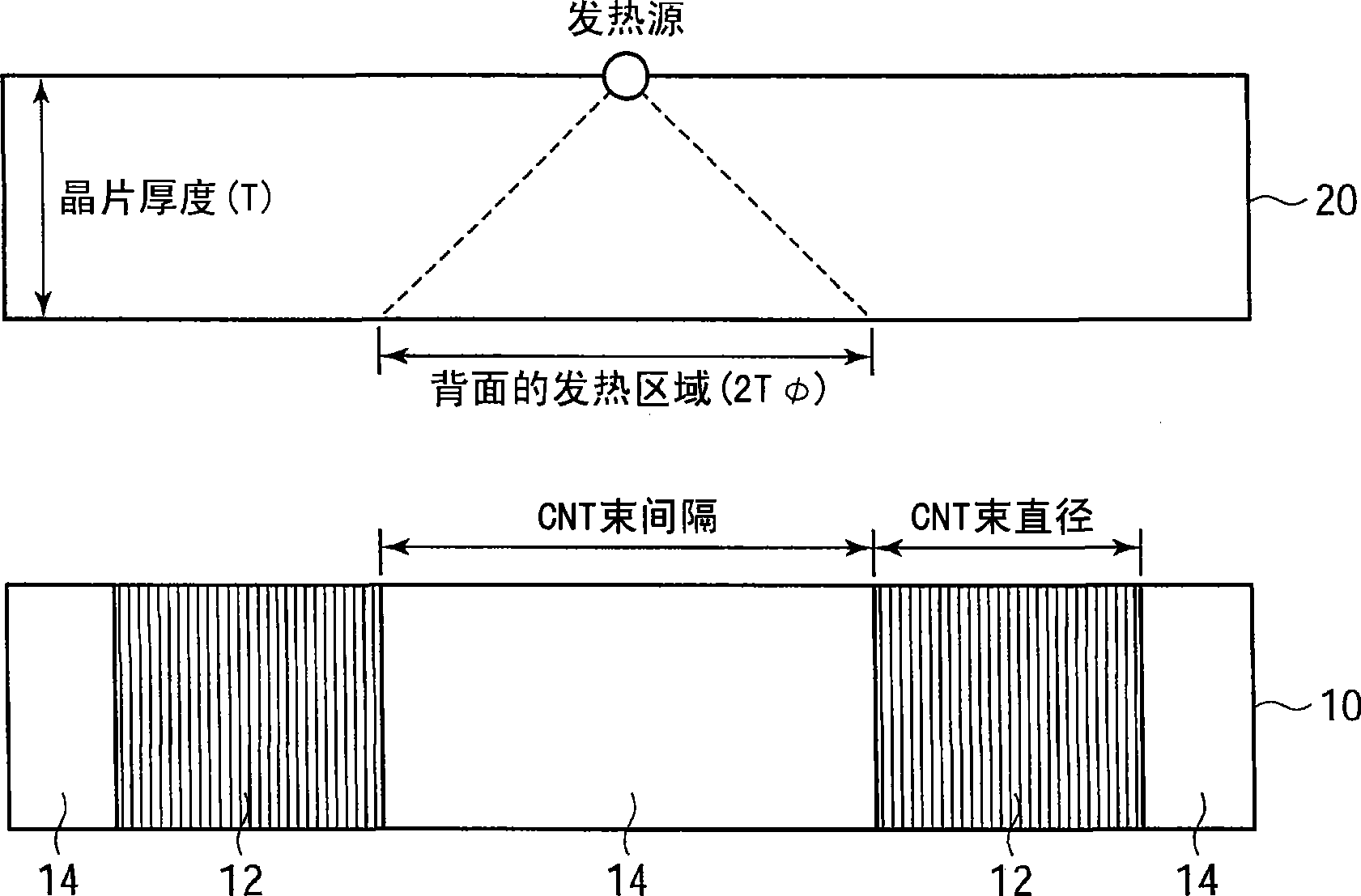

Sheet structure, semiconductor device and method of growing carbon structure

ActiveCN101959788APrevent shape changeImprove thermal conductivityMaterial nanotechnologyIndividual molecule manipulationGraphiteEngineering

The sheet structure contains a linear structure composed of multiple carbon elements disposed with a first space from each other and has multiple linear structure bundles (12) disposed with a second space larger than the first space from each other, a graphite layer (14) provided in interspaces of the multiple linear structure bundles (12) and connected to the multiple linear structure bundles and a filling layer (16) placed in the first space and second space so as to hold the multiple linear structure bundles (12) and graphite layer (14).

Owner:FUJITSU LTD

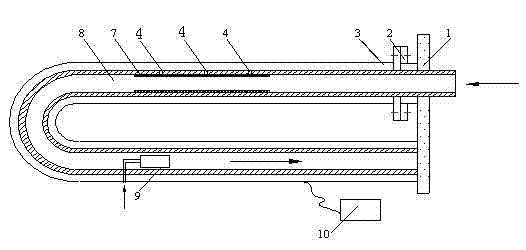

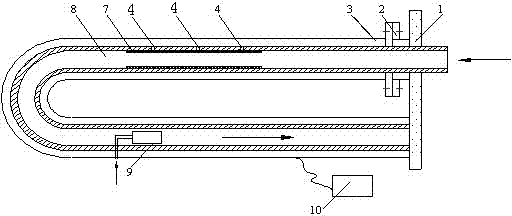

Ash-free smoke sampling device

InactiveCN102353565AAvoid accumulationAvoid frequent replacementWithdrawing sample devicesJet flowPorous ceramics

The invention relates to an ash-free smoke sampling device. The device which comprises a U-shaped sampling gun, an electric heating element, a temperature controller, a porous ceramic tube lining and a jet mechanism is characterized in that: the intermediate section of the U-shaped sampling gun is provided with the porous ceramic lining, the porous ceramic lining is provided with three sampling holes, the jet mechanism is arranged in the tail section of the U-shaped sampling gun, and the outside of the U-shaped sampling gun is provided with the built-in electric heating element and the temperature controller. The device, which is suitable for the measurement of the low ash or ash-free smoke and allows the measurement of a high ash smoke to be realized, has a very wide application temperature range, so the instantaneous sampling of a smoke from coal firing can be realized, and components of the smoke and the form thereof in various atmospheres can be accurately measured. The device of the invention, which has a simple system, provides an effective method for the research of the purification treatment of the smokes in coal-fired boilers.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

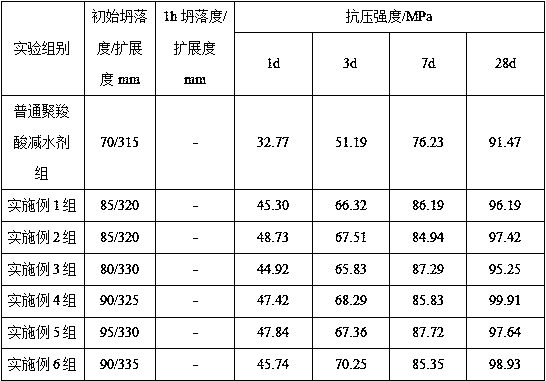

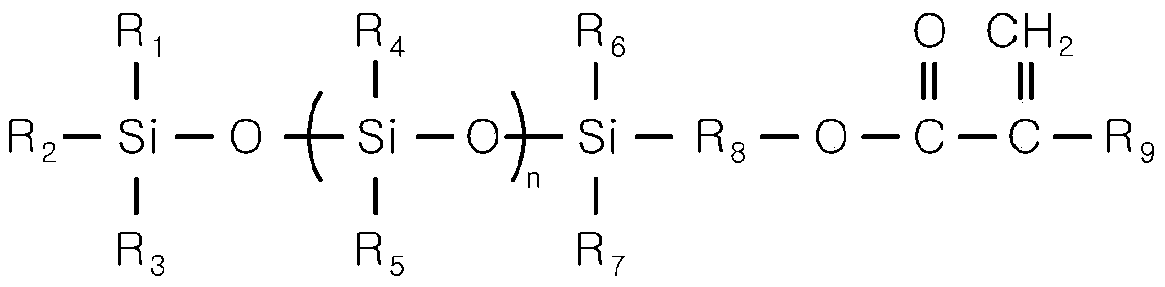

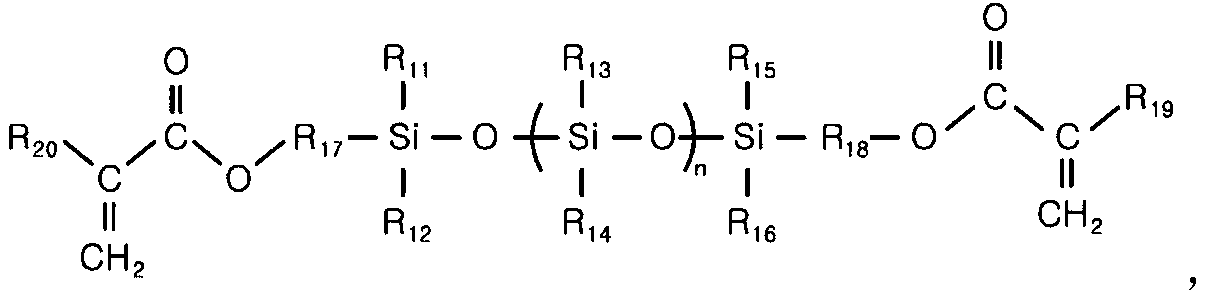

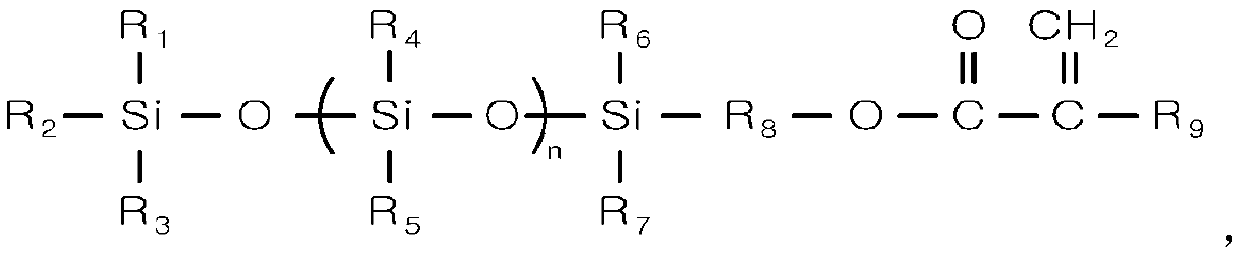

Early strength type polycarboxylic acid water reducing agent for C80 pipe pile concrete

The invention provides an early strength type polycarboxylic acid water reducing agent for C80 pipe pile concrete, wherein 1000 parts of the polycarboxylic acid water reducing agent are prepared fromthe following components by weight: 331-344 parts of a polyether macromonomer with a molecular weight of 3500-3800, 27-34 parts of acrylic acid, 4-10 parts of an amide-based small monomer, 4-10 partsof a rigid small monomer, 2-6 parts of 27.5% industrial-grade hydrogen peroxide, 2-5 parts of unsaturated sulfonate, 0.4-1.5 parts of a reducing agent, 1.8-2.4 parts of a chain transfer agent, 6-12 parts of a neutralizing agent, and the balance of water, wherein the prepared finished product has a mass fraction of 40%, and an acid-to-ether ratio is controlled at 4.3-4.8. According to the present invention, the water reducing agent molecule having the long main chain and the long branched chain is obtained by matching the amine ether macromonomer and the polyether macromonomer according to a mass ratio of 7:2, and the rigidity of the main chain can be strengthened by introducing the rigid small monomer, such that the main chain shape change caused by the too large steric hindrance of the side chain can be avoided, and the good anchoring effect of the water reducing agent molecule on the surface of the cement particles can be ensured.

Owner:HUBEI UNIV OF TECH

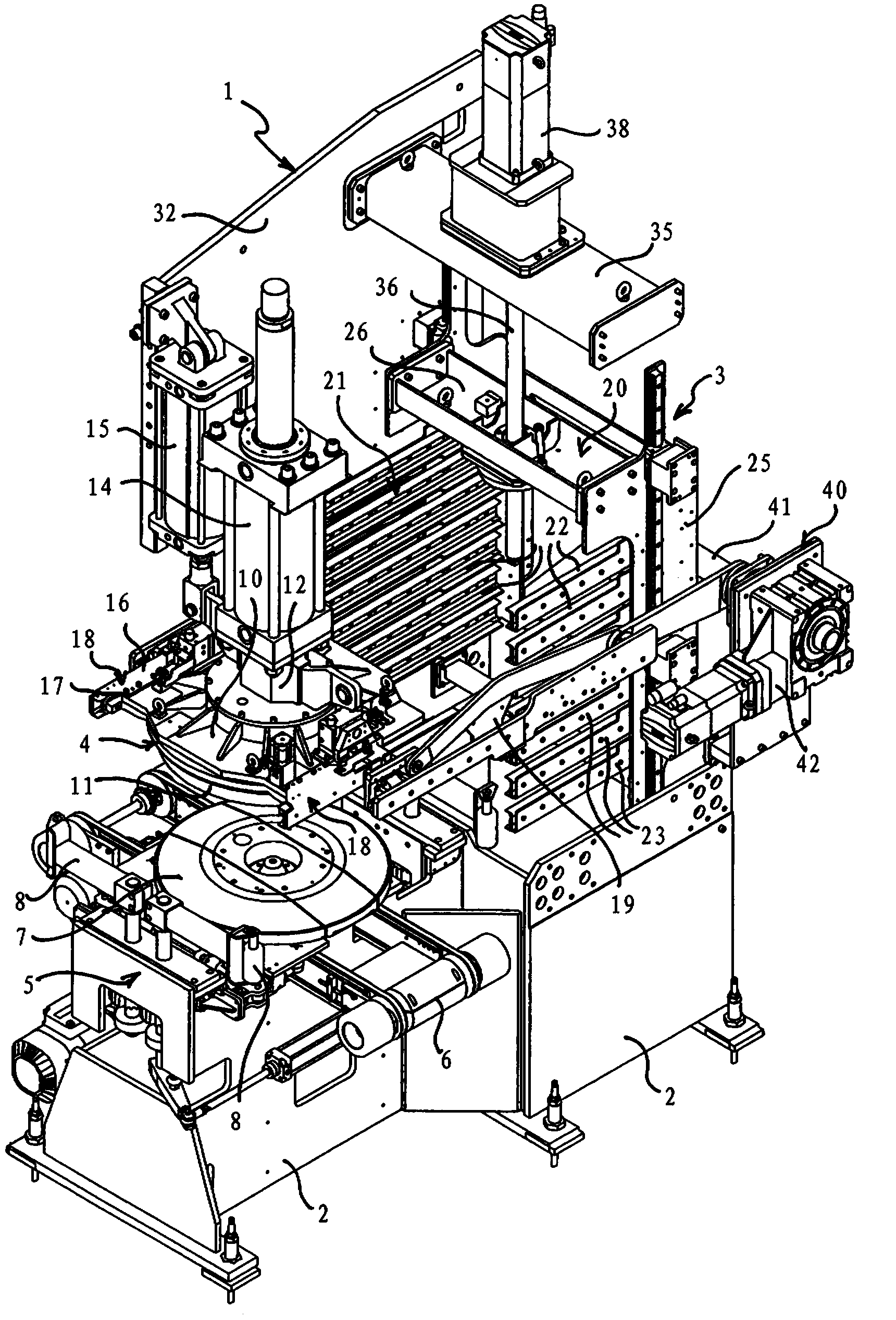

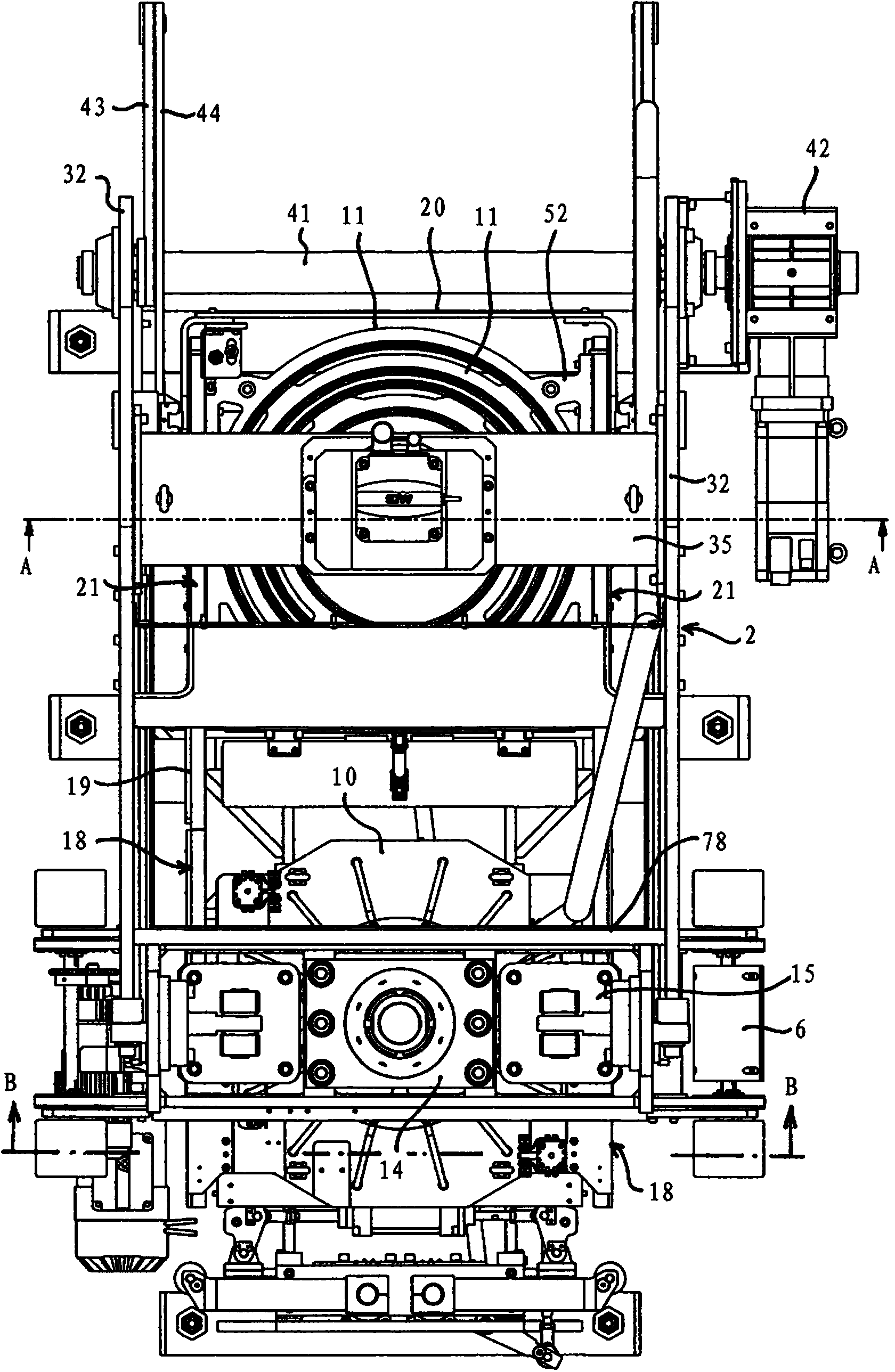

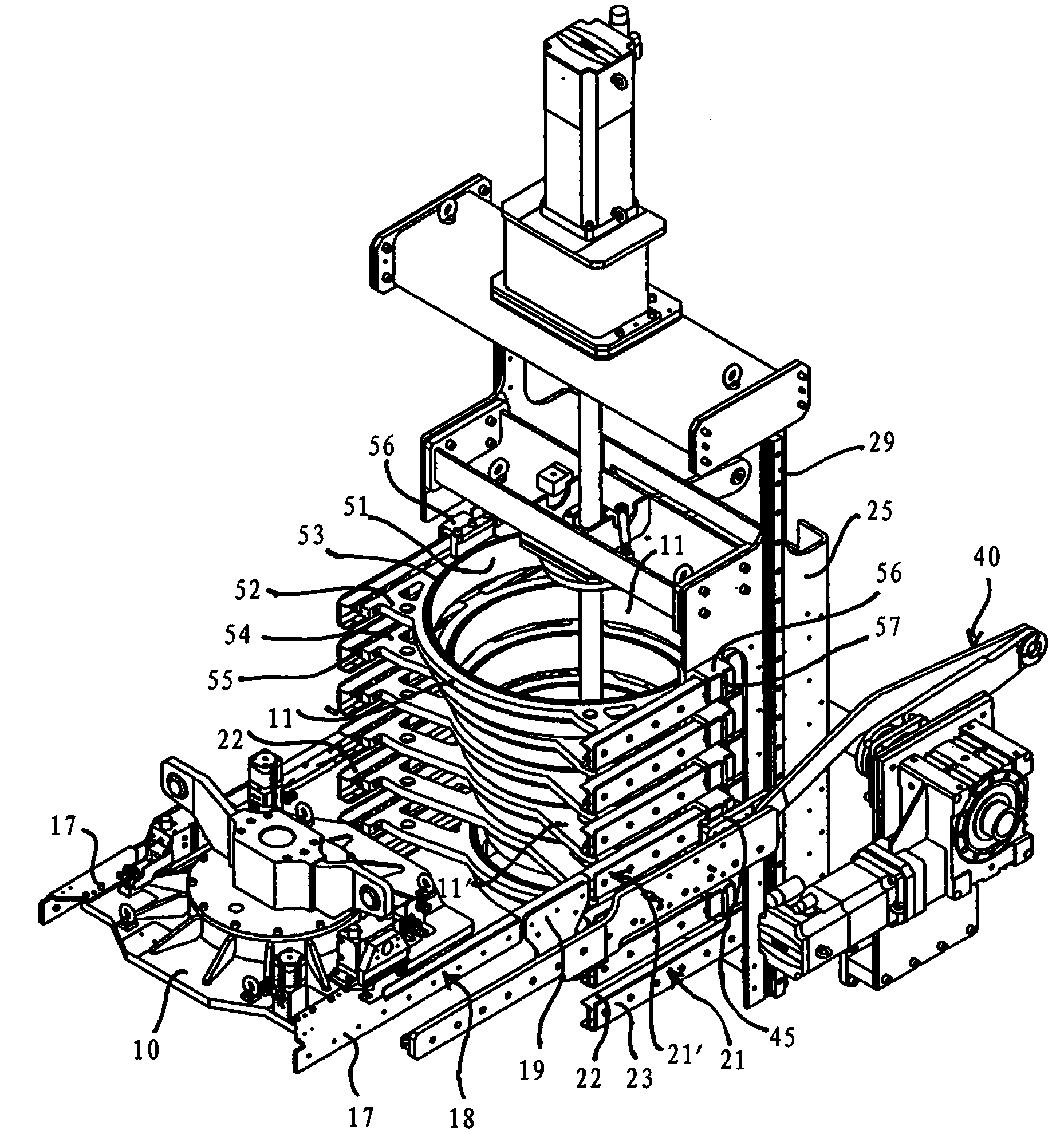

Tyre inflation device

ActiveCN104108381AReduced Tolerance RequirementsAutomatic decouplingVehicle servicing/repairingTyre repairingMechanical engineeringParallel plane

In a tire inflating device having a machine frame (2), a tire filling bell (4) arranged on the machine frame (2) and a supporting and sealing device (5) for sealing a filling chamber. The tire filling bell (4) is comprised of a filling plate (10) and a separate filling ring (11). A magazine (3) has a magazine rack (20) and magazine guides (21) lying in a plurality of parallel planes, each of said guides being able to hold a filling ring (11, 11′) mounted so that it can move. The magazine rack (20) and the filling plate (10) can be moved with respect to each other into a plurality of transfer positions in the direction of the axis of rotation. The magazine guide (21) in each case is connected to a filling plate guide (18) arranged on the filling plate (10) in said transfer positions. A filling ring (11) which is located in the magazine guide (21) arranged in the transfer position can be conveyed by a conveying device (40) into a filling plate guide and a centered position on the filling plate (10).

Owner:SCHENCK ROTEC GMBH

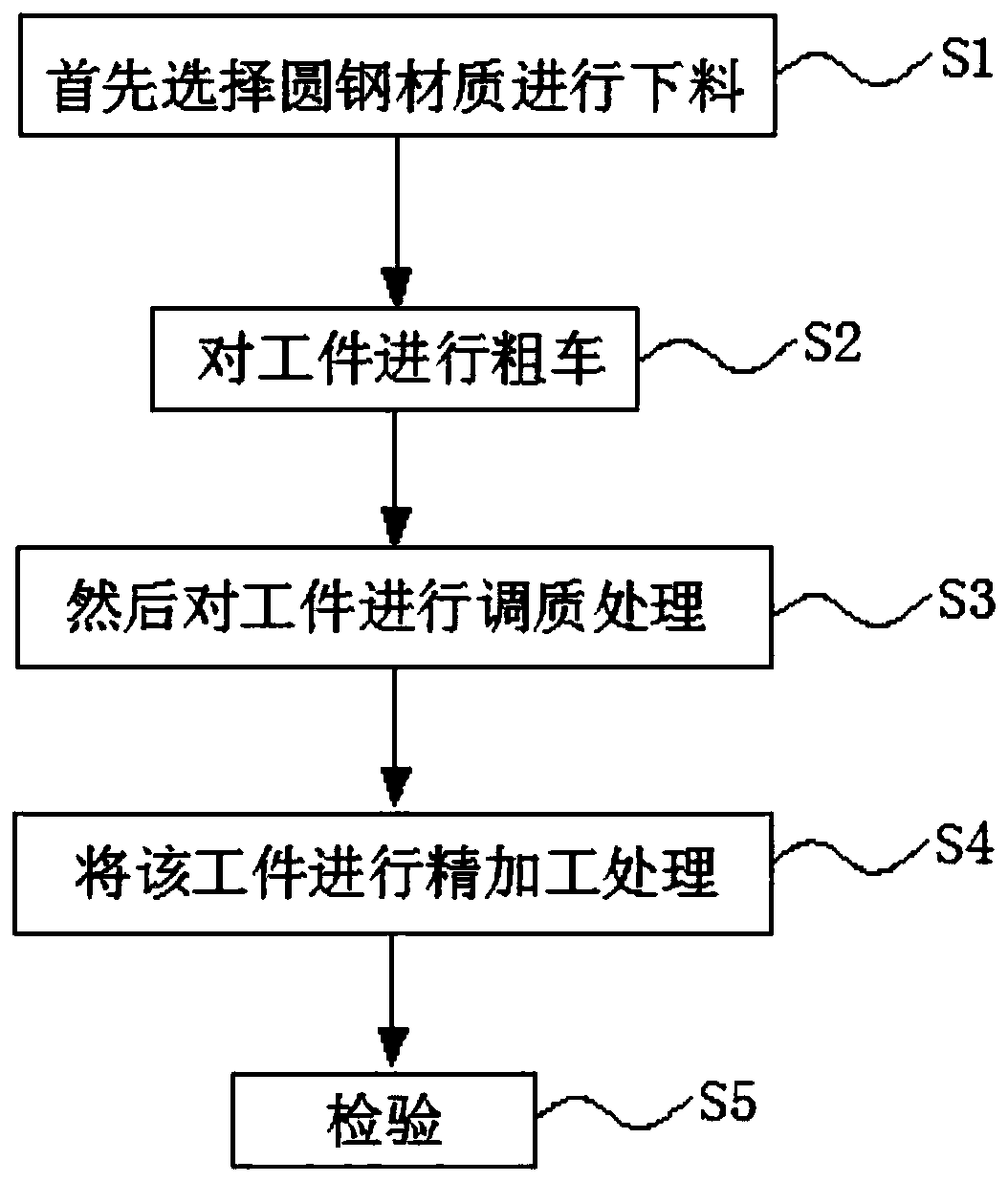

Gear broaching process for thin-wall internal spline shaft

The invention discloses a gear broaching process for a thin-wall internal spline shaft, and relates to the technical field of internal spline shaft machining. The gear broaching process specifically comprises the following steps that S1, firstly, a round steel material is selected for blanking, and the round steel material is cut into the size required by an internal spline shaft through cutting equipment according to the required workpiece size to form a workblank; and S2, rough turning is carried out on the workpiece, the cut workblank is polished through polishing equipment, after polishingis completed, the workpiece is clamped through a clamp, then rough machining is carried out on an inner hole, an outer circle and the length of the workpiece through a horizontal lathe, so that the workpiece is made to be close to the final shape and size, and 0.4mm - 1mm machining allowance is correspondingly reserved for the inner hole, the outer circle and the length of the workpiece after rough turning. According to the gear broaching process for the thin-wall internal spline shaft, the gear broaching process is adopted to replace a gear shaping process to machine an internal spline, theproduct machining precision is improved, the product quality is stabler, the product damage rate is reduced, the economic loss is reduced, and the loss of a cutter is small.

Owner:HUBEI JIANFENG TECH INC

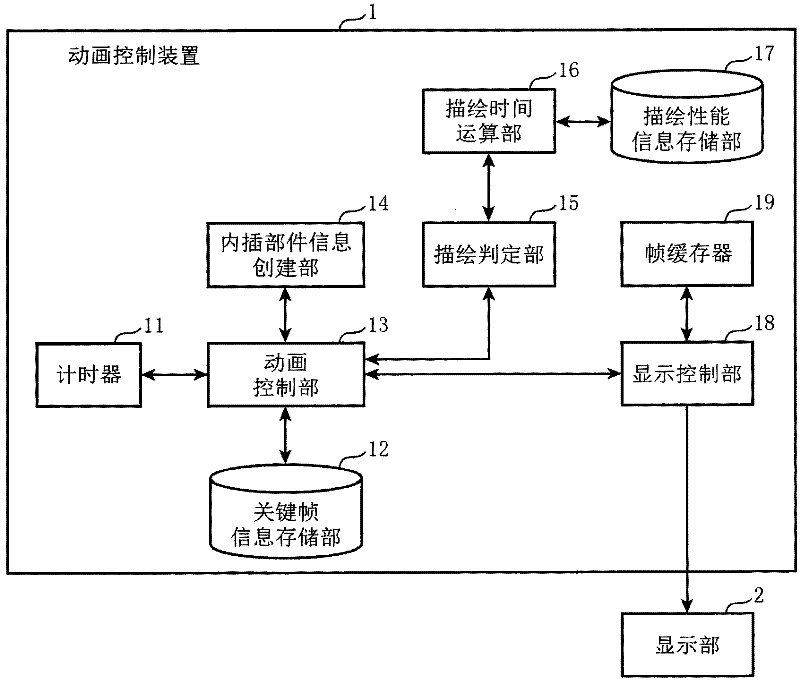

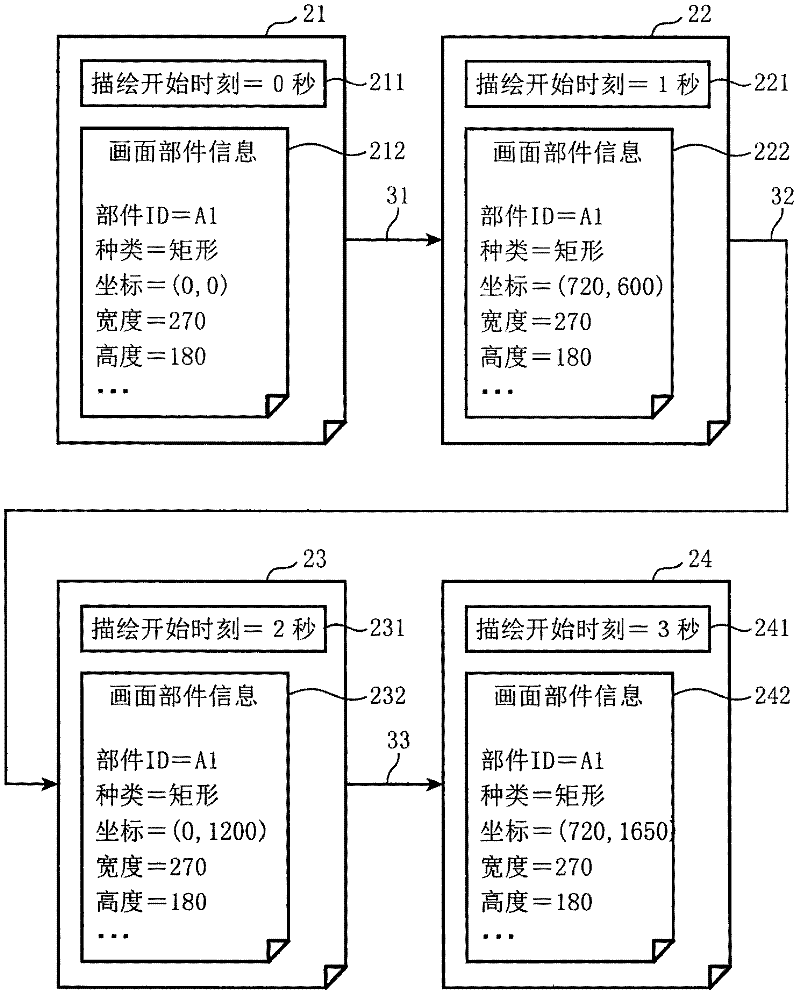

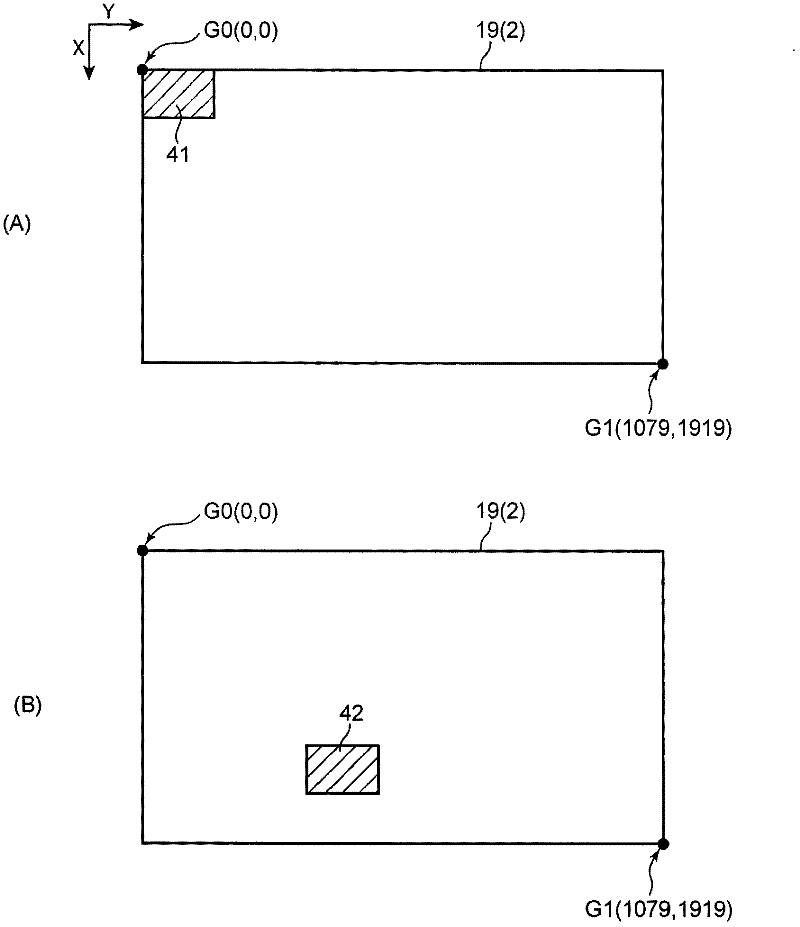

Animation control device, animation control method and animation control program

Owner:PANASONIC CORP

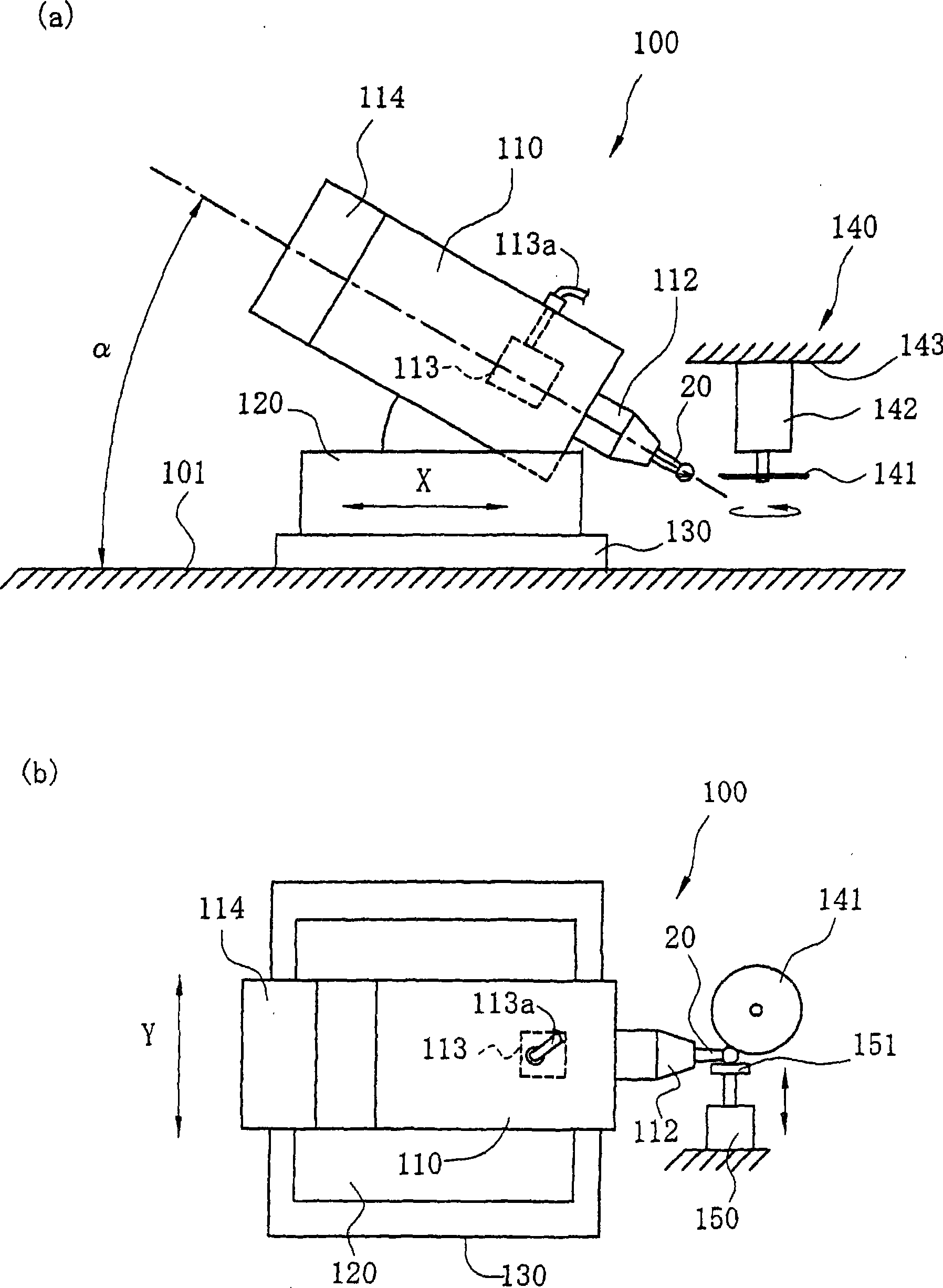

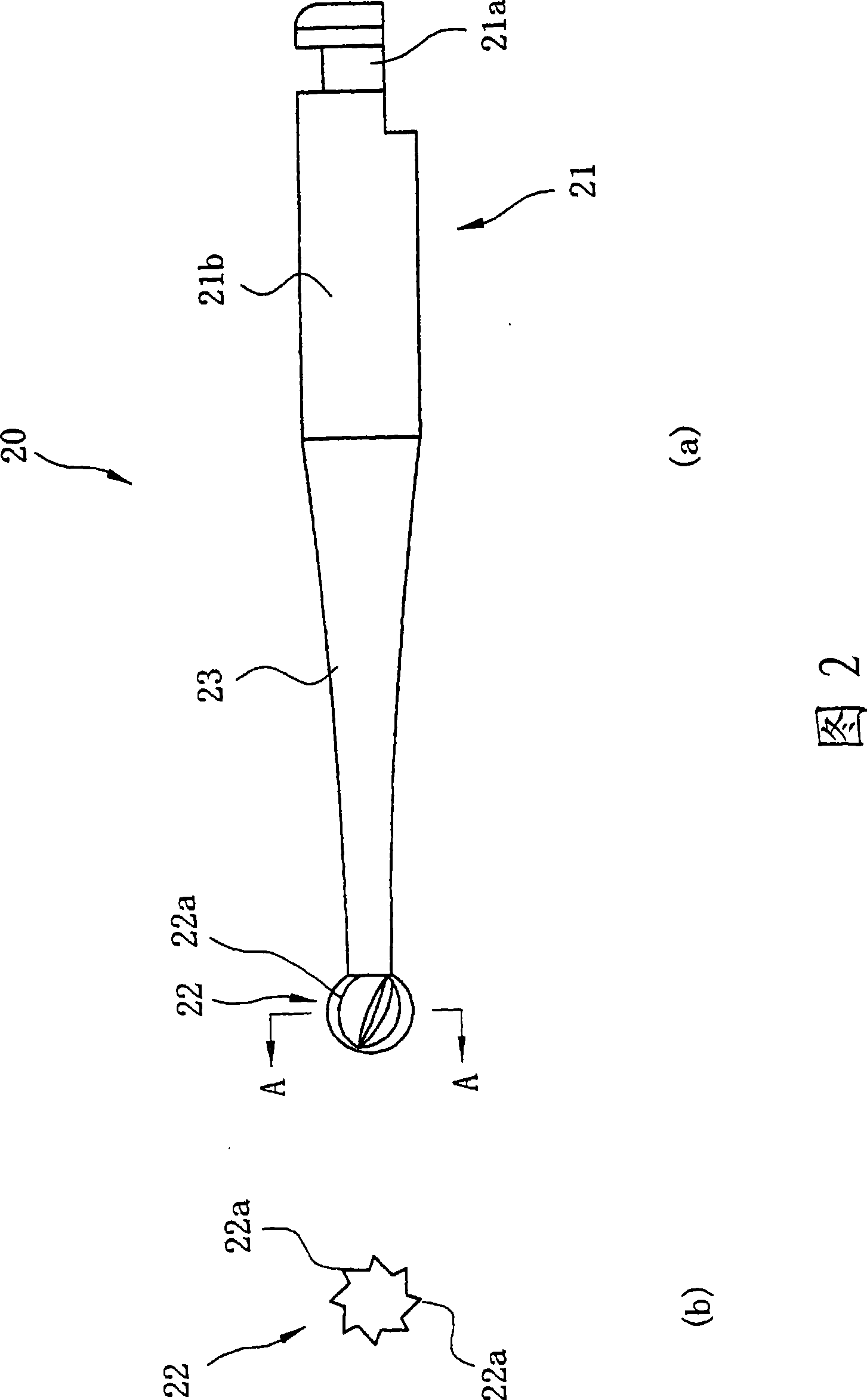

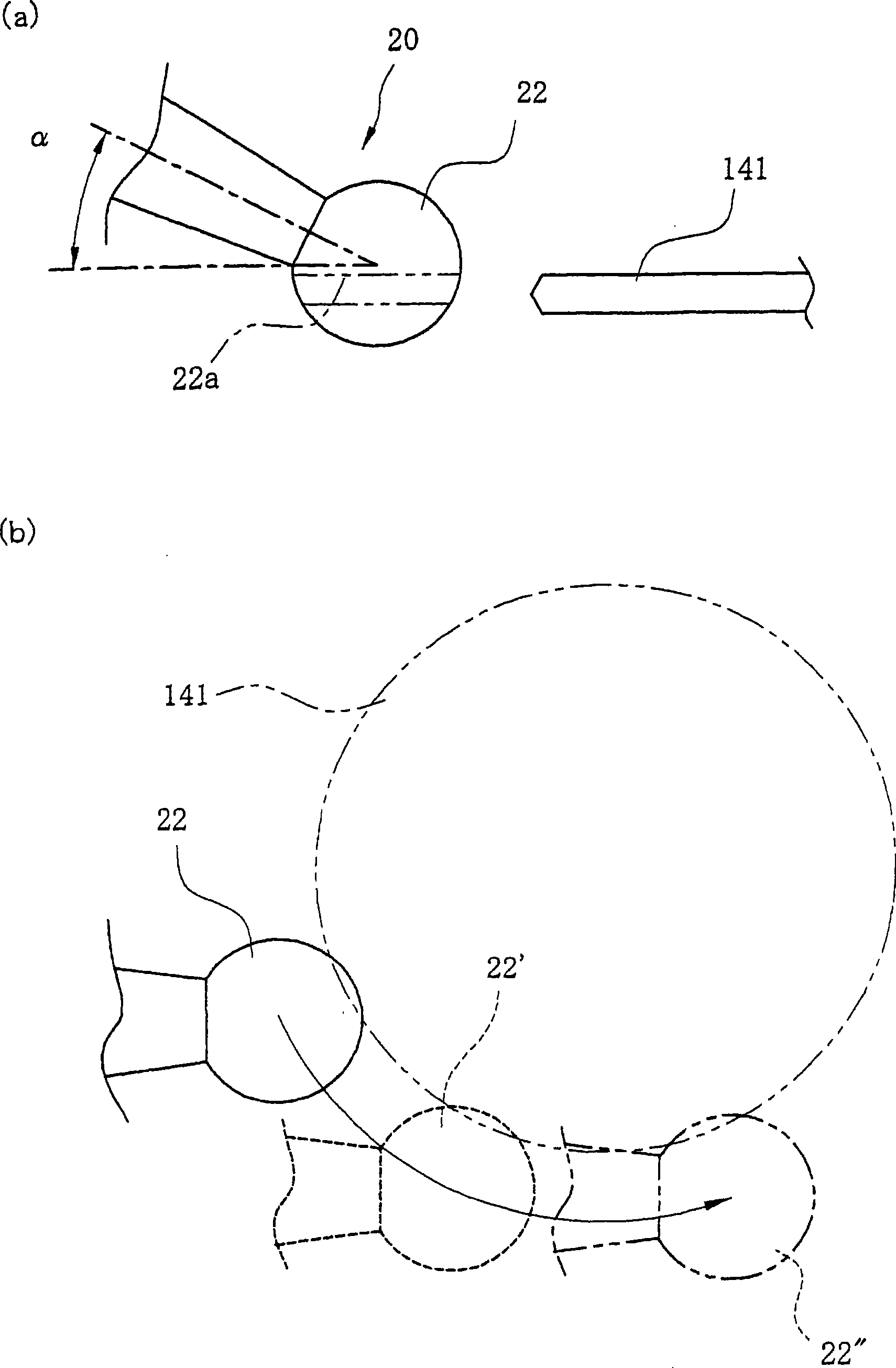

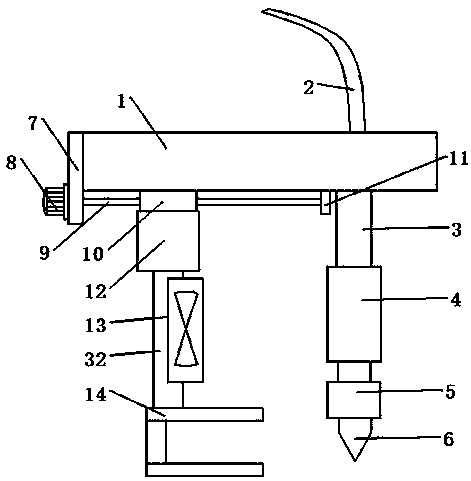

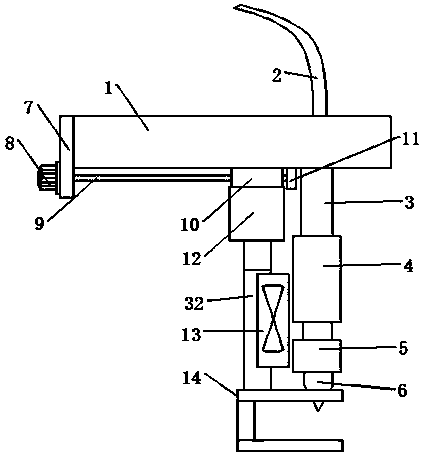

Medical cutting tool manufacturing apparatus and method

The invention provides a medical cutting tool manufacturing apparatus, which can form cutting blades to the top face with a simple structure, and a manufacturing method for the same are provided. The medical cutting tool manufacturing apparatus of the present invention, which manufactures a medical cutting tool such as a steel bar having a plurality of cutting blades at the tip of a working section, includes a main shaft, which includes a chuck that holds the steel bar in a freely detachable manner; a main shaft support, which holds the main shaft allowing change in a slant angle of the main shaft; an XY table, which freely moves the main shaft support in X and Y axis directions; and a rotatable disc whetstone, which forms the cutting blades in the working section of the medical cutting tool held by the chuck. The whetstone has a structure within the horizontal plane (XY plane).

Owner:MATSUTANI SEISAKUSHO CO LTD

Sheet structure and method of manufacturing the same

InactiveCN101420840AWell formedImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringMulti beam

The invention provides a plate structure with heat diffusivity and high electrical conductivity comprising the linear structure of the carbon element and manufacturing method thereof and an electric device using the plate structure. The plate structure has multiple beam linear structure (12), including each other to maintain their space the way the first configuration includes a number of linear carbon structure, and a number of thread-like structures described in beam (12) to each other than the first gap to maintain the second largest allocation of space the way; filler layer (14), filled between the first and the second gap for the structure to maintain a number of linear beams (12).

Owner:FUJITSU LTD

Separator enclosures for electrodes and electrochemical cells

ActiveUS9991492B2Improve battery performanceAvoid material lossBatteries circuit arrangementsCell electrodesEngineeringContact force

The disclosure provides electrochemical cells including a separator enclosure which encloses at least a portion of a positive or negative electrode. In an embodiment, the separator generates a contact force or pressure on at least a portion of the electrode which can improve the performance of the cell. The disclosure also provides methods for charging an electrochemical cell.

Owner:CALIFORNIA INST OF TECH

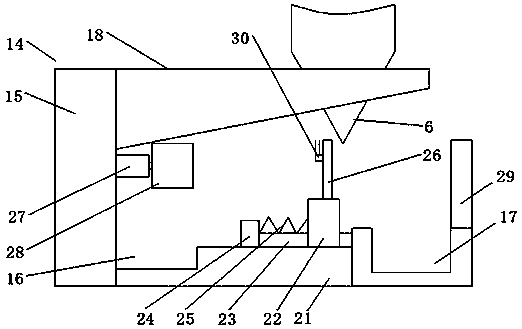

Improved 3D printing device

ActiveCN107553903AGuaranteed temperatureAvoid damageAdditive manufacturing apparatus3D object support structuresState of artSpray nozzle

The invention discloses an improved 3D printing device. The improved 3D printing device comprises a first support, a feeding pipe, a spraying head, a raw material pipe, a spray nozzle, a heater, a first motor, a screw rod, a first slider, a cylinder and a cleaning part; the cleaning part comprises a third support; a first scraper blade is connected to the upper portion of the outer side of the third support, and is provided with a first notch; the edge of the first notch is connected with an elastic film; a bottom plate is connected to the lower portion of the outer side of the third support;a slide rail is connected to the bottom plate, and is movably sleeved with a second slider; a fixing block is further fixedly connected to the inner side of the slide rail; a spring is connected between the fixing block and the second slider; a second scraper blade is connected to the upper portion of the fixing block; a second notch is formed in the top of the second scraper blade; a brush is further connected to the upper portion of the second scraper blade; a second material storing box is further fixedly connected to the outer side of the bottom plate; and a blocking plate is fixedly connected to the outer side of the second material storing box. The improved 3D printing device can overcome the defects in the prior art and has a better remaining glue clearing effect.

Owner:ZHONGSHAN GREATSIMPLE TECH CO LTD

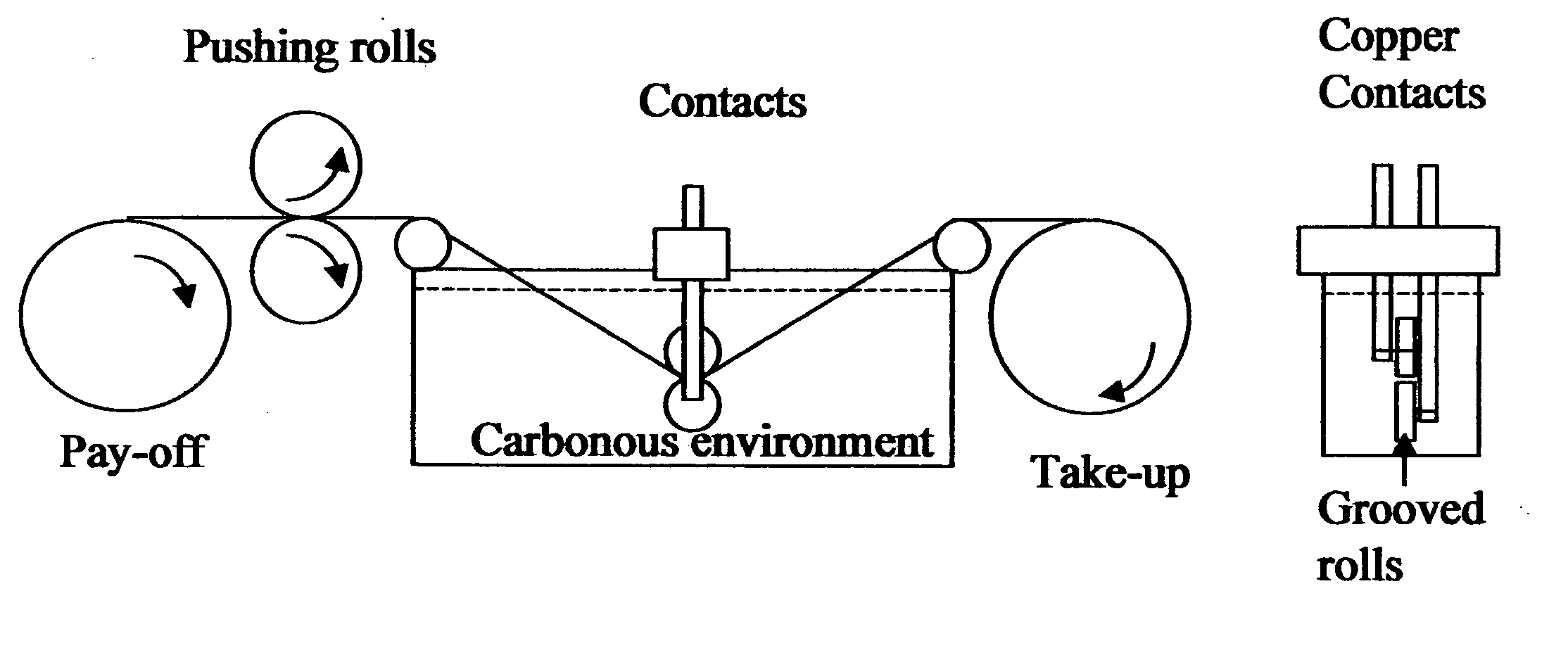

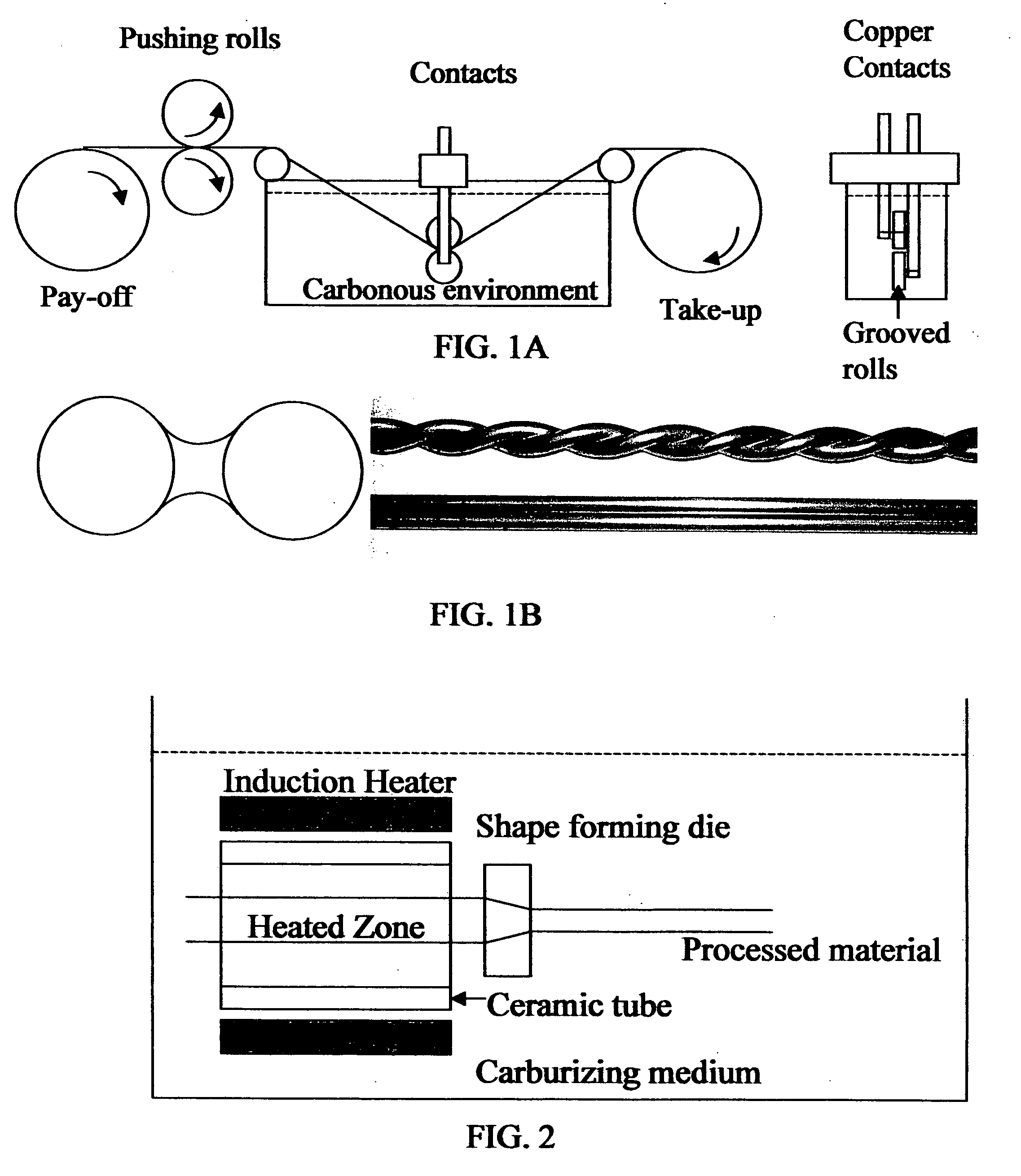

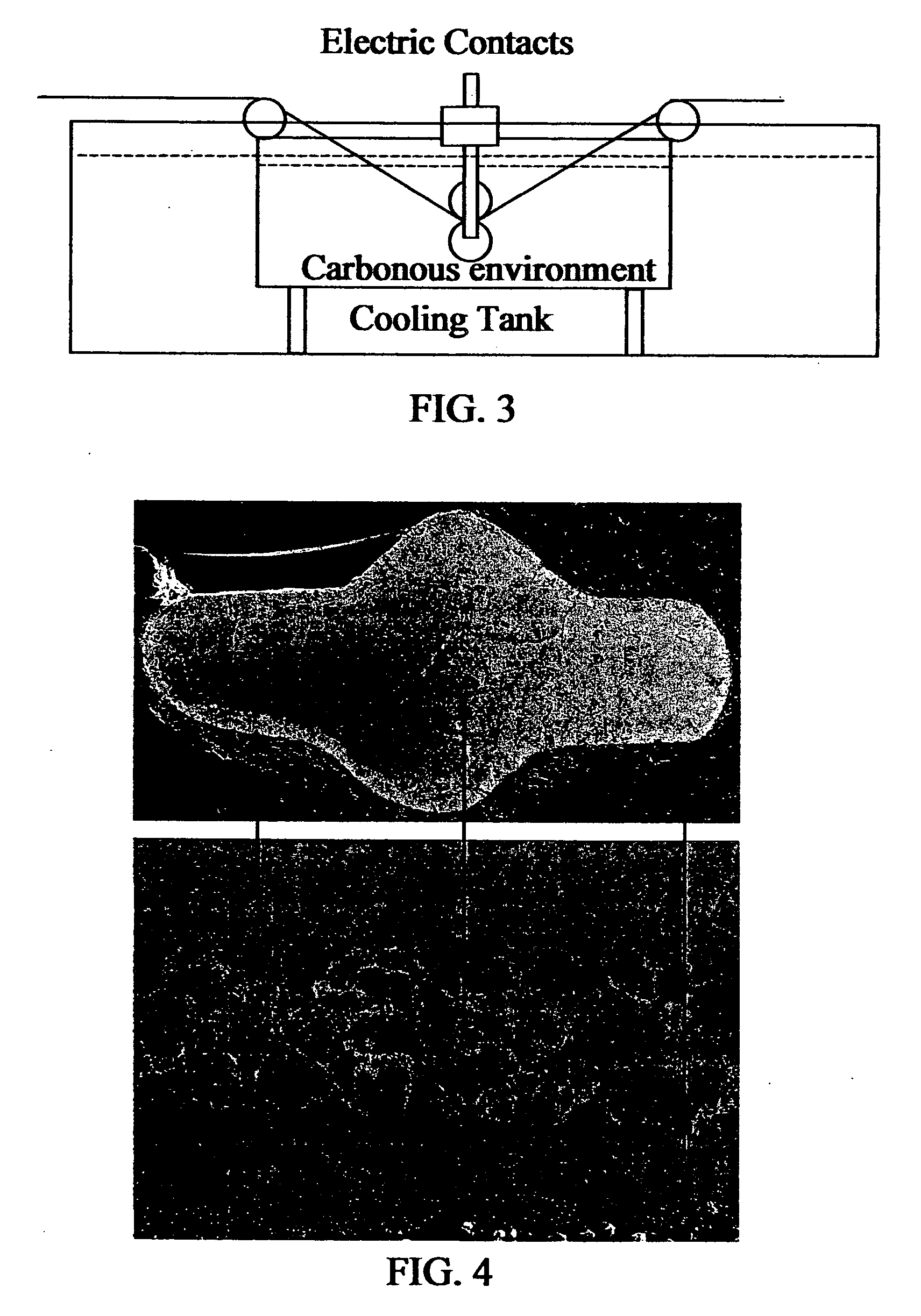

Long products, method of thermo-chemical treatment and apparatus

InactiveUS20070095434A1Add depthLarge depthSolid state diffusion coatingBiomedical engineeringThermo chemical

The invention provides long products with stiffness controlled by the cross sectional shape, method of their thermo-chemical treatment, and apparatus for forming the final shape of the long products and thermo-chemical treatment.

Owner:ZELIM MICHAEL GREGORY

Adhesive film and optical member comprising same

PendingCN111094483AAvoid damagePrevent shape changeNon-macromolecular adhesive additivesOptical filtersPolymer scienceMeth-

Provided are an adhesive film and an optical member comprising same, the adhesive film comprising at least two types of (meth)acrylic monomers for a (meth)acrylic prepolymer, and (meth)acrylate containing silicon, wherein the release force of the adhesive film with respect to a polyimide film is approximately 0.5 gf / in to 5 gf / in.

Owner:SAMSUNG SDI CO LTD

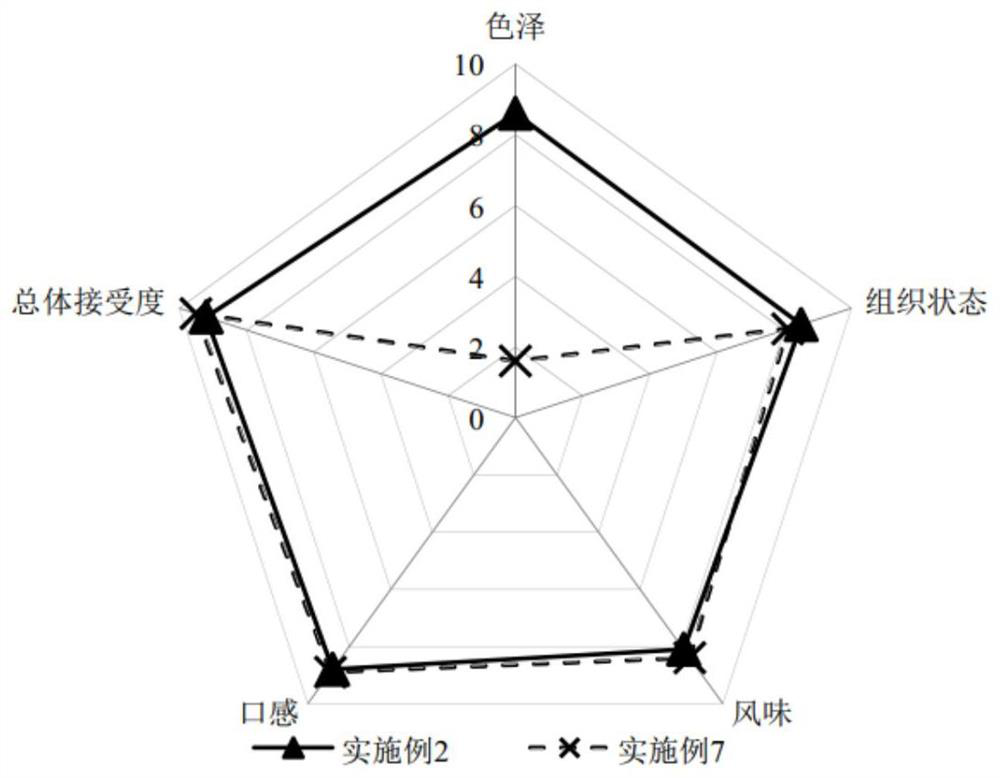

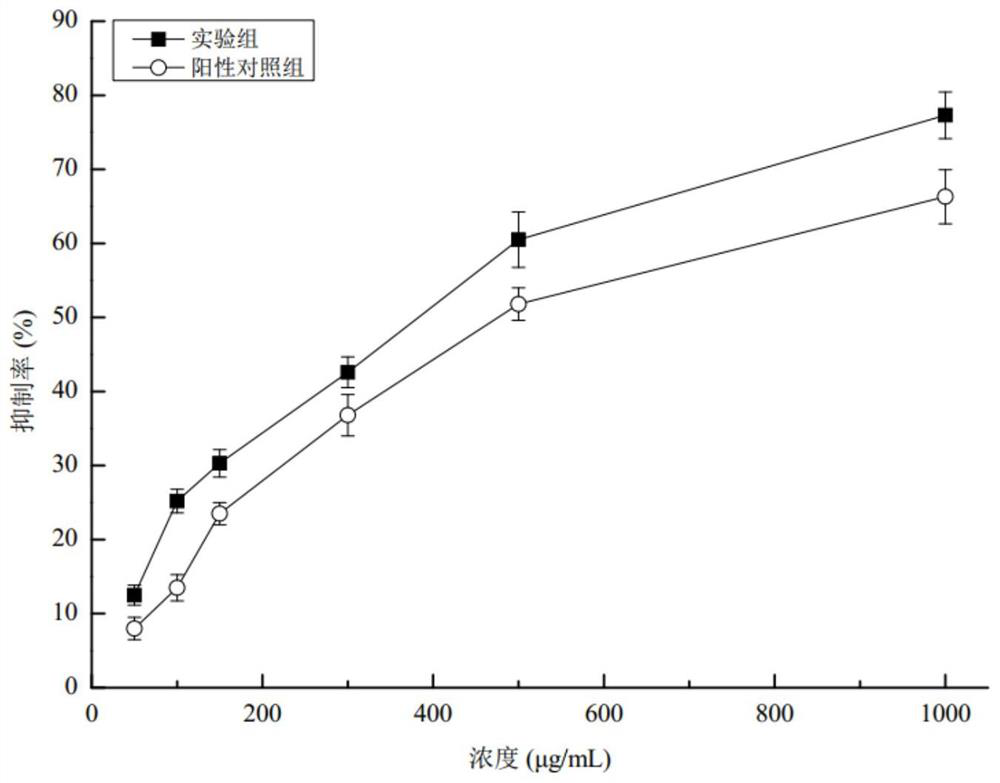

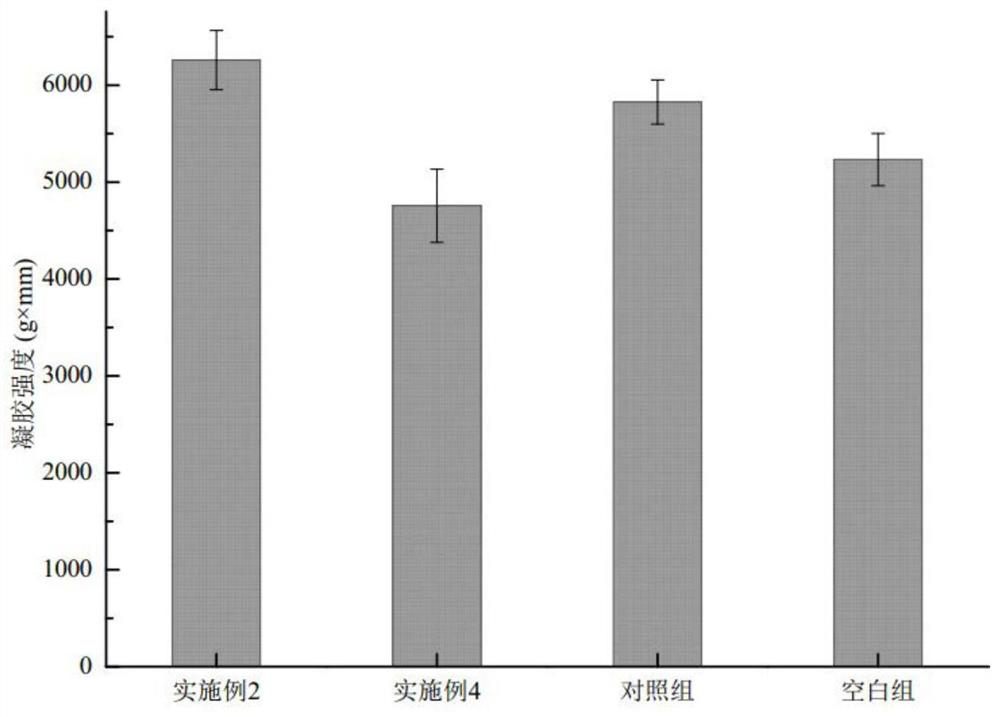

Vegetable protein vegetarian sausage and preparation method thereof

PendingCN112450447AReduce contentImprove healthOrganic chemistryMetabolism disorderChemistryGlycemic

The invention provides a vegetable protein vegetarian sausage and a preparation method thereof, and relates to the technical field of food processing. The vegetable protein vegetarian sausage comprises a casing and stuffing. The stuffing comprises main raw materials composed of vegetable protein. The stuffing further comprises a gel accelerator, and the gel accelerator is a ferulic acid derivative. The preparation method comprises the following steps of emulsifying the vegetable protein to obtain an emulsion; mixing and stirring the emulsion, an auxiliary material and the gel accelerator to prepare the stuffing; filling the casing with the stuffing to form a semi-finished product; and curing and cooling the semi-finished product to obtain the vegetable protein vegetarian sausage. The vegetarian sausage provided by the invention has the characteristics of high protein, low cholesterol and low fat, provides sufficient amino acids, remarkably reduces the calories of the sausage, has no obvious difference from meat sausages in sense, and has high gel strength and stability; and after being eaten, the vegetable protein vegetarian sausage can show the effect of inhibiting the activity ofalpha-glucosidase, is helpful to reduce the fluctuation of postprandial blood sugar, and has the effect of inhibiting postprandial hyperglycemia.

Owner:浙江波拉波拉食品股份有限公司 +1

Information acquisition apparatus, cross section evaluating apparatus and cross section evaluating method

InactiveCN101266909APrevent shape changeAccurate Morphological AnalysisMaterial analysis using wave/particle radiationElectric discharge tubesBiomedical engineeringInformation acquisition

The invention provides a cross section evaluating apparatus capable of analyzing the cross sectional structure in a state where the temperature of the specimen is regulated. There is disclosed an information acquisition apparatus comprising a stage for placing the specimen, temperature regulation means for regulating the temperature of the specimen, exposure means for exposing a surface, of which information is desired, of the specimen, and information acquisition means for acquiring information relating to the surface exposed by the exposure means.

Owner:CANON KK

Fabric press for garment processing

ActiveCN110924026APrevent shape changeAvoid problems requiring higher power operationTextile shapingRatchetElectric machinery

The invention discloses a fabric press for garment processing. The fabric press comprises a main machine body; pipe troughs are formed on both front and rear lateral surfaces of the main machine body,and a water tank is clamped and fixed on the main machine body; a motor slot is pre-formed on the front lateral surface of the main machine body, and a servo motor is fixedly mounted in the motor slot; a motor shaft of the servo motor is connected with one end of a first belt gear by a first ratchet mechanism; and the motor shaft of the servo motor is connected with one end of a second belt gearby a second ratchet mechanism. The fabric press for garment processing can be convenient to fulfill the aim of pressing a fabric by a structure similar with a scissor jack, avoids a problem that a conventional press requires a high power to operate, and is beneficial for saving electric energy; moreover, when the fabric is conveyed, the press can absorb heat energy absorbed on the fabric due to pressing so as to avoid a change of the shape of the fabric in the fabric winding process; and meanwhile, the fabric press for garment processing can be convenient to regulate a pressure for pressing, so that the press can be applicable to fabrics made of different materials.

Owner:HUNAN UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com