Plastic pipe shape correcting device for plastic pipe production line

A plastic pipe and production line technology, applied in applications, household appliances, tubular objects, etc., can solve the problems of plastic pipe final product impact, plastic pipe deformation, etc., to ensure product quality and prevent shape changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

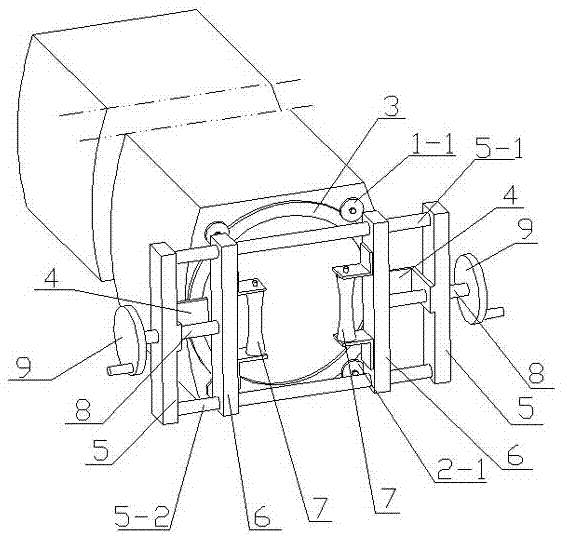

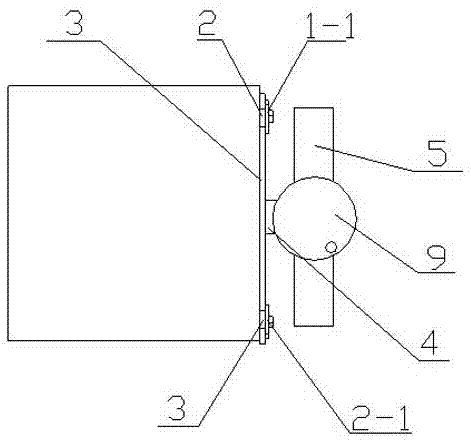

[0008] Such as figure 1 As shown, the present invention consists of a pair of upper positioning rollers 1, a pair of lower positioning rollers 2, a rotating disk 3, a pair of upper limit blocks 1-1, a pair of lower limit blocks 2-1, a pair of bearings 4, a pair of Fixed plate 5, upper connecting rod 5-1, lower connecting rod 5-2, a pair of clamping blocks 6, a pair of correction rollers 7, a pair of screw mandrels 8 and a pair of hand wheels 9, a pair of upper positioning rollers 1 and A pair of lower positioning rollers 2 are respectively installed at the entrance of the cooling spray box of the plastic pipe production line. In contact with the lower positioning roller 2, a pair of upper positioning blocks 1-1 are respectively installed on a pair of upper positioning rollers 1, a pair of lower positioning blocks 2-1 are respectively installed on a pair of lower positioning rollers 2, and a pair of bearings 4 Installed on the rotating disk 3, a pair of fixed plates 5 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com