Patents

Literature

551 results about "Thermo chemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy Efficient Methods to Produce Products

InactiveUS20080193989A1Improve energy efficiencyEnergy efficiencyBiofuelsWaste based fuelBiomassChemistry

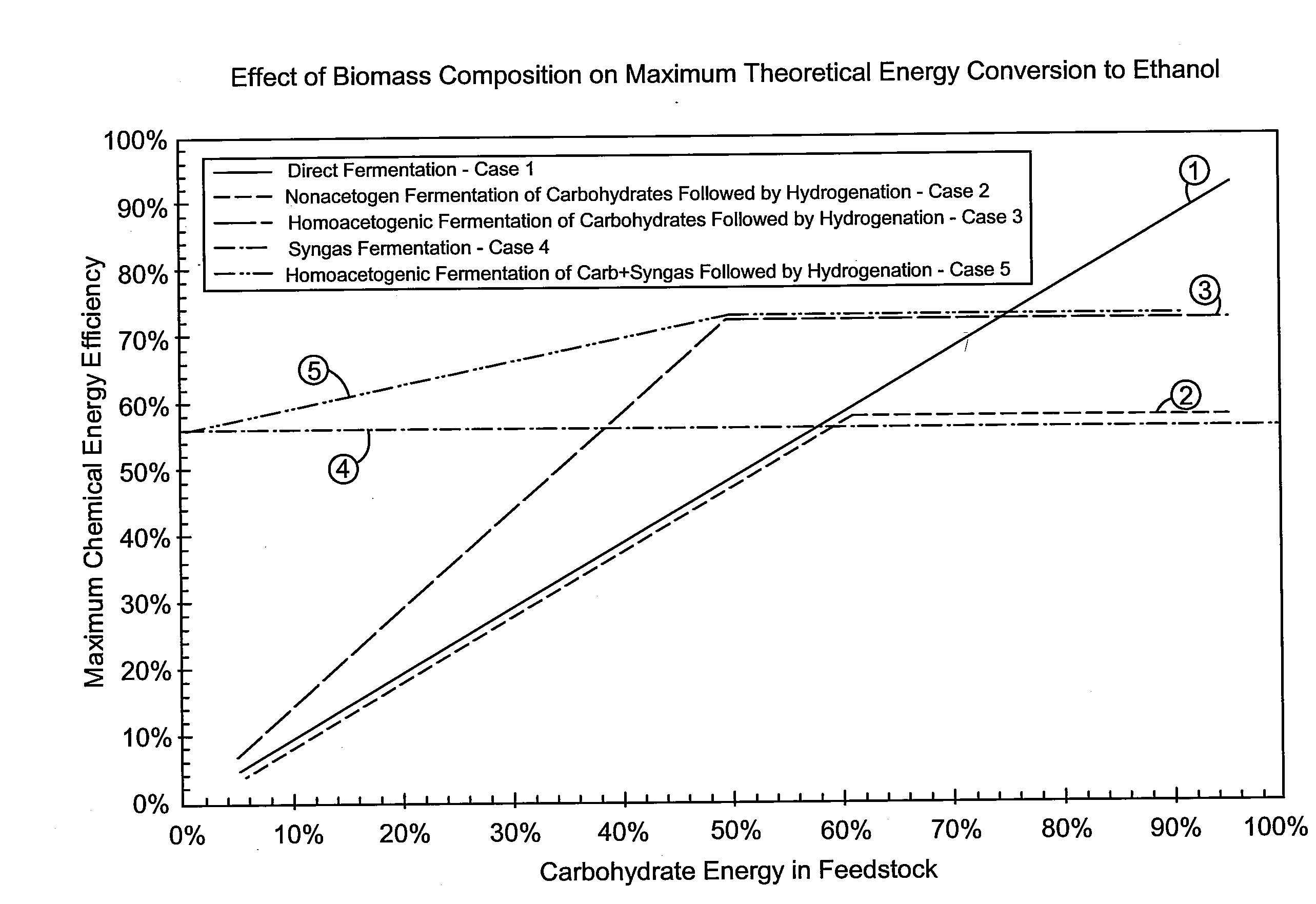

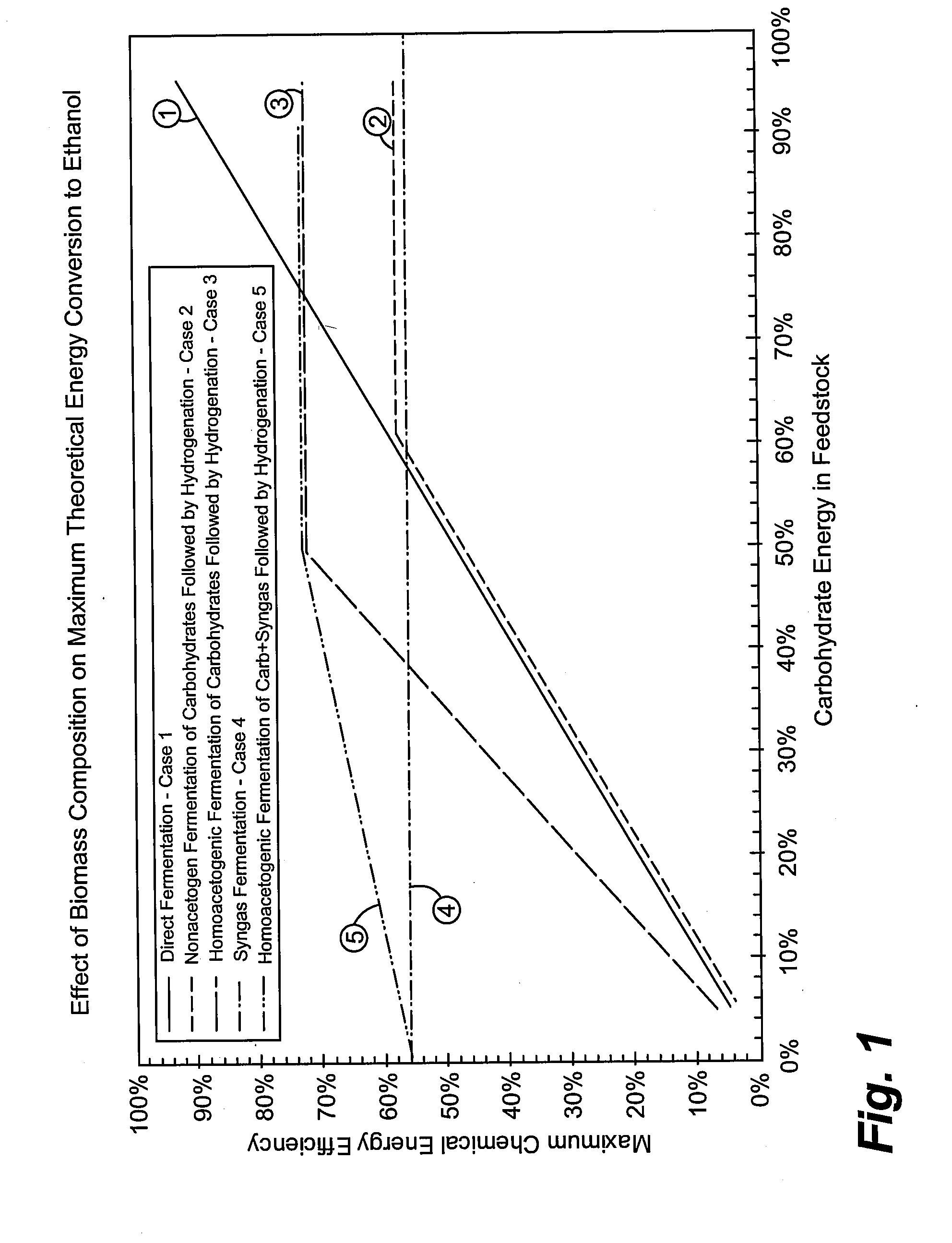

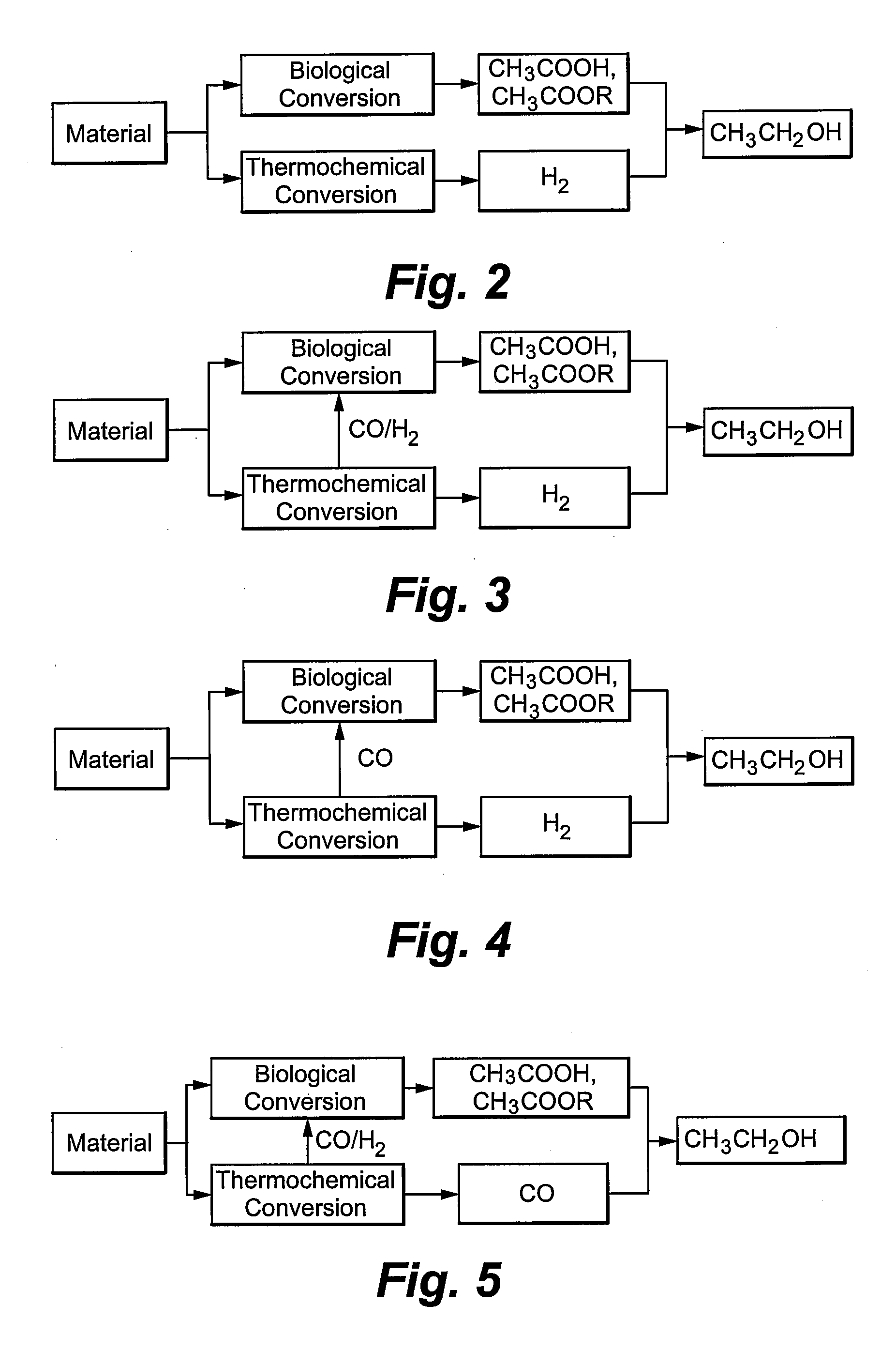

The invention relates to processes that efficiently convert carbon-containing materials, such as biomass, into products in such a manner that the energy, carbon, and mass content of the materials are efficiently transferred into such products. Such methods include converting the materials into at least one intermediate by a biological conversion process and at least one intermediate by a thermochemical conversion process and reacting the intermediates to form the product. Such methods have a chemical energy efficiency to produce the product that is greater than the chemical energy efficiency of a solely biological conversion process to produce the product and that is greater than the chemical energy efficiency of a process in which all of the material is initially subjected to a thermochemical conversion step as part of the process to produce the product.

Owner:ZEACHEM

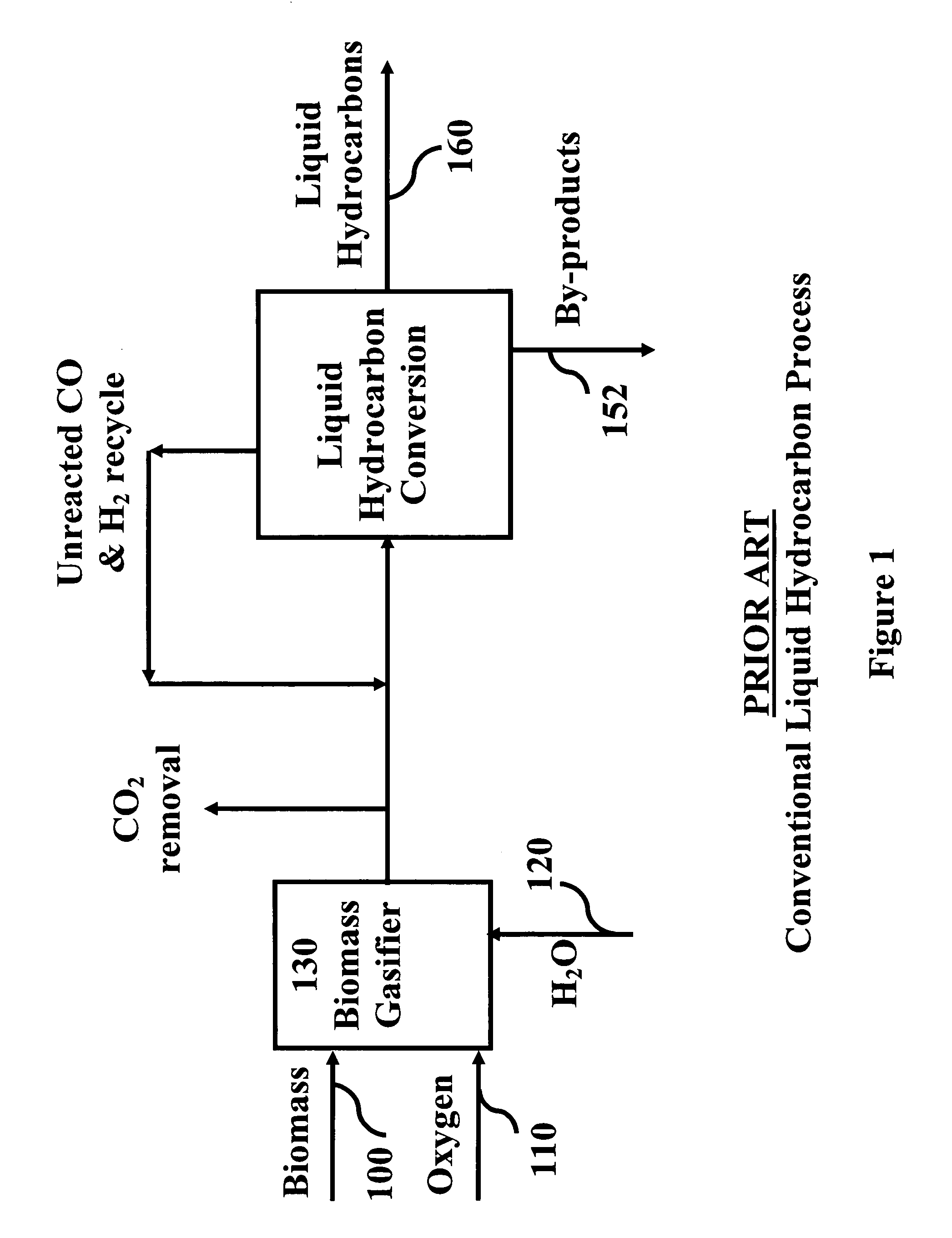

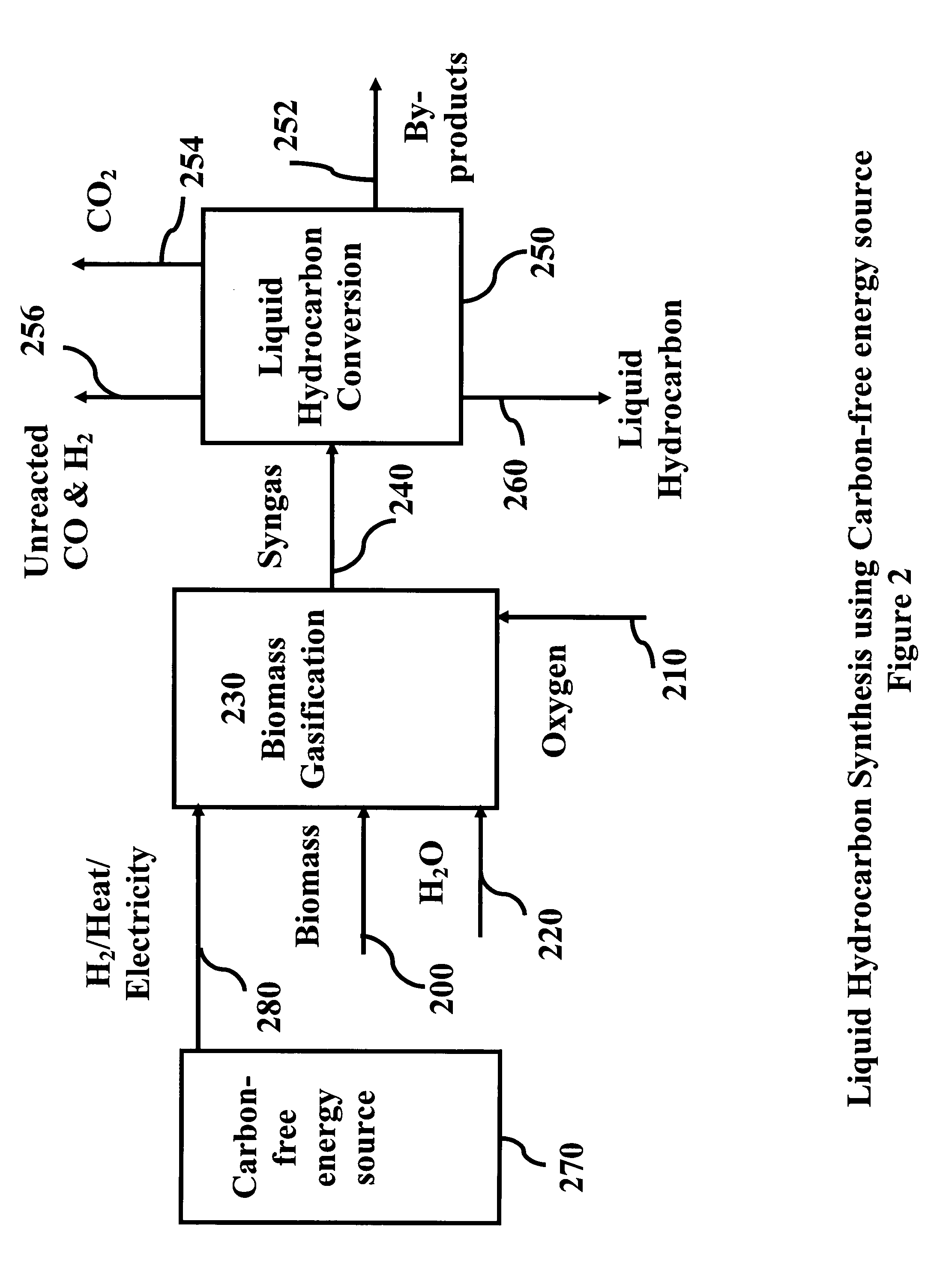

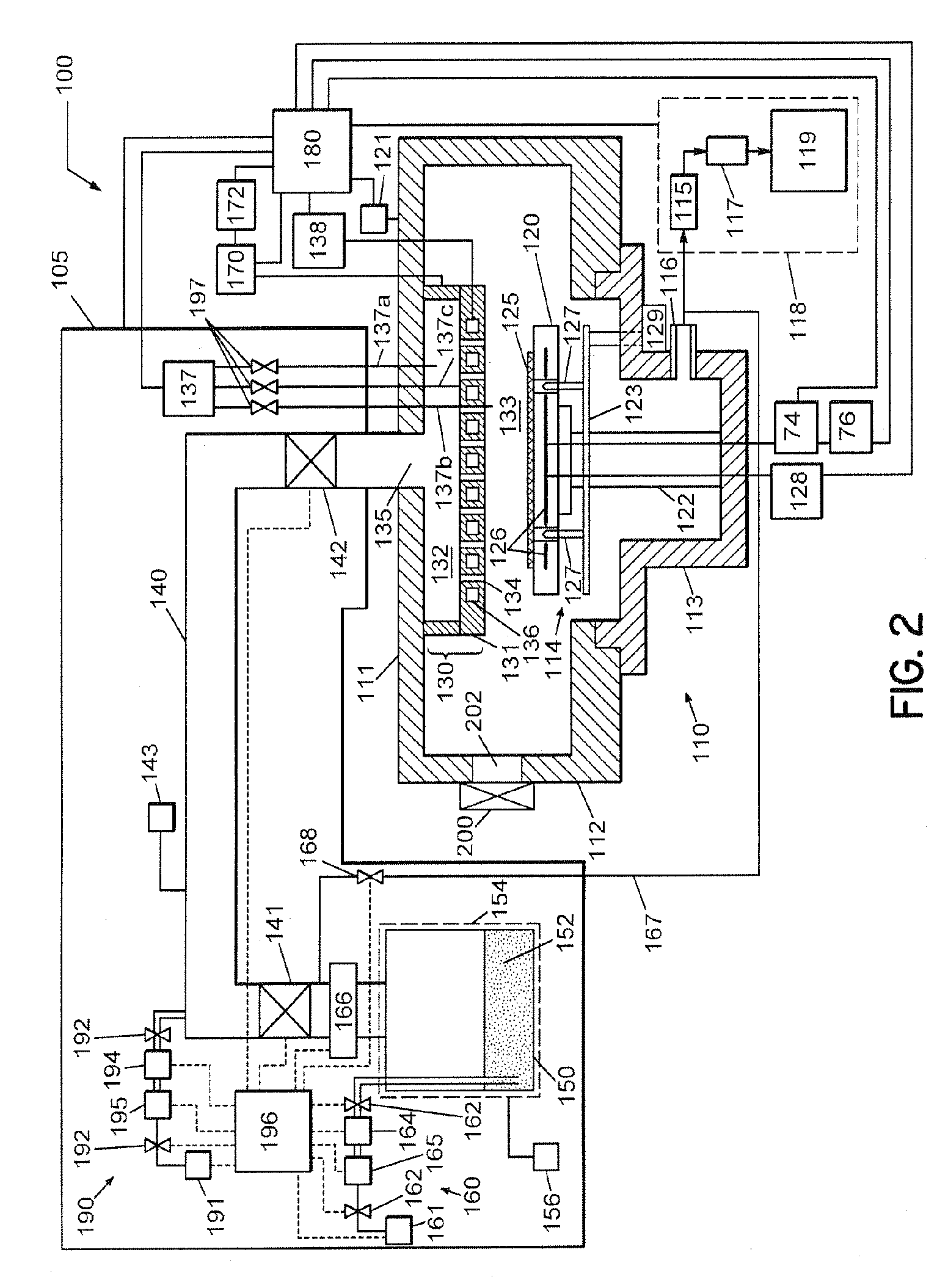

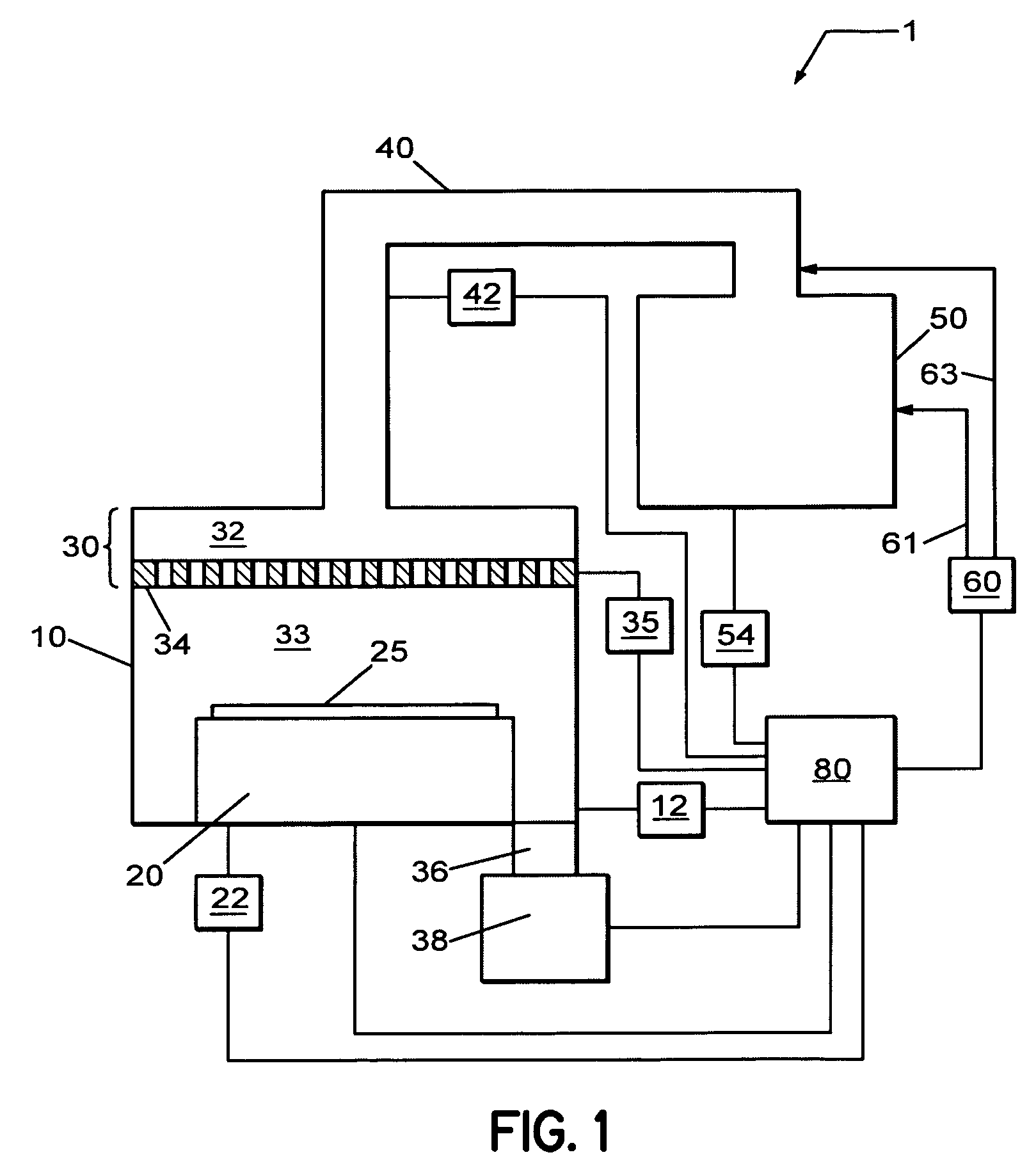

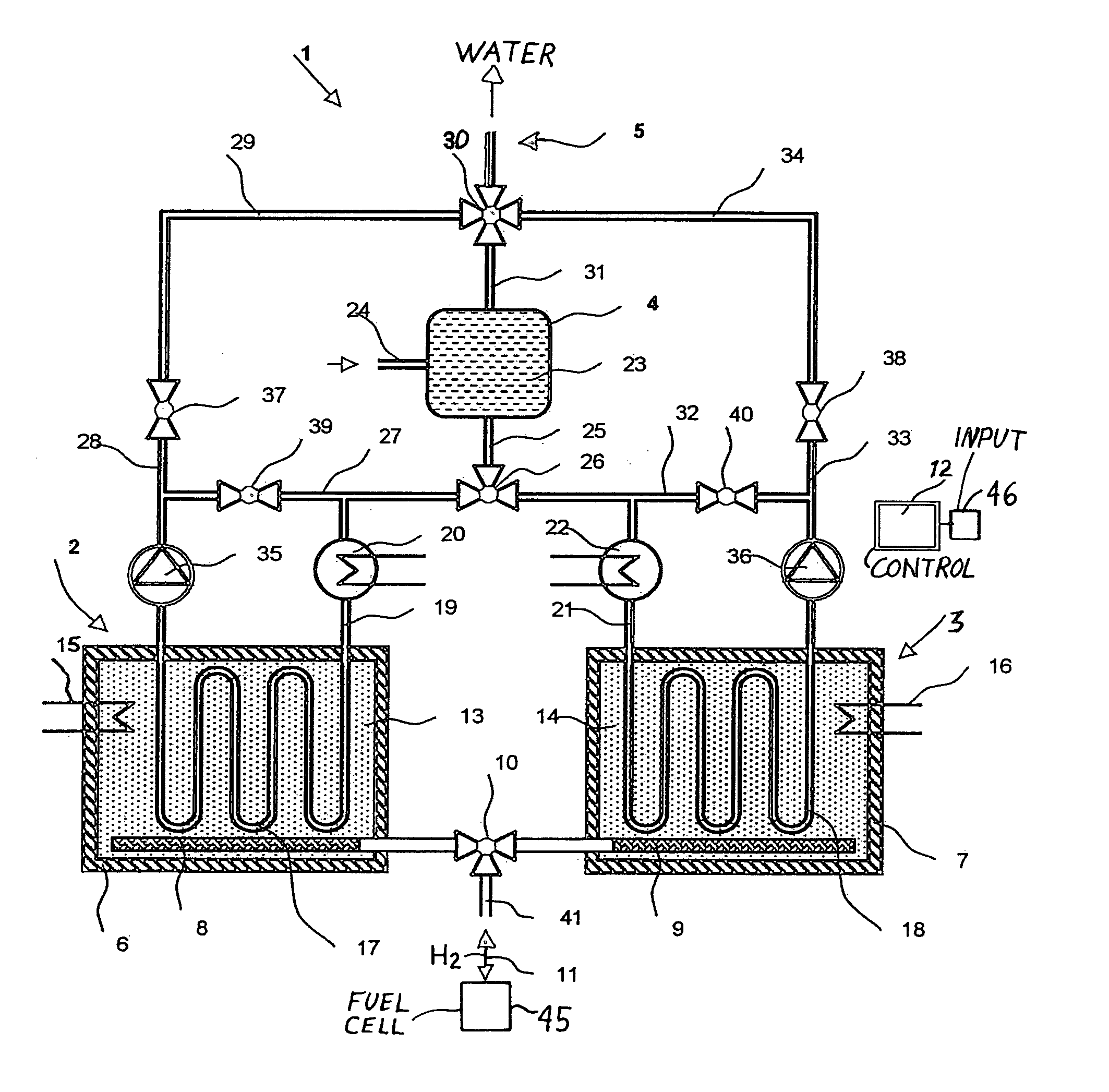

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

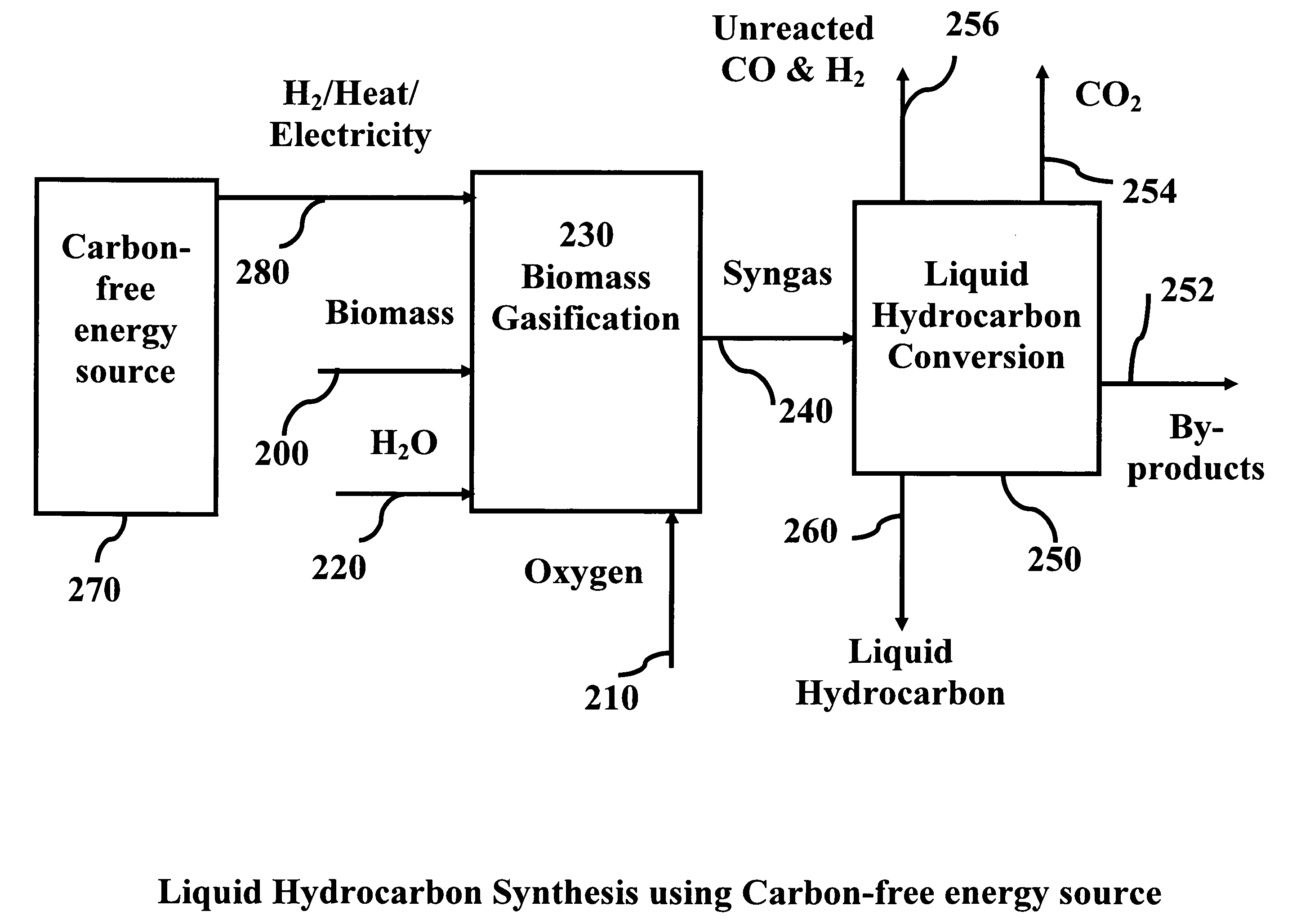

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

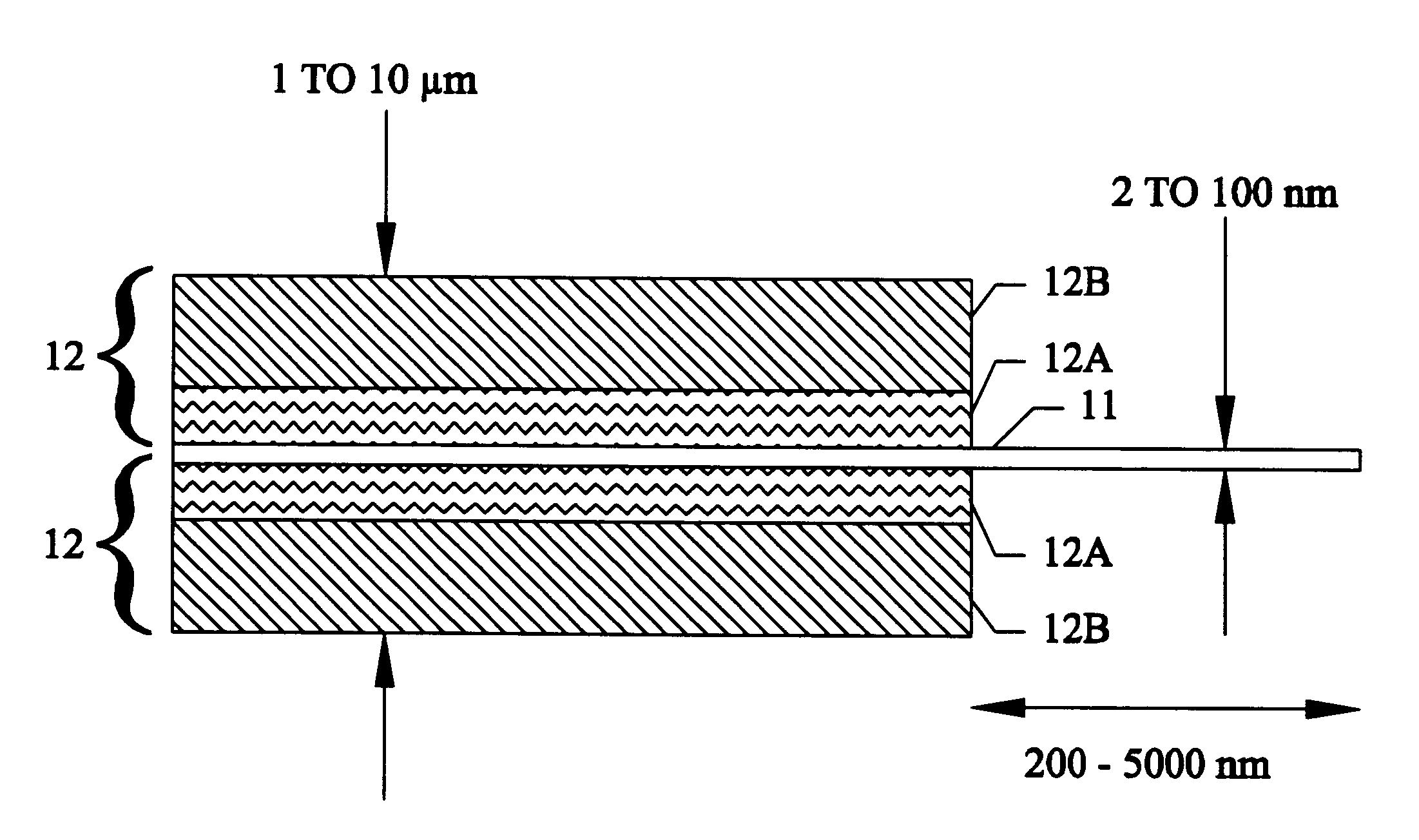

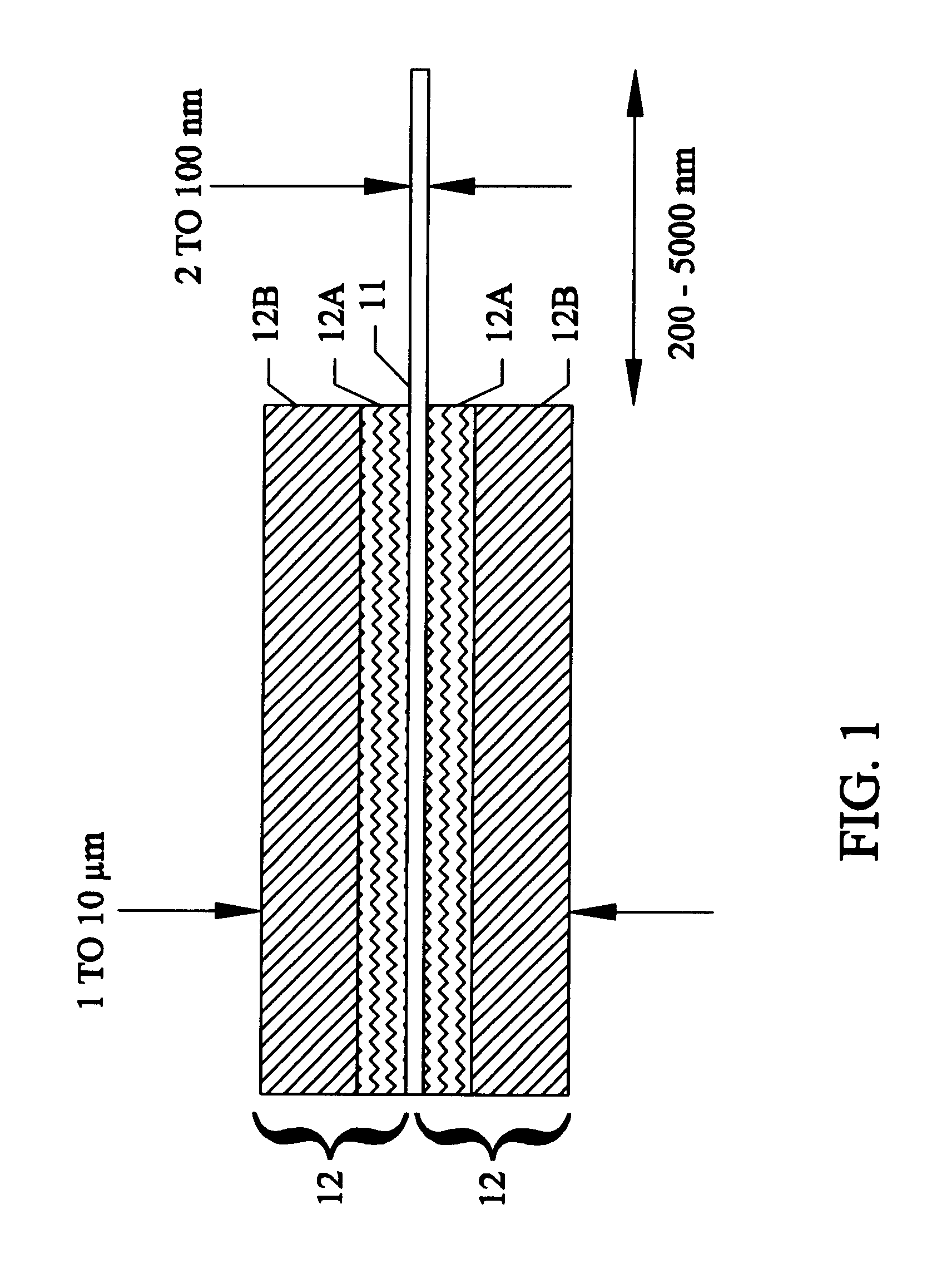

Carbon nanotube with a graphitic outer layer: process and application

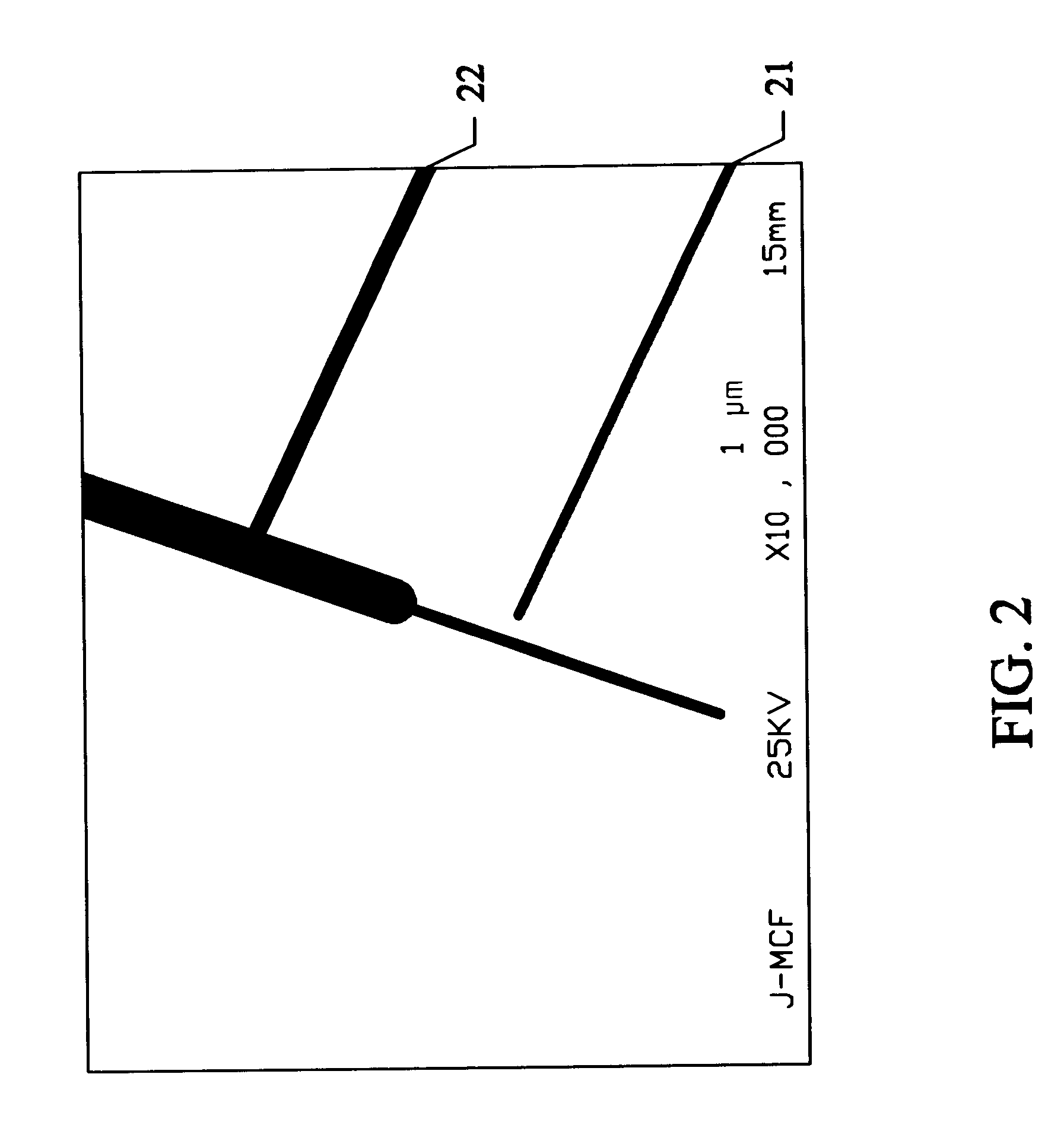

InactiveUS6582673B1Increase profitLarge caliberMaterial nanotechnologyPigmenting treatmentScanning probe microscopyNanometer size

A method for manufacturing carbon nanotubes with an integrally attached outer graphitic layer is disclosed. The graphitic layer improves the ability to handle and manipulate the nanometer size nanotube device in various applications, such as a probe tip in scanning probe microscopes and optical microscopes, or as an electron emitting device. A thermal chemical vapor deposition reactor is the preferred reaction vessel in which a transition metal catalyst with an inert gas, hydrogen gas and a carbon-containing gas mixture are heated at various temperatures in a range between 500° C. and 1000° C. with gases and temperatures being adjusted periodically during the reaction times required to grow the nanotube core and subsequently grow the desired outer graphitic layer.

Owner:CENT FLORIDA UNIV OF

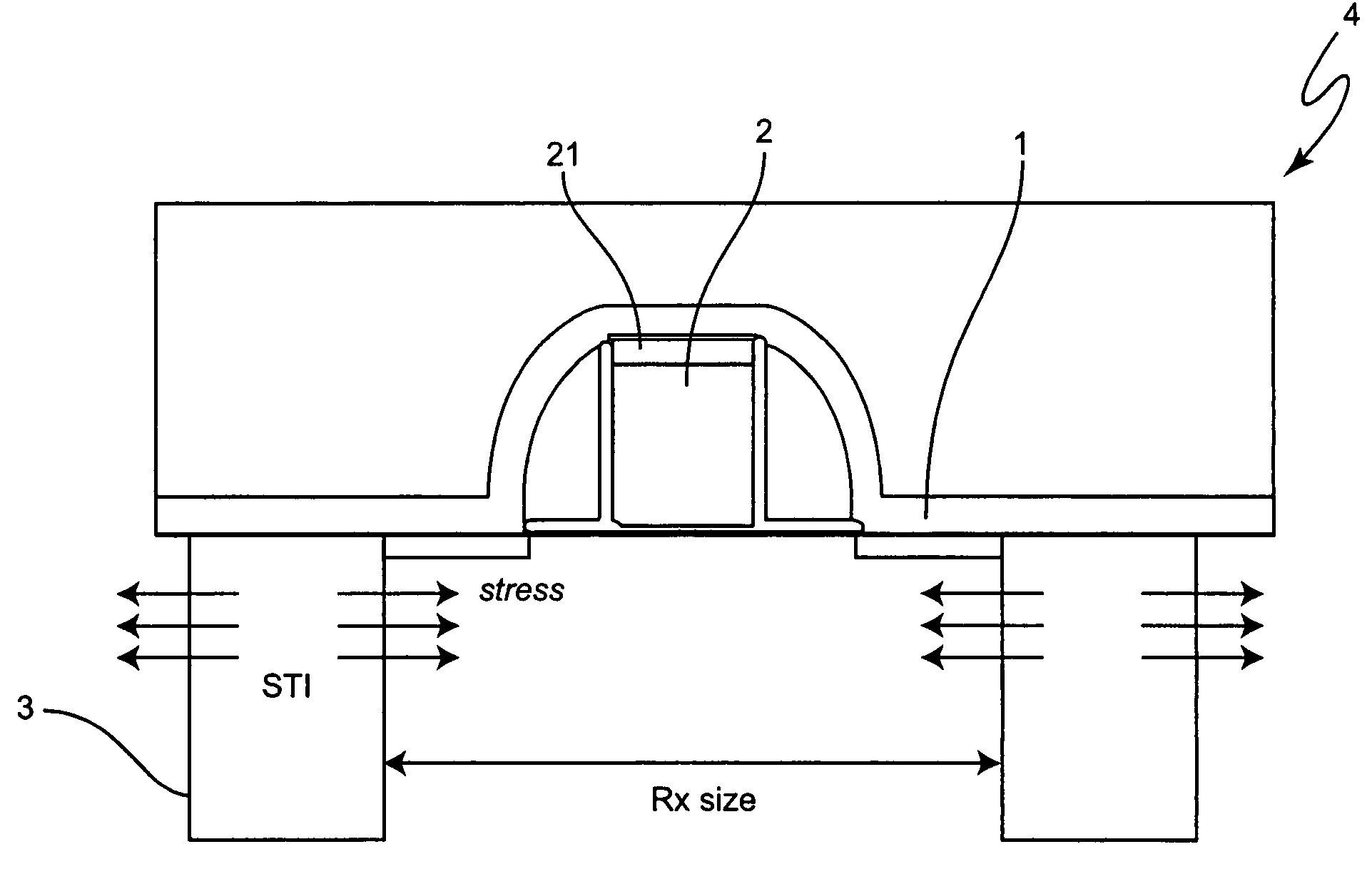

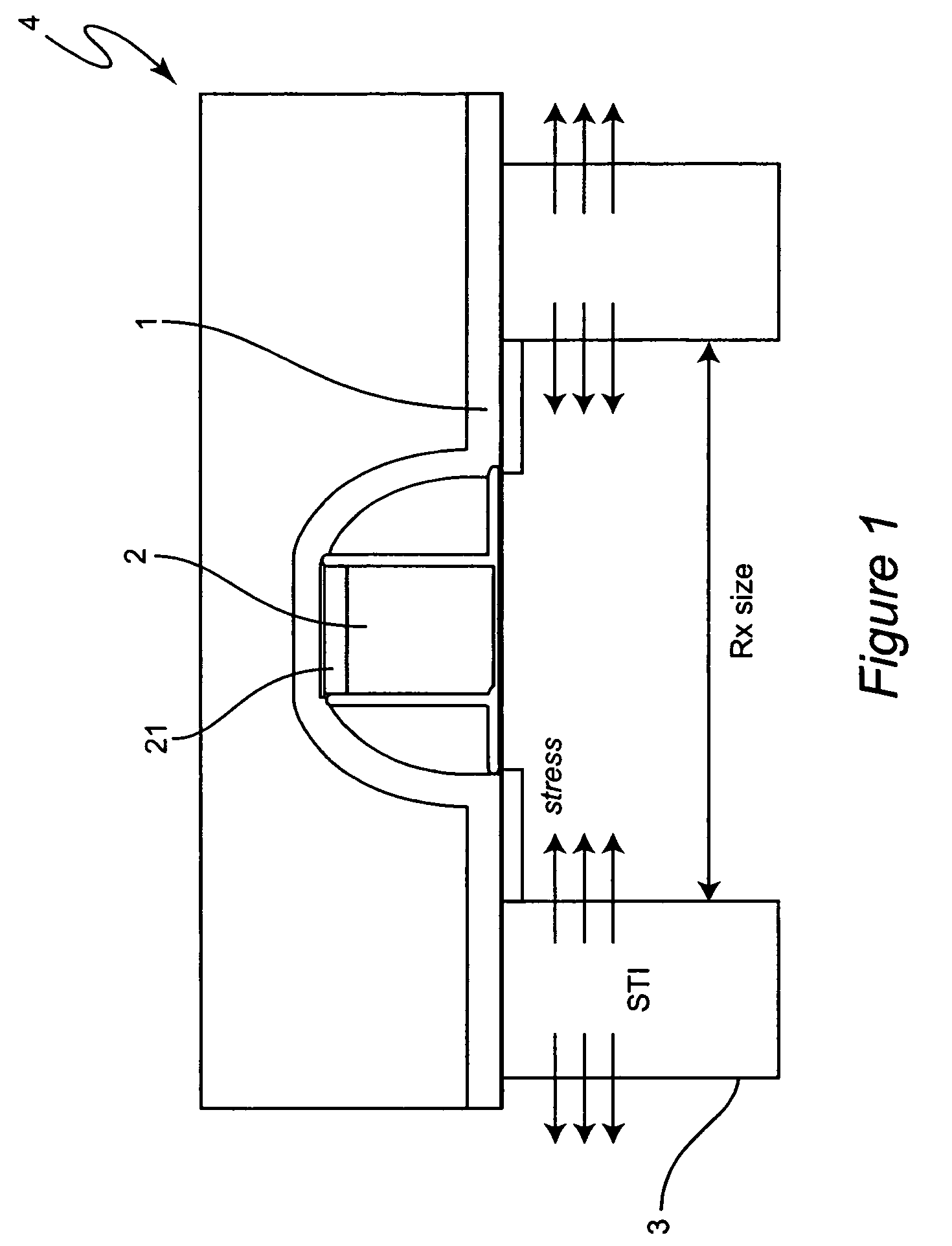

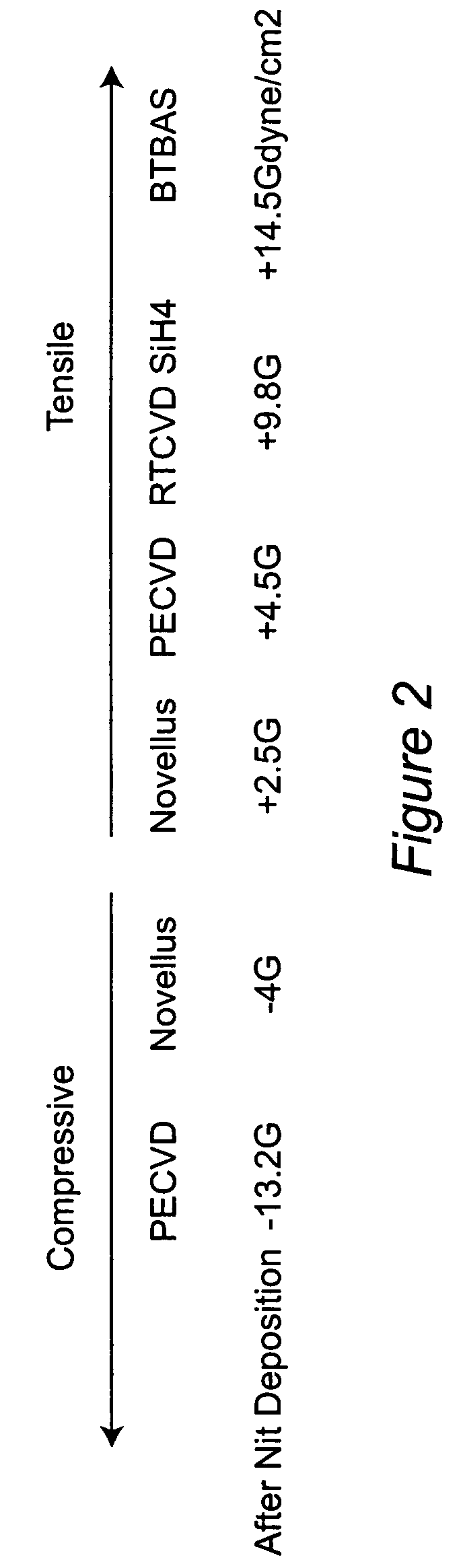

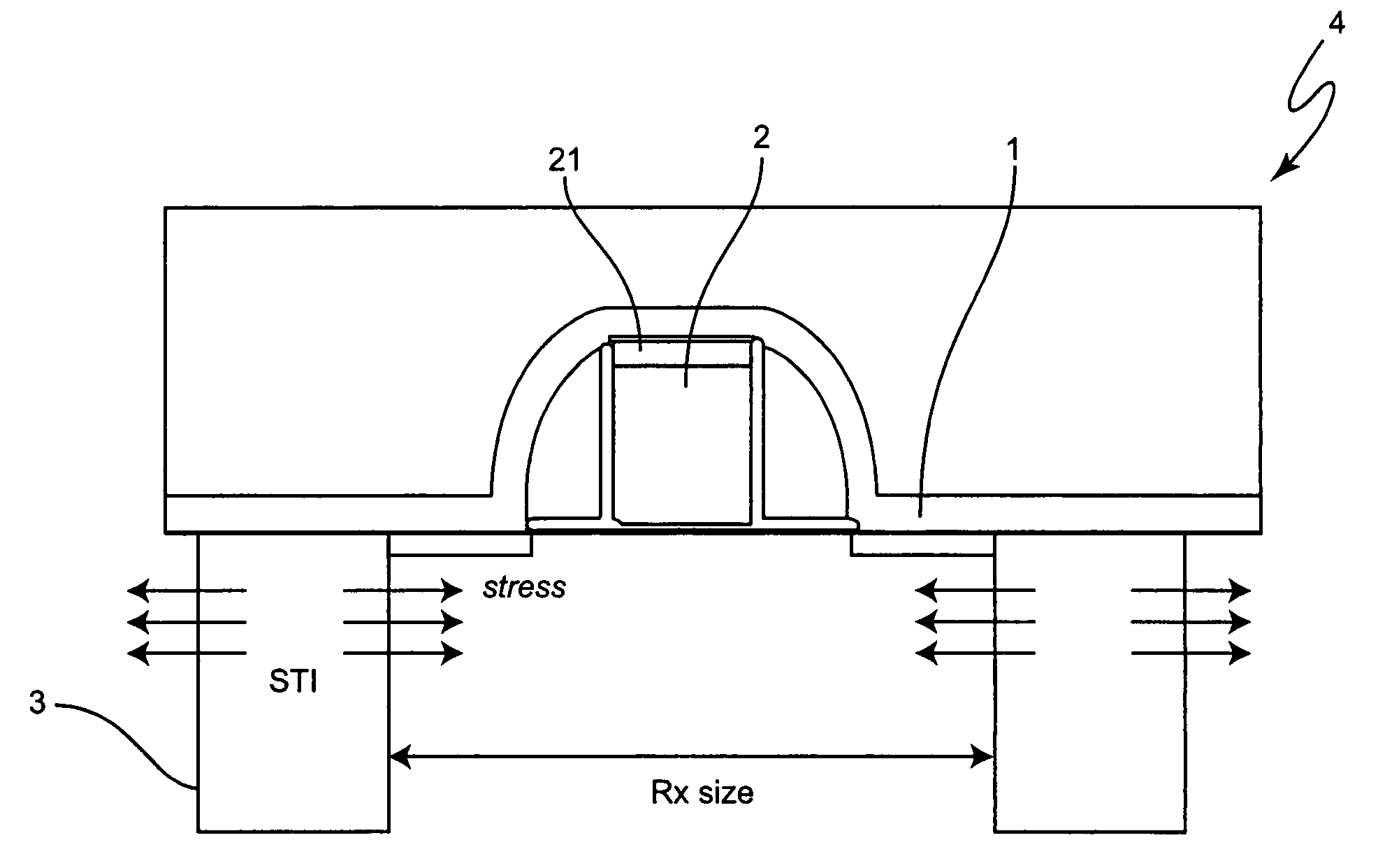

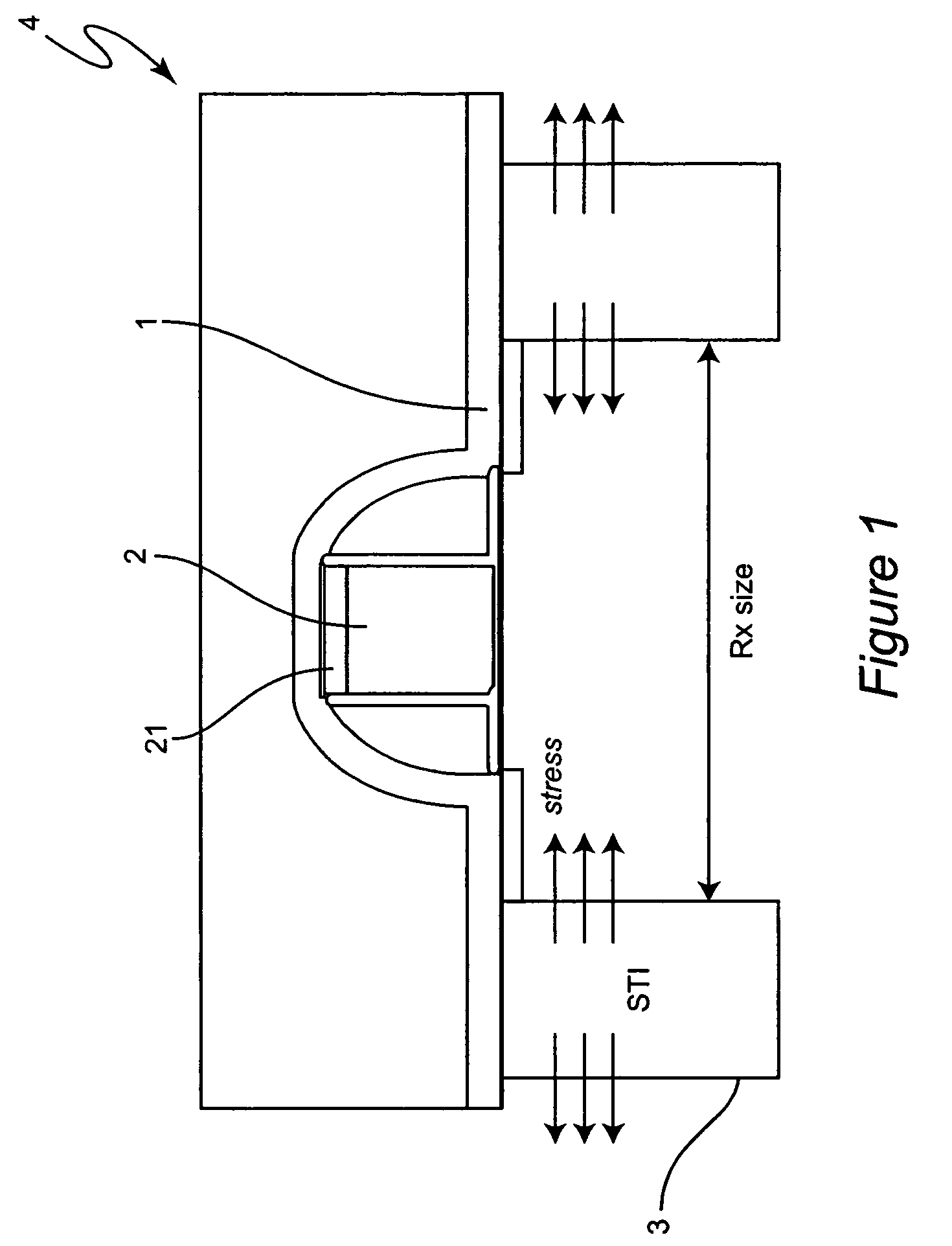

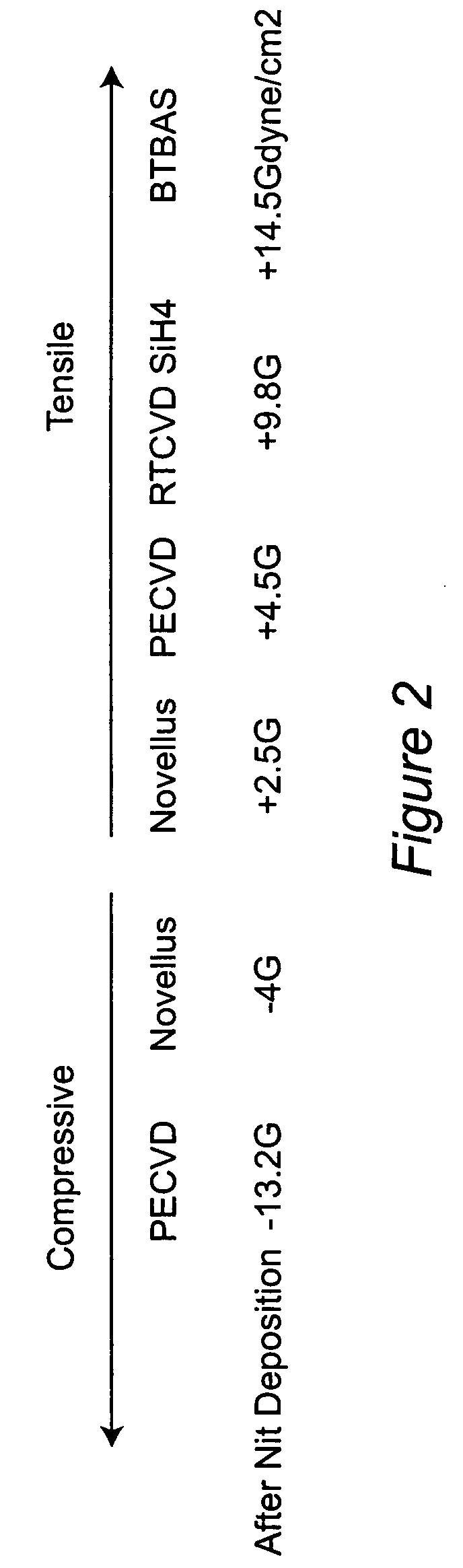

Material for contact etch layer to enhance device performance

InactiveUS7001844B2Little changeNot easy to influenceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal chemical vapor depositionSilanes

Stress level of a nitride film is adjusted as a function of two or more of the following: identity of a starting material precursor used to make the nitride film; identity of a nitrogen-containing precursor with which is treated the starting material precursor; ratio of the starting material precursor to the nitrogen-containing precursor; a set of CVD conditions under which the film is grown; and / or a thickness to which the film is grown. A rapid thermal chemical vapor deposition (RTCVD) film produced by reacting a compound containing silicon, nitrogen and carbon (such as bis-tertiary butyl amino silane (BTBAS)) with NH3 can provide advantageous properties, such as high stress and excellent performance in an etch-stop application. An ammonia-treated BTBAS film is particularly excellent in providing a high-stress property, and further having maintainability of that high-stress property over repeated annealing.

Owner:IBM CORP

A method for forming a ruthenium metal layer on a patterned substrate

ActiveUS20060211228A1Semiconductor/solid-state device detailsSolid-state devicesThermal chemical vapor depositionRuthenium

A method for forming a ruthenium metal layer includes providing a patterned substrate in a process chamber of a deposition system, where the patterned substrate contains one or more vias or trenches, or combinations thereof, depositing a first ruthenium metal layer on the substrate in an atomic layer deposition process, and depositing a second ruthenium metal layer on the first ruthenium metal layer in a thermal chemical vapor deposition process. The deposited ruthenium metal layer can be used as a diffusion barrier layer, a seed layer for electroplating, or both.

Owner:TOKYO ELECTRON LTD

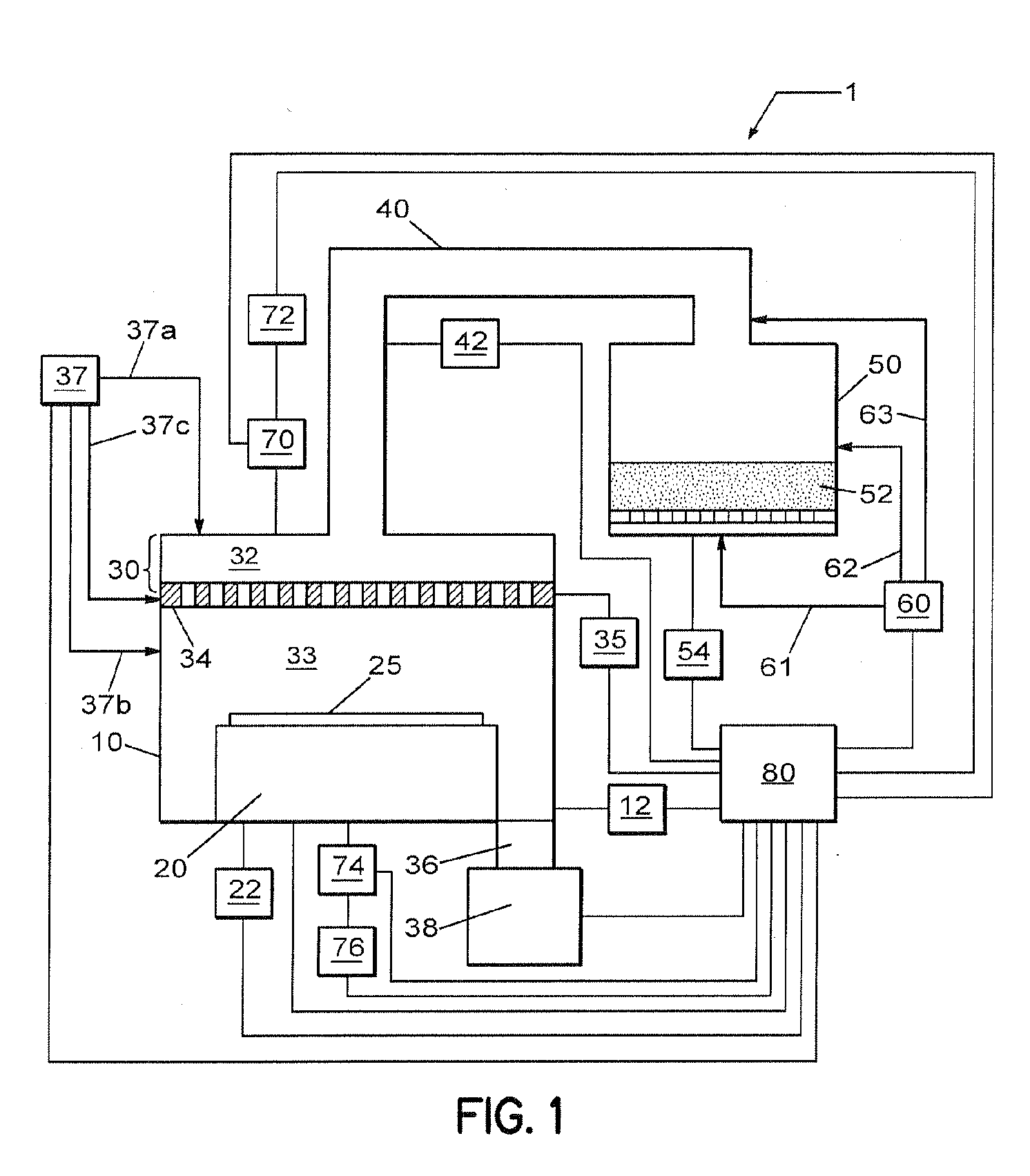

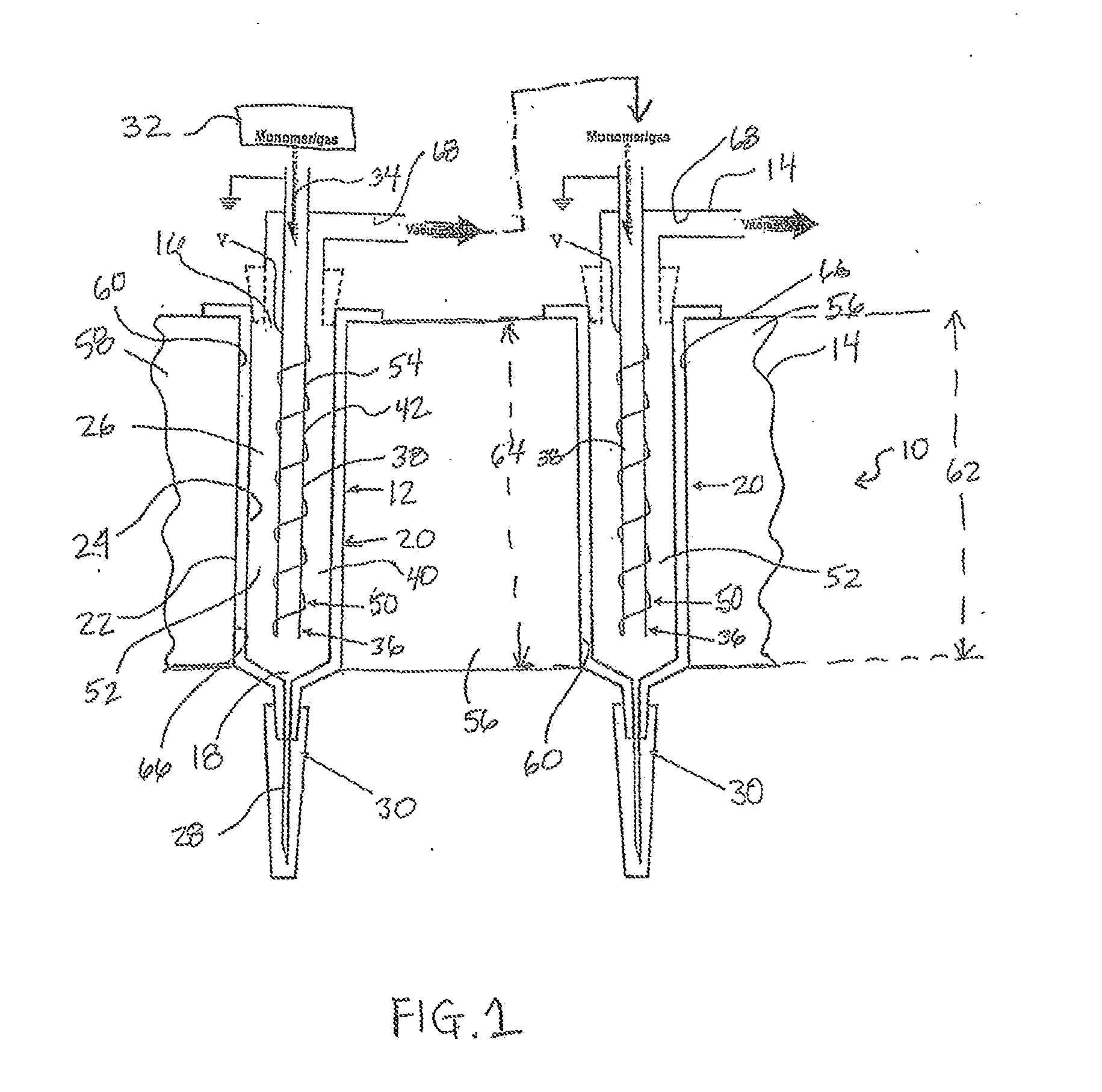

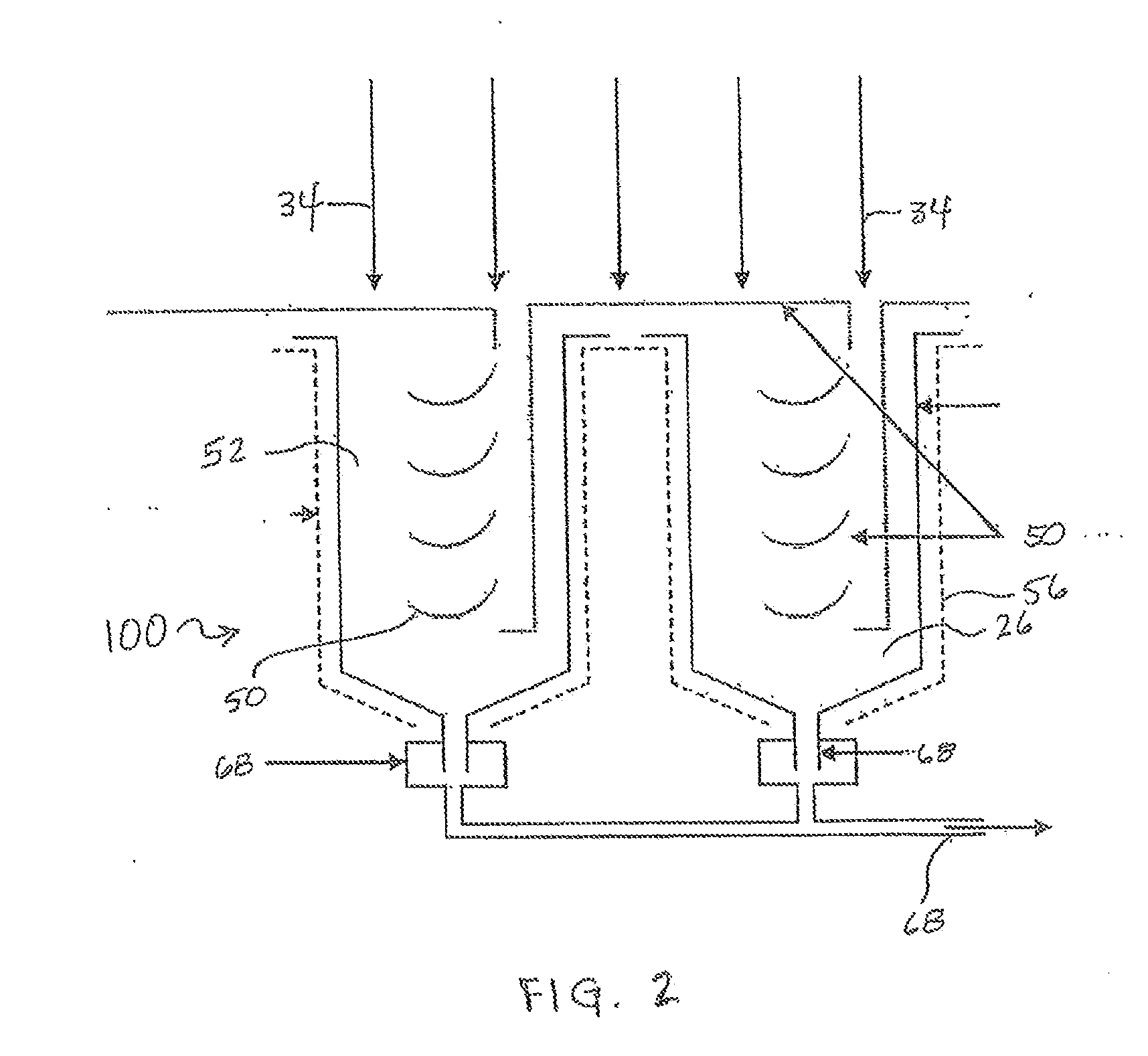

Systems, Apparatus and Methods for Coating the Interior of a Container Using a Photolysis and/or Thermal Chemical Vapor Deposition Process

InactiveUS20110186537A1Facilitate deposition and polymerizationLiquid surface applicatorsClosuresTemperature controlPolymer science

Systems, apparatus and methods are provided to apply barrier and / or lubricant materials onto the interior surface of a container, such systems including a container having a chamber; a gas supply source for supplying monomer gas through a gas inlet duct having a portion extending into the chamber; a photolysis source and / or pyrolyzing surface for photolyzing and / or pyrolyzing at least a portion of the monomer gas to form a reactive gas comprising at least one reactive moiety; optionally a temperature controller for maintaining the interior surface of the container at a temperature which is less than the temperature of the pyrolyzing surface to facilitate deposition and polymerization of the reactive moiety on the interior surface of the container; and an outlet duct at the open end or a second end of the container for removing excess reactive gas from the chamber.

Owner:BECTON DICKINSON & CO

Eco-engineering for systematic carbon mitigation

InactiveUS20100120128A1Reduce amountGood reliefHydrogen sulfidesDispersed particle separationEnvironmental resistanceResource utilization

To deal with climate change, the present invention provides an eco-engineering for systematic carbon mitigation, in particular, a comprehensive carbon management system with a group of Stabilized Functional Carbons (SFCs) to reduce the total amount of carbons in atmosphere. SFCs are sourced and manufactured from the carbon-fixed biomass by one of the seven thermo-chemical treatments or one dehydration treatment with no less than 75% carbon conversion rates of the source material. The present invention transforms the perishable biomass into SFCs, which act as a carbon sink with stability and safety for at least 40 years' storage. The primary eco-friendly carbon and non-carbon mitigation are achieved by the sourcing, manufacturing and storage of SFCs. The advanced eco-friendly carbon and non-carbon mitigation are achieved at various pollution emission sources by the resource utilization of SFCs. An annual total amount of 0.5-10 billion tons of carbon emission could be reduced globally.

Owner:LIANG

Mass production of carbon nanostructures

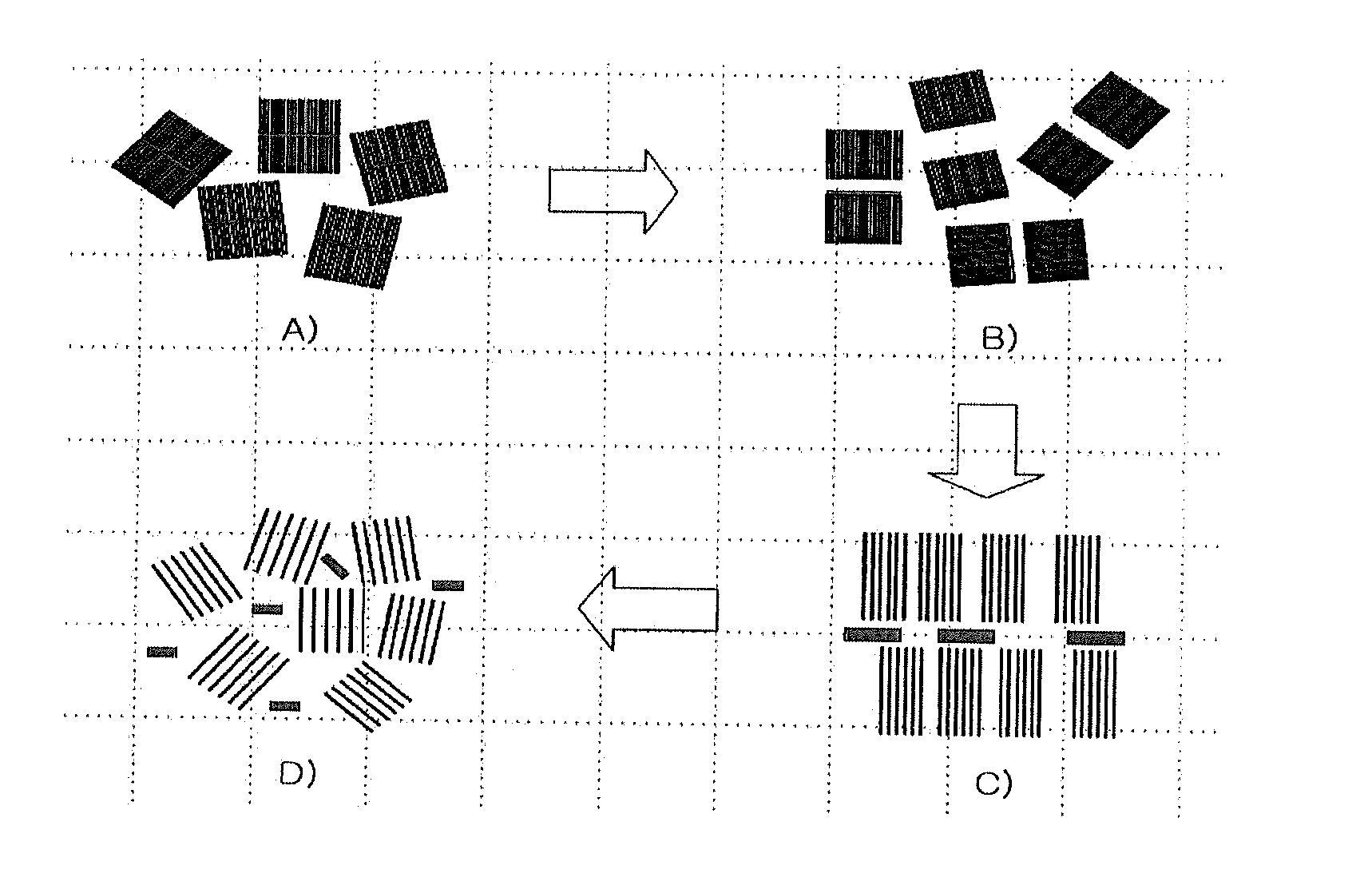

Carbon nanostructures are mass produced from graphite. In particularly preferred aspects, graphene is thermo-chemically derived from graphite and used in numerous compositions. In further preferred aspects, the graphene is re-shaped to form other nanostructures, including nanofractals, optionally branched open-ended SWNT, nanoloops, and nanoonions.

Owner:PETRIK VIKTOR I

Protective coating for application to a substrate and method for manufacturing a protective coating

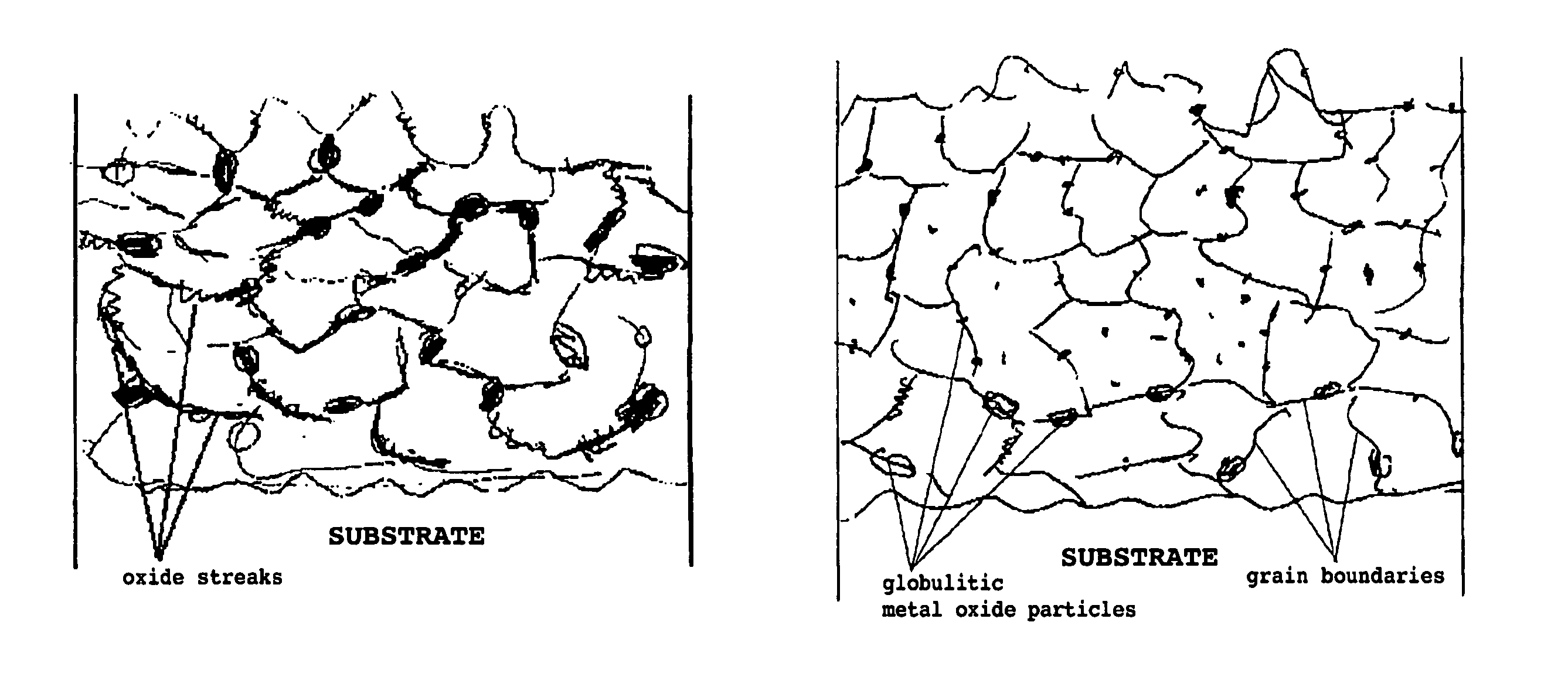

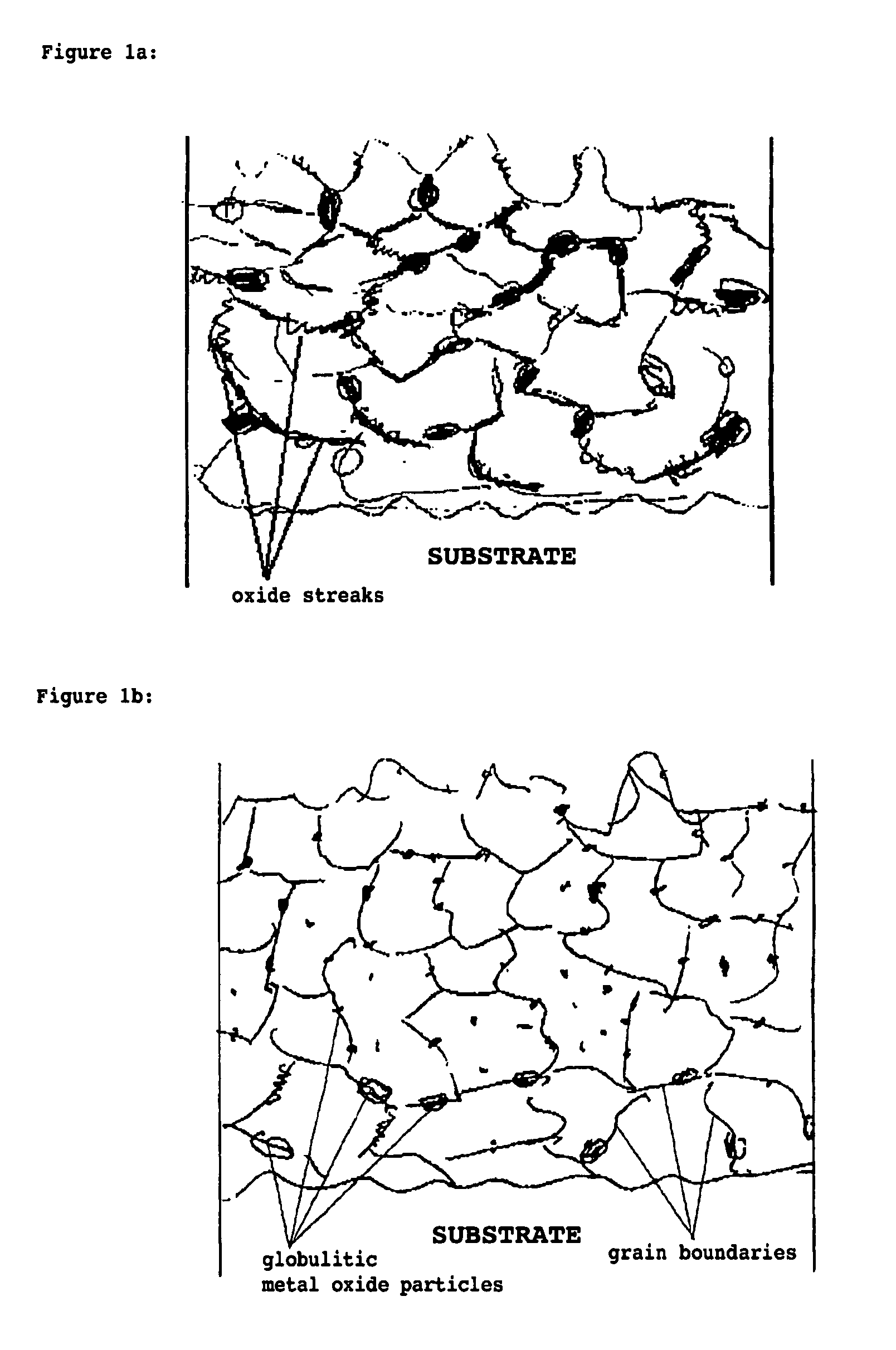

InactiveUS20060292390A1High heat and corrosion resistanceCost-effective manufacturingMolten spray coatingPretreated surfacesMetallic materialsSpray coating

A refractory, oxidation-resistant, and corrosion-resistant protective coating for application to a substrate, in particular for application to parts of turbines or aircraft propulsion engines, is described, including a spray coating made of a thermally sprayed, primarily metallic material, the coating being at least partially subjected to a thermochemical aluminum (Cr, Si) deposition process having a specifically high aluminum deposition activity after the application of the protective coating to the substrate, in such a way that the protective coating has alloy gradients of Al (Cr, Si) which increase from the substrate surface to the coating surface and isolated globulitic metal oxide particles. Furthermore, a method for manufacturing this protective coating and its use are described.

Owner:MTU AERO ENGINES GMBH

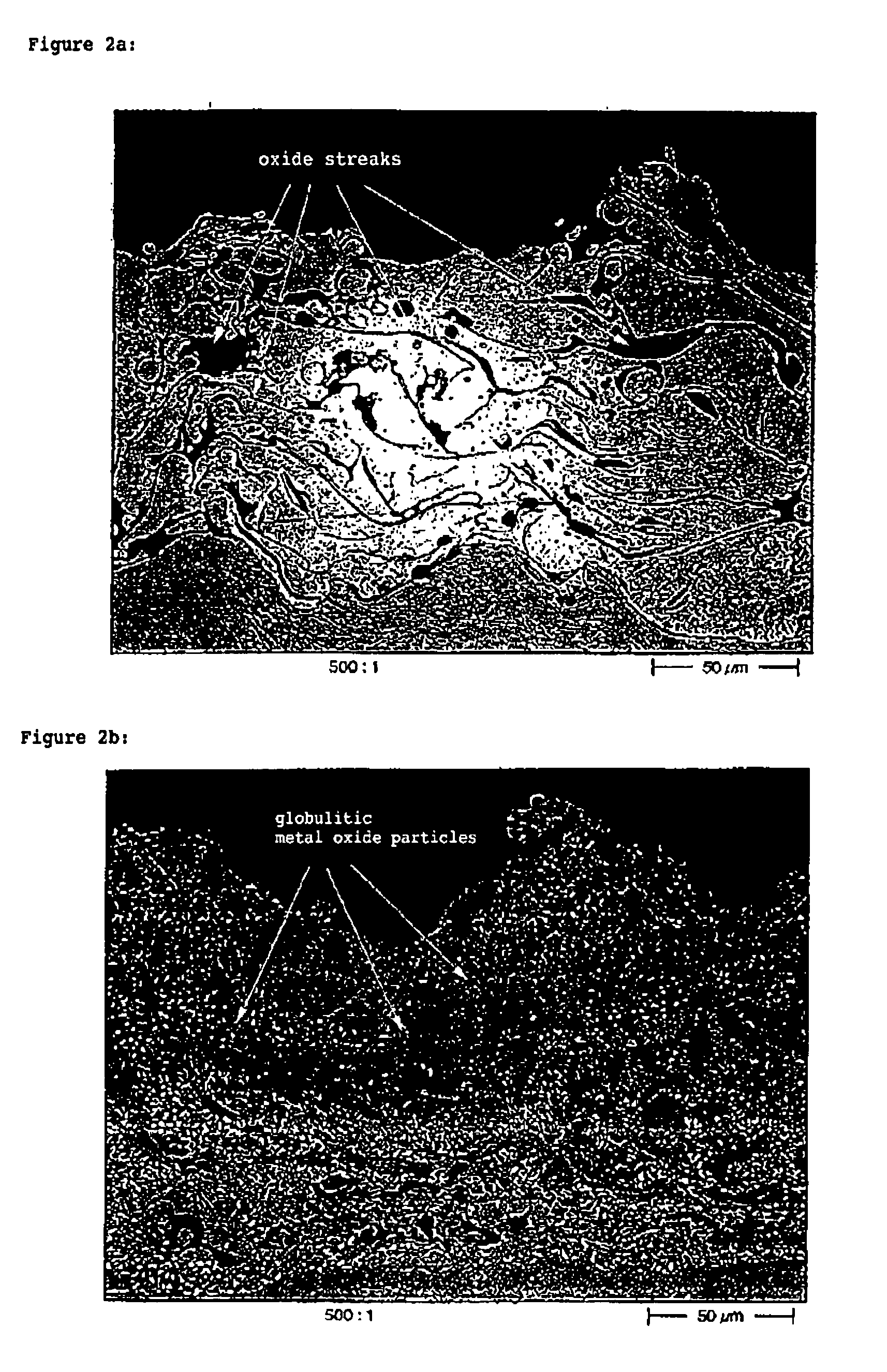

Method for preparing complete methanation catalyst for hydrothermal chemical process

ActiveCN102029161AGood activity and stabilityGood hydrothermal stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationChemical synthesisPtru catalyst

The invention provides a method for preparing a complete methanation catalyst for a hydrothermal chemical process. The catalyst comprises the following components: 10 to 75 percent of active nickel ingredient, 10 to 90 percent of high-temperature resistant carrier and 0.1 to 15 percent of rare-earth auxiliary agent, wherein the content is counted on the basis of metal oxide, and the percentage is weight percentage of the total weight of the active ingredient, the carrier and the auxiliary agent. The preparation method comprises the following steps of: (a) forming a catalyst precursor by using the hydrothermal chemical synthesis process; and (b) preparing the obtained catalyst precursor into the complete methanation catalyst by filtering, washing, drying, roasting, forming, re-roasting and reducing. The method is convenient for crystallization and precipitation of catalyst materials, and has simple process and good repeatability. The method provides guarantee for meeting the current increasing clean energy requirement, and has irreplaceable important effect on the enhancement of energy / resource safety at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing phenolic chemicals through thermo-chemical conversion of industrial lignin

InactiveCN102173980ALow priceObvious cost advantageOrganic compound preparationBulk chemical productionCelluloseBiofuel

The invention provides a method for preparing phenolic chemicals through the thermo-chemical conversion of industrial lignin. The method is as follows: under the common functions of solid acid catalyst and hydrogen supply solvent, industrial lignin performs atmospheric thermo-chemical conversion in high boiling point organic reaction medium to prepare homogeneous low molecular weight organic matter with rich phenolic compounds such as phenol, methoxyphenol, dimethoxyphenol and 2-methoxy-4-methylphenol, and the organic reaction medium is recycled through the technologies such as vacuum distillation. The method has simple process, good stability and low production cost; and the yield of the prepared phenolic compounds is more than 54%. The method plays an important role in the high-valued comprehensive utilization of the renewable resource, namely ndustrial lignin; and the converted phenolic chemicals can be used to synthesize phenolic resin, prepare high efficiency cement water-reducing agent and further separate, purify and prepare bio-chemicals. Particularly, by adopting the method, the lignin in papermaking black liquid and preparation residue of biological fuel ethanol prepared from cellulose can be converted to phenolic chemicals; and the method has wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

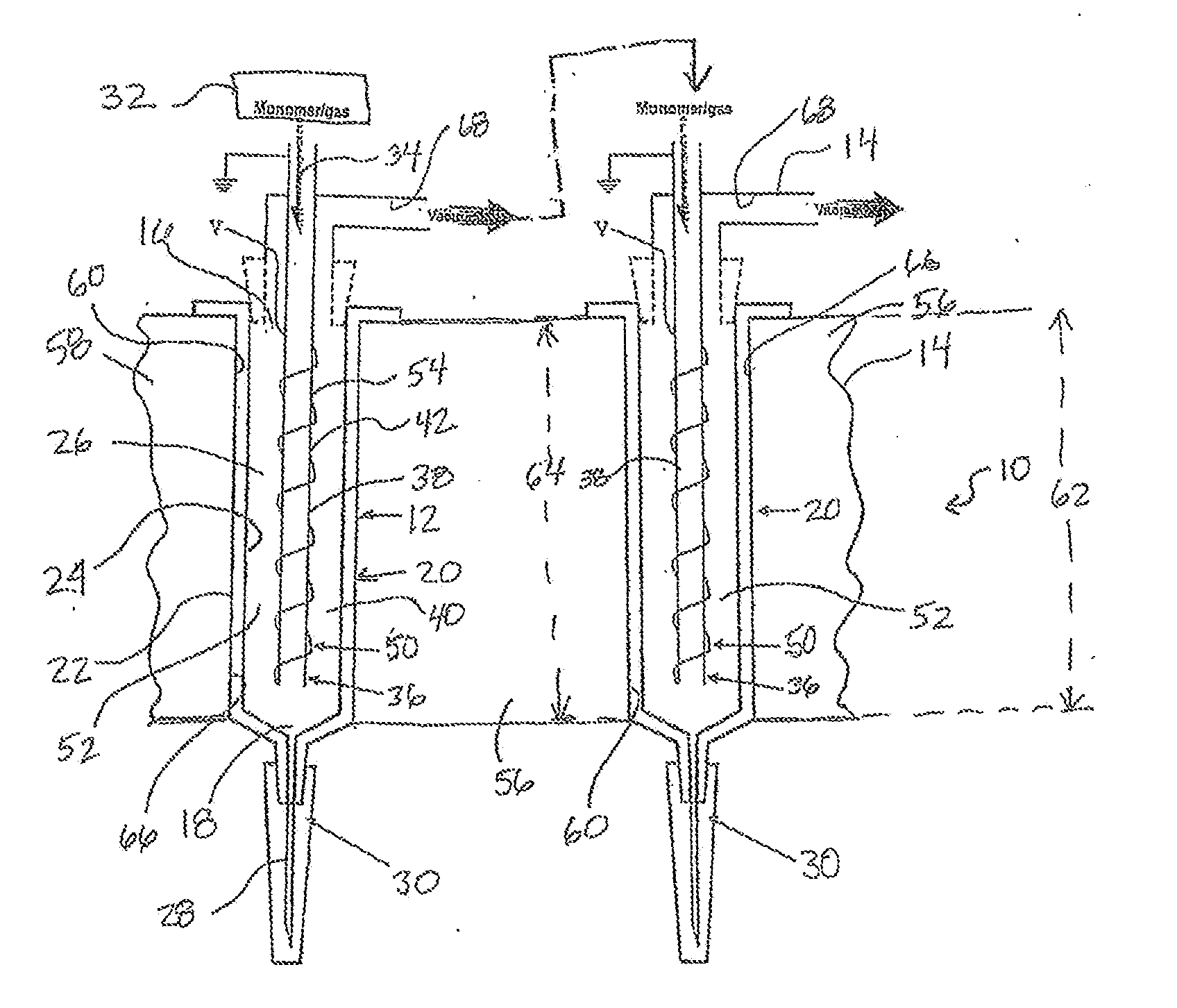

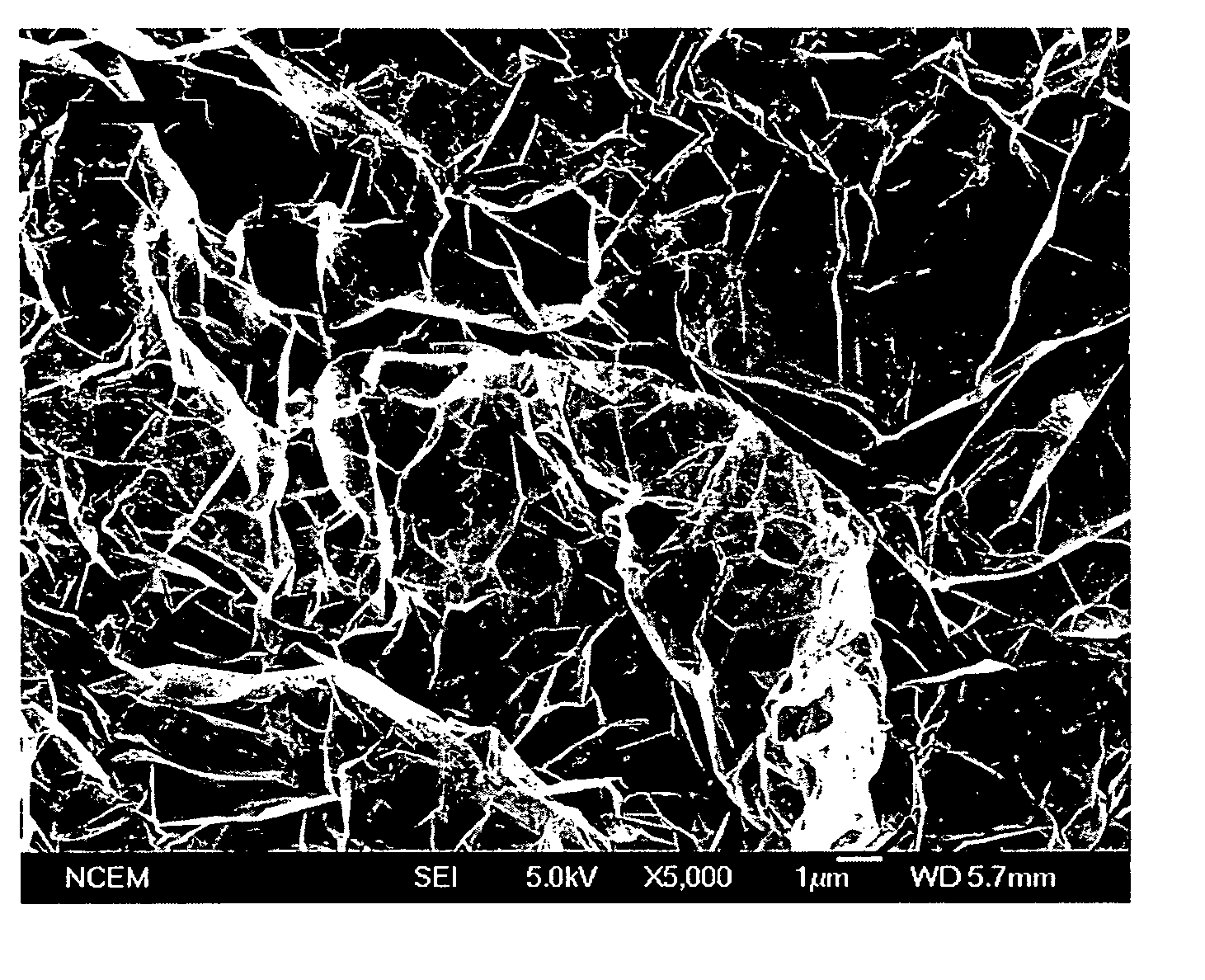

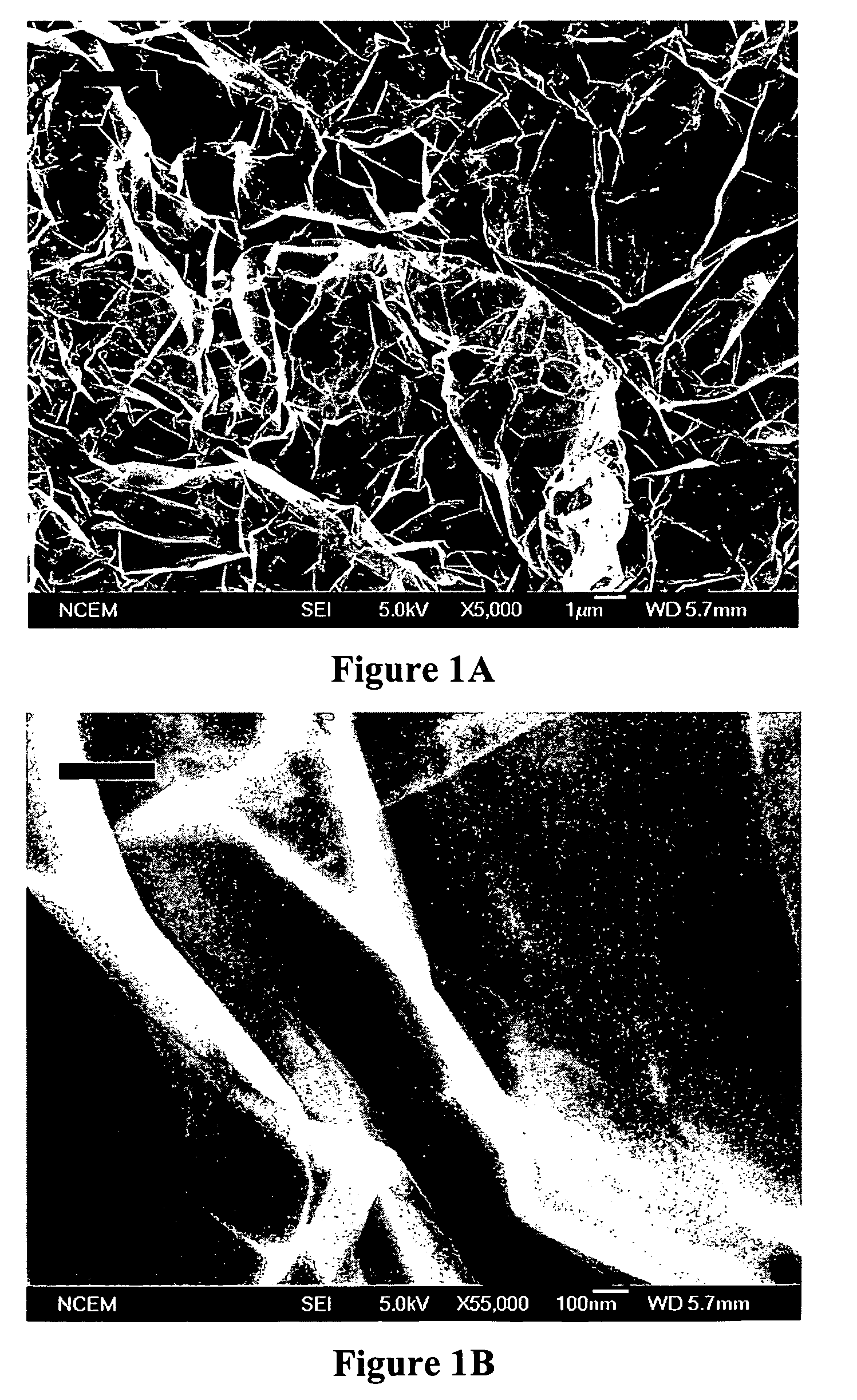

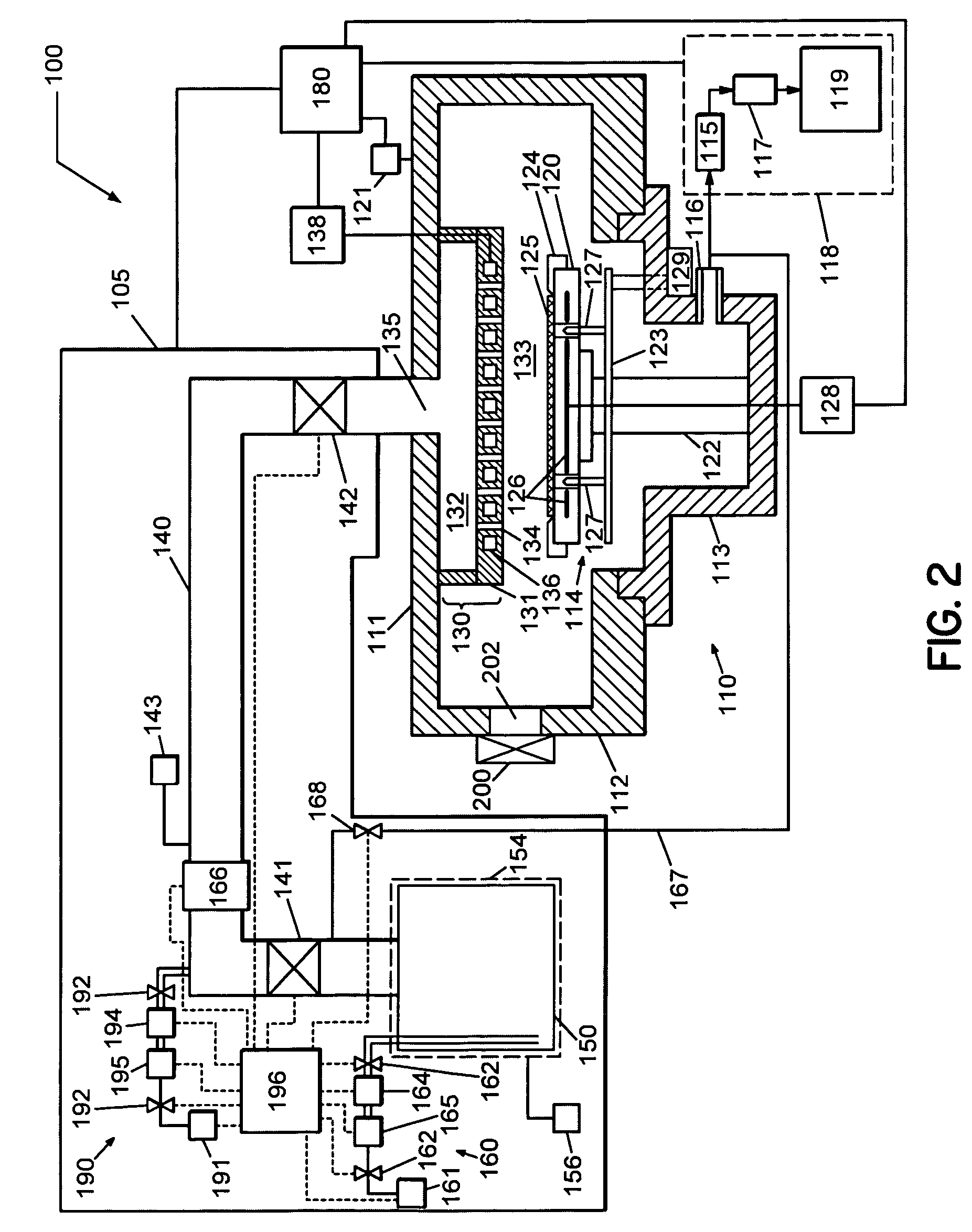

Rapid thermal chemical vapor deposition apparatus and method

InactiveUS20050109280A1Avoid damageMaterial nanotechnologyCarbon compoundsThermal radiationProcess window

A carbon nanotube fabricating system and method that includes a process chamber that supports a substrate. The system employs a high intensity thermal radiation source for heating the chamber, and a temperature regulation chuck that supports the substrate. In process, the chuck cools the substrate so as to prevent damage to the substrate, while CNT fabrication is preferably regulated to occur in a process window.

Owner:CHEN XIANGQUN S +1

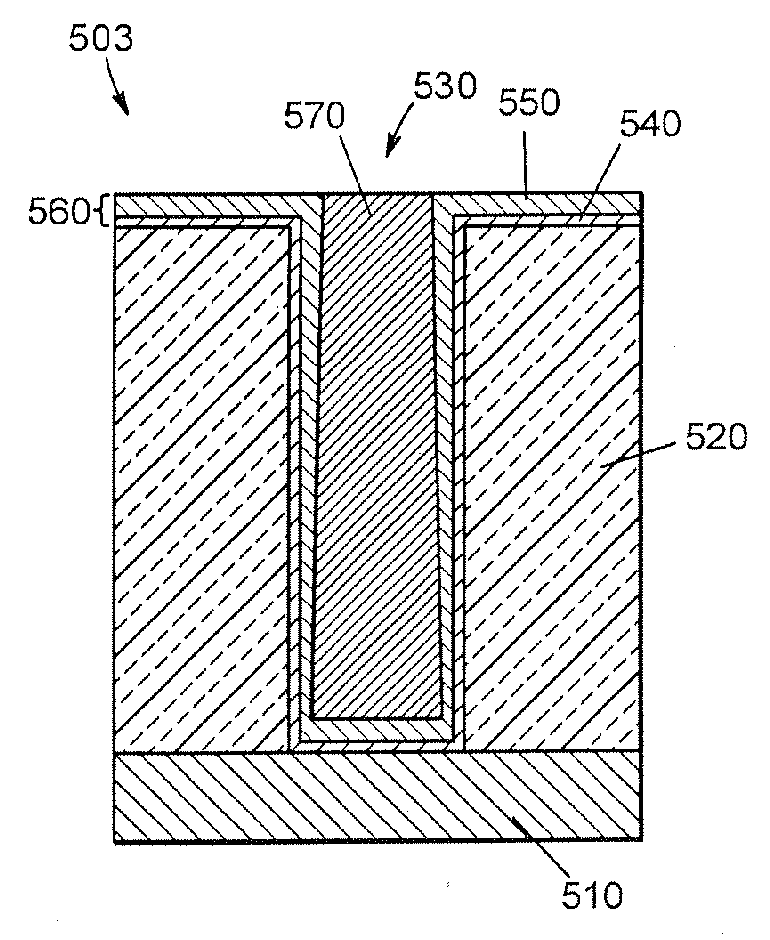

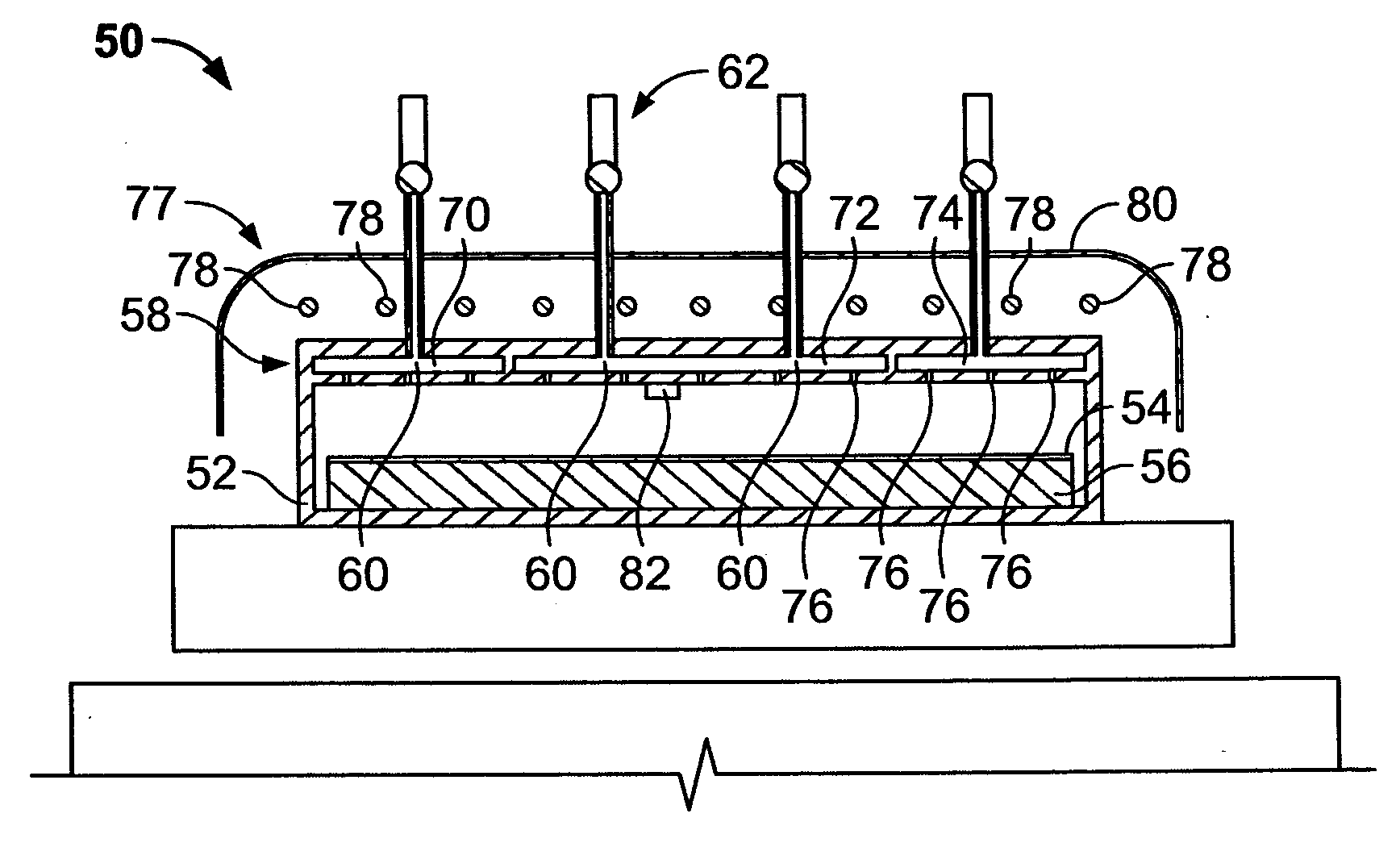

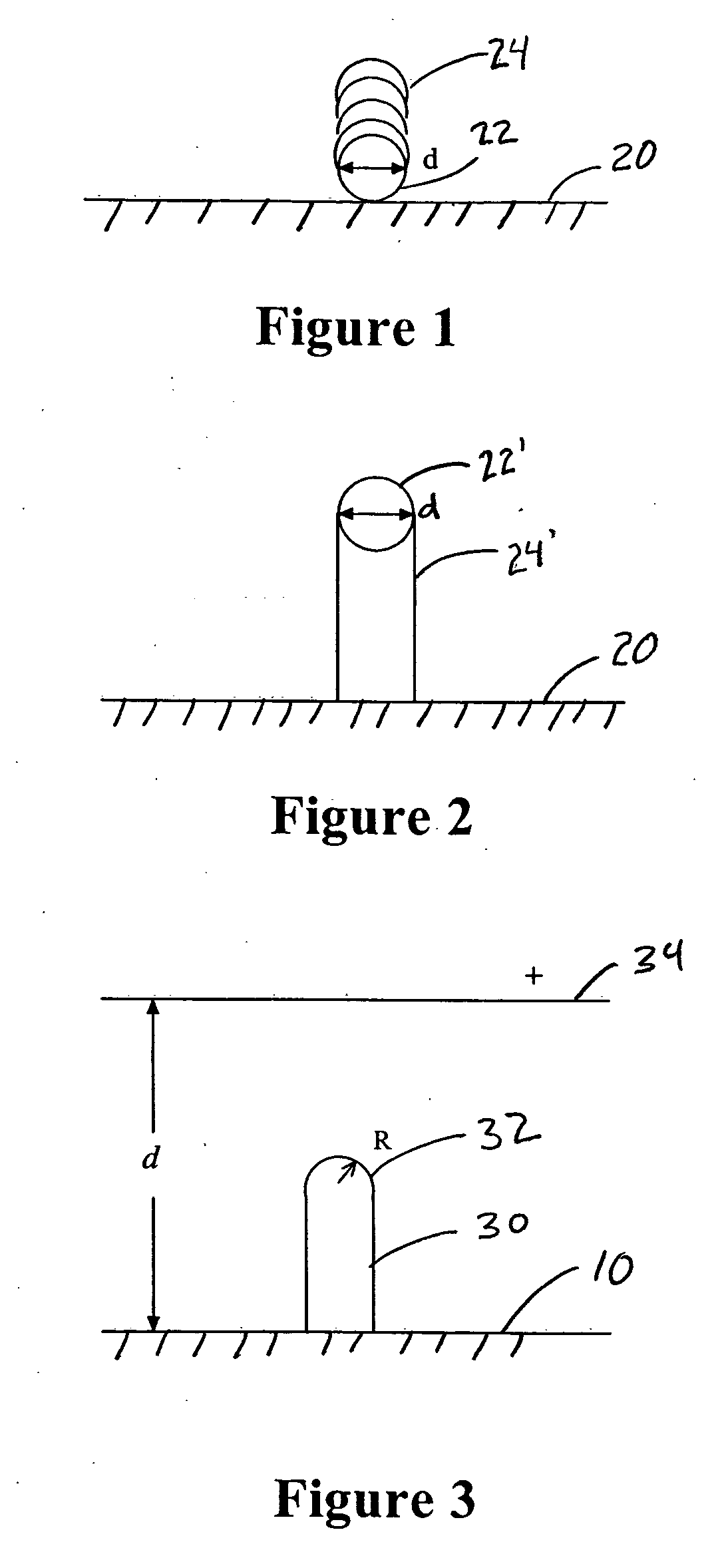

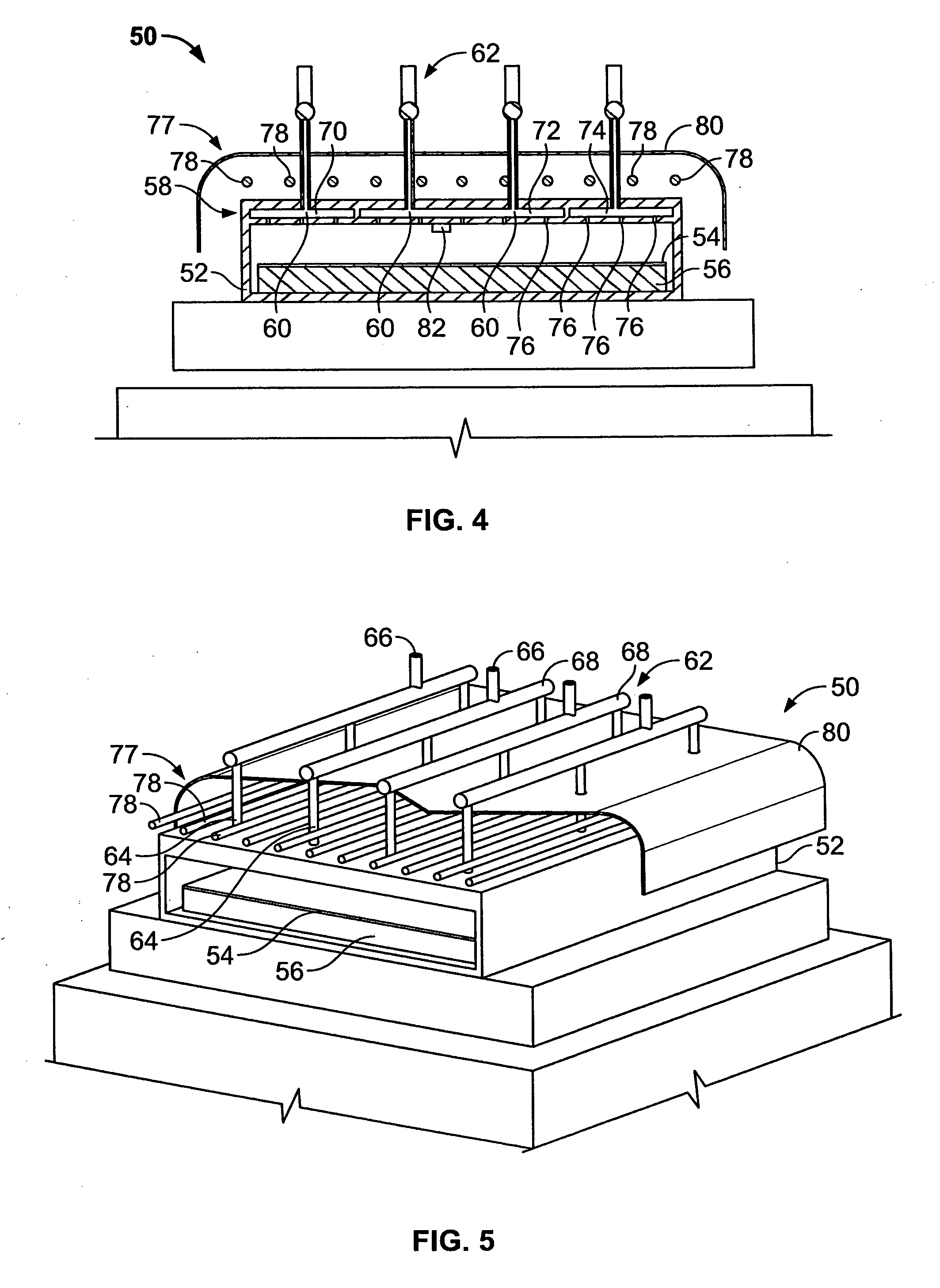

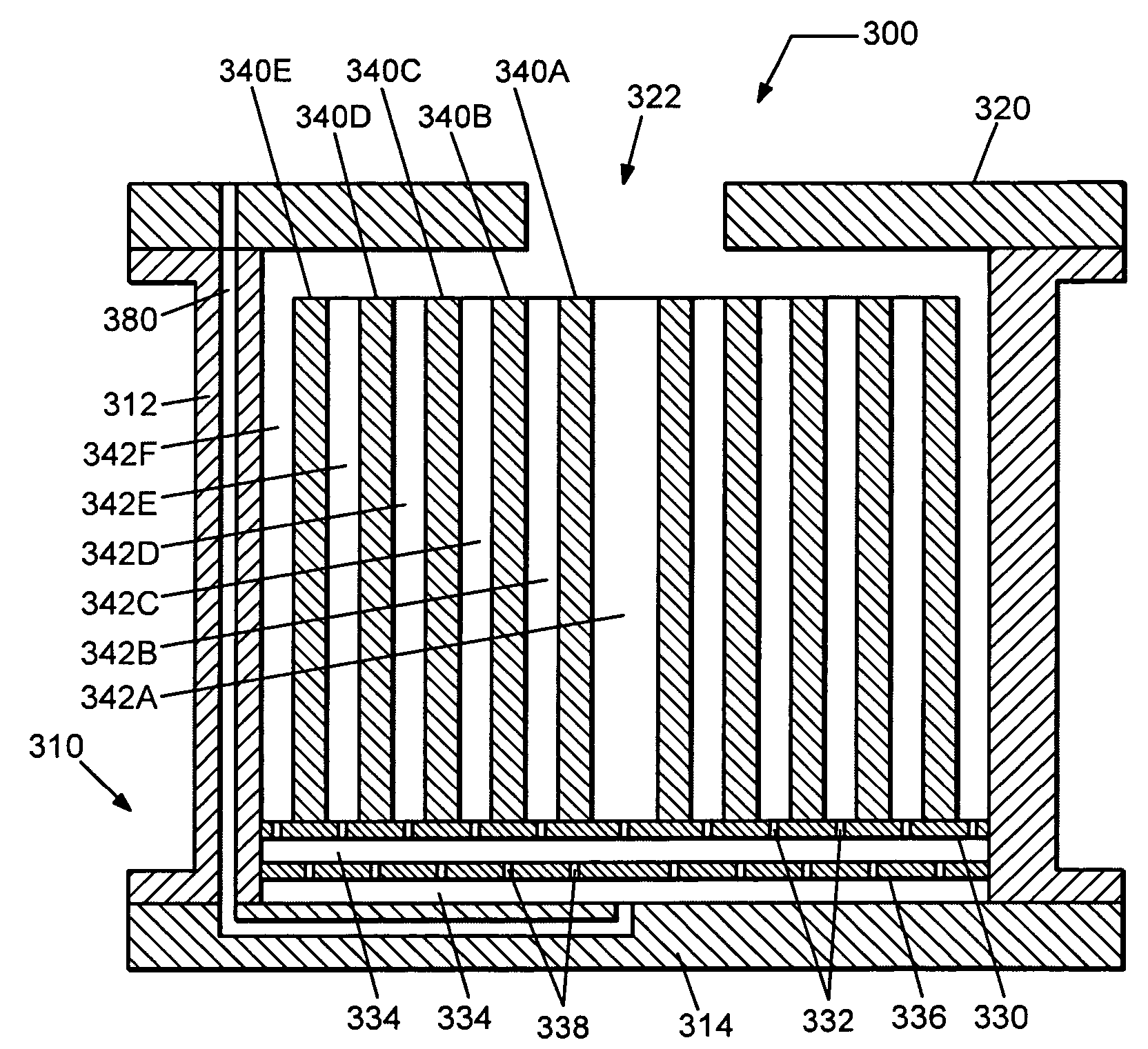

Solid precursor vaporization system for use in chemical vapor deposition

InactiveUS7651570B2Chemical vapor deposition coatingThermal chemical vapor depositionPhysical chemistry

A solid precursor vaporization system configured for use in a deposition system, such as thermal chemical vapor deposition (TCVD), is described. The solid precursor vaporization system comprises a plurality of concentric solid precursor cylinders supported on a gas distribution plate and configured to provide a substantially constant surface area as solid precursor is consumed.

Owner:TOKYO ELECTRON LTD

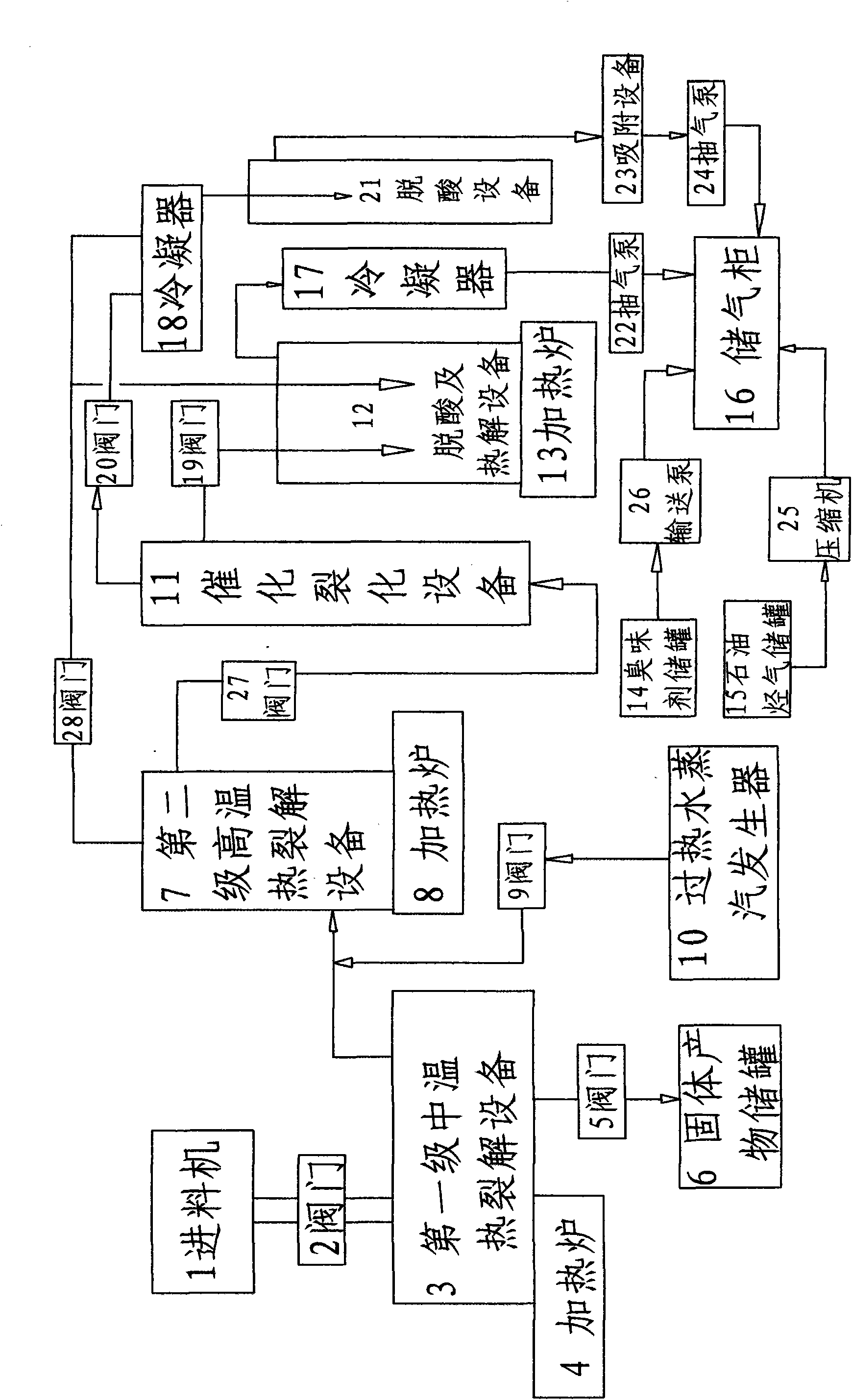

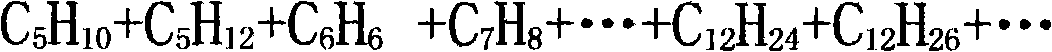

Method for preparing engine fuel gas by using biomass and/or organic waste

InactiveCN102154044AHydrogenCombustible gas catalytic treatmentProcess engineeringInternal combustion engine

The invention discloses a method for preparing an engine fuel gas by using biomass and / or organic waste and particularly relates to a method for producing high-heat value fuel gases for engines (or internal combustion engines) for vehicles and ships by performing primary medium-temperature thermal cracking of a raw material, performing secondary high-temperature thermal cracking and / or catalytic cracking, refining fuel gas, mixing the fuel gas and other steps and by a thermochemical conversion technique.

Owner:周鼎力 +1

Method for preparing active semicoking H2S desulphurizer

InactiveCN1621498AWide variety of sourcesLow pricePhysical/chemical process catalystsOther chemical processesSorbentCoking plant

The present invention discloses the preparation process of active semi-coke H2S desulfurizer. The active semi-coke H2S desulfurizer is prepared with lignite semi-coke, anthracite or soft coal semi-coke and other carbon containing material and through first pressurized hydrothermal chemical modification, subsequent soaking with cuprammonia, CuSO4 solution or K2CO3 solution, drying and high temperature calcining. The present invention has the features of wide material source, low cost, repeated use of the adsorbent product, final use in waste water treatment and as fuel and no secondary pollution. The present invention may be used widely in purifying gas in various plants and environment protecting industry.

Owner:OCEAN UNIV OF CHINA

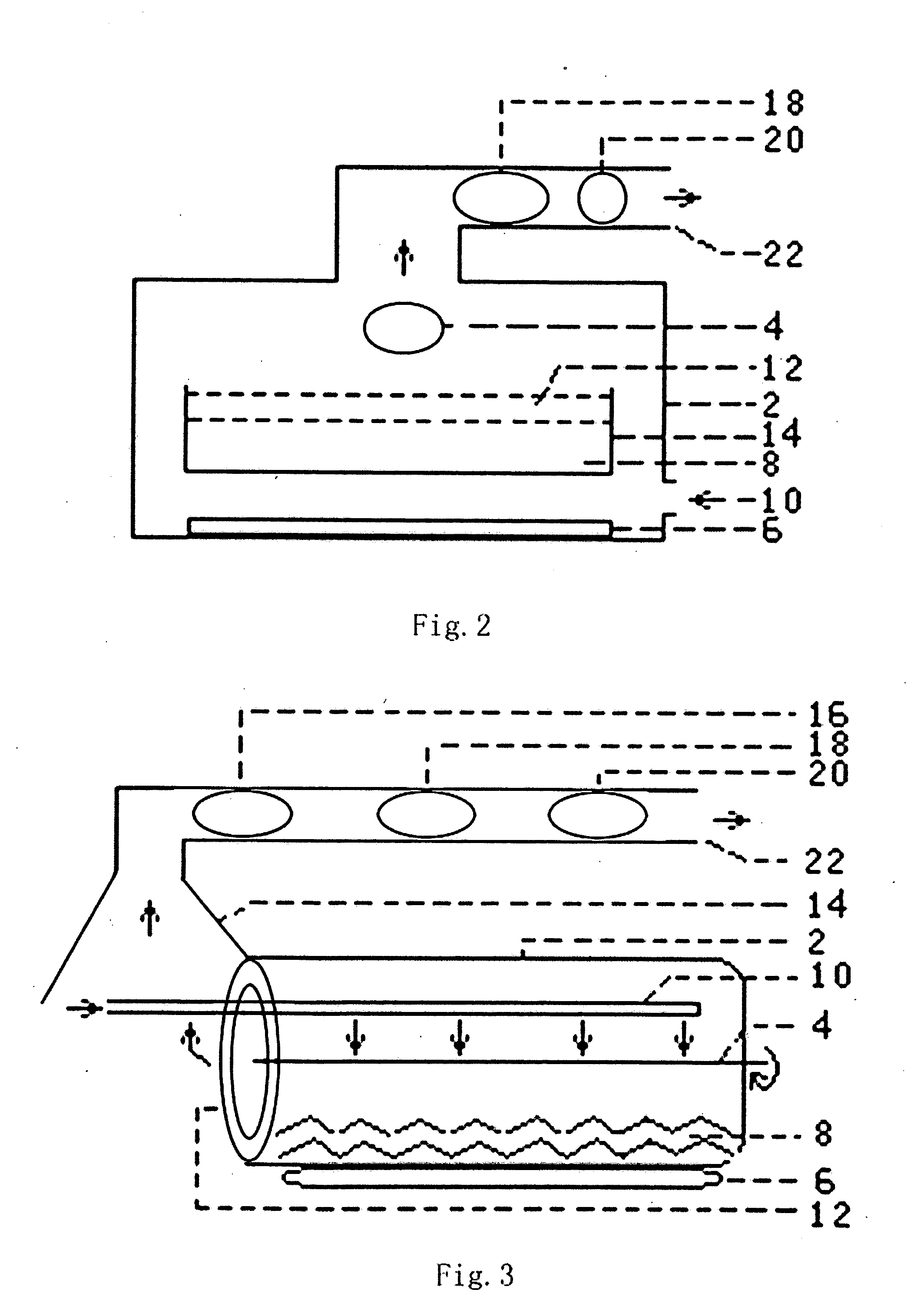

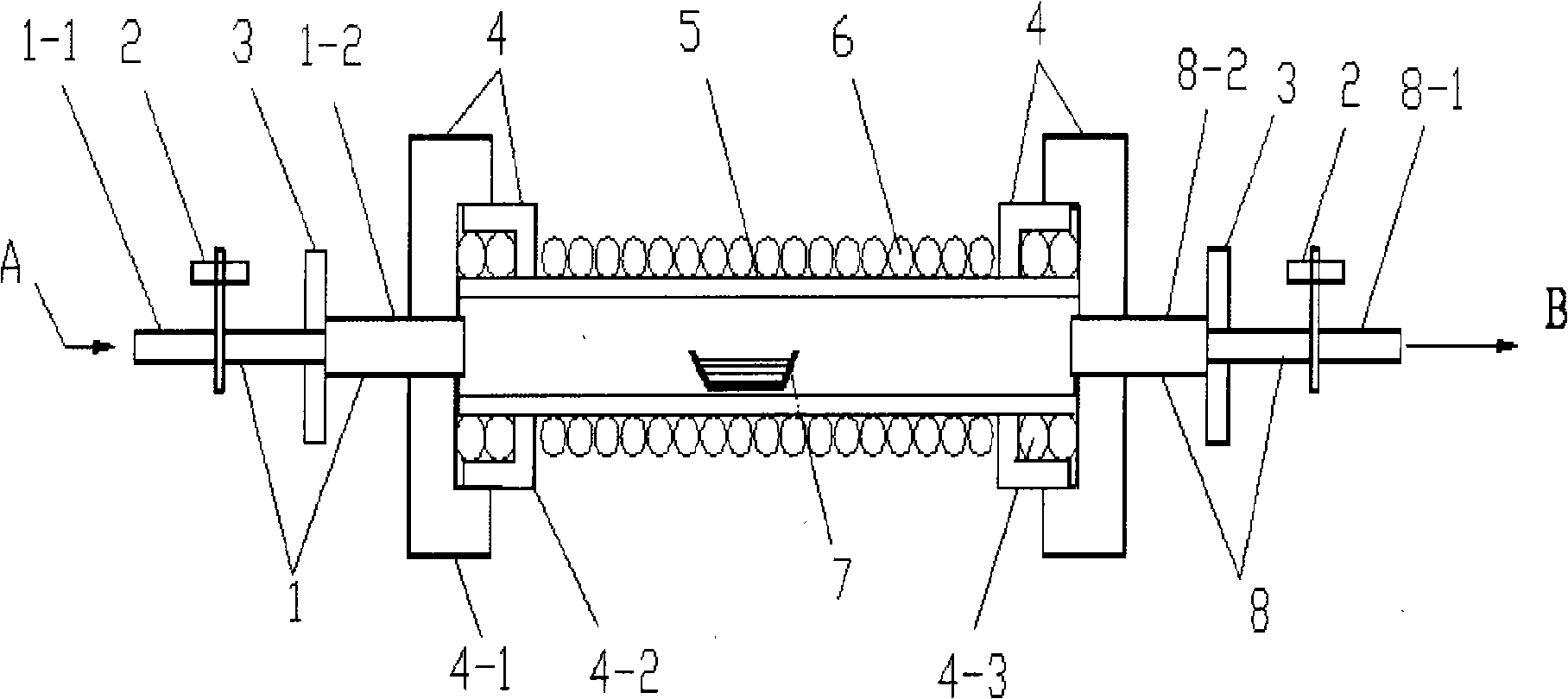

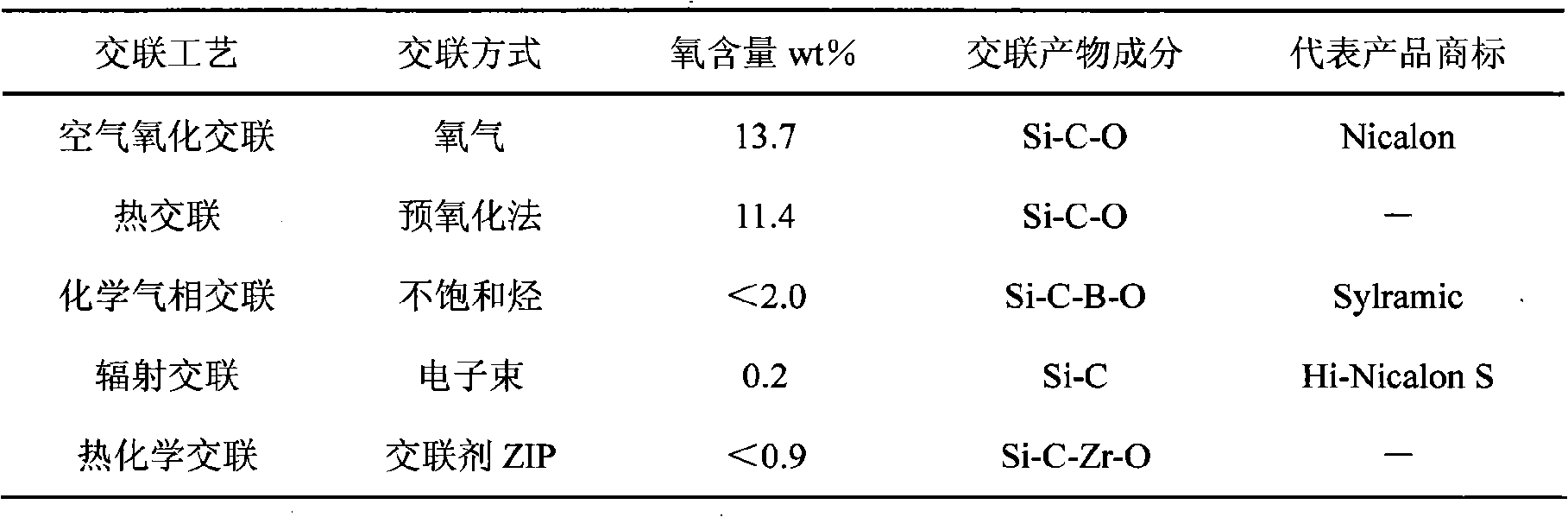

Method for preparing silicone carbide fibre by thermochemical crosslinking and crosslinking apparatus therefor

InactiveCN101280474AReduce dosageIncrease the degree of cross-linkingFibre chemical featuresCross-linkSlurry

A thermo-chemical cross-linking preparation method of silicone carbide fiber and a cross-linking device relates to a silicone carbide fiber, in particular to a method that the thermo-chemical cross-linking of organometallic compounds is used for the preparation of silicone carbide fiber and the cross-linking device of the method, which provides a thermo-chemical cross-linking preparation method of silicone carbide fiber and a cross-linking device of the method and provided with a quartz glass tube, an inlet tube, an outlet tube, a sealing steel sleeve, a gas flow control valve, a heating coil and a quartz boat. The heating coil is arranged outside of the quartz glass tube. The inlet and outlet tubes are respectively linked on both ends of the quartz glass tube through the sealing steel sleeve, and the quartz is disposed inside the quartz glass tube. The PCS and a cross-linking agent are dissolved in the trtrahydrofuran, and the slurry is produced. The slurry is in ageing and with the dry-spinning, thus the precursor fiber is produced. The precursor disposed into the quartz is then disposed into the cross-linking device for the thermo-chemical cross-linking. The PCS cross-linking fiber is obtained, which is then disposed into a high-temperature furnace for pyrolysis and sintering. Therefore, the silicon carbide fiber is produced.

Owner:XIAMEN UNIV

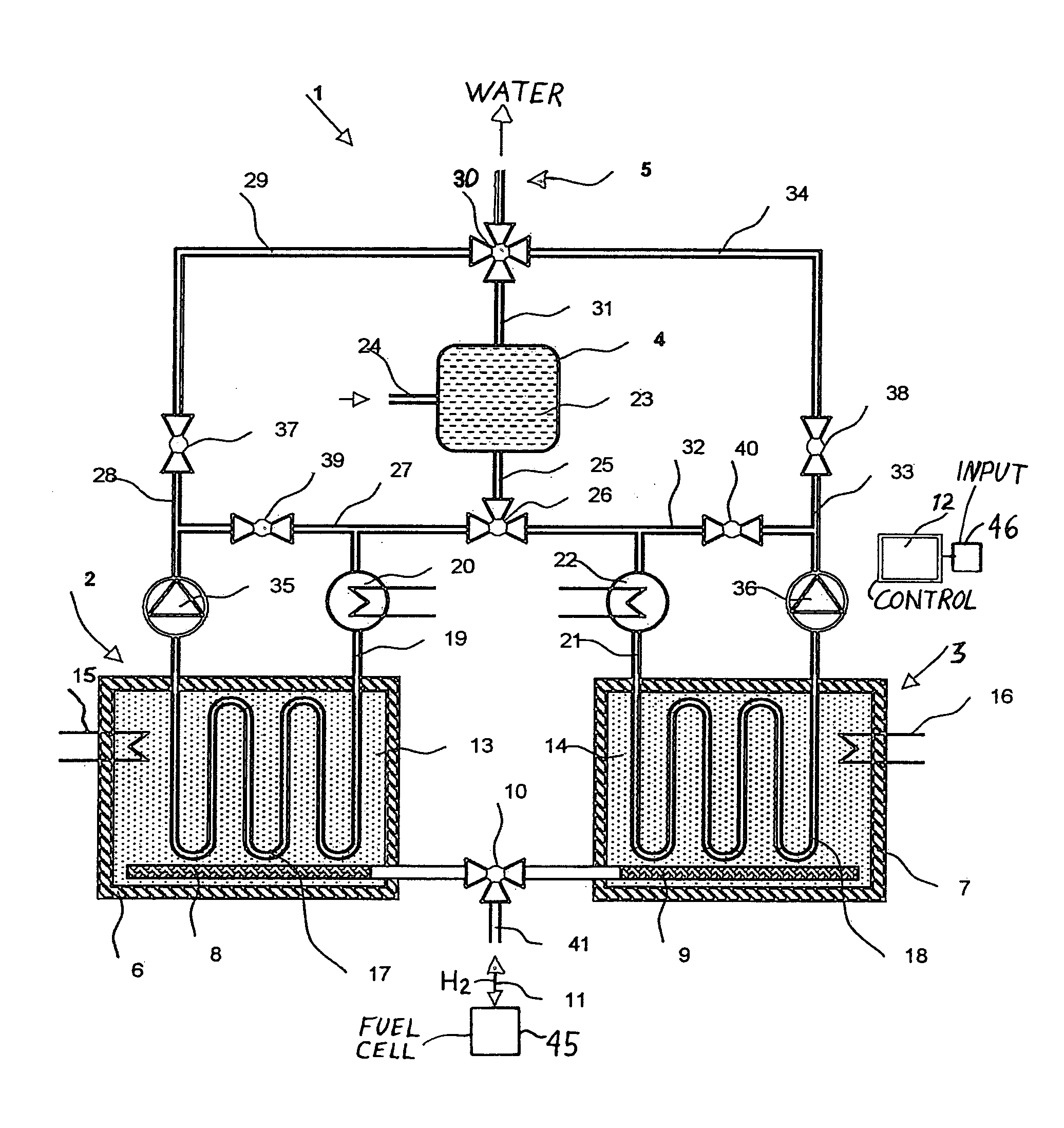

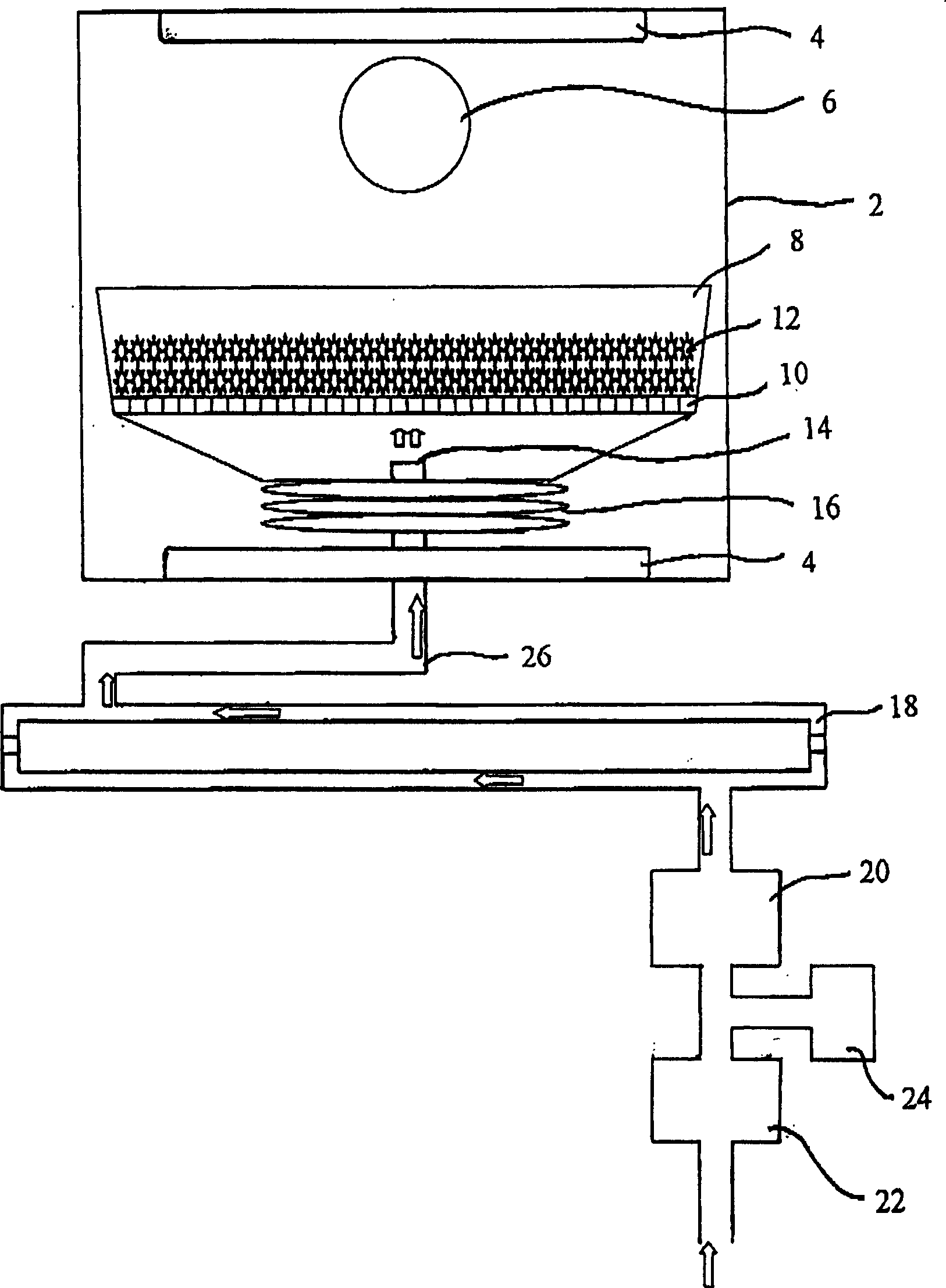

Method and apparatus for tempering gaseous and/or liquid media in transportation vehicles, particularly in aircraft

InactiveUS20050253019A1Heating up fastSupply will become excessiveHeat storage plantsAir-treatment apparatus arrangementsAirplaneHydrogen sorption

For example an aircraft includes a fluid tempering arrangement to supply a gaseous and / or liquid, heated and / or cooled, fluid such as water. At least one thermochemical reservoir is in heat exchange relation with a conduit system, having at least one valve and a controller that controls the transfer of heat between the fluid and the thermochemical reservoir to adjust the temperature of the fluid provided to an outlet. Preferably two interconnected thermochemical reservoirs respectively contain hydride-forming metals having different hydrogen sorption-desorption temperatures. A method involves supplying and chemically storing heat energy in at least one thermochemical reservoir, then performing a reverse reaction to release and transfer heat from at least one thermochemical reservoir to the fluid, preferably involving the sorption and desorption of hydrogen in respective hydride-forming metals in two reservoirs exhibiting different hydrogen reaction temperatures. Heat energy produced electrically during low electrical demand can be chemically stored and later released for heating the fluid during high electrical demand.

Owner:AIRBUS OPERATIONS GMBH

Changing of hydrophilic/hydrophobic characteristics of natural organic substances in oxidation thermo-chemical drying course

InactiveCN1529632ASimple processLow costSludge treatment by oxidationOther chemical processesNatural organic matterCarbonate

Owner:梁知维 +1

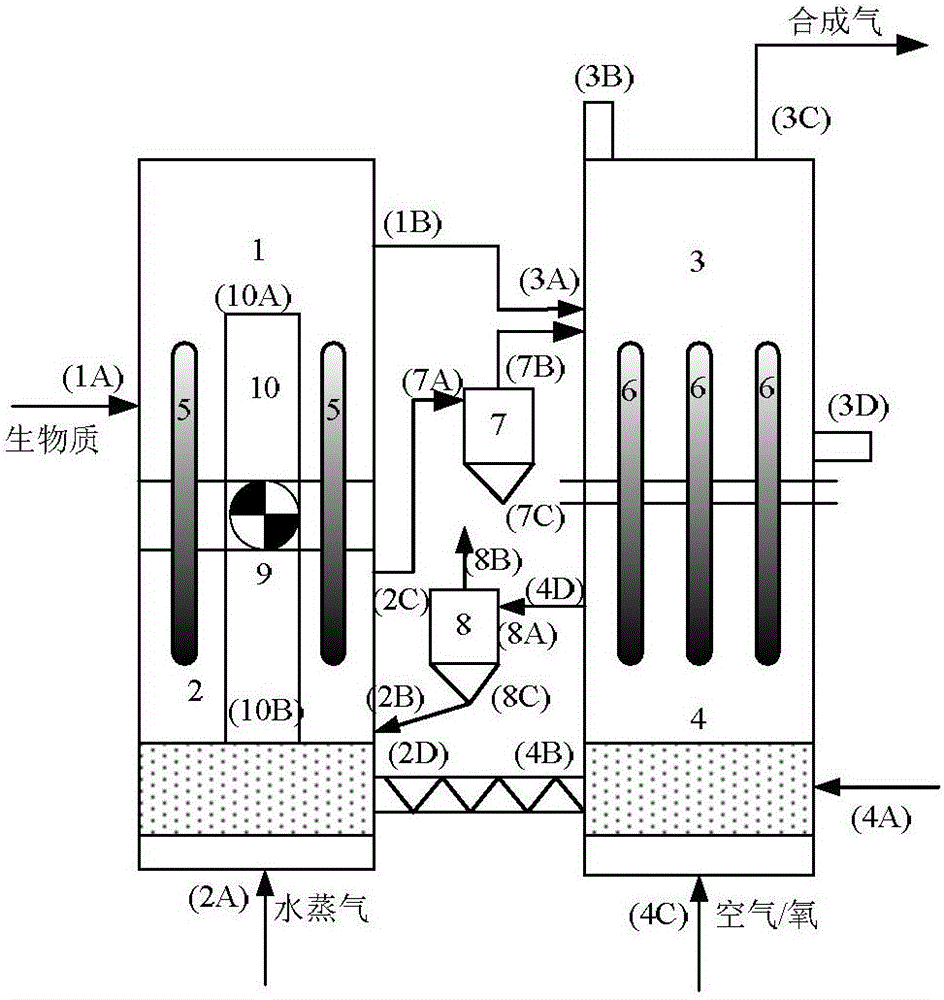

Device for producing synthesis gas through biomass gasification and method of device

ActiveCN105907430AFacilitated hydrocrackingFacilitate catalytic reformingCombustible gas chemical modificationGasification processes detailsHigh concentrationCo2 absorption

The invention discloses a device for producing synthesis gas through biomass gasification and a method of the device. The device mainly comprises a pyrolysis reactor, a gasification reactor, a reforming reactor, a regeneration reactor and heat pipes. In the technological process, biomass is firstly pretreated with a sylvite solution, the pretreated biomass is subjected to pyrolysis in the pyrolysis reactor, coke is gasified in the gasification reactor, the gasification reactor and the regeneration reactor generate hydrogen-rich gas through circulation bed material heat loading and CO2 absorption, and the hydrogen-rich gas enters the reforming reactor to carry out hydrogenation catalytic cracking and reforming on pyrolysis gas. Therefore, the synthesis gas with low tar and high-concentration H2 and CO is obtained through step-by-step pyrolysis, gasification, reforming and regenerative combustion at mild reaction temperature, meanwhile, potassium-rich agricultural fertilizer is by-produced, stepped transfer of heat in the biomass thermo-chemical conversion process is achieved, the energy utilization efficiency is improved, and economic additional value is increased.

Owner:SOUTHEAST UNIV

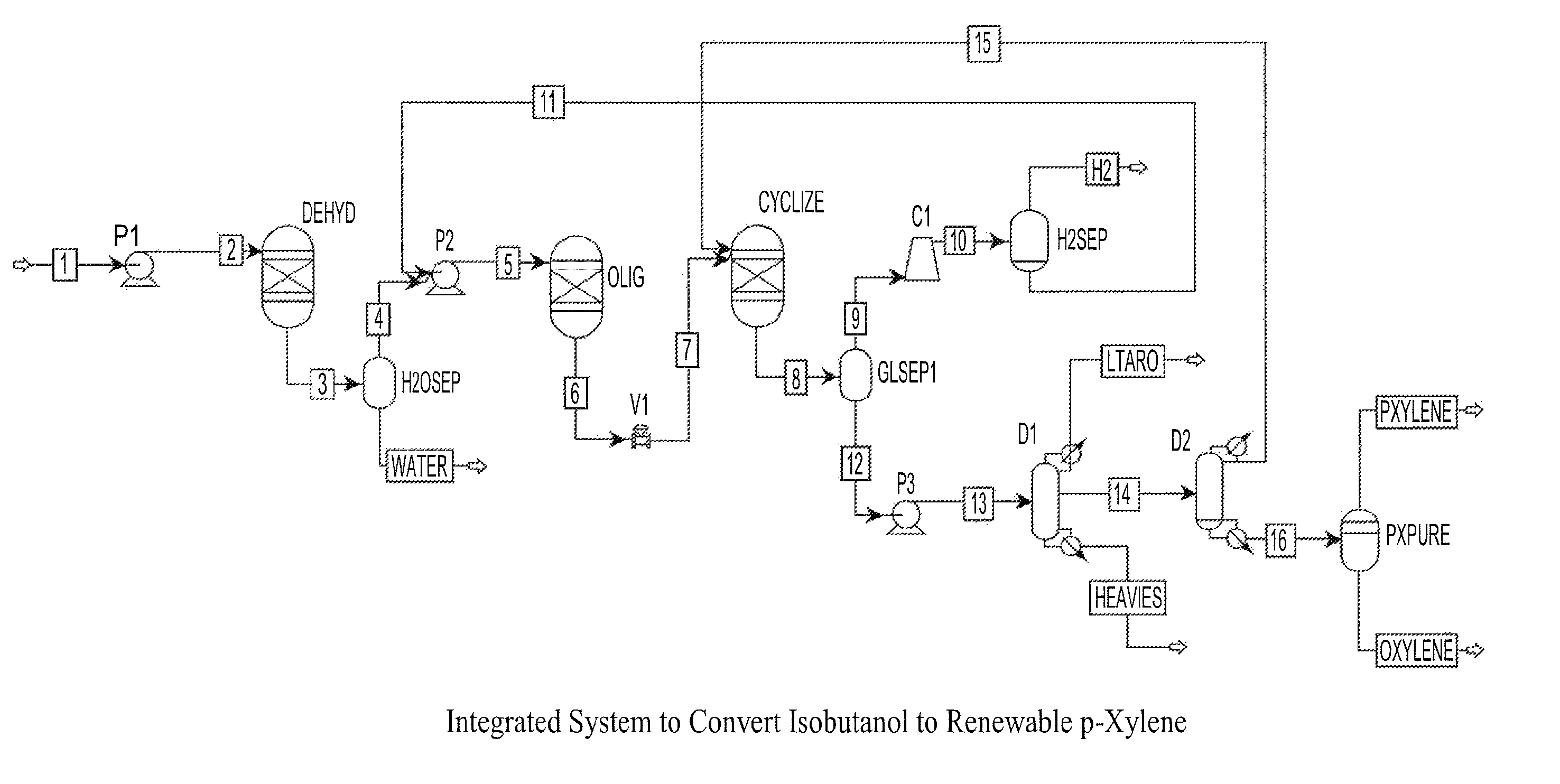

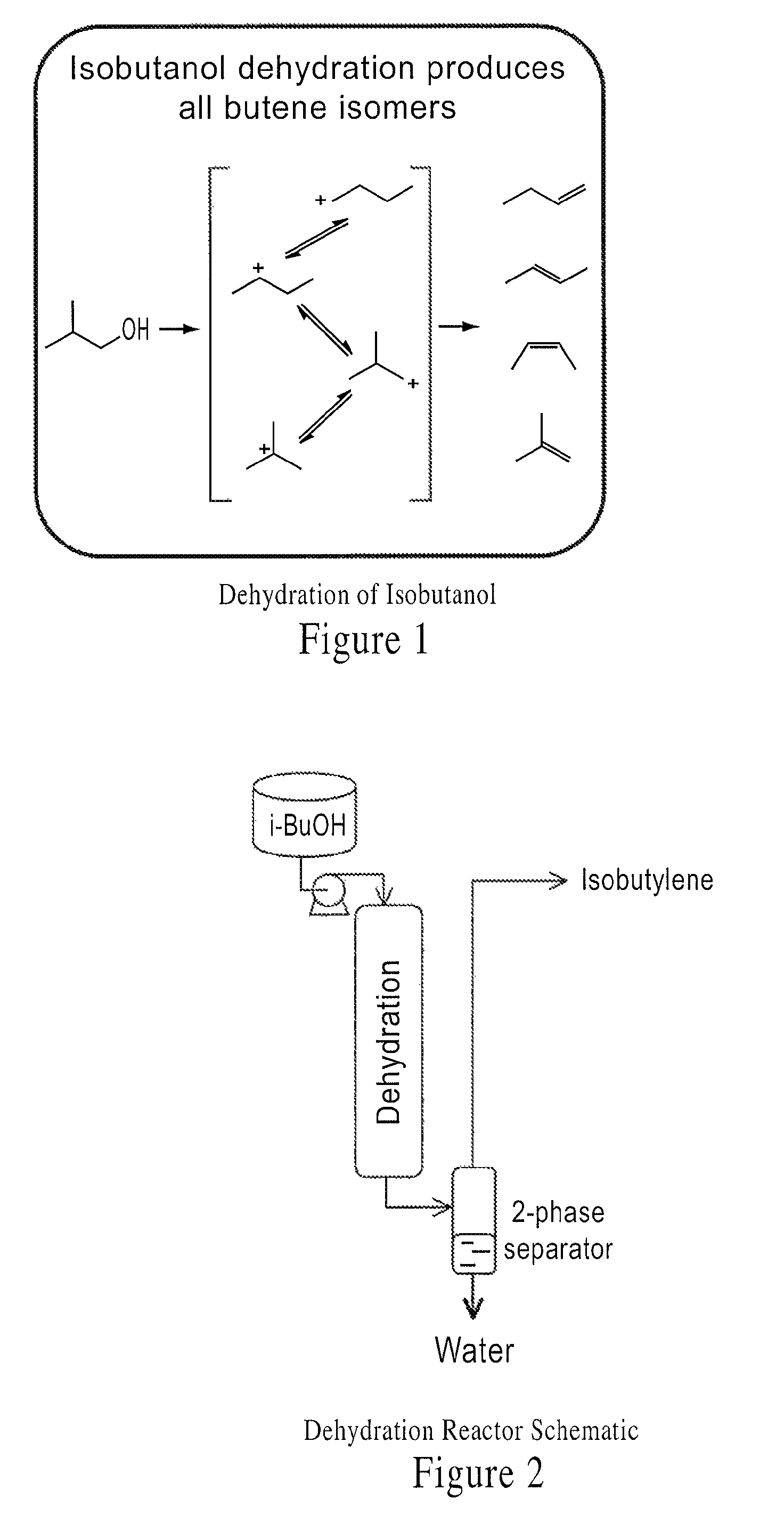

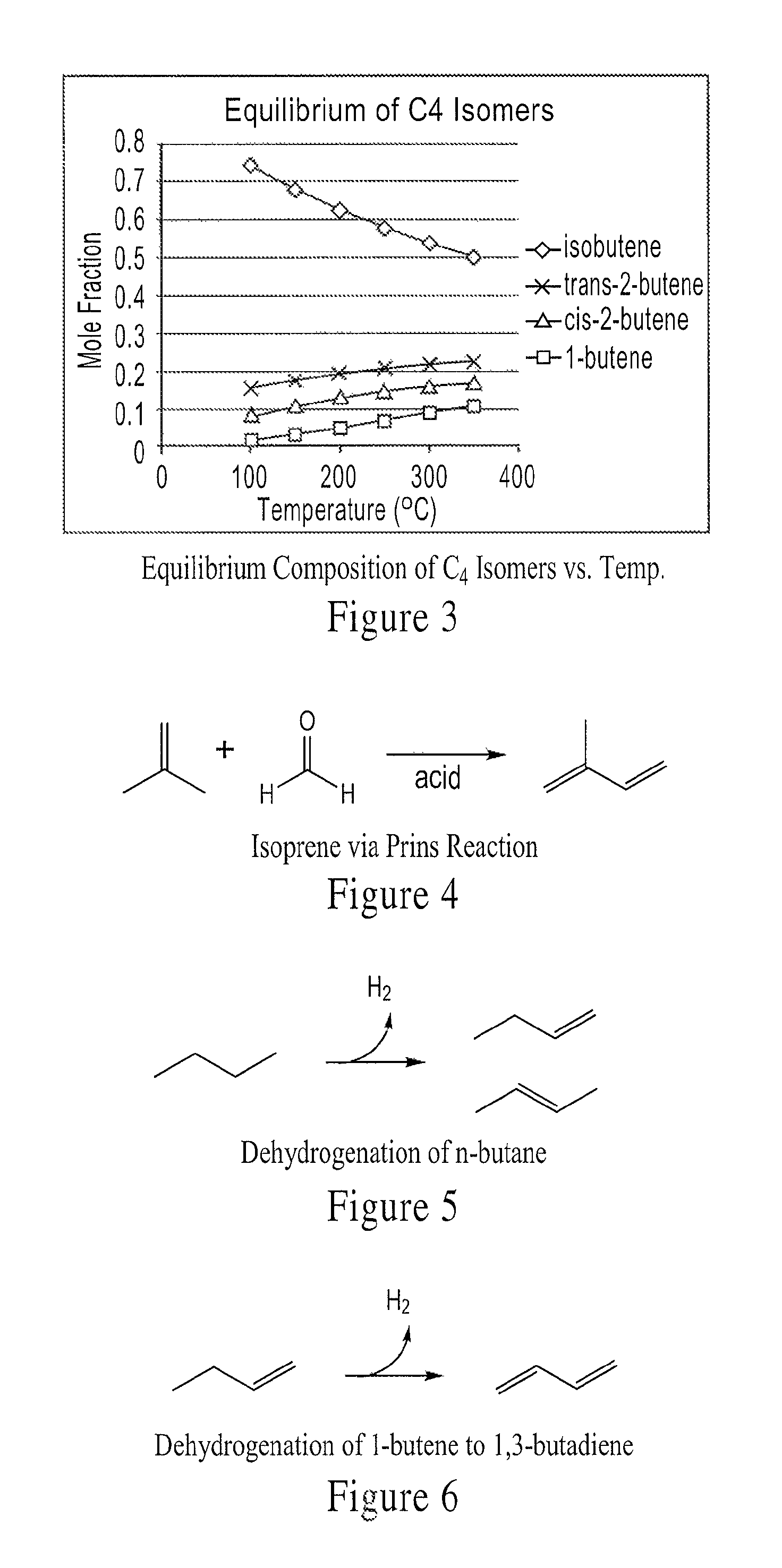

Integrated methods of preparing renewable chemicals

ActiveUS8450543B2Readily and flexibly adaptHydrocarbon by dehydrogenationHydrocarbon by hydrogenationPolyesterPolymer science

Isobutene, isoprene, and butadiene are obtained from mixtures of C4 and / or C5 olefins by dehydrogenation. The C4 and / or C5 olefins can be obtained by dehydration of C4 and C5 alcohols, for example, renewable C4 and C5 alcohols prepared from biomass by thermochemical or fermentation processes. Isoprene or butadiene can be polymerized to form polymers such as polyisoprene, polybutadiene, synthetic rubbers such as butyl rubber, etc. in addition, butadiene can be converted to monomers such as methyl methacrylate, adipic acid, adiponitrile, 1,4-butadiene, etc. which can then be polymerized to form nylons, polyesters, polymethylmethacrylate etc.

Owner:GEVO INC

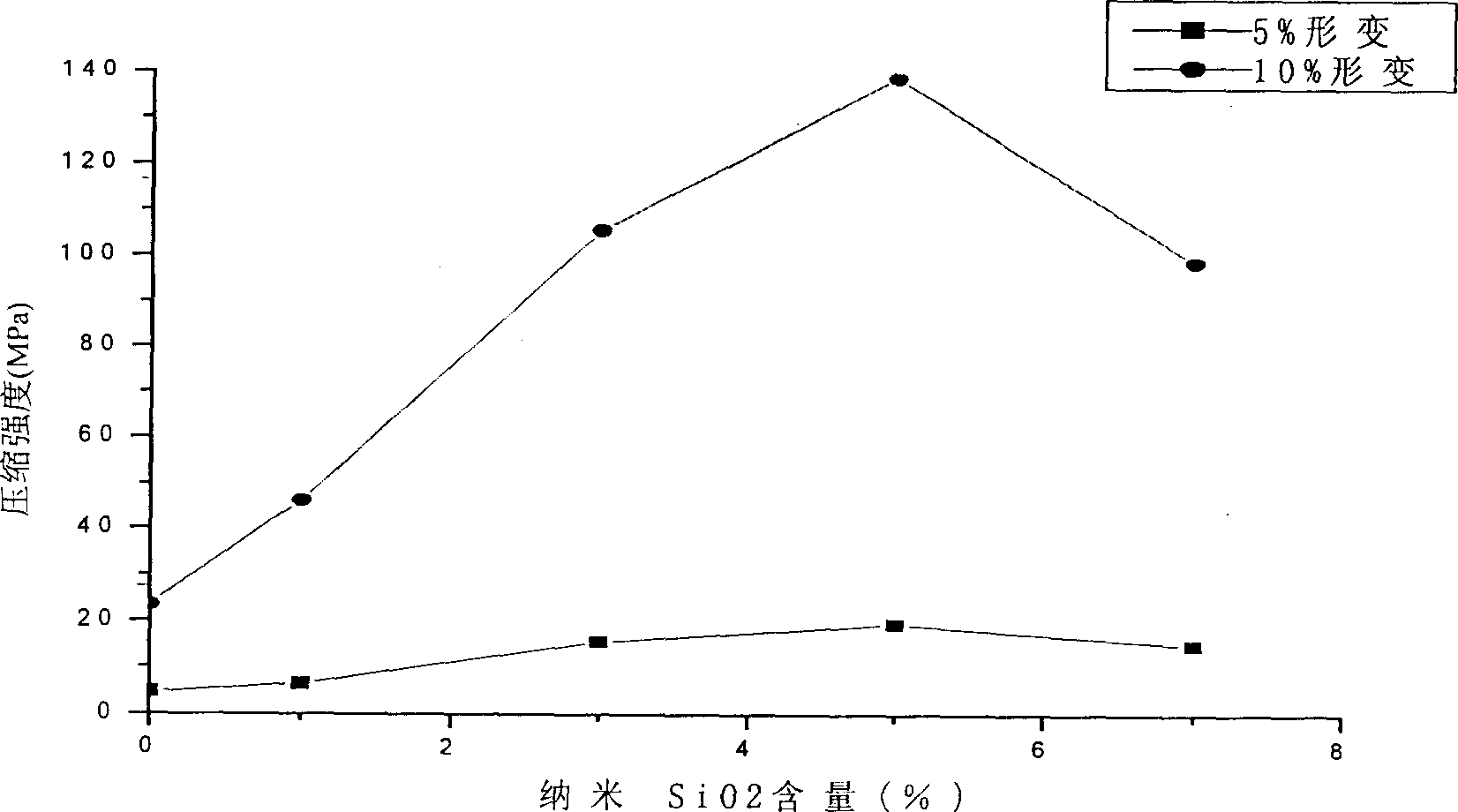

Prepn. process of nano SiO2/boron bakelite resin nano composite material

InactiveCN1834151AImprove heat resistanceImproves ablation resistanceFireproof paintsNano compositesResin matrix

This invention is attributed to the technology of nano-composite materials and specifically relates to a method to prepare nano-sized silicon dioxide / boron phenolic resin nano-composite materials. In this method, solution blending and ultrasonic wave-aided dispersion are combined so as to ensure nano-sized dispersion of the nano-particles in composite materials. The nano-sized silicon dioxide is surface treated so as form good interfaces with boron phenolic resin matrix and to adequately take advantages of nano-sized silicon dioxide and boron phenolic resin. This invention aims at preparing boron phenolic resin nano-composites with different nano-sized silicon dioxide content by reasonable technique control. The rigidity, wear resistance and thermo-chemical stability of nano-sized silicon dioxide and good mechanical properties, thermo resistance and ablation resistance of boron-modified phenolic resin are utilized, and therefore the prepared nano-sized silicon dioxide / boron phenolic resin nano-composite materials can be widely used in high-temperature abrasion materials, ablation resistant materials, special structural materials and thermo resistant materials.

Owner:TONGJI UNIV

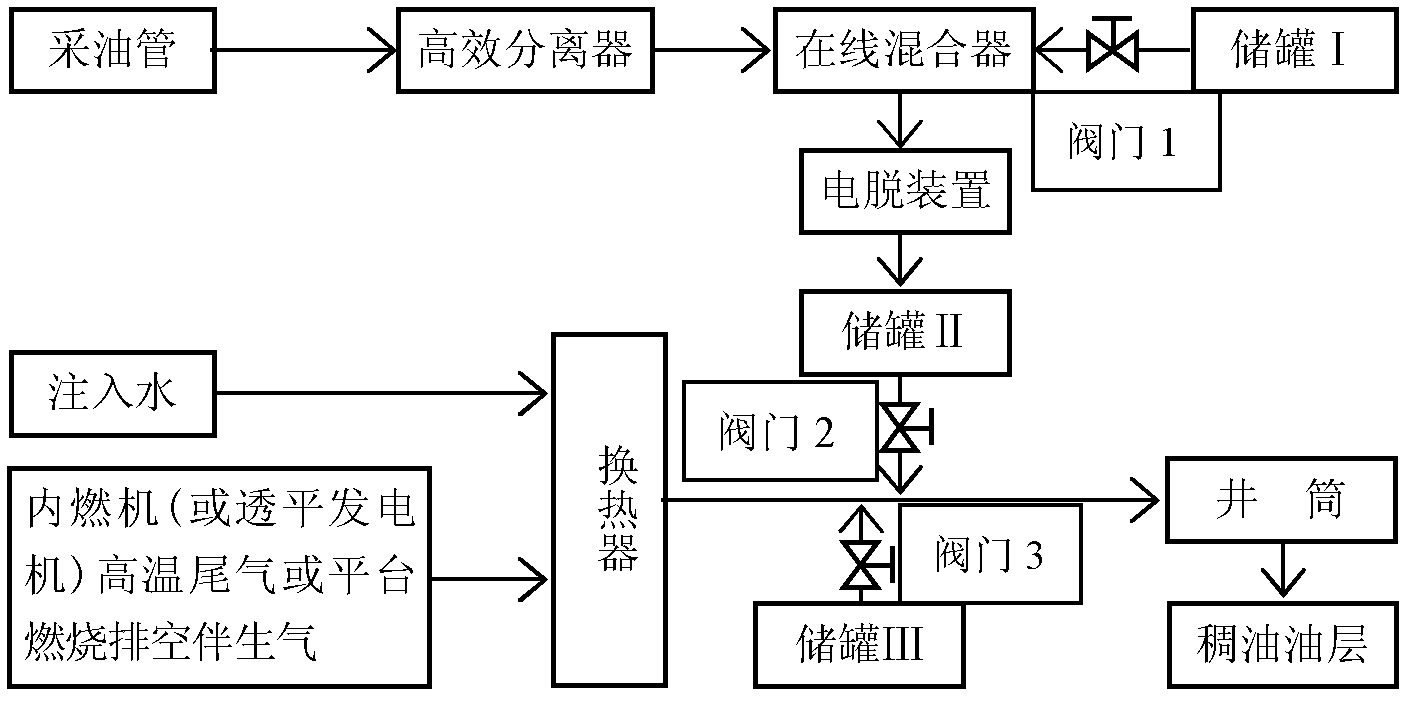

Thermo-chemical oil extraction method of offshore thickened oil

ActiveCN102635342AGood emulsification and viscosity reduction effectLow priceFluid removalCombustionSURFACTANT BLEND

The invention discloses a thermo-chemical oil extraction method of offshore thickened oil. The method comprises the following steps of: heating water injected into a heat exchanger to 150-200 DEG C by utilizing high-temperature tail gas or combustion waste heat; then, carrying a surfactant on line by the injected water; injecting a catalyst solution into a section plug; and injecting the surfactant and the catalyst solution into a thickened oil layer to carry out chemically reinforced heat oil displacement. The method disclosed by the invention takes full advantages of local conditions, recycles the waste heat and saves energy; the temperature of the injected water is raised on line to realize low-temperature heat water oil displacement; the conditions are more alleviated (compared with the traditional thickened oil thermo-chemical oil extraction by injecting steam); and the investment cost and the maintenance cost are lower and the energy-saving and synergistic offshore thermo-chemical oil displacement can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Material for contact etch layer to enhance device performance

InactiveUS20050245081A1Minimize impactImprove conformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal chemical vapor depositionSilanes

Stress level of a nitride film is adjusted as a function of two or more of the following: identity of a starting material precursor used to make the nitride film; identity of a nitrogen-containing precursor with which is treated the starting material precursor; ratio of the starting material precursor to the nitrogen-containing precursor; a set of CVD conditions under which the film is grown; and / or a thickness to which the film is grown. A rapid thermal chemical vapor deposition (RTCVD) film produced by reacting a compound containing silicon, nitrogen and carbon (such as bis-tertiary butyl amino silane (BTBAS)) with NH3 can provide advantageous properties, such as high stress and excellent performance in an etch-stop application. An ammonia-treated BTBAS film is particularly excellent in providing a high-stress property, and further having maintainability of that high-stress property over repeated annealing.

Owner:IBM CORP

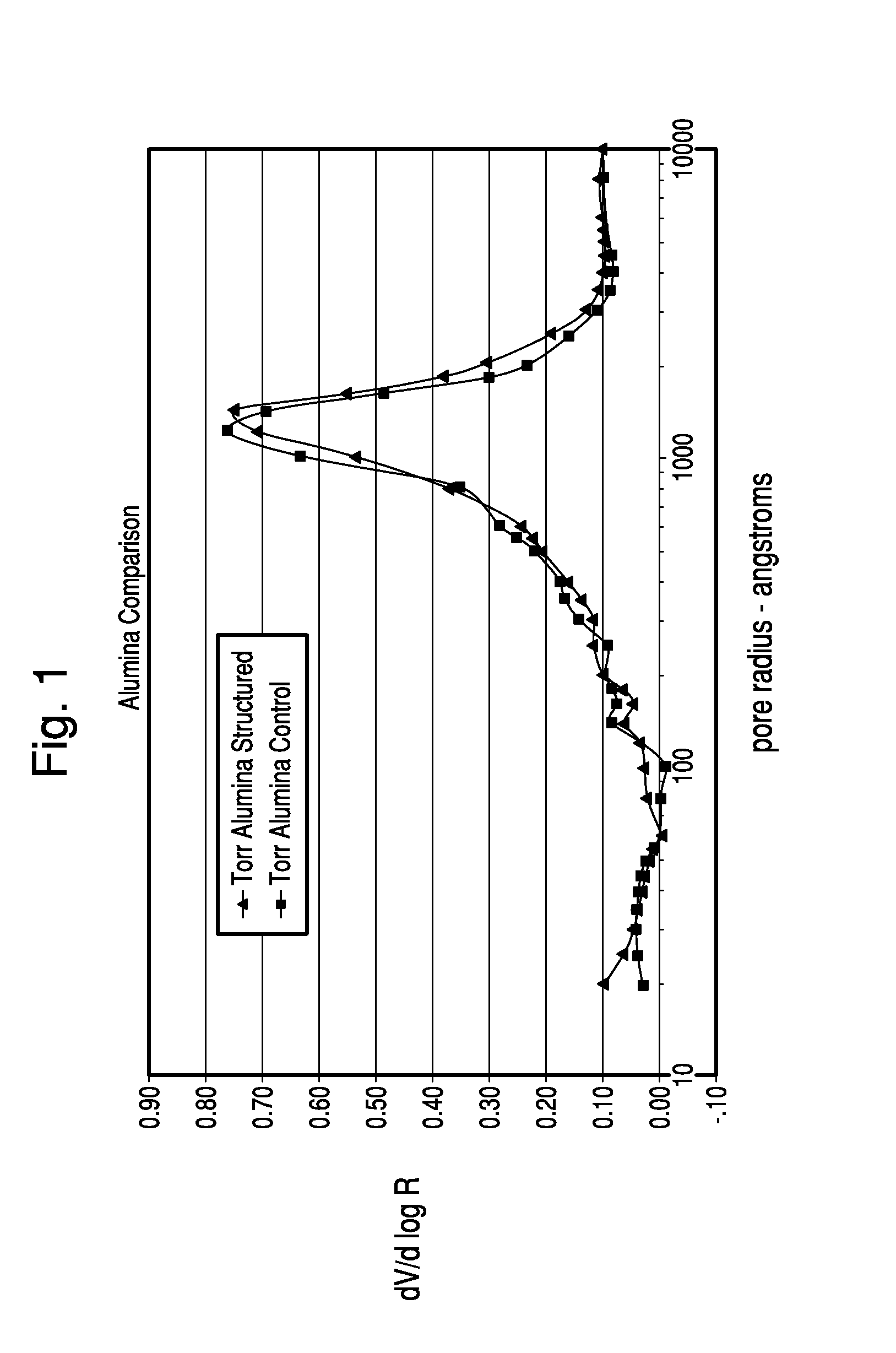

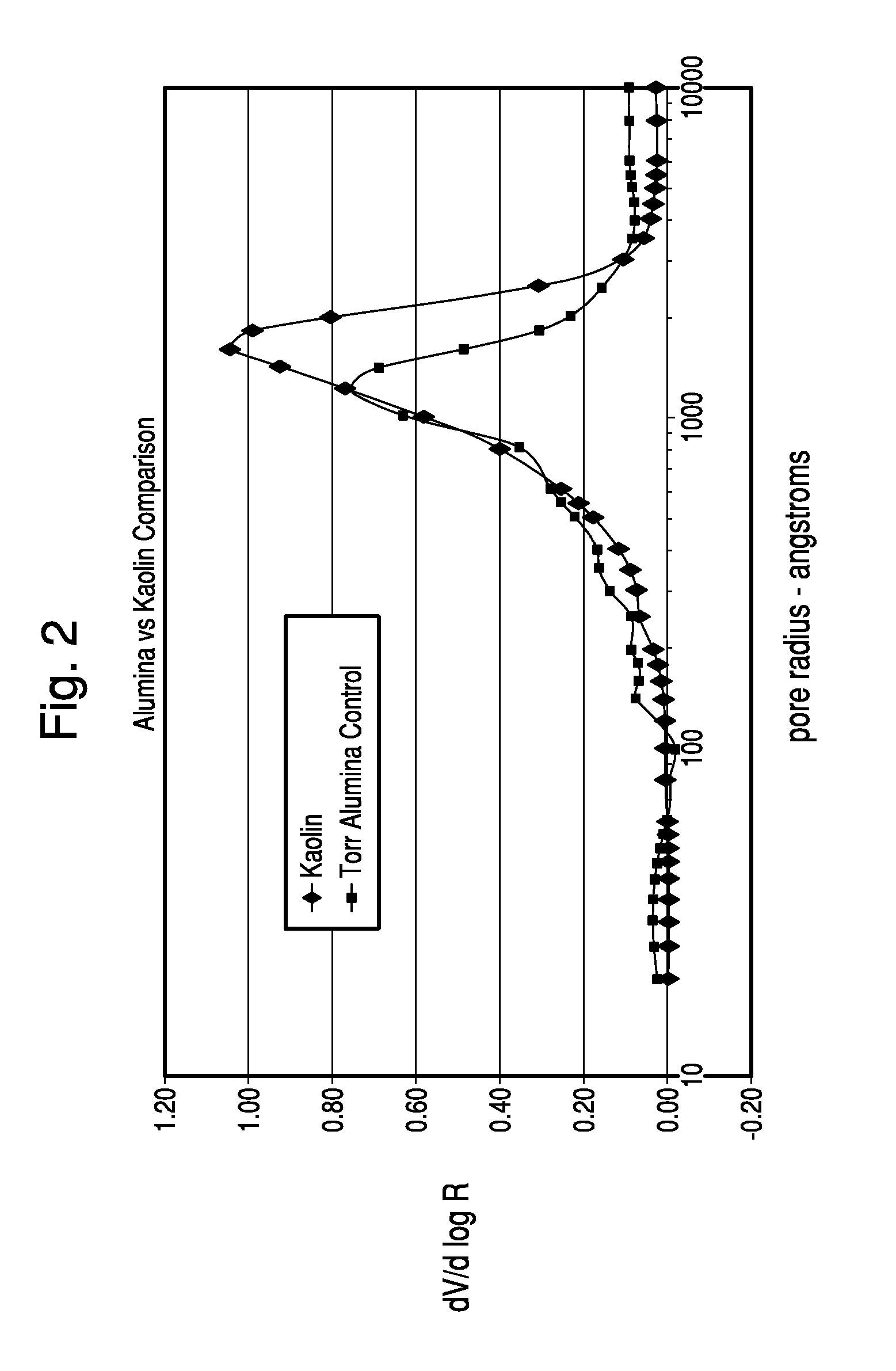

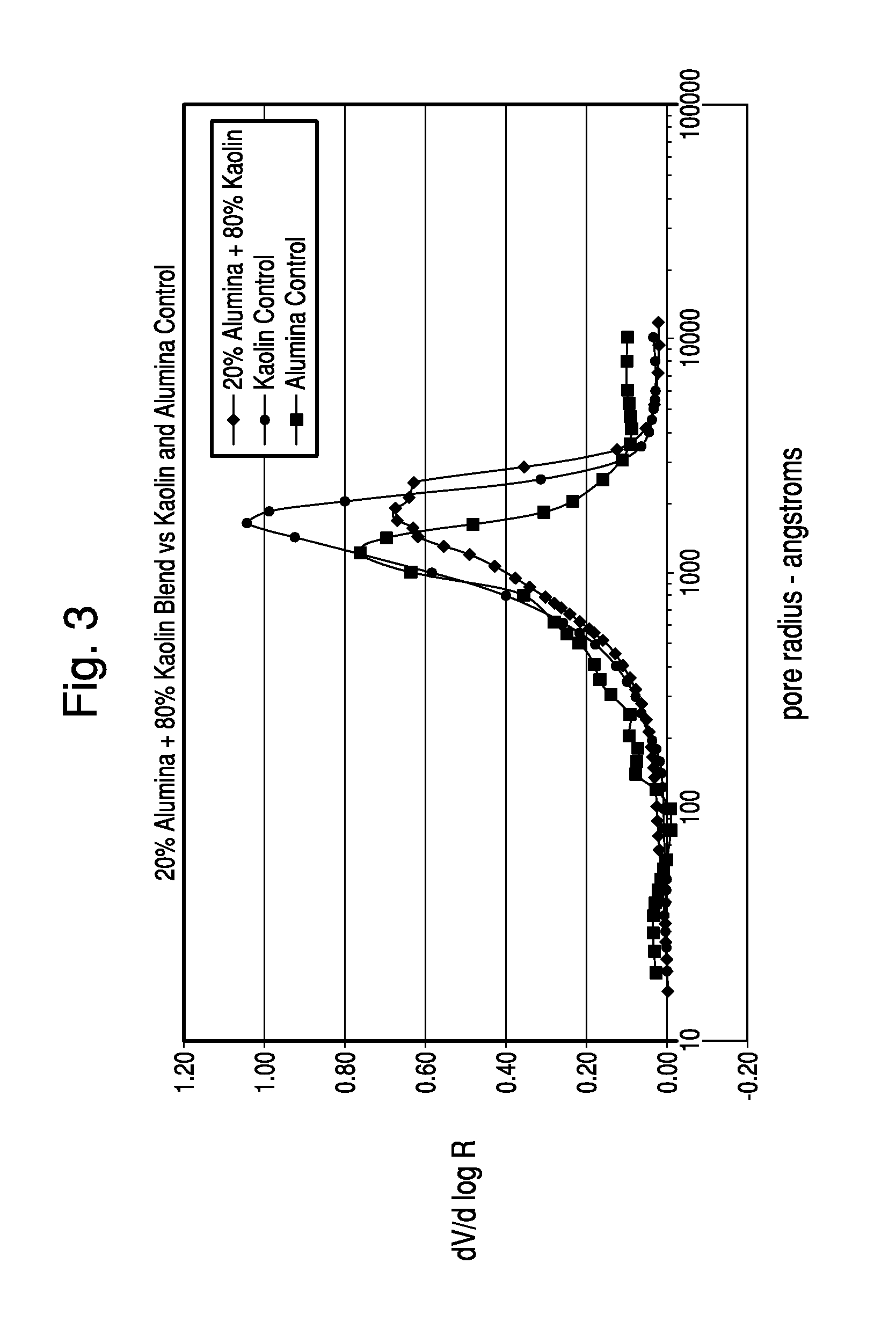

Thermochemical Structuring of Matrix Components for FCC Catalysts

InactiveUS20120228194A1Increase internal porosityCatalytic crackingMolecular sieve catalystsPolyphosphateMetal

A catalyst particle which comprises a metallic oxide such as kaolin is provided with the unique structure by mixing small amounts of a polyphosphate structuring agent with the metallic oxide and heating the mixture of metallic oxide and polyphosphate to allow reaction of the structuring agent with the metallic oxide.

Owner:BASF CORP

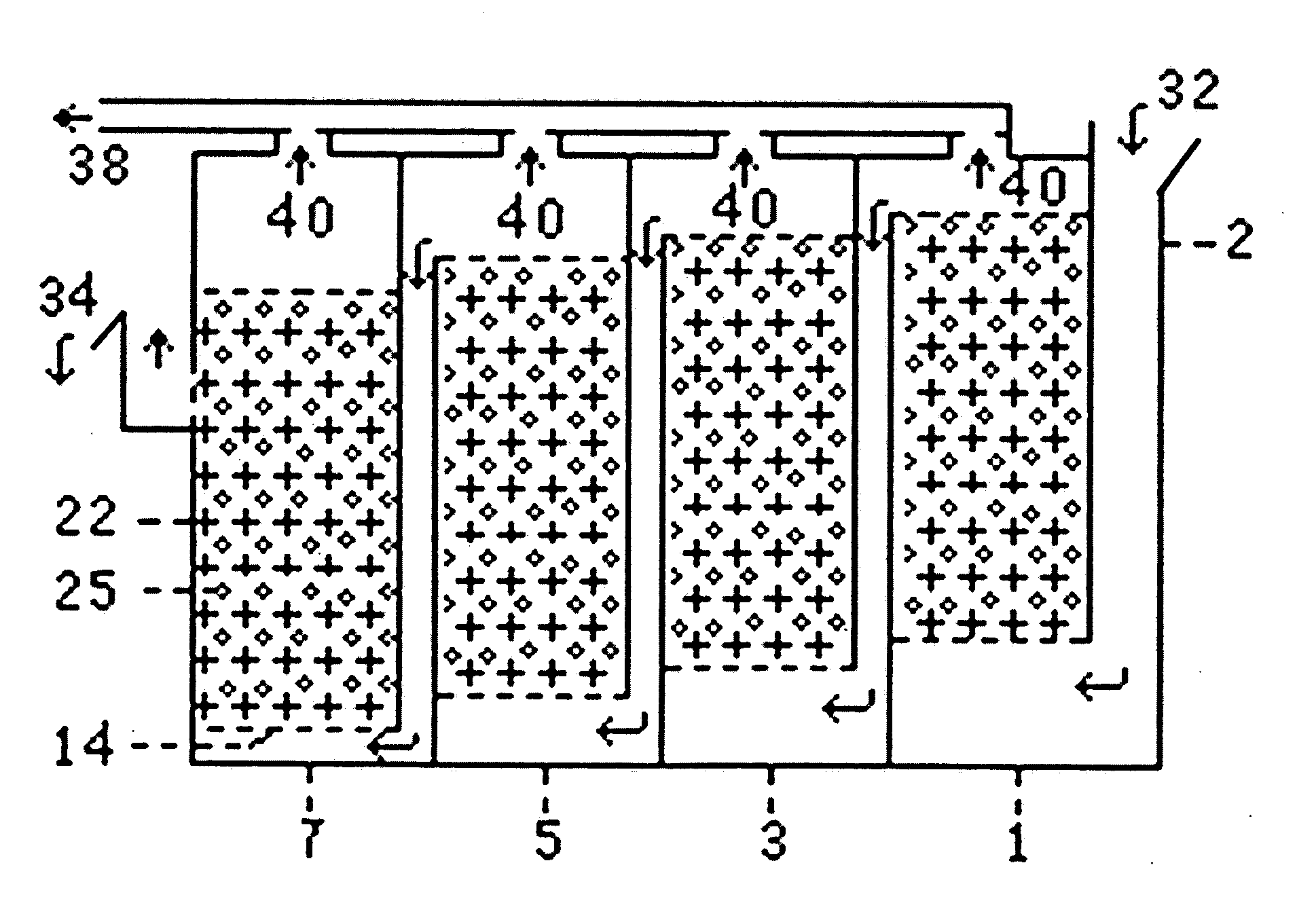

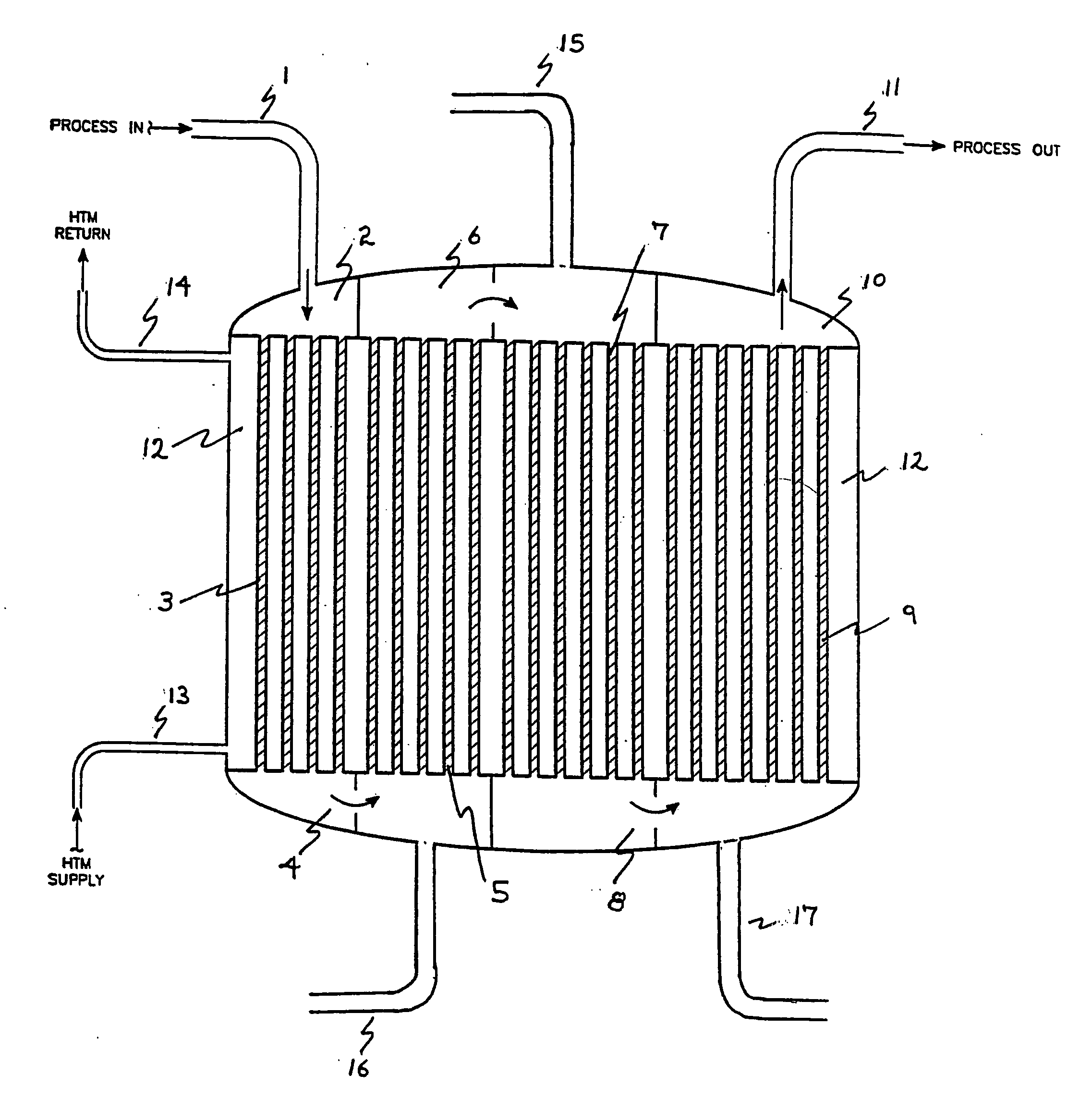

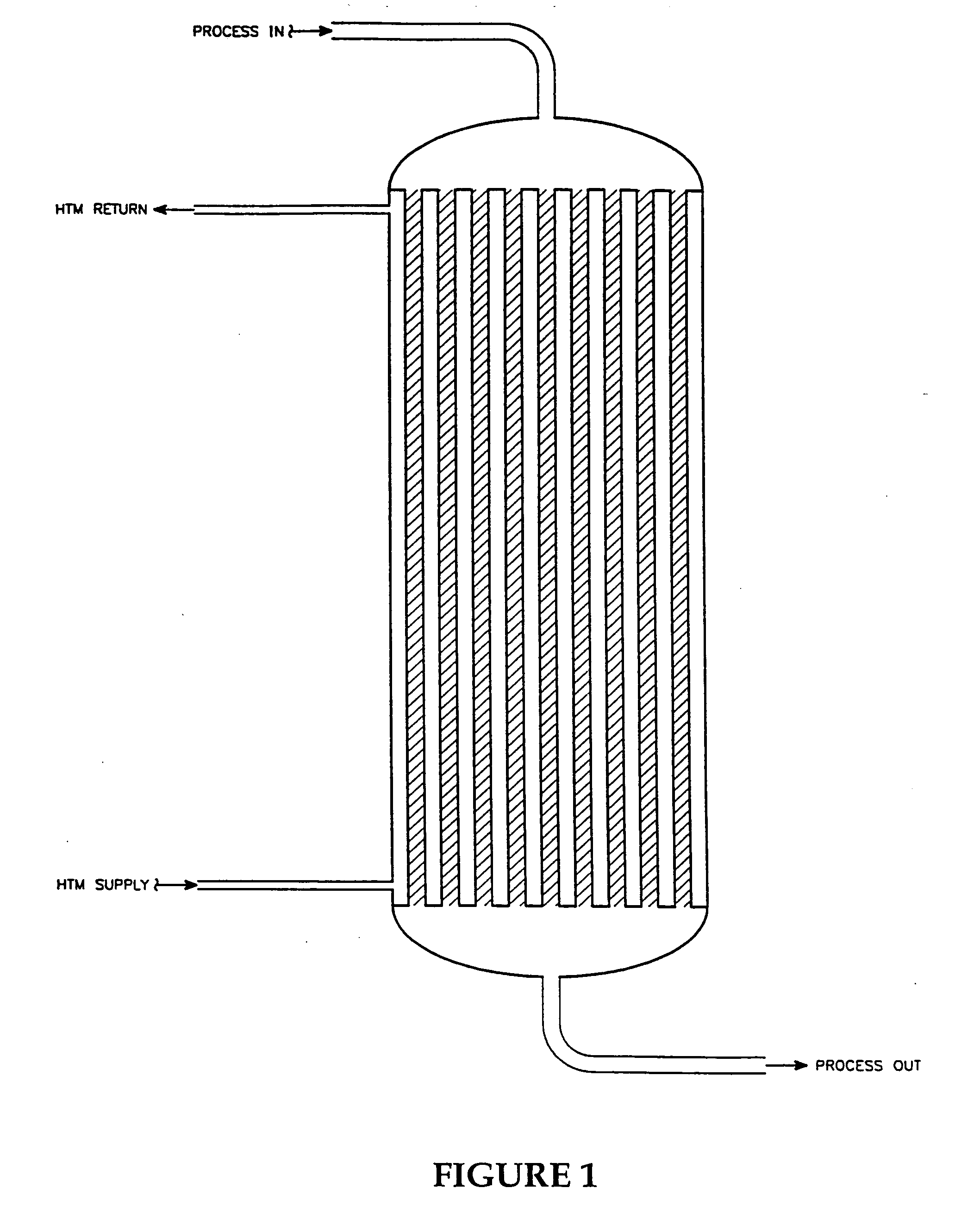

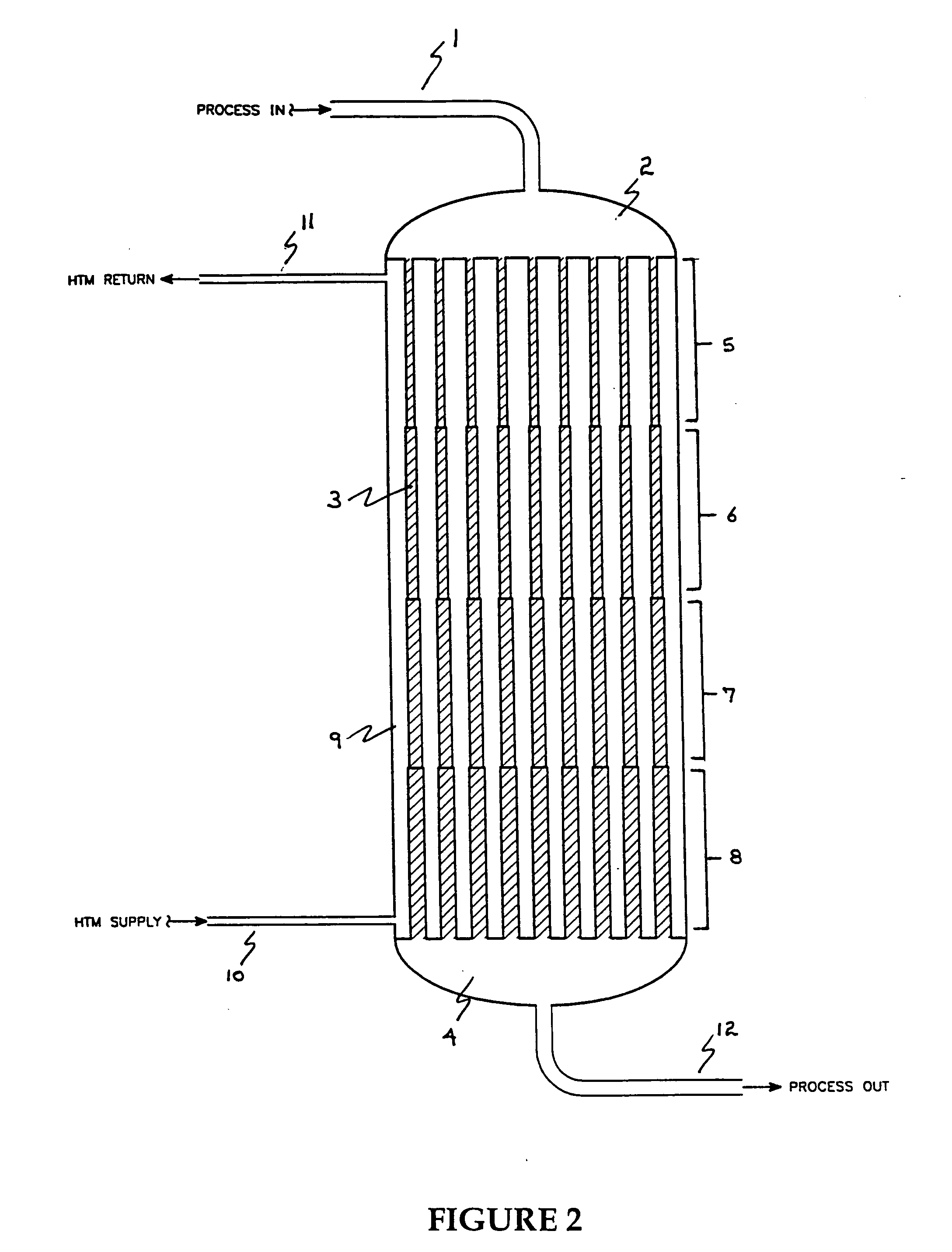

Flow reactors for chemical conversions with heterogeneous catalysts

InactiveUS20090043114A1Organic compound preparationOrganic chemistry methodsProcess systemsProcess engineering

Improved apparatus for use in process systems which include exothermic chemical conversions of organic compounds to value added products is disclosed, more particularly, flow reactors for exothermic chemical conversions using a fixed heterogeneous catalyst with means for control of the exotherm. Flow reactors of the invention comprise a plurality of walled conduits each having an outer surface disposed for contact with a heat-transfer medium, an inlet distribution manifold adapted for flow communication with a downstream manifold through channels formed by heterogeneous catalytic material disposed within each conduit during operation in a sequence of zones for catalyst having the same or different length along the longitudinal coordinate of the conduit and within each zone essentially uniform cross-section of the conduit measured in a plane perpendicular to the longitudinal coordinate thereby defining volume of the zone, and the sequence of zones comprising of at least two zones such that each downstream zone has a larger or smaller cross-section than the contiguous upstream zone. Another aspect of the invention includes processes which use such flow reactors, for example the continuous manufacture of maleic anhydride.

Owner:BP CORP NORTH AMERICA INC

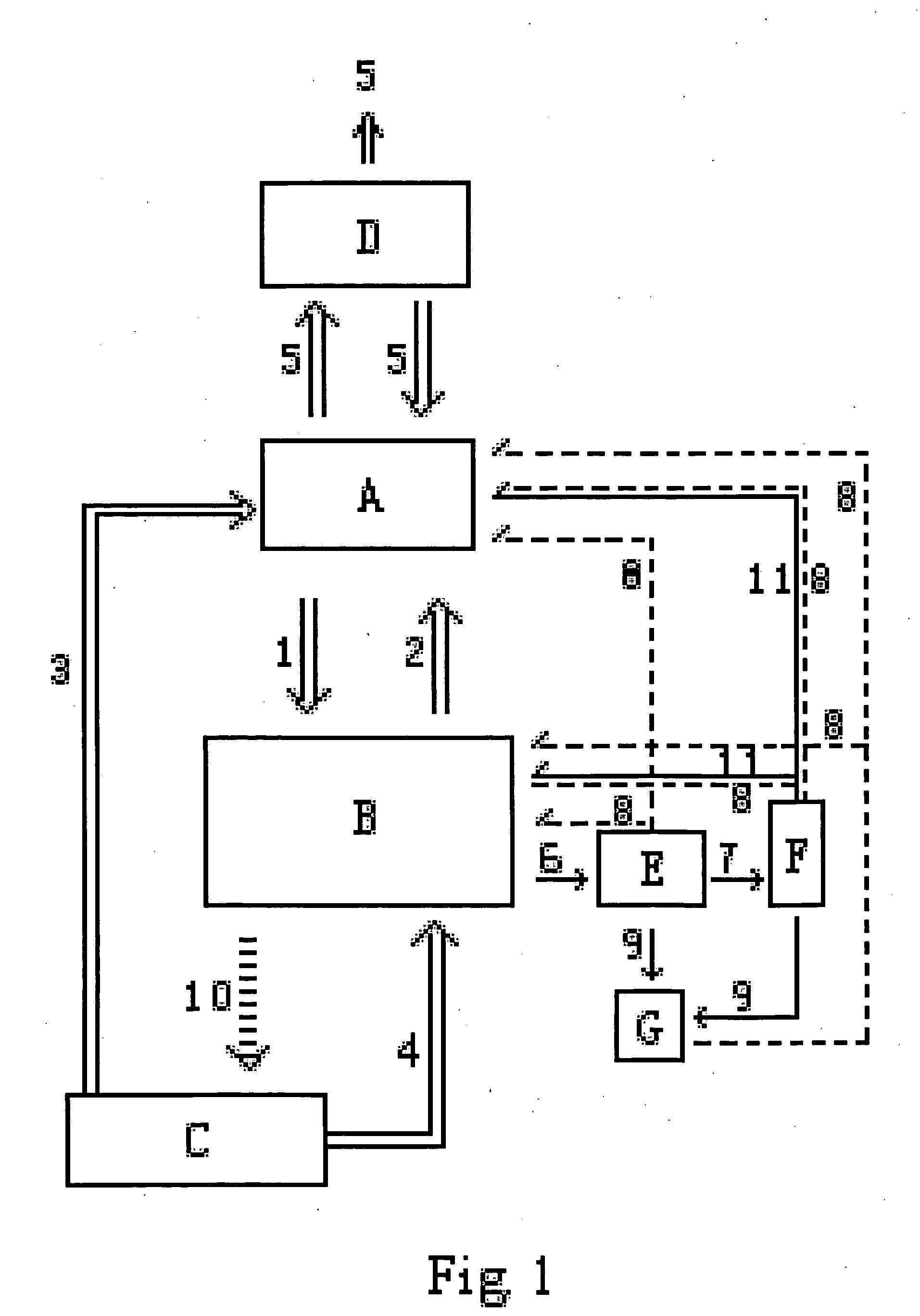

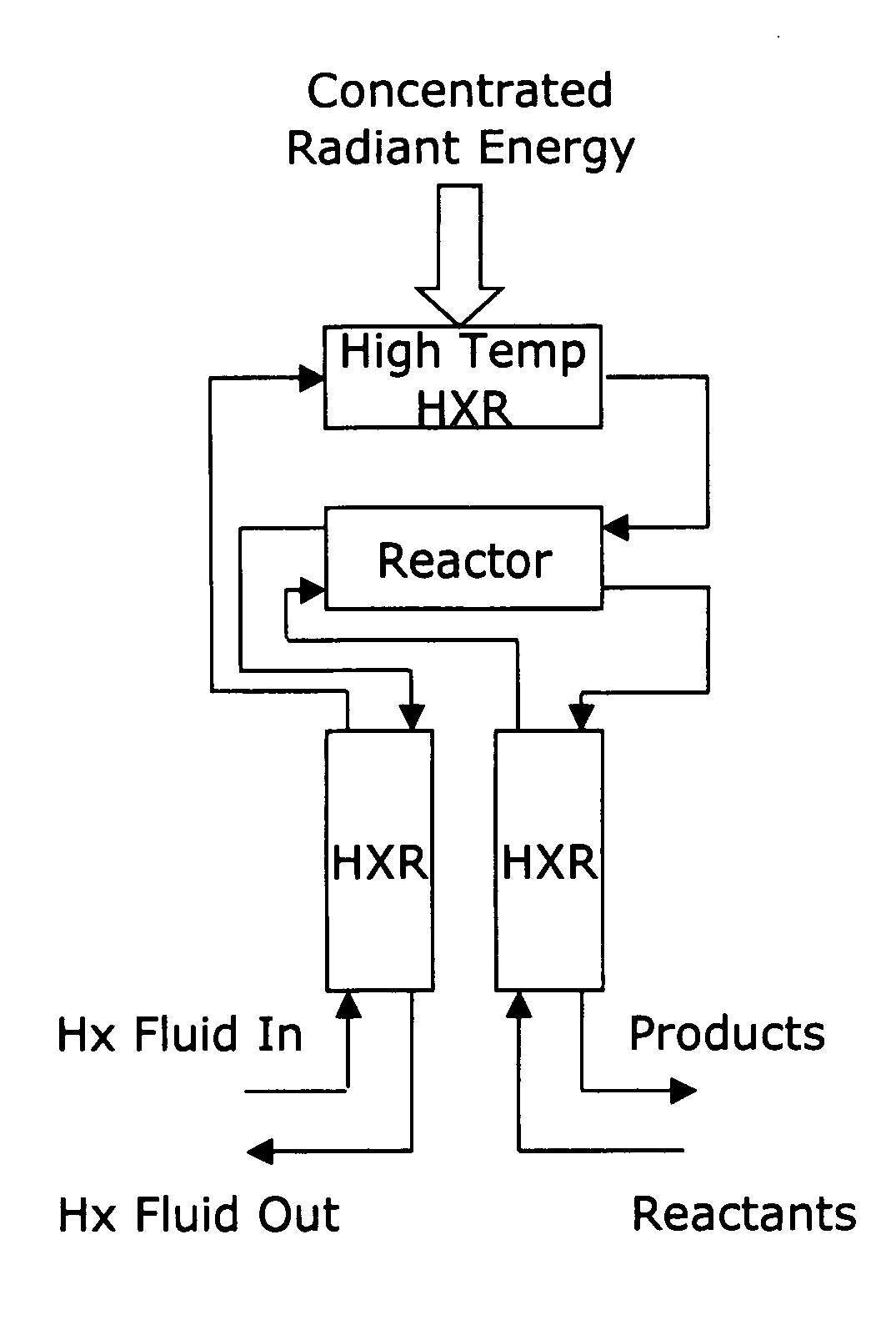

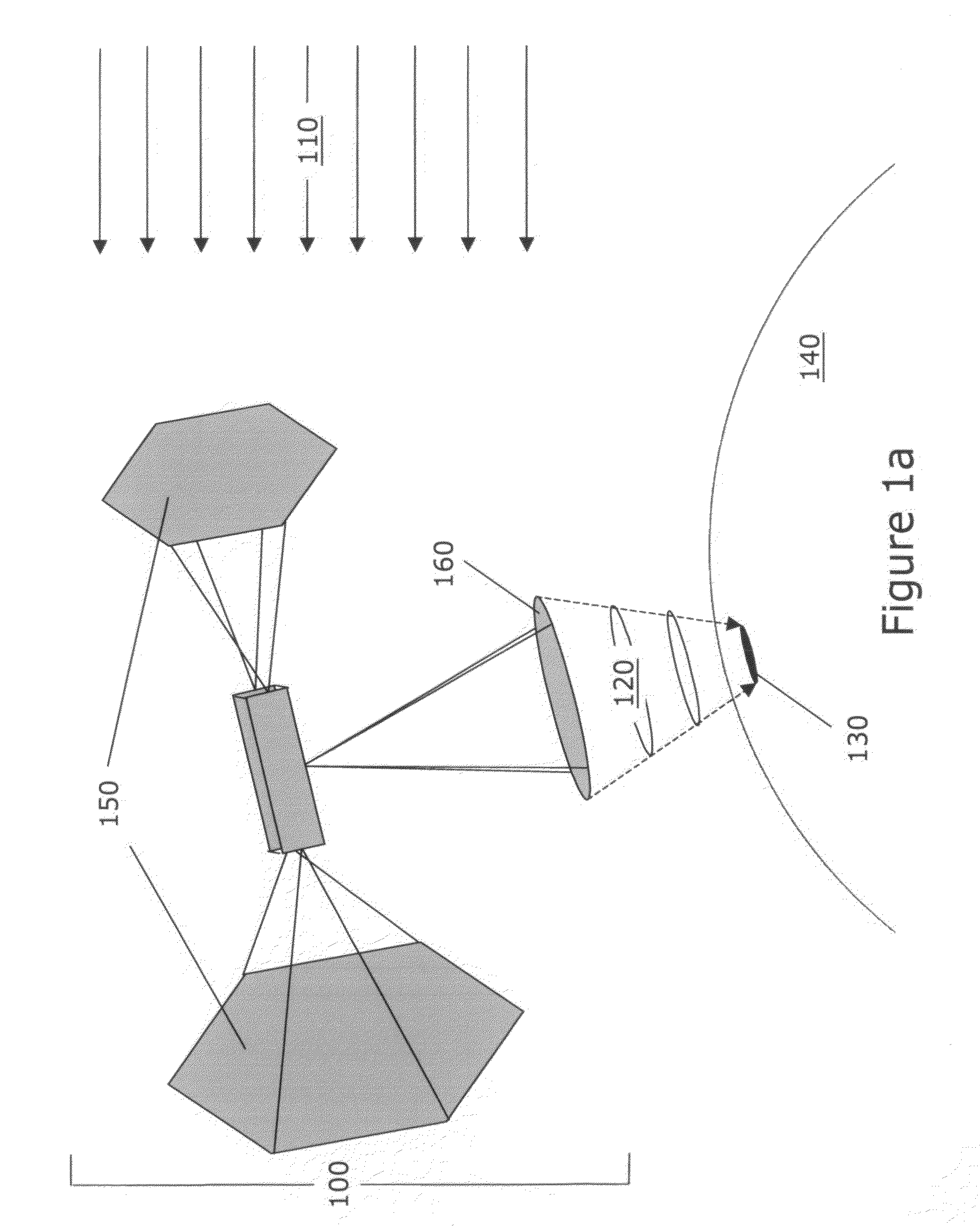

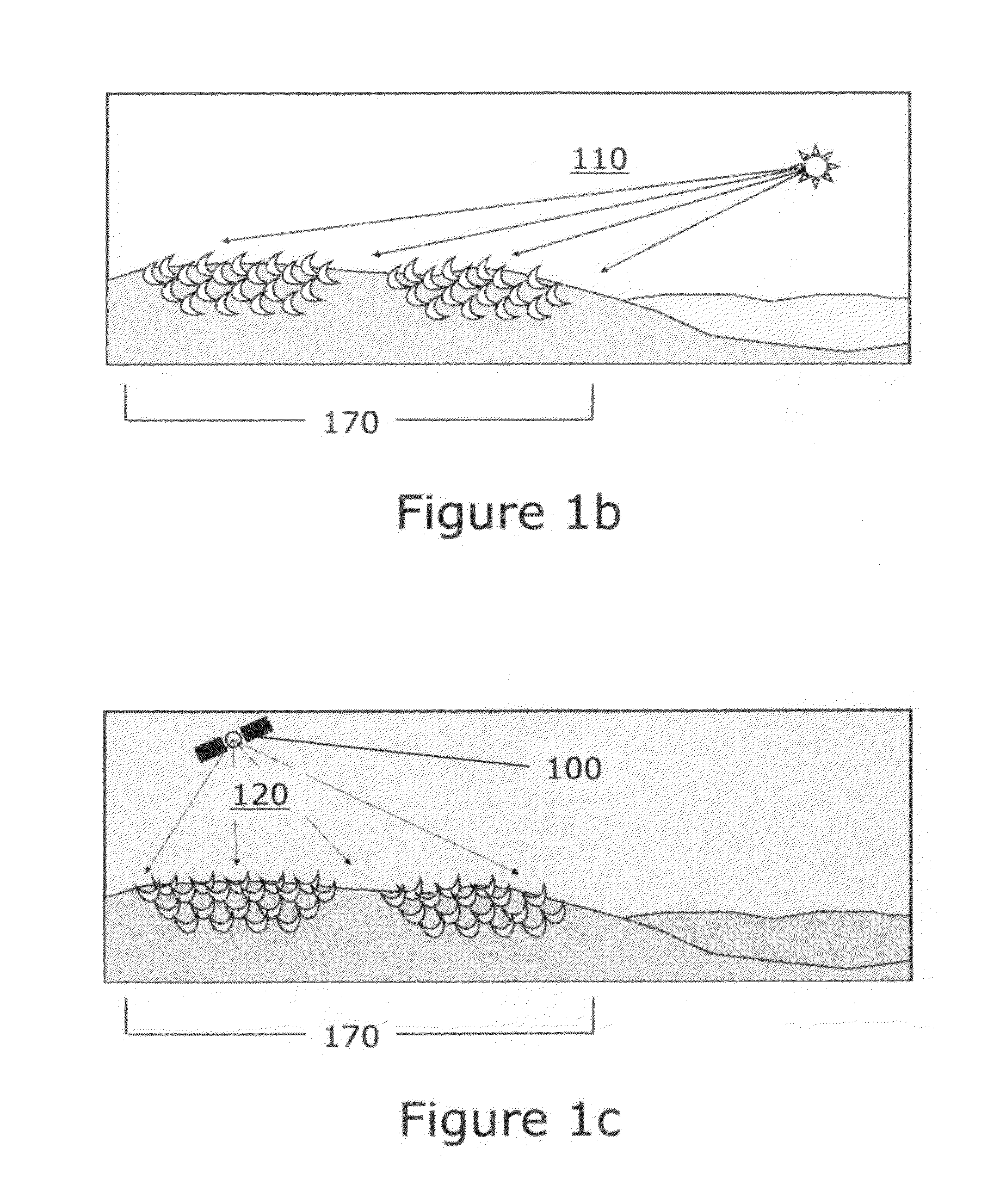

Process and method of making space-solar fuels and other chemicals

InactiveUS20080173533A1Promote absorptionImprove abilitiesSolar heating energyElectrolysis componentsProcess systemsElectricity

Processes and methods of making fuels and other chemicals, in conjunction with electricity production, using energy from a powerbeam (120) from an orbiting satellite (100), radiant energy receivers (310) and thermochemical process systems. Includes methods of directing the powerbeam so that, when solar energy 110) is available to drive the concentrators (170), the powerbeam is chiefly focused on rectenna structures (220) for the production of electricity, and then is reconfigured so that it powers the concentrator structures when solar energy is not available.

Owner:MANKINS JOHN CARLTON +1

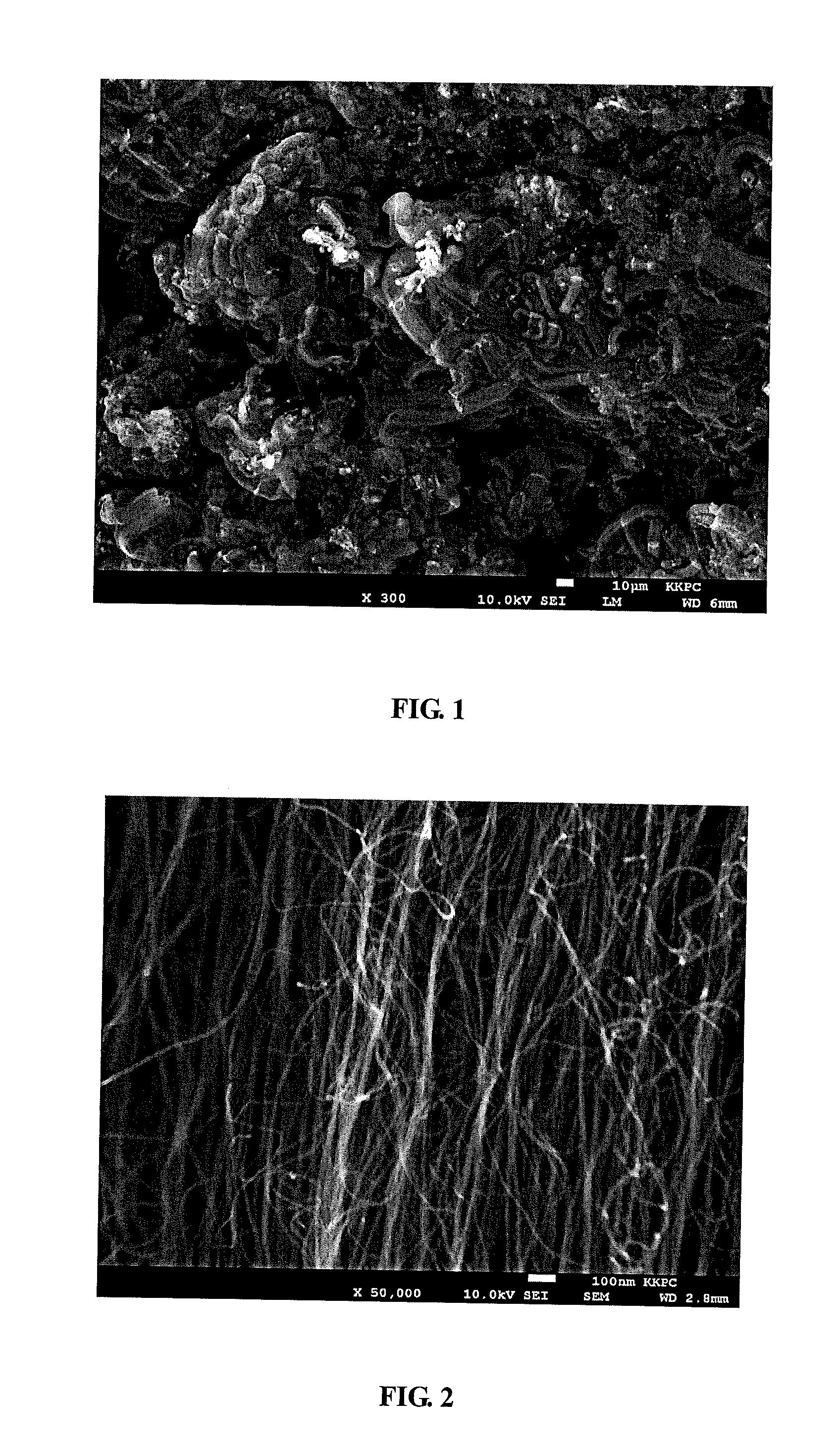

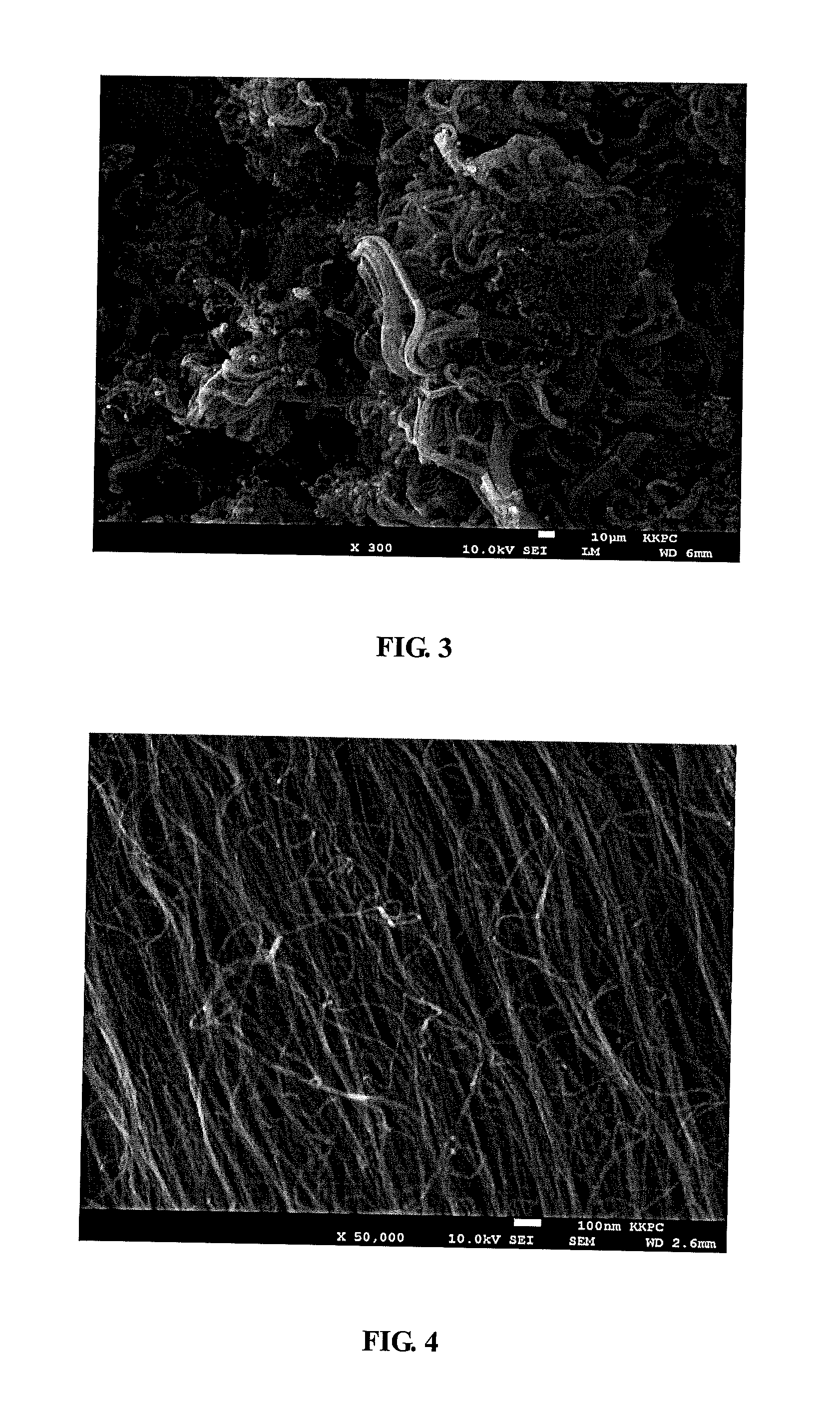

Highly Conductive Carbon Nanotube Having Bundle Moieties With Ultra-Low Bulk Density and Its Manufacturing Method

ActiveUS20130207026A1Ultra-low bulk densityImprove conductivityMaterial nanotechnologyConductive materialApparent densityMetal catalyst

The present invention relates to a highly conductive carbon nanotube having bundle moieties with ultra low apparent density less than 0.01 g / cc. More specifically, this invention relates to a highly conductive carbon nanotube prepared by following preparation steps of i) preparing the sphere shape of metal catalyst by spray pyrolysis of catalytic metal precursor solution including low molecular weight polymer, ii) synthesizing carbon nanotube using carbon source and obtained metal catalyst according to thermal chemical vapor deposition method; and iii) obtaining a highly conductive carbon nanotube having bundle moieties with ultra-low bulk apparent density.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Method for preparing active carbon based adsorbent for adsorbing SO2 in smoke gas

InactiveCN1569325AImprove desulfurization effectLow priceOther chemical processesDispersed particle separationSorbentAnthracite

The invention discloses a manufacturing method for smoke SO2 sorbent with active carbon base. The feature is it uses lignite or anthracite, soft coal semicoke as material, and it is modified with pressing water thermochemical method, being activated by ozone, immersing KI with the same volume, then it is activated in air or N2. The product has an excellent desulphurizing performance, the price is low, and it can be used for industrial smoke desulphurization.

Owner:OCEAN UNIV OF CHINA

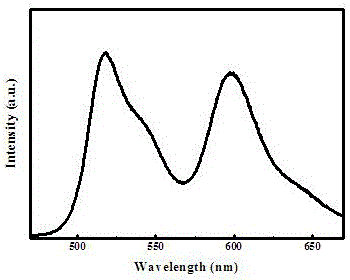

Rare-earth-free fluorescent powder for white light LED and preparation method of rare-earth-free fluorescent powder

InactiveCN105694849ASolve the disadvantage of missing red light part emissionHigh color rendering indexEnergy efficient lightingLuminescent compositionsRare-earth elementCarboxylic acid

The invention discloses rare-earth-free fluorescent powder for a white light LED and a preparation method of the rare-earth-free fluorescent powder. The rare-earth-free fluorescent powder is prepared from, by mass, 98-99.98% of metal-organic frame material, 0.01-1% of yellow light or green light emission dyestuff and 0.01-1% of red light emission dyestuff. The preparation method includes the following steps that an aromatic carboxylic acid organic ligand and metal salt are subjected to solvothermal / hydrothermal reaction synthesis to obtain the metal-organic frame material; the metal-organic frame material is soaked in a dyestuff solution, and dyestuff molecules / ions enter the metal-organic frame material. The process is simple, conditions are mild, the yield is high, the prepared fluorescent powder is free of a rare earth element, internal quantum efficiency is higher than 75%, and thermo-chemical stability is high. The rare-earth-free fluorescent powder is combined with a blue light LED chip, the color rending index of the prepared white light LED is higher than 80, the color temperature can be continuously adjusted between 2,500 K and 7,000 K, brightness is high, and under injection at the current density of 20 A / cm<2>, the lighting efficiency is higher than 140 lm / W, and luminous decay is low.

Owner:ZHEJIANG UNIV

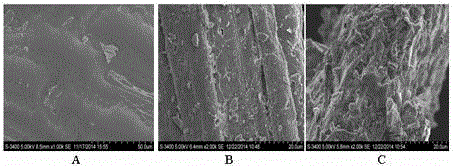

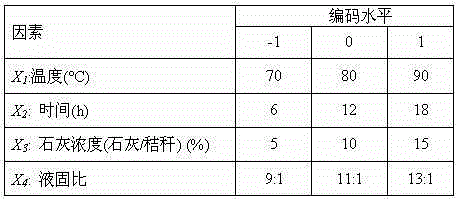

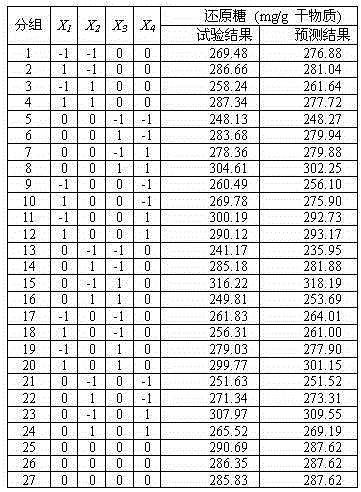

Novel process for jointly degrading and saccharifying crop straw by means of thermo-chemical treatment, microbial fermentation and enzymatic hydrolysis

InactiveCN105039457APromote degradationIncrease saccharification rateFermentationXylanaseFermentation

The invention relates to a novel process for jointly degrading and saccharifying crop straw by means of thermo-chemical treatment and enzymatic hydrolysis. The novel process includes steps of 1), mixing the smashed crop straw and soak liquid with each other according to a solid-to-liquid ratio of 1g:9-13ml to obtain mixtures, then carrying out heat-insulation treatment on the mixtures at the temperature of 70-90 DEG C for 6-18h, adding hydrogen peroxide into the mixtures after the heat-insulation treatment is completed, keeping the mixtures at the temperature of 50 DEG C for 6-18h, and fetching and drying the mixtures; 2), transferring the straw obtained in the step 1) into distilled water, adding straw with 20-60 FPU / g of cellulase and straw with 300-600U / g of xylanase into the straw, regulating the pH (potential of hydrogen) of the straw until the pH reaches 4-5, then carrying out enzymatic hydrolysis by the aid of shaking tables at the temperature of 45-50 DEG C for 24-48h, treating the straw at the temperature of 100 DEG C for 30min after enzymatic hydrolysis is completed so as to terminate enzymatic hydrolysis reaction and drying and smashing enzymatic hydrolysis products. The volume of the hydrogen peroxide is 3% of that of the soak liquid. The soak liquid is a lime supernatant with sodium hydroxide, the sodium hydroxide accounts for 2% of the weight of the crop straw, and lime accounts for 5-15% of the weight of the crop straw. The novel process has the advantage that the degradation rate of the straw and the reduced sugar yield (442.85mg / g) of the straw can be obviously increased.

Owner:河南德邻生物制品有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com