Method for preparing engine fuel gas by using biomass and/or organic waste

A technology of organic waste and biomass, applied in the petrochemical field, can solve the problems of many impurities, unable to meet the requirements of engine fuel, and low calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

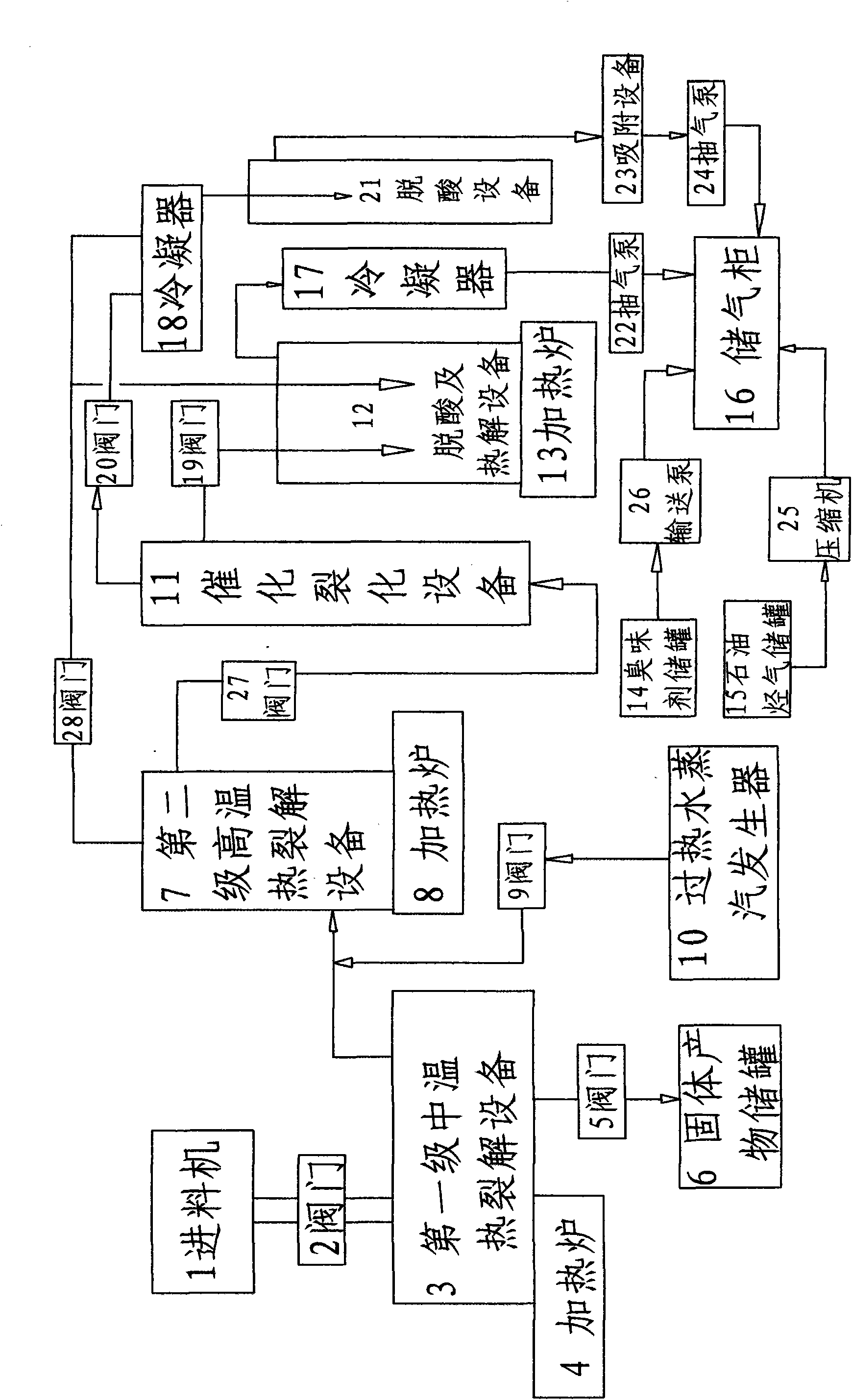

Method used

Image

Examples

Embodiment 1

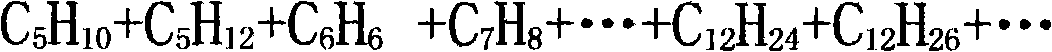

[0077] ①.Crush 150kg of corn stalks, 100kg of sorghum stalks and 200kg of wheat stalks into 3-10mm pieces, and then transport them to the airflow dryer. Use hot air as the airflow agent to airflow dry the straws to remove moisture. Collect the dried stalk fragments from the cyclone collection tank configured behind the airflow dryer, and its water content is controlled below 15% (Wt%); get the above-mentioned 450 kg of straw fragments with a water content below 15%, and the size is 3-10mm The dry 550 kilograms of waste plastic fragments are mixed, as the raw material of this embodiment 1; By feeder (1), described raw material is transported to airtight internal configuration with screw rod stirring In the horizontal thermal cracking equipment (2) of the device, the outer wall of the thermal cracking equipment (2) is carried out indirect heating with a heating furnace (4), and the screw agitator in the starting equipment (2) rotates, and is subjected to the action of the screw a...

Embodiment 2

[0118] ①. Break 350 kg of straw and 650 kg of sawdust into 3-10mm pieces, and then mix them to form 1000 kg of biomass chip raw materials, and then transport the raw materials of the chips to the air dryer, use hot air as the air flow agent, and dry the chips The raw material is air-dried to remove moisture, and the dried fragment raw material is collected from the cyclone collection tank configured behind the airflow dryer, and its water content is controlled below 15% (Wt%); get the above-mentioned fragment raw material containing water below 15% 1000 kilograms, as the raw material of present embodiment 2; According to the same method, equipment and operating conditions of above-mentioned embodiment 1, described raw material is carried out thermal cracking; Finally, the gas phase product of equipment (3) is drawn equipment (3);

[0119] 2. The gas phase substance that the equipment (3) of above-mentioned 1. is drawn is directly input in the pyrolysis equipment (7); According ...

Embodiment 3

[0158] ①. 500 kilograms of waste plastics (PE, PP, PS) and 500 kilograms of waste tires are broken into 3-10mm fragments respectively, and then mixed to form 1000 kilograms of hydrocarbon organic waste fragment raw materials, as the raw materials of this embodiment 3; The same method, equipment and operating conditions of above-mentioned embodiment 1 carry out thermal cracking to described raw material; Finally, the gas phase product of equipment (3) is drawn out equipment (3);

[0159] 2. The gaseous phase material that above-mentioned 1. equipment (3) draws is directly input in the pyrolysis equipment (7); The present embodiment adopts conventional split-tube reactor, and the heated gaseous phase material that flows is in the tube, and the gaseous phase material is heated The heat of the high-temperature furnace gas outside the split tube is thermally cracked or decomposed; the thermal cracking tube configured in the equipment (7) is heated by the combustion furnace (8); the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com