Prepn. process of nano SiO2/boron bakelite resin nano composite material

A nano-composite material and nano-silica technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of high brittleness of phenolic resin, limit the development of high-performance materials, poor toughness, etc., and achieve the effect of excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

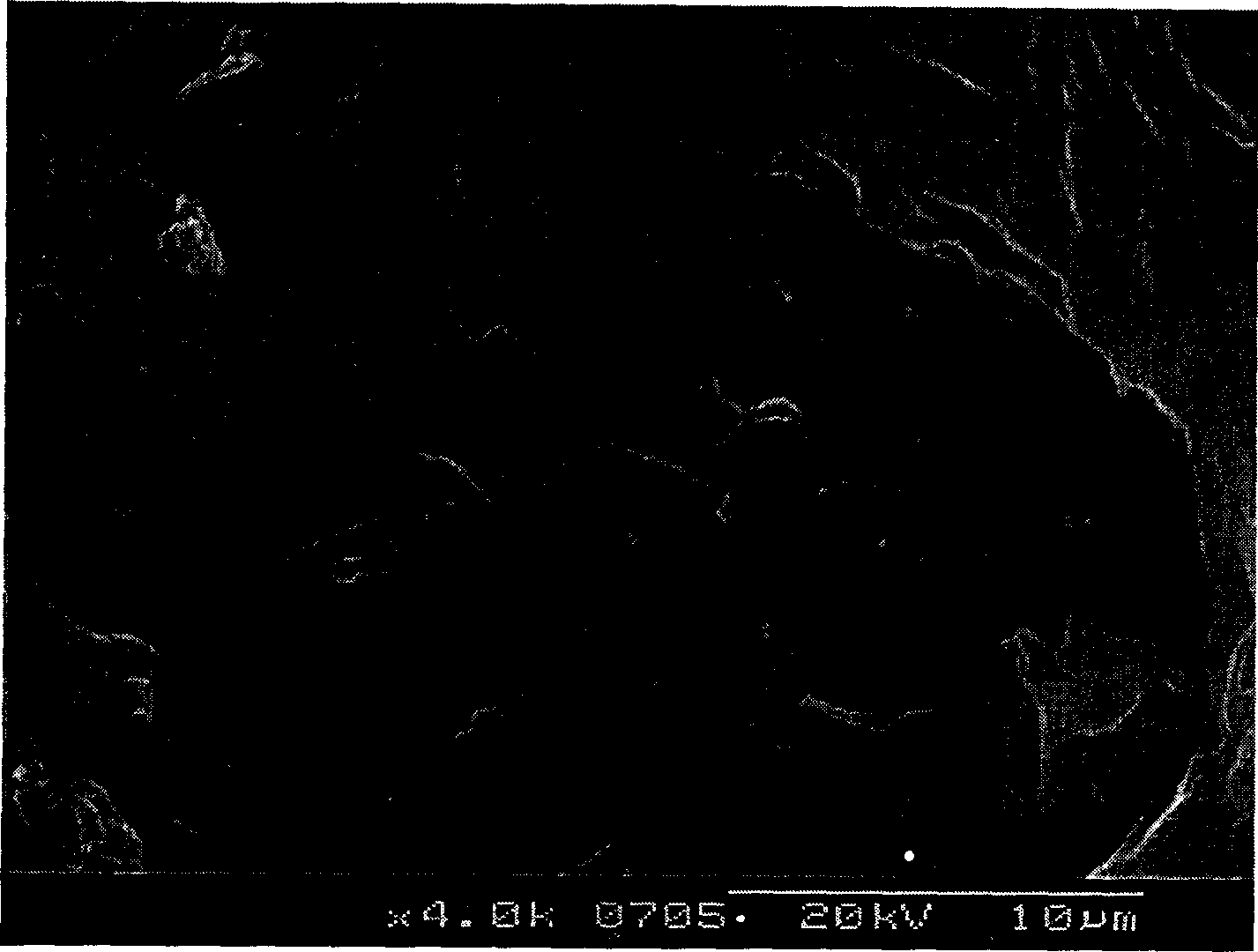

[0023] Step (1): Dissolve 1g of surface treatment agent KH550 with 50ml of ethanol solvent. Then add 15g gas-phase method nano-SiO to the solution 2 (average diameter 12nm), disperse for 30 minutes under the action of 40kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ;

[0024] Step (2): 500 g of block-shaped modified boron phenolic resin containing quantitative boron is pulverized with a powder pulverizer, dissolved in 500 ml of ethanol solvent, stirred for 30 minutes and left still for 24 hours to obtain a boron phenolic resin solution;

[0025] Step (3): the surface-treated nano-SiO obtained in step (1) 2 Mix with the boron phenolic resin solution obtained in step (2), disperse for 60 minutes under the action of 40kHz ultrasonic waves, separate and recover the solvent by decompression, and obtain nano-scale dispersed nano-SiO 2 / boron phenolic resin premix.

[0026] Step (4): the nano-SiO obtained in step (3) 2 / The boron phenol...

Embodiment 2

[0030]Step (1): Dissolve 1.25g of surface treatment agent KH570 in 100ml of isobutanol solvent. Add 12.5g gas-phase method nano-SiO to the solution again 2 (average diameter 8nm), disperse for 20 minutes under the action of 100kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ;

[0031] Step (2): Pulverize 250 g of block-shaped modified boron phenolic resins containing quantitative boron with a powder pulverizer, dissolve it in 250 ml of ethanol solvent, stir for 30 minutes and then stand still for 10 hours to obtain a boron phenolic resin solution;

[0032] Step (3): the surface-treated nano-SiO obtained in step (1) 2 Mix with the boron phenolic resin solution obtained in step (2), disperse for 100 minutes under the action of 60kHz ultrasonic waves, separate and recover the solvent by decompression, and obtain nano-scale dispersed nano-SiO 2 / boron phenolic resin premix.

[0033] Step (4): the nano-SiO obtained in step (3) 2 / The bo...

Embodiment 3

[0036] Step (1): Dissolve 2.8g of surface treatment agent NDZ401 with 100ml of acetone. Then add 28g gas-phase method nano-SiO in the solution 2 (average diameter 25nm), disperse for 10 minutes under the action of 1000kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ;

[0037] Step (2): 400 g of block modified boron phenolic resin containing quantitative boron is pulverized with a powder pulverizer, dissolved in 400 ml of ethanol solvent, stirred for 30 minutes and then left still for 36 hours to obtain boron phenolic resin solution;

[0038] Step (3): the surface-treated nano-SiO obtained in step (1) 2 Mix with the boron phenolic resin solution obtained in step (2), disperse for 180 minutes under the action of 400kHz ultrasonic waves, separate and recover the solvent under reduced pressure, and obtain nano-scale dispersed nano-SiO 2 / boron phenolic resin premix.

[0039] Step (4): the nano-SiO obtained in step (3) 2 / The boron phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com