Thermo-chemical oil extraction method of offshore thickened oil

A thermochemical and heavy oil technology, which is applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems such as the effect of auxiliary chemical agents is greatly affected, the boiler occupies a large space, and the environment is sensitive. Achieve the effects of low price, low investment and maintenance costs, and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, offshore heavy oil thermochemical oil recovery

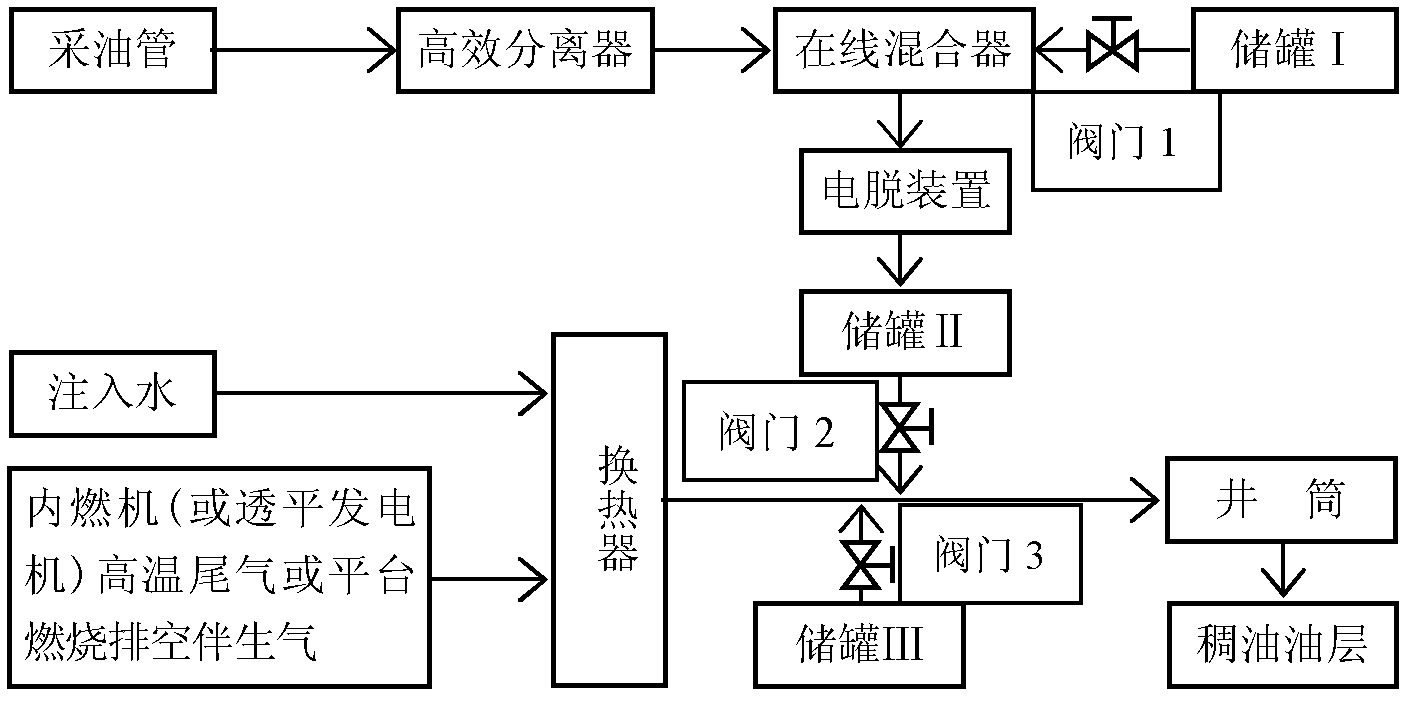

[0023] use figure 1 The flow shown is for offshore heavy oil thermochemical recovery.

[0024] Install a heat exchanger at the outlet of the tail of the internal combustion engine in an oilfield site (the heat exchange efficiency is calculated as 80%), and the high-temperature exhaust gas is 165,000 m 3 / d meter, adjust the flow rate of water in the heat exchanger to 8.5m 3 / h, using the high-temperature exhaust gas of the internal combustion engine to heat the injection water temperature online to 150°C, at this time, the pressure in the heat exchanger is 6.40MPa; use 4-1 / 2″ vacuum insulation oil pipe, control single well injection water at 7m 3The flow rate of / h is injected into the heavy oil reservoir, and the temperature of the injected water near the wellbore at the 1000m reservoir can still be kept above 140°C. The heavy oil coming out of the oil production line is separated by high-efficiency sepa...

Embodiment 2

[0025] Embodiment 2, offshore heavy oil thermochemical oil recovery

[0026] use figure 1 The flow shown is for offshore heavy oil thermochemical recovery.

[0027] Install a heat exchanger at the outlet of the turbine generator tail in an oilfield site (the heat exchange efficiency is calculated as 80%), and the high-temperature exhaust gas is 165,000 m 3 / d meter, adjust the flow rate of water in the heat exchanger to 8.5m 3 / h, using the high-temperature tail gas of the turbine generator to heat the injection water temperature online to 150°C, at this time, the pressure in the heat exchanger is 6.40MPa; use 4-1 / 2″ vacuum insulation oil pipe to control single well injection water at 7m 3 The flow rate of / h is injected into the heavy oil reservoir, and the temperature of the injected water near the wellbore at the 1000m reservoir can still be kept above 140°C. The heavy oil coming out of the oil production line is separated by high-efficiency separator oil-water sediment...

Embodiment 3

[0028] Embodiment 3, offshore heavy oil thermochemical oil recovery

[0029] use figure 1 The flow shown is for offshore heavy oil thermochemical recovery.

[0030] Install a heat exchanger (calculated as 80% of the heat transfer efficiency) at the outlet of the associated gas exhausted in an oil field, and the associated gas drained by the oil field is 12,000 m 3 / d meter, adjust the flow rate of water in the heat exchanger to 20.8m 3 / h, using waste heat from oilfield evacuation of associated gas to heat the injected water online to 200°C, at this time, the pressure inside the heat exchanger is 6.40MPa; use 4-1 / 2″ vacuum insulation tubing to control single well injection water at 7m 3 The flow rate of / h is injected into the heavy oil reservoir, and the temperature of the injected water near the wellbore at the 1000m reservoir can still be kept above 190°C. The heavy oil coming out of the oil production line is separated by high-efficiency separator oil-water sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com