A kind of pickering emulsion and its preparation method and its application in heavy oil emulsification and viscosity reduction

An emulsion and heavy oil technology, applied in chemical instruments and methods, mechanical equipment, drilling compositions, etc., can solve the problems of long-term stability, high cost, low utilization rate of waste slag, etc., and achieve emulsification and viscosity reduction. Good effect, cost reduction, and the effect of reducing the cost of heavy oil extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The stability study of embodiment 1 Pickering emulsion

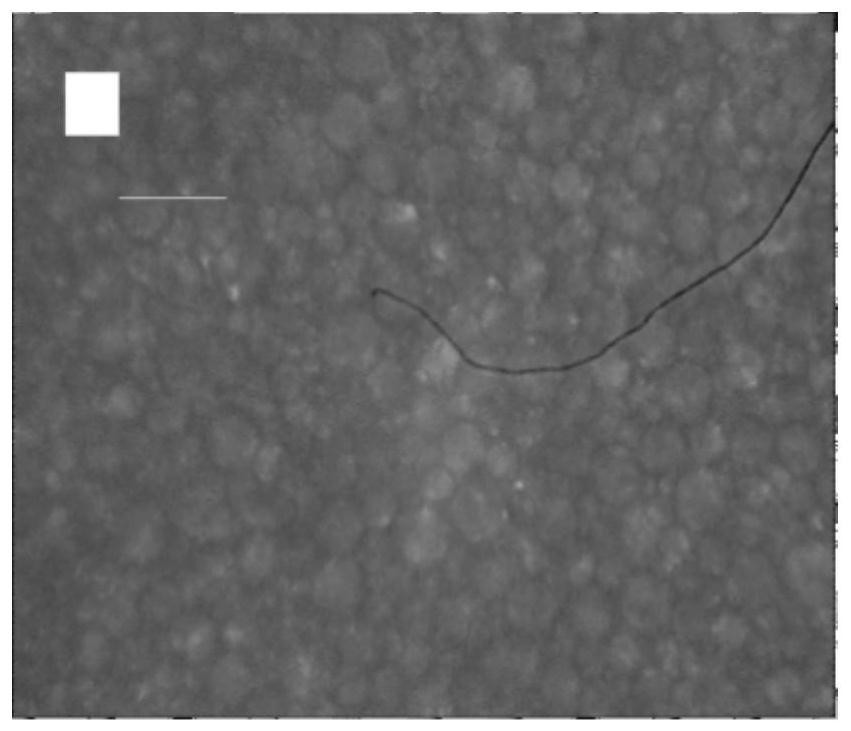

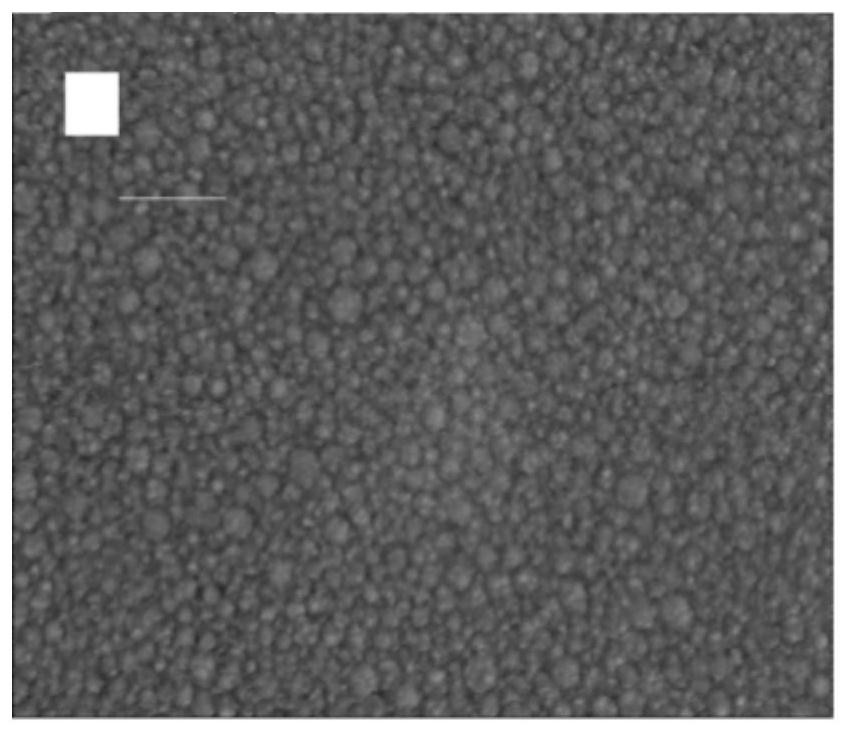

[0041] 1.1 Effect of solid particle type on the stability of Pickering emulsion

[0042] At room temperature (25°C), the oil-water volume ratio in the aviation kerosene-water system is selected to be 25ml / 25ml, and different solid particles (S115 type mineral powder, nano-SiO 2 , MgAl hydrotalcite, nano-Al 2 o 3 , nanometer ZnO) 1g, after preparing the Pickering emulsion, let it stand for a week, and observe the emulsion water phase height, emulsion height and oil phase height. The stability of the emulsion prepared with different solid particles is shown in Table 3.

[0043] Table 3: Stability of Pickering emulsions prepared with different solid particles

[0044] Solid particles S115 SiO 2

MgAl hydrotalcite Al 2 o 3

ZnO Emulsification index / % 78 70 65 34 5 Proportion of water phase / % 22 30 0 42 45 Proportion of oil phase / % 0 0 35 24 50

[0045] ...

Embodiment 2

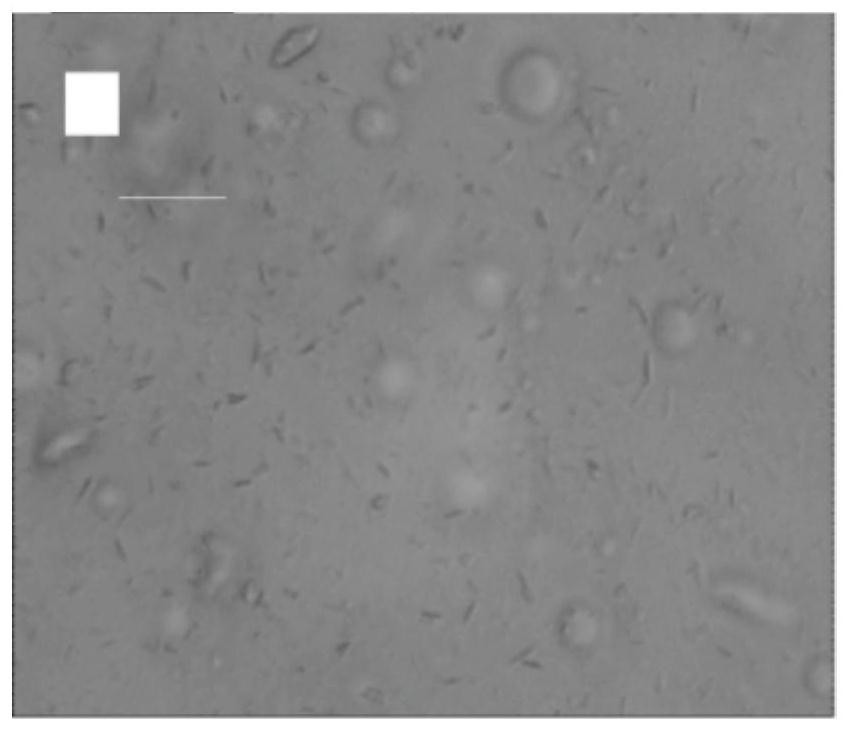

[0076] Example 2 Research on the Viscosity Reducing Effect of Pickering Emulsion to Crude Oil

[0077] 2.1 Comparison of the effects of Pickering emulsion, aviation kerosene-polymer water system and aviation kerosene-deionized water system on the viscosity reduction effect of crude oil

[0078] At 60°C, prepare a heavy oil-water system (the volume ratio of heavy oil-mineralized water is 3:7), and then add the same amount of Pickering emulsion, solid particle-free Aviation kerosene-water system solution (containing carboxyethyl cellulose and sodium dodecylbenzene sulfonate in the water phase), aviation kerosene-water system solution not containing solid particles and polymers, after measuring respectively adding the same amount, the The impact on the viscosity of the heavy oil-water system is shown in Table 12, 13 and 14.

[0079] Table 12: Changes in Viscosity of Heavy Oil-Water System with the Addition of Pickering Emulsion

[0080] Amount / % 0 2 4 6 8 10 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com