Lucid Ganoderma cultivation bag material and method for cultivating Lucid Ganoderma by same

A cultivation bag and cultivation material technology, applied in the direction of botanical equipment and methods, applications, fertilizer mixtures, etc., to achieve quick results, sufficient raw material sources, and save miscellaneous wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

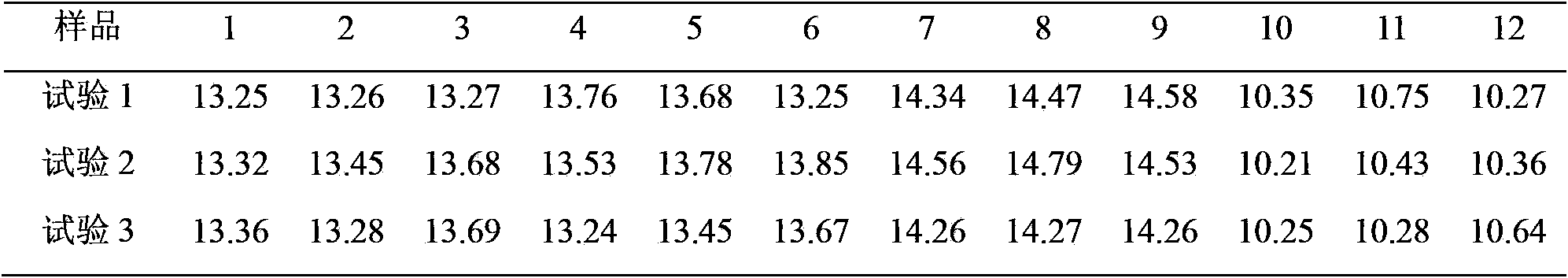

Examples

Embodiment 1

[0024] Embodiment 1 preparation of Ganoderma lucidum cultivation bag material and adopting the bag material to cultivate Ganoderma lucidum

[0025] Including the following steps:

[0026] 1) Material preparation: dry and crush the bean stalks to obtain 0.4-0.5cm bean stalks; dry bean dregs, maple wood chips and chestnut wood chips mixed wood chips; component ratio (mass percentage): 35% bean stalks, 30% bean dregs, 33% sawdust, 2% gypsum powder;

[0027] 2) Prepare water: prepare soybean yellow pulp water with 1.2 times the quality of cultivation material;

[0028] 3) Ingredients: bean stalks and soybean yellow pulp water are pre-moistened and softened. After 24 hours, mixed wood chips and gypsum powder are added and stirred evenly, then soybean yellow pulp water and bean dregs are added, and the cultivation material is fully stirred;

[0029] 4) Put the cultivation material into a 20cm×35cm bottom-sealed bag to make a cultivation bag, sterilize it with high temperature and ...

Embodiment 2

[0033] Embodiment 2 Preparation of ganoderma lucidum cultivation bag material and adopting the bag material to cultivate ganoderma lucidum

[0034] Including the following steps:

[0035] 1) Preparation of materials: drying and crushing bean stalks to obtain 0.4-0.5cm bean stalks; sun-dried bean dregs, mixed wood chips of maple wood chips and chestnut wood chips; component ratio (mass percentage): 25% bean stalks, 20% bean dregs, 53% sawdust, 2% gypsum powder;

[0036]2) Prepare water: prepare soybean yellow pulp water with 1.2 times the quality of cultivation material;

[0037] 3) Ingredients: bean stalks and soybean yellow pulp water are pre-moistened and softened. After 24 hours, mixed wood chips and gypsum powder are added and stirred evenly, then soybean yellow pulp water and bean dregs are added, and the cultivation material is fully stirred;

[0038] 4) Put the cultivation material into a 20cm×35cm bottom-sealed bag to make a cultivation bag, sterilize it with high te...

Embodiment 3

[0040] Embodiment 3 preparation of Ganoderma lucidum cultivation bag material and adopting the bag material to cultivate Ganoderma lucidum

[0041] Including the following steps:

[0042] 1) Preparation of materials: drying and crushing bean stalks to obtain 0.4-0.5cm bean stalks; sun-dried bean stalks, mixed wood chips of maple wood chips and chestnut wood chips; component ratio (mass percentage): 30% bean stalks, 25% bean dregs, 43% sawdust, 2% gypsum powder;

[0043] 2) Prepare water: prepare soybean yellow pulp water with 1.2 times the quality of cultivation material;

[0044] 3) Ingredients: bean stalks and soybean yellow pulp water are pre-moistened and softened. After 24 hours, mixed wood chips and gypsum powder are added and stirred evenly, then soybean yellow pulp water and bean dregs are added, and the cultivation material is fully stirred;

[0045] 4) Put the cultivation material into a 20cm×35cm bottom-sealed bag to make a cultivation bag, sterilize it with high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com