A temperature-resistant and salt-resistant thick oil emulsifying viscosity reducer and preparation method thereof

A technology for emulsifying viscosity-reducing and heavy oil, which is applied in the direction of chemical instruments and methods, drilling compositions, etc. It can solve the problems of emulsified viscosity-reducing agent's temperature resistance and salt resistance, low interfacial tension, etc., and achieve emulsification and viscosity reduction Good effect, improved high temperature resistance, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

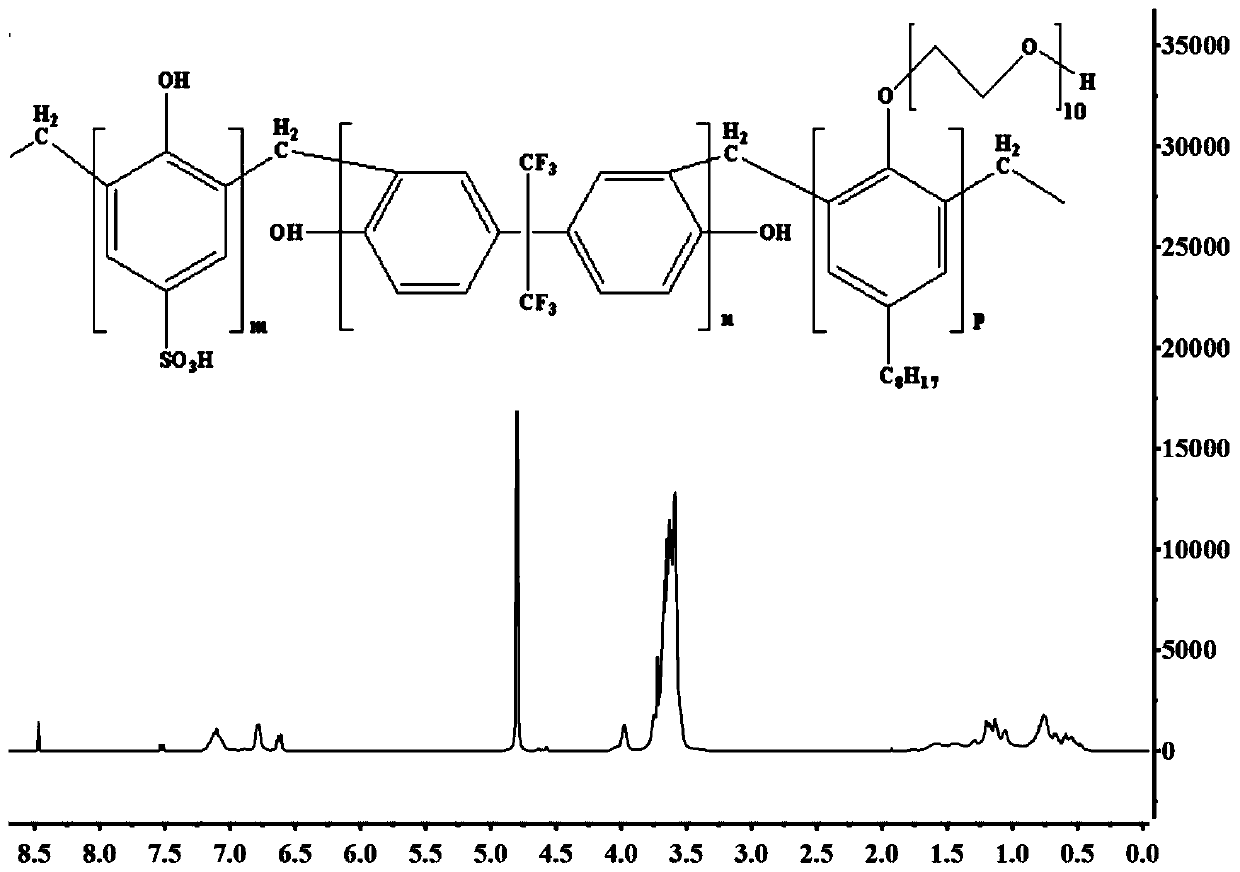

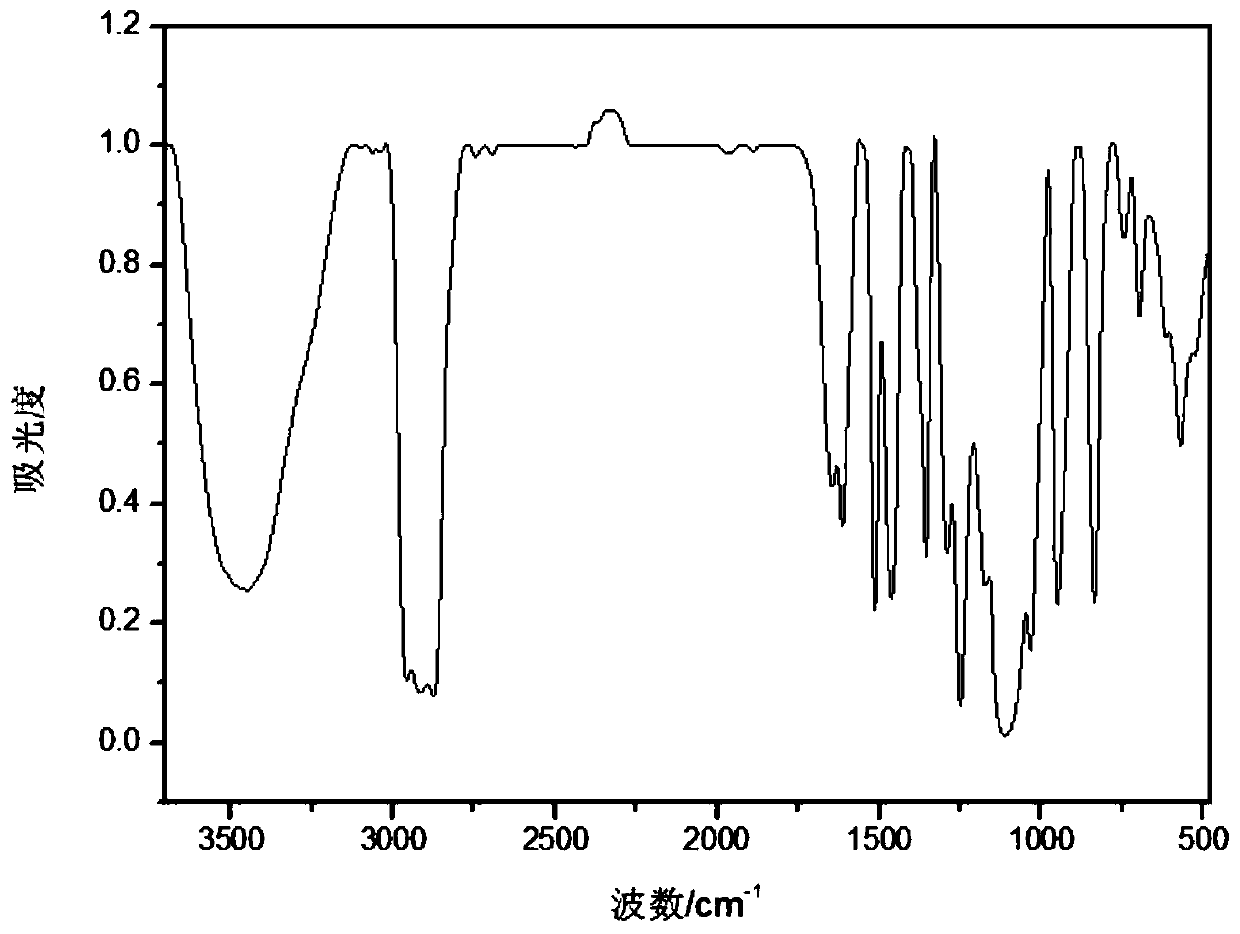

[0021] The embodiment of the present invention provides a method for preparing a temperature-resistant and salt-resistant thick oil emulsified viscosity reducer, comprising the following steps:

[0022] S1: Co-condensation of bisphenol AF, p-hydroxybenzenesulfonic acid and formaldehyde under alkaline conditions to obtain reaction solution I.

[0023] In this step, it should be noted that bisphenol AF is also called 2,2-bis(4-hydroxyphenyl)-hexafluoropropane. Under alkaline conditions, both bisphenol AF and p-hydroxybenzenesulfonic acid will generate phenoxide negative ions. Due to the electron delocalization of the phenoxide anion, the ortho-position carbon of the hydroxyl group on the benzene ring in bisphenol AF and p-hydroxybenzenesulfonic acid It has a negative charge on the surface, which is conducive to the nucleophilic addition reaction with the carbonyl of formaldehyde to generate different hydroxymethyl phenoxides; further, the phenoxide anion and the generated hydrox...

Embodiment 1

[0037] Add 0.015mol of bisphenol AF into the reaction kettle, add 50mL of water, add dropwise an aqueous solution of sodium hydroxide with a mass fraction of 40% to adjust the pH of the system to 12-13, add p-hydroxybenzenesulfonic acid and an aqueous formaldehyde solution, of which the aqueous solution of formaldehyde The mass fraction is 40%, the molar ratio of bisphenol AF and p-hydroxybenzenesulfonic acid is 1:2, and the addition of formaldehyde is 0.75 times of the total molar weight of bisphenol AF and p-hydroxybenzenesulfonic acid; the reaction kettle is placed at 65 Reaction at ℃ for 1.5h to obtain reaction solution Ⅰ;

[0038] Add OP-10 and formaldehyde aqueous solution to the above reaction solution I, wherein the amount of OP-10 added is 6 times the molar amount of bisphenol AF when preparing the reaction liquid I, and the added amount of formaldehyde is 2.75 times the molar amount of OP-10 ; Use 30% sulfuric acid solution to adjust the pH of the system to 3-4, put ...

Embodiment 2

[0040] Add 0.015mol of bisphenol AF to the reaction kettle, add 50mL of water, dropwise add 40% sodium hydroxide aqueous solution to adjust the pH of the system to 12-13, add p-hydroxybenzenesulfonic acid and formaldehyde aqueous solution, wherein the formaldehyde aqueous solution The mass fraction of bisphenol AF and p-hydroxybenzenesulfonic acid is 40%, the molar ratio of bisphenol AF and p-hydroxybenzenesulfonic acid is 1:1, and the addition of formaldehyde is 0.75 times of the total molar weight of bisphenol AF and p-hydroxybenzenesulfonic acid; React at 75°C for 2 hours to obtain reaction solution Ⅰ;

[0041] Add OP-10 and formaldehyde aqueous solution to the above reaction liquid I, wherein the amount of OP-10 added is 3 times the molar amount of bisphenol AF when preparing the reaction liquid I, and the amount of formaldehyde added is 3 times the molar amount of OP-10 ; Use 30% sulfuric acid solution to adjust the pH of the system to 3-4, put the reaction kettle at 85°C...

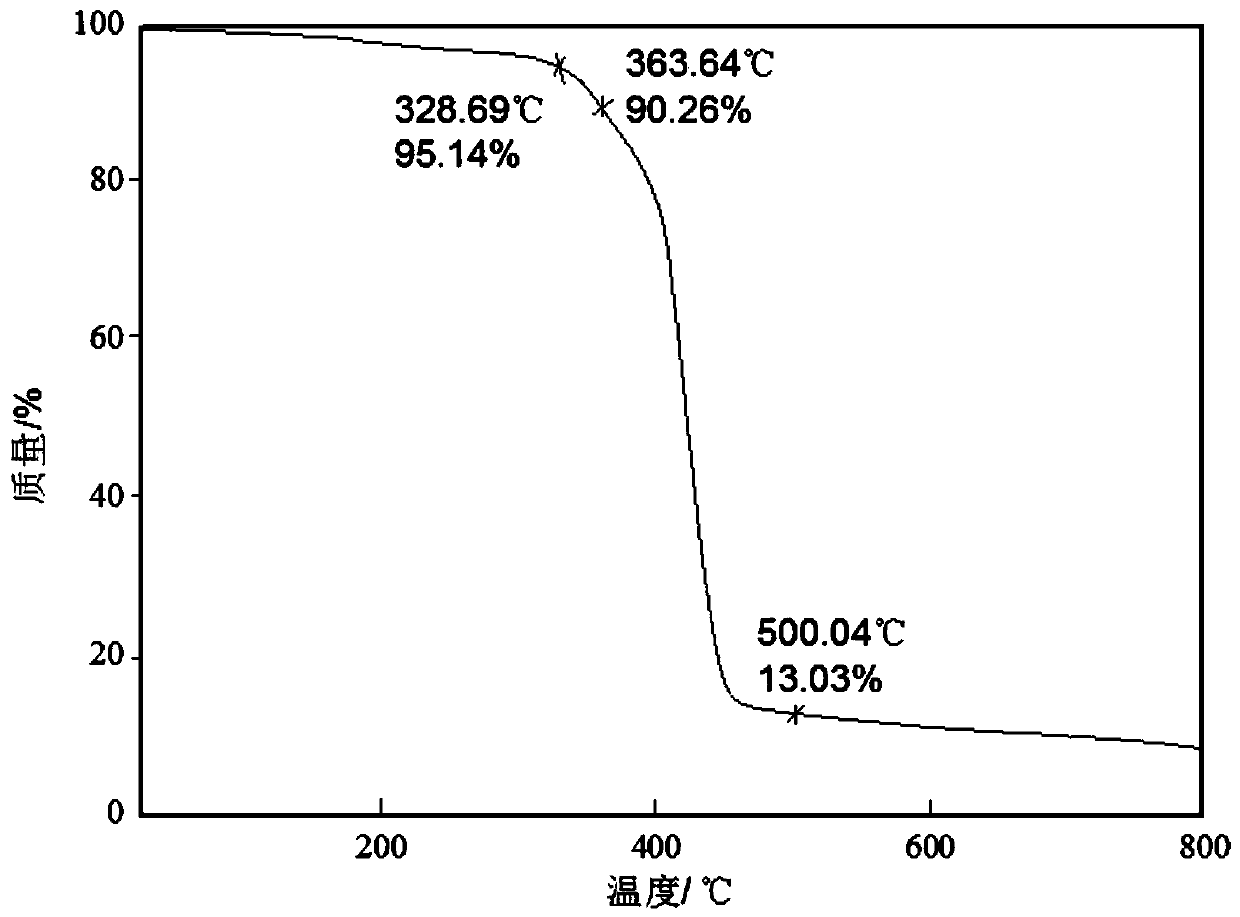

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com