Long products, method of thermo-chemical treatment and apparatus

a technology of thermo-chemical treatment and long products, applied in the direction of solid-state diffusion coating, coating, metal material coating process, etc., can solve the problems of long processing time, high cost and complex equipment, and achieve the effect of increasing the depth of the processed layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

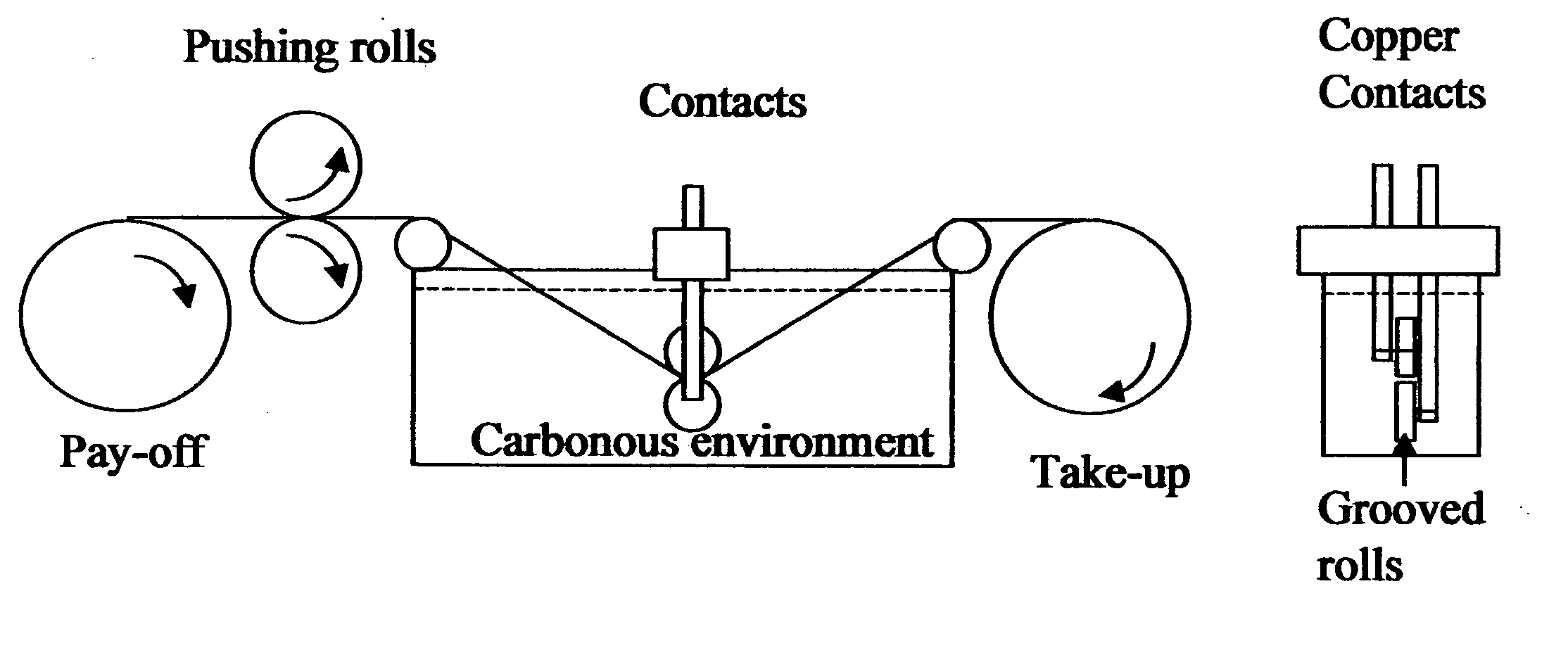

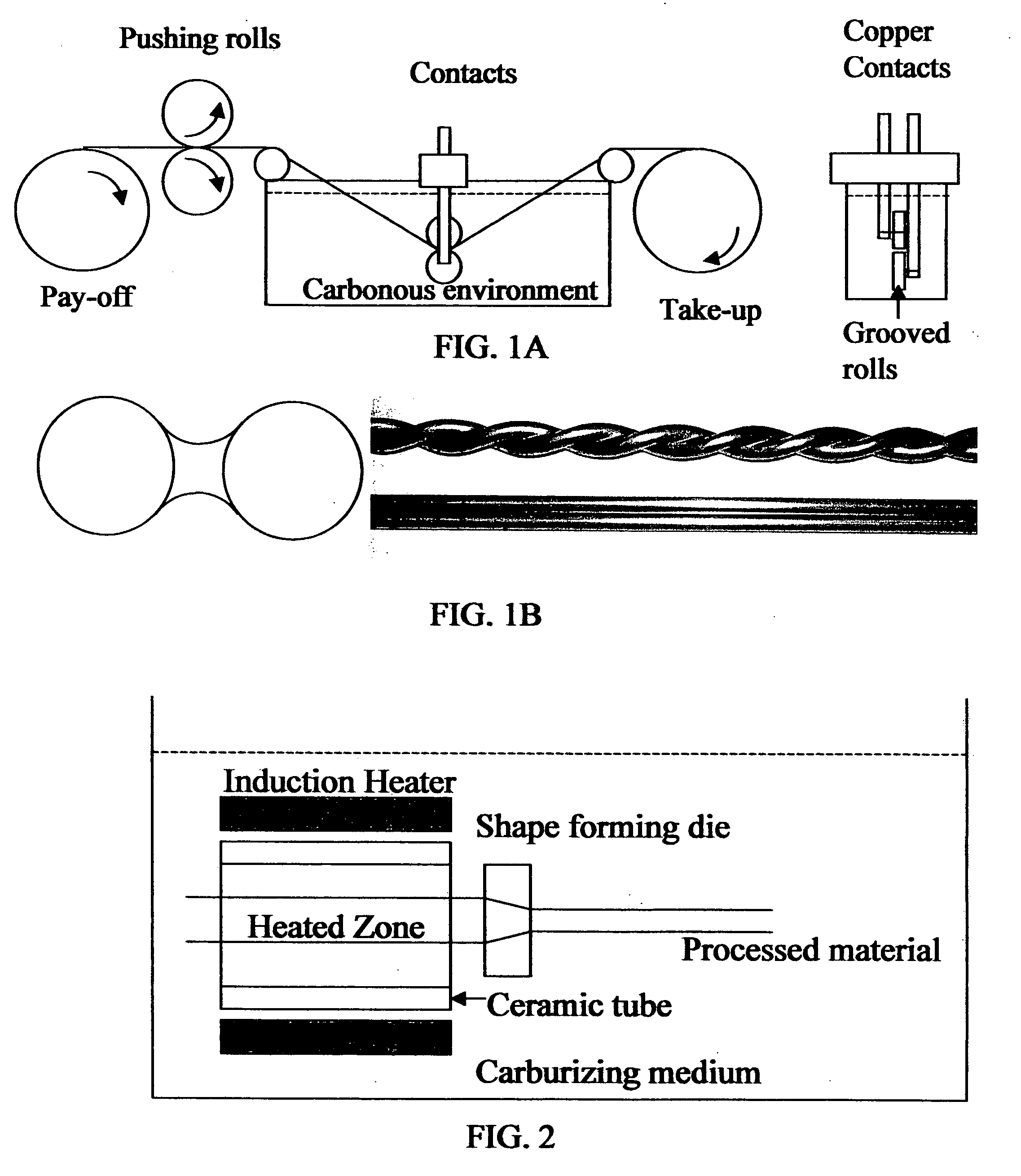

Method used

Image

Examples

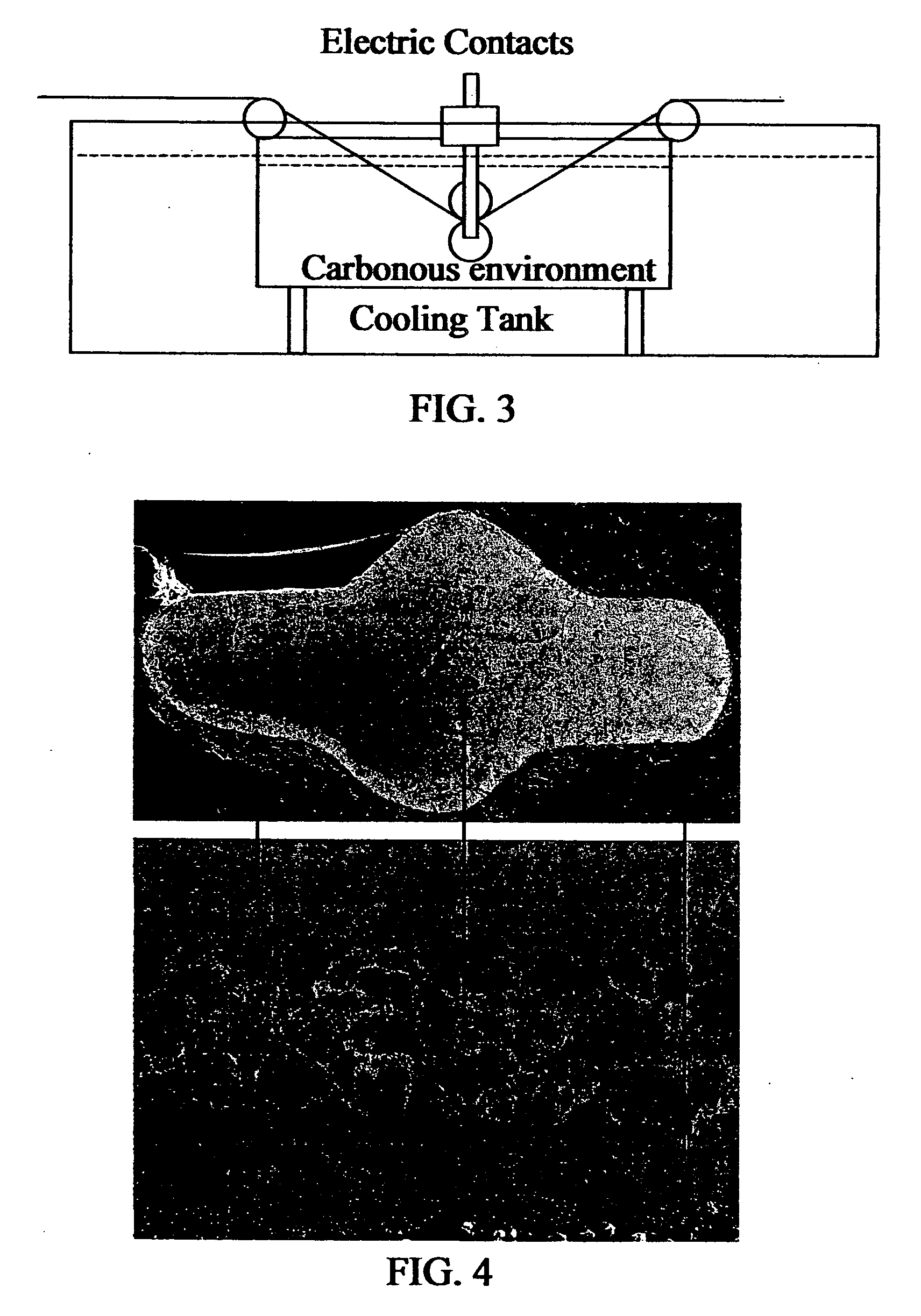

example 1

[0117] Low carbon steel wire (1020 grade) with diameter of 1.5 mm was carburzed by using current process. Wire sample, 100 mm long, was clamped at the ends of two copper electrodes, and submerged in a silicon oil. The wire was heated by passing electric current through it to different temperatures, held at the temperature for a specified time, and then cooled down to ambient temperatures inside the processing tank or in the air. Various microstructures were achieved When wire was heated to temperature below 950 C, maximum carbon content at the surface was less than 1.2%, and corresponding microstructure was comprised pearlite and secondary cementite network. Structure of the wire core did not change and was comprised ferrite and pearlite. When wire was heated to temperature in the range from 1200 C and 1450 C, carbon concentration at the surface as high as close to 4.5% was achieved. Corresponding microstructure was comprised pearlite and primary cementite when cooling rate controll...

example 2

[0118] High carbon steel wire (1090 grade) with diameter of 0.5 mm was carburized by using current process. Wire sample was continuously fed through two copper electrodes submerged in a machine oil. The wire was heated by passing electric current through it to different temperatures. Wire feeding speed and take-up speed were synchronized. Various microstructures were achieved similar to the stationary heated wire. When wire was heated to temperature below 950 C, surface microstructure was comprised pearlite and secondary cementite network, while in the bulk was comprised ferrite and pearlite. When wire was heated to temperature in the range from 1200C and 1450 C, surface microstructure was comprised pearlite and primary cementite.

example 3

[0119] A high carbon steel wire (1080 grade) with diameter of 0.3 mm was liquid nitrided by using present method. Wire sample was continuously fed through a nitriding salts bath. A thin compound layer was produced after treatment giving wire excellent corrosion resistance properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric charge | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com